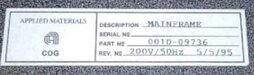

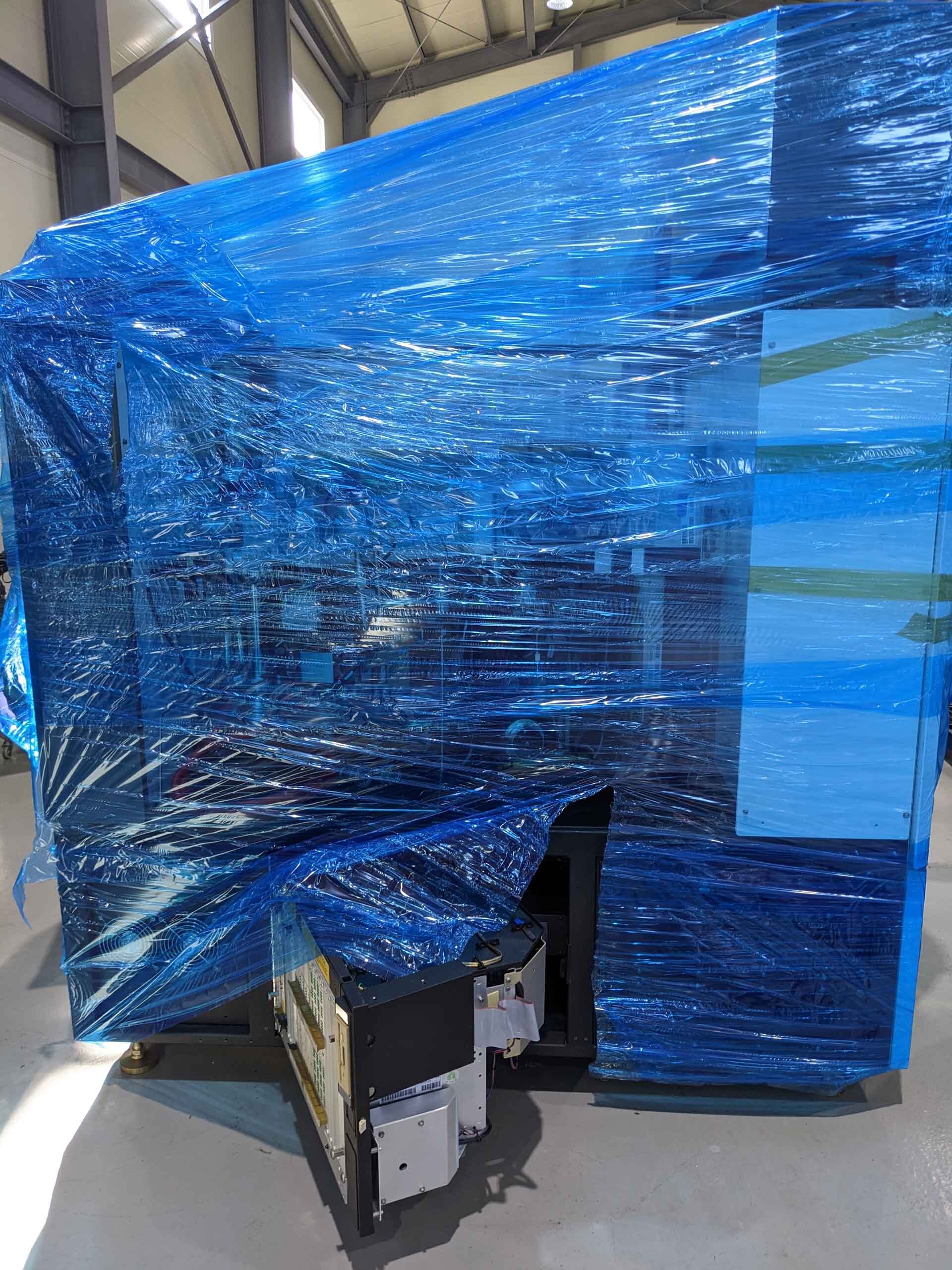

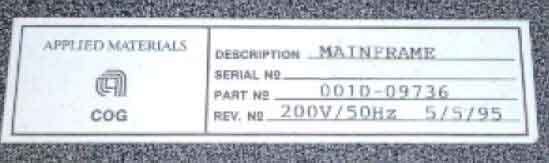

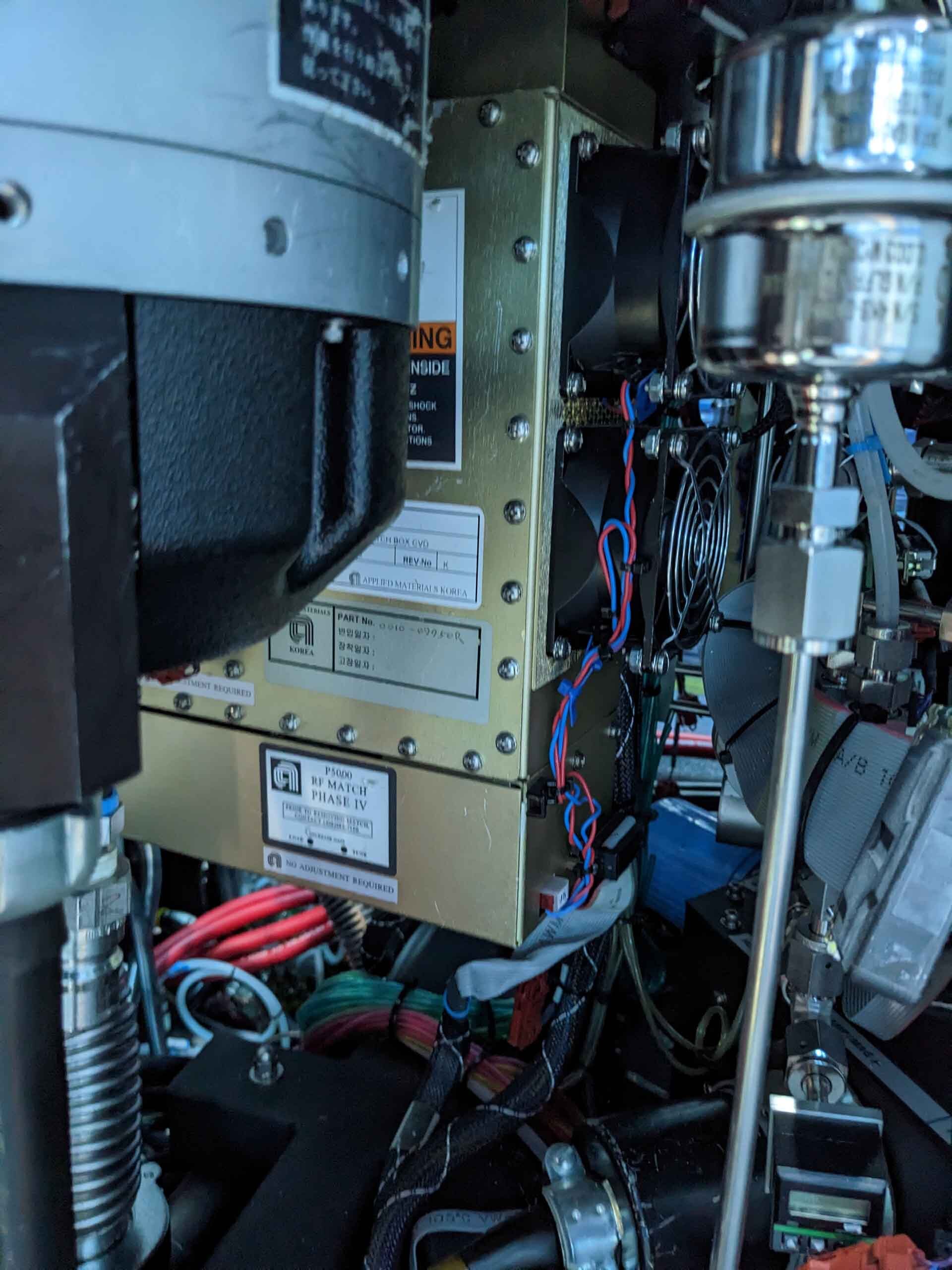

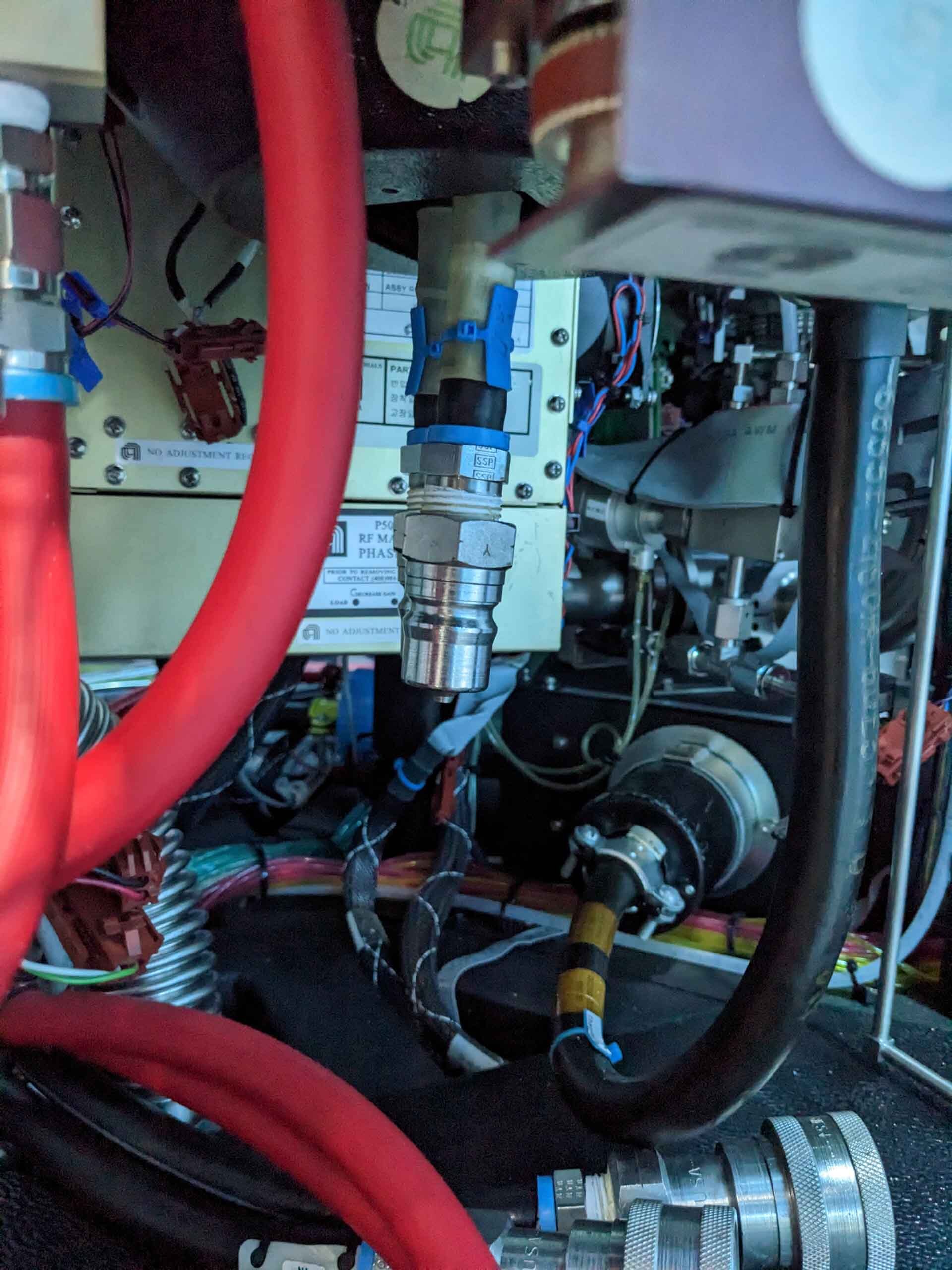

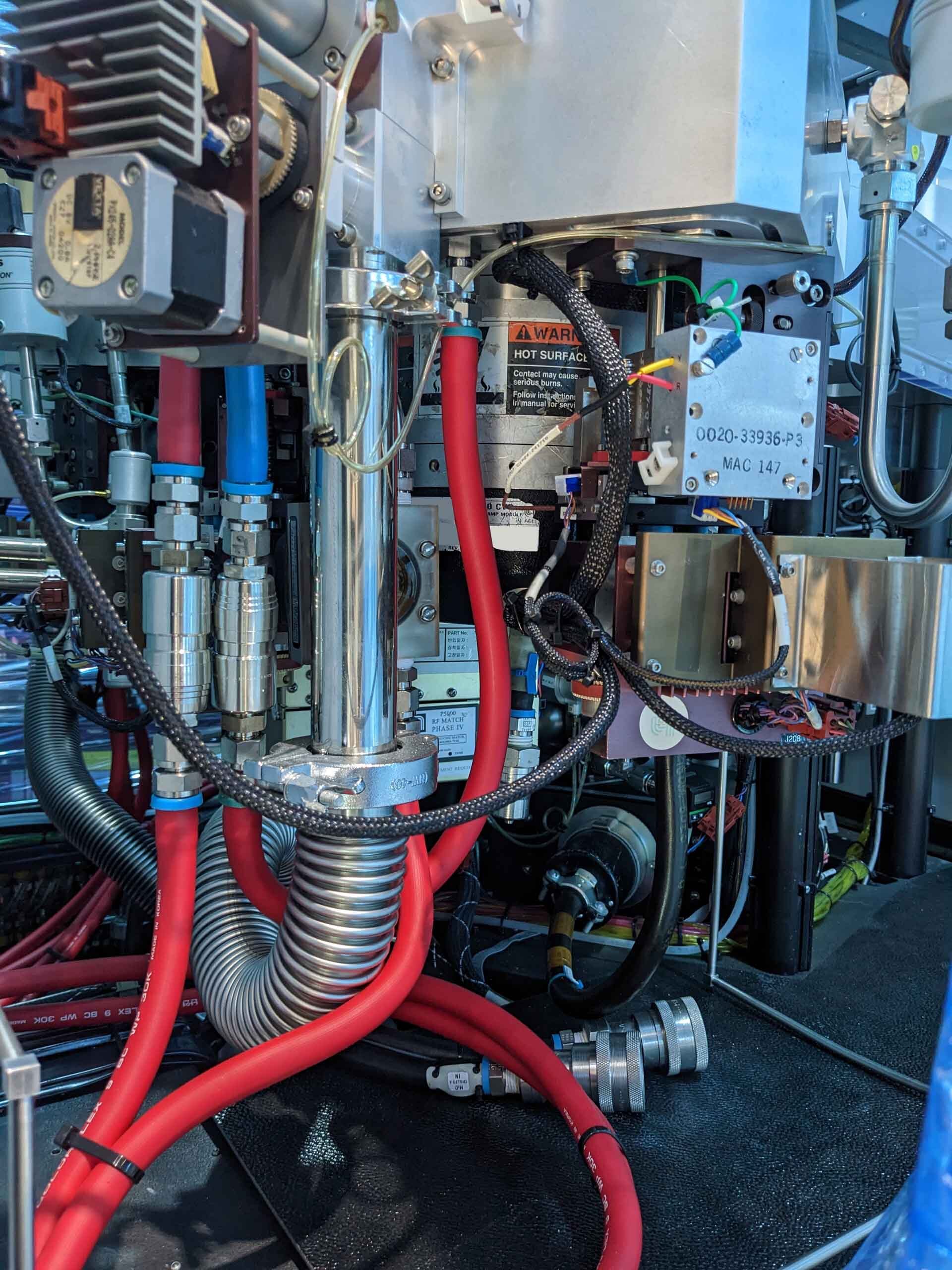

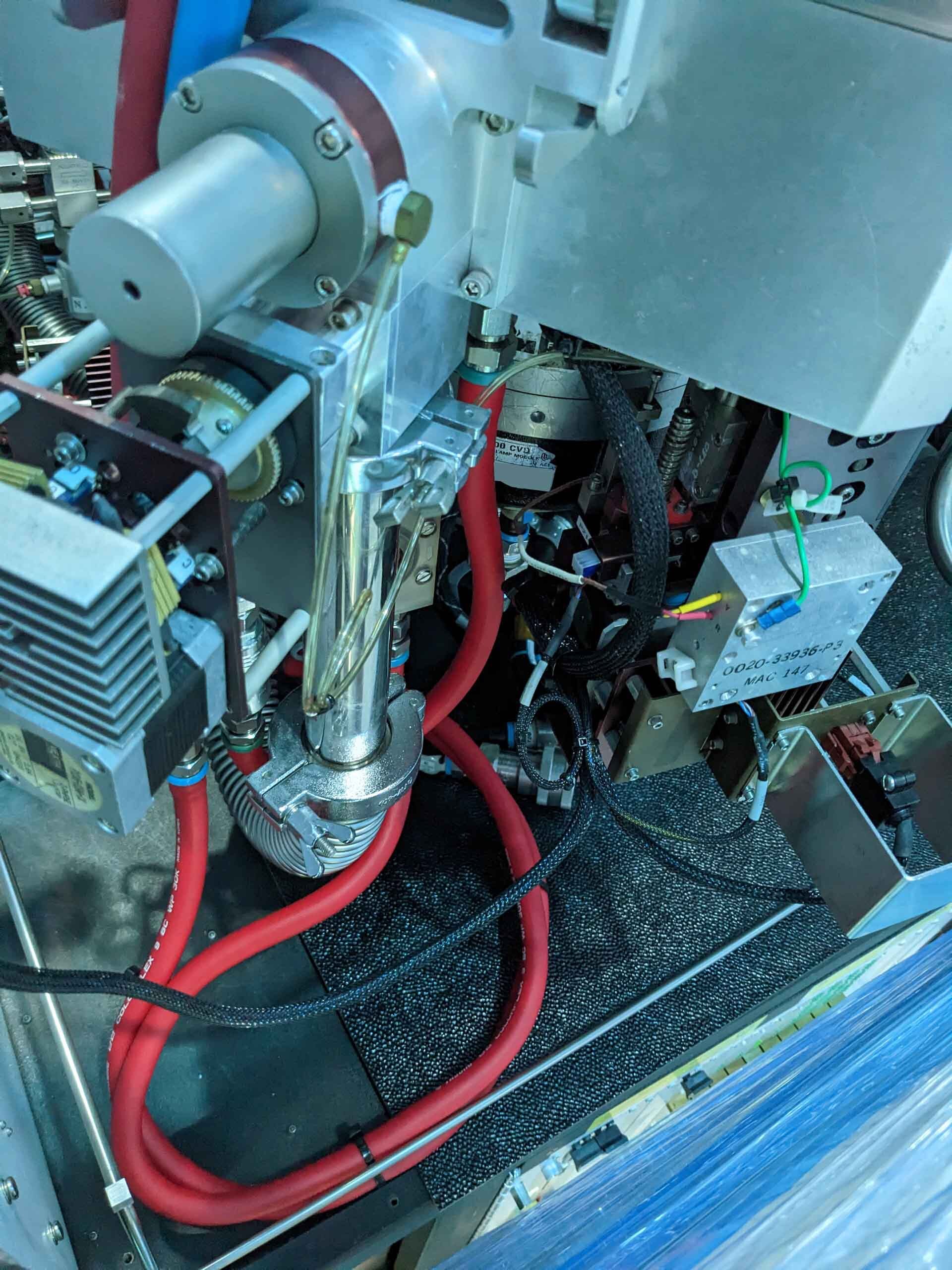

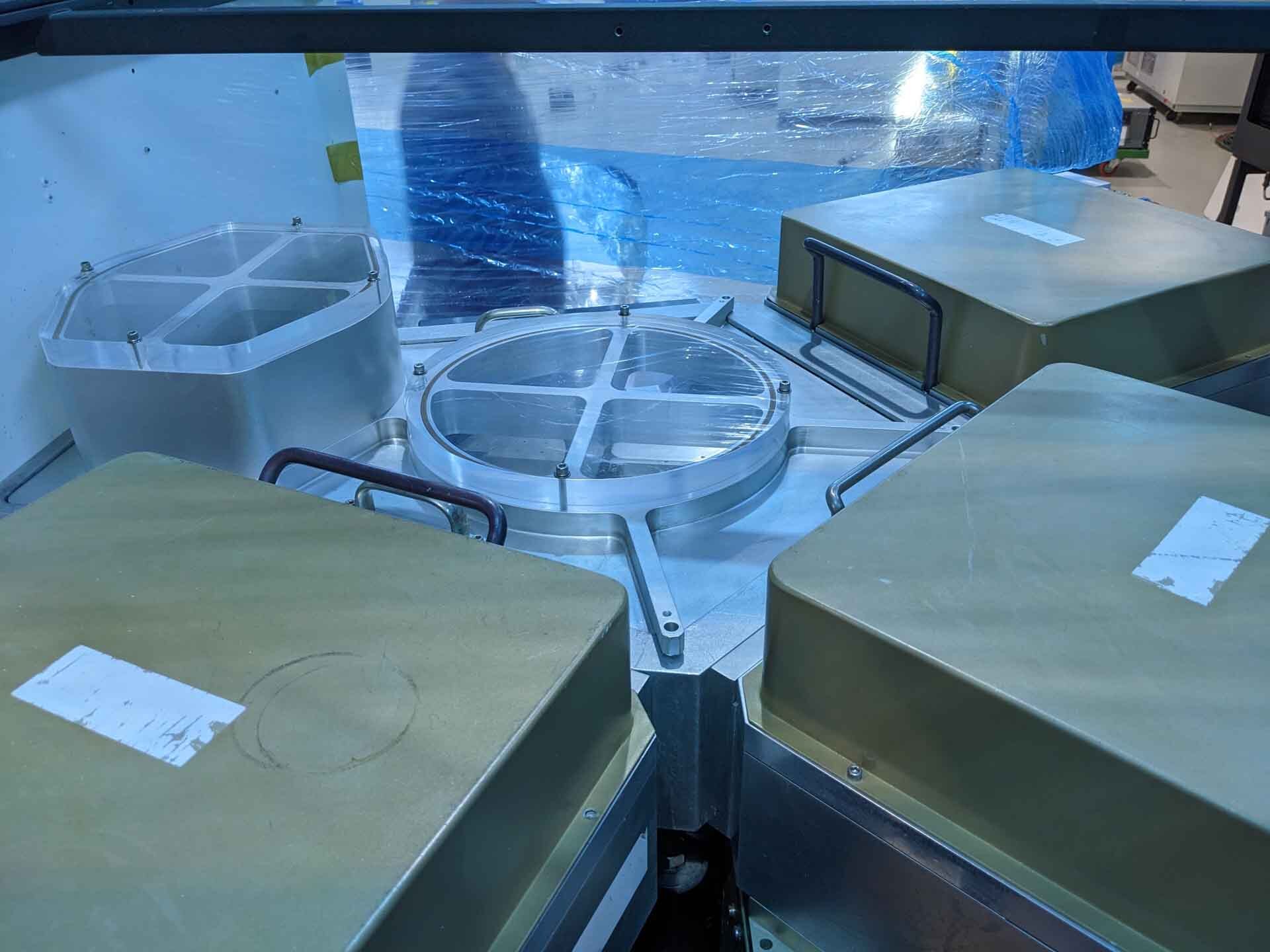

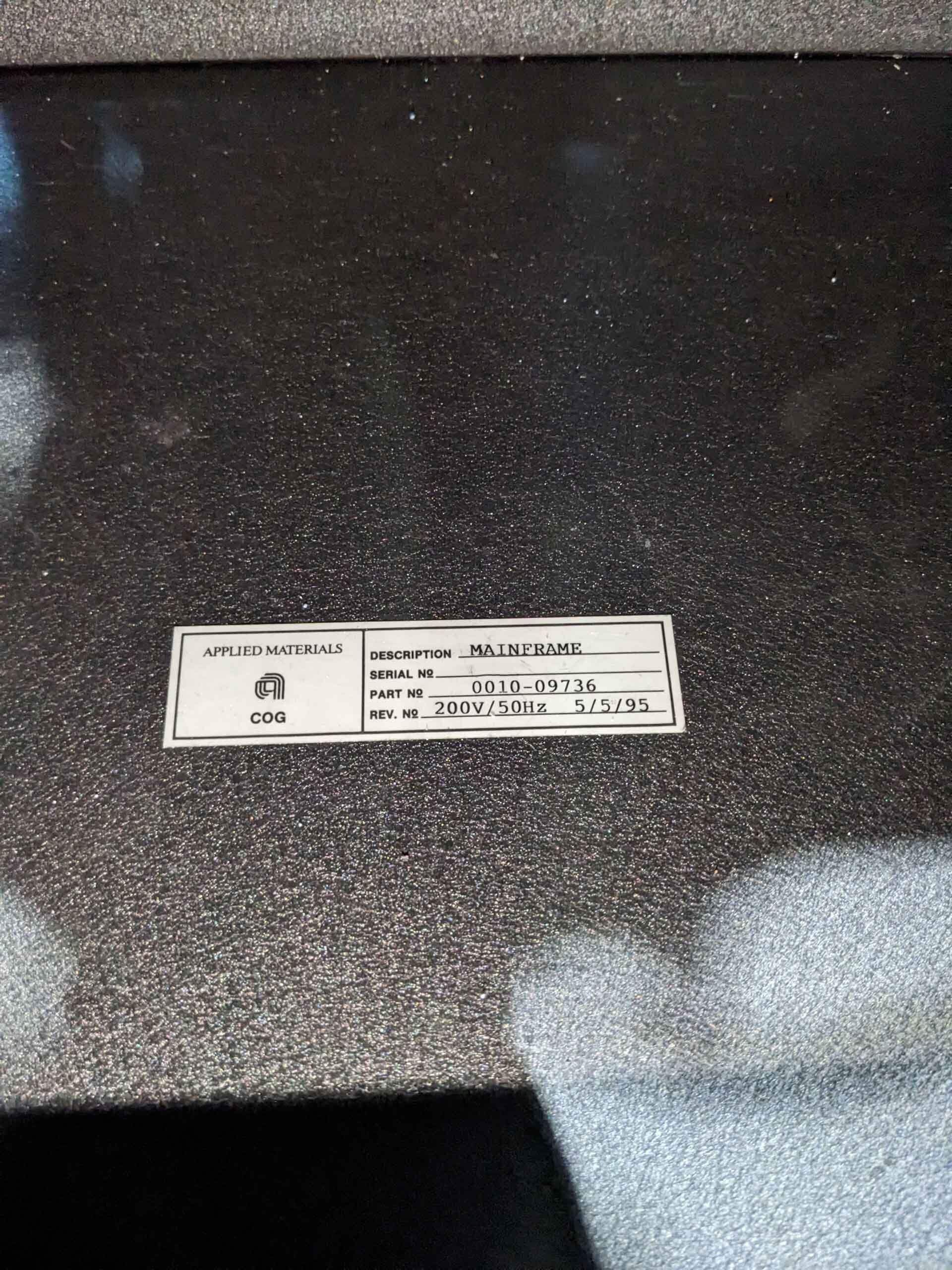

Used AMAT / APPLIED MATERIALS P5000 Mark II #9389398 for sale

URL successfully copied!

Tap to zoom

ID: 9389398

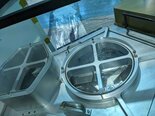

Wafer Size: 6"

Vintage: 1995

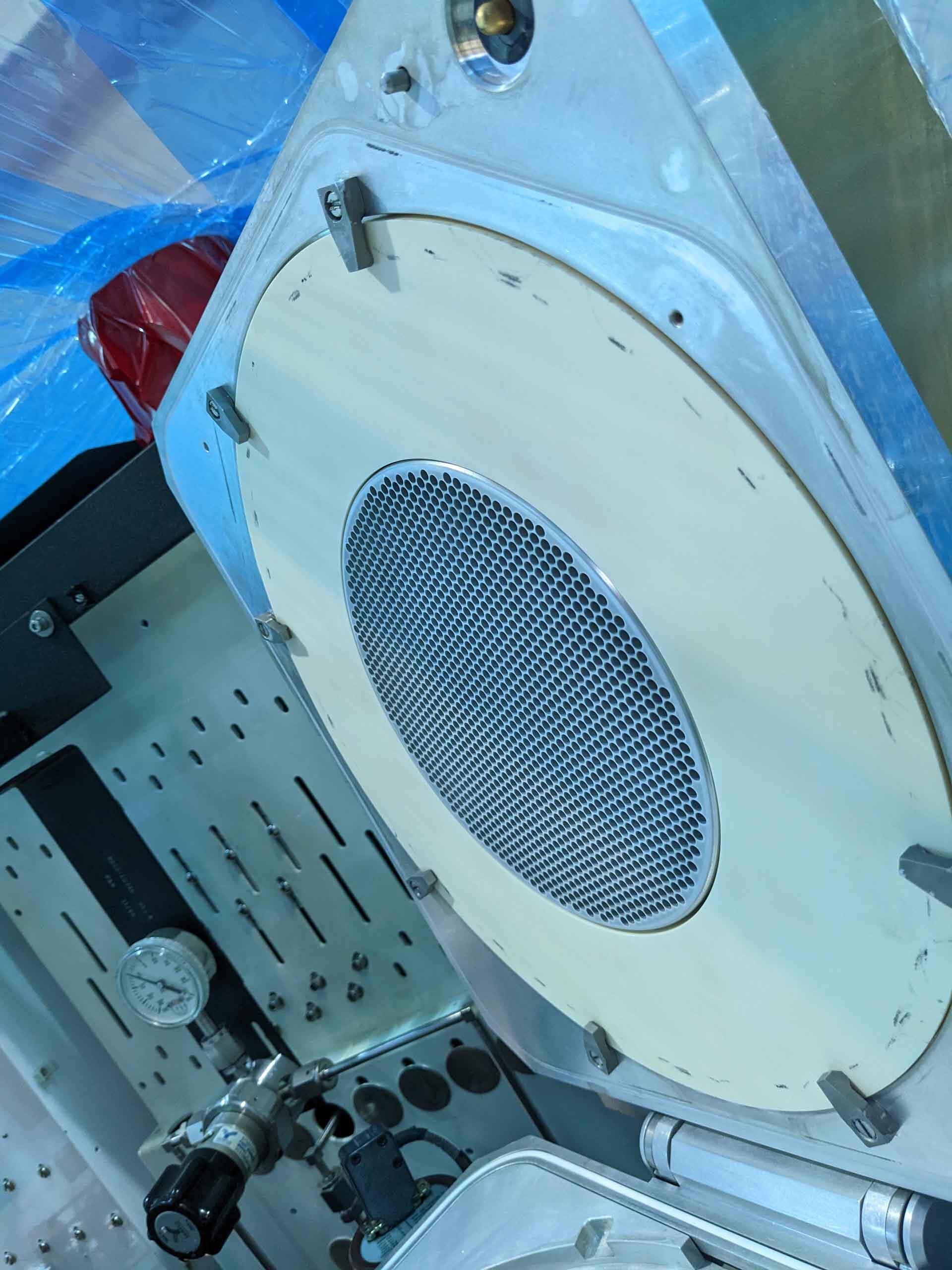

CVD System, 6"

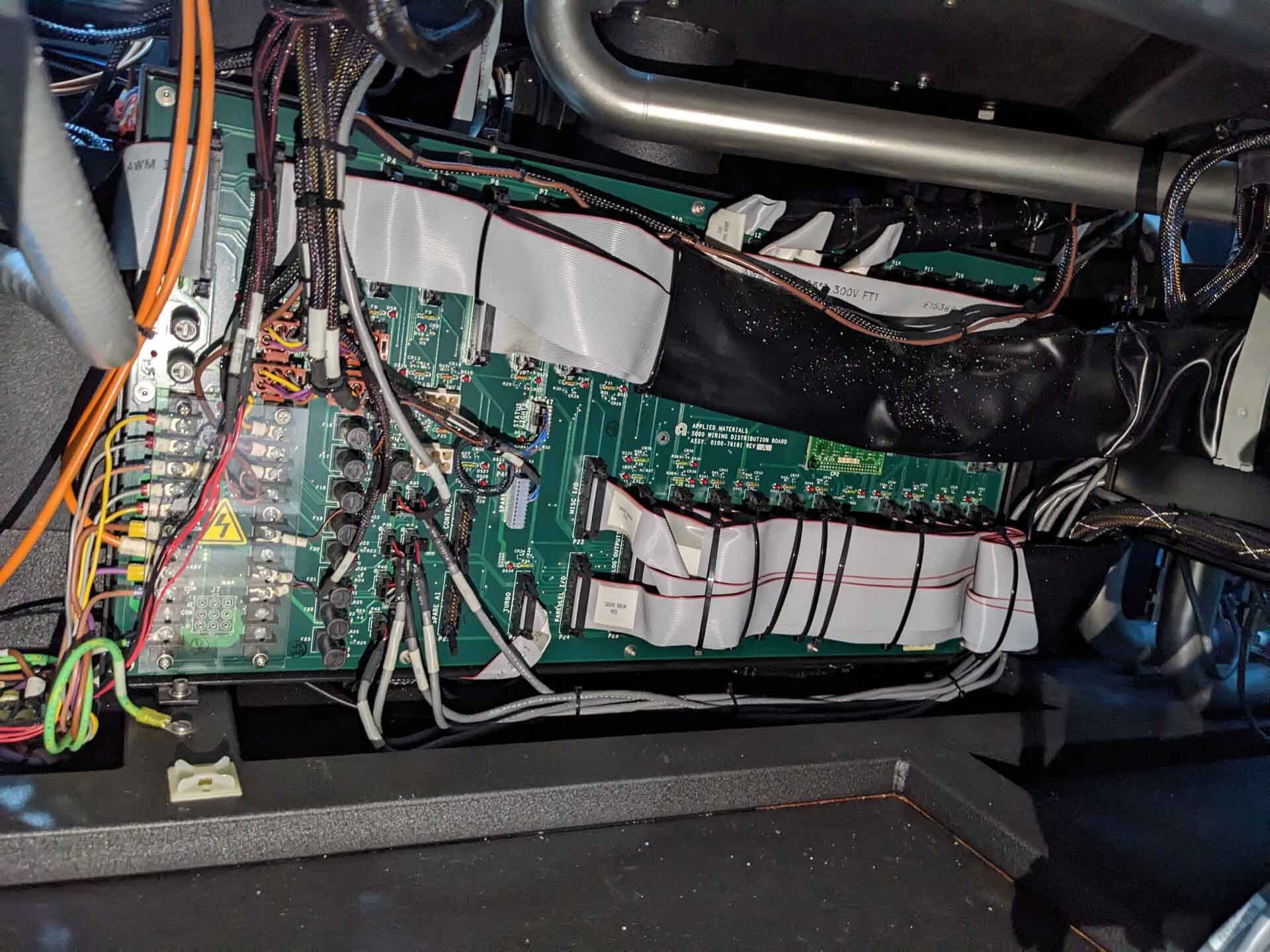

SV21 SBC Board

Hard Disk Drive (HDD) Flush type

FDD, 3.5"

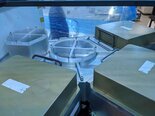

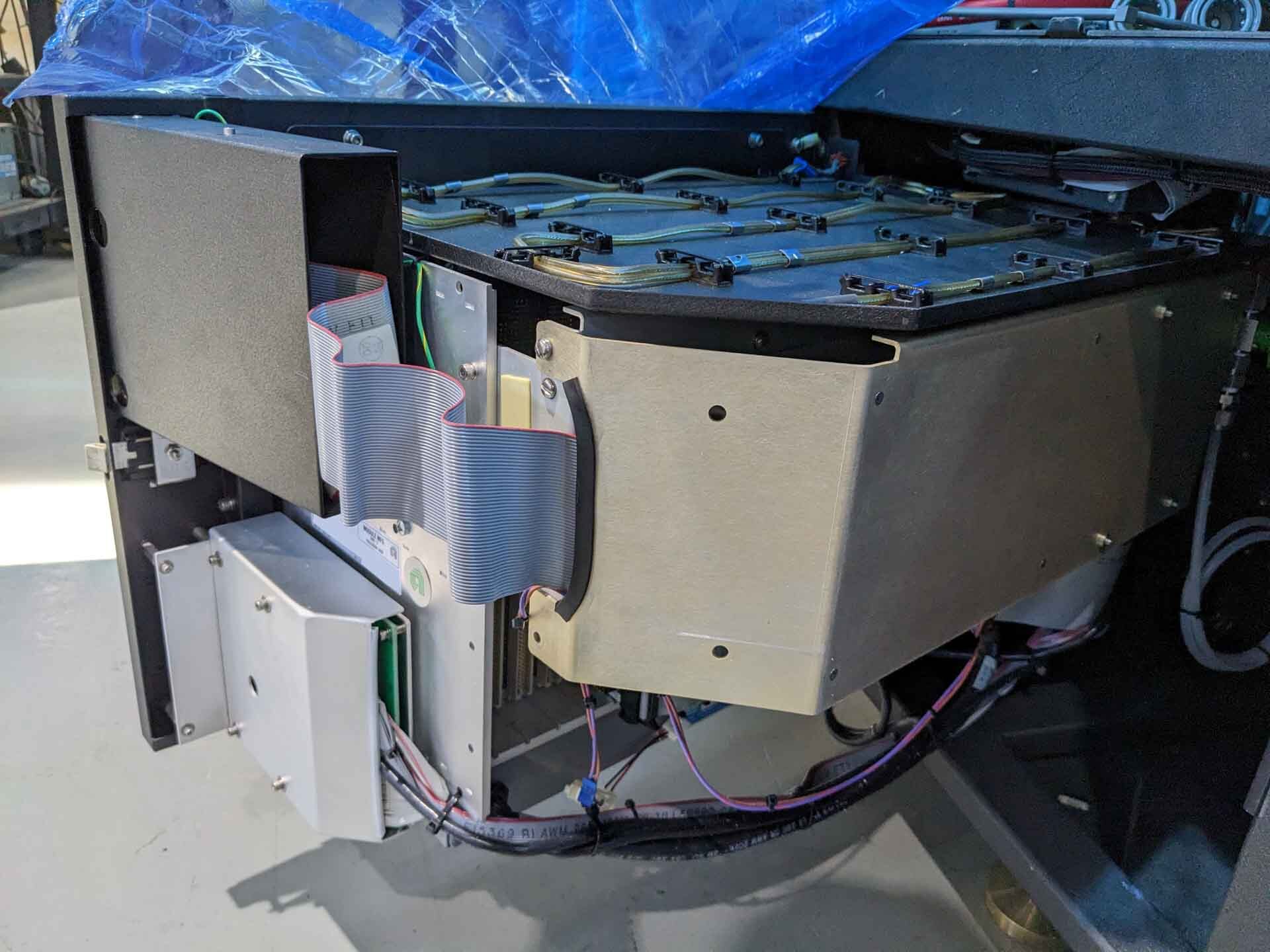

Cassette indexer

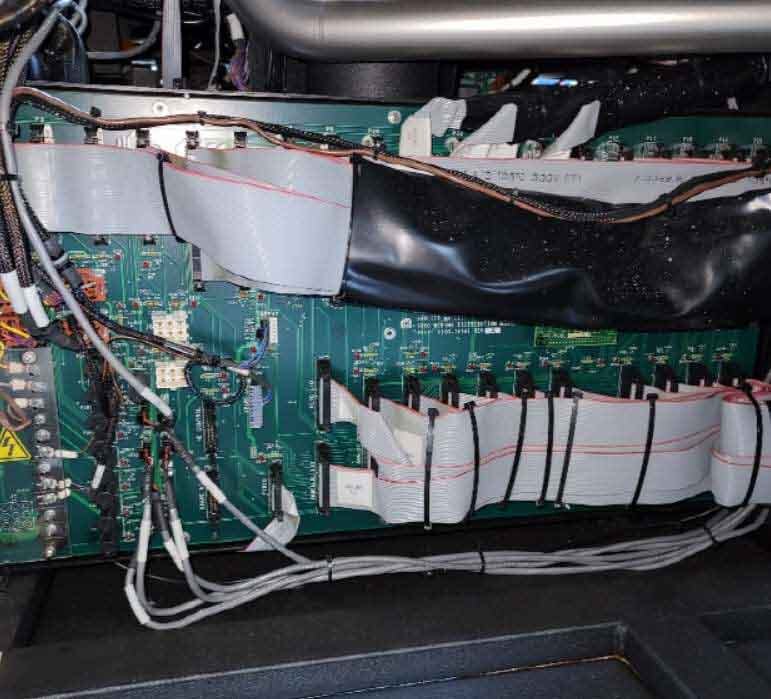

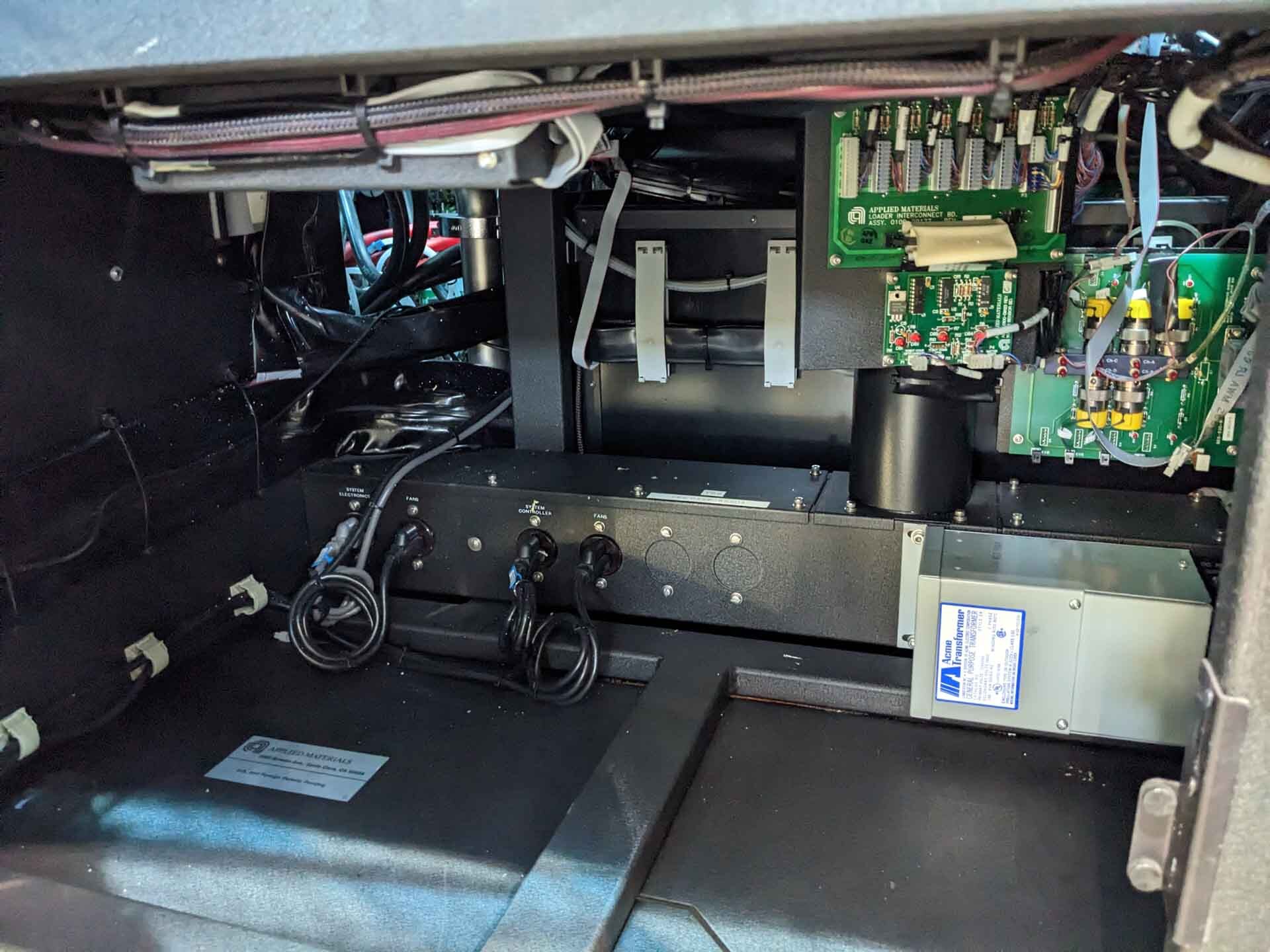

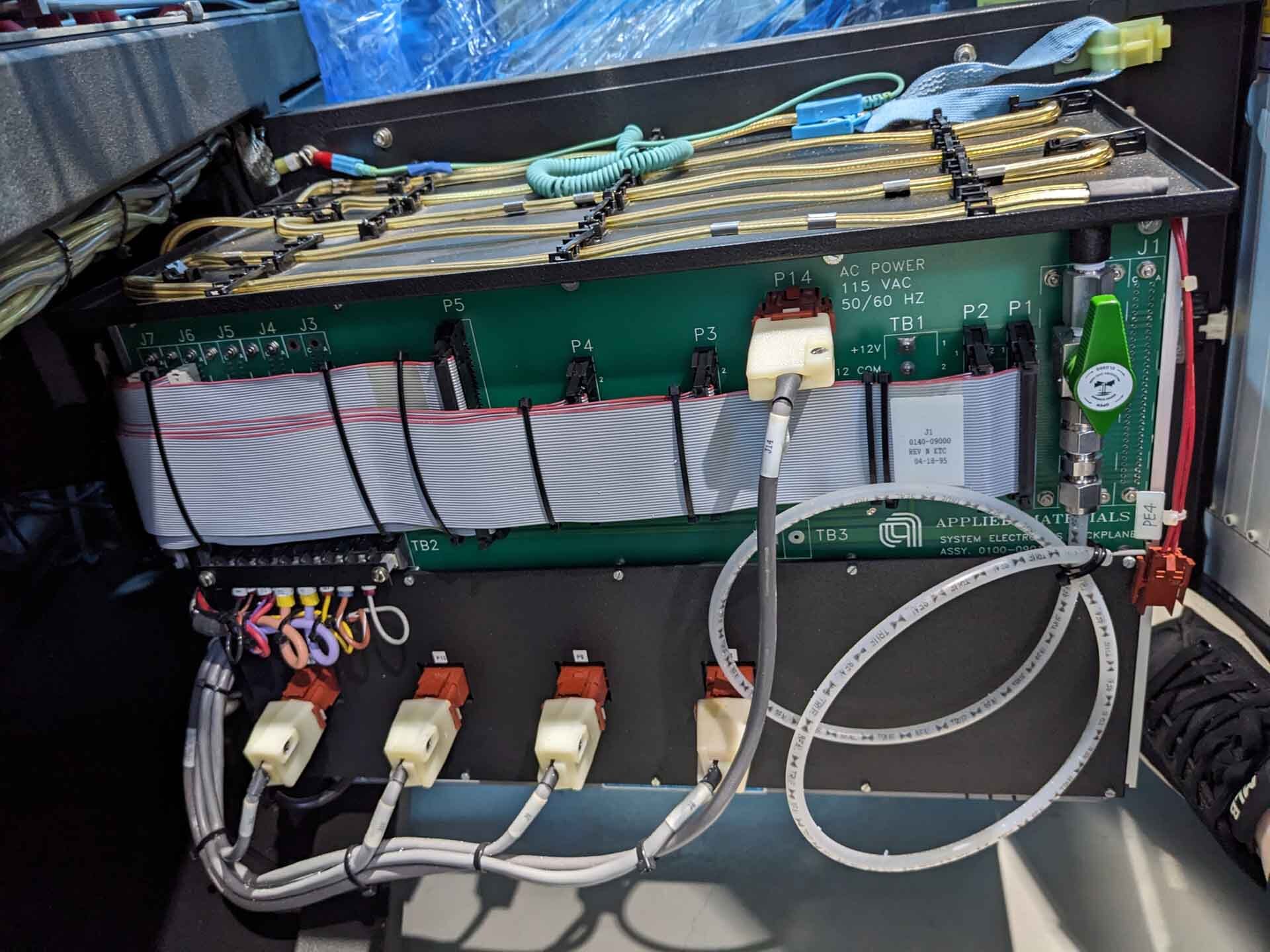

Electrical controller

Elevator type: 8-Slots, 6"

(2) CRT Monitors, 17"

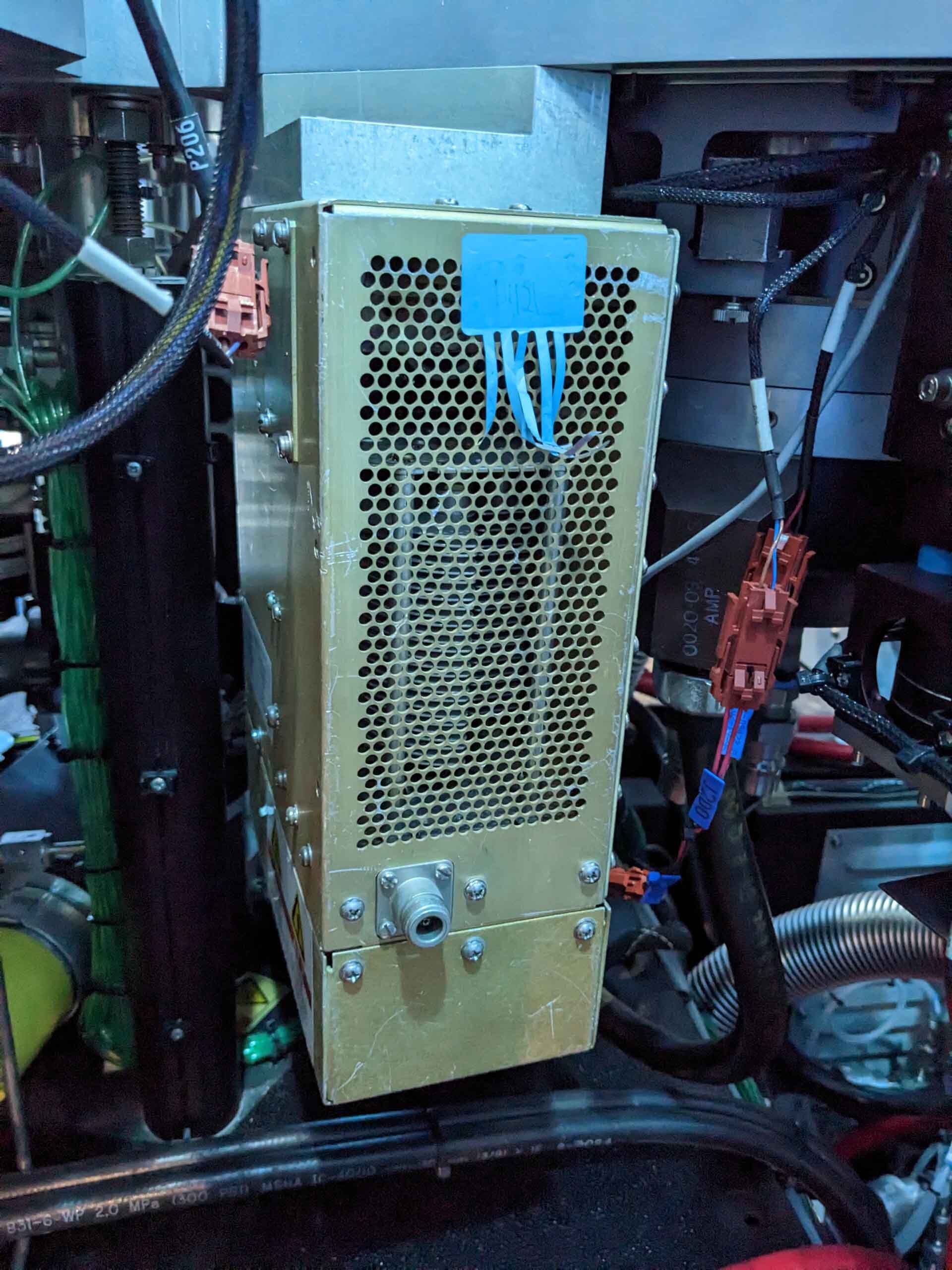

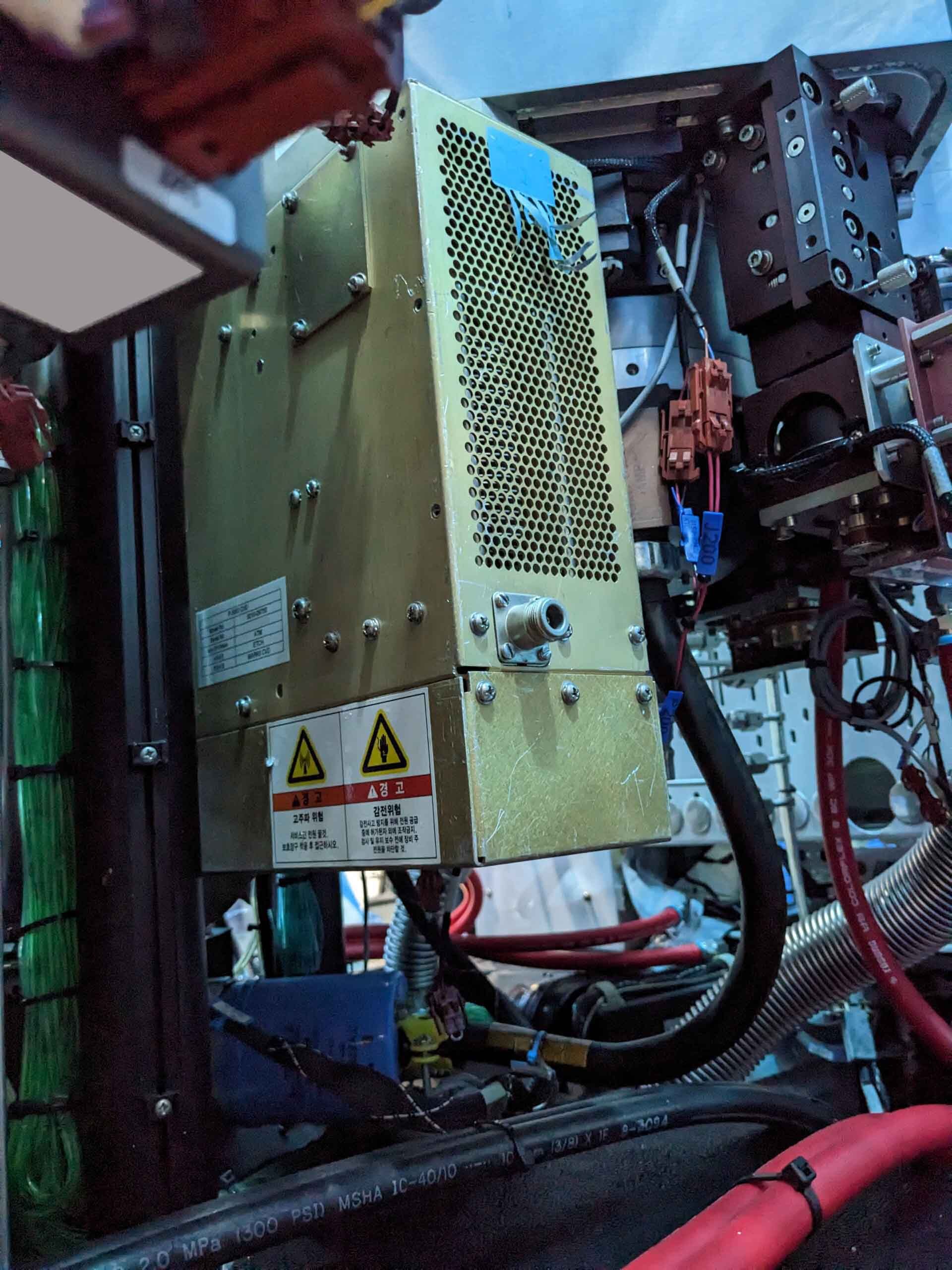

(4) Chopper driver power packs

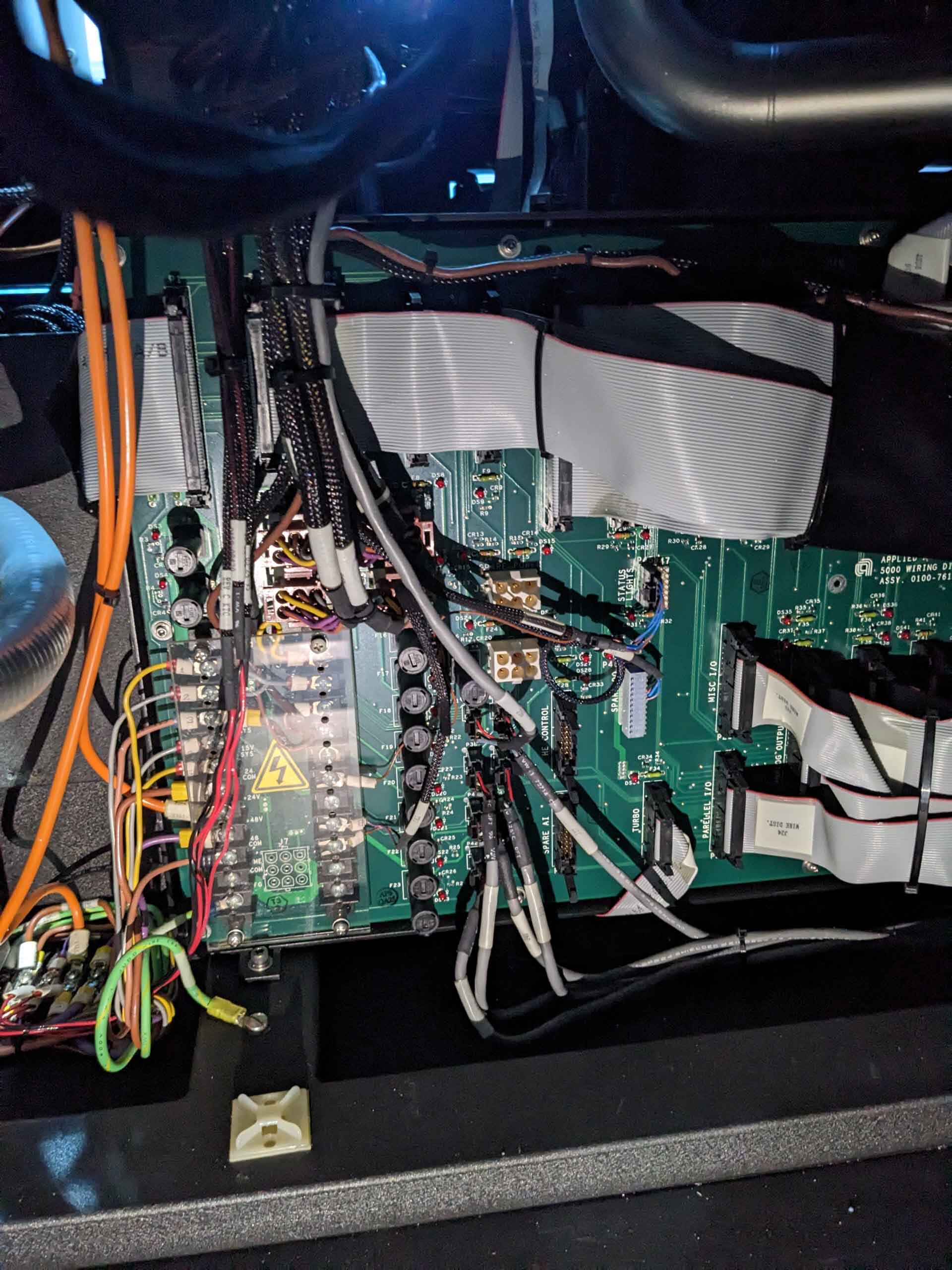

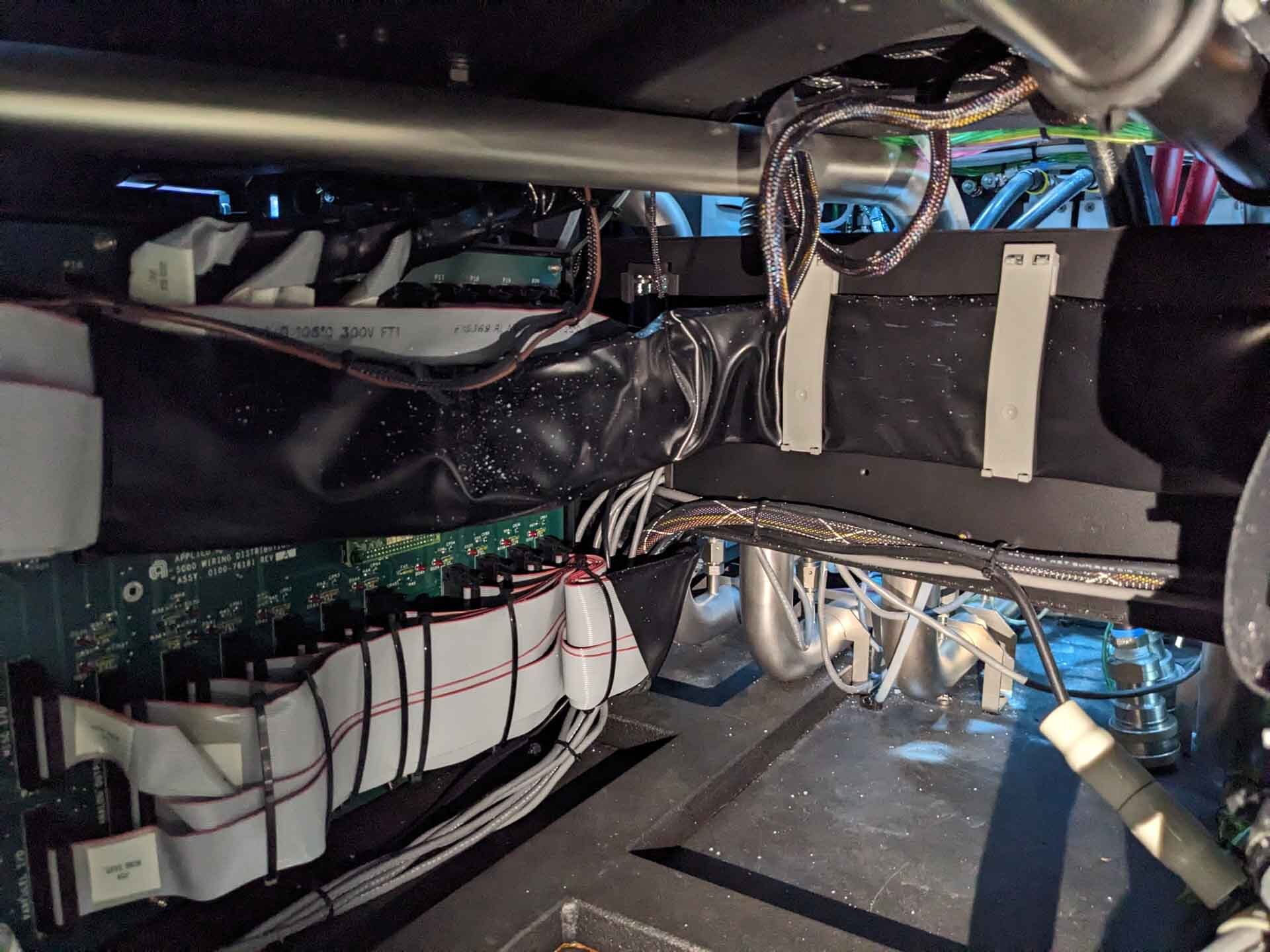

(2) Opto I/O BD

Buffer I/O BD

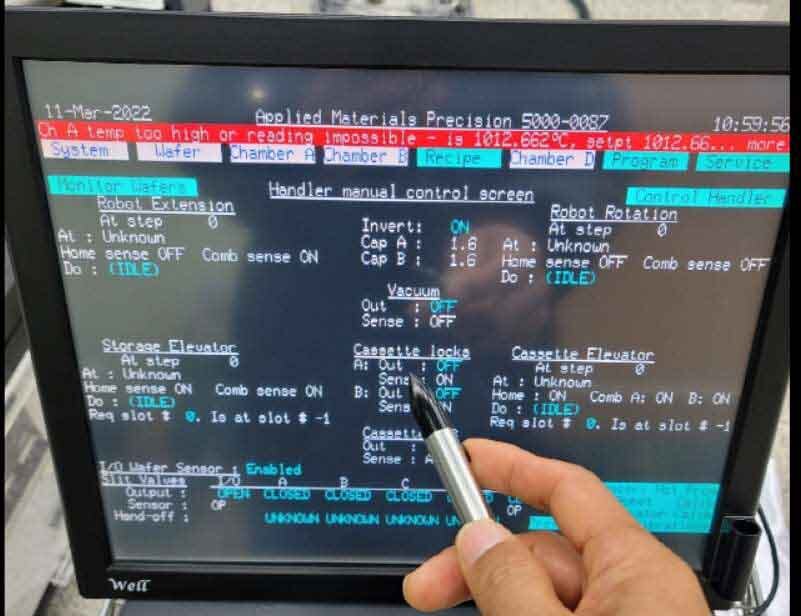

Robots: Phase-III

Robot blade: Standard vacuum

Centerfinder: USE

I/O Sensor

I/O Door

Vacuum sensor

Cap wafer sensor

Slit valve

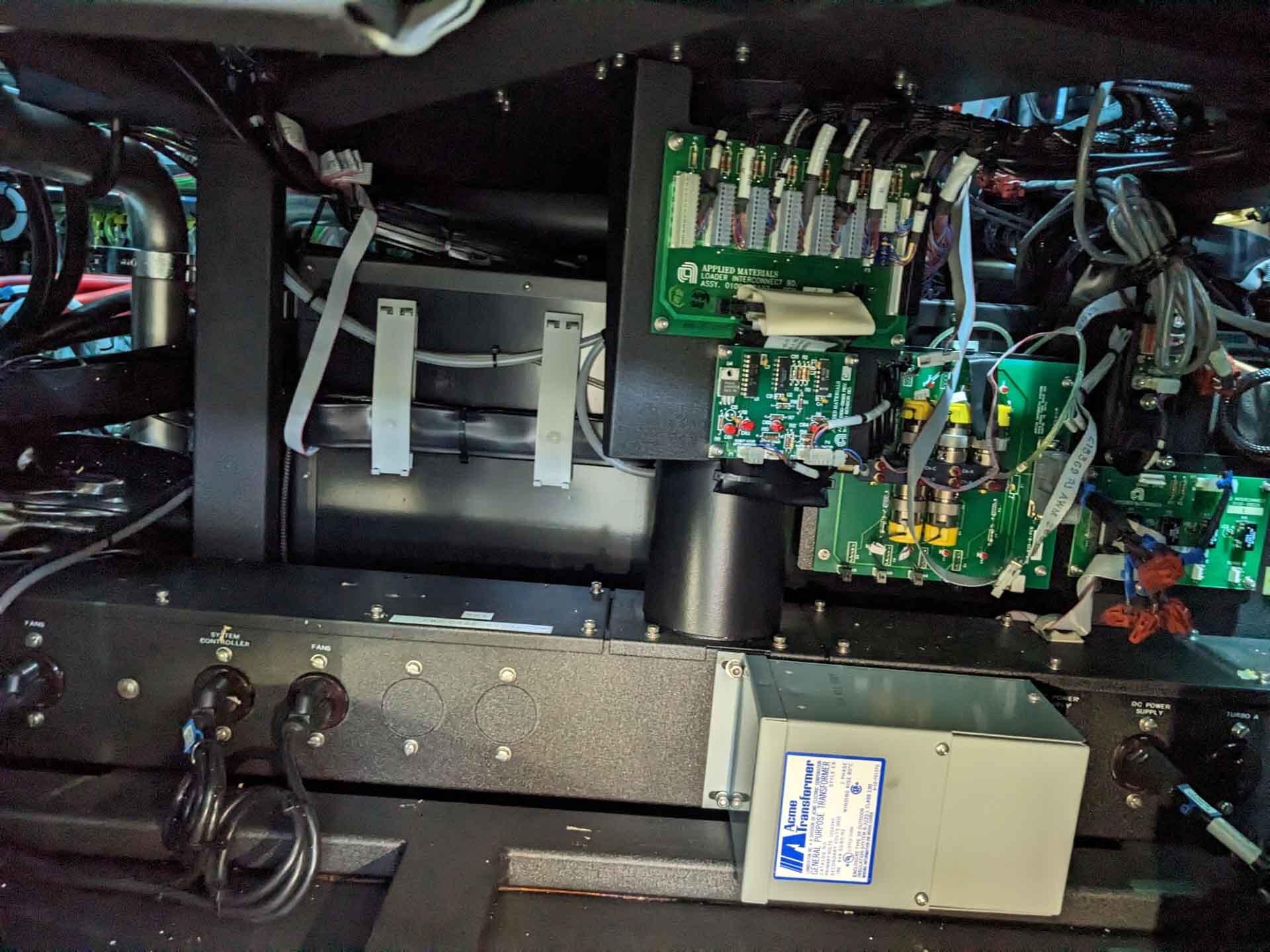

AC Rack: 1 Shrink

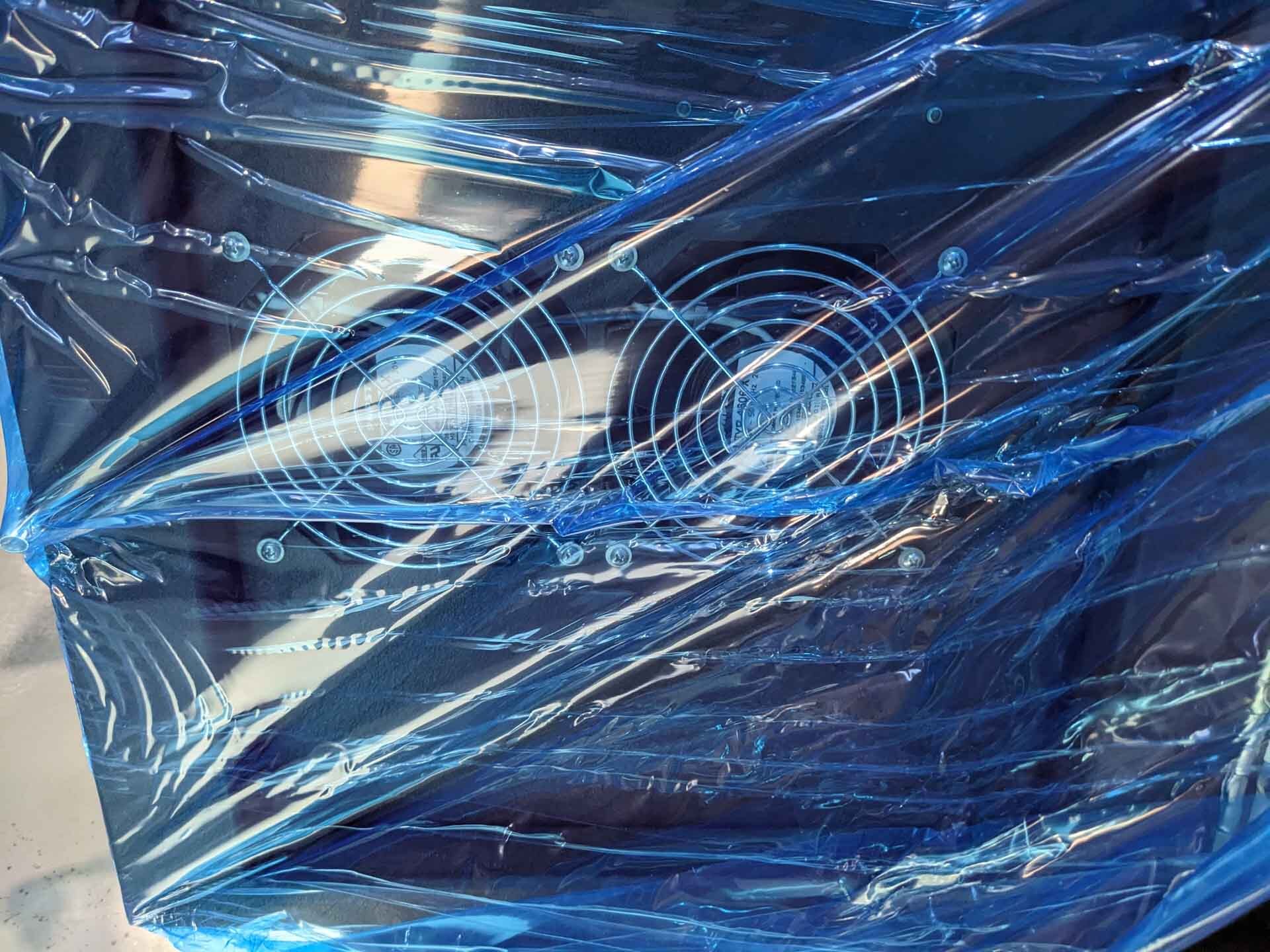

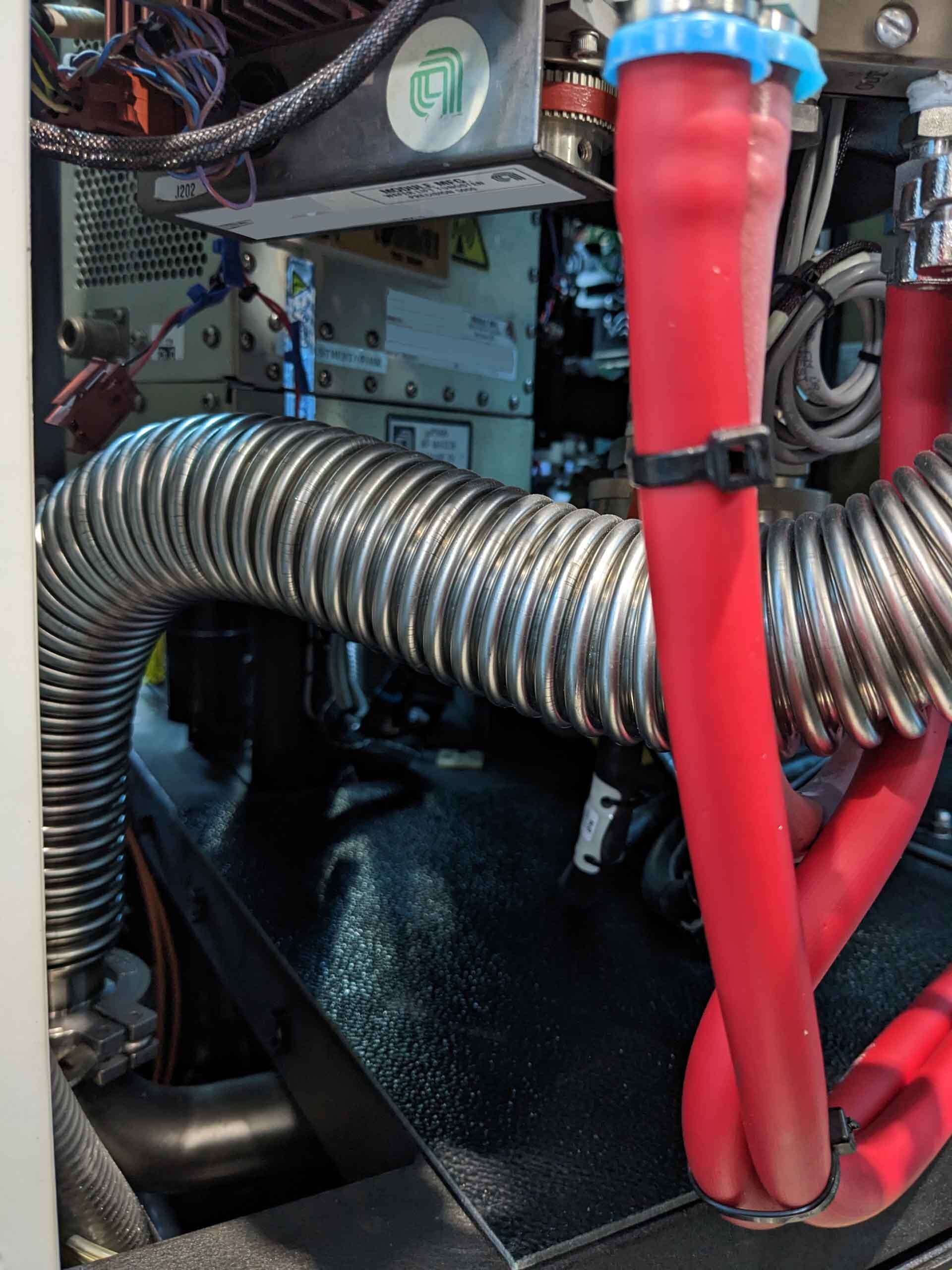

Heat exchanger

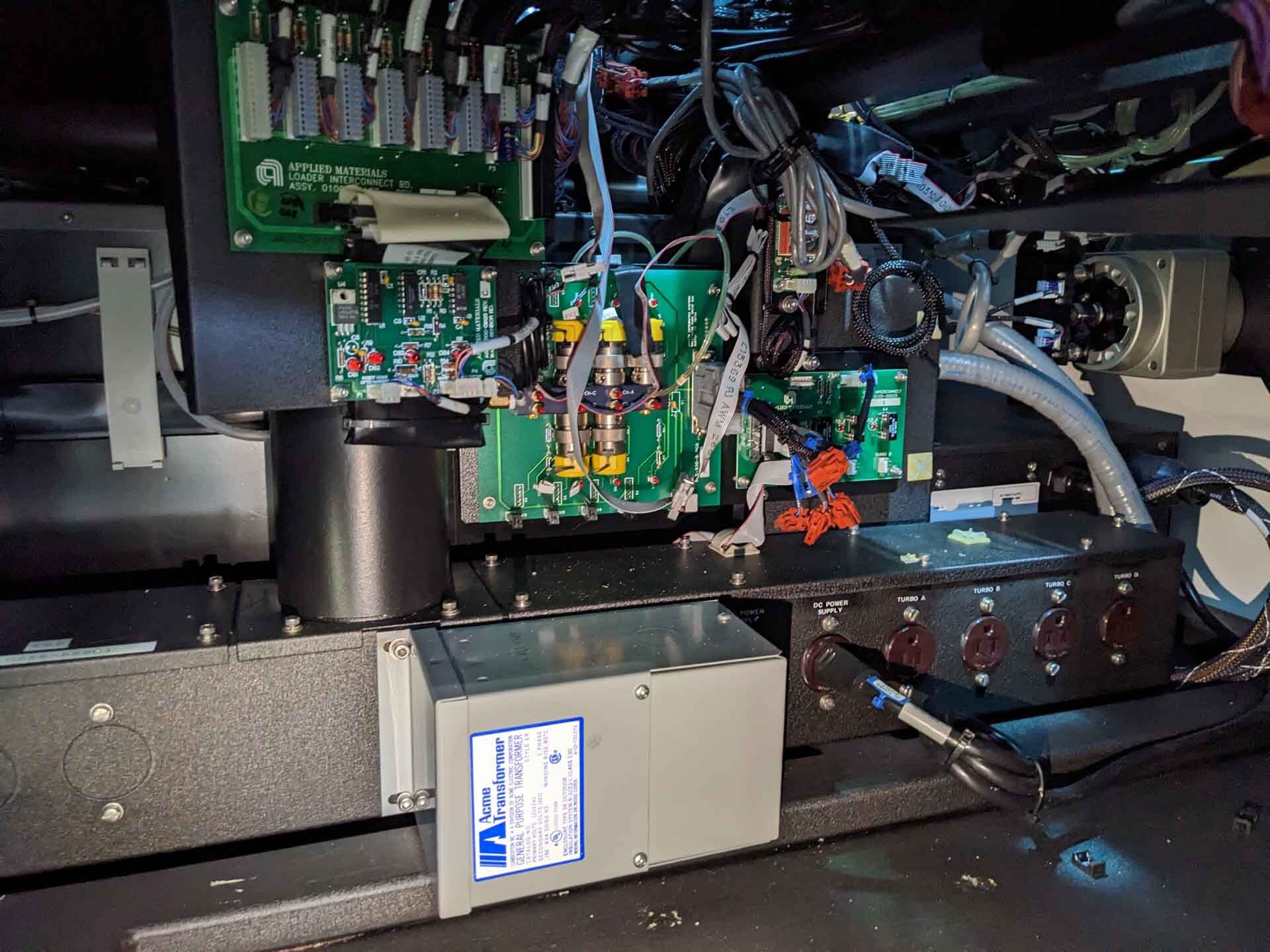

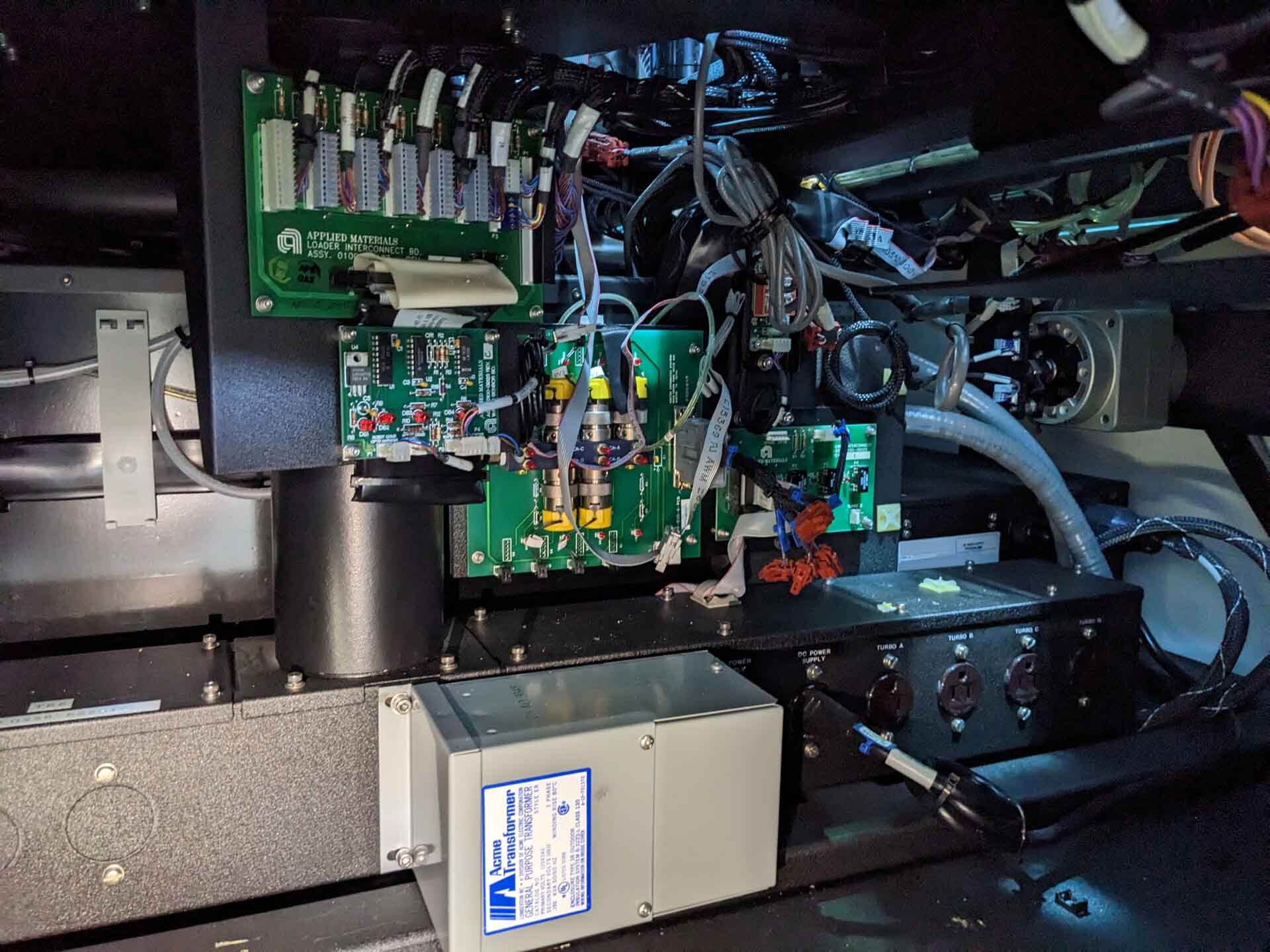

VME Controller

Stepper control BD

EMO Option: Turn to release

EMO Button guardrings

Status light tower (Color / Position): Red, yellow, green

Signal cable: 25"

Flash hard disk drive

Floppy: 3.5" SCSI Driver

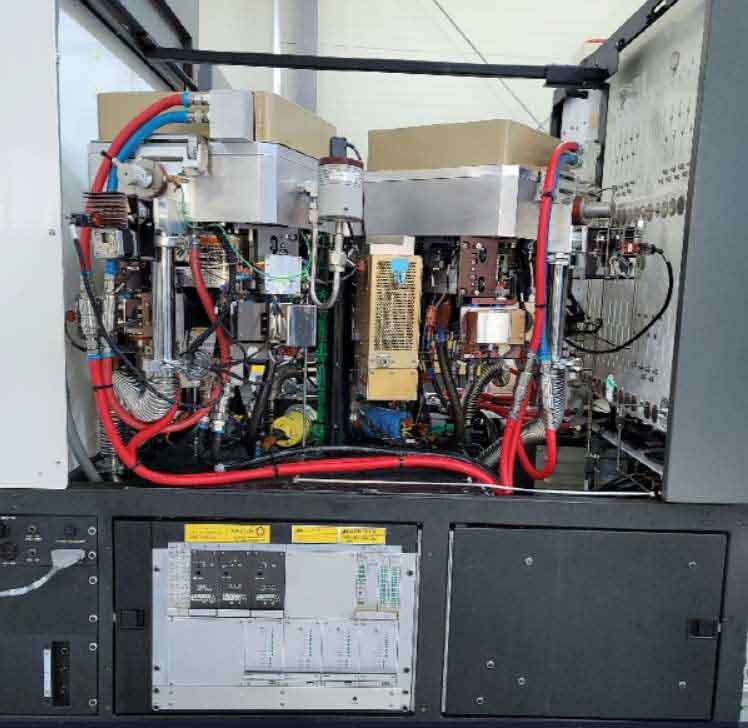

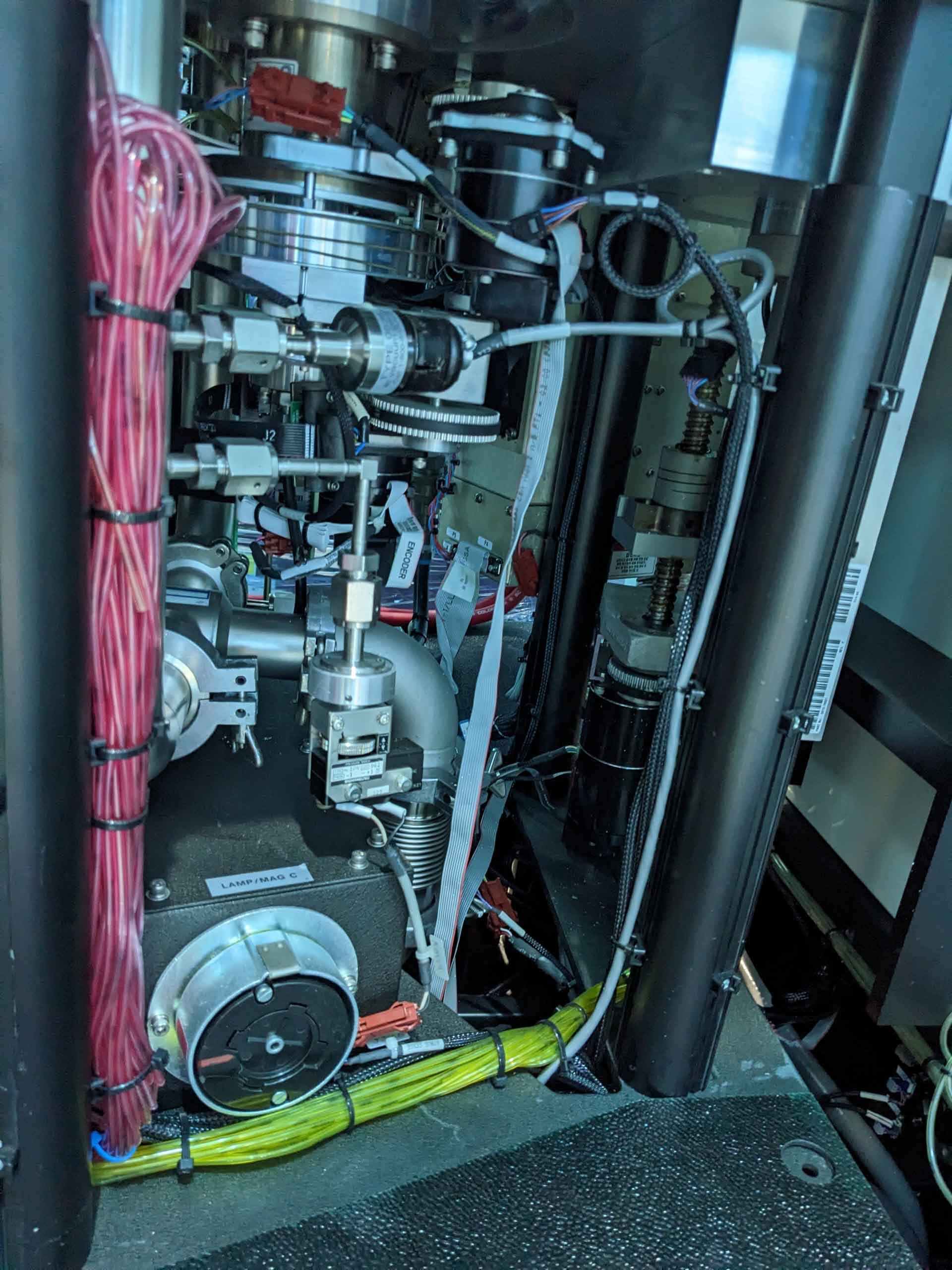

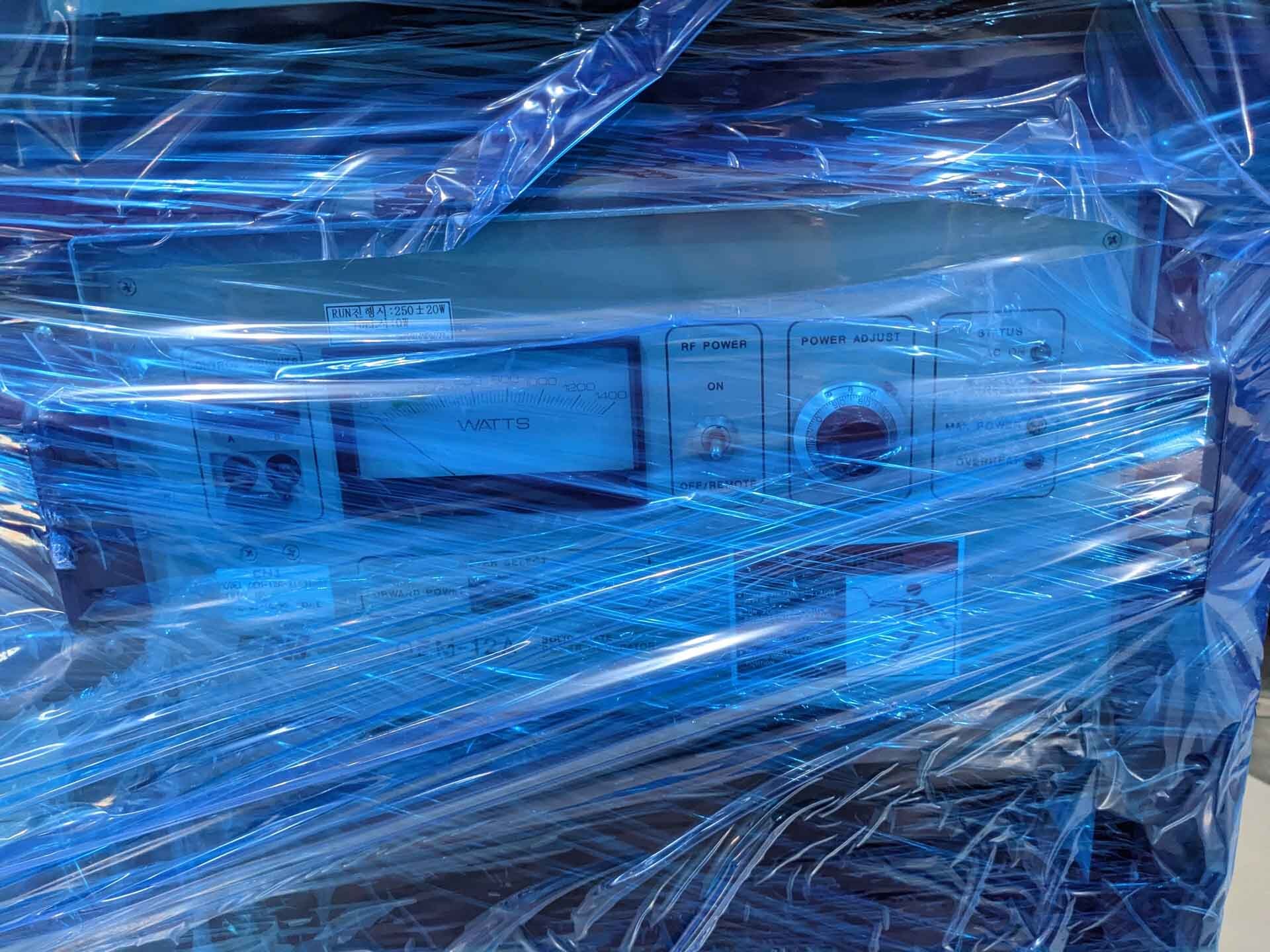

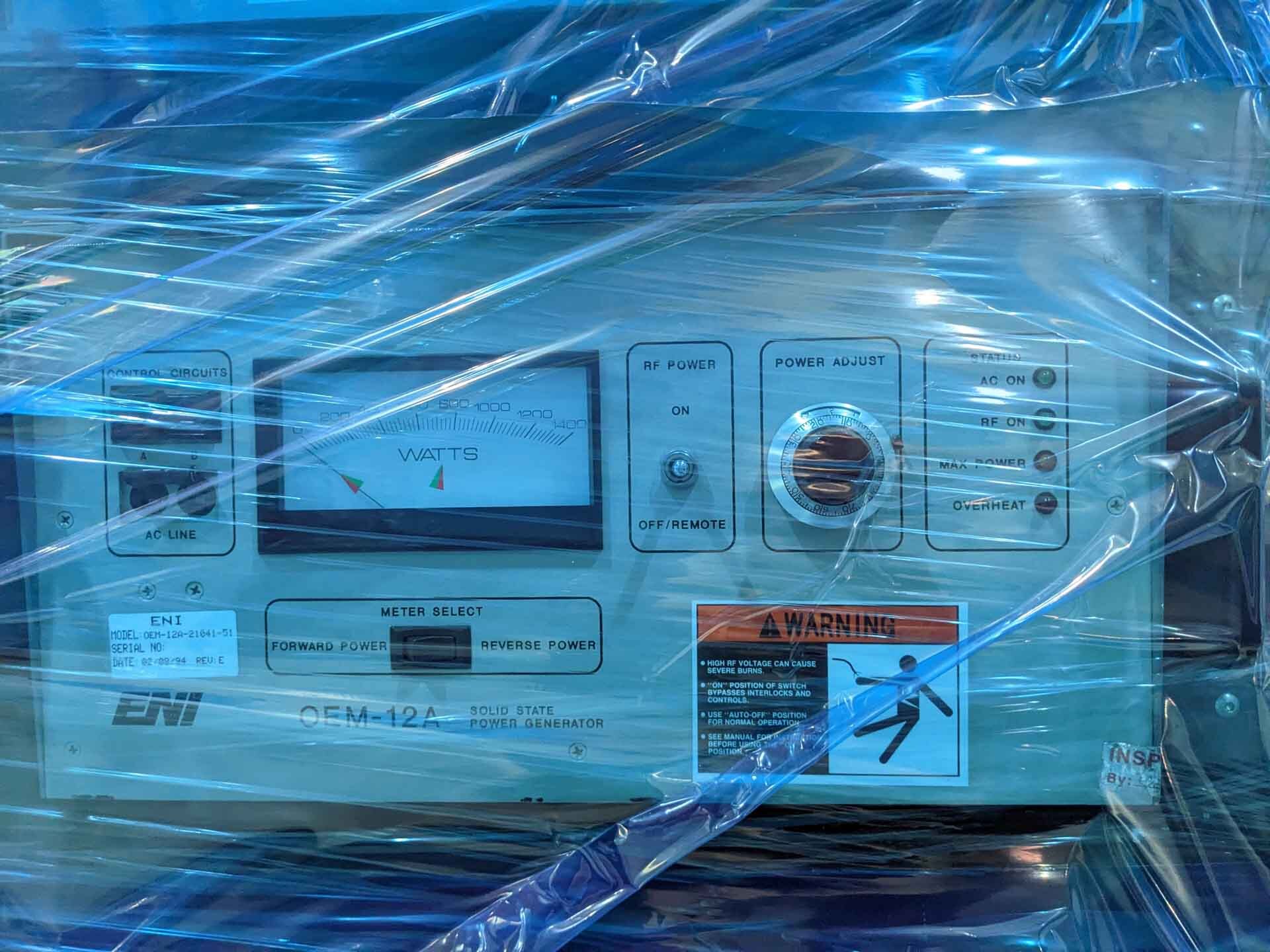

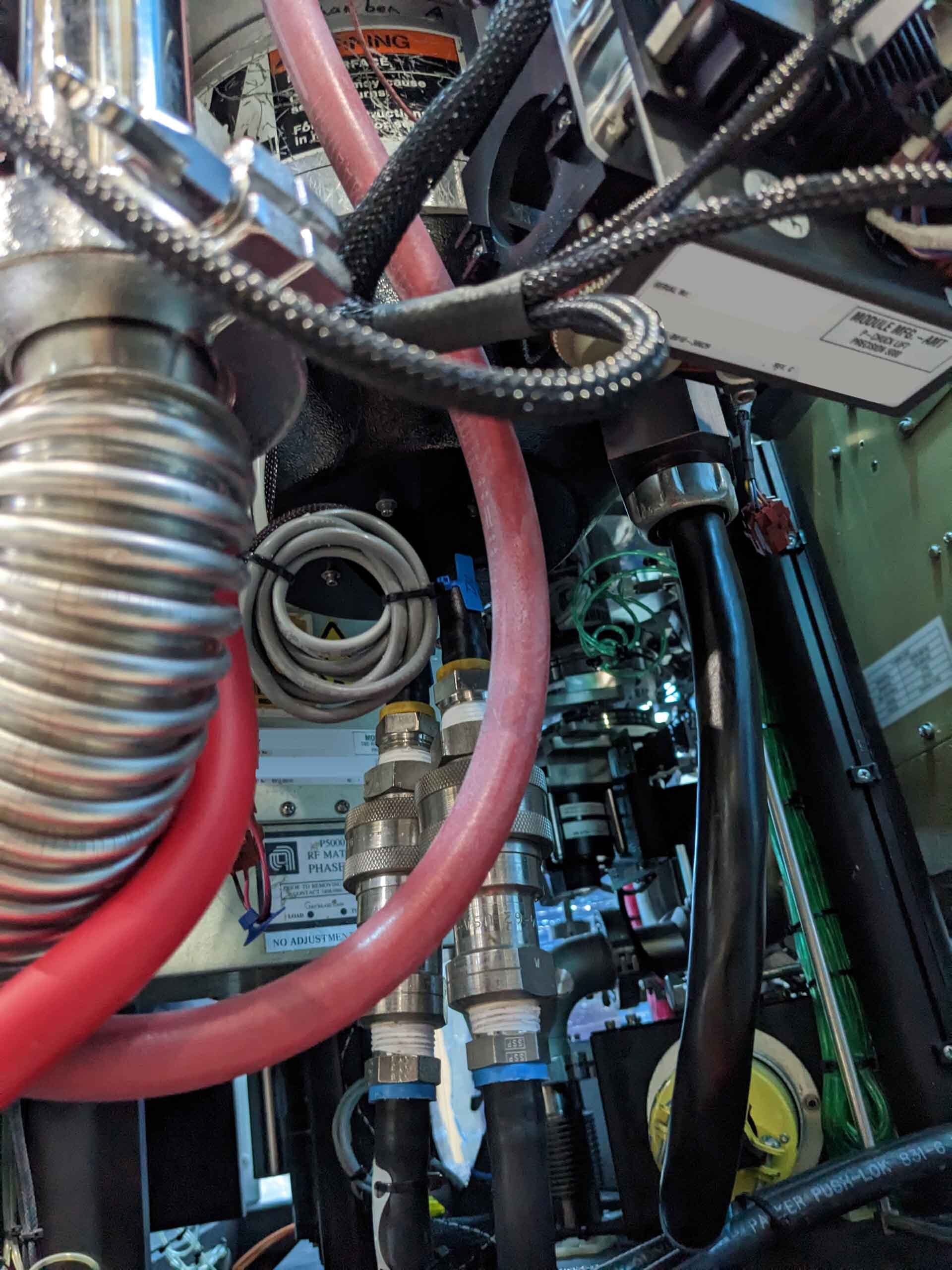

(3) ENI OEM-12A RF Generators

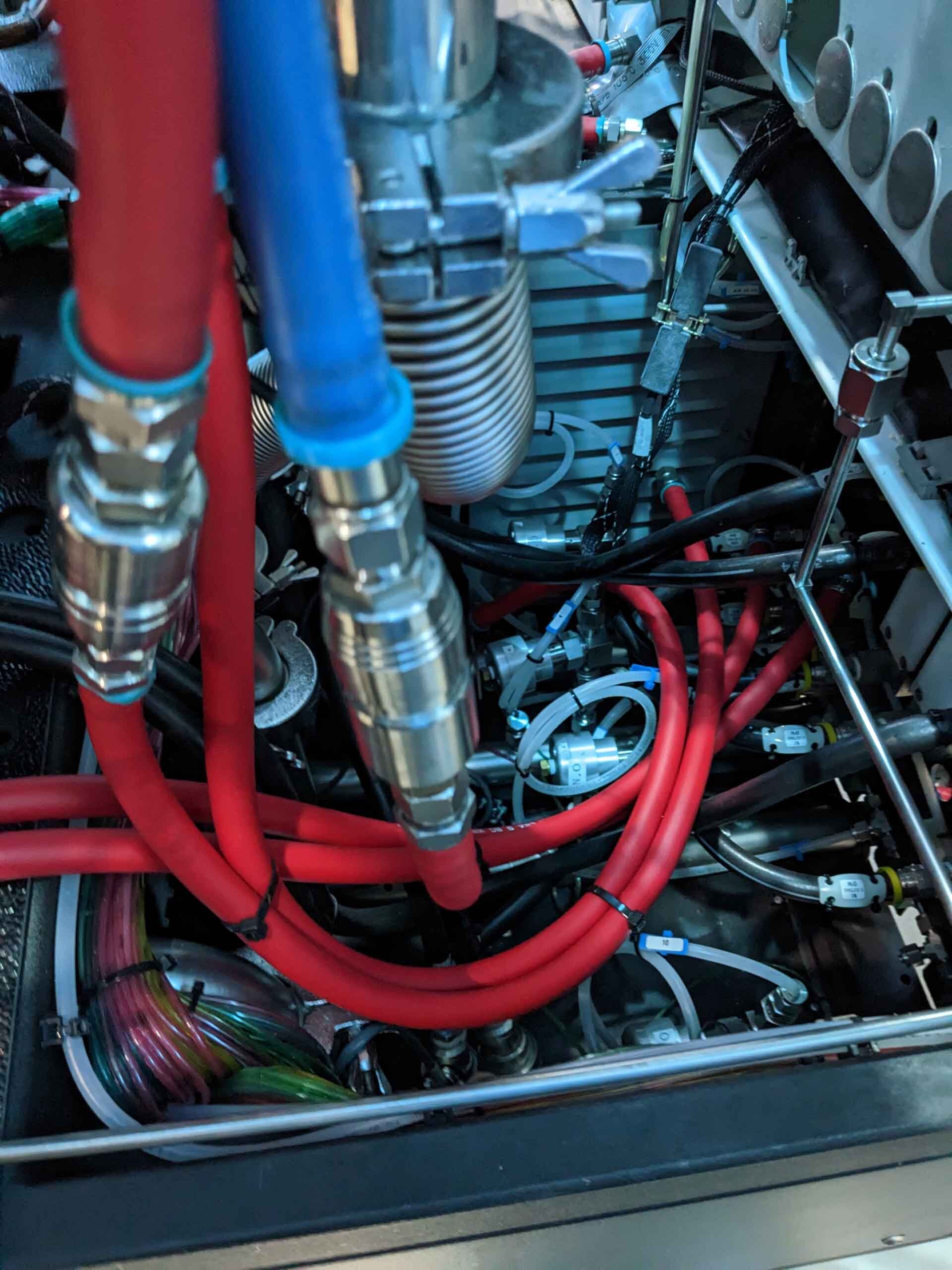

HX Seperate mani fold

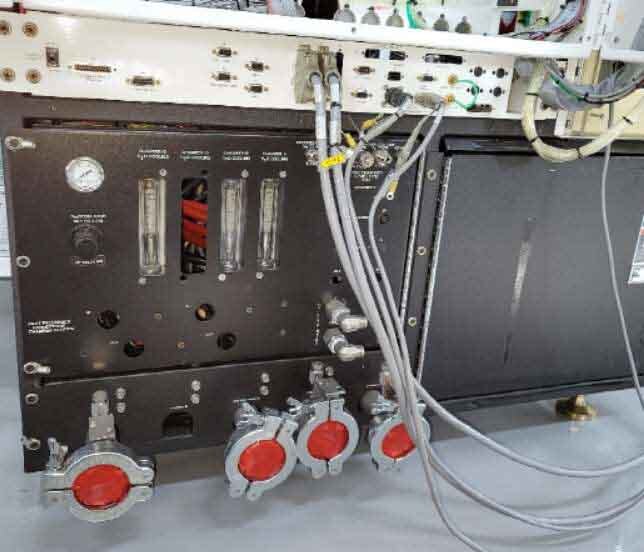

Gas panel: 12 Channels standard / Minicontroller

RF Generator:

Chamber A: OEM12B-02

Chamber B: OEM12B-07

Chamber C: OEM12B-07

Electrical controller:

(2) TC Gauge boards

Power rack, 12 VDC; (2) 15 VDC

Buffer I/O board

(2) Opto I/O boards

(4) Chopper driver power racks

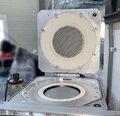

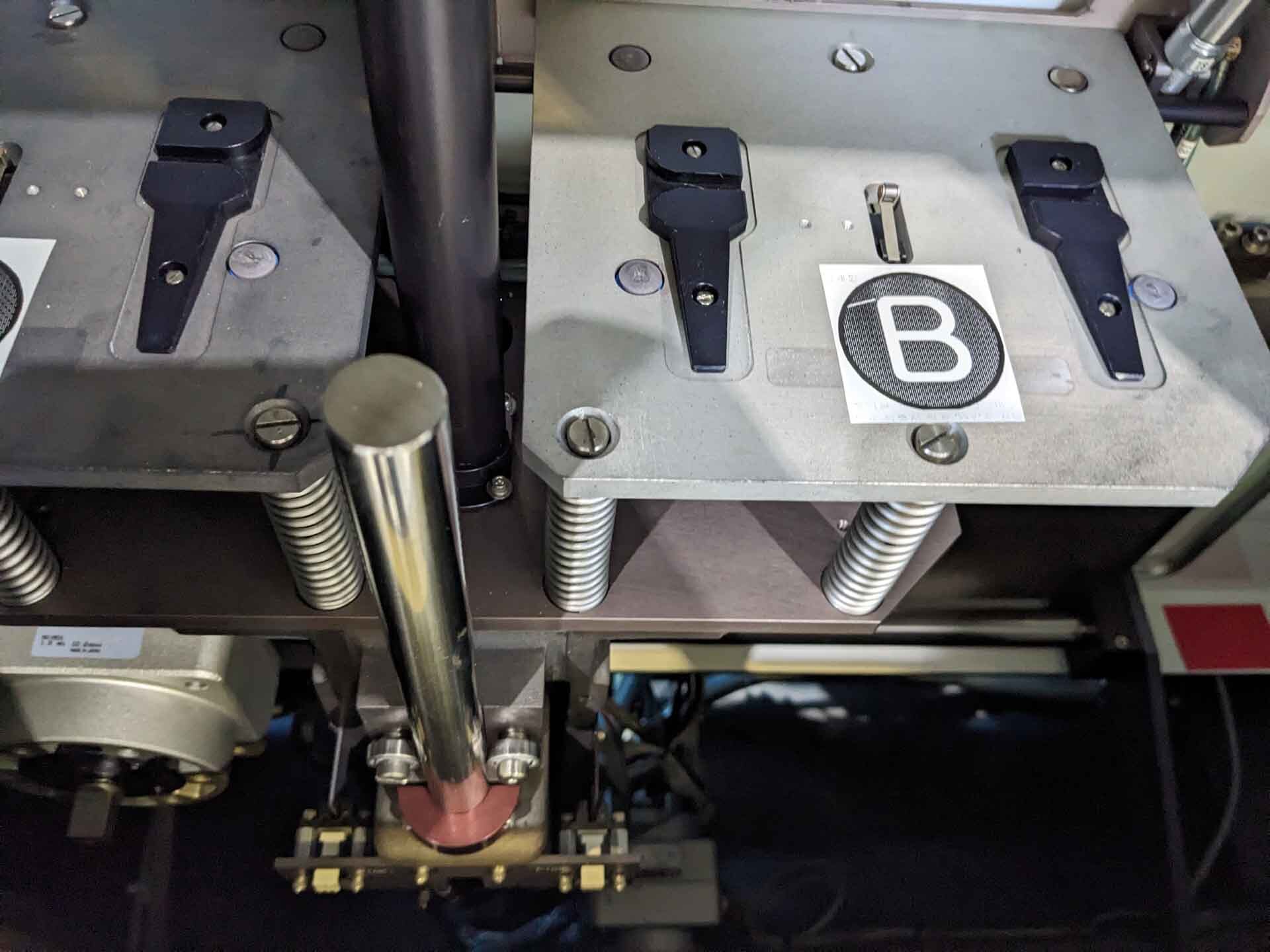

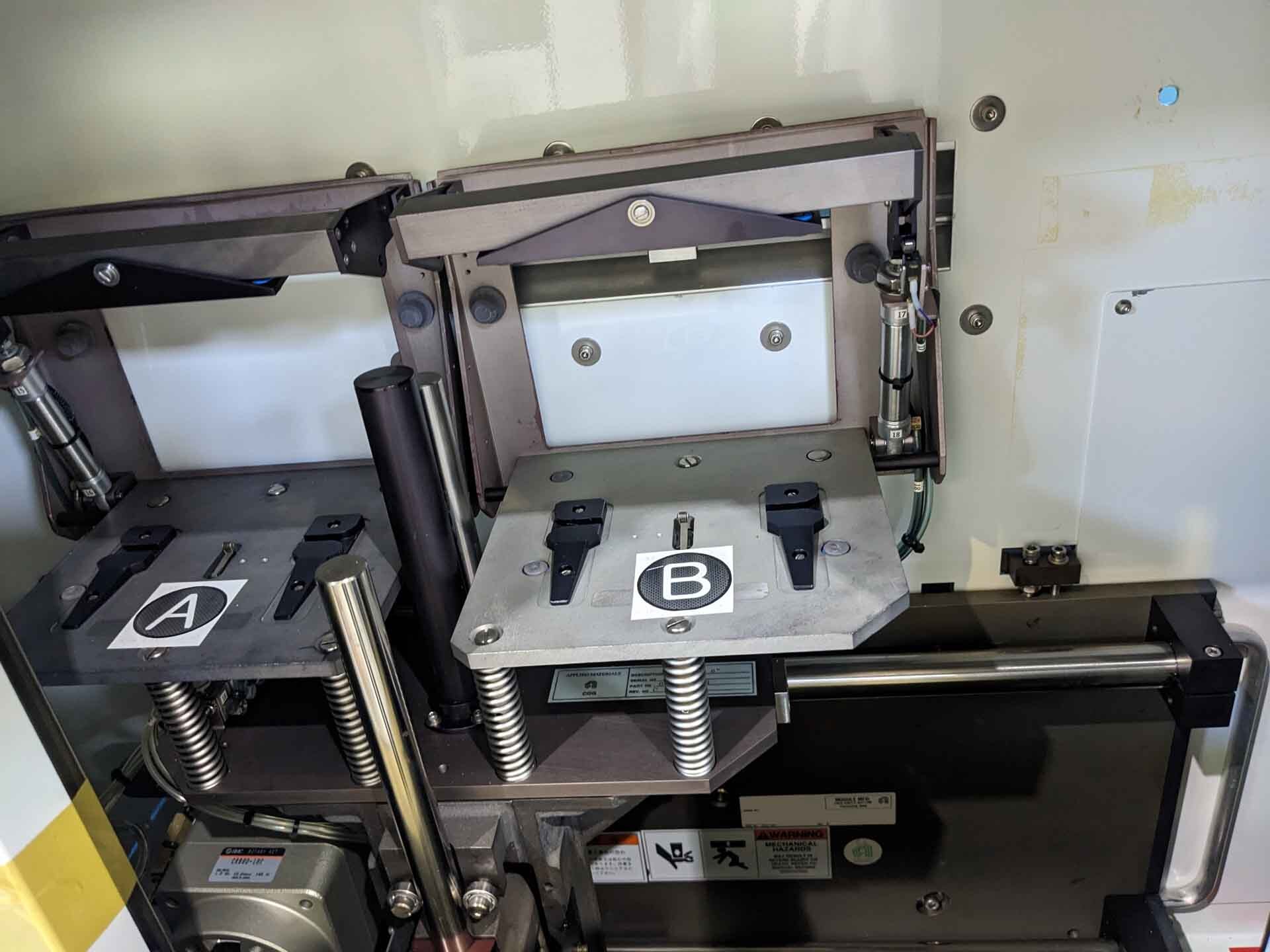

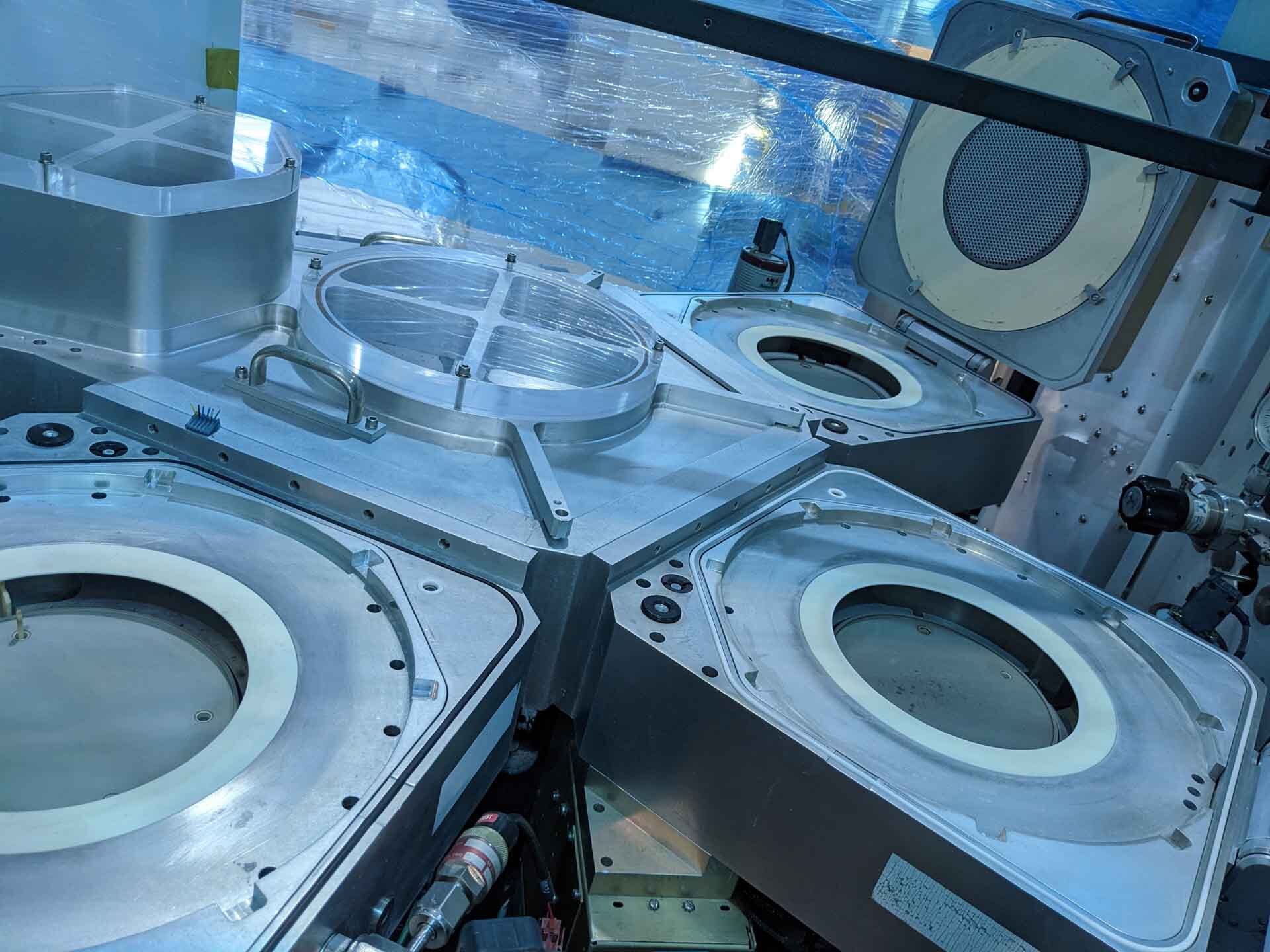

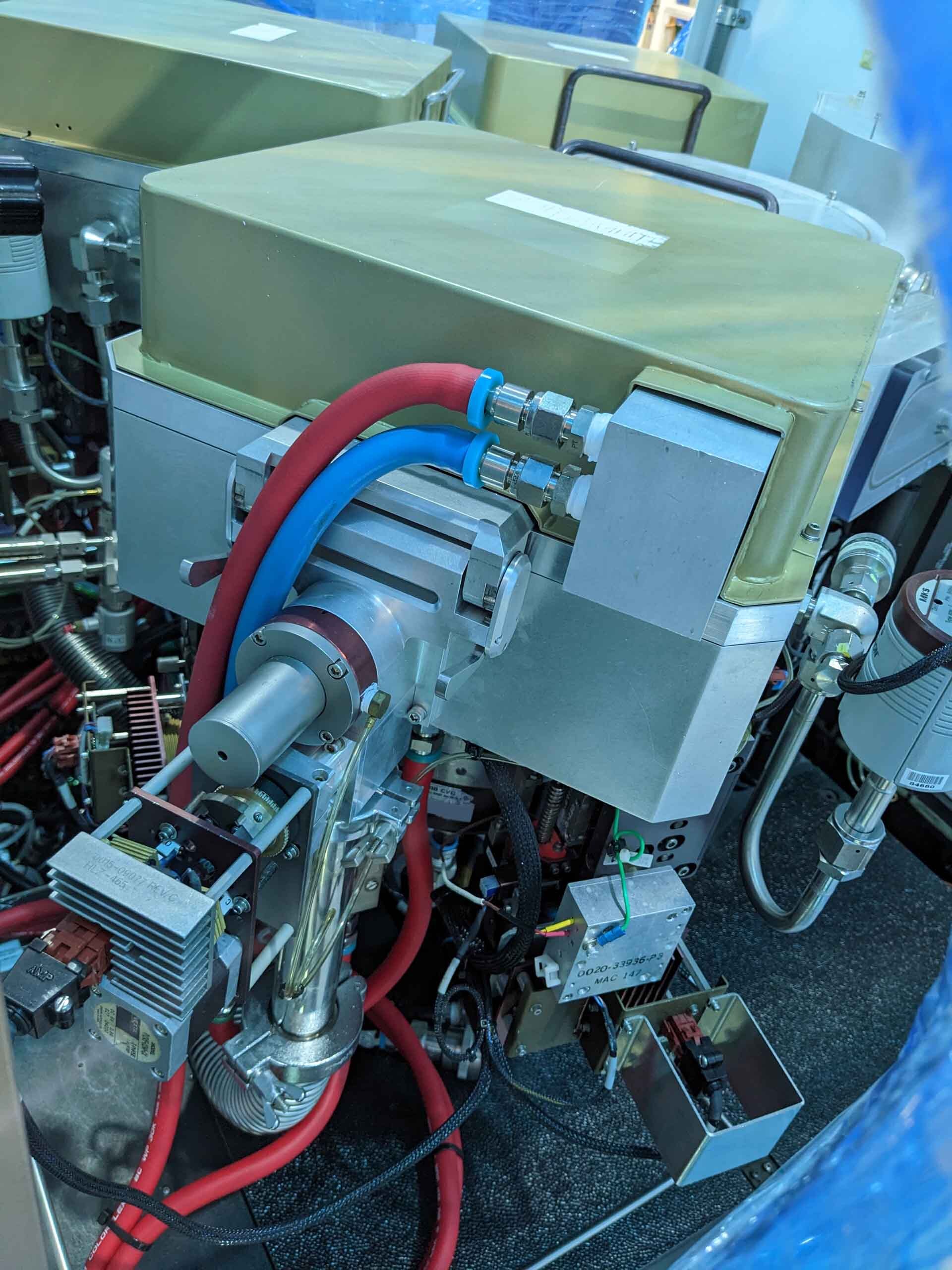

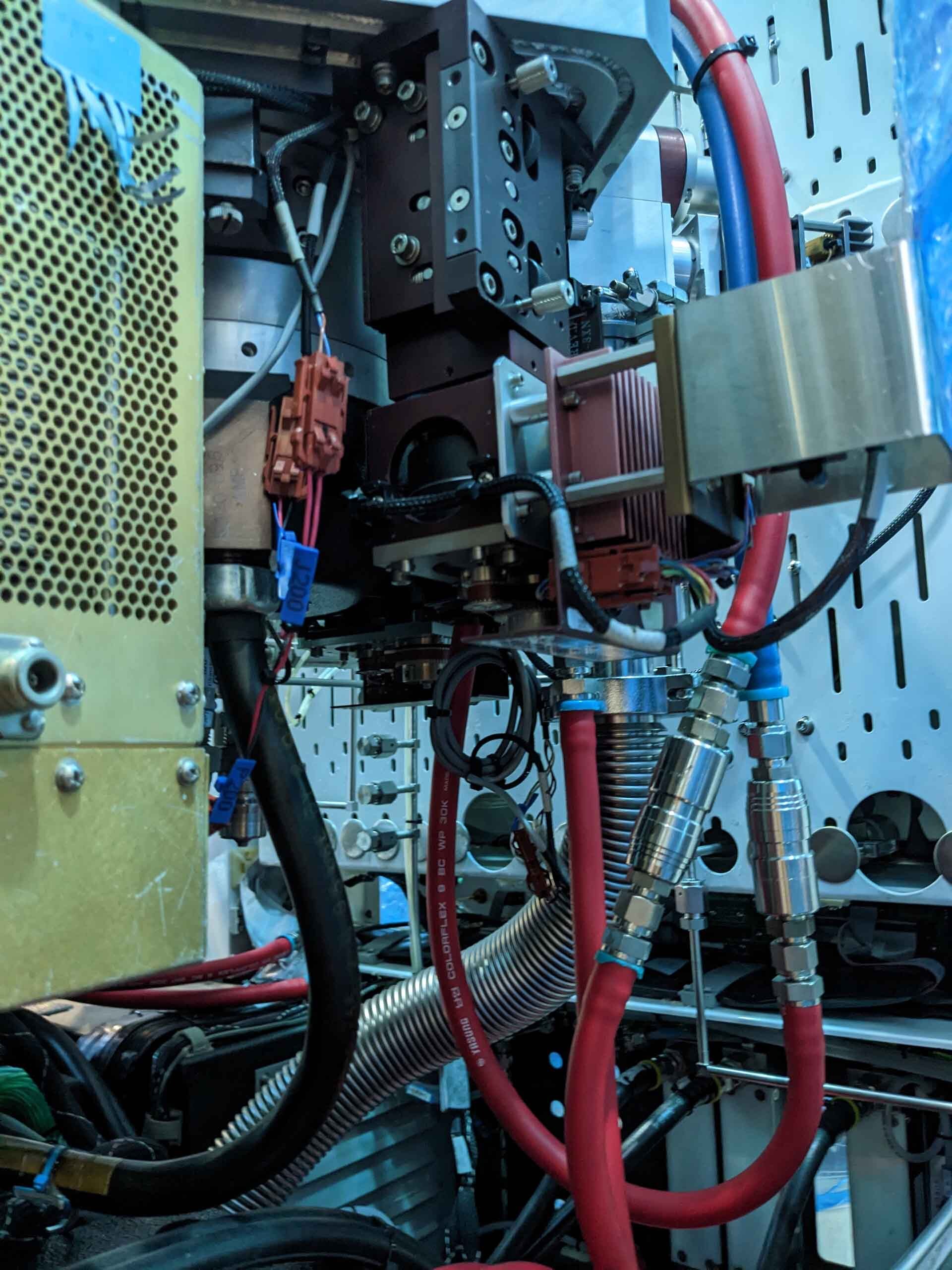

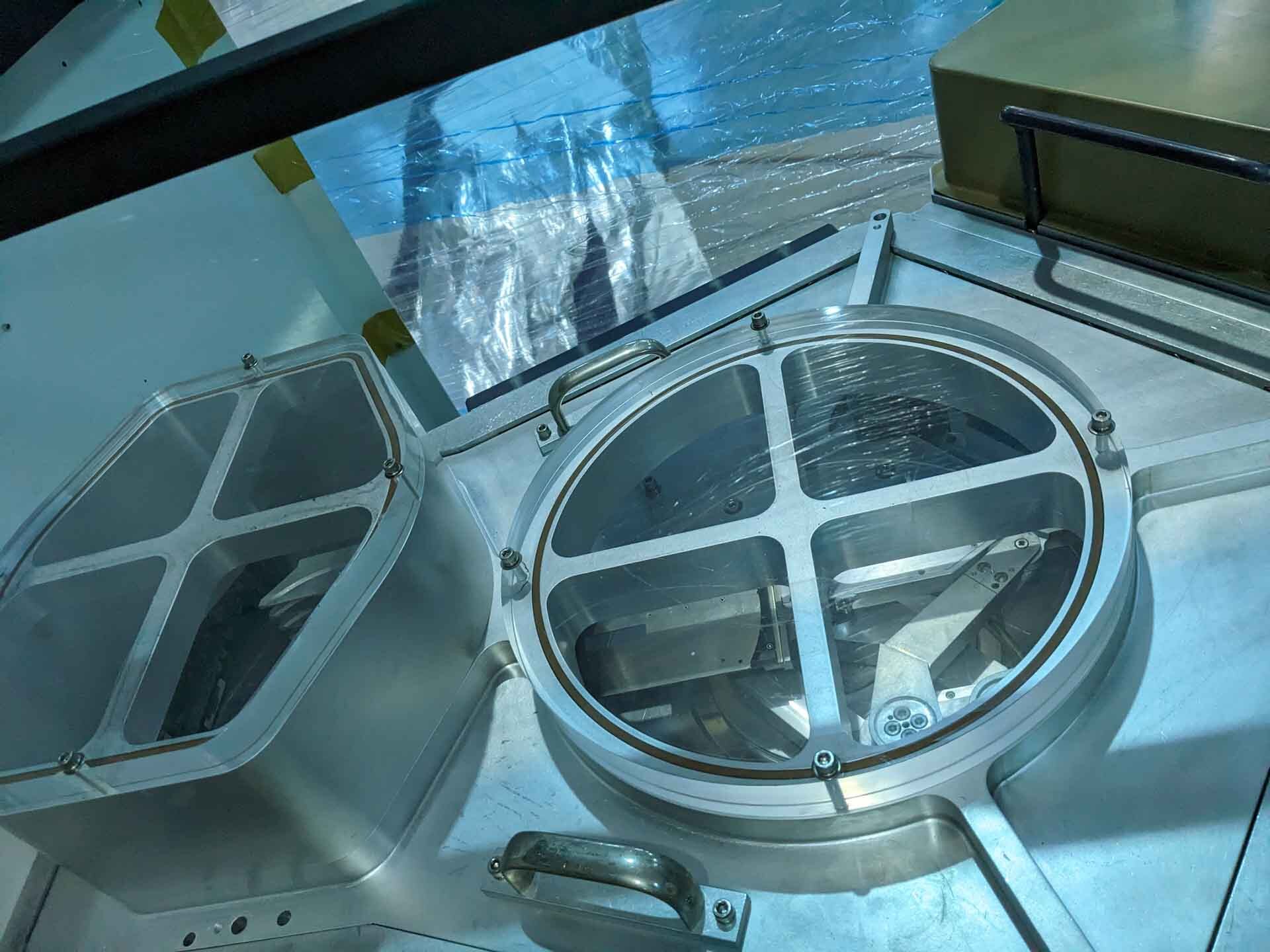

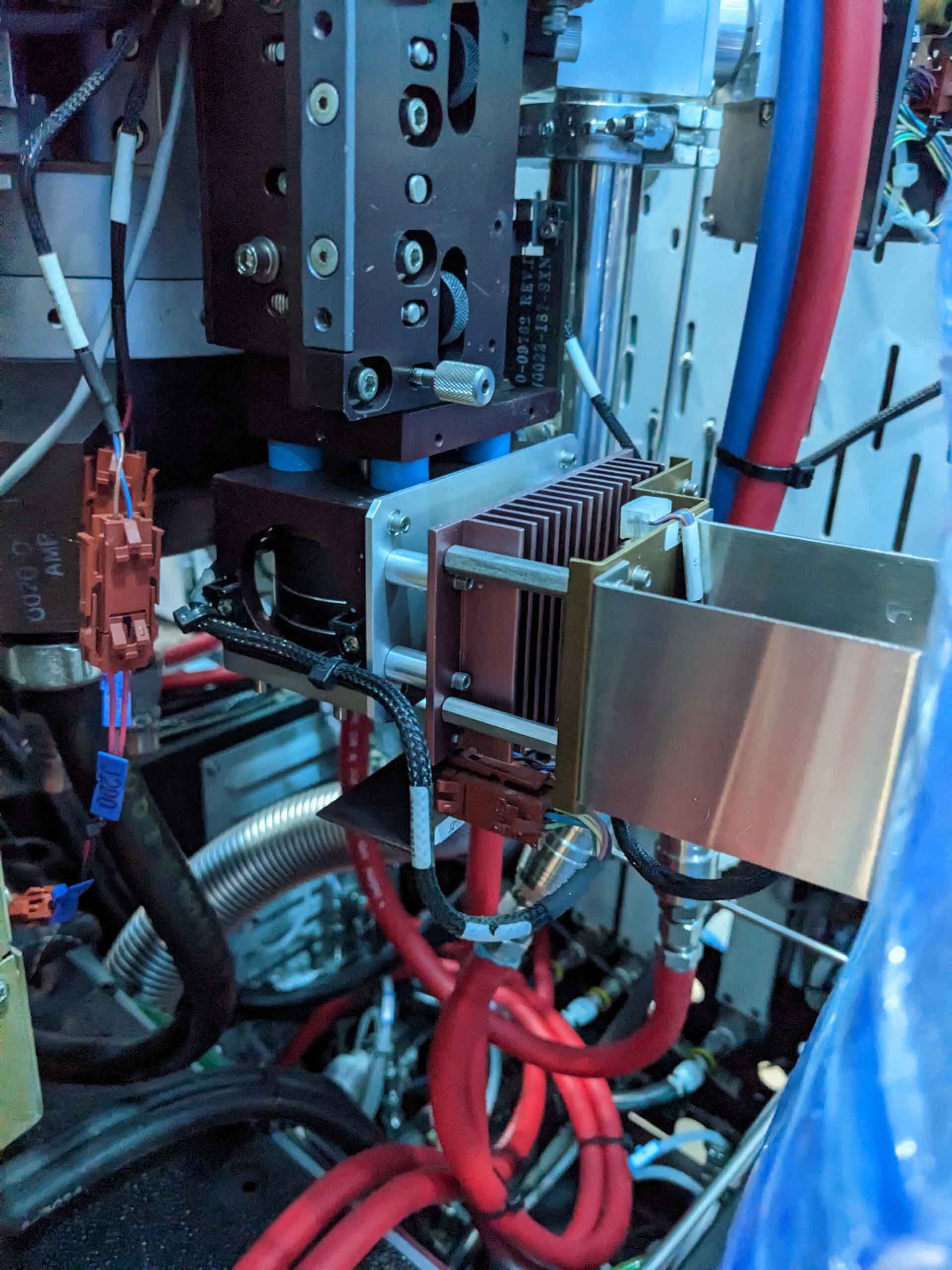

Chamber:

Chamber position: A, B, D

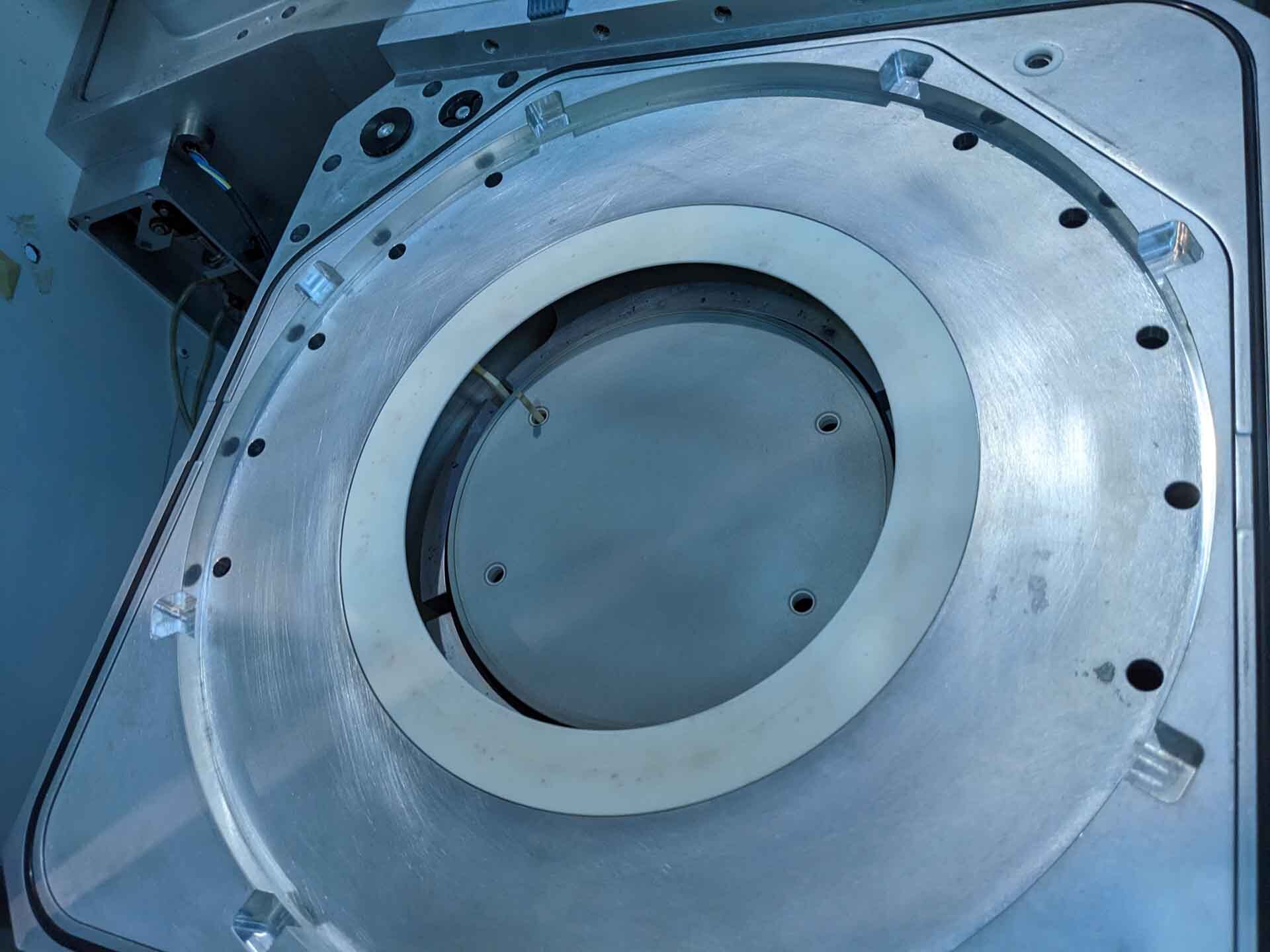

Chamber type: DLH 1-Hole

Process: SiH4 Oxide

Heater type: Lamp

Susceptor type: Al

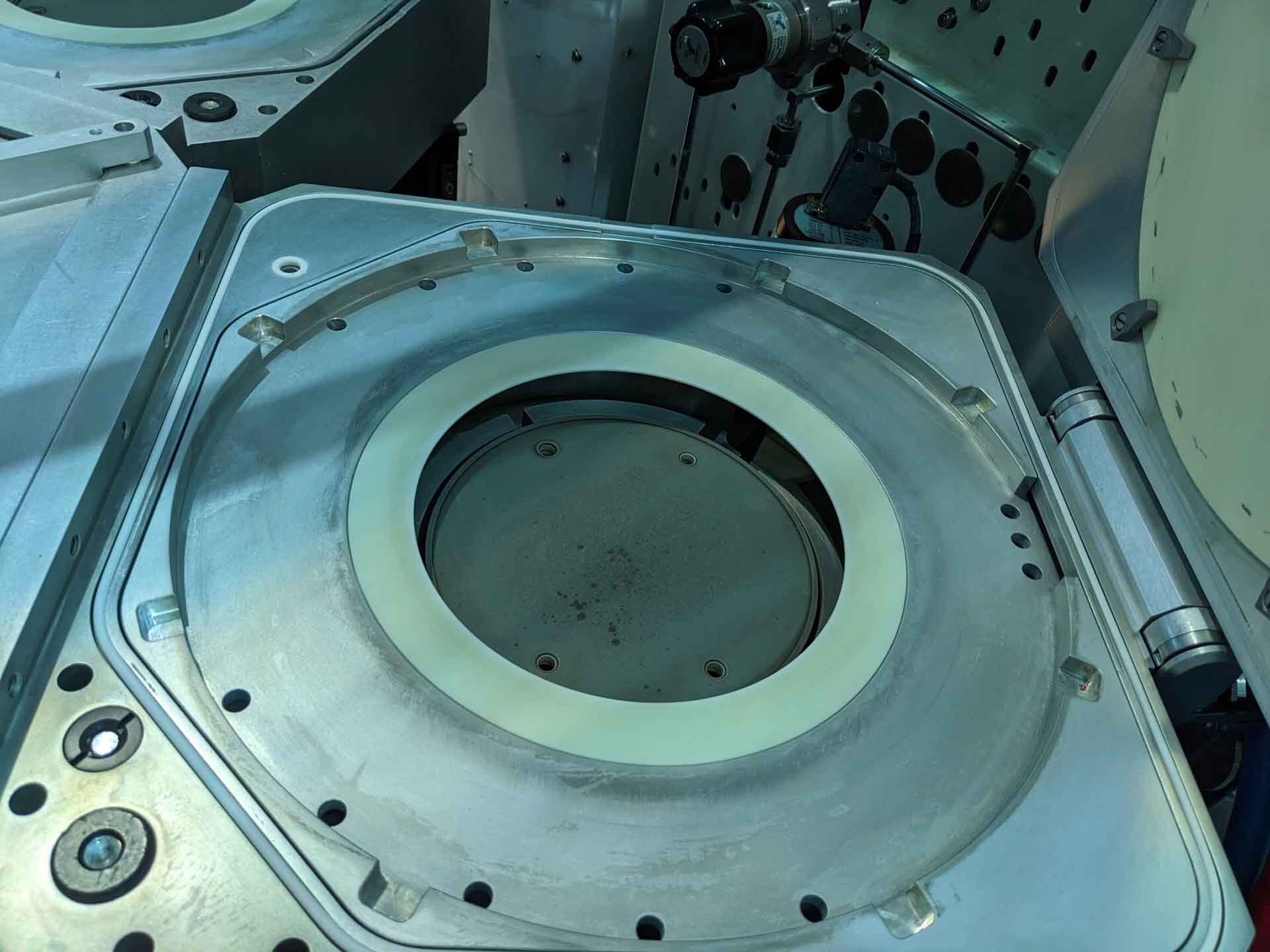

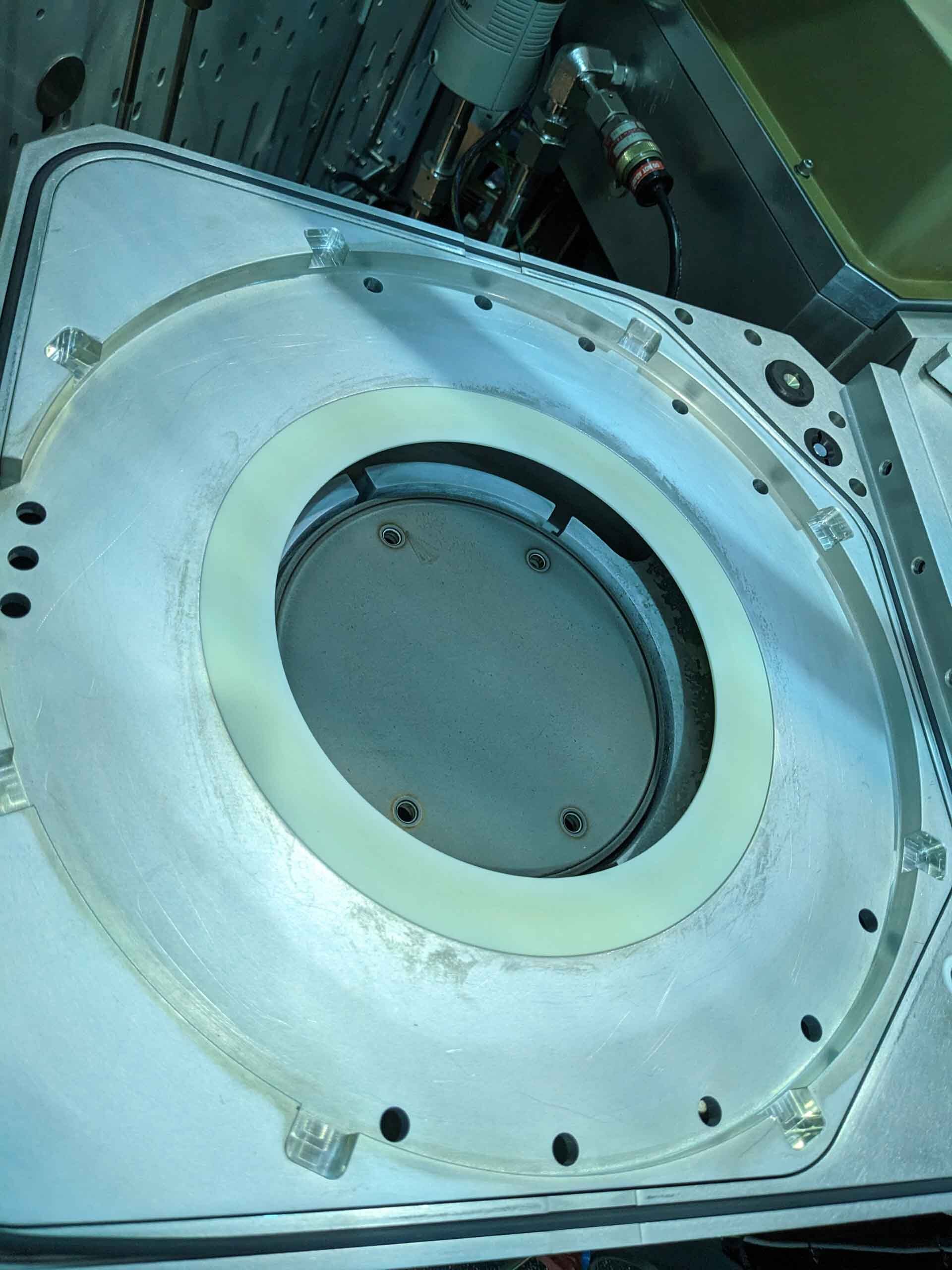

Water lift type: Ceramic hoop

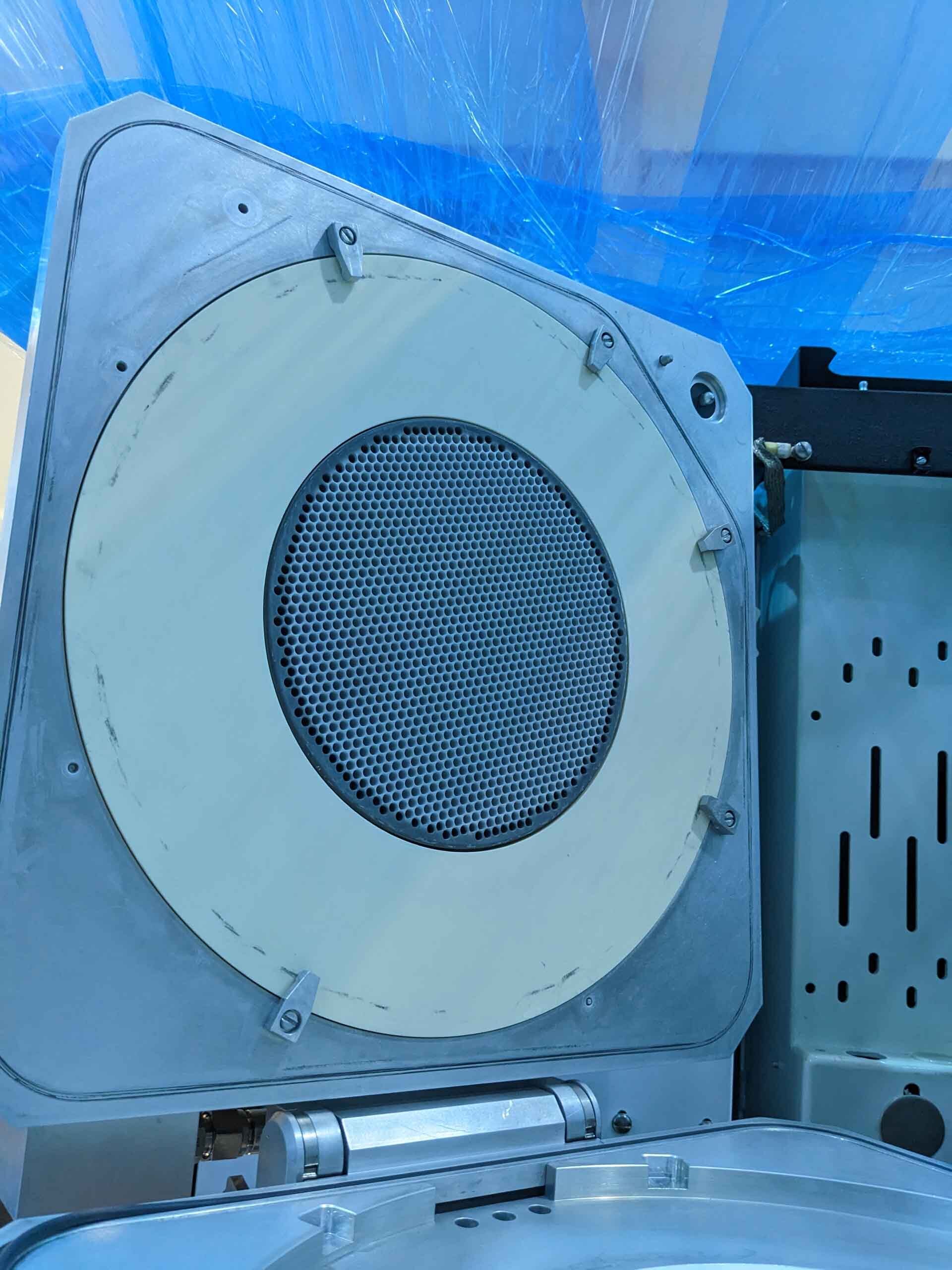

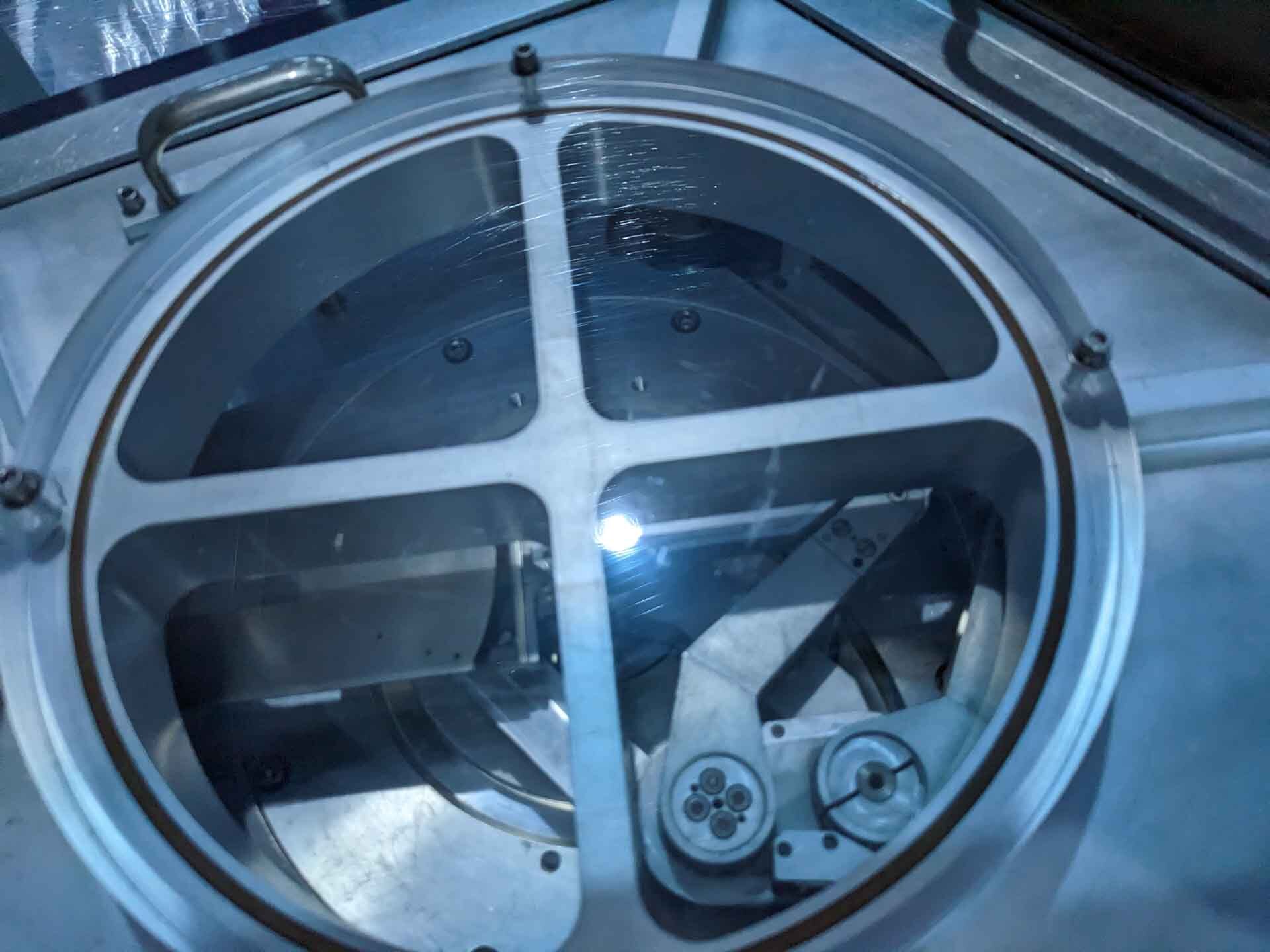

(3) Pumping plates

(3) Ceramic focus rings

(3) Shower heads

(3) Blocker plates

(3) Heater windows

(3) Bellow susceptors, 6"

(3) Bellows water lifts, 6"

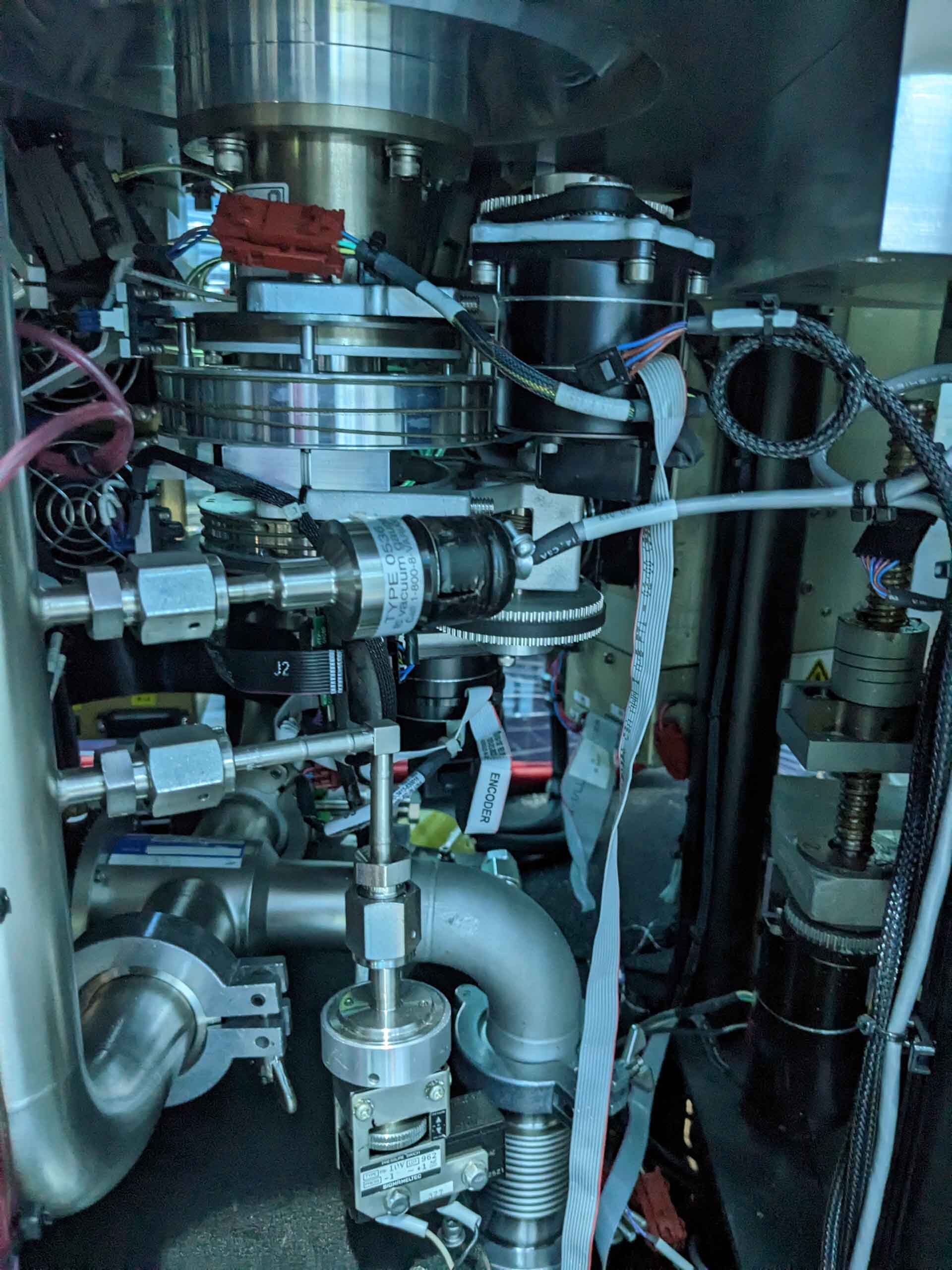

(3) Lamp drivers

Delta nitride dual spring throttle valve

Gas panel: 20 Standard channels

Gas supply: Top down

MFC: UFC 1660

Manual valve: BENKAN

Pneumatic 2-Way valve: NUPRO

MKS 122B Baratron gauge, 10 Torr

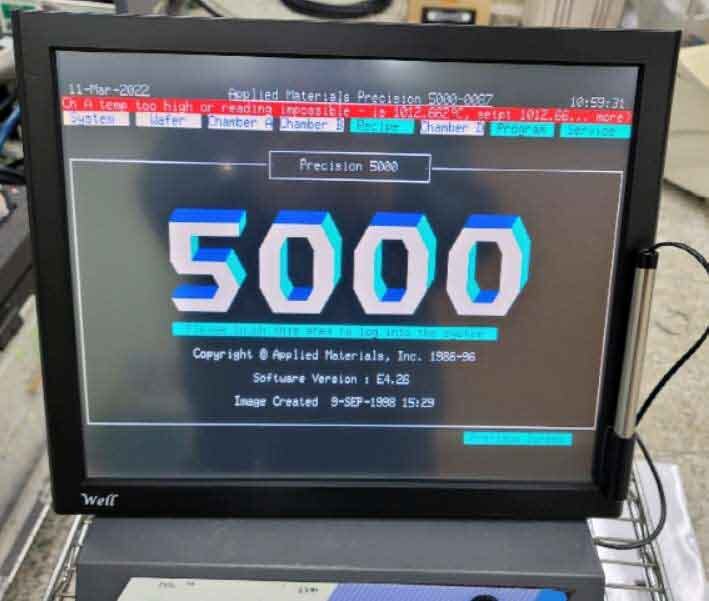

VME Controller:

1 / SBC Board

2 / SV21 SBC Board

3 / SEI Board

4-5 / -

6 / VGA

7 / AO-1

8 / AI-1

9-12 / Stepper control board

13-16 / Digital I/O board

17-20 / -

Gases:

Gas / Range

N2 / 3 SLM

SiH4 / 100 SCCM

CF4 / 2 SLM

N2O / 2 SLM

1995 vintage.

AMAT / APPLIED MATERIALS P5000 Mark II semiconductor reactor is a medium-voltage photoresist chemistry equipment designed to provide high throughput, reliable and controllable performance. It is a fully automated system which enables tight control of the lithography process to achieve tight drug release capsule formation onto substrates such as silicon wafers. AMAT P5000 Mark II unit is capable of running multiple processes simultaneously and is designed in such a way as to ensure maximum utilization of resources with low operating costs. APPLIED MATERIALS P 5000 MARK II reactor features a three chamber design, which includes the main chamber, the top side chamber and the bottom side chamber. P 5000 MARK II is capable of a range of photoresist processing steps, including thermal and reactive thermal oxide, organometallic chemistries, large area uniformity down to below 10 nanometers, and chemically enhanced etching. AMAT P 5000 MARK II reactor has an output rate of up to 5 million wafers/hr and is capable of connecting up to 4 P5000 reactor systems for multi-processor lithography operations. P5000 Mark II is equipped with a large number of dedicated hardware and software components which enables tight process control, allowing for extreme accuracy. The machine is based on a distributed control architecture with redundant processors, ensuring high tool availability. It also comes with an advanced graphical user interface, capable of displaying the detailed process results in the form of charts and diagrams. As a result, it provides a comprehensive tool to assist lithographers in process selection and optimisations. It is equipped with a range of advanced metrology components to provide exact process control. APPLIED MATERIALS P5000 Mark II reactor also comes with a number of dedicated protection systems, which help to ensure a safe operating environment. For instance, the asset includes an ESD protection model which helps to protect people and equipment from electrostatic discharge. Furthermore, the equipment has a built-in safety interlock system which helps to reduce the risk of an unsafe work environment caused by unexpected component failure. Additionally, the unit is equipped with monitors which alert the user to any potential fault and enable them to take appropriate corrective action. In summary, AMAT / APPLIED MATERIALS P 5000 MARK II reactor is a powerful and reliable semiconductor processing machine. It is equipped with a range of sophisticated features, combined with advanced safety features, which ensure high performance and ultra-precise processing results. It offers a comprehensive, automated solution for achieving tight drug release capsule formation onto substrates such as silicon wafers.

There are no reviews yet