Used AMAT / APPLIED MATERIALS P5000 Mark II #9300021 for sale

URL successfully copied!

Tap to zoom

ID: 9300021

Wafer Size: 8"

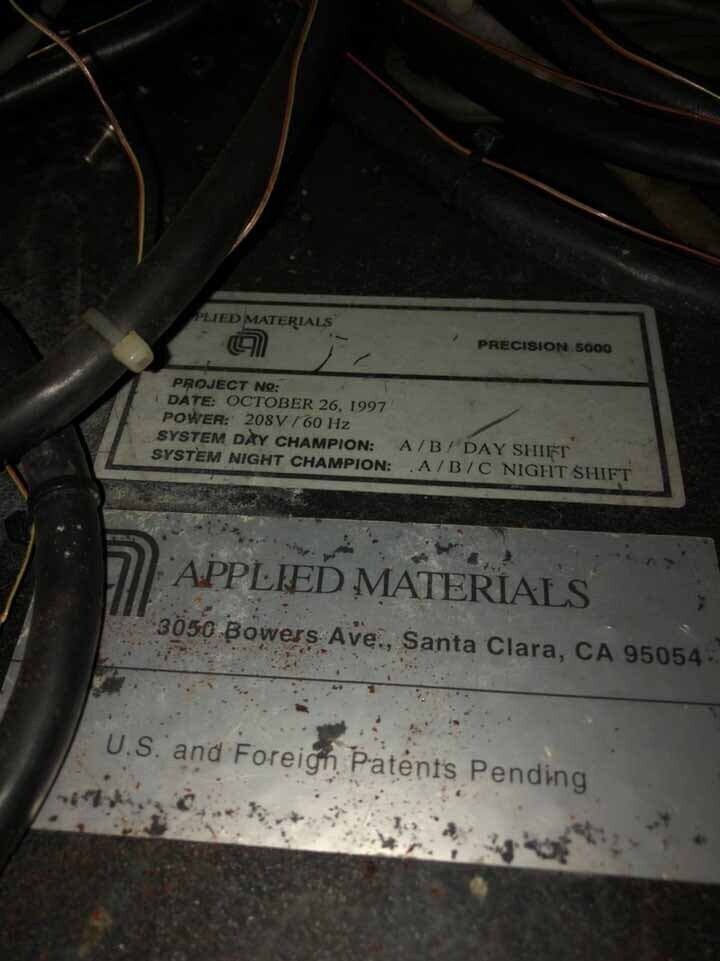

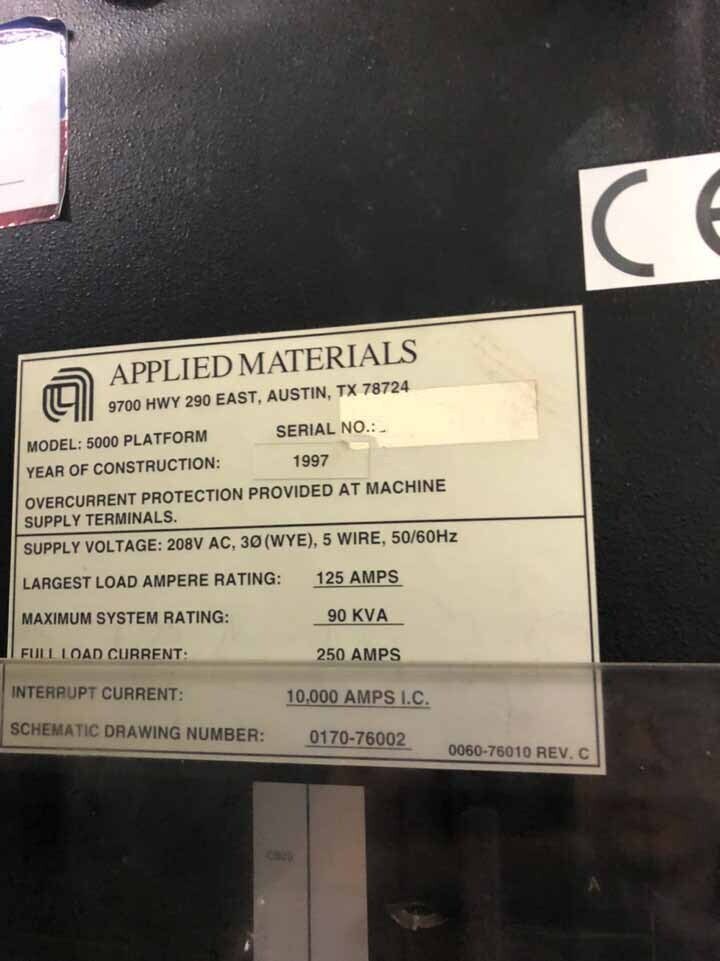

Vintage: 1997

CVD Etcher, 8"

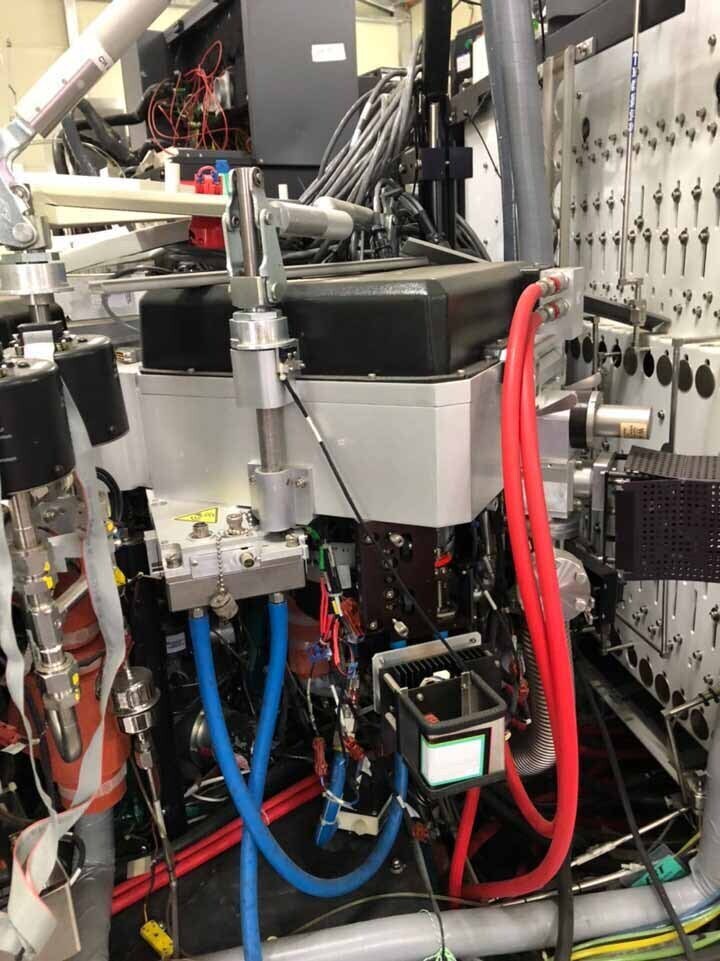

Mainframe

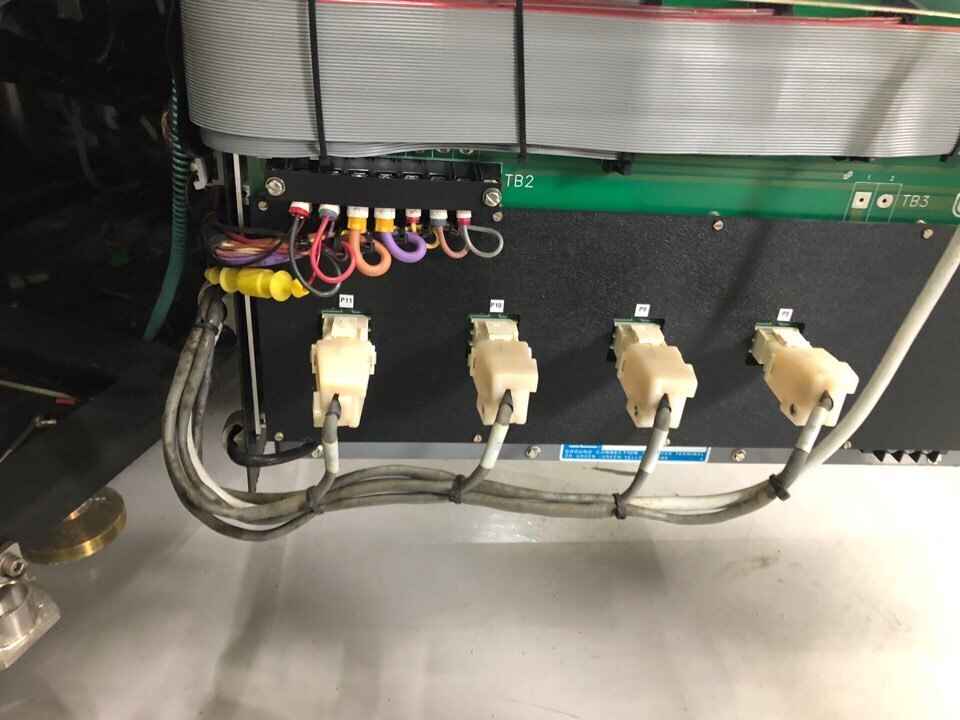

Mainframe cables

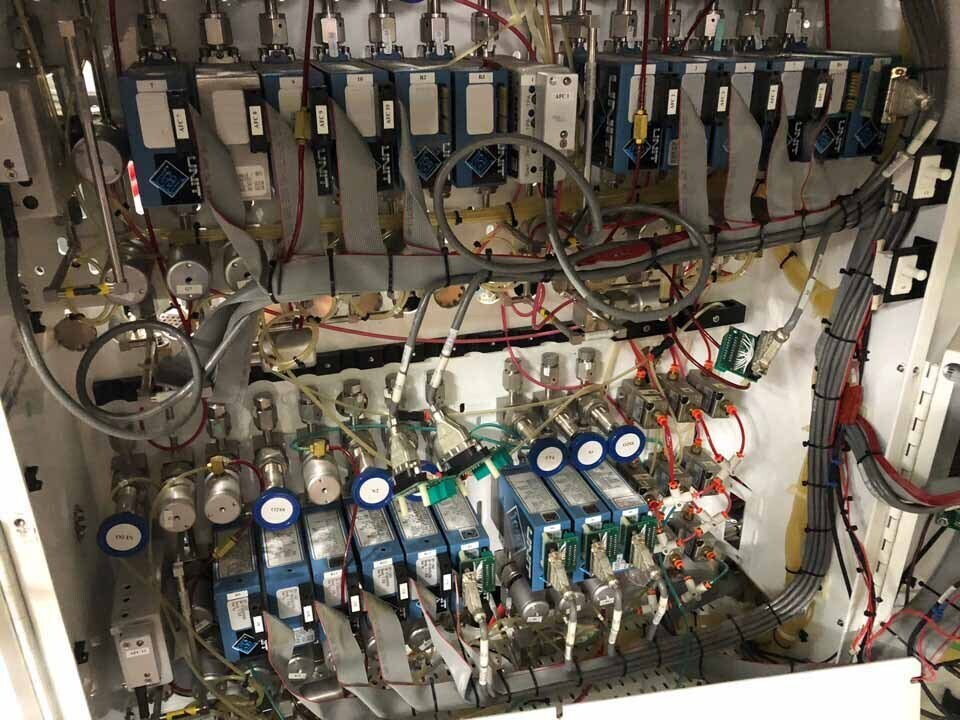

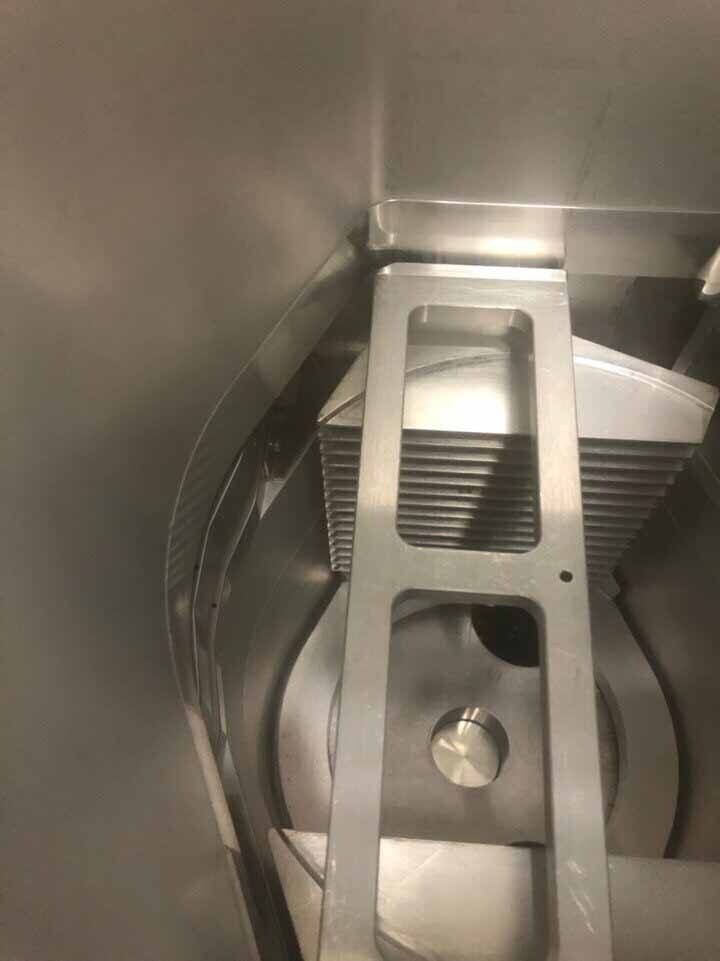

Chamber A / B / C:

Type: DCVD Universal

Process: SA / Delta / TEOS

Process kit: Plasma C-chuck

Manometer: Dual 20-1000 Torr/MKS

Clean method: RF Clean

Throttle valve: Direct drive dual spring W/C plug

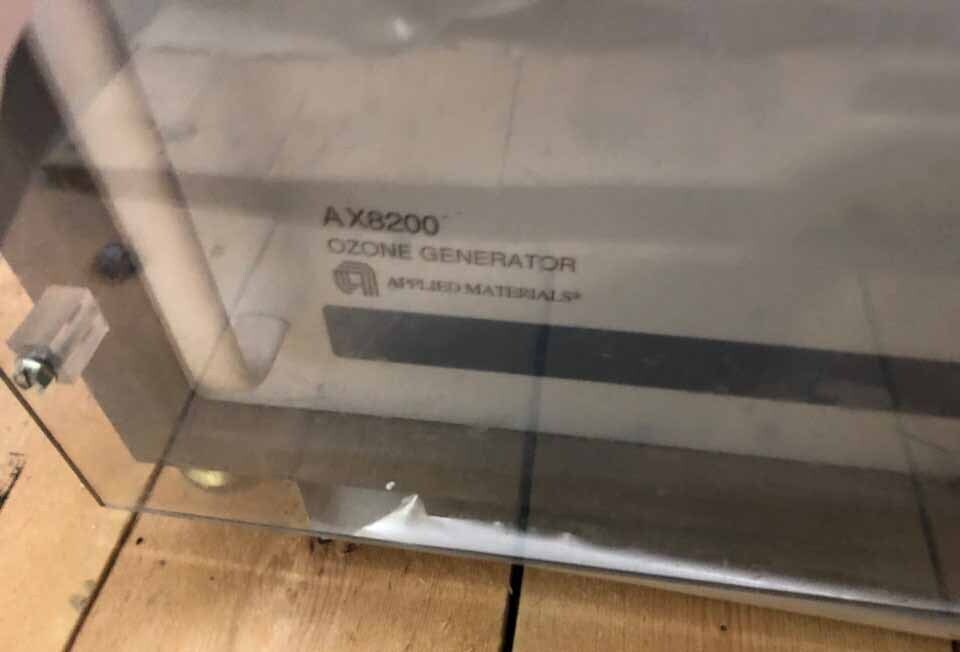

ASTEX AX8200 Ozone generator

Gas box MFC: UNIT MFC

Lamp driver

RF Gen I / II: RFDS 2000-2V/RFPP LF-5

RF Match: Phase IV

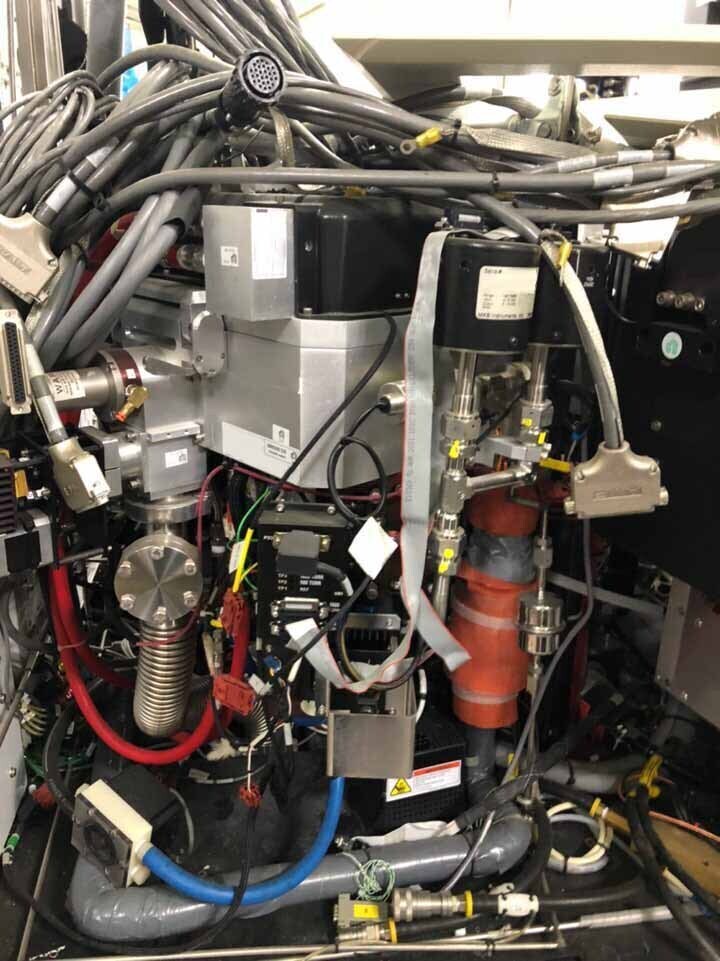

Chamber D:

Process: Sputter etcher

Process kit

Manometer: Single Torr/MKS

Clean method: RF Clean

Throttle valve

Turbo pump

Magnet driver

Gas box MFC: UNIT MFC

RF Gen I / II: ENI OEM 12B

RF Match: Phase IV

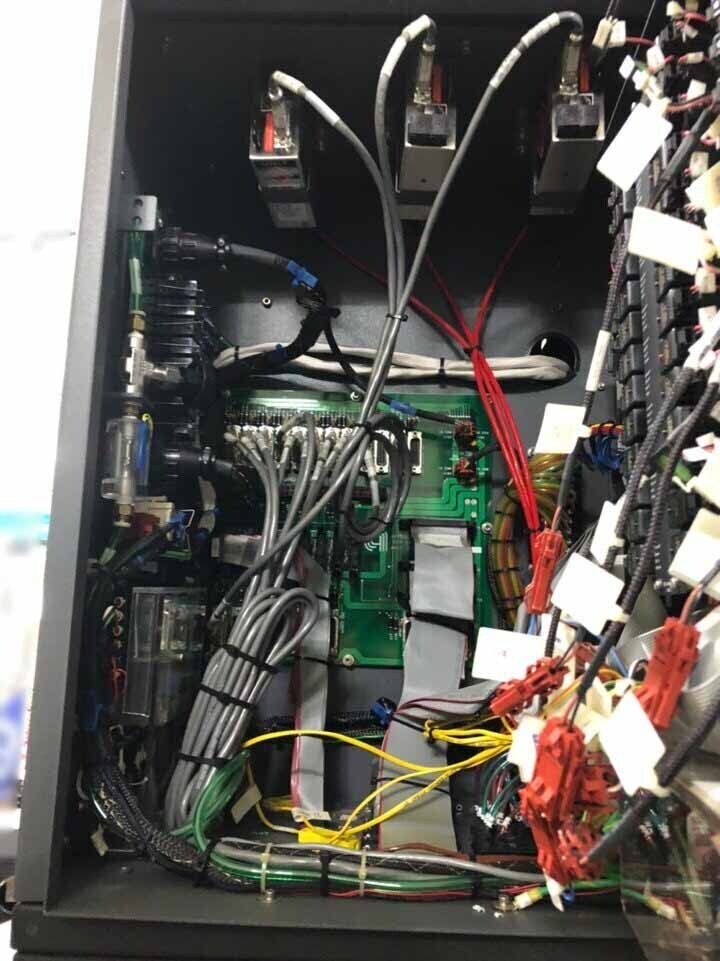

21-Controller slots

SBC Board type: V21 SYNERGY

Boss ROM version: E4.8

Video board type: VGA

Floppy Disk Drive (FDD), 3.5"

Robot type: Phase III

Auto-load / Unload cassette handler

Silicon-Tin-Oxide (STO) elevator type: 15-Slots

WPS Sensor

I/O Wafer sensor

Loadlock Purge

Loadlock Slow vent

Slit valve type: ZA Slit valve

Hot box version: Version IV

Top / Standard exhaust line

(28) Gas line panels

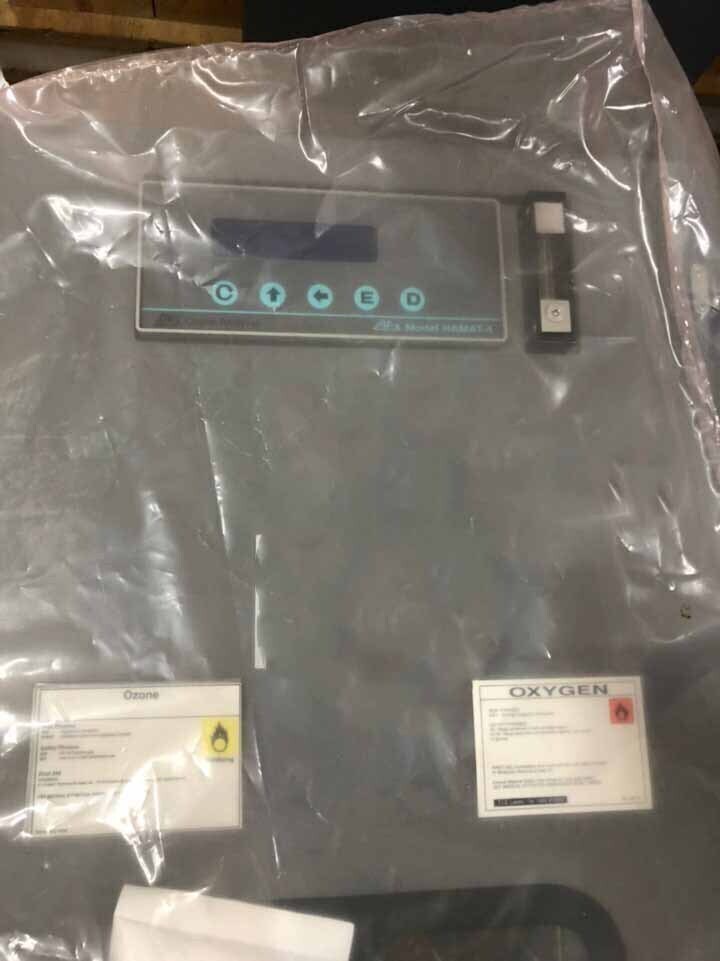

HAMART-4 Ozone monitor

Mini controller

Chiller

Safety module: (2) EMO Switches

Remote frame

EMO Switch

Expanded VME: (15) Slots

No Monitor rack

CRT Monitor

Light pen

Service monitor rack

Miscellaneous:

No Hard Disk Drive (HDD)

Transformer

Laminar flow hood

No mainframe cover

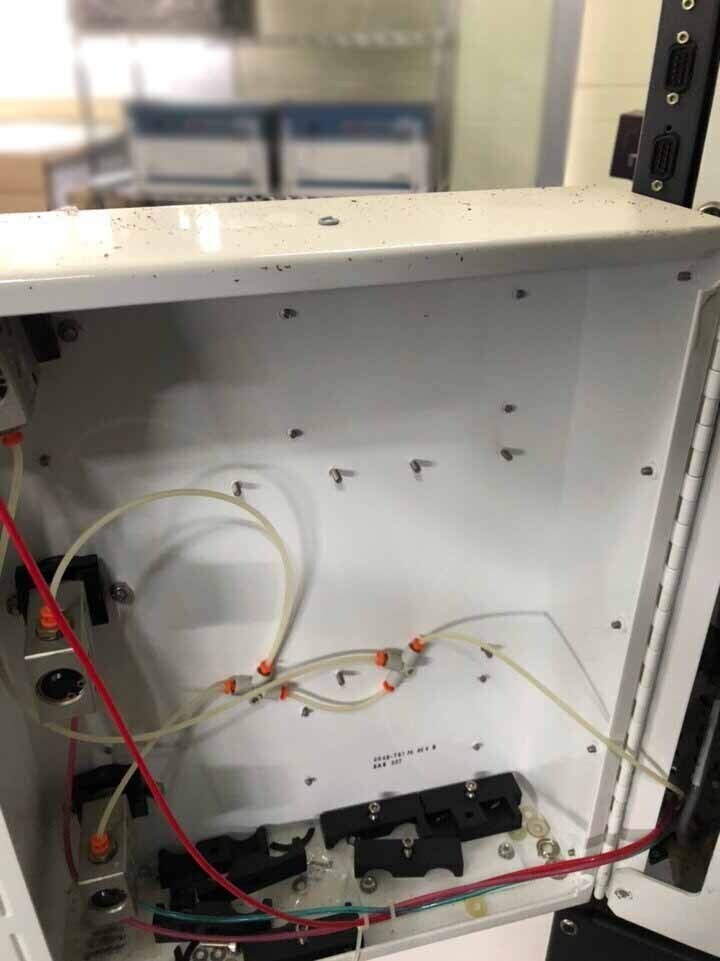

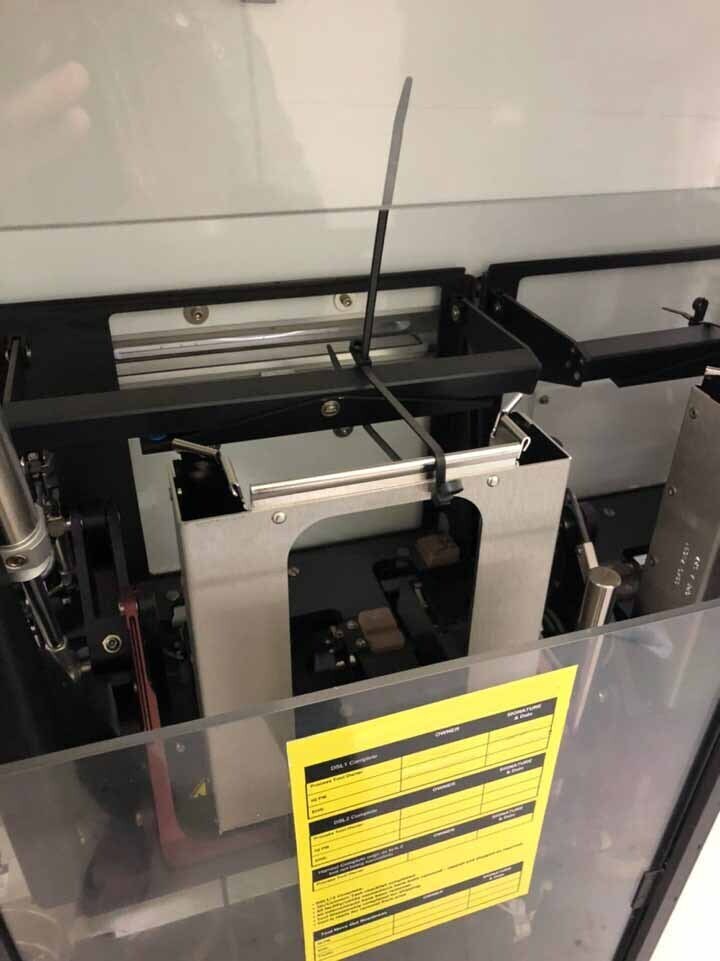

Load lock chamber:

Robot type: Phase III robot

Robot blade: 8"

Continuous purge

Center finder board

TC Gauge

ATM Switch

Vacuum switch

Vacuum sensor (TC)

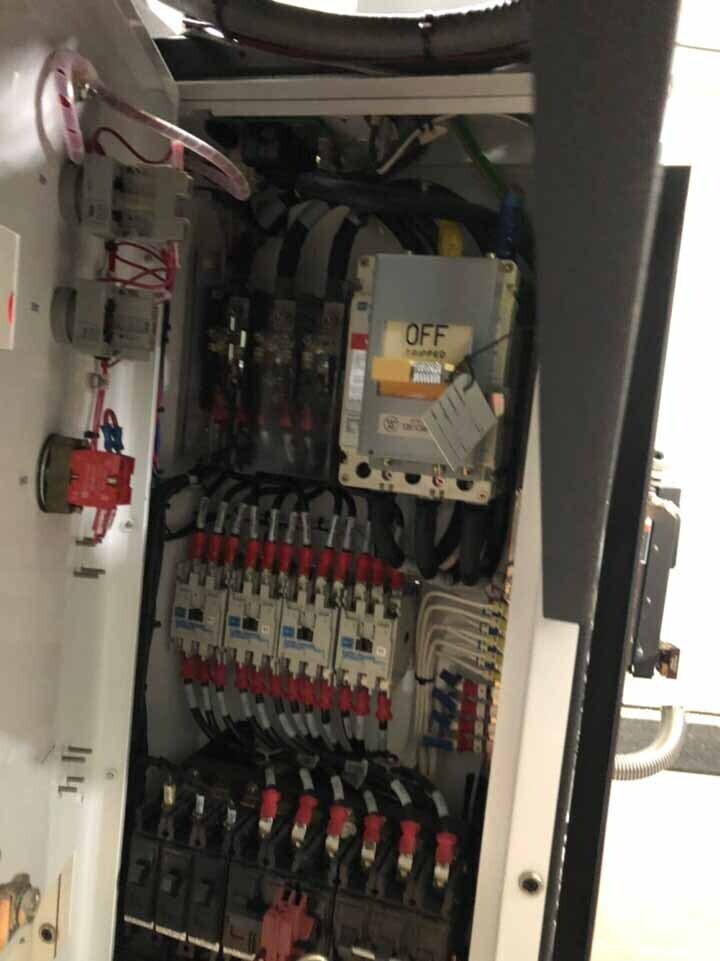

System electronics:

(2) TC Gauge boards

+12 VDC Power supply

+15 VDC Power supply

-15 VDC Power supply

Buffer I/O board

AI MUX Board

Optical sensor boards

Chopper driver boards

Pneumatic control PCB

Main DC power supply

VME Controller:

Intelligent interface board

Missing SBC board

SEI Board

Co-processor board

(4) AI/AO / AI/O Boards: (1 AI and 1 AO)

Missing video board (VGA)

(4) Stepper boards

(4) DI/DO / DI/O Boards (7)

System misc:

Remote wiring dist board

System wiring dist board

No I/O Distribution board

Mini controller

Heat exchanger

Process / A / B / D

Mark II TEOS / CVD TEOS / CVD TEOS

RF Generator 1 / RFDS 2000-2V / RFDS 2000-2V / RFDS 2000-2V

O3 Generator / AX-8200 / AX-8200 / AX-8200

LF Generator / RFPP LF-5 / RFPP LF-5 / RFPP LF-5

TC Gauge

Isolation V/V / Cluster type

Interlock:

Coolant flow

Half ATM switch

Lamp module

CVD Lamp driver

Lift assy:

Susceptor lift assy

Wafer lift assy

Gas panel:

Gas panel interface

Expanded gas panel PCB

Standard or expanded module

Air maker

1997 vintage.

AMAT / APPLIED MATERIALS P5000 Mark II reactor is a powerful, large-scale production plasma etching and deposition equipment. This system is widely used in the fabrication of integrated circuits, such as memory and logic chips, as well as display panels, sensors, and other microelectronic devices. It utilizes a proprietary high-density inductively coupled radio-frequency powered plasma source to create an ionized gas which reacts with a substrate to create the desired process outcome. The engine of AMAT P5000 Mark II reactor consists of a vacuum chamber, microwave generator, support structures, and a high-power RF generator. The high-power RF generator generates an electric field of up to 200,000 volts at a frequency of 13.56 MHz. This high-power field ionizes the process gas, providing a plasma that is capable of completing the etching process and deposition. The generator also controls the deposition rate and temperature, thus allowing for accurate control of the final result. The reactive gas of APPLIED MATERIALS P 5000 MARK II reactor consists of a combination of chemical compounds including chlorine and nitrogen-based gases. These react with the substrate to create a variety of processes such as etching, deposition, and passivation. The reactor is also capable of performing oxygen ashing and chemical-mechanical polishing (CMP) processes. P 5000 MARK II reactor has numerous safety features and automation to ensure a high level of safety. For example, the reactor is housed within an inert-gas filled chamber to protect both the equipment and the operator from a potentially hazardous environment. Furthermore, the unit includes a temperature monitor and alarm machine that shuts down the tool if the temperature exceeds certain levels. In conclusion, P5000 Mark II reactor is a powerful, advanced plasma etching and deposition asset that provides precise control over the deposition rate and temperature. It is designed for high-volume production and safety, and is used extensively in the fabrication of ICs and other electronic devices.

There are no reviews yet