Used AMAT / APPLIED MATERIALS P5000 #159344 for sale

URL successfully copied!

Tap to zoom

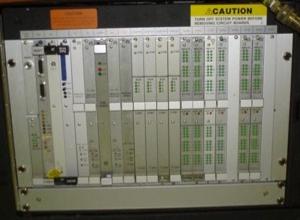

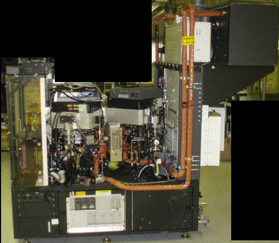

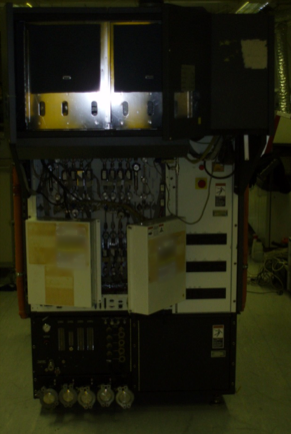

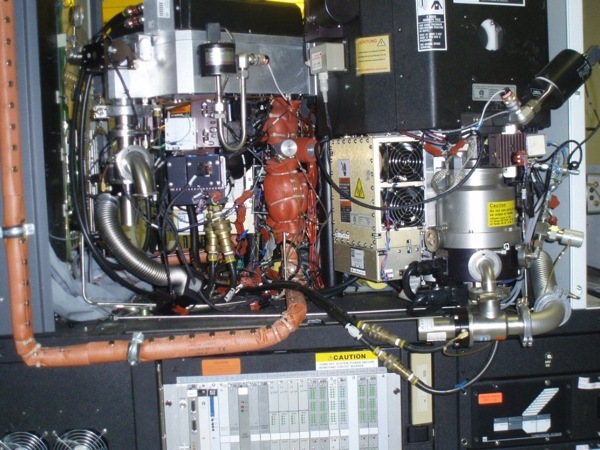

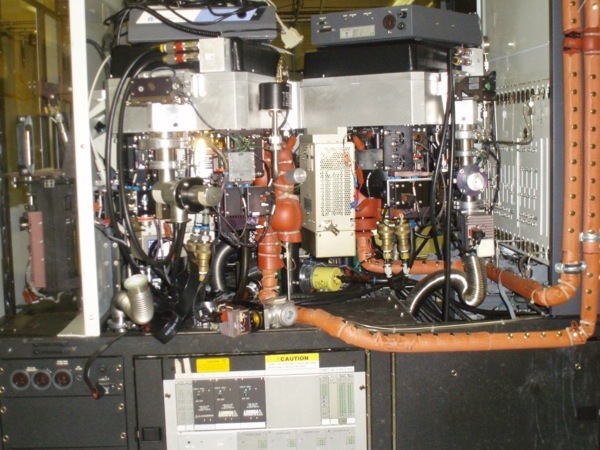

AMAT / APPLIED MATERIALS P5000 reactor is a tool designed for the etching and deposition of semiconductor materials. It is commonly used in the fabrication of integrated circuits, thin films, and various other optoelectronic devices. AMAT P-5000 is capable of operating at low and high temperatures, as well as pressures of up to 10-3 to 10-5 mbar. It can also be used for rapid thermal processing (RTP) and rapid thermal annealing (RTA). The basic chamber of APPLIED MATERIALS P 5000 consists of a 9" quartz tube heated to temperatures of up to 850C by its RF induction coil, and a quartz dome above it. The core of the reactor is a gas distribution equipment that distributes the etching or deposition gas in a uniform manner. There are two external gas inlets that can be controlled independently to either the quartz tube or the quartz dome. AMAT P5000 also has a built-in mass flow controller (MFC) to accurately control the flow rate of the gases. Substrate support is an integral part of AMAT / APPLIED MATERIALS P 5000, which includes an adjustable shelf and a 6-point electrical contact system. This ensures a uniform temperature across the sample surface. An implant locking mechanism is integrated into the top of the unit as well, allowing users to place substrates in their respective locations for etching and deposition. APPLIED MATERIALS P5000 is controlled by AMAT special programmable logic controller (PLC). This provides a high degree of repeatability and accuracy. It is also integrated with substrate and process monitoring systems that allow users to monitor their process parameters in real-time. Diagnostics software also allows users to access data, view performance graphs, troubleshoot problems, and modify machine settings remotely. Finally, AMAT P 5000 also offers additional configurations and features that can be tailored to meet customer requirements. Options include various types of heating, cooling, and gas mixing systems, as well as additional material inputs, sensors, and process monitoring. All in all, P 5000 is an essential and reliable tool for etch and deposition process in the semiconductor and optoelectronics industries.

There are no reviews yet