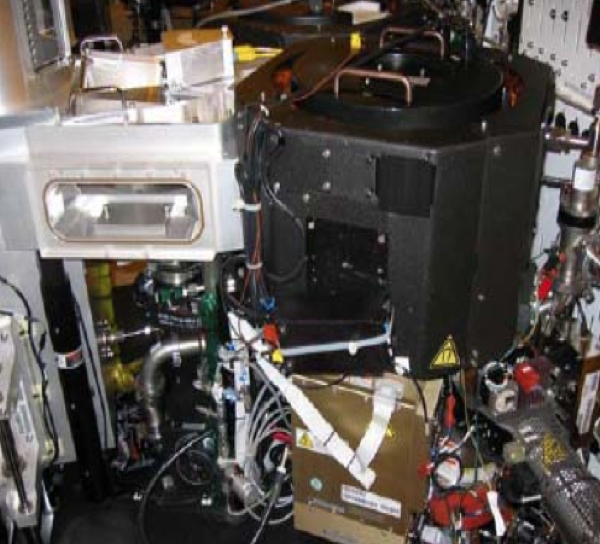

Used AMAT / APPLIED MATERIALS P5000 MxP #181092 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 181092

Wafer Size: 8"

Vintage: 1997

Poly etch system, 8"

Specifications:

Wafer Diameter: 8"

Process: 42 Poly

Software Version: L4.70B

System Power Rating: 208 VAC 3-Phase

Loading Configuration: 2 Cassette Handler / 29-Slots Storage

ESC Type: Electrostatic

1Torr Manometer: MKS 127AA-00001B

Chamber Dry pump model and size: Ebara A70W

Loadlock Dry pump model and size: Ebara A10S (sharing between chamber A/B)

Turbo pump model and size: Seiko Seiki 301CB1

Turbo pump controller: SCU-21D

Cathode Chiller model: AMAT Neslab HX150

Wall Chiller model: AMAT Steelhead 1 CHX (sharing between chamber A/B)

EP system: Monochrometer

Heater Stack/Gate valve: Standard

RF generator model: ENI OEM-12B

RF match model: Hybrid RF Match

IHC manometer: 10 Torr Manometer

IHC mfc size: 20 sccm

High Voltage Module: Chuck

Process Configuration:

Chamber Position 1 / Etch Chamber A:

Chemicals/Gases used: CHF3 HBr NF3 O2 HeO2 CF4 Ar Cl2

Chamber Position 2 / Etch Chamber B:

Chemicals/Gases used: CHF3 HBr NF3 O2 HeO2 CF4 Ar Cl2

1997 vintage.

AMAT / APPLIED MATERIALS P5000 MxP is a high capacity plasma etch reactor, designed for use in the semiconductor fabrication industry. It is a single-wafer, high-density plasma (HDP) etch equipment, designed for maximum throughput and precision etching. AMAT P5000 MxP features a process chamber that is configured in a multi-stage configuration, which enables it to deliver the optimum etching profile for a variety of applications. The load-lock and transfer chamber provide high throughput while ensuring that the etch process is highly repeatable. The automated on-board gas handling system also provides consistent gas flow rate throughout the etching process, while two plasma sources allow for high-fidelity etching. The powerful source power coupled with the effective closed-loop flow control unit provides a reliable etching process that produces the desired results consistently and accurately. The large wafer size (up to a 10" wafer) enhances the throughput and makes APPLIED MATERIALS P5000 MxP cost-effective for large-scale production. The automated process control and monitoring machine also helps to ensure a safe etching process. The tool can be used for etching of a wide range of materials, from metals to dielectric films. Additionally, it is suitable for etching of MOSFETs, BJTs, and MEMS devices. It is also designed to ensure that parts are etched without damage due to over-etching or under-etching. To ensure reliable operations, P5000 MxP is equipped with diagnostics to monitor the performance of the tool. It also includes a supply of spare parts and safety interlocks in order to protect the tool and its operation in the event of unexpected failure. Overall, AMAT / APPLIED MATERIALS P5000 MxP is an efficient, reliable, and cost-effective plasma etch reactor, ideal for production of a variety of semiconductor components and other delicate materials. It offers a high level of process control and high throughput, while its automated control tool helps ensure that the etching process is performed safely and effectively.

There are no reviews yet