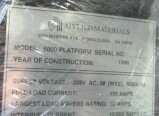

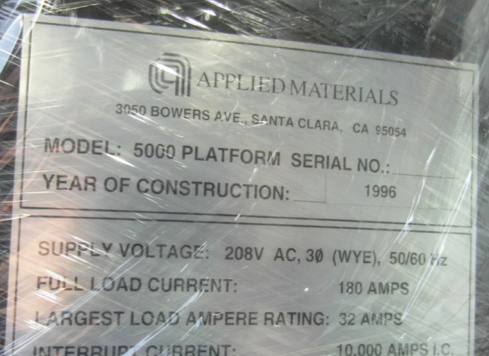

Used AMAT / APPLIED MATERIALS P5000 Mark II-J #9051380 for sale

URL successfully copied!

Tap to zoom

ID: 9051380

Wafer Size: 8"

Vintage: 1996

CVD Systems, 8"

(3) Chambers

Wafer type: Notch

Vacuum processing type

MFC:

Gas #1: SIH4 200 sccm

Gas #2: N2 10 slm

Gas #3: NH3 100 sccm

Gas #4: NF3 1 slm

Gas #5: N2O 3 slm

Gas #6: CHF4 3 slm

Gauges:

(2) MKS 122BA Baratron, 10 torr

MKS 628A Baratron, 10 torr

Includes:

AD TEC Generator AX-1000AM2

AMAT Matcher

AC Rack

Gas box

(2) Chillers

Heat exchanger

(3) Dry pumps

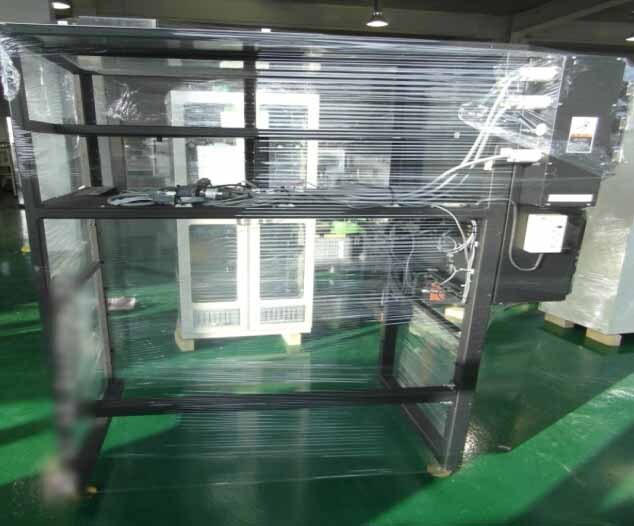

Mainframe

PC Rack

GEN Rack

(2) Regulator boxes

(2) FAPC Racks

(9) Accessory boxes

(2) Power boxes

(3) RF Power supplies

AMAT-0 H / E

(2) Panels

(3) Columns

Abatement system

(2) Column boxes

(3) Abatement filter

Transformer

(3) Gas detectors

Currently stored in cleanroom

1996 vintage.

AMAT / APPLIED MATERIALS P5000 Mark II-J reactor is a robust and high-performance PECVD equipment for the deposition of dielectric, semiconductor, and metal films. Equipped with a radio frequency (RF) power source, this reactor is capable of depositing films at reduced performance to drastically reduce material costs. It is designed for semiconductor device manufacturing, and is well-suited for use in both research laboratories and industrial fabs. AMAT P5000 Mark II-J utilizes a single-wafer design to offer reliable and uniform film uniformity with excellent repeatability on each wafer. The design allows for complete uniformity, allowing better performance than other systems. This system, featuring dual cold walls, is capable of generating high-quality, low-stress films with superior packing density when depositing dielectric and semiconductor materials on the wafer. It is also capable of depositing metal oxides by metal-organic chemical vapor deposition (MOCVD). APPLIED MATERIALS P5000 Mark II-J is equipped with advanced annealing capabilities to ensure process control. The unit provides uniform temperature control with active temperature monitoring and an embedded controller for improved temperature accuracy. It is also configured with an integrated remote chamber for additional monitoring and diagnostics capabilities. The design also affords outstanding efficiency as it maximizes film deposition rates up to 20nm/min with consistent uniformity across wafers. P5000 Mark II-J is designed with a robust process chamber and a modular design with easy maintenance. This allows for quick repair time and minimal downtime. The machine also comes with a range of accessories, including an automated scanner, an RF source, an ultra-sensitive optical sensor, and an auxiliary gas supply. The combination of its advanced monitoring and diagnostic features, robust design, and high performance make AMAT / APPLIED MATERIALS P5000 Mark II-J a powerful and reliable reactors for use in applications such as semiconductor devices, dielectric films, and metal oxides deposition.

There are no reviews yet