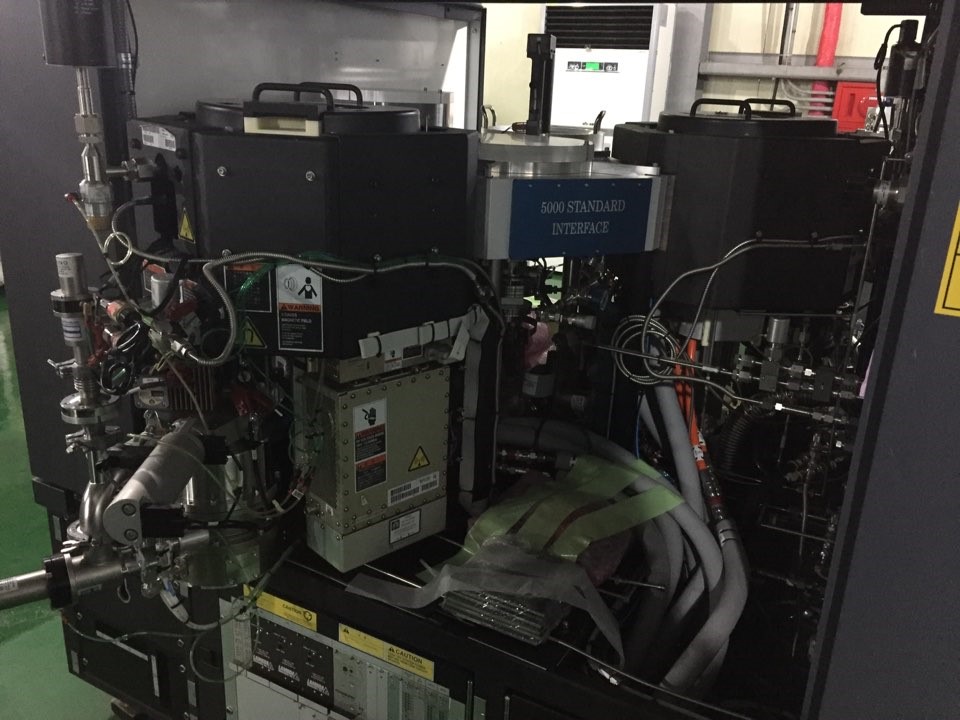

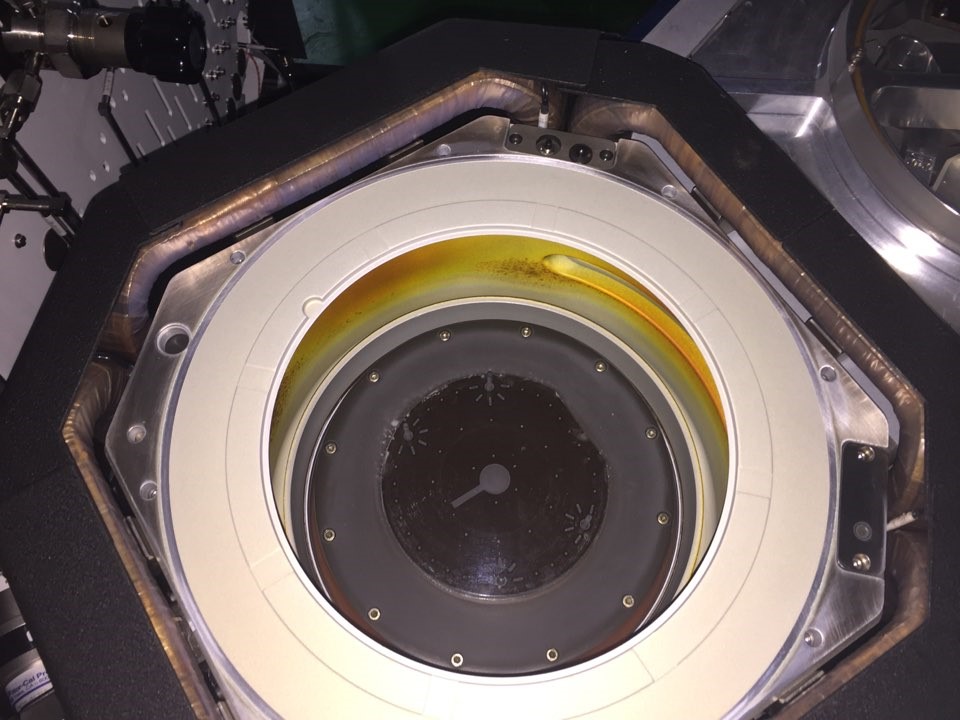

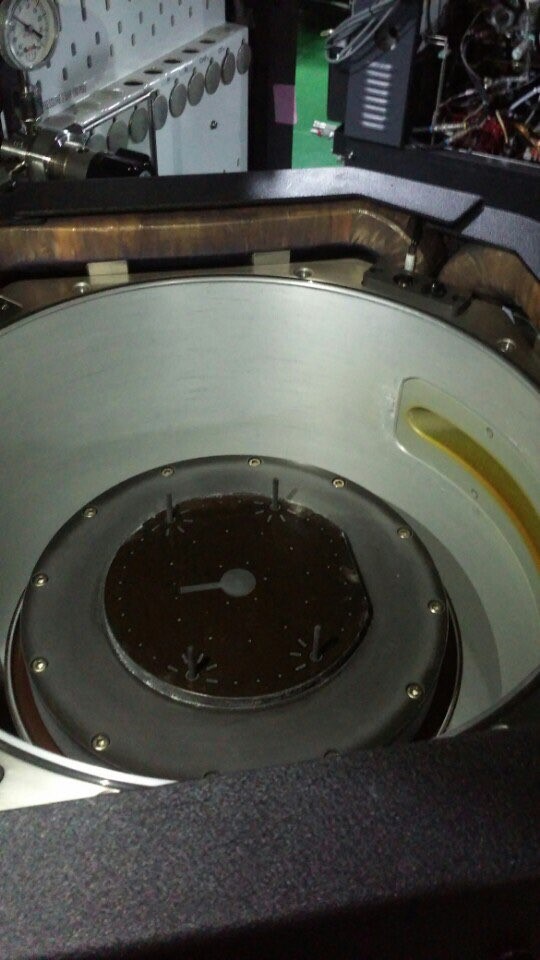

Used AMAT / APPLIED MATERIALS P5000 MxP+ #9116735 for sale

URL successfully copied!

Tap to zoom

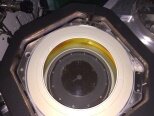

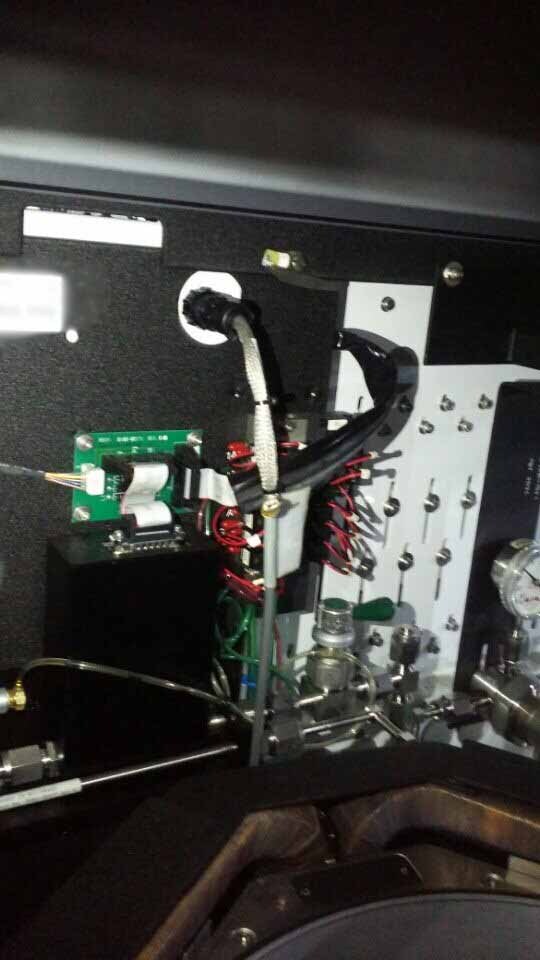

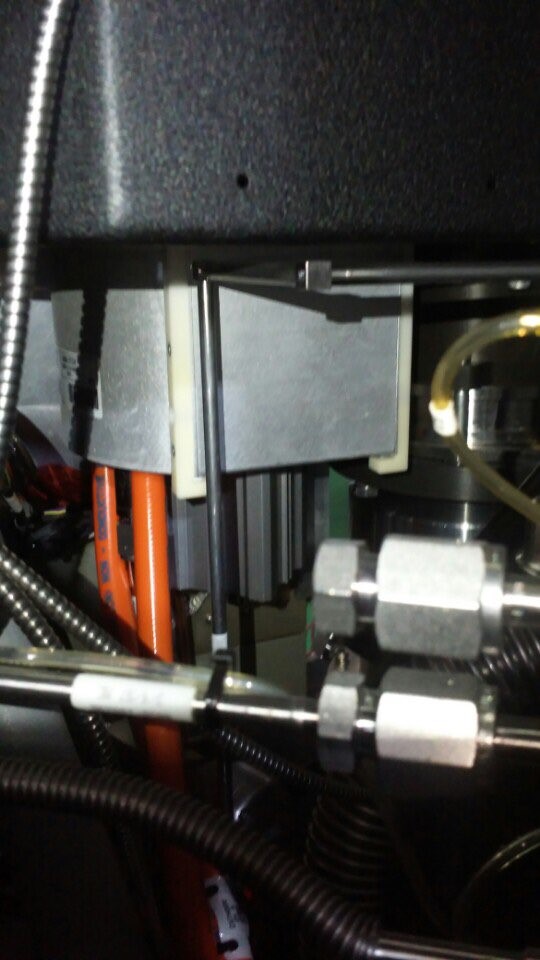

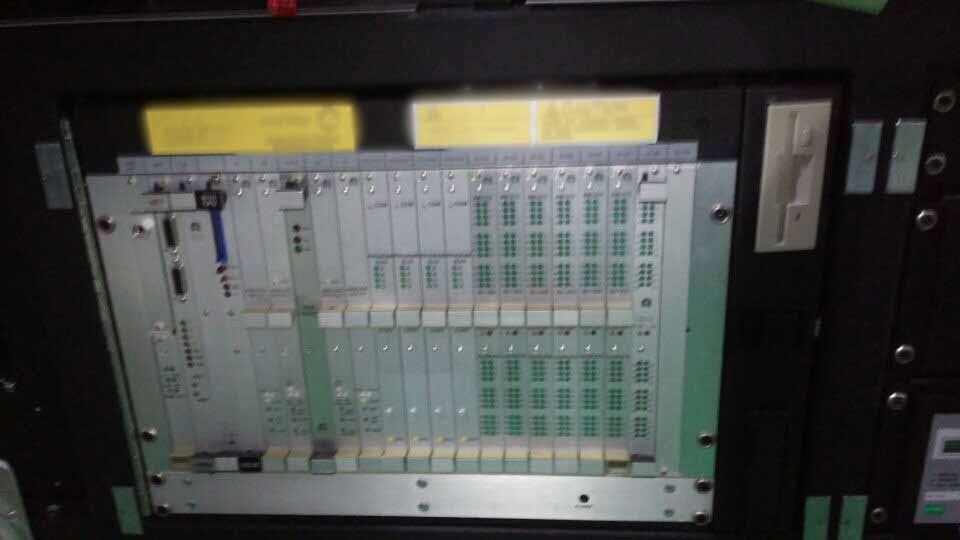

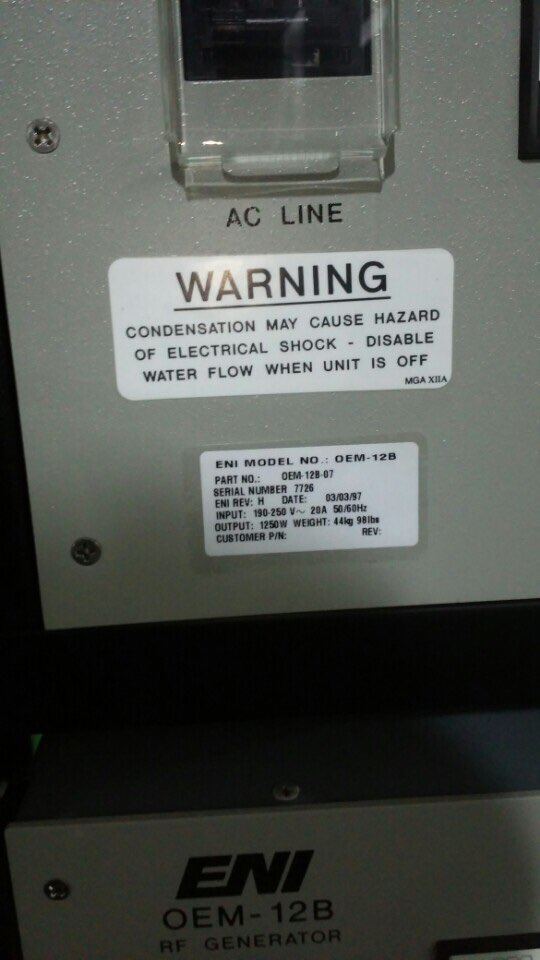

AMAT / APPLIED MATERIALS P5000 MxP+ is a state-of-the-art ceramic coil-type reactor that has been designed to provide outstanding performance in a range of process applications. The reaction chamber of AMAT P5000 MxP+ is formed from a two-piece, ceramic-coated metal bell-jar. The outer bell-jar is capable of withstanding temperatures up to 1000°C, while the inner bell-jar is able to operate up to a maximum temperature of 1200°C. The inner bell-jar features a Teflon lid, which is designed to minimize particle contamination and allow easy sample transfer in and out of the inner chamber. The stainless steel coil serves as the reactor body, while the perforated plasma guard is designed to provide maximum plasma confinement and uniform heating of the reaction chamber. Inside the reaction chamber, APPLIED MATERIALS P5000 MxP+ uses a combination of various highly efficient processes, including low-pressure chemical vapor deposition (LPCVD) and plasma enhancement. This allows for highly controlled growth, characterization, and processing of materials at high temperatures. The reactor also features an automated equipment for managing the gas flow, ensuring that the chemical and other vapors used in the process are kept safely contained and degraded. In addition to its advanced chemical vapor deposition processes, P5000 MxP+ also offers specialized thermal processing capabilities. The temperature of the reaction chamber can be quickly adjusted by the operator or automatically via the reactor's digital control system. With temperatures up to 1200°C, AMAT / APPLIED MATERIALS P5000 MxP+ is capable of processing a wide range of materials and processes. These processes include localized annealing, metal deposition, and etching processes. The final feature of AMAT P5000 MxP+ is its multi-axis motion unit. This motion machine is designed to improve the accuracy of the sample processing, as well as reduce thermal gradients within the chamber. The motion tool utilizes three degrees of freedom, with the ability to rotate, tilt, and swing along three axes. This allows the sample to be placed and manipulated in greater detail than would otherwise be possible. In summary, APPLIED MATERIALS P5000 MxP+ is a state-of-the-art ceramic coil-type reactor that offers a variety of highly efficient processes for growth, characterization, and processing of materials at high temperatures. The reactor includes specialized capabilities such as low-pressure chemical vapor deposition and plasma enhancement, as well as advanced thermal processing technologies and an automated gas flow management asset. P5000 MxP+ also utilizes a multi-axis motion model for improved sample placement and manipulation.

There are no reviews yet