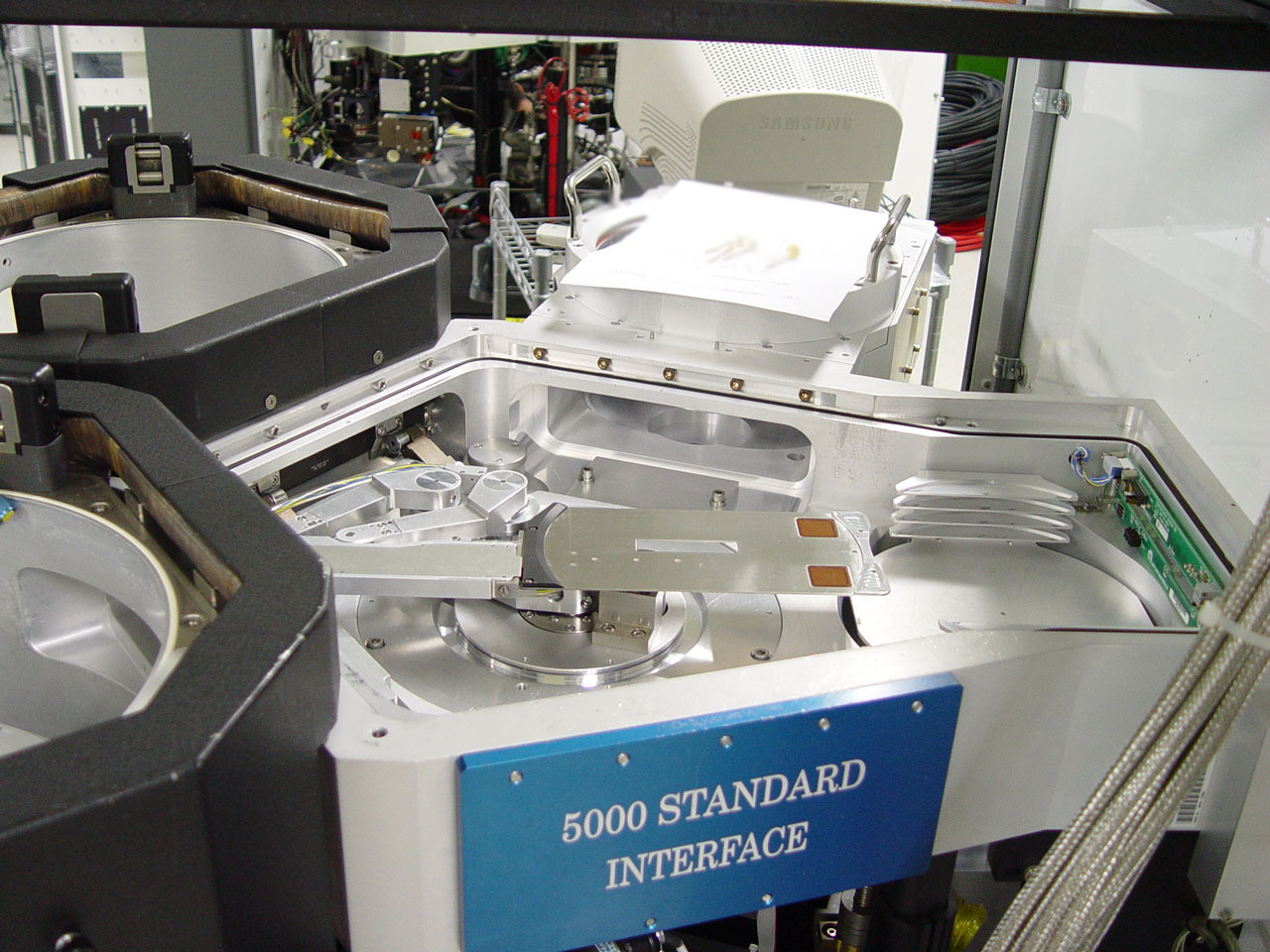

Used AMAT / APPLIED MATERIALS P5000 #131584 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS P5000 is a deposition tool based on the Physical Vapor Deposition (PVD) process. The tool is designed to deposit thin films of materials onto any suitable substrate, creating a heterostructure of thin layers with precise control of thickness, composition, and doping for semiconductor, energy storage, and other innovative device fabrication requirements. AMAT P-5000 reactor employs an ultra-high vacuum environment to vaporize solid source materials such as metal, ceramic, and dielectric in the form of crucibles, sources, and other feeding components. Once de-vaporized and ionized, the source materials are accelerated by a high voltage electric field and deposited in an exact stoichiometric ratio on any thermally stable substrate surface. The process temperature of the tool varies from room temperature to 900°C, a temperature that is adjustable with a thermo-electric cooler (TEC) to achieve precise and uniform film deposition over the full substrate surface. The highest achievable deposition rate is 2 nanometers (nm) per second. In addition to offering high process reproducibility and deposition rate, the tool boasts a separable chamber to facilitate parts replacement or maintenance while the deposition process is running, without incurring any undesired effects on the thin film. APPLIED MATERIALS P 5000 is capable of creating nanoscale architectures on the surface of the substrate, through a series of different deposition techniques such as plasma-enhanced chemical vapor deposition (PECVD), sputtering, and E-Beam evaporation. It is also possible to reduce source particles and contaminants in order to create clean, uniform layers with low defect density, high adhesion, and superior surface uniformity for a wide variety of applications. In addition, P 5000 is equipped with a versatile process controller that allows easy manipulation of process parameters for precise control of film thickness, composition, and doping. The tool also enables users to monitor the growth of thin films in real-time. Furthermore, numerous data collection and analysis methods can be used to extract relevant properties from the tool and optimize the process for higher yield and efficiency. In conclusion, AMAT P 5000 is an excellent deposition tool that facilitates thin film deposition with a precise control of the structure and properties of the thin film layers. By employing a variety of deposition techniques, the tool ensures high reproducibility and uniformity that can be applied to numerous applications in materials science research, as well as semiconductor device fabrication.

There are no reviews yet