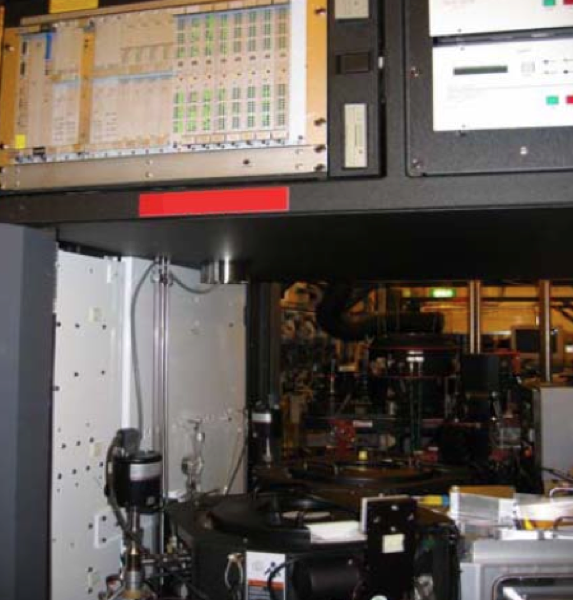

Used AMAT / APPLIED MATERIALS P5000 MxP #181093 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 181093

Wafer Size: 8"

Vintage: 1997

Etch Chamber, 8"

Process: 50 and 55 spacer

Loading Configuration: 2 Cassette Handler/ 29 Slot Storage

System Power Rating: 208VAC 3-Phase

Software Version: L4.70B

Mainframe body

System AC power box

CRT monitor/Monitor Base/Light pen

ESC Type Electrostatic

1Torr Manometer MKS 127AA-00001B

Turbo pump model and size Seiko Seiki 301CB1

Turbo pump controller SCU-21D

Cathode Chiller model AMAT Neslab HX150

Wall Chiller model AMAT Steelhead 1 CHX

EP system Monochrometer

Heater Stack/Gate valve Standard

RF generator model ENI OEM-12B

RF match model Hybrid RF Match

IHC manometer 10 Torr Manometer

IHC mfc size 20 sccm

High Voltage Module Chuck

Etch Chamber A: CHF3 CH2F2 NF3 O2 N2 CF4 Ar Cl2

Etch Chamber B: CHF3 CH2F2 NF3 O2 N2 CF4 Ar Cl2

1997 vintage.

AMAT / APPLIED MATERIALS P5000 MxP is a processing equipment designed to enable maximum flexibility and performance over a range of batch and single-wafer applications. The MxP is a reactor system featuring an automated process chamber that includes a pre-installed multiport loadlock, electrostatic chuck and substrate heating elements, three input/output ports for gas and liquid sources and a series of process control and monitoring components. The unit is equipped with an advanced vision machine for wafer placement, as well as motion controls for precision substrate handling. The MxP provides high-temperature solid-phase films and interfaces for a wide variety of applications. Through its built-in multi-stage thermal process, the MxP performs anneal and diffusion processes. Moreover, the MxP also offers advanced oxidation and chemical vapor deposition (CVD) processes. Its plasma source enables the creation of amorphous SiO2 films, plasma nitrided films, and plasma doped films. The MxP uses real-time process monitoring, automated wafer handling, and intelligent recipe development to ensure wafer feature accuracy. Its operator interface provides visibility and control of each process step by enabling the review and selection of recipes and parameters. The chamber environment is closely monitored with real-time process parameters, including temperature, pressure, plasma levels, and process gases. In addition, AMAT also offers several other solutions that are specifically designed to enhance the performance of the MxP. These solutions include both current and upcoming versions of the MxP reactor, as well as turnkey process solutions that support the revolutionary capabilities of the MxP. AMAT P5000 MxP is designed to provide users with the capability to maximize the performance of the device, allowing them to take advantage of a wide range of thermal processes. With its precise temperature control, superior fabrication tools and process monitoring capabilities, the MxP reactor is an ideal choice for a wide range of applications.

There are no reviews yet