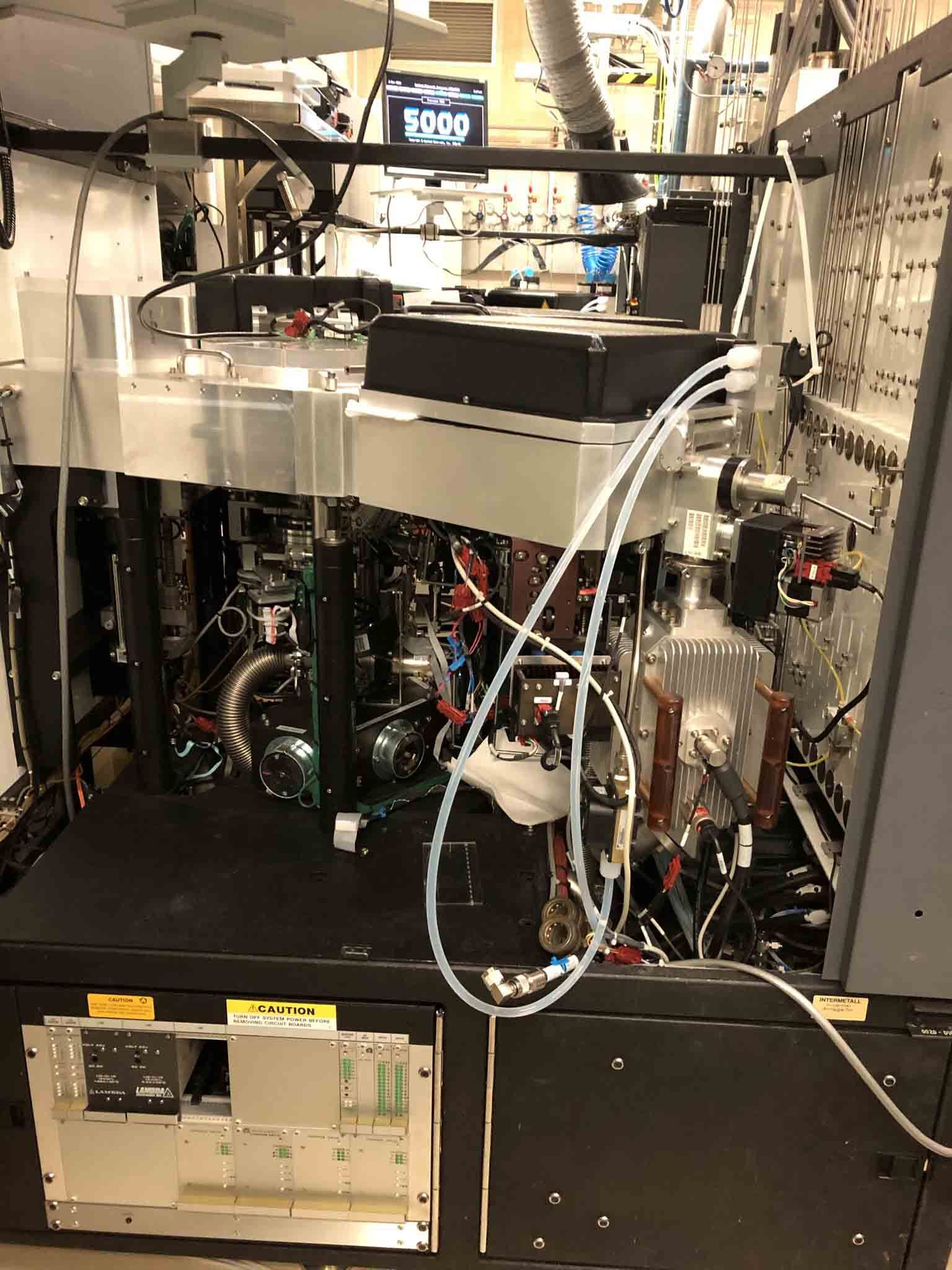

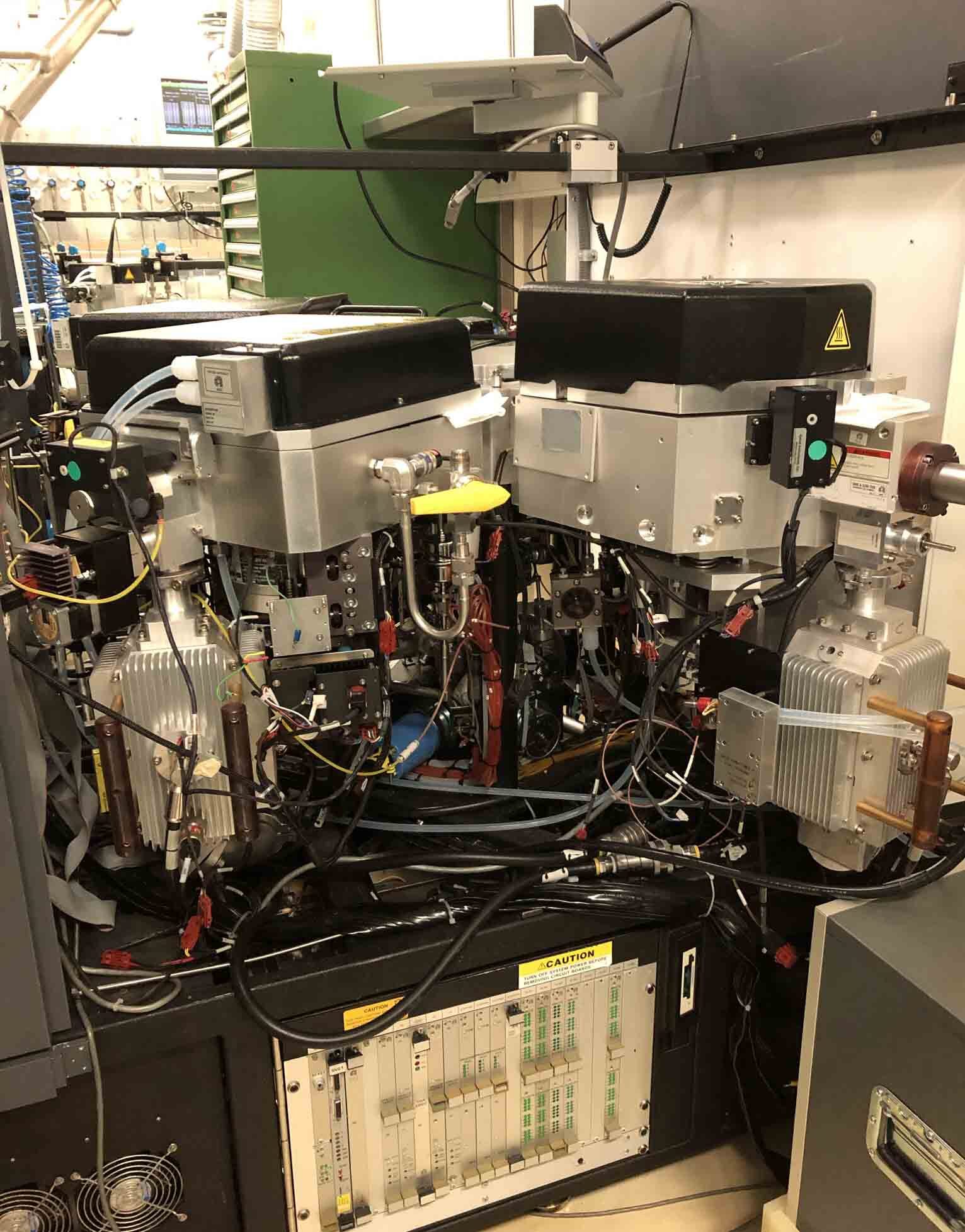

Used AMAT / APPLIED MATERIALS P5000 #293594313 for sale

URL successfully copied!

Tap to zoom

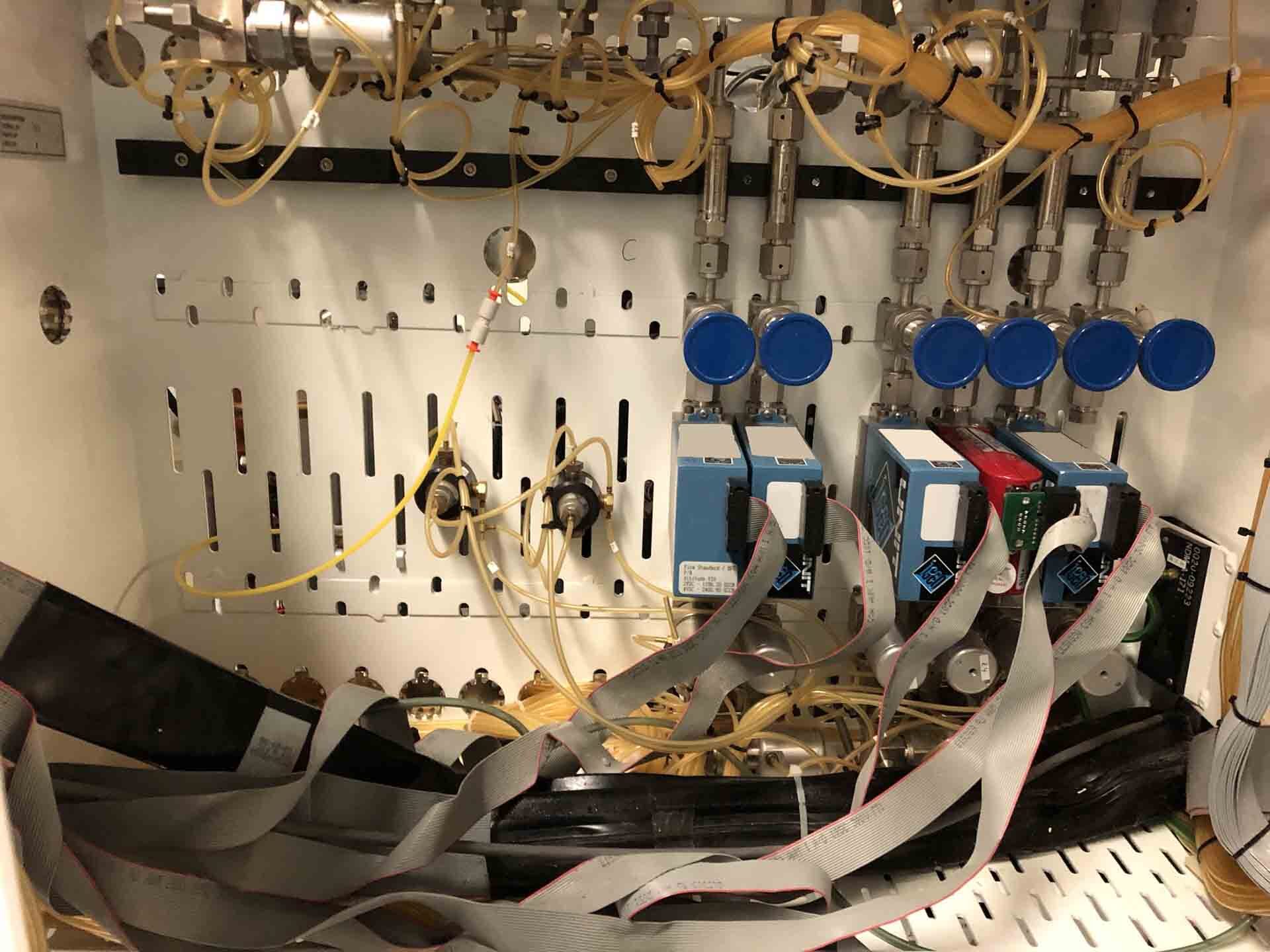

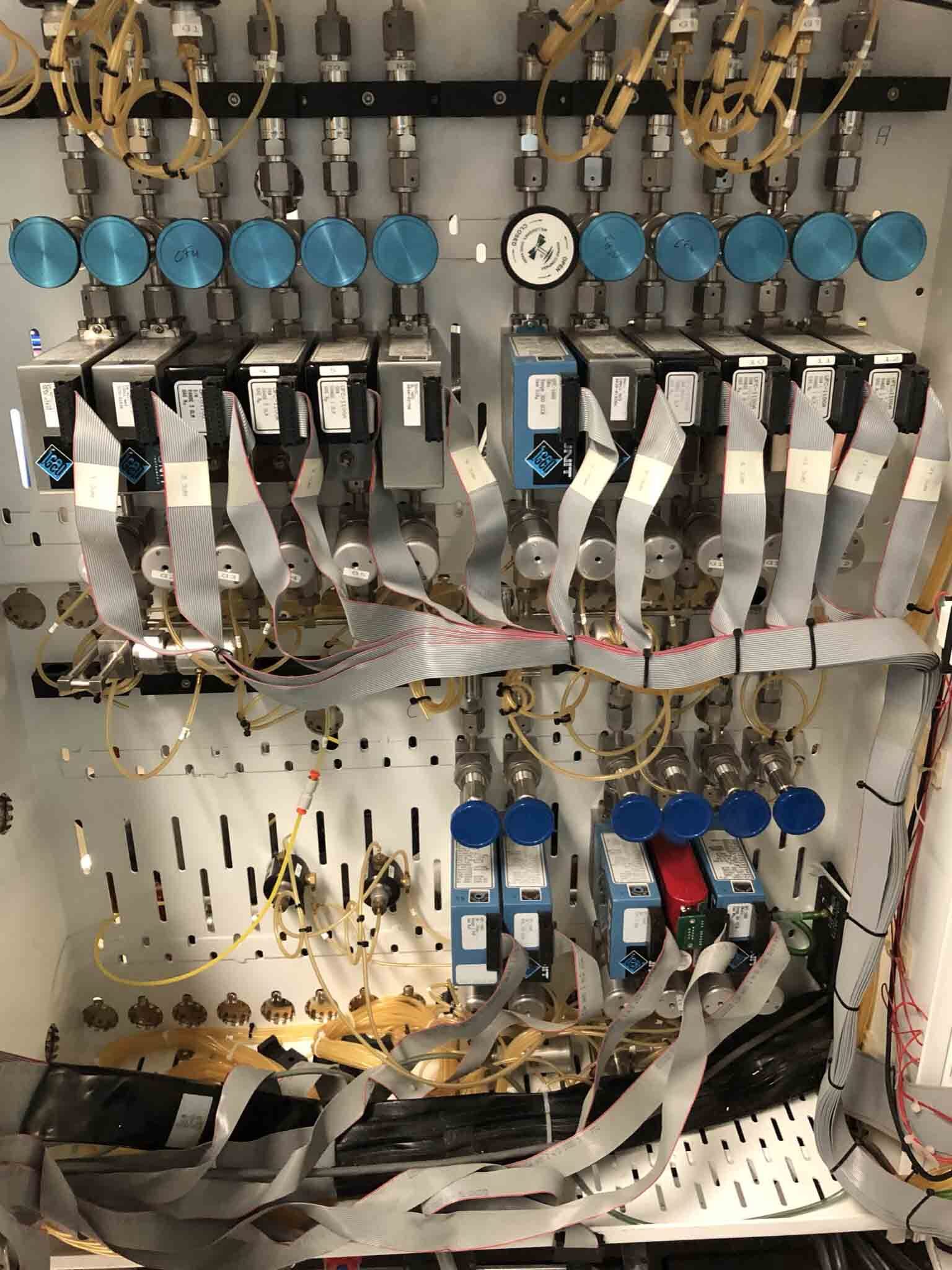

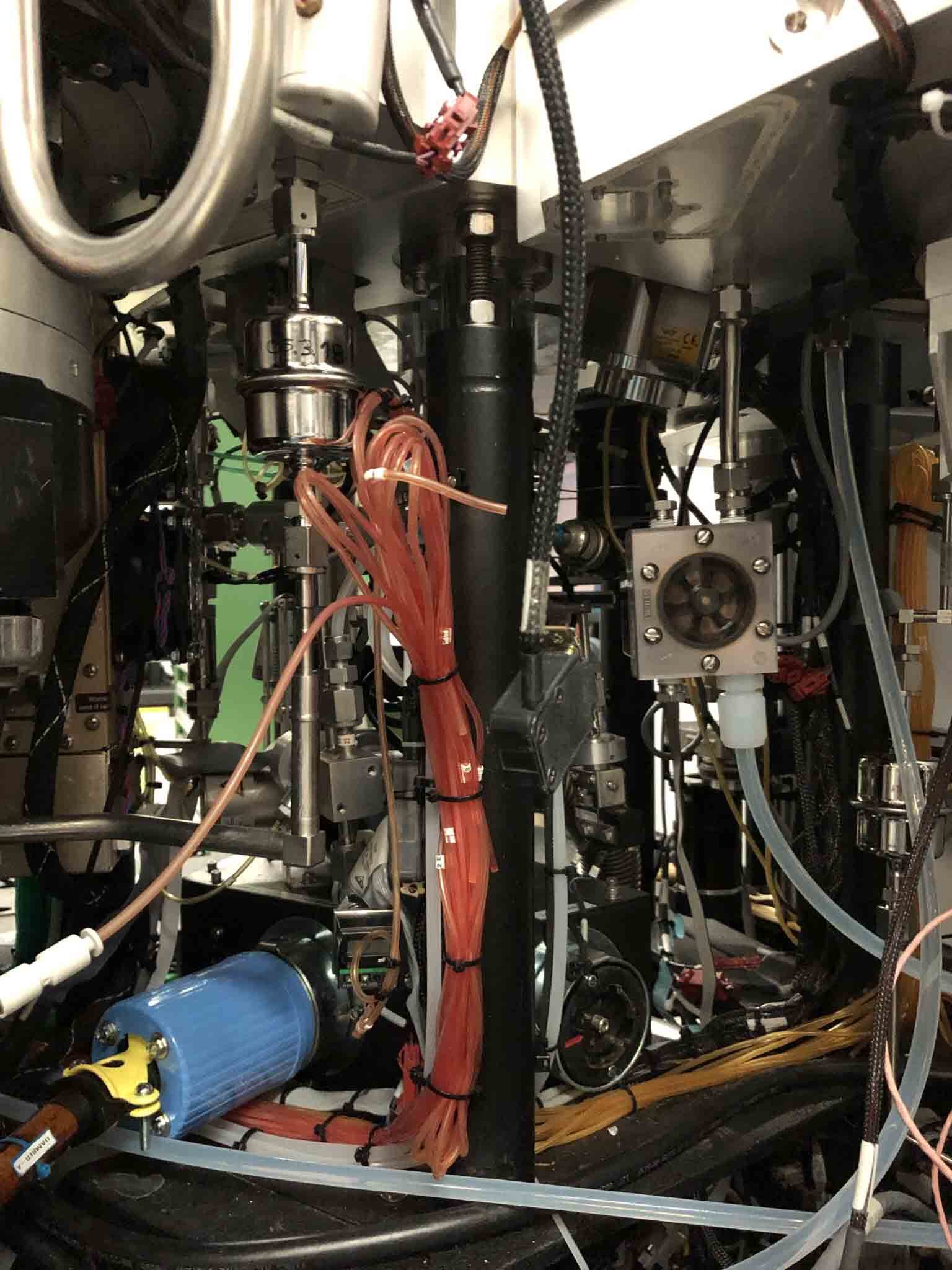

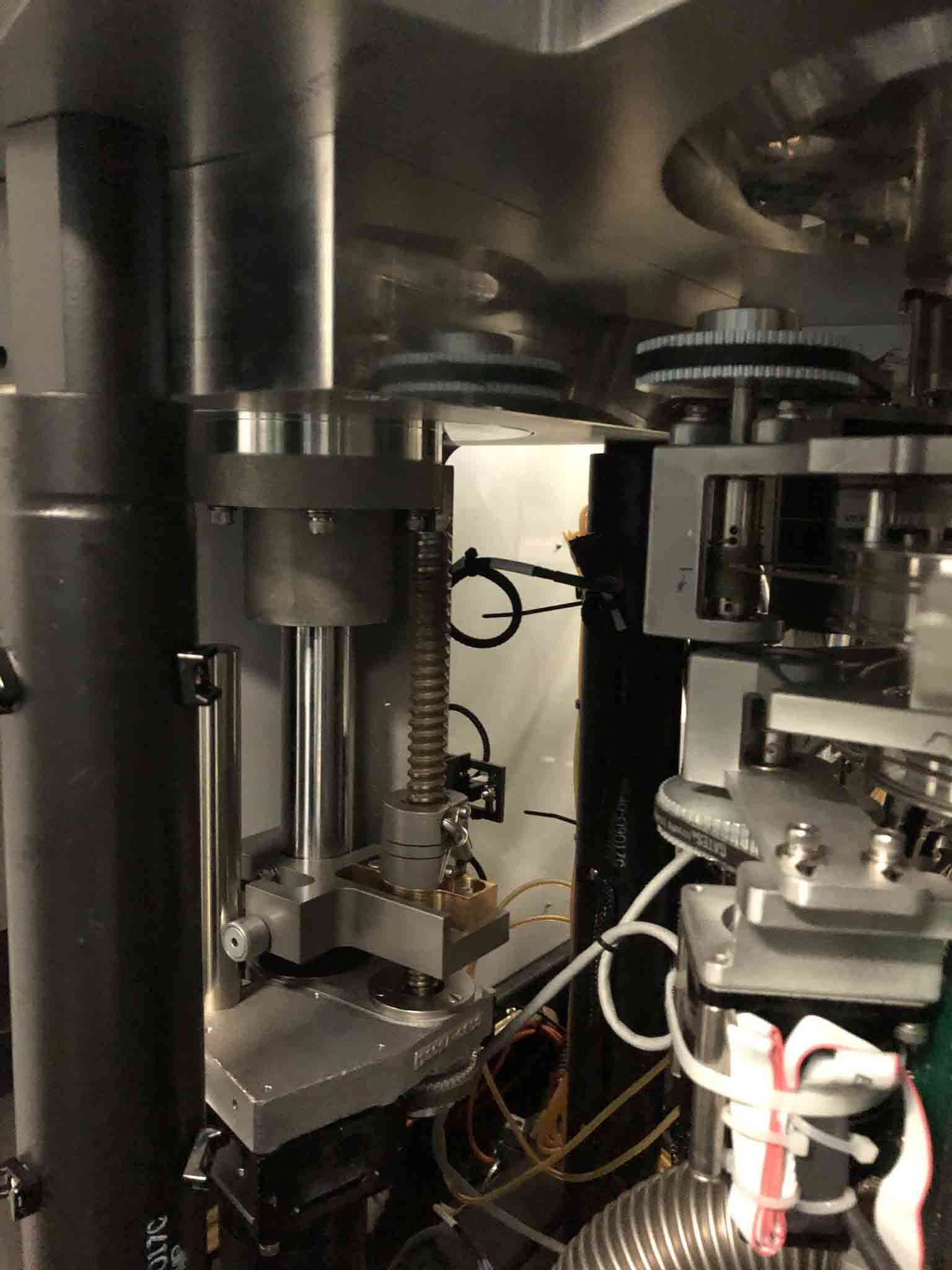

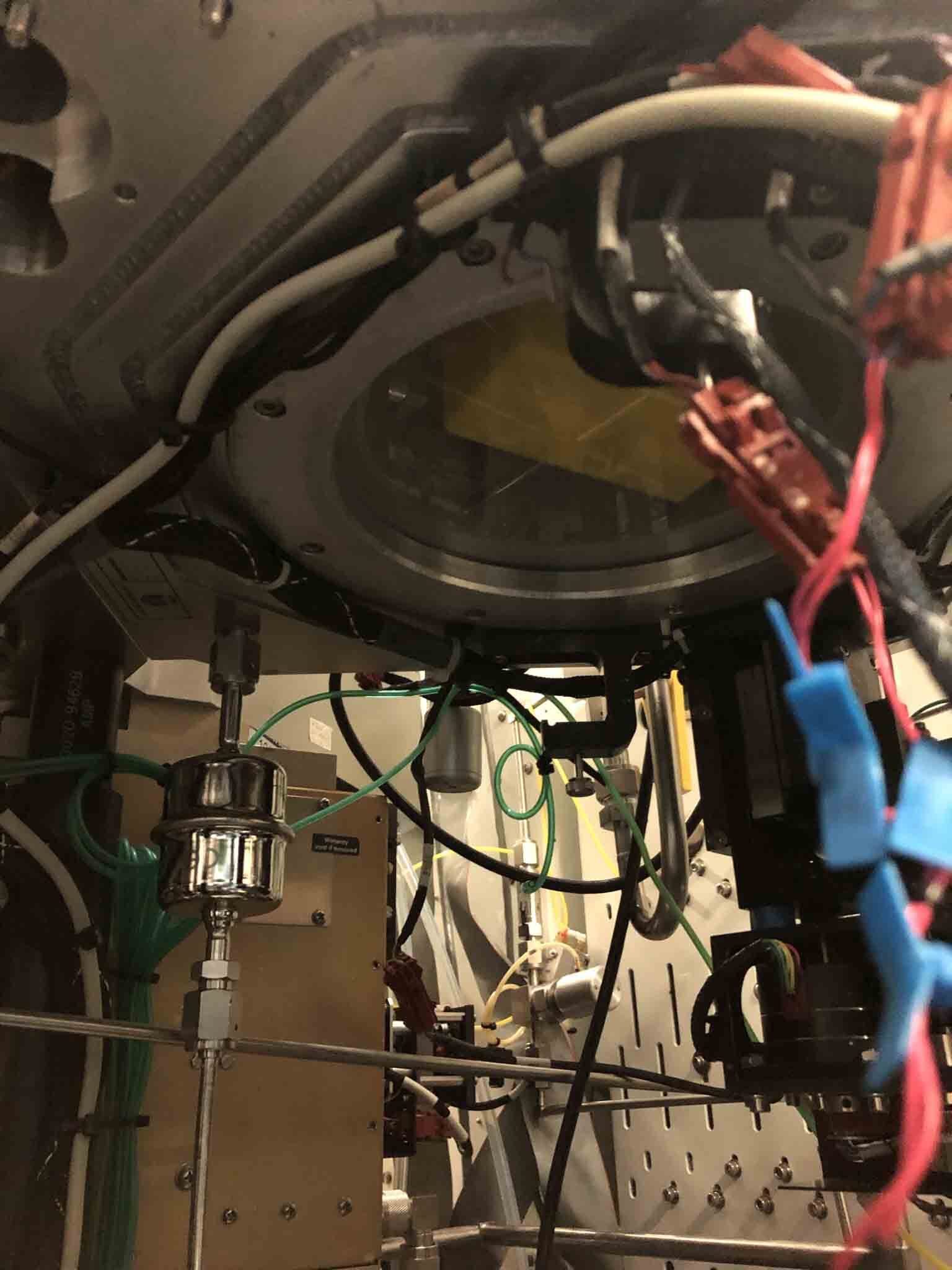

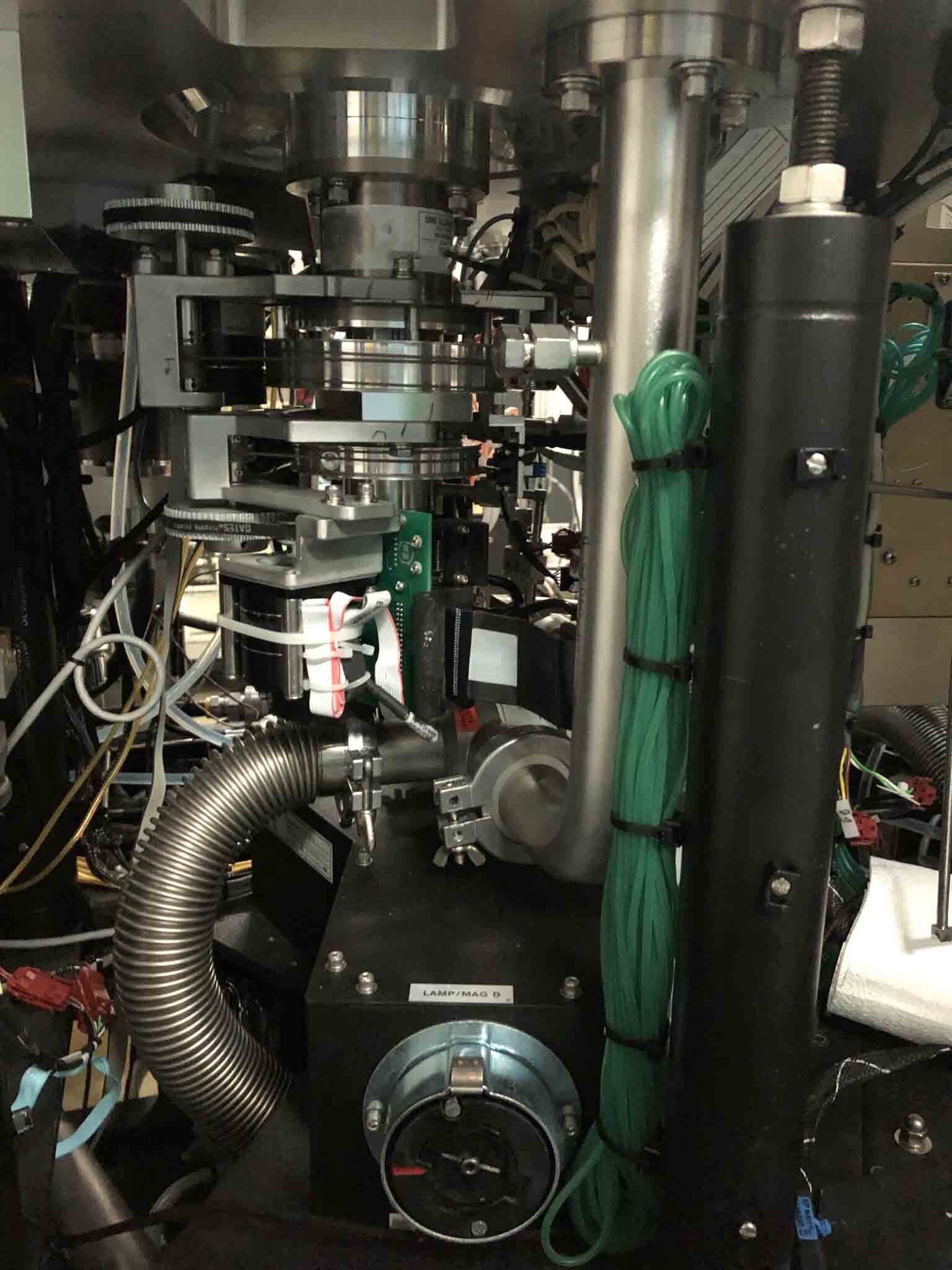

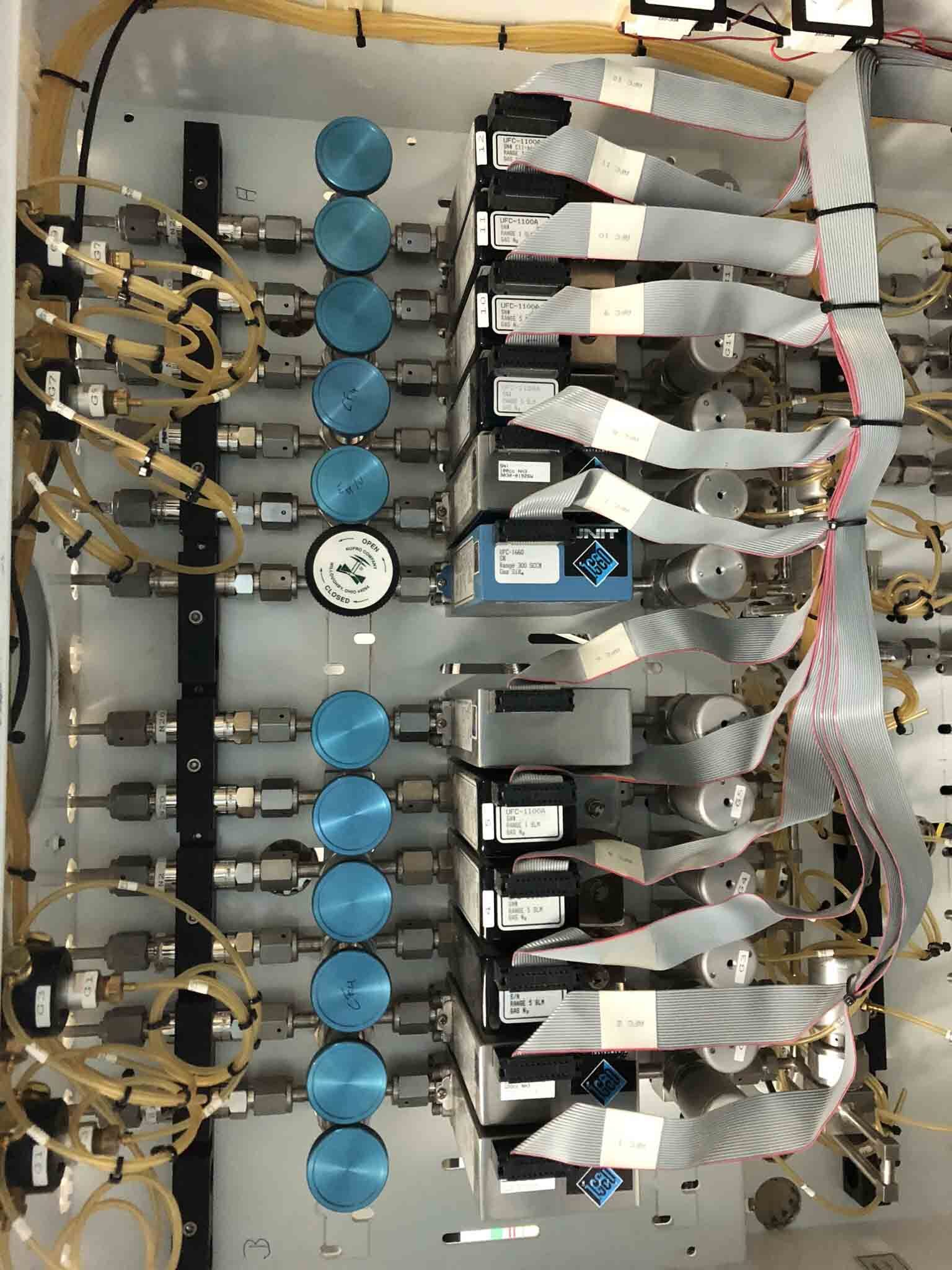

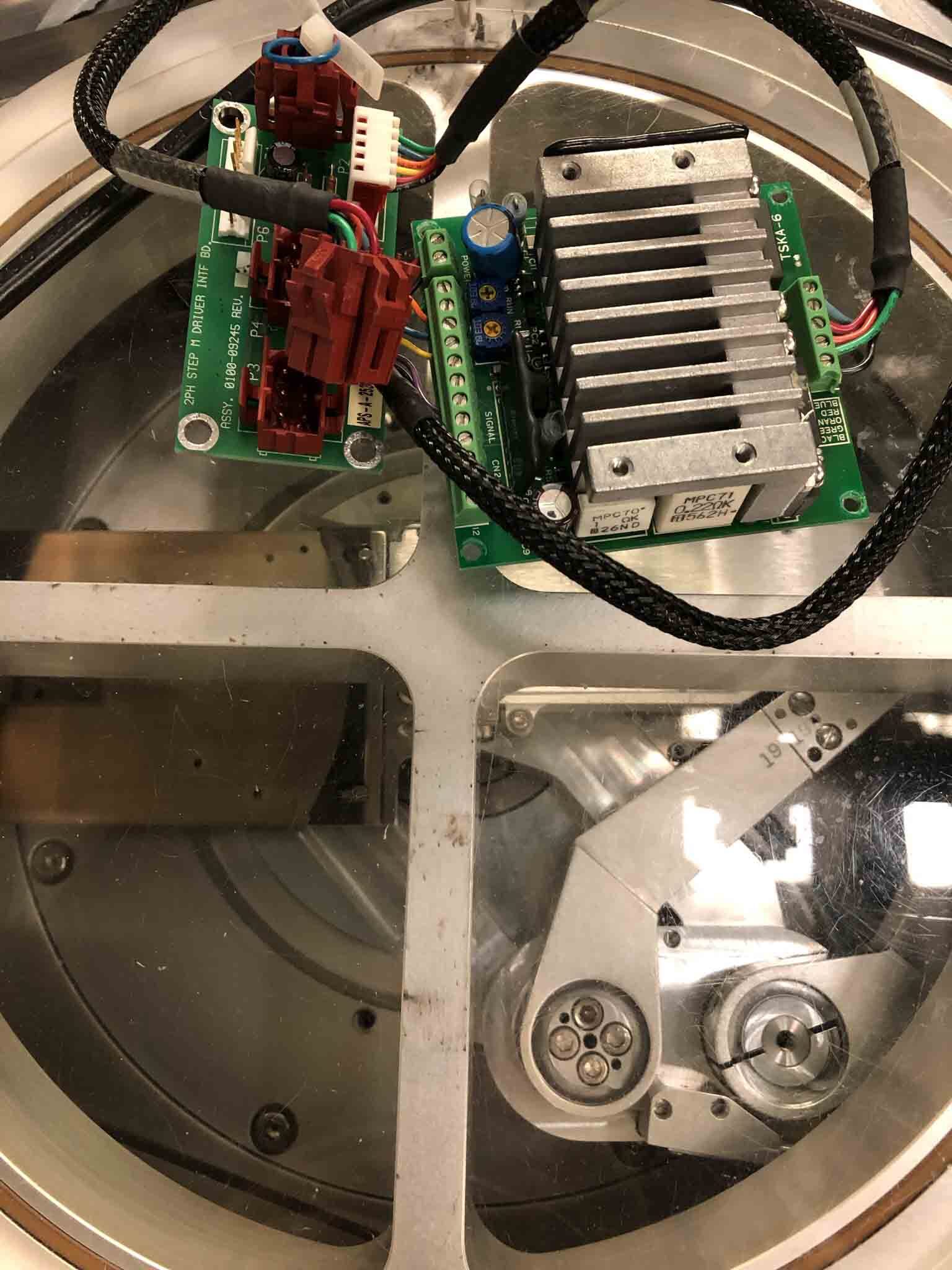

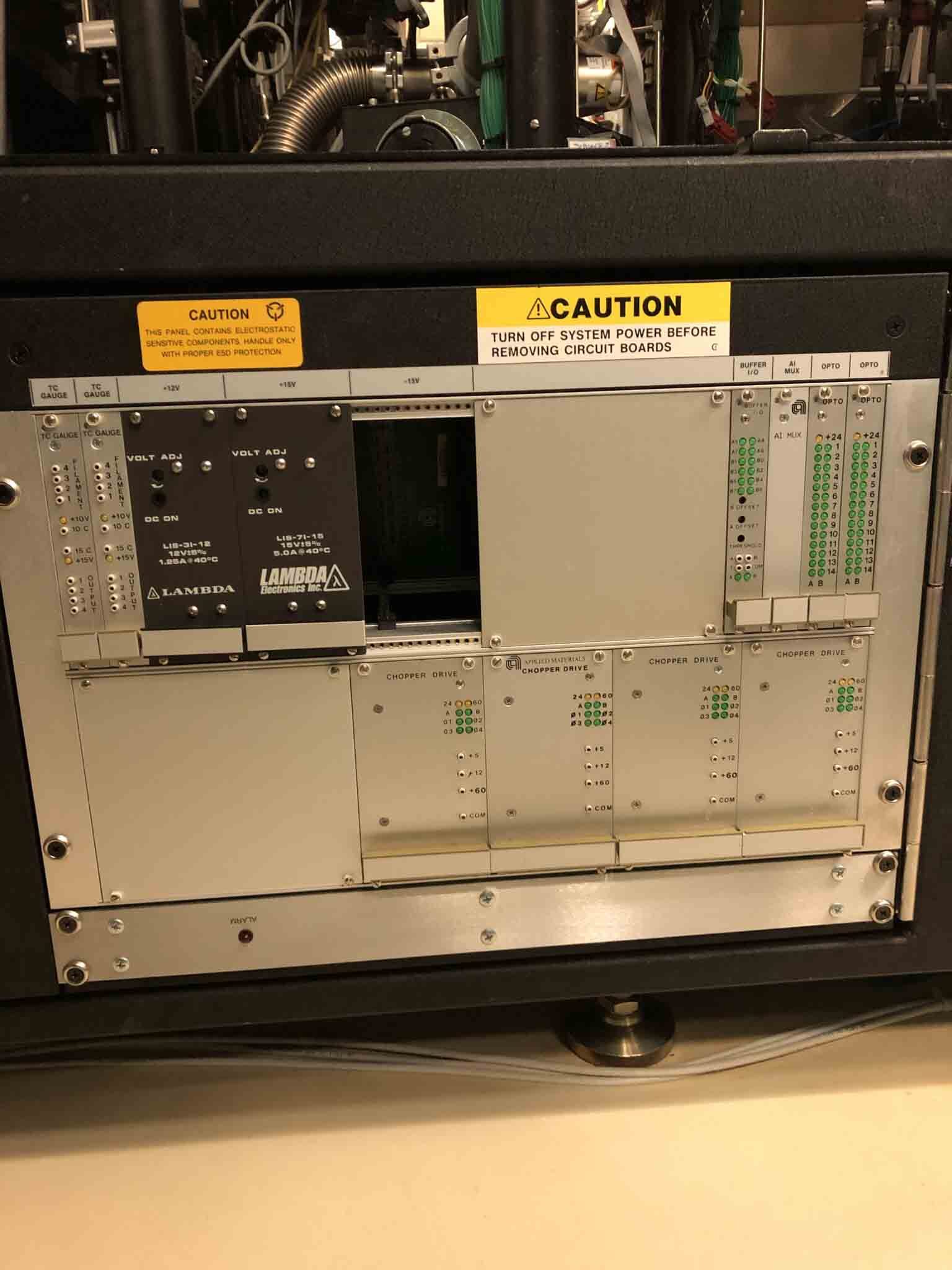

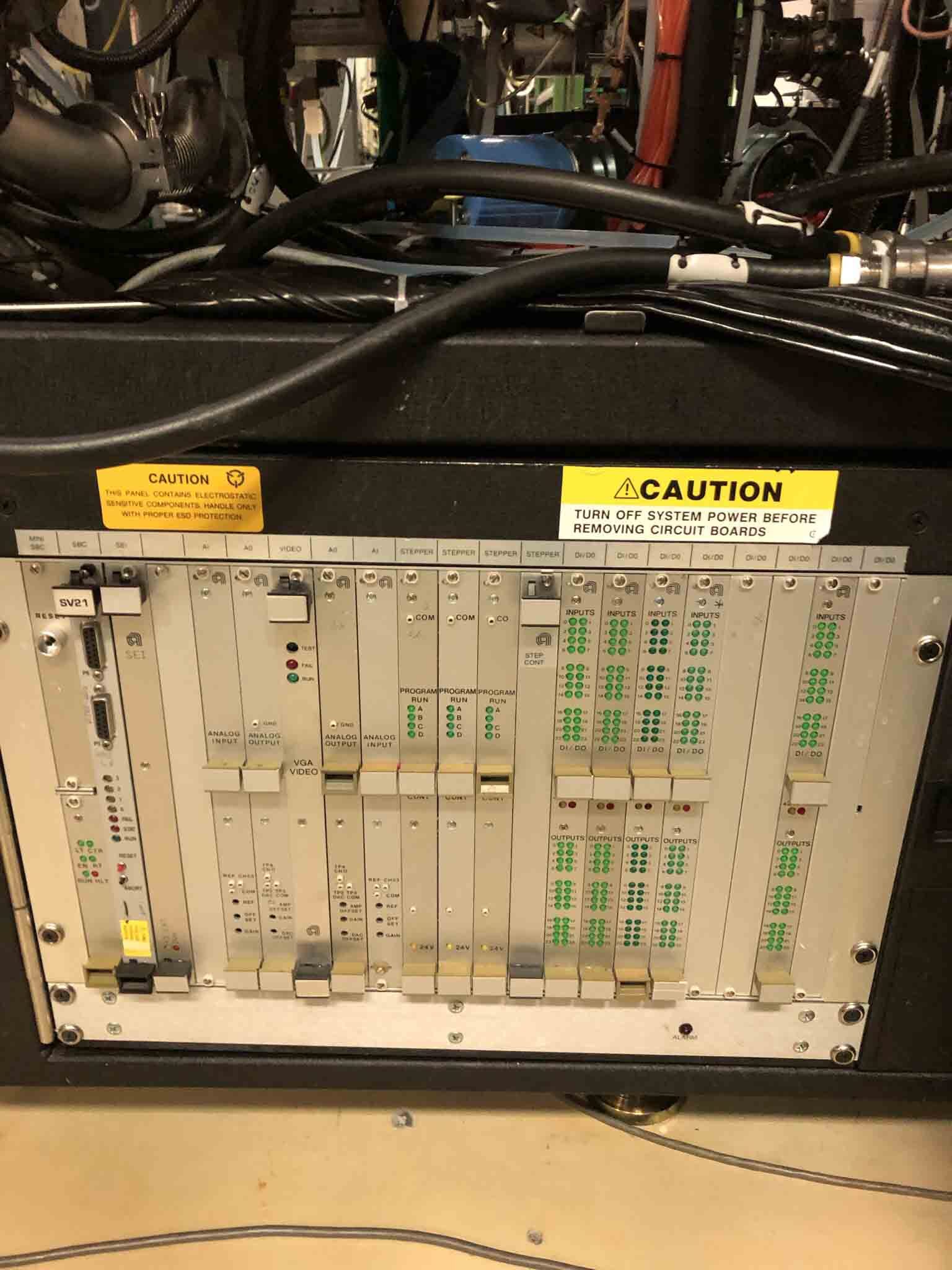

AMAT / APPLIED MATERIALS P5000 is a single wafer reactor used in semiconductor manufacturing. This reactor is used for various applications such as chemical-mechanical polishing (CMP), oxidation, nitridation and the deposition of metals and insulating materials. Its versatile design makes it the ideal tool for the production of the latest high-performance integrated circuits. AMAT P-5000 reactor utilizes a flow-type process that enables precise and consistent control of the environment within the reaction chamber. This flow process also allows for tight control of the gas mixtures used in different processes. The reaction chamber is equipped with multiple sources of reactive plasmas as well as an advanced wafer transport system. APPLIED MATERIALS P 5000 reactor provides a number of features that enable it to deliver superior performance. It has tremendous uniformity of coverage across the entire wafer, ensuring that the process produces the desired results. The integrated CMP system supports multiple techniques, such as slurry, fixed abrasive and chemical-mechanical planarization (CMP), for superior planarity across the entire wafer. The platform also has a high-precision robotic arm that ensures precise and repeatable wafer handling and handling, enabling precise placement of the wafer within the reaction chamber and enabling optimization of the results for critical applications. It has automated recipe management for consistent repeatability across processes and is capable of handling multiple process variables. APPLIED MATERIALS P-5000 reactor also offers superior temperature variability and monitoring so that precise control is maintained during processing. It also provides enhanced reactive gas control, ensuring that only the desired gases are used in the reaction. Finally, the reactor also supports advanced recipes, allowing it to be used in challenging and complex processes. In summary, APPLIED MATERIALS P5000 reactor is a highly sophisticated and versatile tool that is ideal for a wide range of semiconductor manufacturing processes. It has advanced uniformity and repeatability achieving precise process control. Its temperature variability, precise reactive gas control, automated recipe management and other advanced features offer superior quality and productivity.

There are no reviews yet