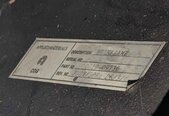

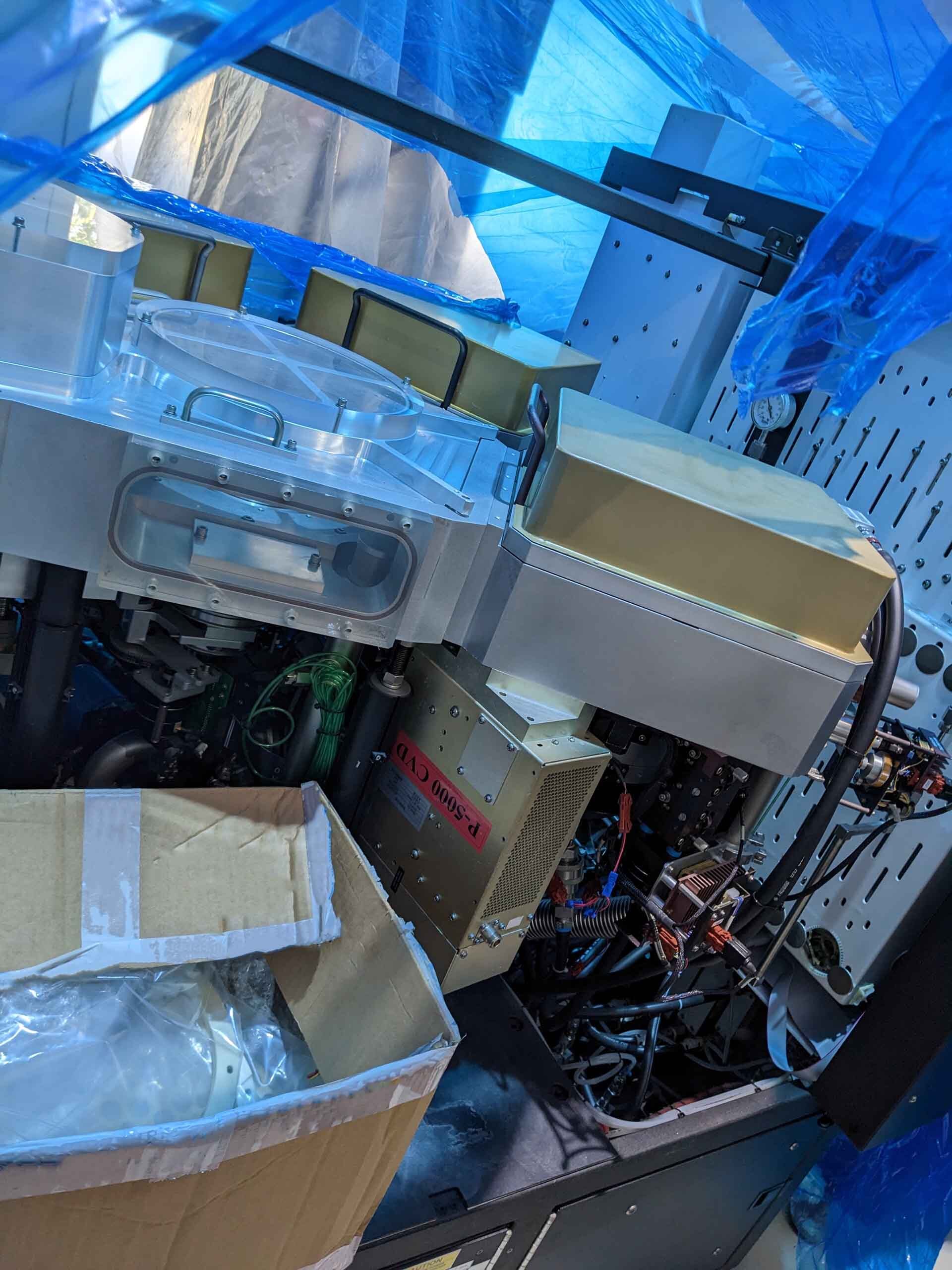

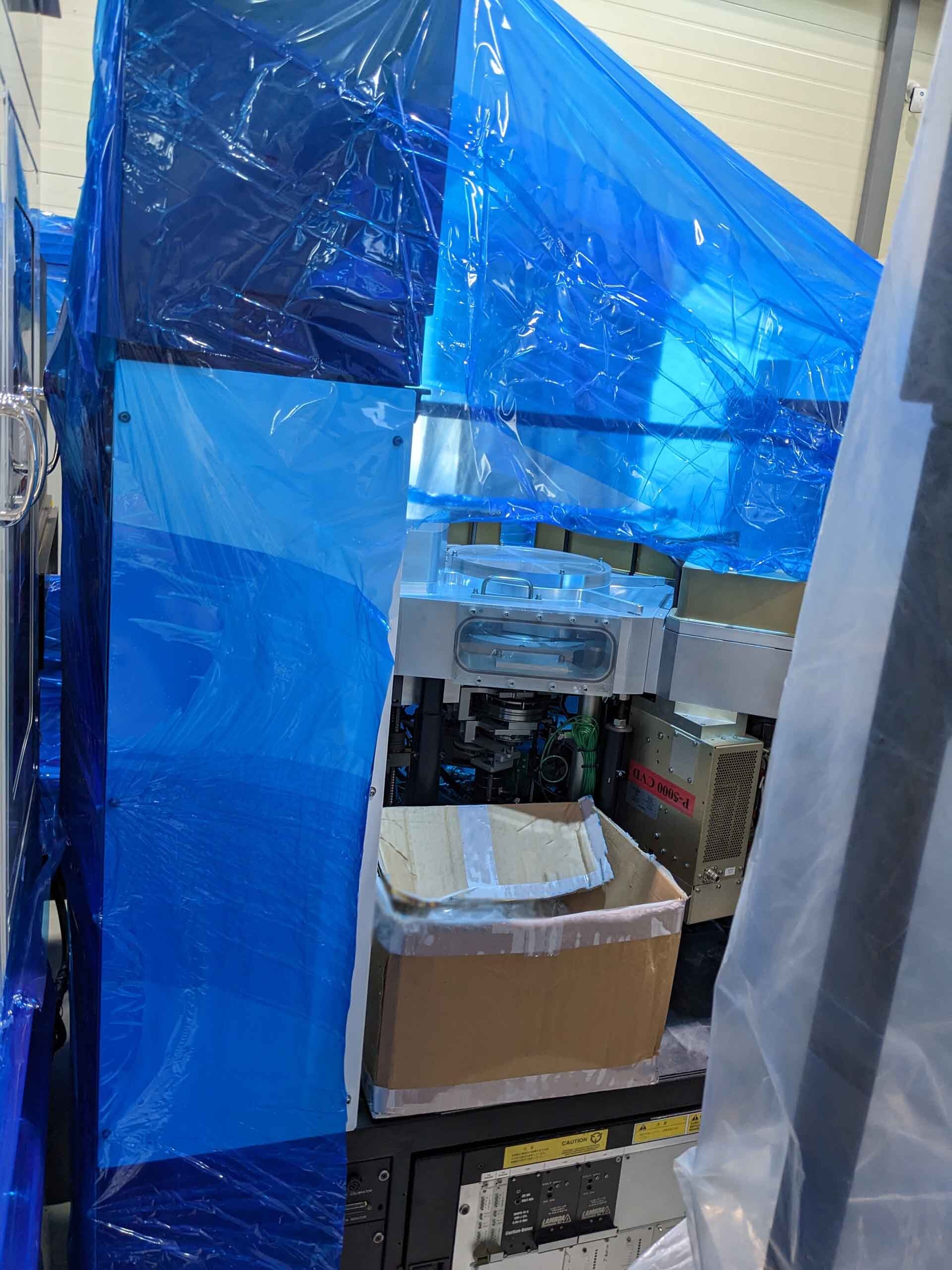

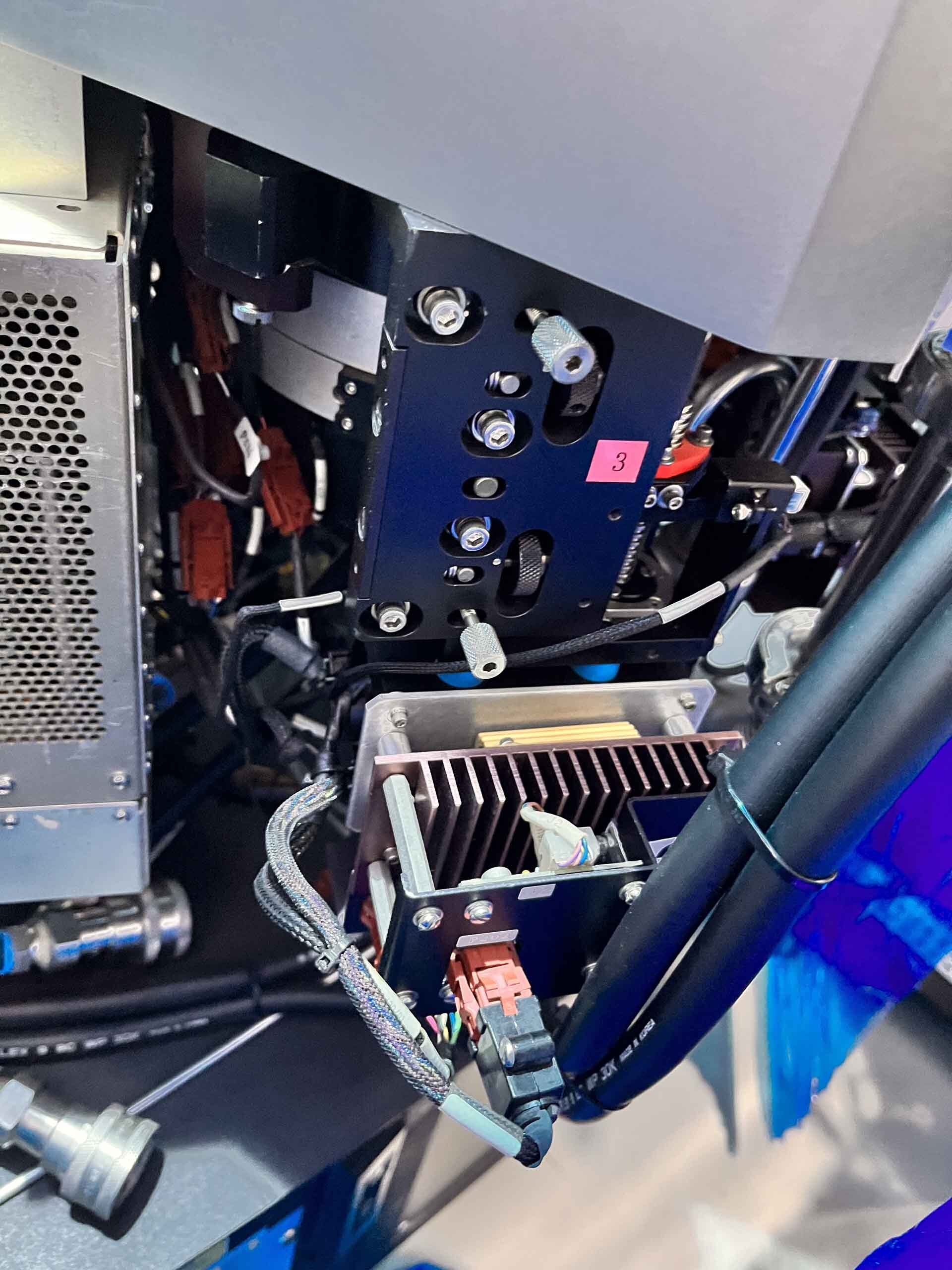

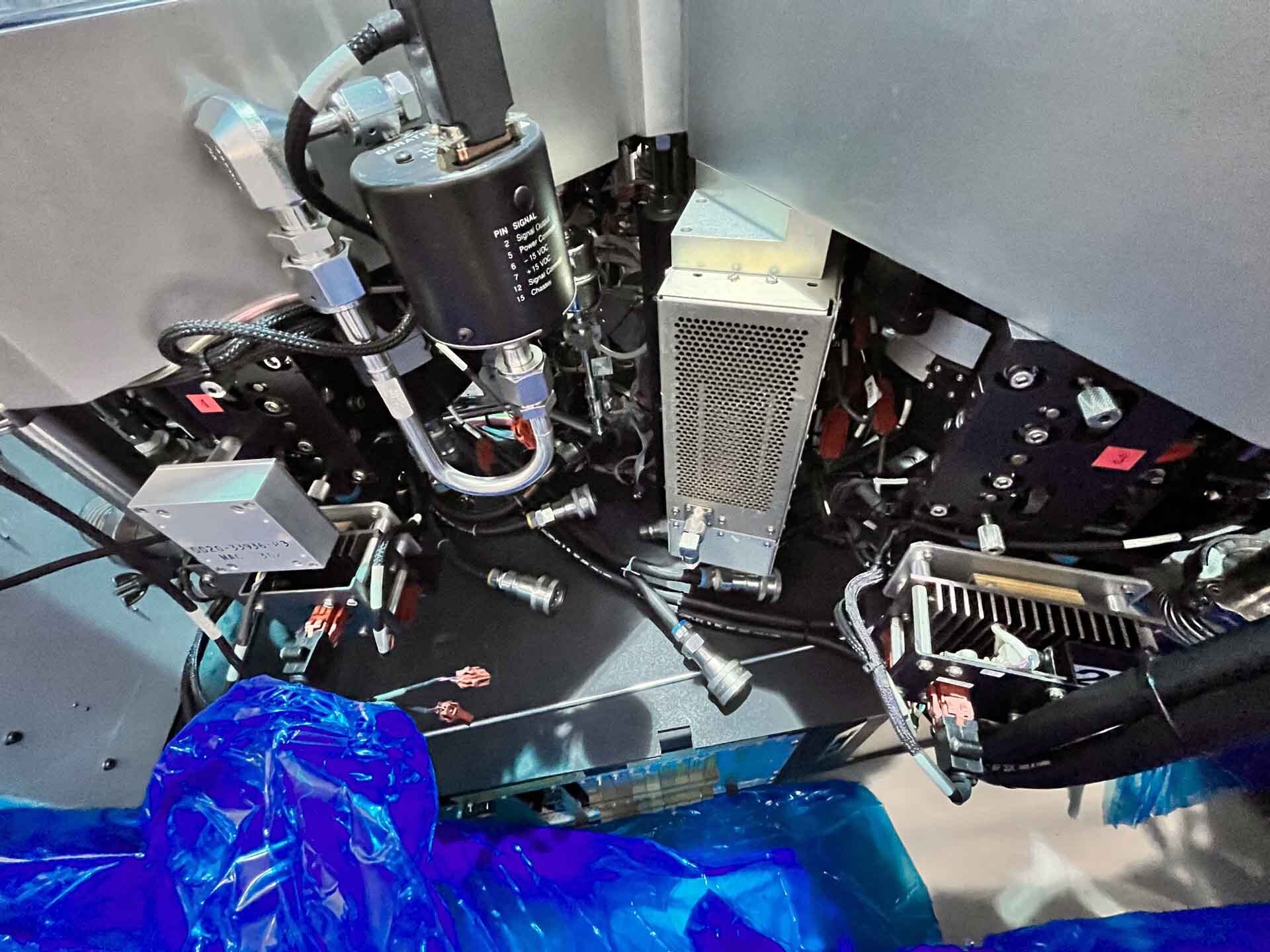

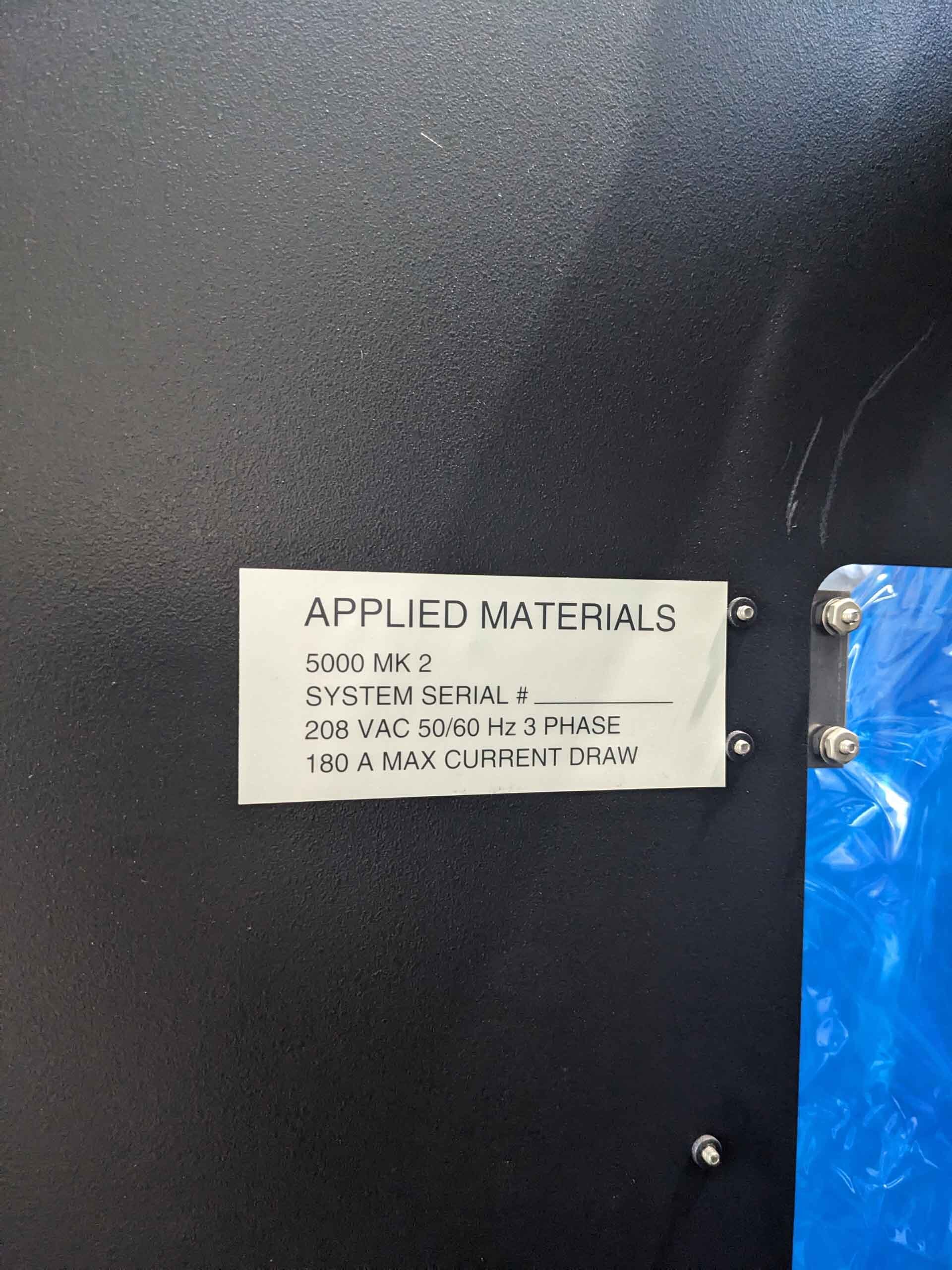

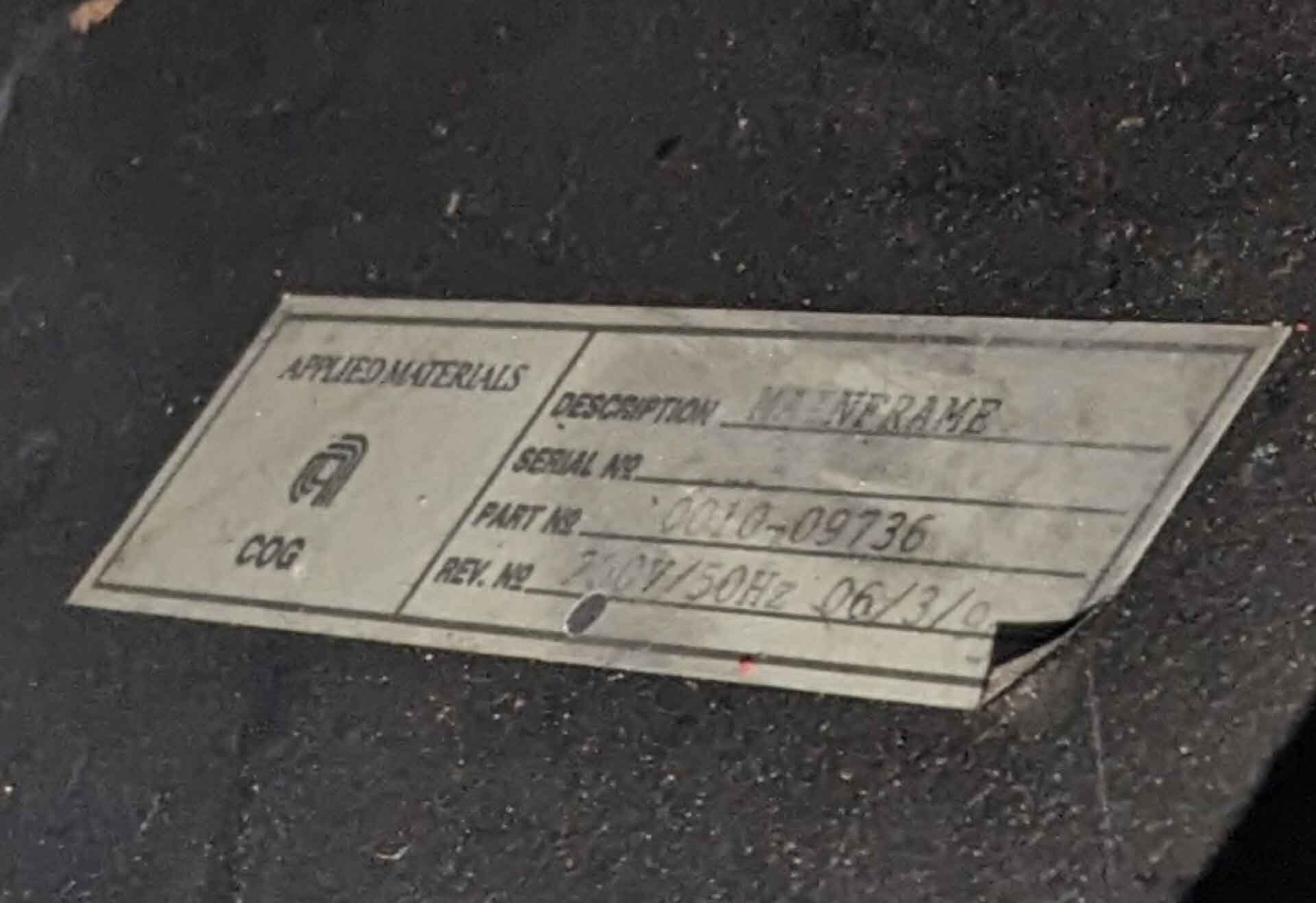

Used AMAT / APPLIED MATERIALS P5000 Mark II #9402055 for sale

URL successfully copied!

Tap to zoom

ID: 9402055

Wafer Size: 8"

Vintage: 1995

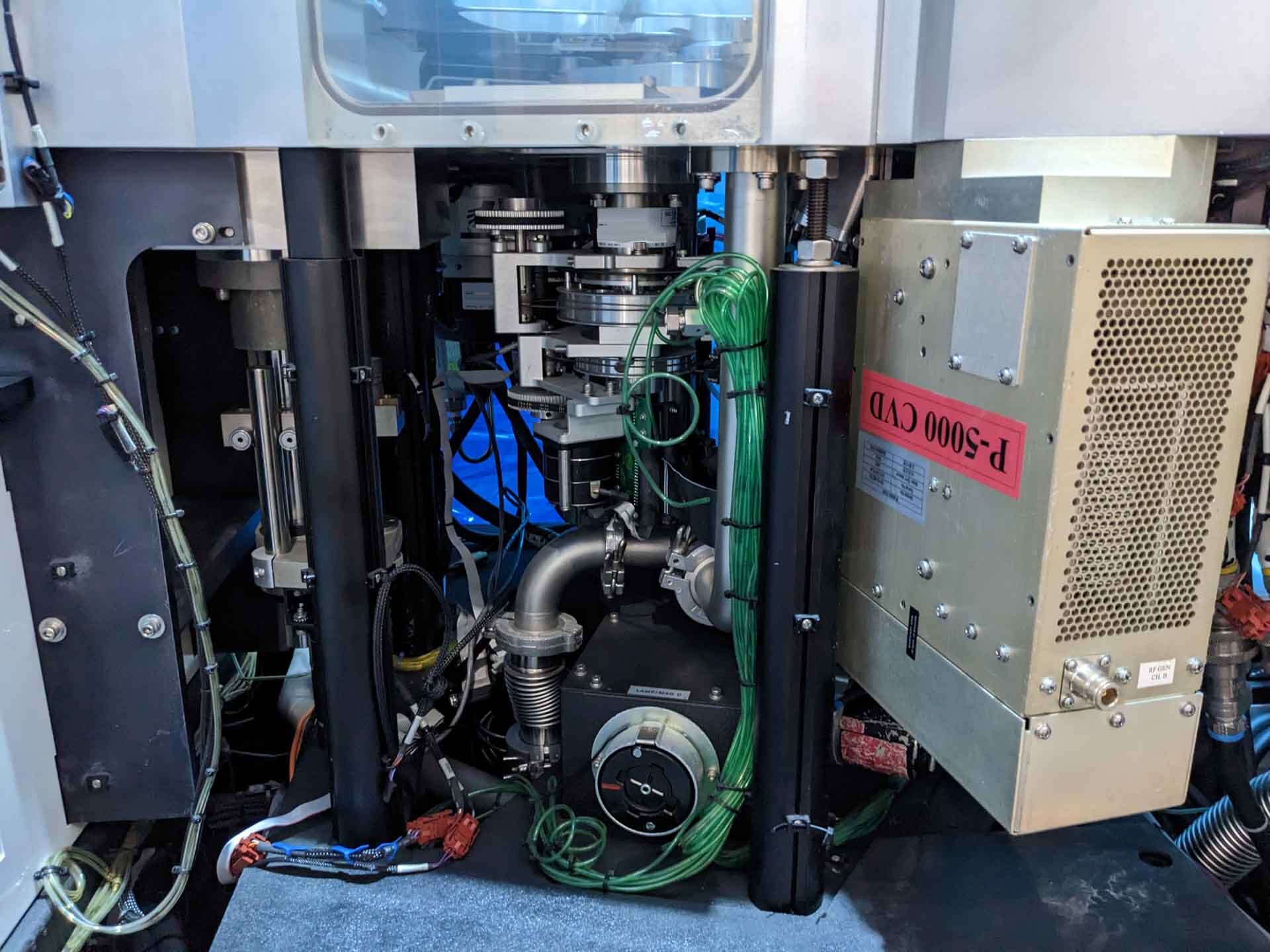

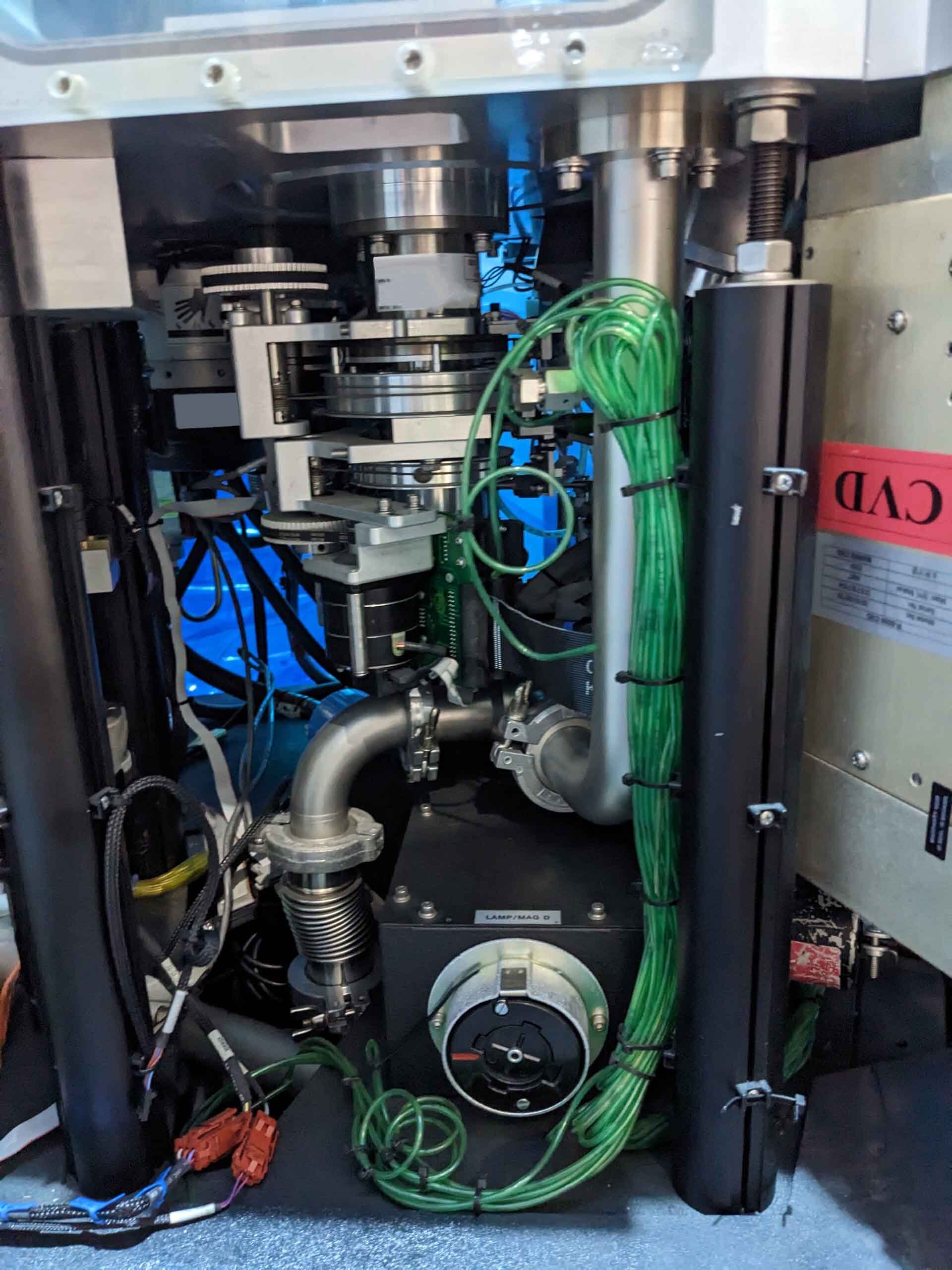

CVD System, 8"

Process: PE SiH4 Oxide / Nitride

Clamp cassette indexer

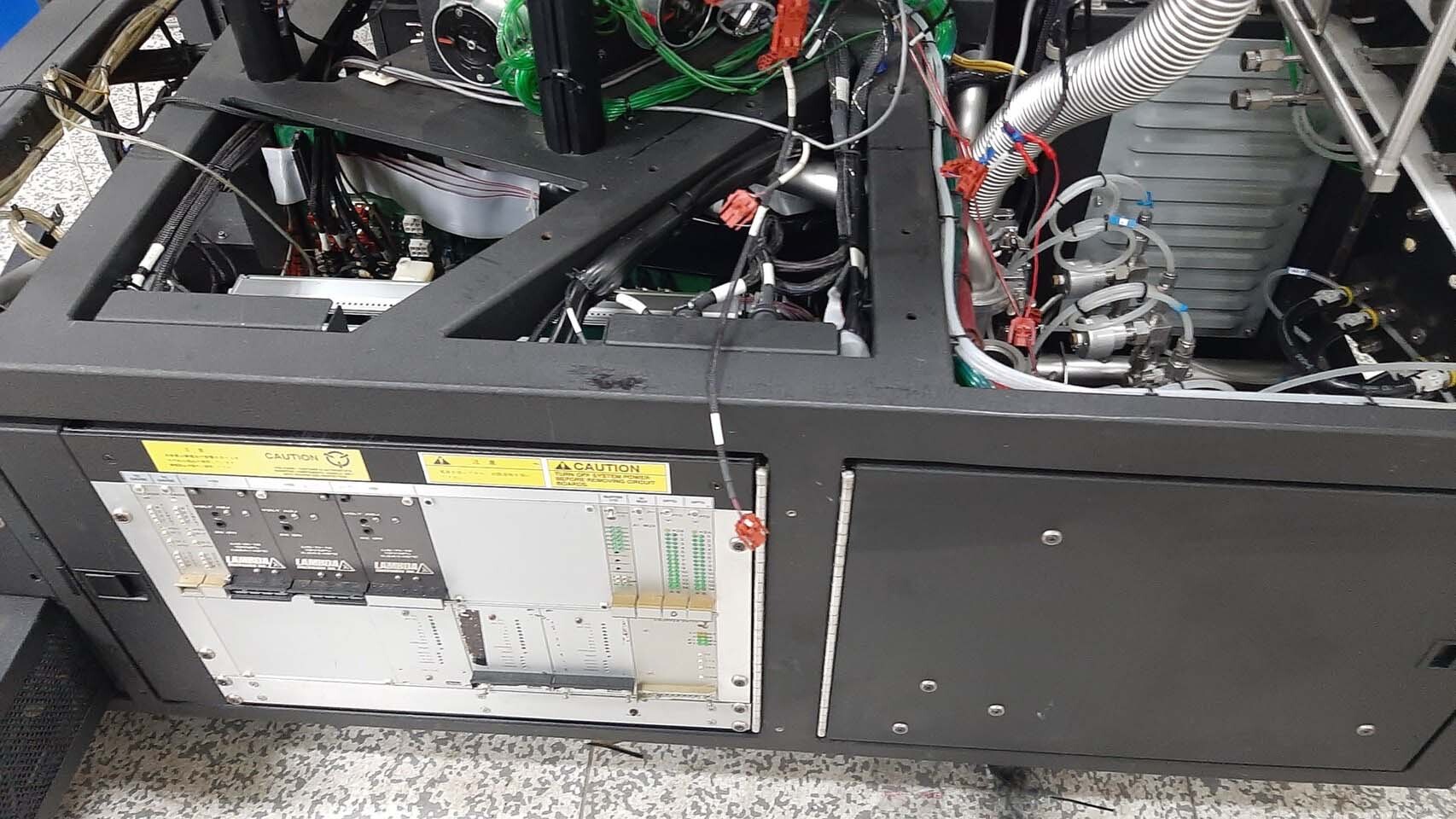

HDD: SSD Type

FDD: SCSI, 3.5"

Elevator type: 8 Slots, 8"

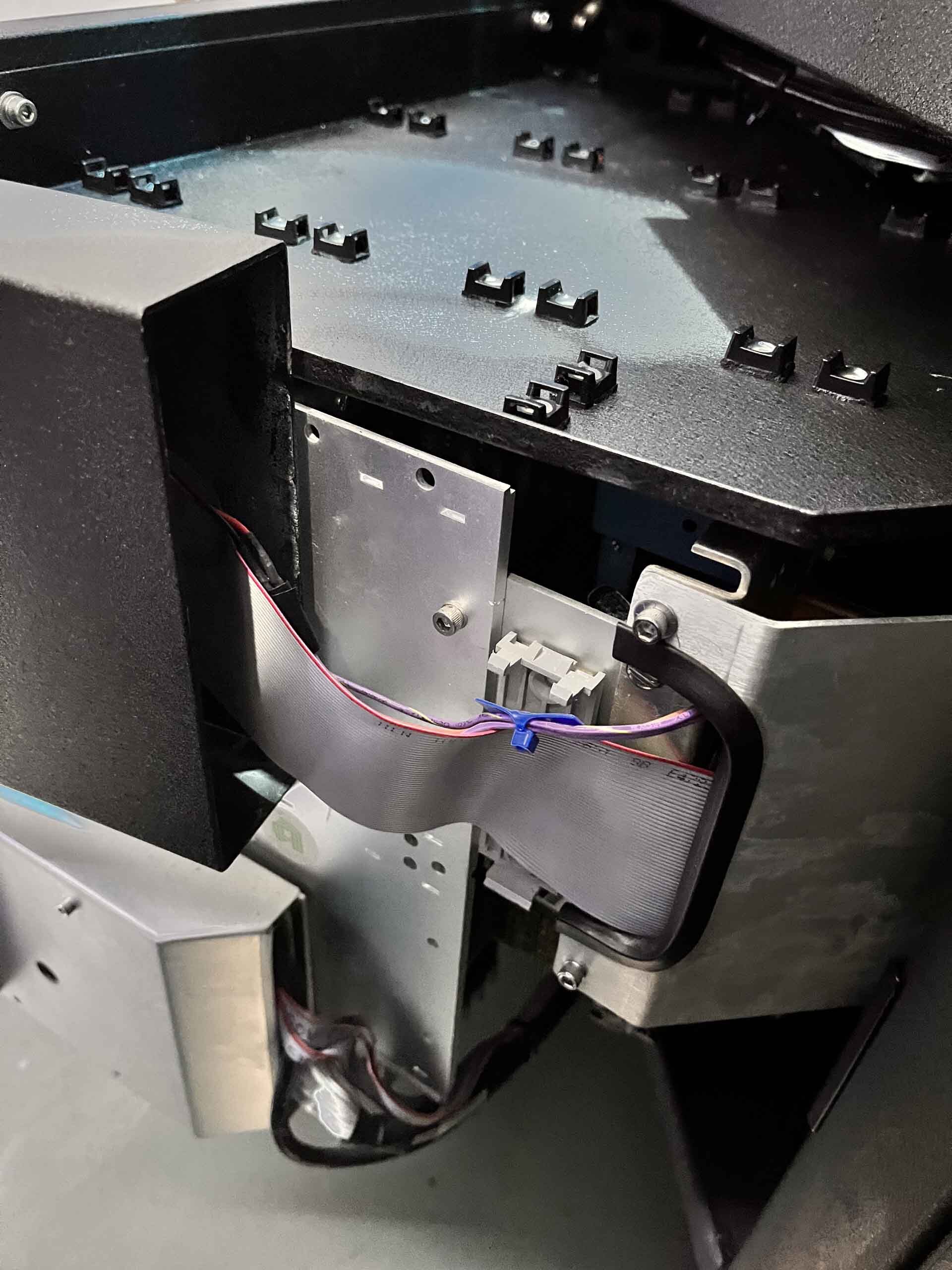

Robot type: AMAT Standard

Blade: Standard, 8"

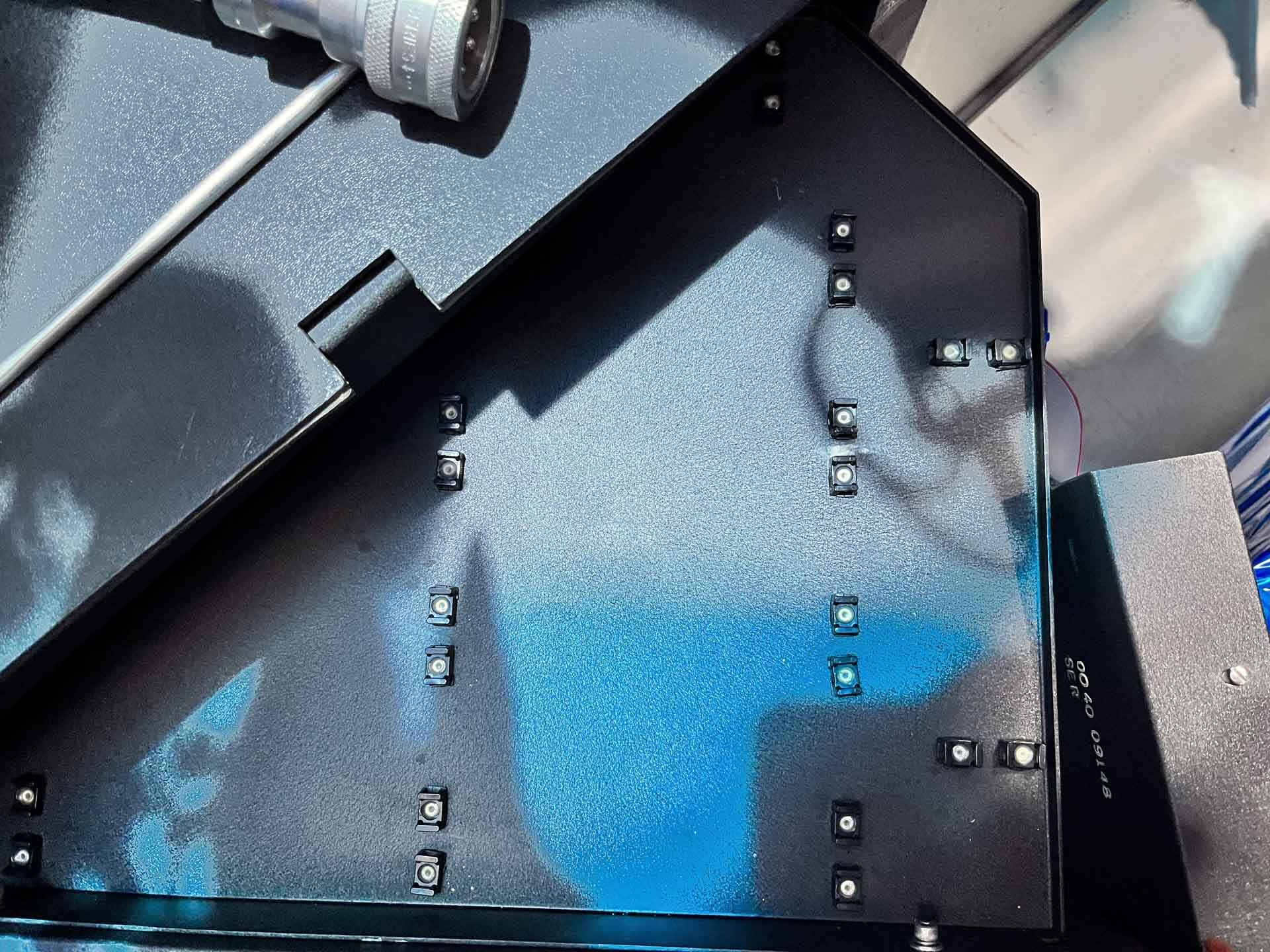

I/O Sensor and door

Center finder

Vacuum sensor

Standard slit value

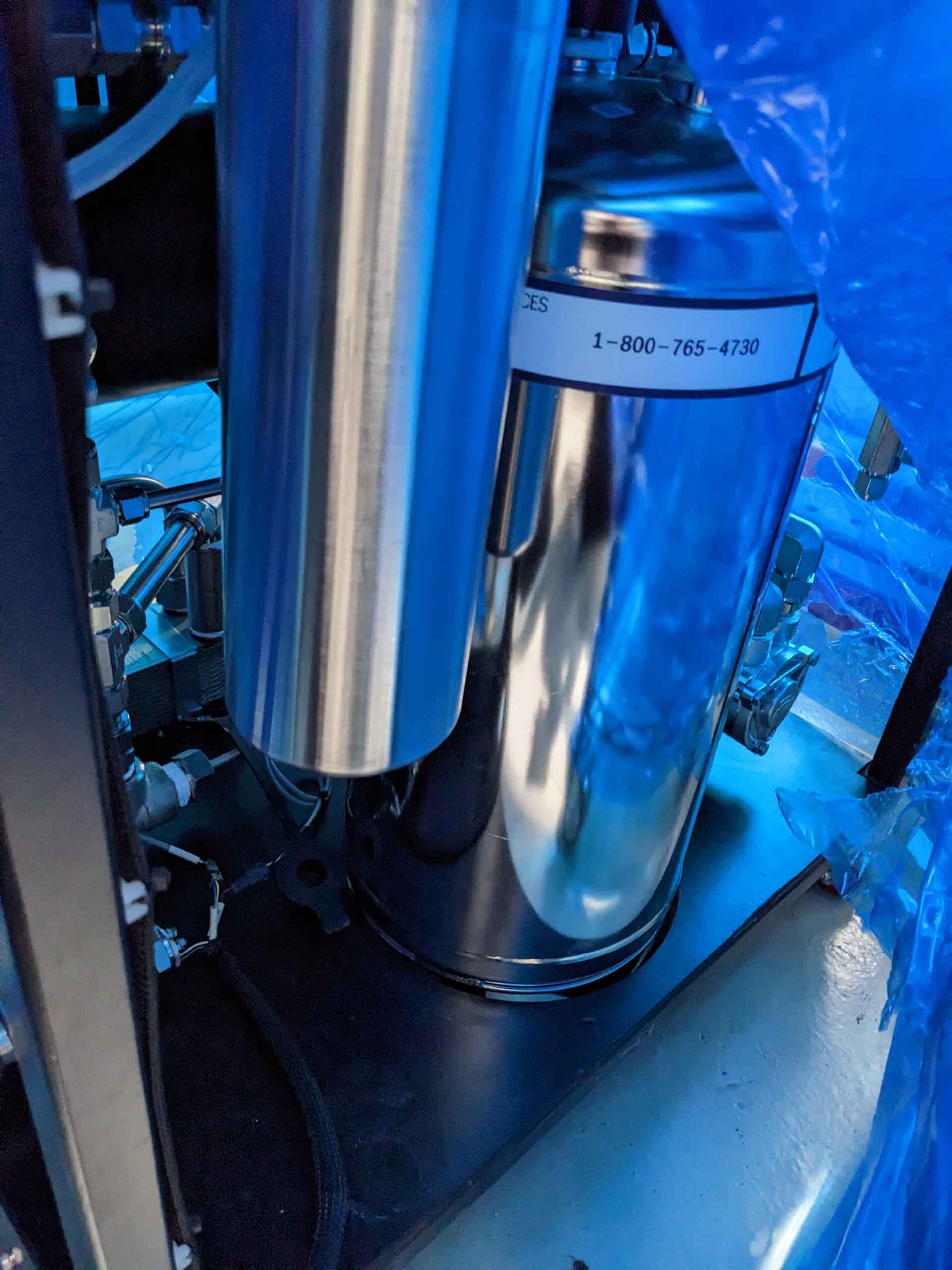

Fore line

Signal tower: R / Y / G / B

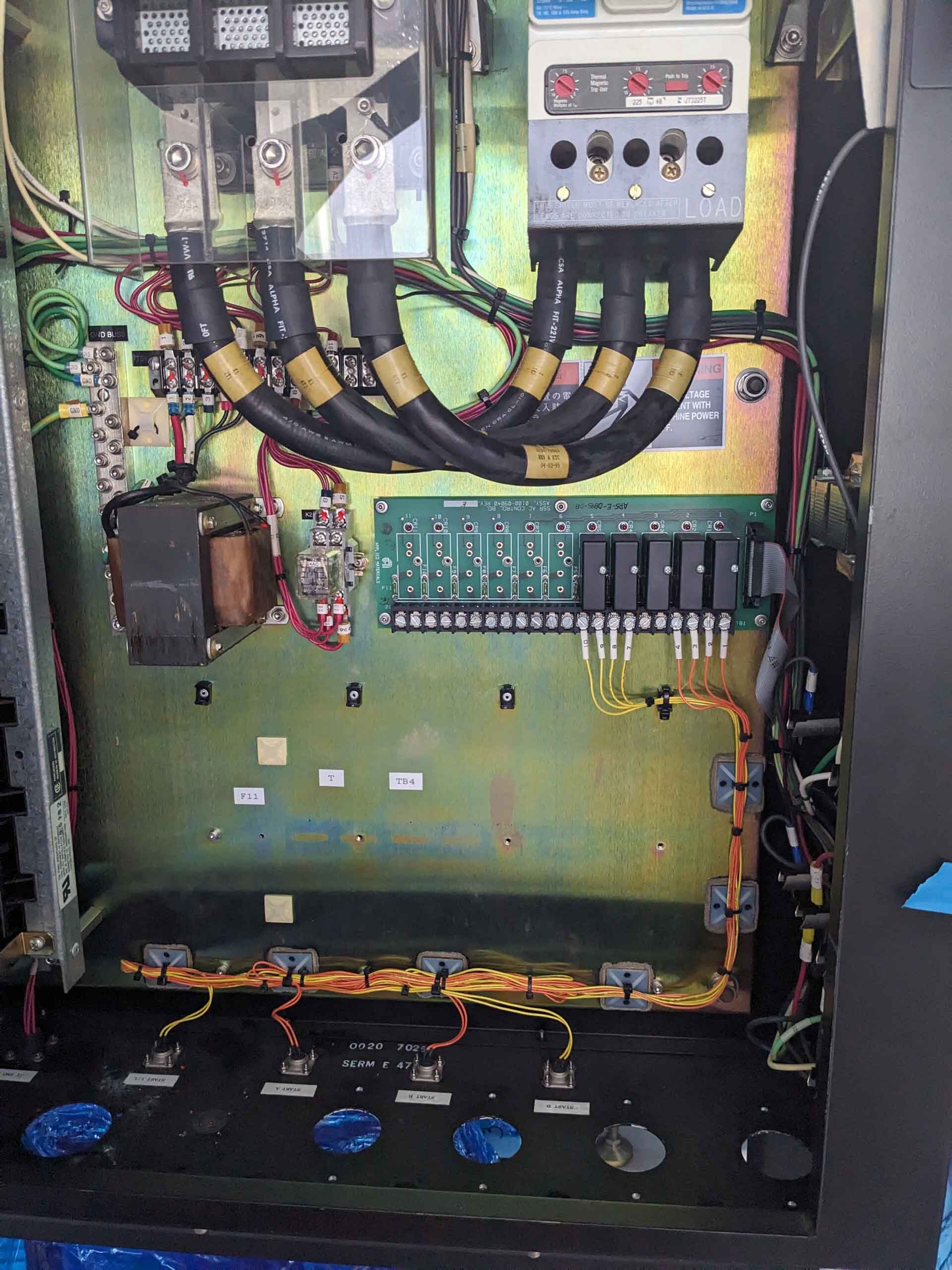

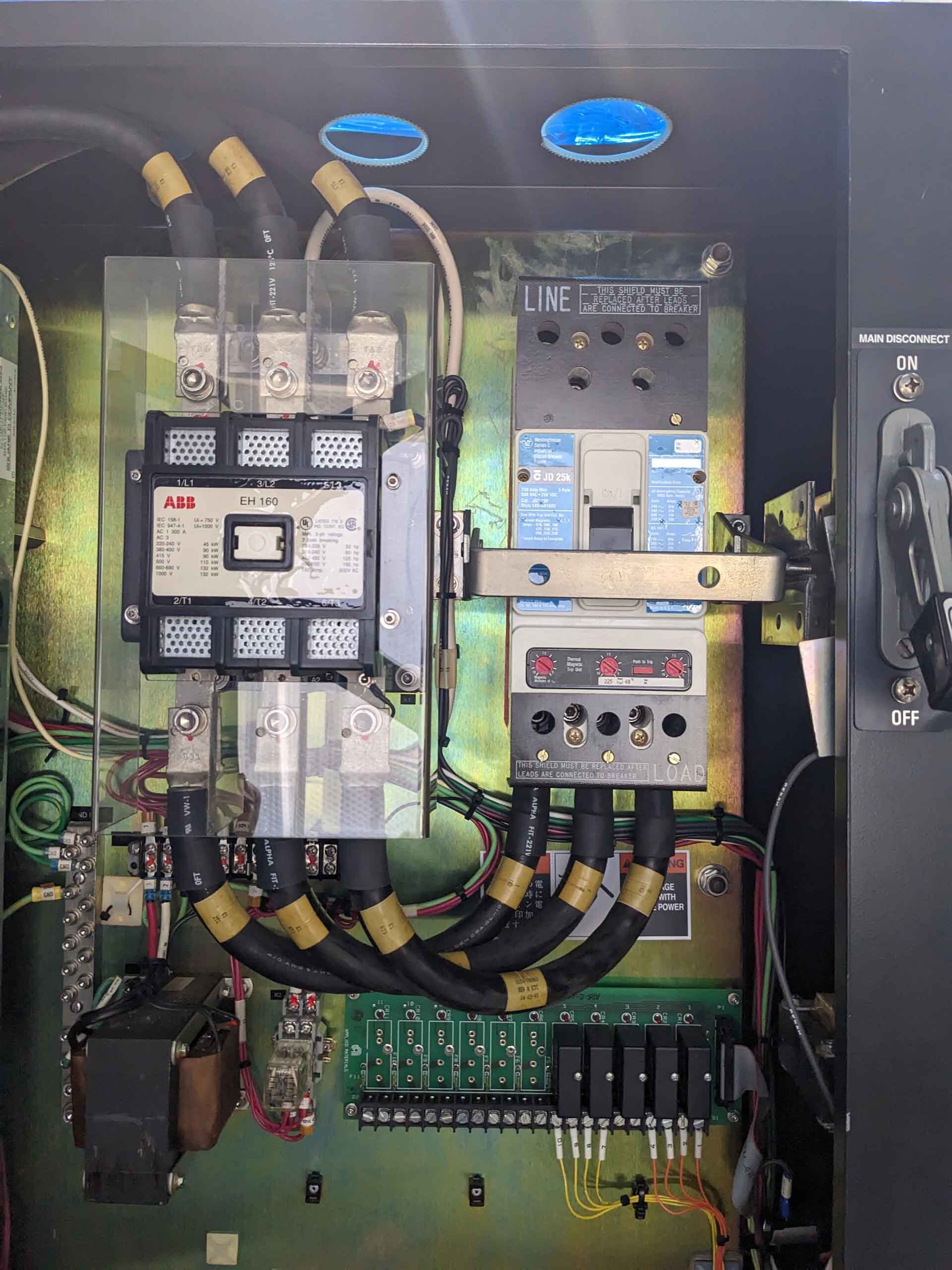

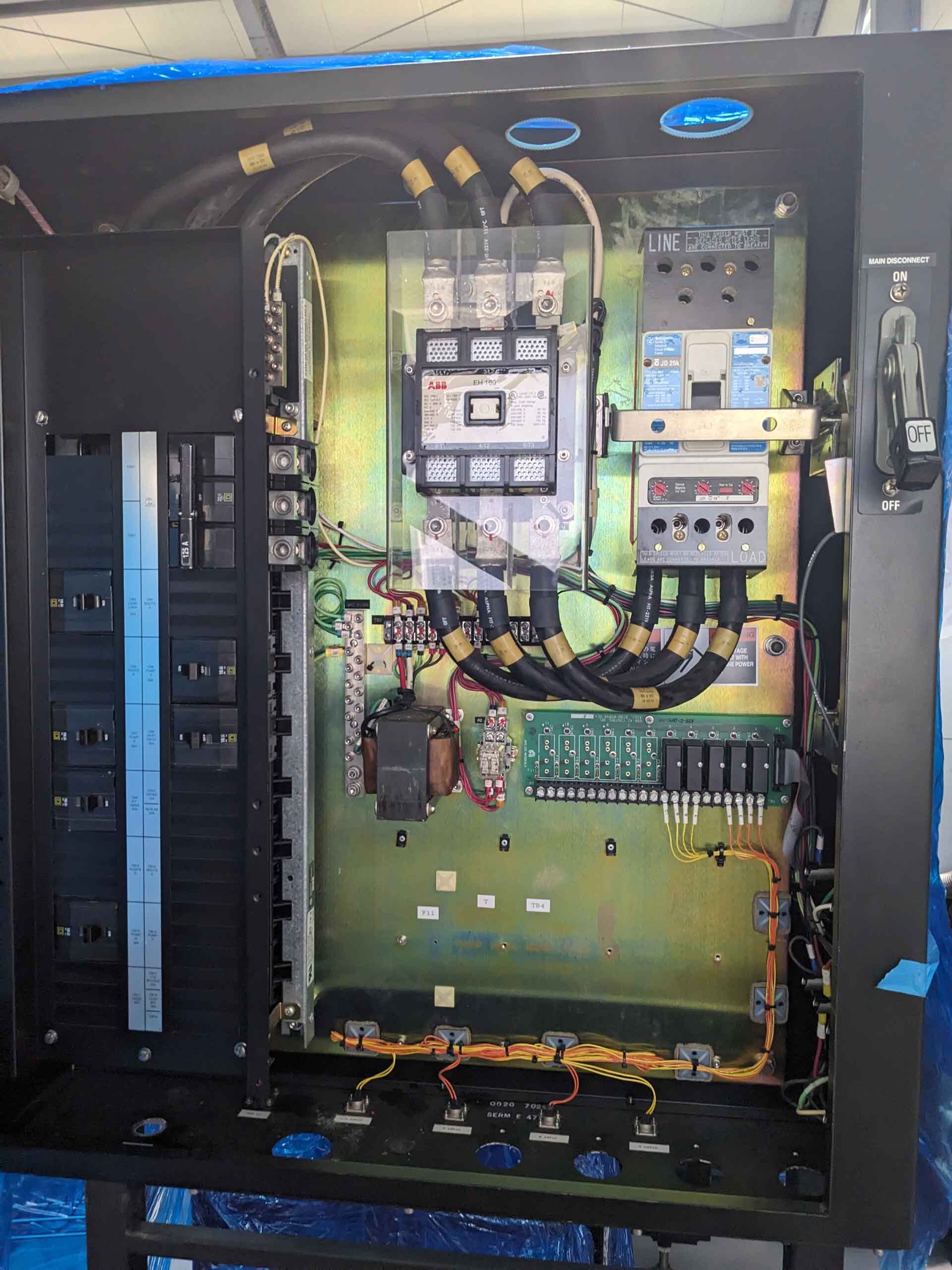

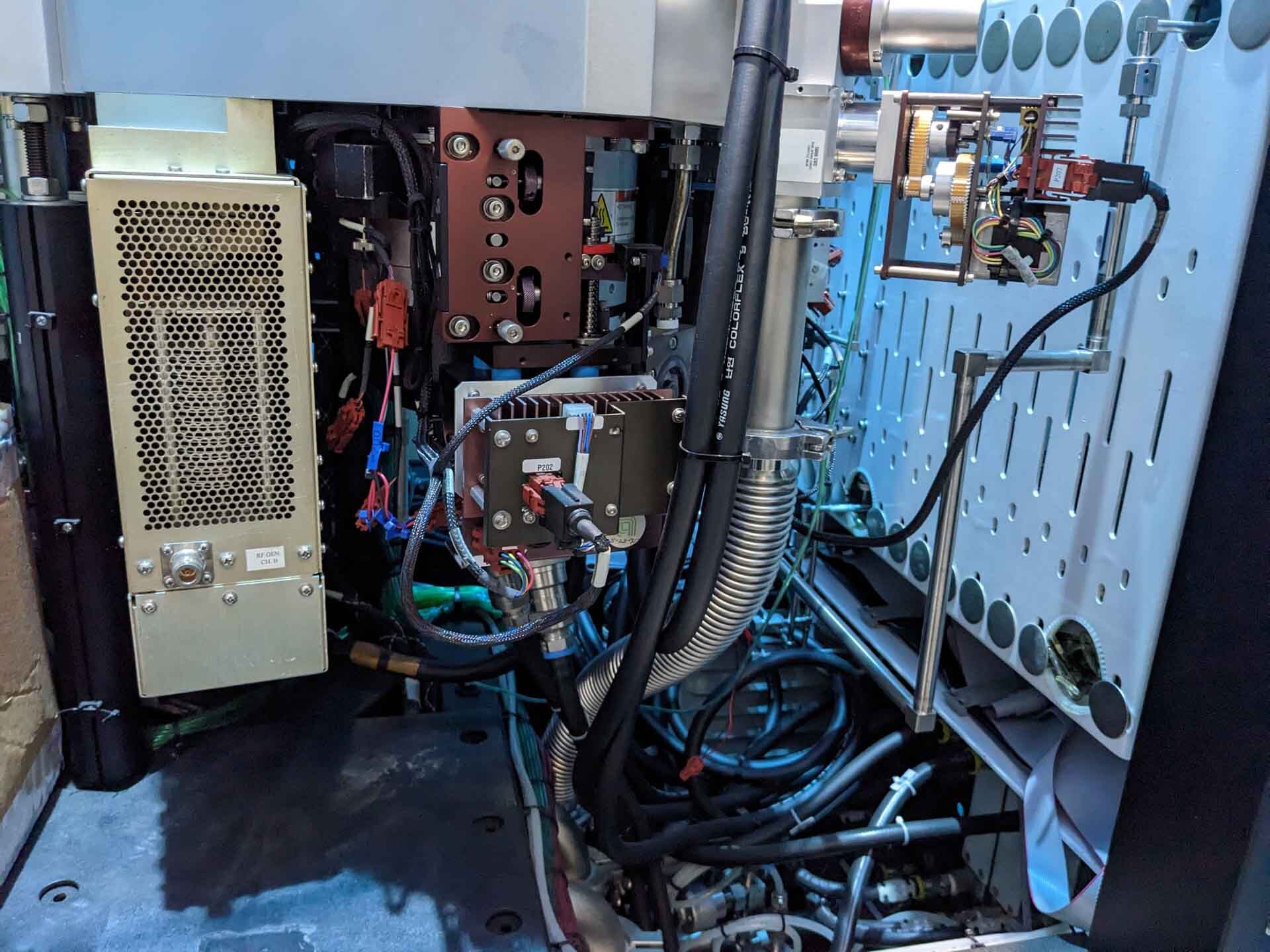

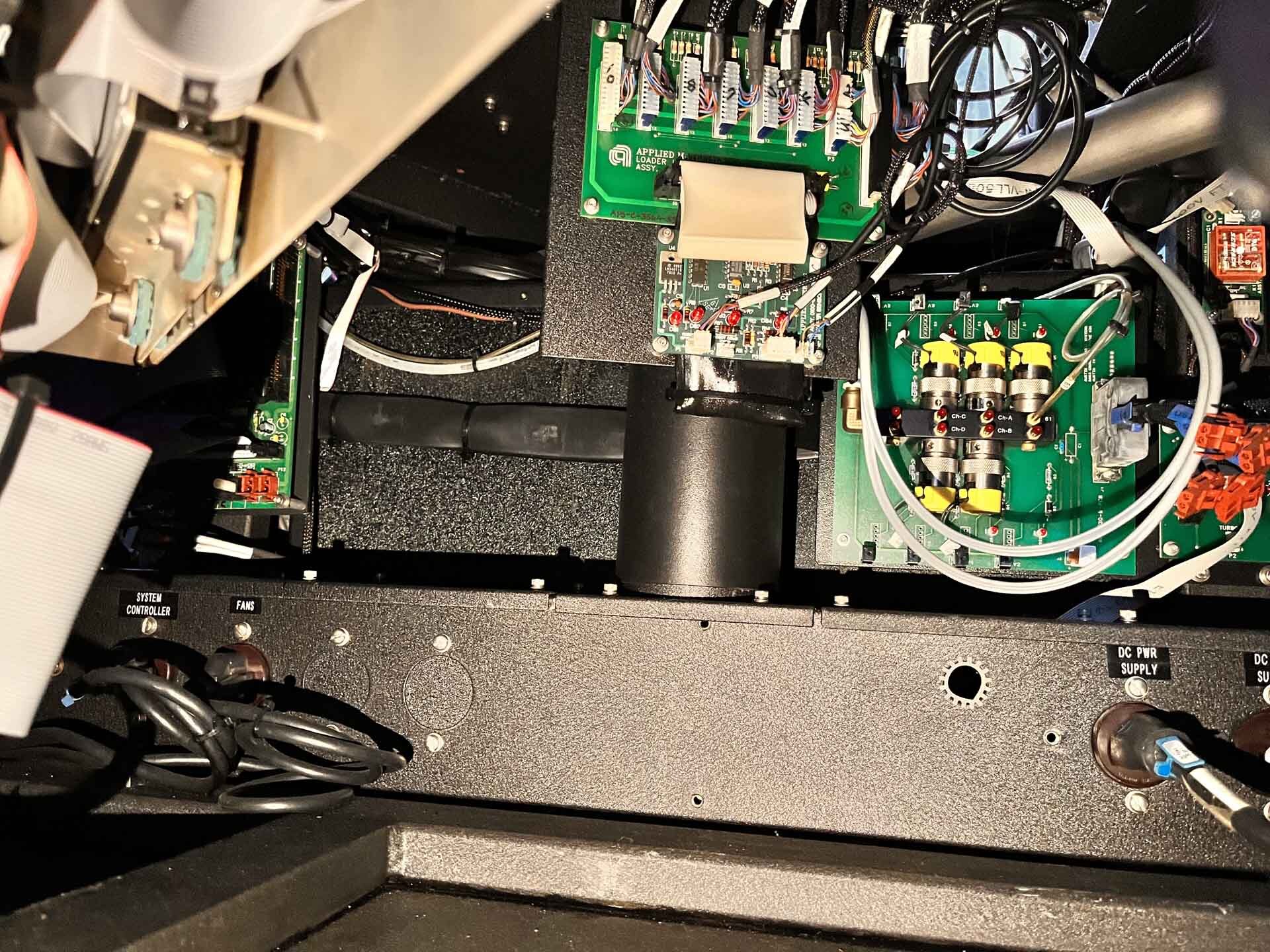

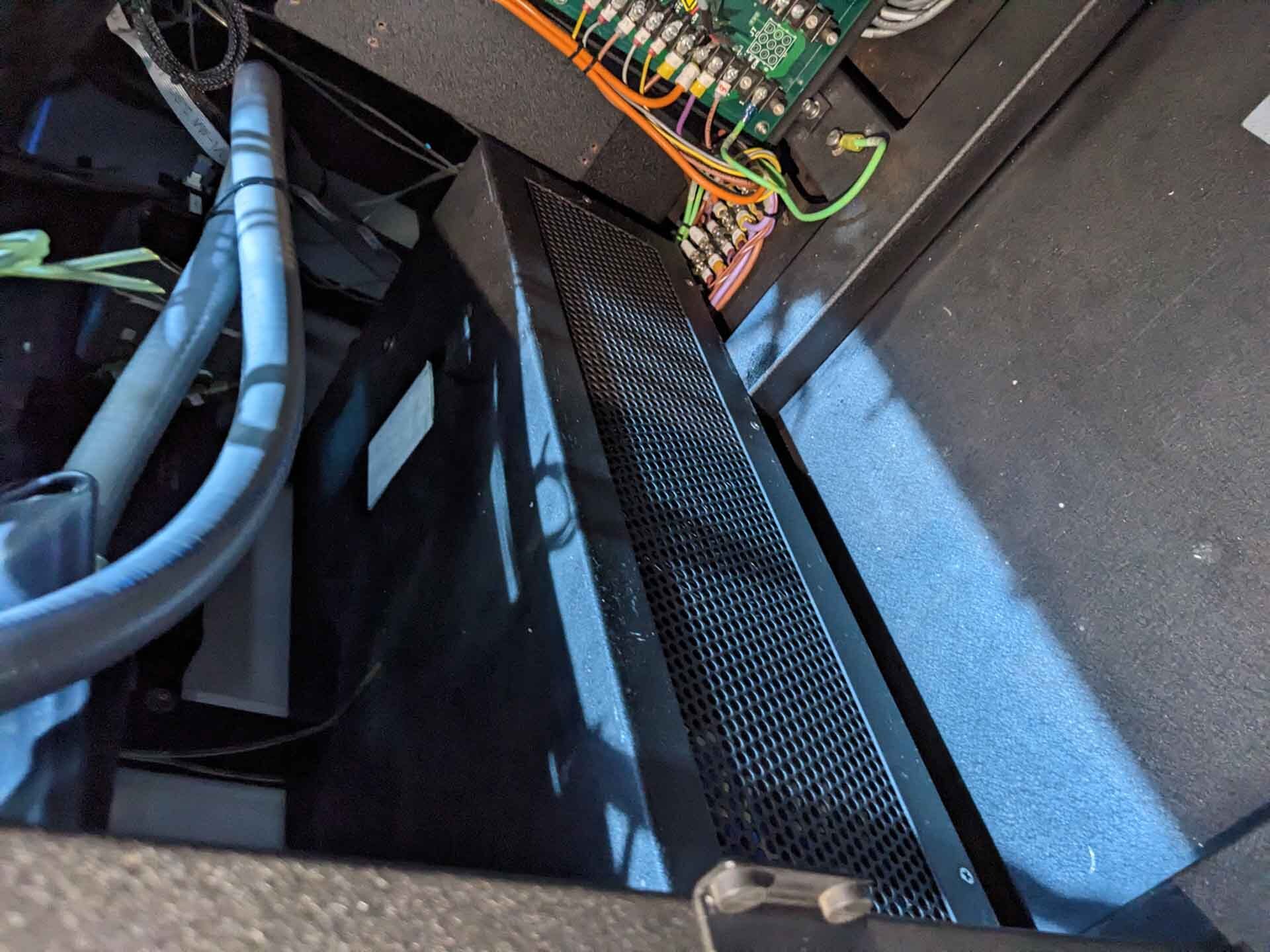

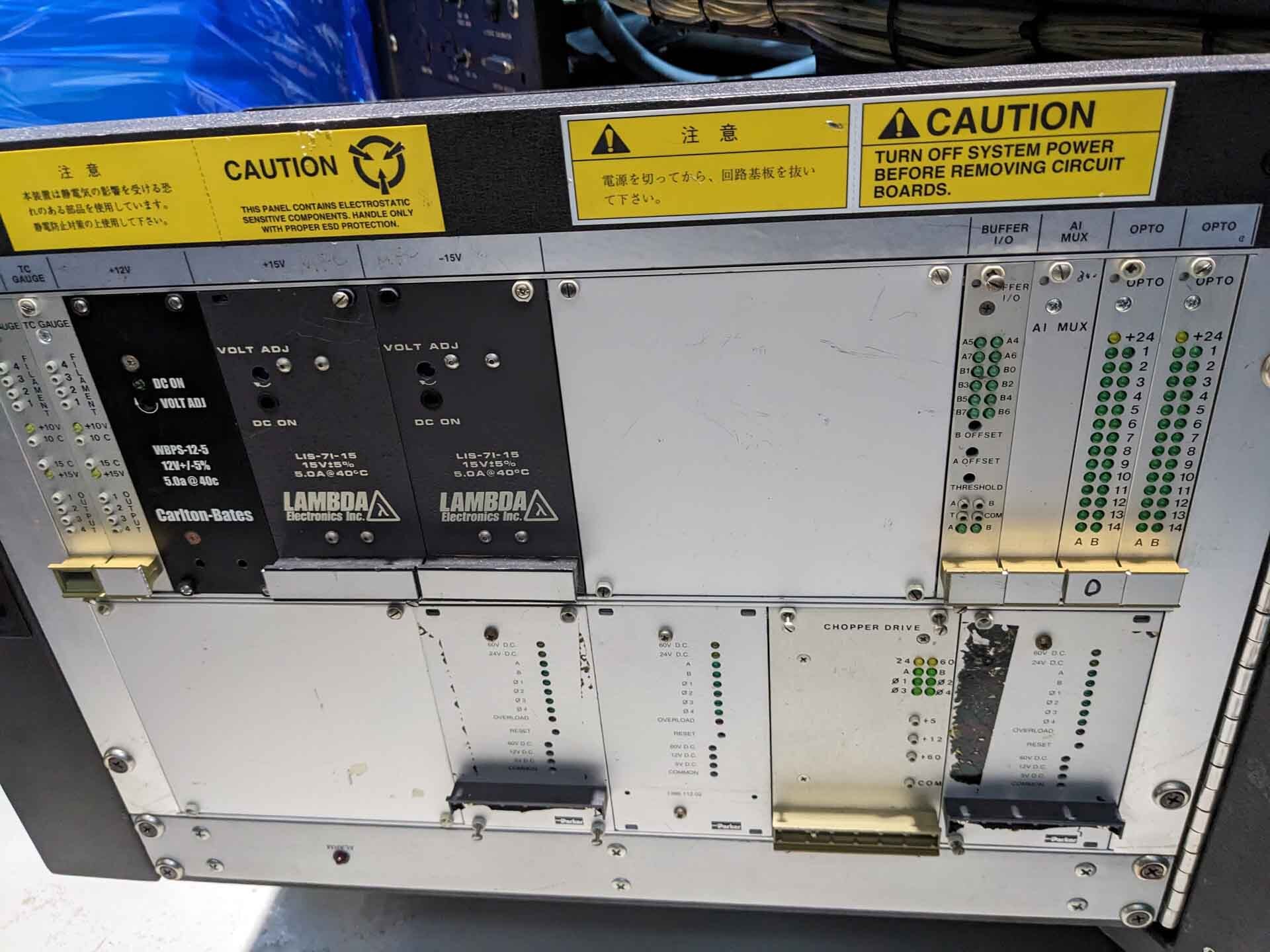

Standard AC Rack

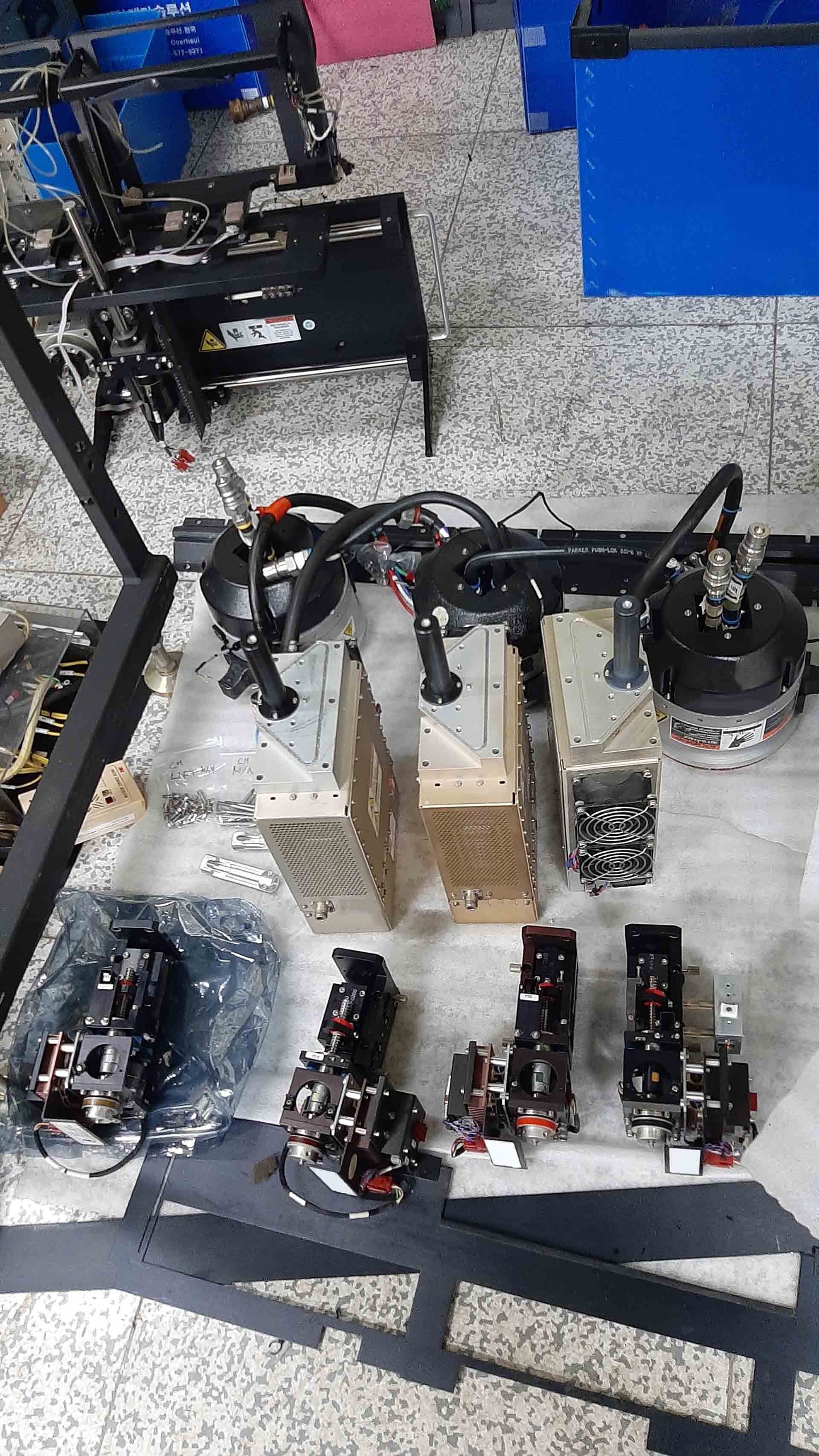

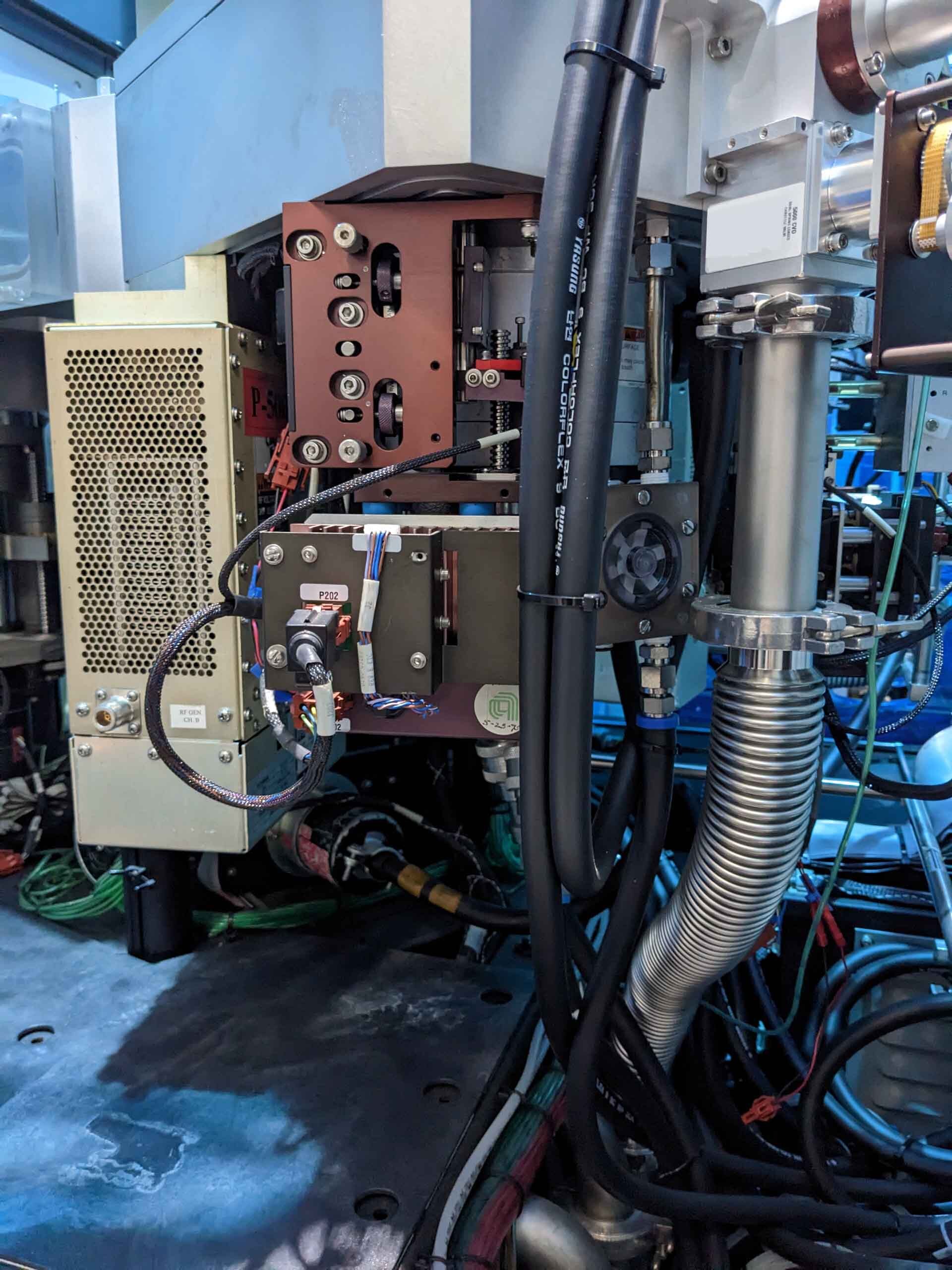

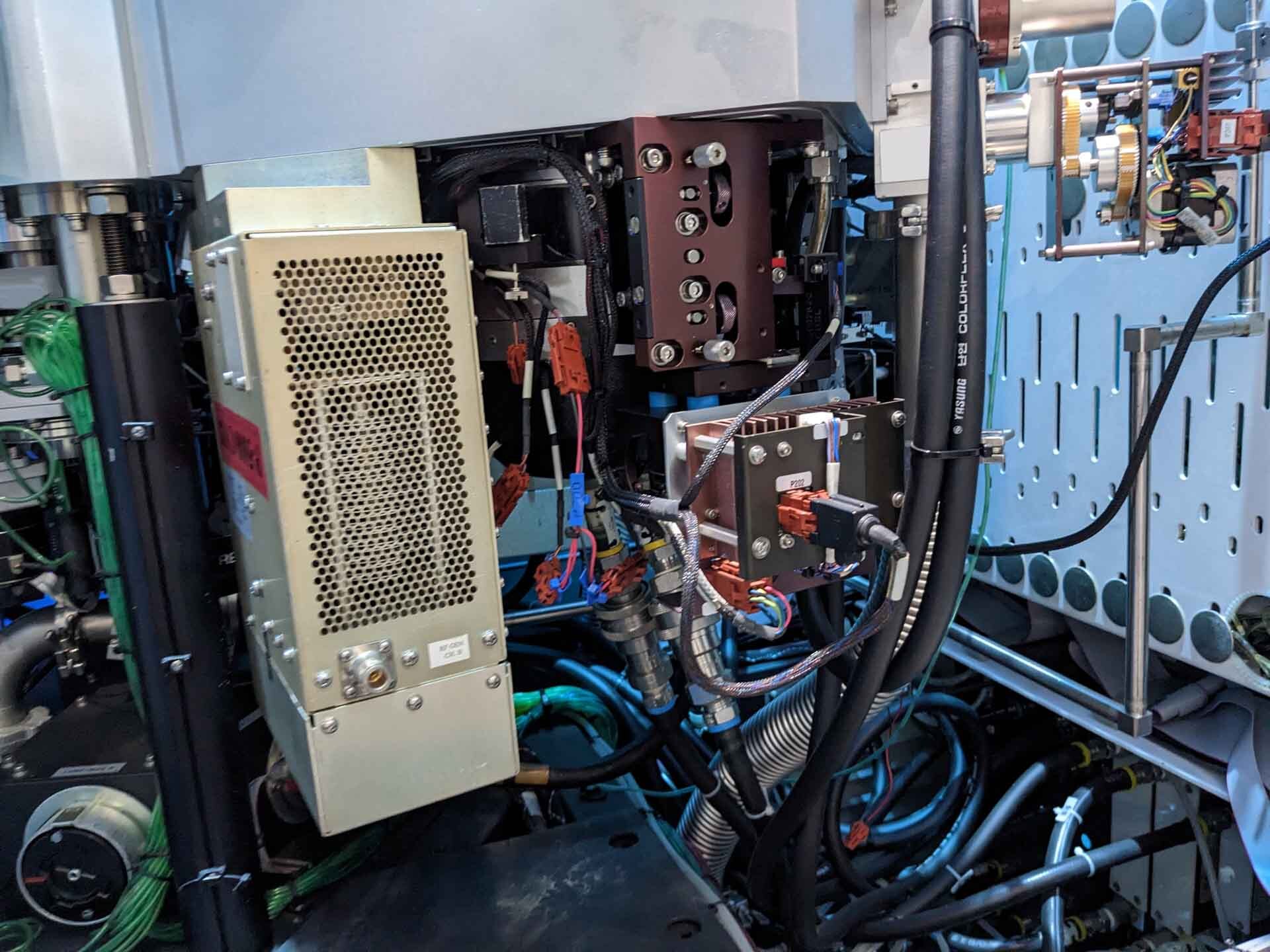

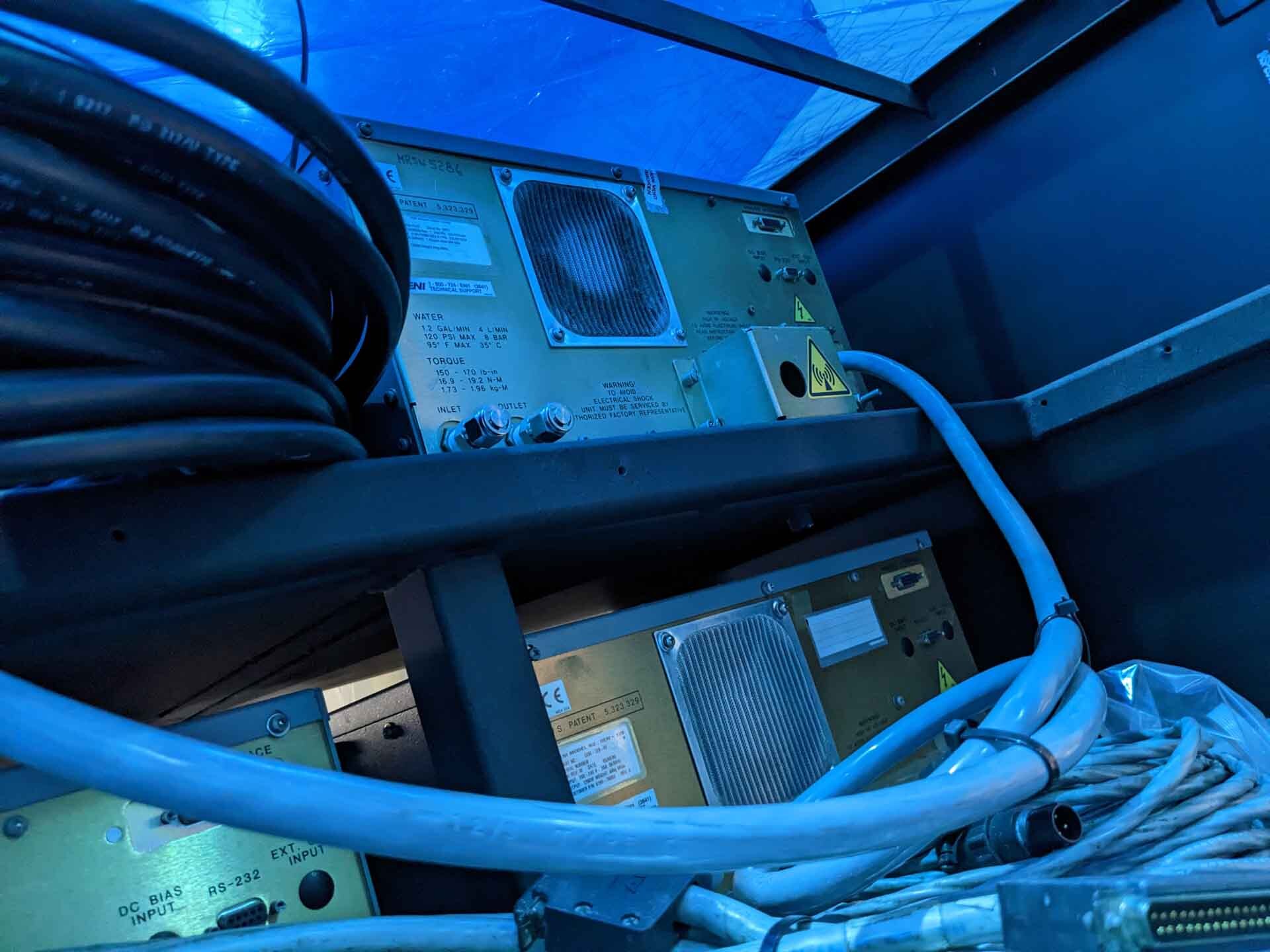

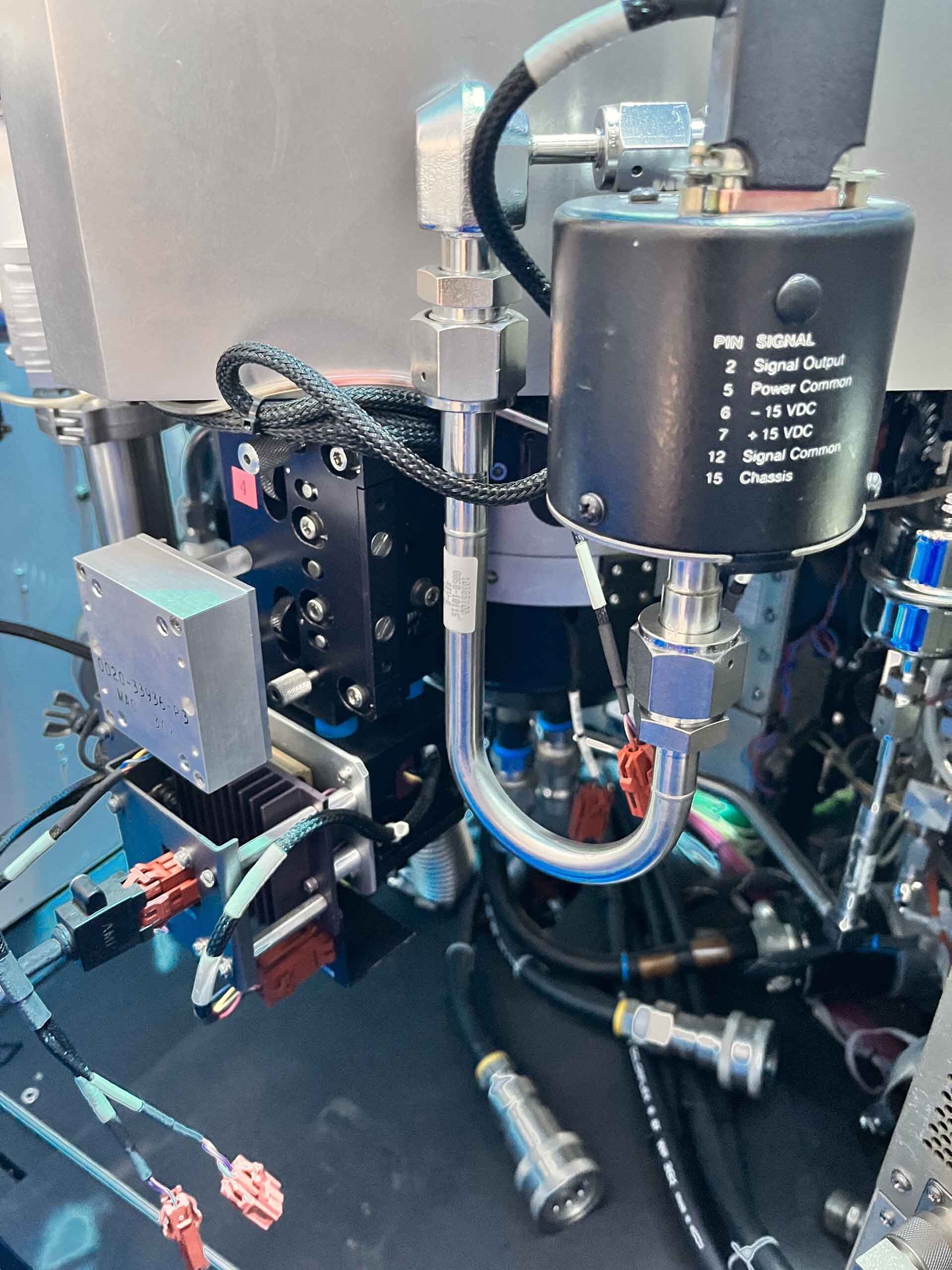

ENI OEM-12B-07 RF Generator

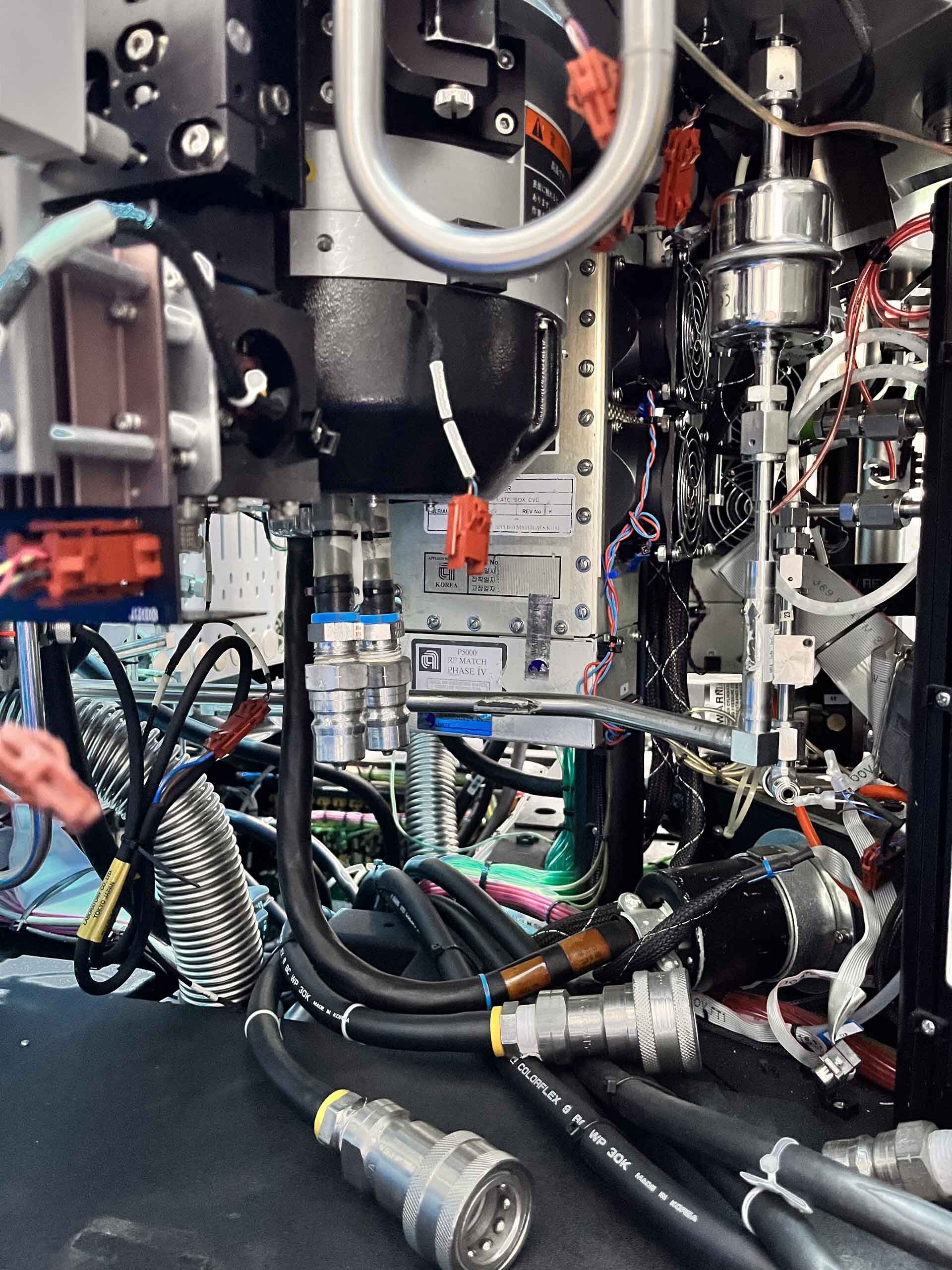

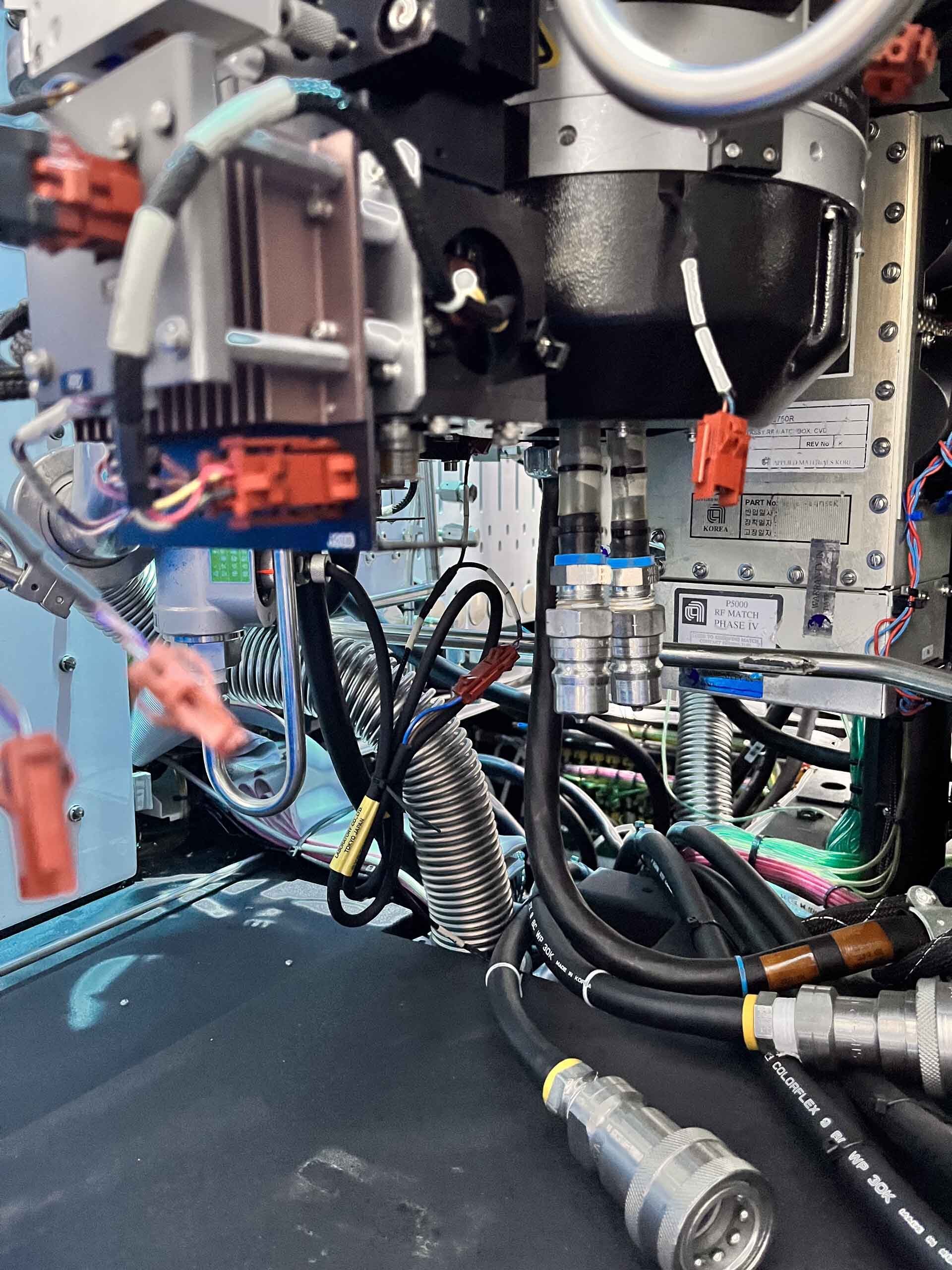

(3) RF Matching network

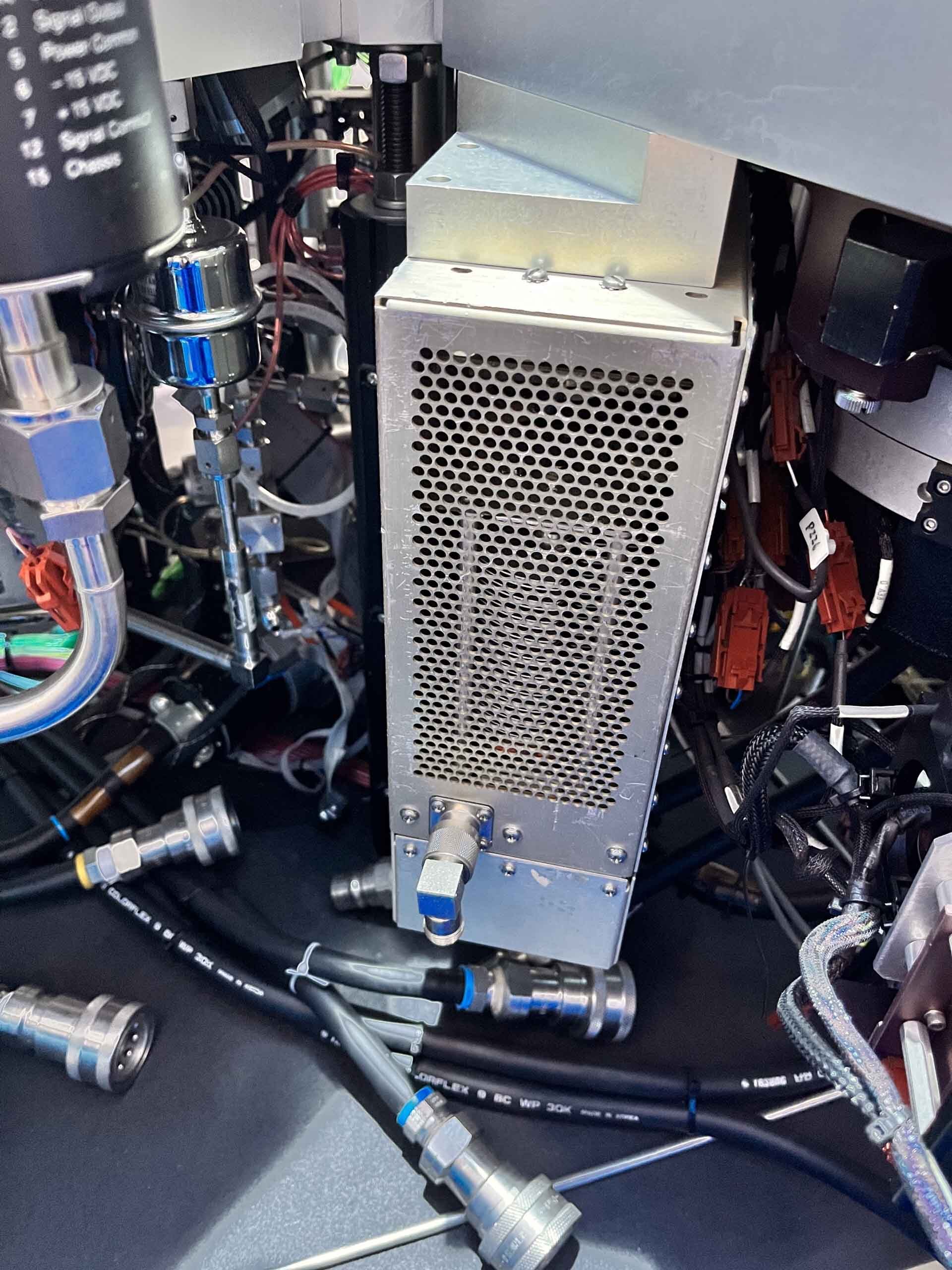

Heater exchanger

Does not include pump

Remote AC rack

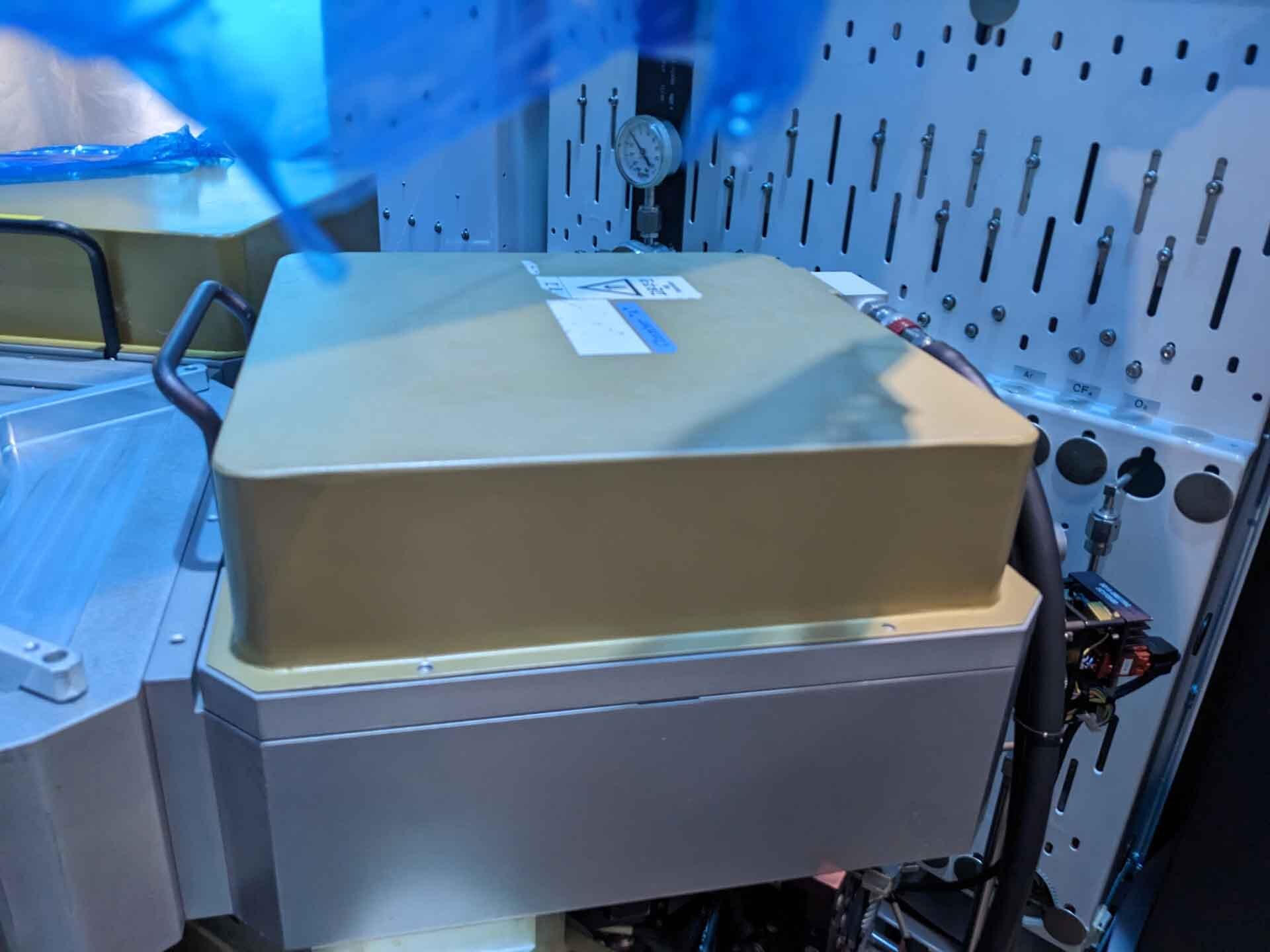

Heat Exchanger: AMAT-1

Mini controller

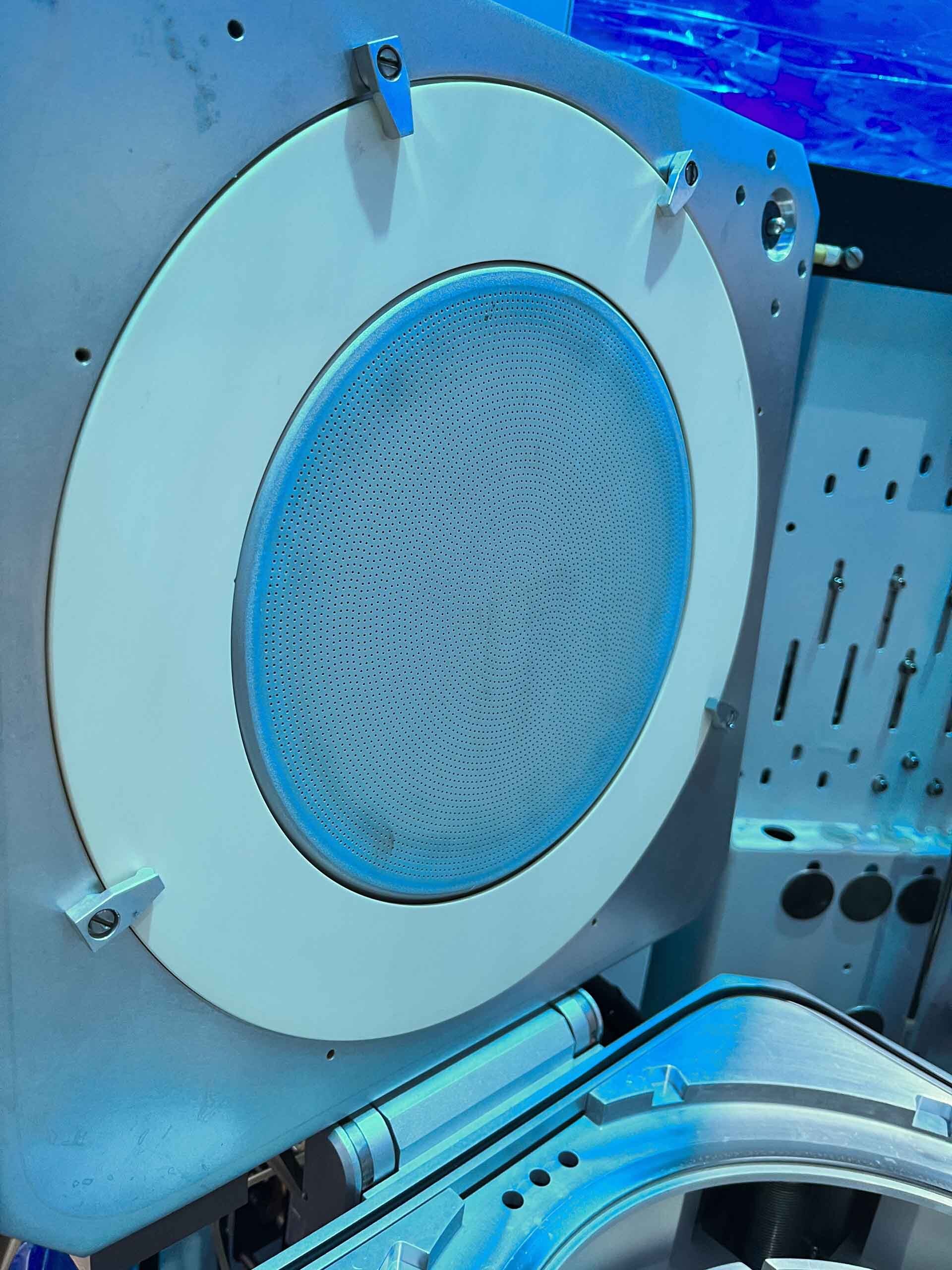

POU Filter

Throttle valve: Cluster

Isolation valve: Nor-Cal

Lamp driver

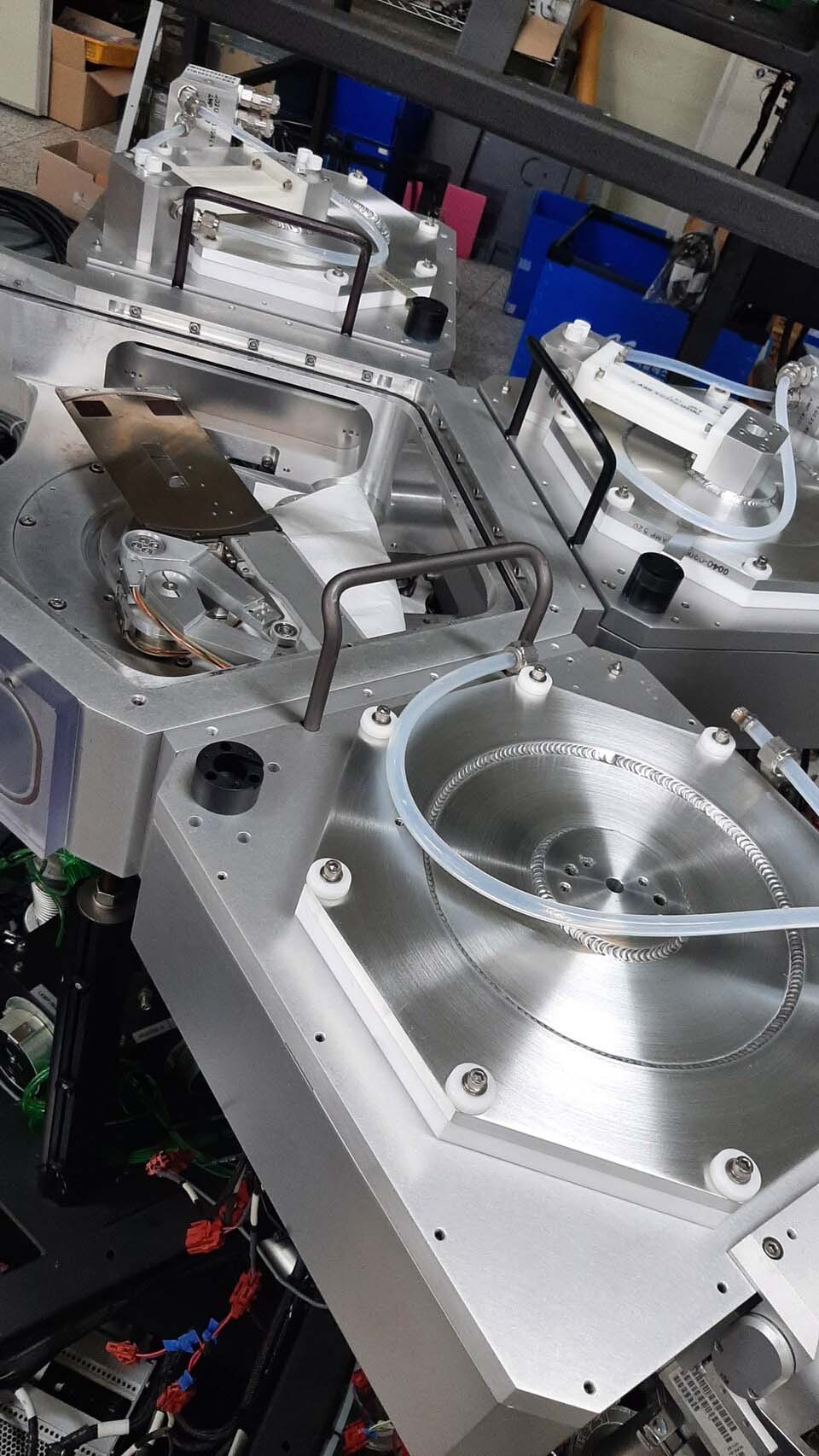

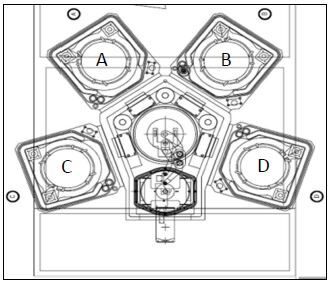

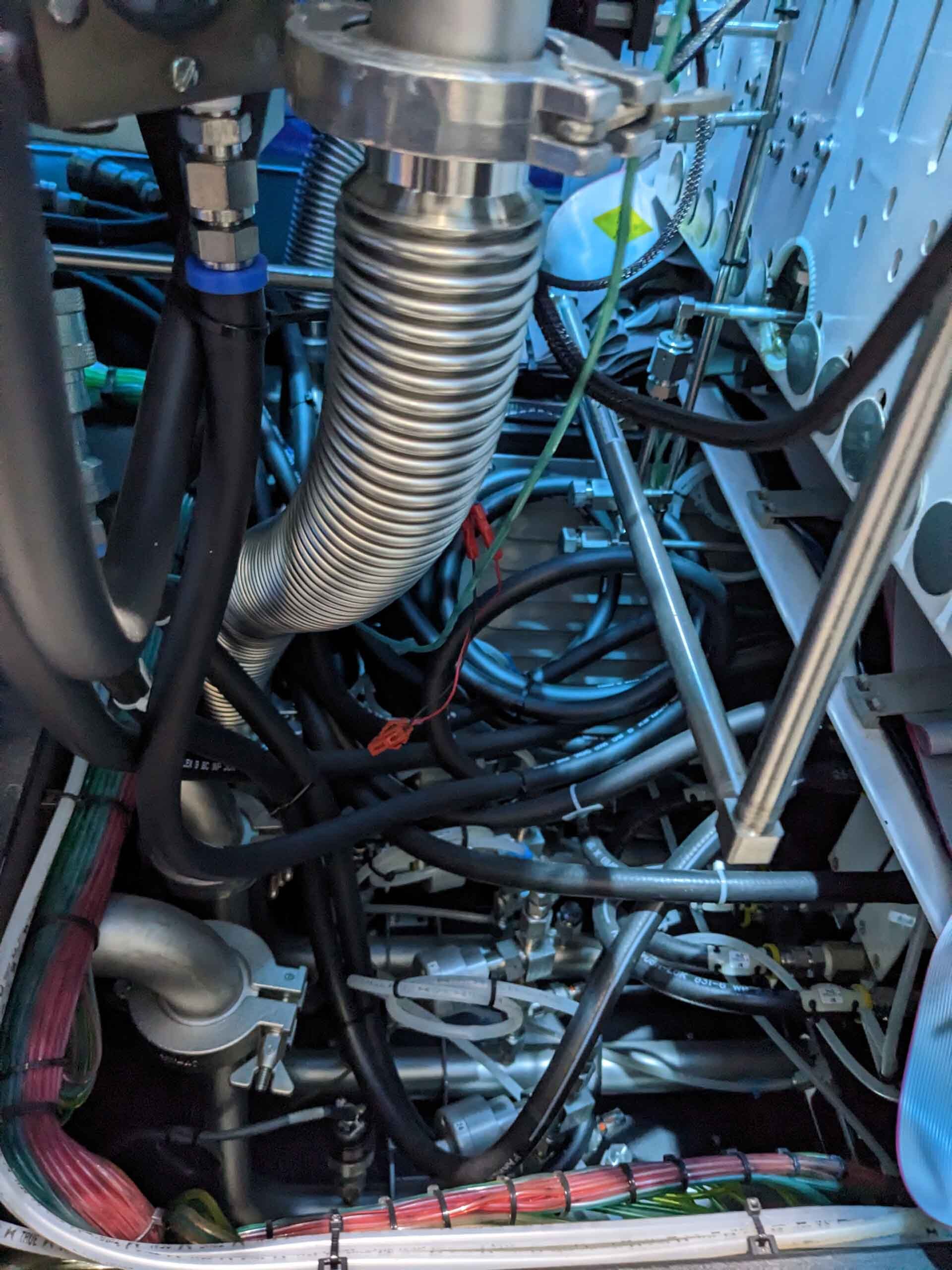

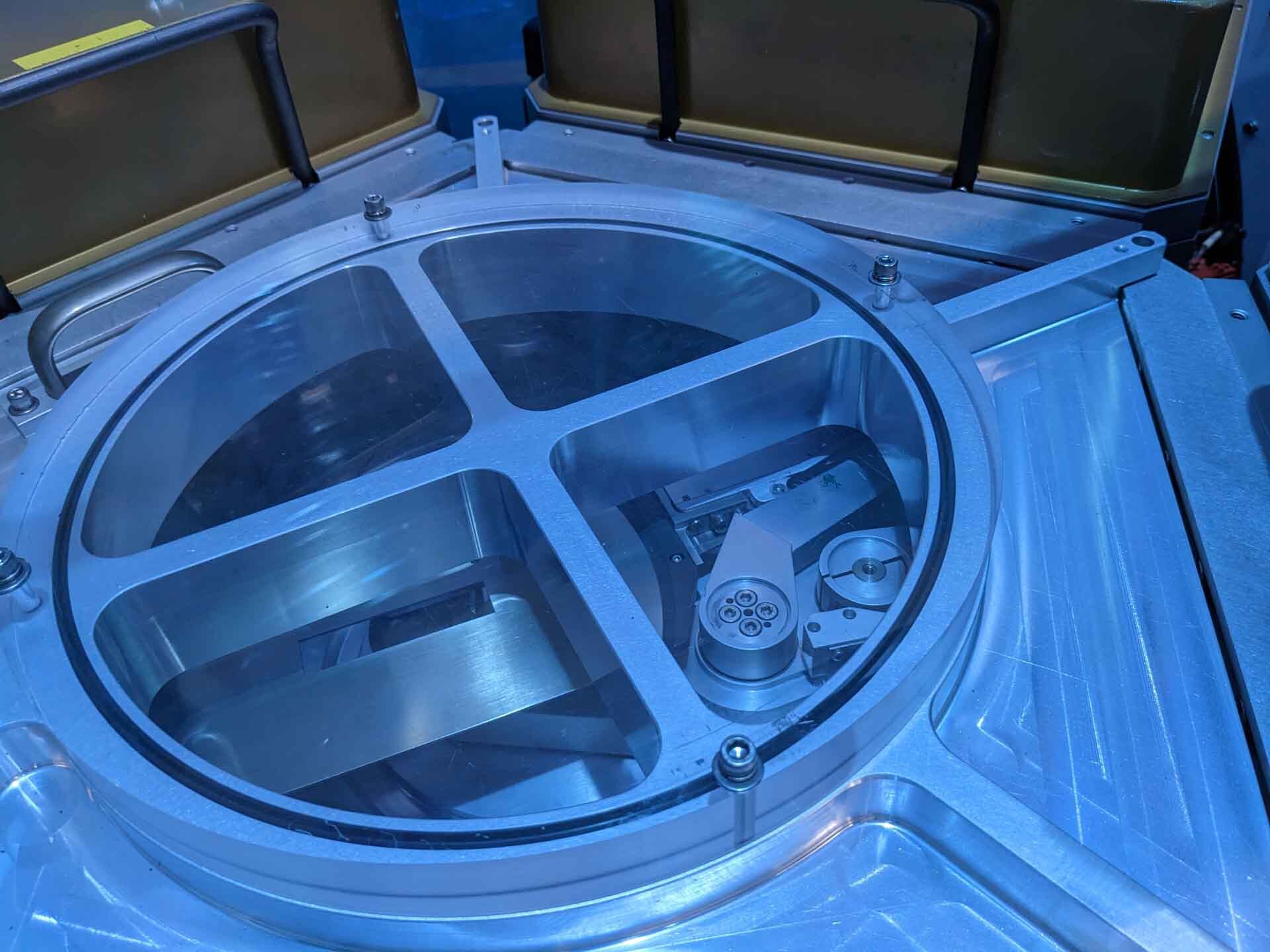

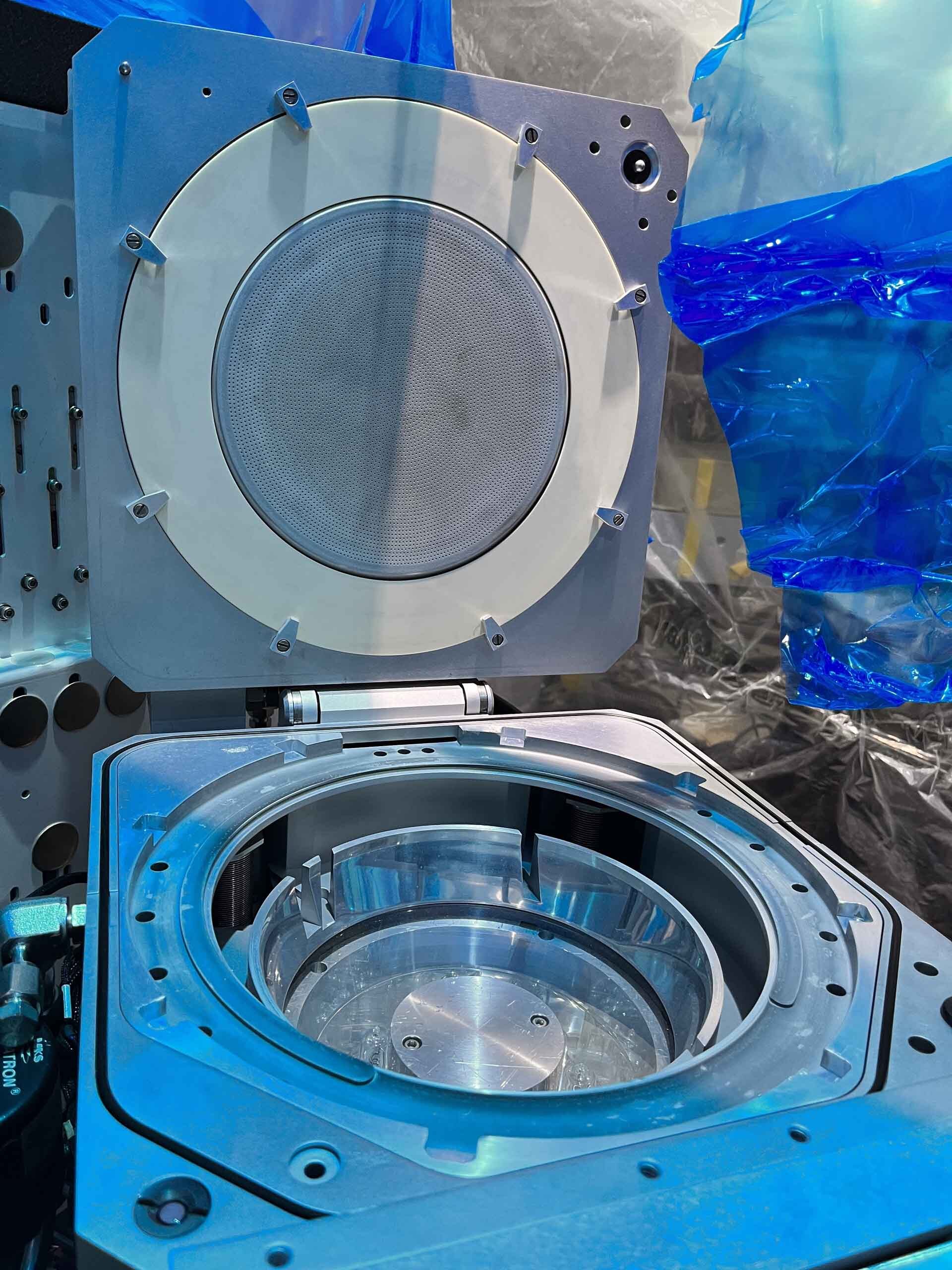

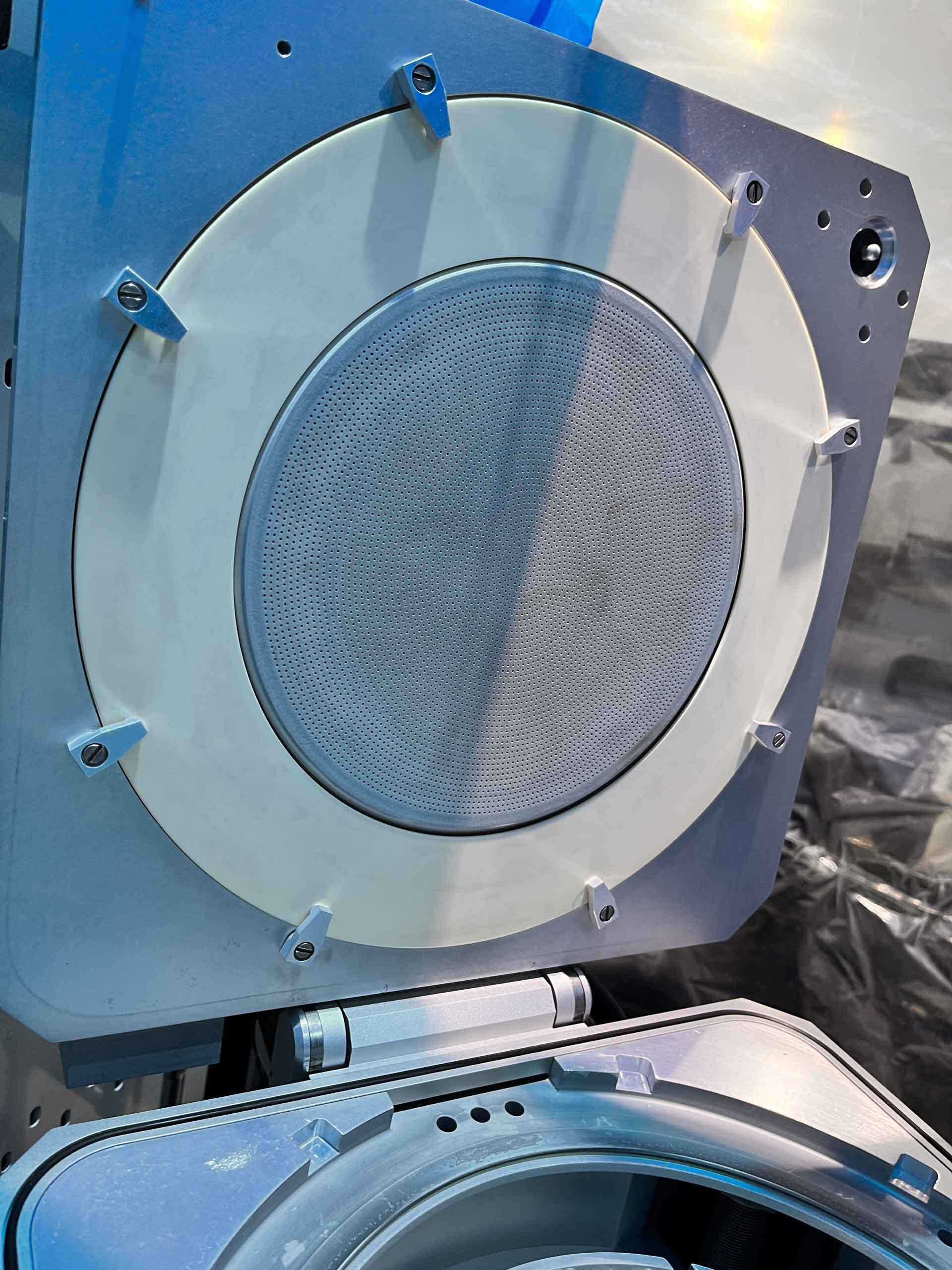

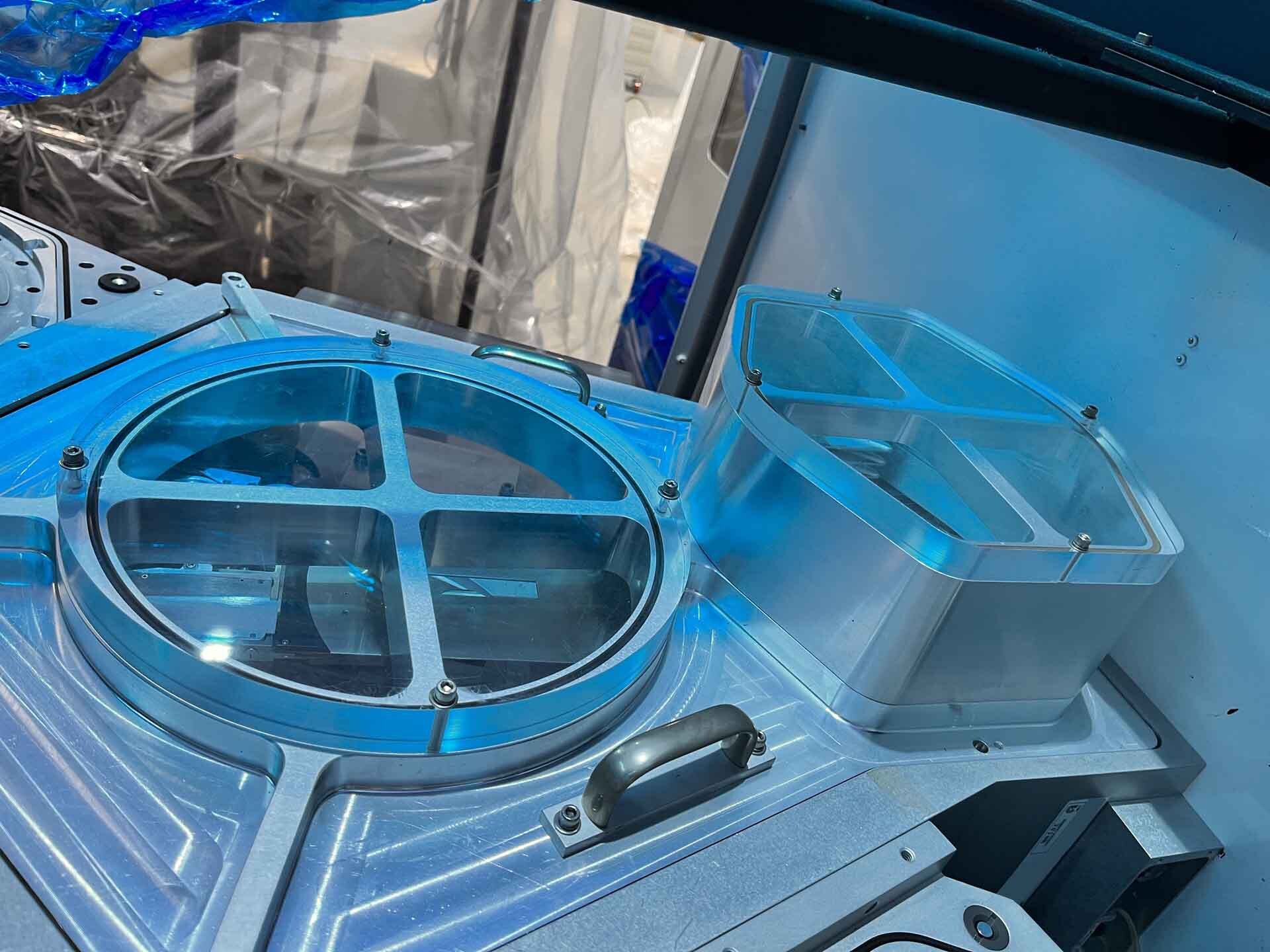

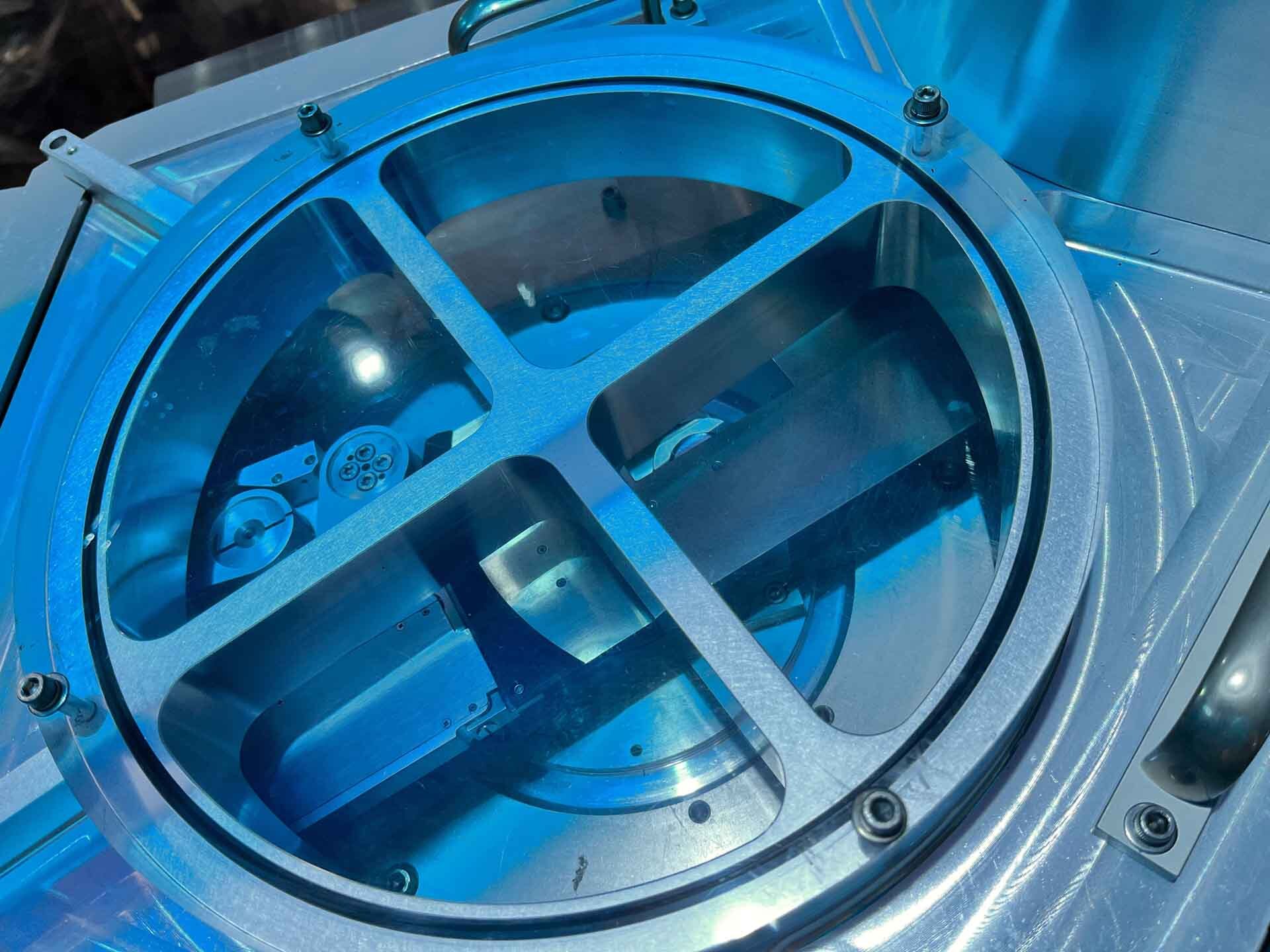

Process chamber:

(3) Chambers: A, B, C

Type: DLH One-hole standard

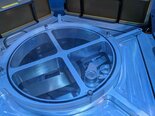

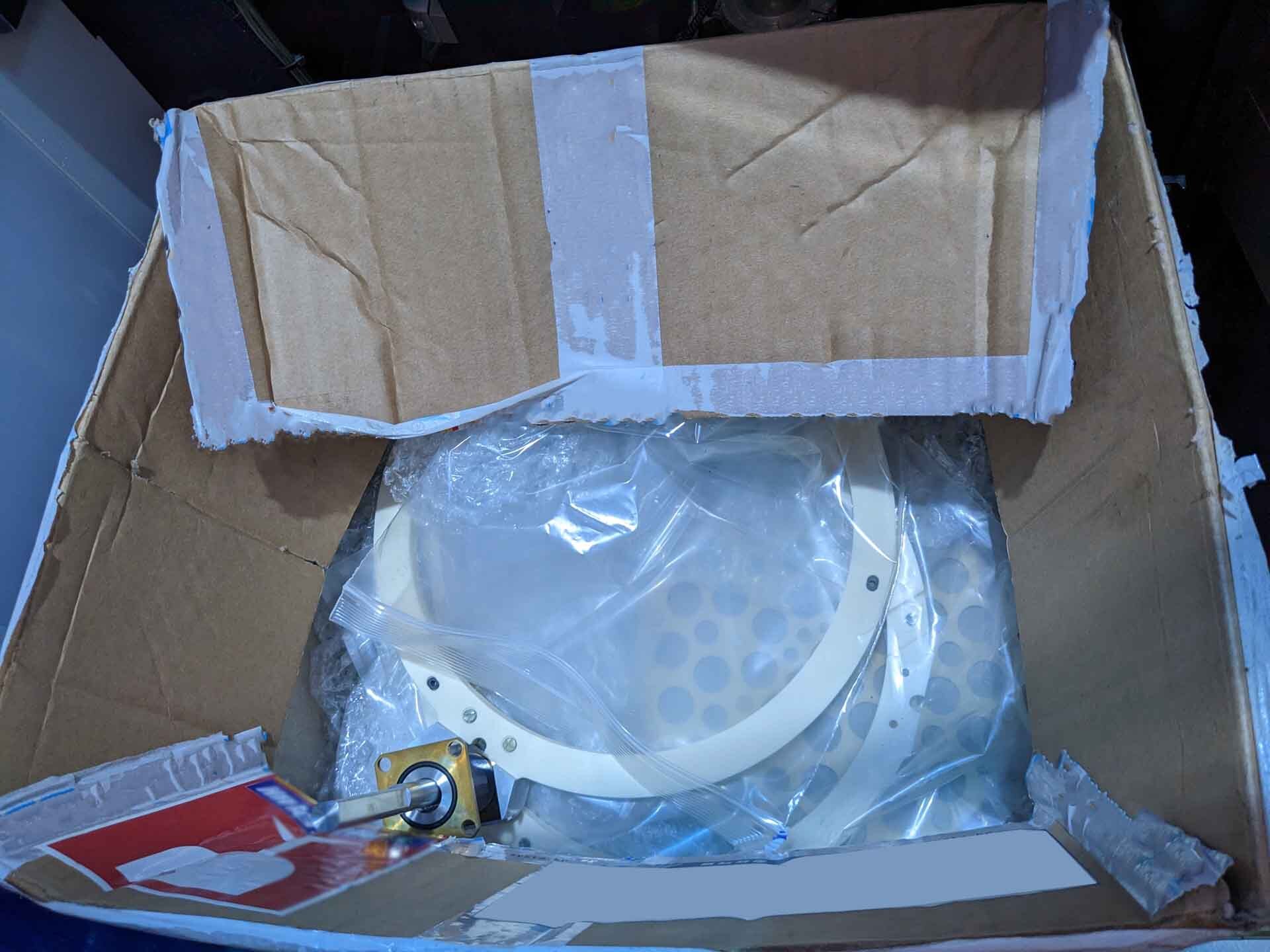

CERAMIC Hoop wafer lift type

Heater: Lamp type

Lid assembly: O-Ring

Susceptor missing

Process kit:

Heater window

Lamp

Lift pin

Susceptor / Wafer lift bellows

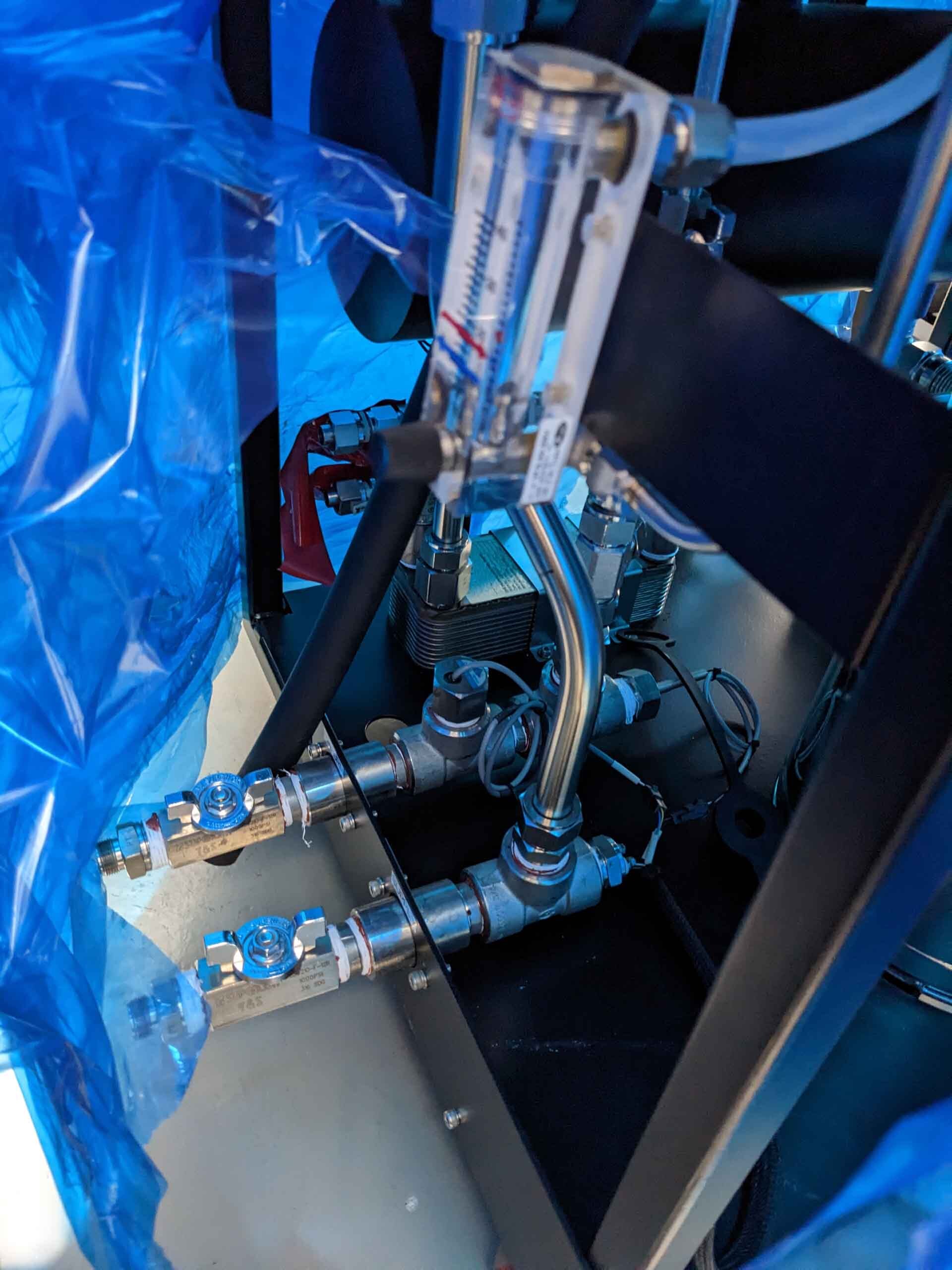

Water Flow Switch:

A and B (modified)

C-Proteus switch

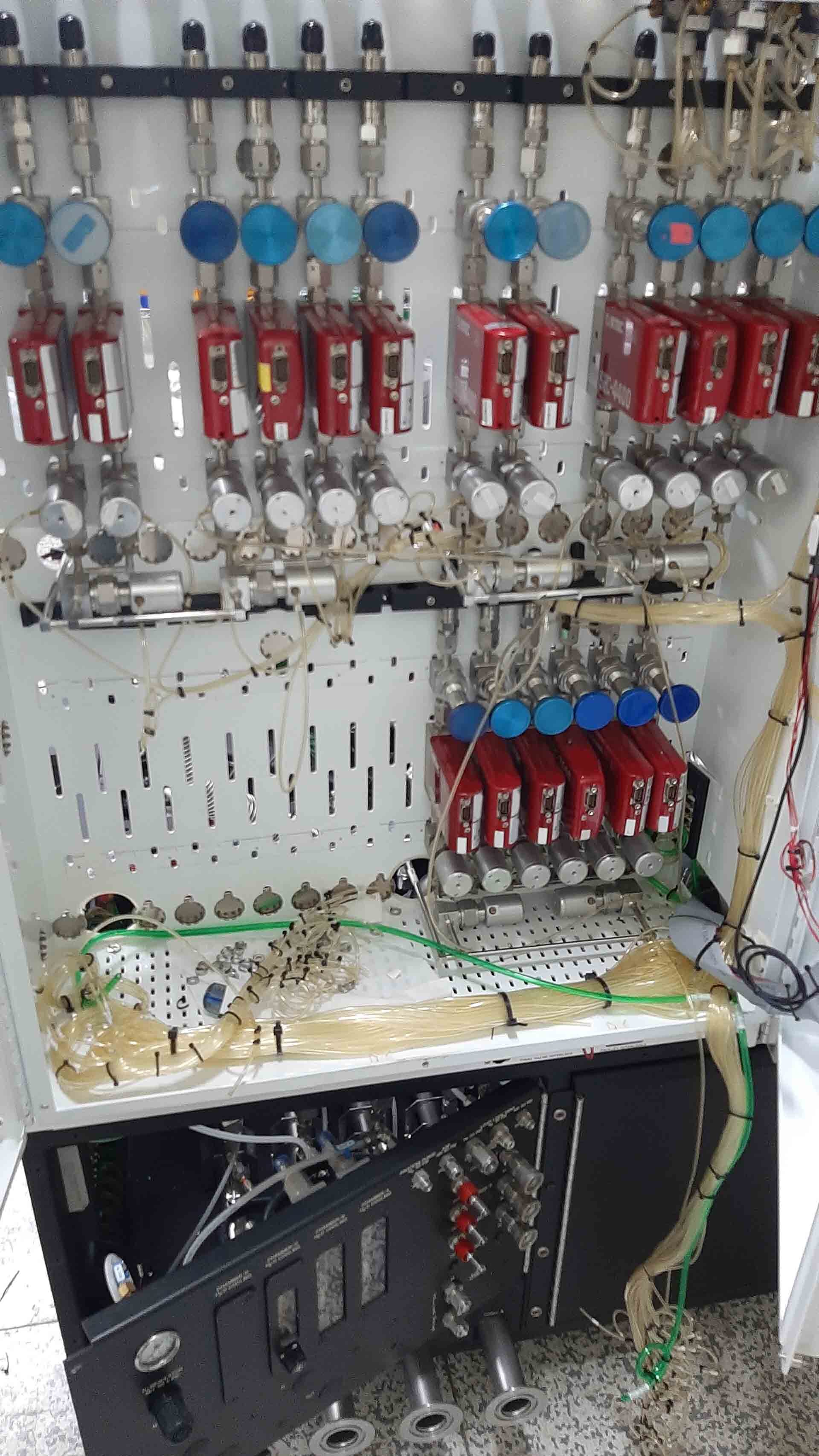

Gas panel:

Type: Standard

MFC: STEC

PNEUMATIC Value: Nupro

Manual shut off

Gas: SiH4 / N2O / NH3 / CF4 / C3F8 / C2F6 / He / N2

Chamber A:

Gas / MFC

N2 / 1000

N2 / 300

O2 / 20

N2 / 3000

N2 / 1000

N2 / 500

Chamber B:

Gas / MFC

N2 / 1000

N2 / 300

N2 / 300

O2 / 20

N2 / 1000

SiH4 / 500

Chamber C:

Gas / MFC

N2 / 1000

N2 / 1000

Ar / 100

N2 / 3000

N2 / 1000

N2 / 5000

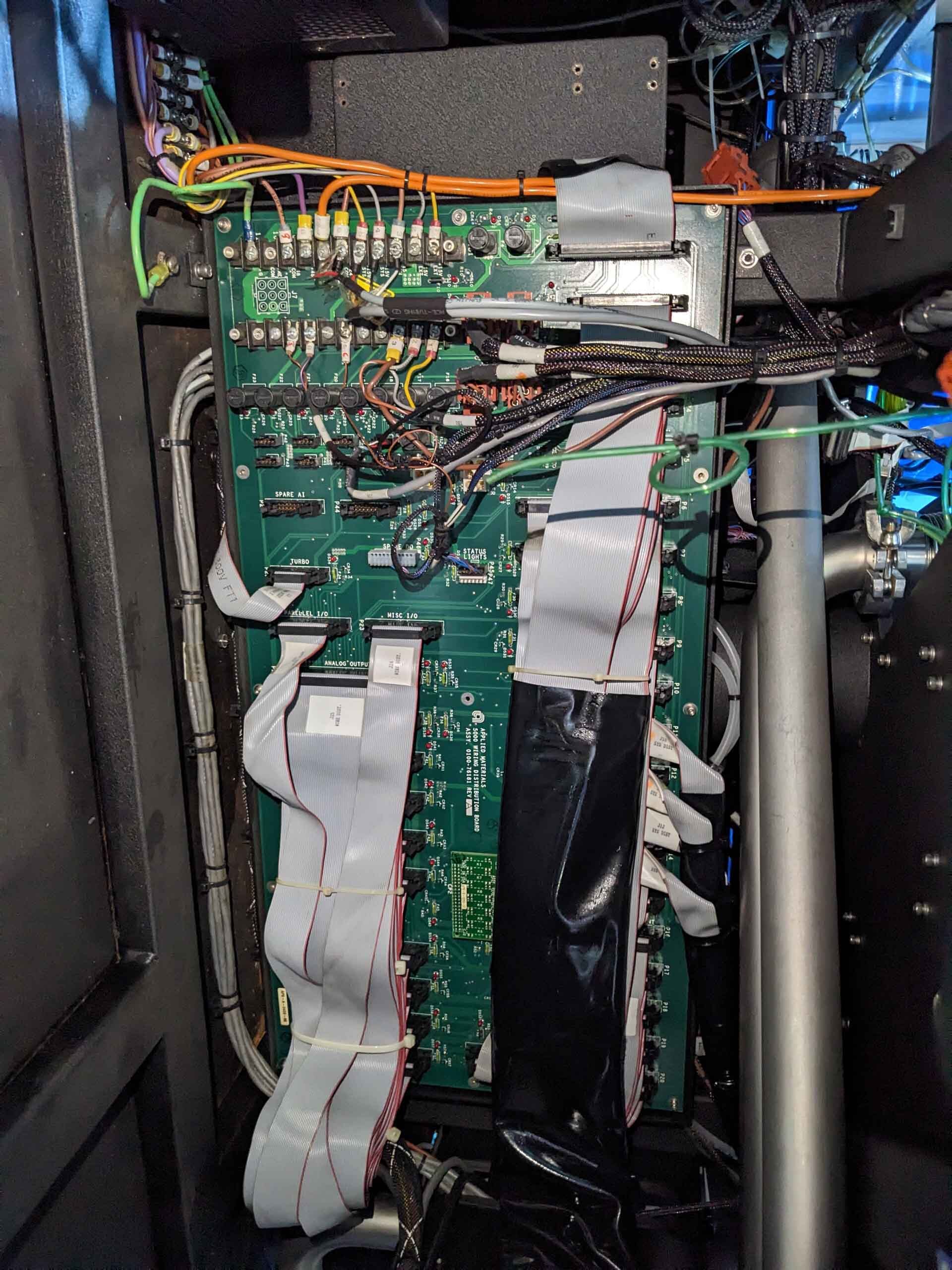

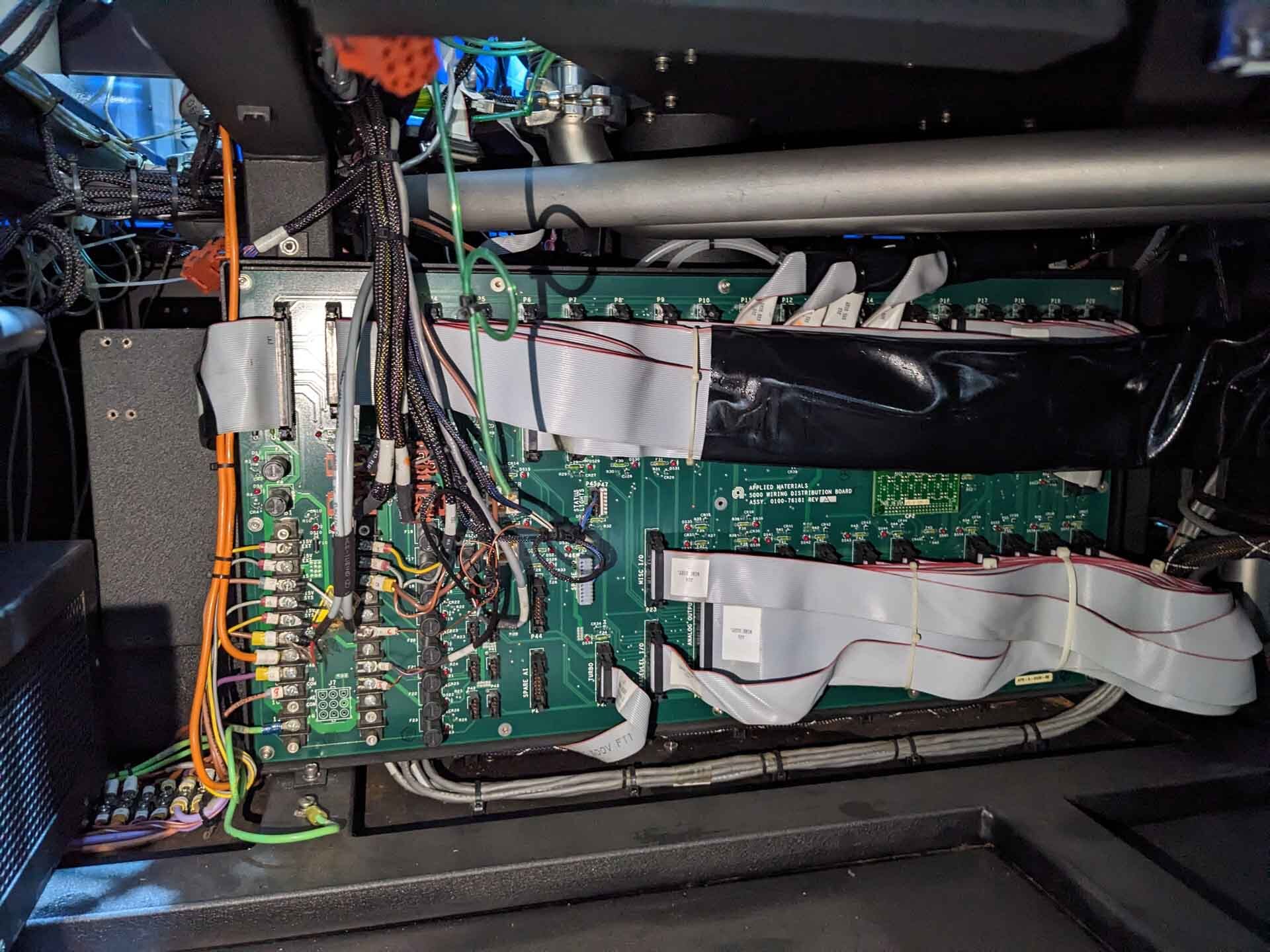

Main DC power supply

VME DC power supply

1995 vintage.

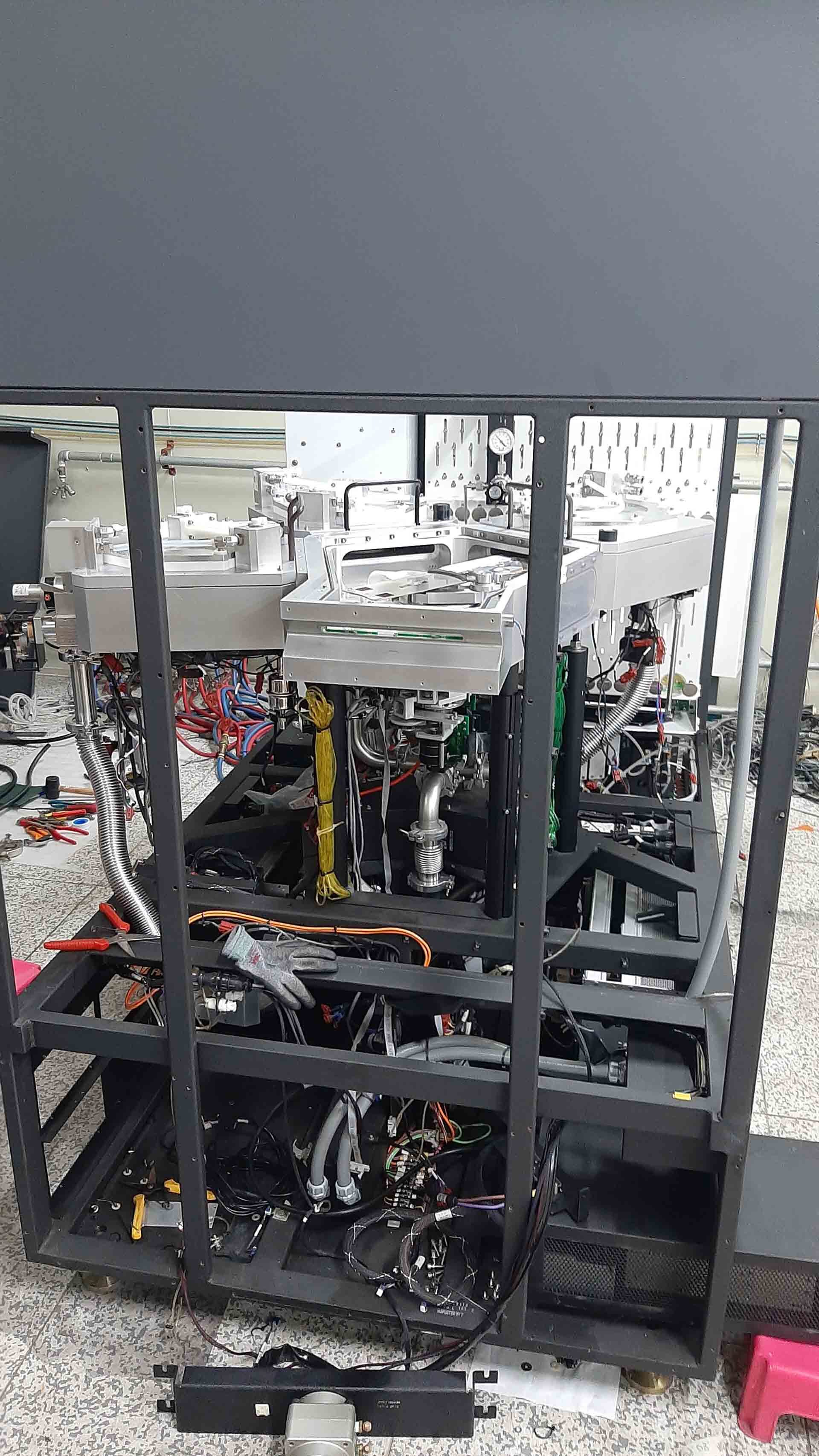

AMAT / APPLIED MATERIALS P5000 Mark II reactor is a generalized semiconductor device production equipment designed to address a wide range of high-volume applications, including those requiring both high purity and low temperature deposition characteristics. AMAT P5000 Mark II is highly customizable, allowing users to adapt it to meet a number of different process requirements. It features high-speed rotating electron beam sources and advanced scanning capabilities, allowing for rapid production rates. APPLIED MATERIALS P 5000 MARK II reactor also features advanced gas and chemical management systems, ensuring that ingredients are accurately dosed and that reactive byproducts are rapidly and safely removed. AMAT / APPLIED MATERIALS P 5000 MARK II features a powerful embedded controller, allowing users to program sophisticated processes from one easy-to-use interface. A range of temperature control capabilities ensure the highest possible product quality during wafer fabrication. The control system includes alarm monitoring capabilities, allowing users to keep their devices running smoothly with minimal downtime. AMAT P 5000 MARK II also includes advanced monitoring and data logging capabilities, allowing for monitoring of integral parameters throughout the process. P 5000 MARK II provides a highly flexible distance-to-wafer variable (DTWV), allowing for up to five distinct distance settings to be configured on a single reactor head. This means that users can easily scale their wafer fabrication setup without having to purchase multiple reactors. APPLIED MATERIALS P5000 Mark II can also be configured with a wide range of physical options, such as robot mounts and custom enclosures. P5000 Mark II is a reliable and powerful device production unit. Its cutting-edge technological capabilities make it the perfect solution for high-volume processes with exacting requirements. It can easily be configured to meet the specific needs of industrial applications, with the necessary levels of control, monitoring, and data logging. With its robust built-in control machine and its easy scalability, AMAT / APPLIED MATERIALS P5000 Mark II is a reliable and advanced semiconductor device production solution.

There are no reviews yet