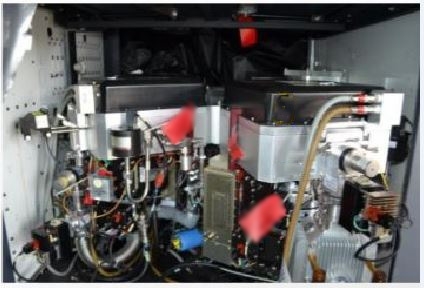

Used AMAT / APPLIED MATERIALS P5000 Mark II #9193242 for sale

URL successfully copied!

Tap to zoom

ID: 9193242

Wafer Size: 6"

Vintage: 1993

CVD Systems, 6"

Chamber A:

TEOS: C2F6 2000 N2, O2.S 1000, NF3 1000 N2, TEOS 1500, Meter 4000, 100 Torr

Chamber B:

Sion / Nitride: SiH4 300, N2 5000, PH3 1000, NH3 100, CF4 5000 N2, N2O 3000 N2, N2 std 200

Purge: 8000 N2, 10 Torr, DPA

Chamber C:

Sion / Nitride: SiH4 300, N2 5000, PH3 1000 N2, NH3 100, CF4 5000 N2, N2O 3000 N2, N2 std 200

Purge: 8000 N2, 10 Torr, DPA

Includes:

Pumps

Chiller

RF Generator

Hot box

Remote gas panel

Mini controller

Currently installed

1993 vintage.

AMAT / APPLIED MATERIALS P5000 Mark II is a High-Density Plasma Reactor that is used in the production of Integrated Circuit (IC) devices. The reactor is composed of several compartments, including the plasma source, the process chamber, the gas distribution equipment, and the vacuum system. The plasma source uses microwave energy, typically 2.45 GHz, to create an energetic plasma in the process chamber. This plasma is used as a production medium for IC components. The process chamber, which is enclosed in a vacuum, typically operates at pressures between 10 and 12 mTorr. Inside the process chamber is the substrate holder where the IC samples are placed. Just above the substrate holder is the gas delivery unit which is the core of AMAT P5000 Mark II. It contains an array of brass nozzles connected to the gas inlet lines for controlling the delivery of the various gases required for the IC production process. The gas distribution machine is designed such that the gas flow is uniform over the substrate plane. The vacuum tool is used to maintain the required process chamber pressure. The vacuum asset includes a turbo-molecular pump, as well as fore-line and diffusion pumps. The turbo-molecular pump ensures the processes will maintain a consistent pressure, while the other pumps provide evacuation of gases that result from the ion bombardment process. APPLIED MATERIALS P 5000 MARK II has a range of control parameters to allow precise process control. The parameters that can be adjusted by the user include the total processing pressure, the process gas flow and composition, the substrate temperature, the power levels of the ion bombardment, as well as other parameters. Together, these parameters allow for the precise control of the process environment to reproduce specific results and adjust for process variations. Overall, AMAT / APPLIED MATERIALS P 5000 MARK II is a highly advanced, versatile reactor used for the production of IC devices. It utilizes multiple compartments and systems in conjunction with varied control parameters for precise process control. This allows for the uniform production of high-quality IC devices.

There are no reviews yet