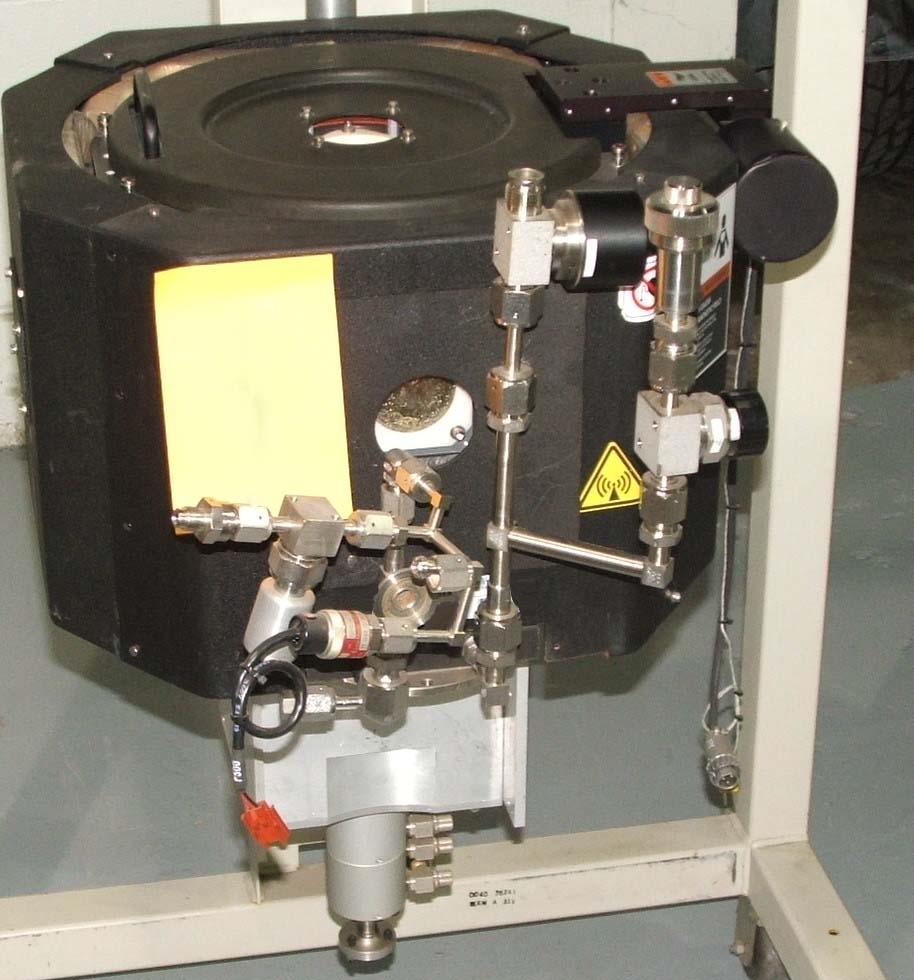

Used AMAT / APPLIED MATERIALS Etch chambers for Mark II #9262213 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS Etch chambers for Mark II is a type of gas etch reactor designed for chemical processes. This reactor uses a method called chemical-vapor-deposition processing (CVD) in order to form thin films on electronic devices. It is especially suitable for industrial production and can accommodate a variety of wafers from 0.25mm to 6 inch. The etch chamber has a design that allows for the efficient transfer of heat and the removal of by-products. It is composed of a stainless steel drum that contains the etching chamber, the RF generator, gas feeders, and the vacuum equipment. An environmental control system is included that maintains the required temperature and pressure within the unit, as well as providing an inert atmosphere. This machine is used to control the temperature of the wafer, to supply the etchant gas, and to evacuate the chamber. The etch chamber is cooled by nitrogen and the gas is heated to around 125°C, depending on the process requirements. A uniform flow of etchant gas is achieved within the chamber and is kept in equilibrium through a structure of calibrated microtubules. An RF generator connected to the chamber is used to create a higher energy electric field that activates the hydrogen and oxygen etchant gas molecules, enabling the molecules to react with the wafer material. The RF generators are itself powered by a DC power supply, and can be set to create an alternating magnetic field with different intensities and frequencies. This permits precise adjustment of the etching rate. It also allows for the removal of by-products created during the etching process, so that they do not react with the wafer during subsequent operations. The chamber walls are coated with a special dielectric material to ensure that the RF energy does not leak out of the chamber and interfere with other components. The RV sputtering chamber can also be used to deposit a metal layer on the wafer to protect the wafer during etching processes. An ion source can also be incorporated in the tool to provide additional corrosion protection to the surface of the wafer. Overall, AMAT Etch chamber for Mark II is suitable for a variety of etching processes. It is designed for stability, ease of maintenance, precision, and temperature and pressure control. It is also highly efficient, and allows for the removal of by-products created during the etching process.

There are no reviews yet