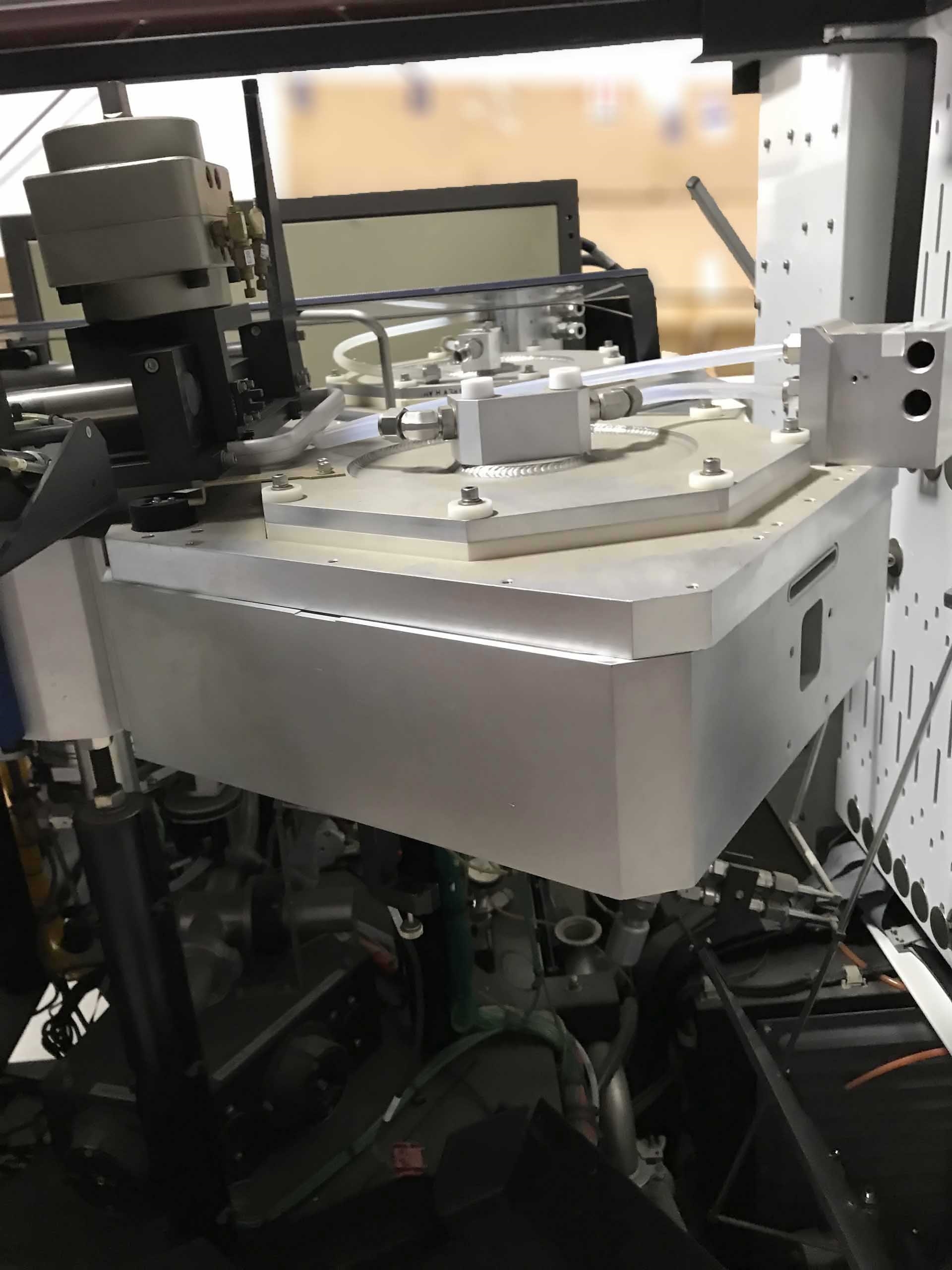

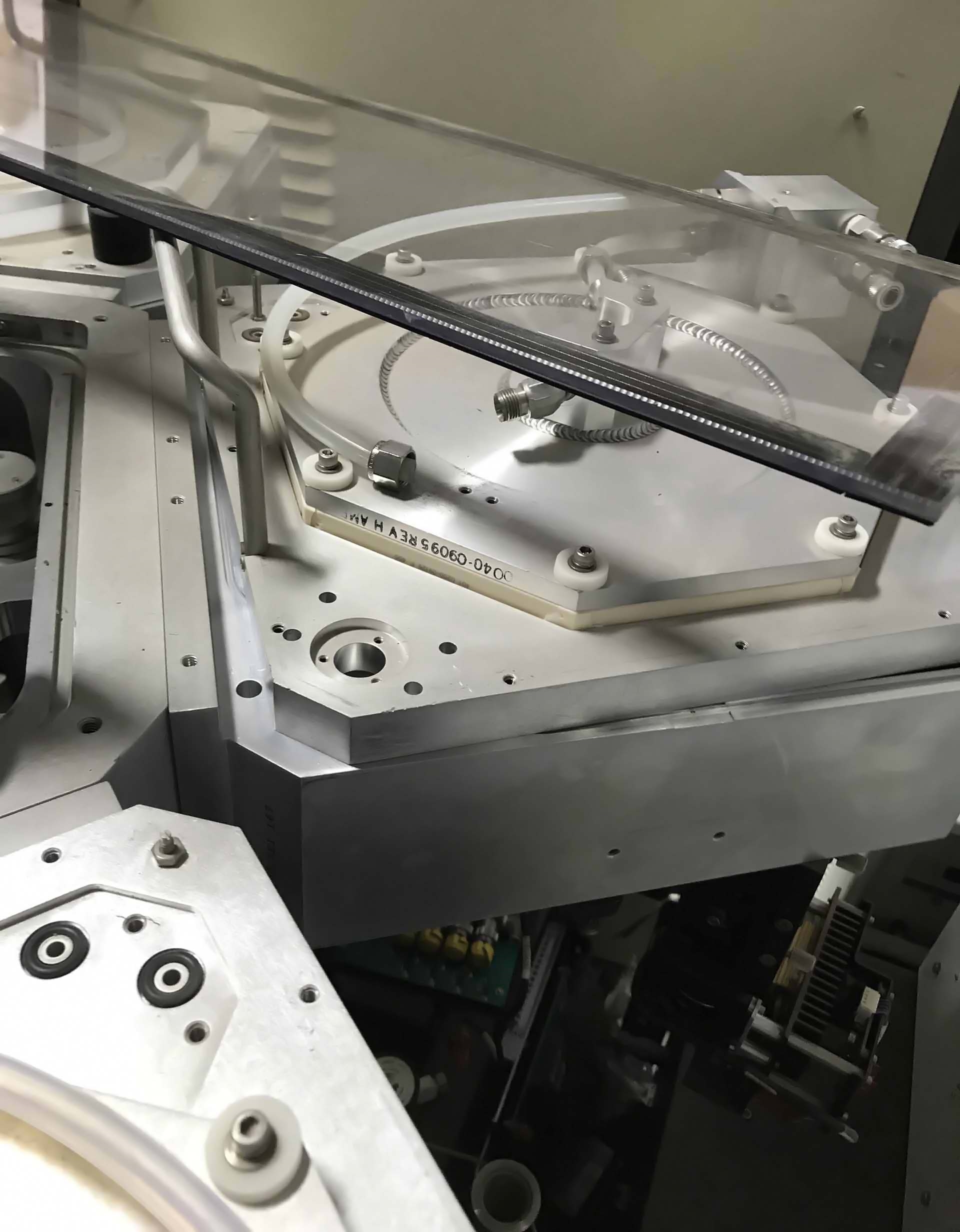

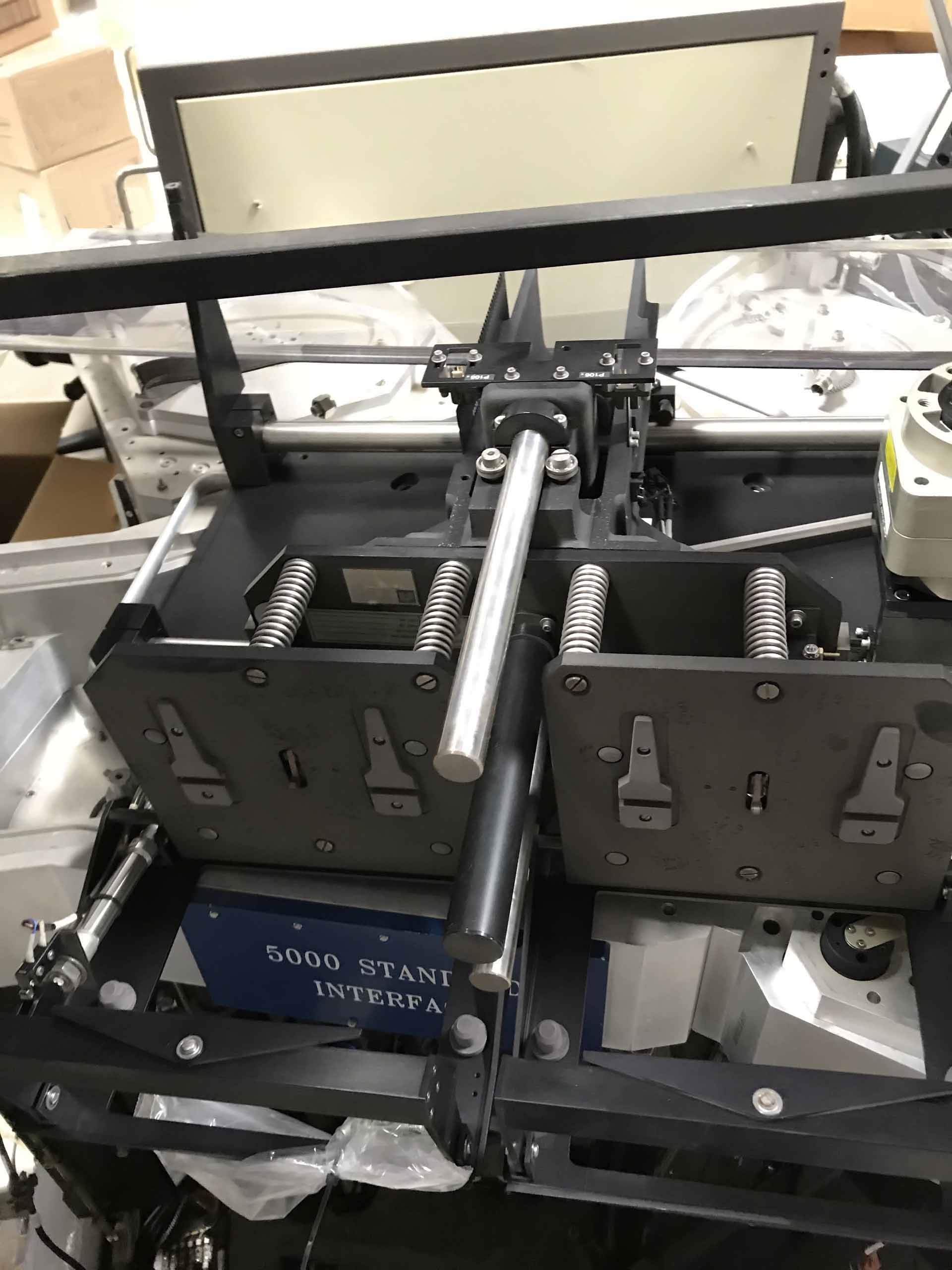

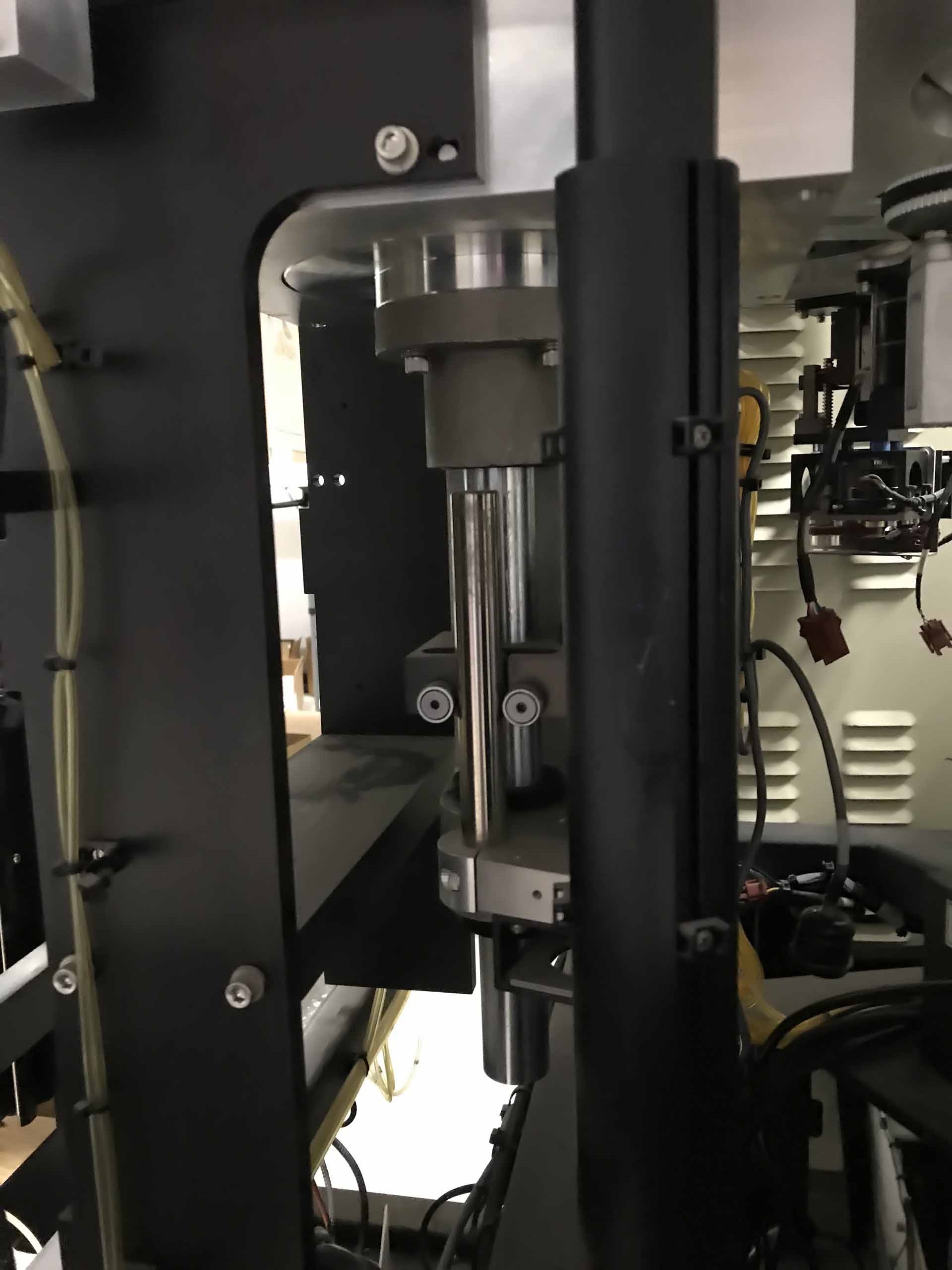

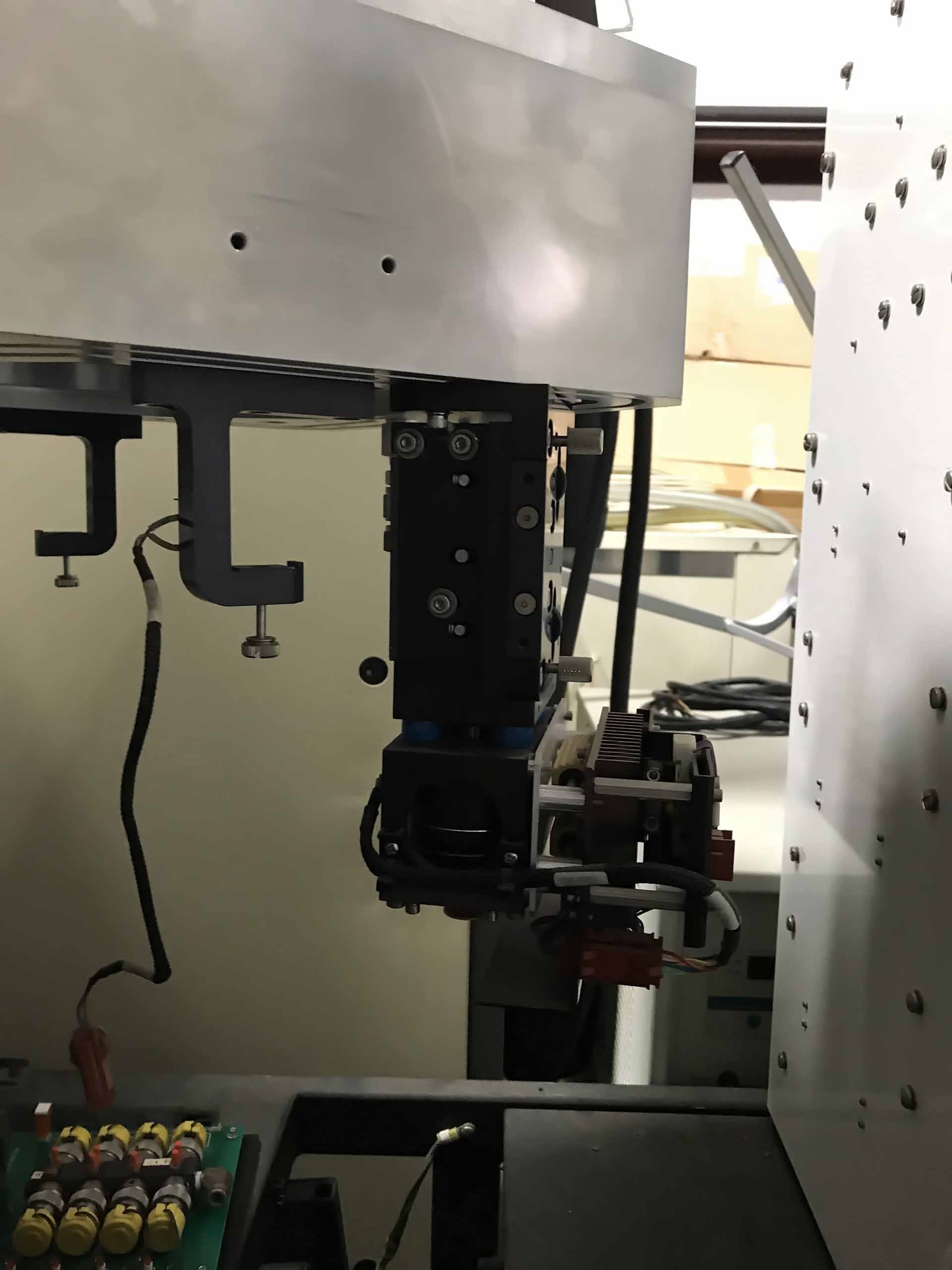

Used AMAT / APPLIED MATERIALS Frame for P5000 #9221729 for sale

URL successfully copied!

Tap to zoom

ID: 9221729

AMAT / APPLIED MATERIALS Frame for P5000 is a high-performance, dual-chamber scalar plasma-enhanced chemical vapor deposition (PECVD) reactor. It is designed to enable high-throughput deposition of a wide variety of materials. This reactor is suitable for a variety of applications such as coatings, thin films, and silicon wafer processing. AMAT Frame for P5000 is constructed from a stainless-steel cylinder on an aluminum base. This cylinder is divided into two reaction chambers: the upper chamber is used for deposition of materials, while the lower chamber is reserved for etch processes. The chambers are equipped with high-efficiency turbo molecular pumps for precise control of pressure and process gas flow. The upper chamber has a variable-frequency source, which generates electrical power to drive the process. The chamber also has a high-power gas box that provides precise control of process gases. APPLIED MATERIALS Frame for P5000 offers a variety of safety features, including overpressure protection, thermal monitoring, and interlock systems. It also has an integrated high-efficiency filter system that ensures clean operating conditions. The chamber also offers a variety of features to maximize process yields, including an auto-bottle program, automatic process control adjustment, and programs for quench throttling. Frame for P5000 is designed to enable consistent, efficient deposition of a variety of materials. It is also capable of handling process gases at high temperatures, enabling high throughput rates while maintaining uniform process parameters. This reactor is ideal for fabricating thin films of semiconductor materials, such as silicon, gallium arsenide, and aluminum nitride. It is also suitable for depositing oxides, nitrides, and polysilicon films. In conclusion, AMAT / APPLIED MATERIALS Frame for P5000 is a high-performance, dual-chamber scalar plasma-enhanced chemical vapor deposition (PECVD) reactor that is suitable for a variety of applications. It offers a range of features to maximize process yields, as well as a variety of safety features for protection and clean operating conditions. The chamber is capable of handling process gases at high temperatures, enabling high throughput rates while maintaining uniform process parameters. This makes it ideal for fabricating thin films of semiconductor materials, such as silicon, gallium arsenide, and aluminum nitride.

There are no reviews yet