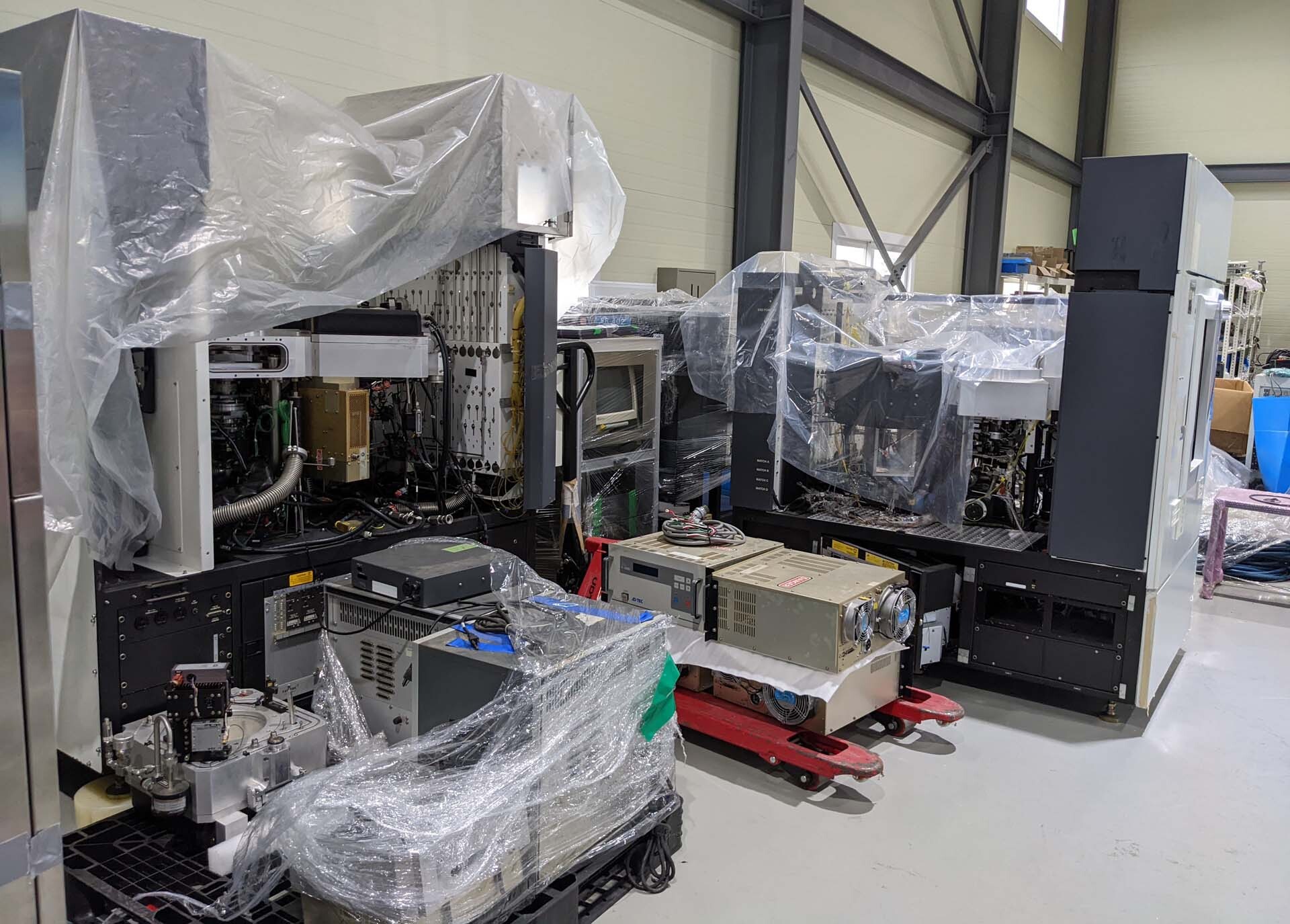

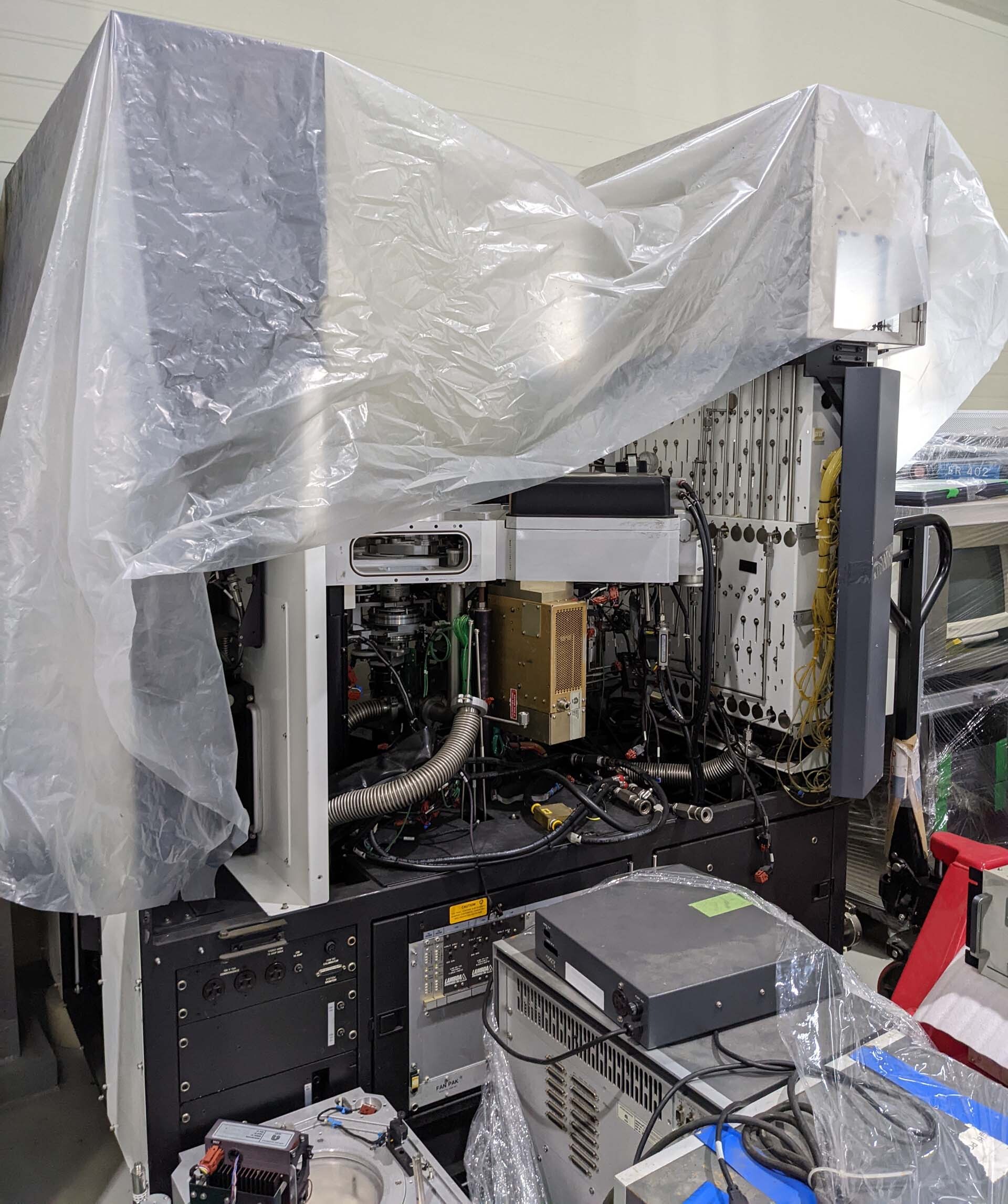

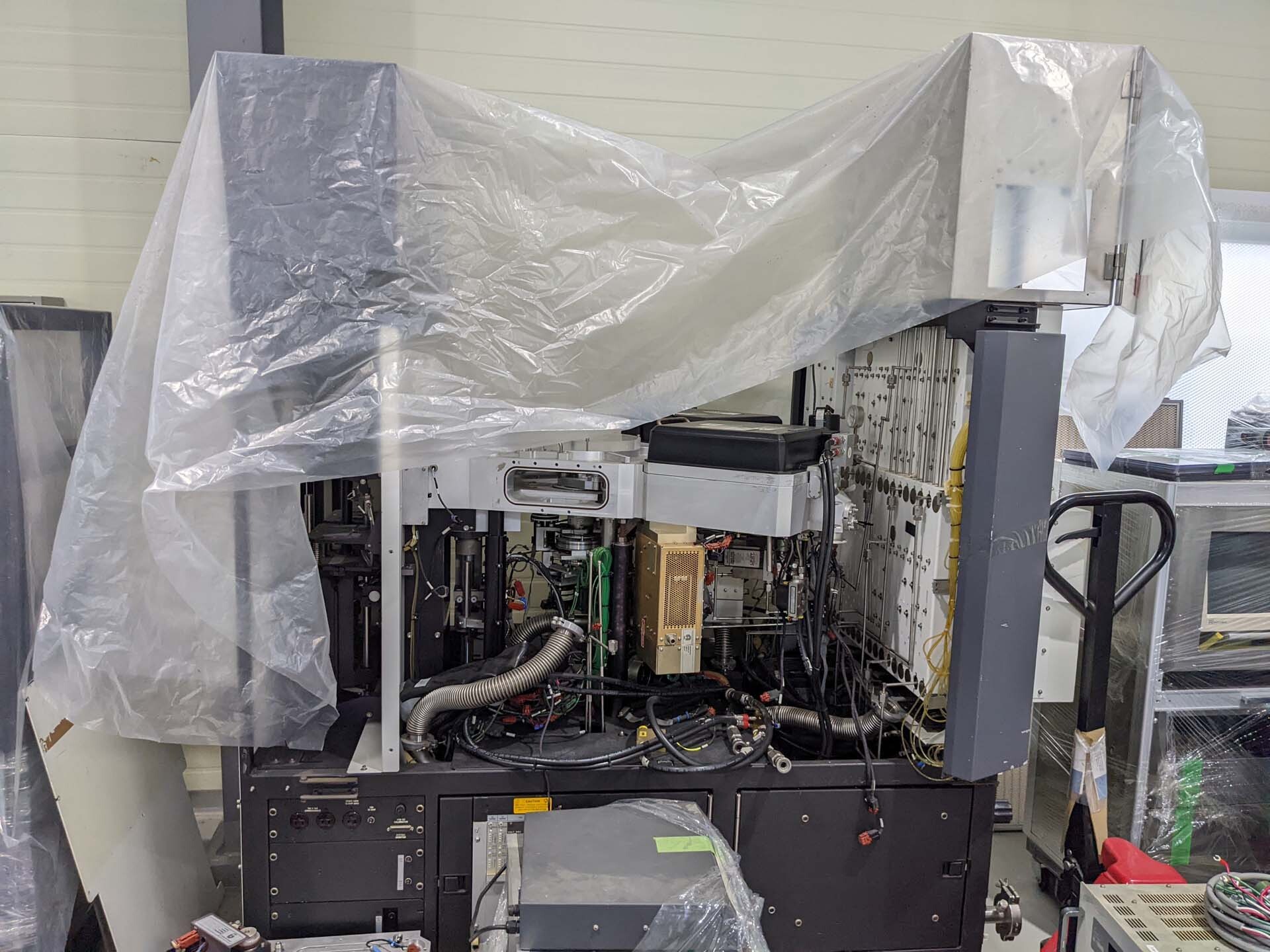

Used AMAT / APPLIED MATERIALS P5000 Mark II-J #293619352 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS P5000 Mark II-J is a specialized reactor designed for a wide range of process applications in the semiconductor industry. It is designed to optimize the etch and deposition processes for precise control over the physical and chemical characteristics of the wafers being processed. This reactor is known for its accuracy, speed, and reliability. The reactor is a horizontally-mounted vacuum chamber, which contains a silicon-based workpiece that can be patterned by either etching or deposition techniques. Its process chamber is equipped with a split-ring electrostatic chuck to secure the workpiece during the etching or deposition operation. The electrostatic chuck is capable of maintaining precise pressure, periodicity, and accuracy, even when the process needs to happen quickly. It also has a special jet cushioning technique to minimize vibration, ensuring precise results. In the deposition process, AMAT P5000 Mark II-J uses linear barrel sources and platen sources to produce a uniform and precise thickness of the film. It is capable of depositing a wide range of advanced materials, including metals, oxides, and nitrides. With its advanced linear barrel technology, APPLIED MATERIALS P5000 Mark II-J is able to achieve a higher level of uniformity than traditional platen-based systems. P5000 Mark II-J is also equipped with advanced single-wafer deposition technology, which is necessary for thinner film deposition. This technique consists of precision valves, control circuitry, and process chambers that are tailored to the deposition of metals, oxides, and nitrides. It is capable of depositing uniform thin films with controlled nucleation, reducing the possibility of defects in the film. AMAT / APPLIED MATERIALS P5000 Mark II-J is capable of achieving precise thickness and uniformity in etching and deposition processes. It uses advanced electrostatic chucks for wafer retention, linear barrel sources for precise deposition, and single-wafer deposition technology for thinner film production. This reactor is a reliable and precise tool that provides consistent results.

There are no reviews yet