Used AMAT / APPLIED MATERIALS P5000 MxP+ #9181328 for sale

URL successfully copied!

Tap to zoom

ID: 9181328

Wafer Size: 8"

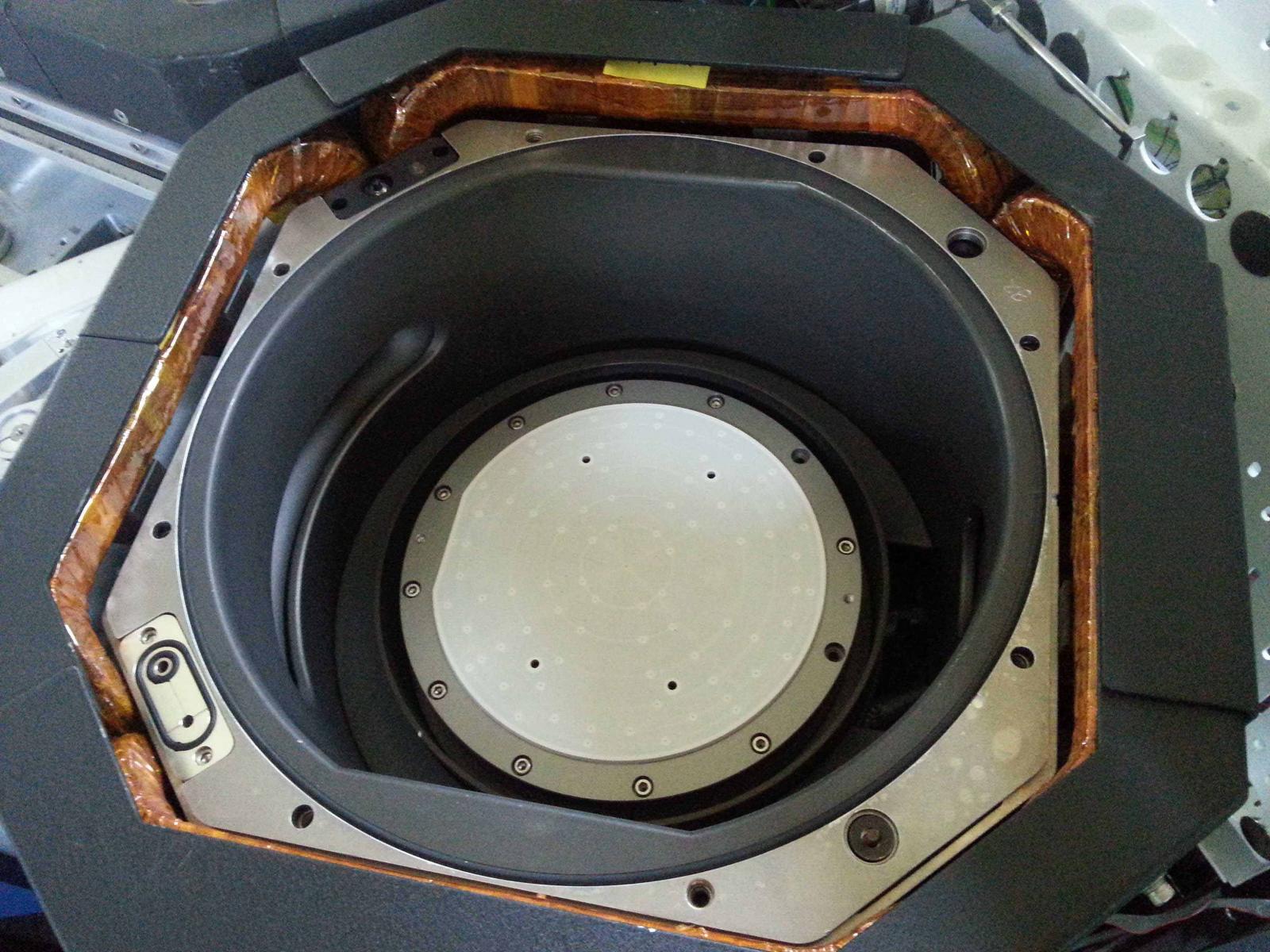

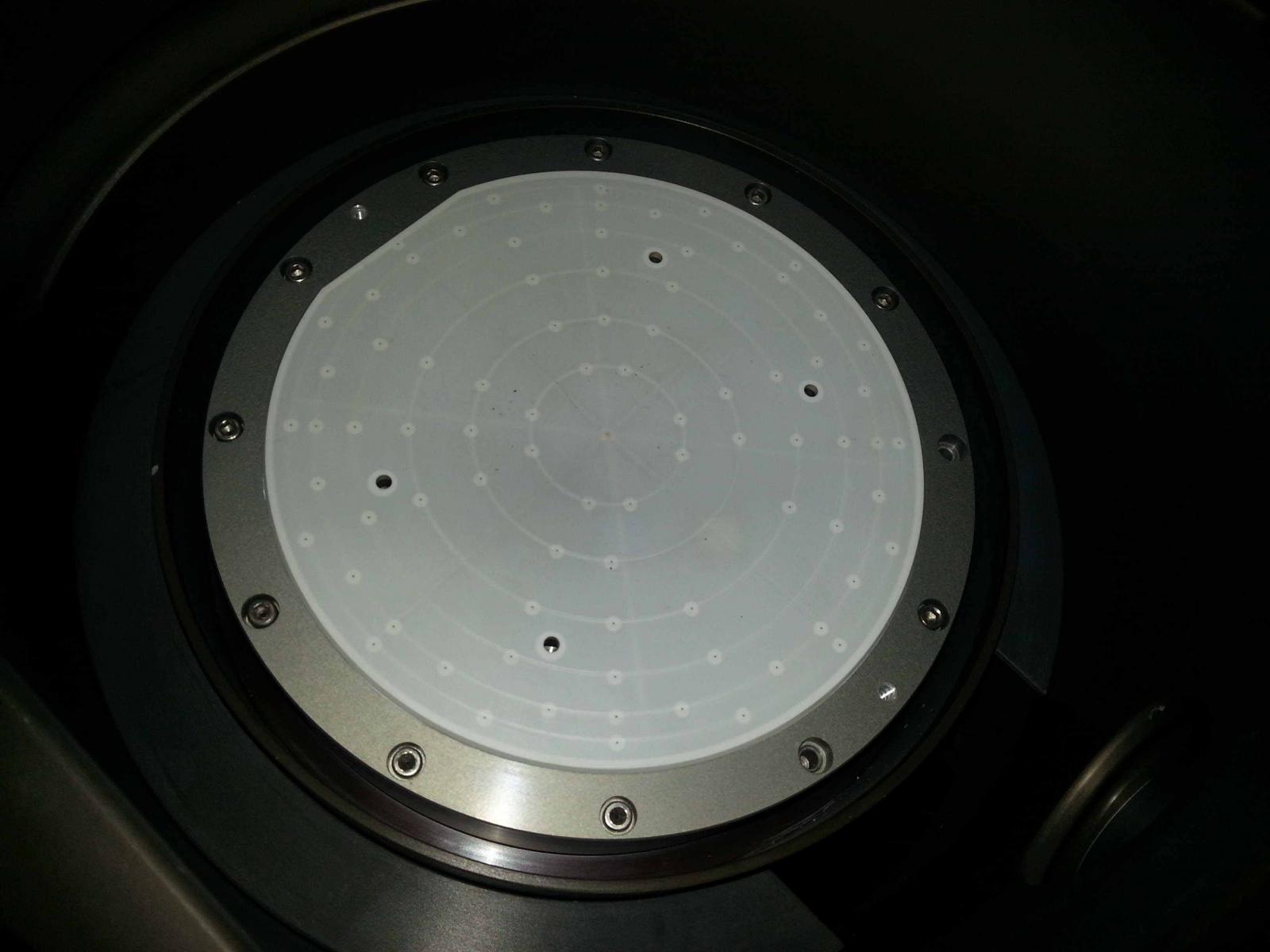

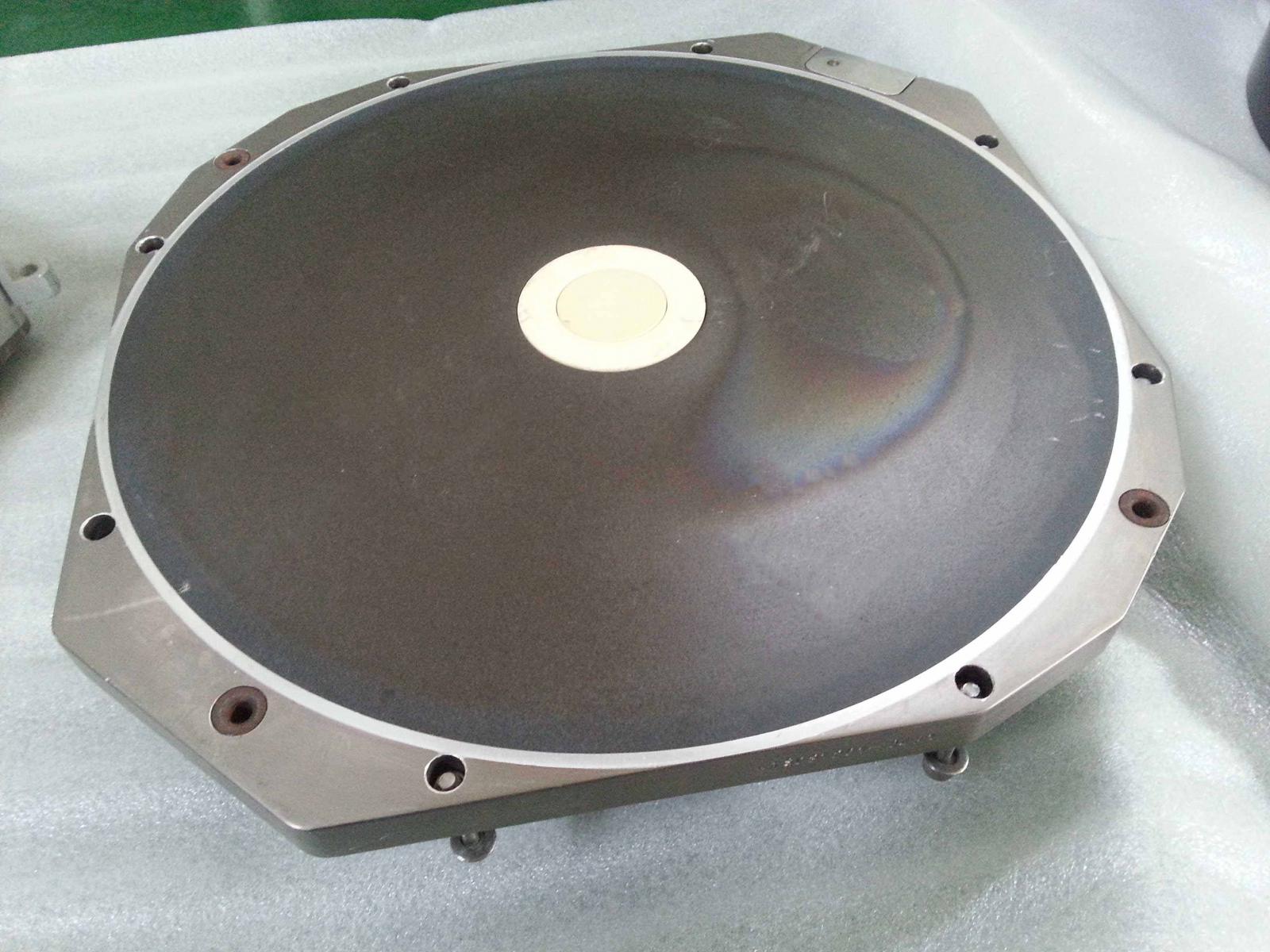

Poly chamber, 8"

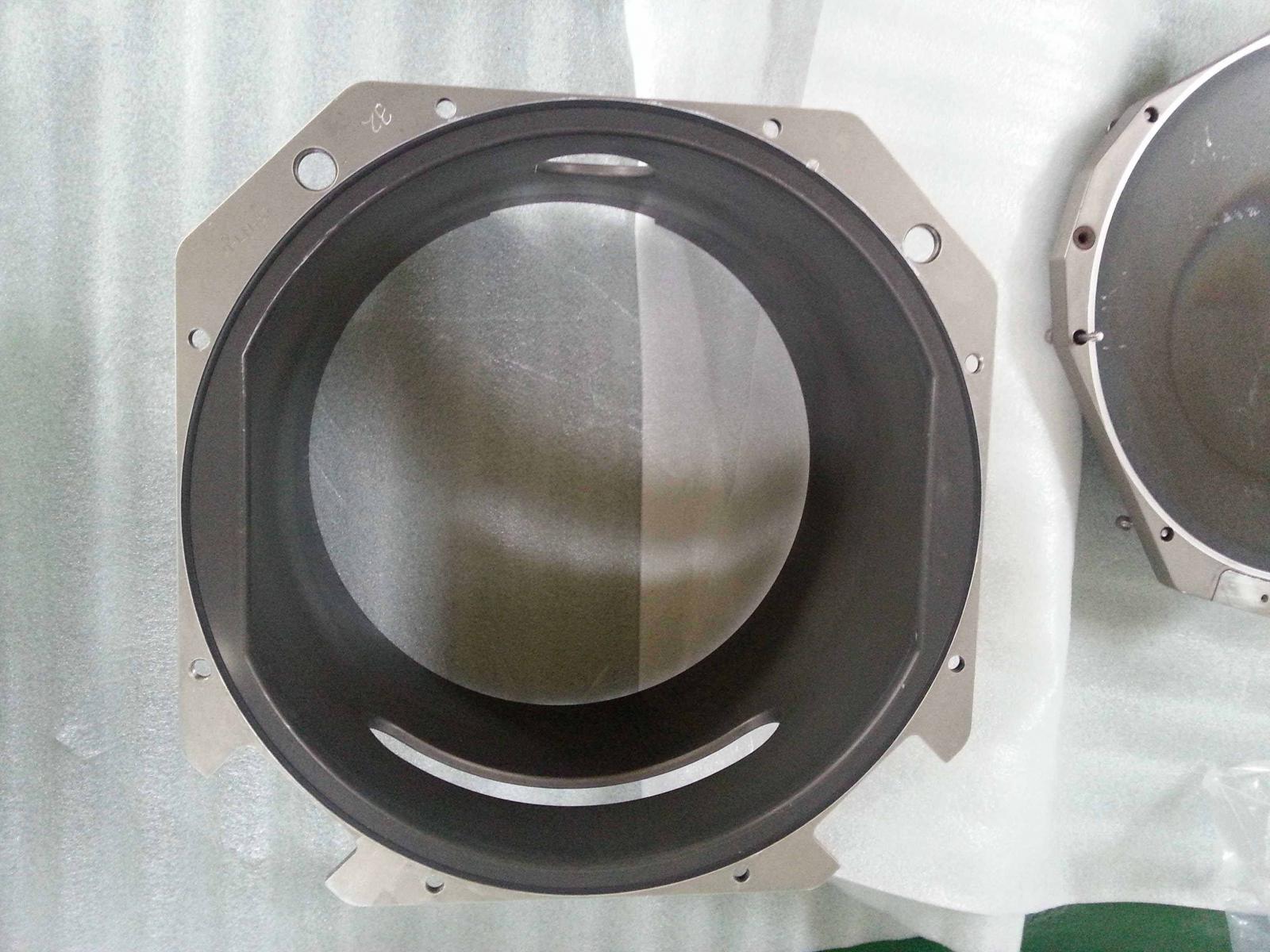

Chamber type: (3) MXP+ R2 Chamber

ESC: Ceramic ESC

(15) Slots storage

Includes:

HV Module

Simple cathode

RF Match

Wall liner

LID: SSGD

Not included:

Throttle VV

Gate VV

Turbo.

AMAT / APPLIED MATERIALS P5000 MxP+ is a modular etch reactor designed for high aspect ratio processing of advanced VLSI and microelectronics devices. It is optimized for photo and high aspect ratio masks, using a combination of conventional reactive ion etching (RIE) and plasma-induced chemical vapor deposition (PICVD) processes. This hybrid chamber enables device-level feature definition and integration of process recipes within one equipment. The MxP+ is a single-wafer system that supports up to 150 mm wafers and has a three-zone design with a gate, main and fore chamber. The gate chamber is optimized to speed up the transition time between the vacuum and nano-turbulence modes, while the main chamber is used to deliver the reactive ions and plasma energy to etch the wafer's surface. The backside of the wafer is exposed to the fore chamber plasma to ensure a homogenous etching process. AMAT P5000 MxP+ is designed for high density device feature patterns, necessary for the most advanced device designs. This is accomplished by providing a highly stabilized process environment, including active and passive environmental clean controlling technologies. The MxP+ also provides fast cycling times and process repeatability, allowing for higher throughputs and device yield. The MxP+ utilizes a combination of etching techniques, including ion beam etching, ion-enhanced plasma etching, high density plasma etching, and sputter etching, allowing for a variety of substrates and materials to be etched. It also allows for the etching of metal wires with minimal undercut or bowing. To ensure a high level of precision and repeatability, the chamber features tighter process control over pressure and temperature, and has versatile power and gas distribution systems. The MxP+ also has an easy-to-use recipe development software unit, which allows engineers to quickly create customized recipes with minimal intervention. The recipe machine also automatically adjusts process settings and displays real-time data such as etch depth, selectivity, and uniformity. Additionally, the recipe maker software has built-in safeguards to ensure quality and reproducibility of process parameters. In conclusion, APPLIED MATERIALS P5000 MxP+ is an advanced reactor tool designed for high aspect ratio processing of advanced VLSI and microelectronics devices. It offers a combination of etching techniques and provides unparalleled precision, repeatability and throughput rates for high-density devices. Additionally, it has an automated recipe development asset, providing engineers with the flexibility to quickly and easily create highly reproduceable process recipes.

There are no reviews yet