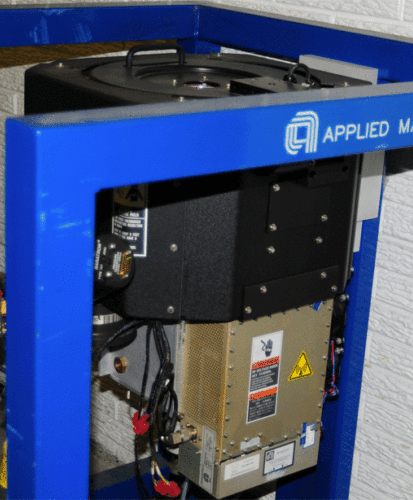

Used AMAT / APPLIED MATERIALS P5000 Mark II #156342 for sale

URL successfully copied!

Tap to zoom

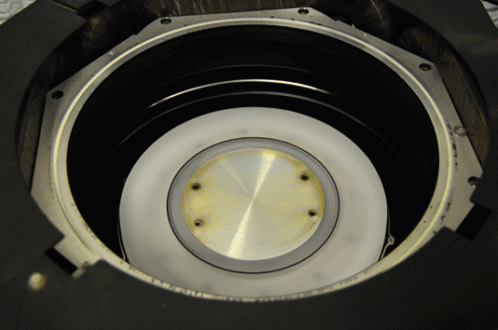

AMAT / APPLIED MATERIALS P5000 Mark II reactor is a high-performance deposition equipment used for the fabrication of semiconductor devices. It is a hot-wall, single-wafer, metal-organic chemical vapor deposition (MOCVD) reactor. The system is designed to allow for superior process flexibility and quality while still delivering good uniformity and repeatability of results. AMAT P5000 Mark II reactor is ideal for semiconductor device manufacturing processes such as metal-oxide-semiconductor (MOS) field-effect transistor (MOSFET) and related compound semiconductor devices. APPLIED MATERIALS P 5000 MARK II unit features advanced reaction technology with multi-level automated control and management. With the machine, wafers can be processed in single-wafer mode or batch wise. The tool offers good process repeatability, stability and uniformity. The asset can also be used to manufacture multiple device layers in the same process chamber in a single run. P 5000 MARK II reactor is capable of process temperatures from 450°C (842°F) up to 950°C (1742°F). It has a maximum process pressure range of up to 5 Torr (0.66 atmospheres). The gas flow rate and the single-wafer uniformity are both adjustable throughout the deposition process. The model can be equipped with up to sixteen gas delivery sources, which can be independently programmable for maximum process flexibility. The equipment also offers a low particle rate for a clean process. AMAT P 5000 MARK II reactor has a four-armed robot system and a high-efficiency cooling unit featuring a silicon carbide (SiC) nozzle. Additionally, the machine provides an ultra-low particle rate, superior process repeatability and a long lifespan of enhanced parts, particularly in the growth of compound semiconductor devices. It can be used with a variety of materials, including gallium arsenide (GaAs), indium phosphide (InP), aluminum gallium arsenide (AlGaAs ) and other III-V compounds. The tool also features an advanced autoloader with wafer-to-wafer process repeatability, ensuring uniformity across different wafers with minimal to no operator intervention. The autoloader also includes a asset for drying wet-processed wafers before entering the chamber. P5000 Mark II reactor also comes with a recipe and fault traceability model, which can enable better process control and refined data analysis. AMAT / APPLIED MATERIALS P 5000 MARK II reactor gives semiconductor device manufacturers the ability to perform a wide range of process and fabrication tasks quickly and accurately, with greater levels of process repeatability and uniformity than before. The equipment's features and functionality make it an invaluable tool for any semiconductor application.

There are no reviews yet