Used AMAT / APPLIED MATERIALS P5000 #293587974 for sale

URL successfully copied!

Tap to zoom

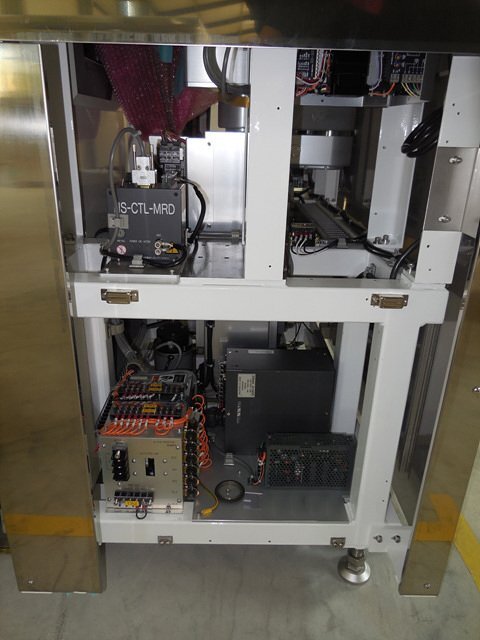

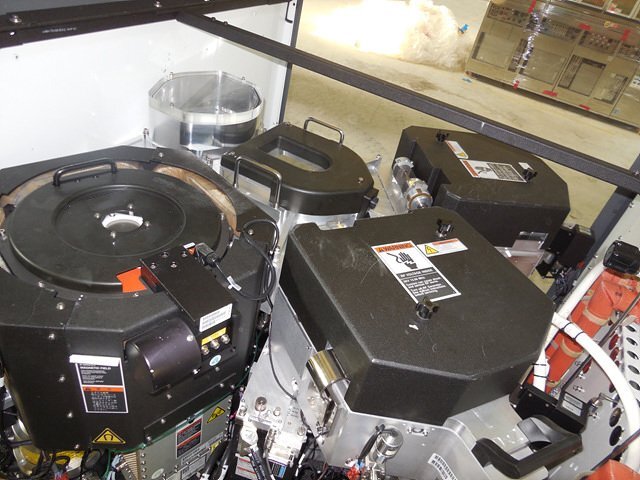

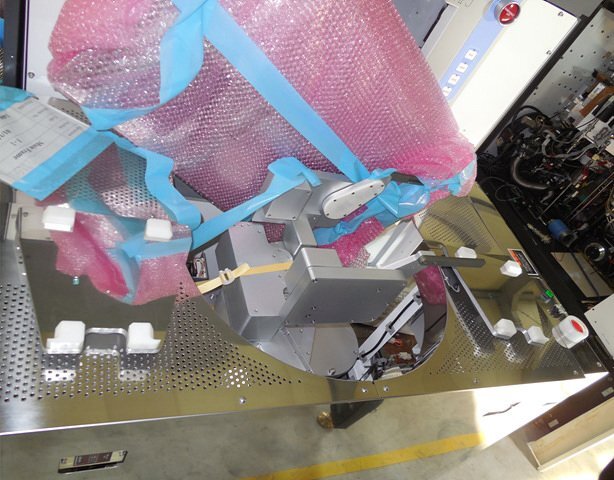

AMAT / APPLIED MATERIALS P5000 reactor is a semiconductor processing tool that is used to deposit thin layers of various materials onto substrates. The reactor is designed to provide precise process control, along with consistent uniformity across each substrate layer. This is achieved through a combination of advanced gas delivery systems and multiple chambers that can be operated independently. AMAT P-5000 process chamber is the main part of the reactor and it is a cylindrical chamber, with a diameter of 12 inches and a height of 16 inches. The chamber is constructed from stainless steel and has a high vacuum capability of over 10-9 Torr. Inside the chamber, the substrate is mounted on a holder and a pair of thermal electrodes are angled at the top of the chamber. Substrate heating is achieved by using the Thermal Silicon-Carbide (SiC) heater with an adjustable temperature range of up to 1000°C. The substrate holder and the thermal electrodes are connected to the base power supply, which allows for accurate temperature control and provides a stable temperature range. APPLIED MATERIALS P 5000 includes a Gas Delivery System (GDS), which consists of three controllable gas valves and three gas lines. The GDS allows gases to be injected into the chamber at predetermined rates and concentrations. The gases are used to create a variety of process chemistries, depending on the materials being deposited. The gases are then exhausted from the chamber by way of a vent line, allowing for precise control of the chamber atmosphere. P 5000 also includes two additional processing chambers, which are commonly referred to as "showerhead" and "damascene" chambers. The showerhead chamber is used for depositing thin layers of materials on the substrate surface. The damascene chamber is used for patterning the substrates with a variety of materials and compounds to create a specific pattern. To ensure consistent deposition process parameters across all substrates and chambers, P-5000 also has an elaborate collection of instrumentation. This includes a pressure gauge, a mass flow meter, a temperature sensor, and an ellipsometer. All of these components are used to monitor the process conditions and adjust the chamber atmosphere and operating parameters as needed. Overall, P5000 reactor is a highly advanced and precise semiconductor processing tool that offers superior process control and uniformity across substrates. It is ideal for fabricating extremely thin layers on complex substrates with specific patterns and is capable of handling a wide range of material combinations and process chemistries.

There are no reviews yet