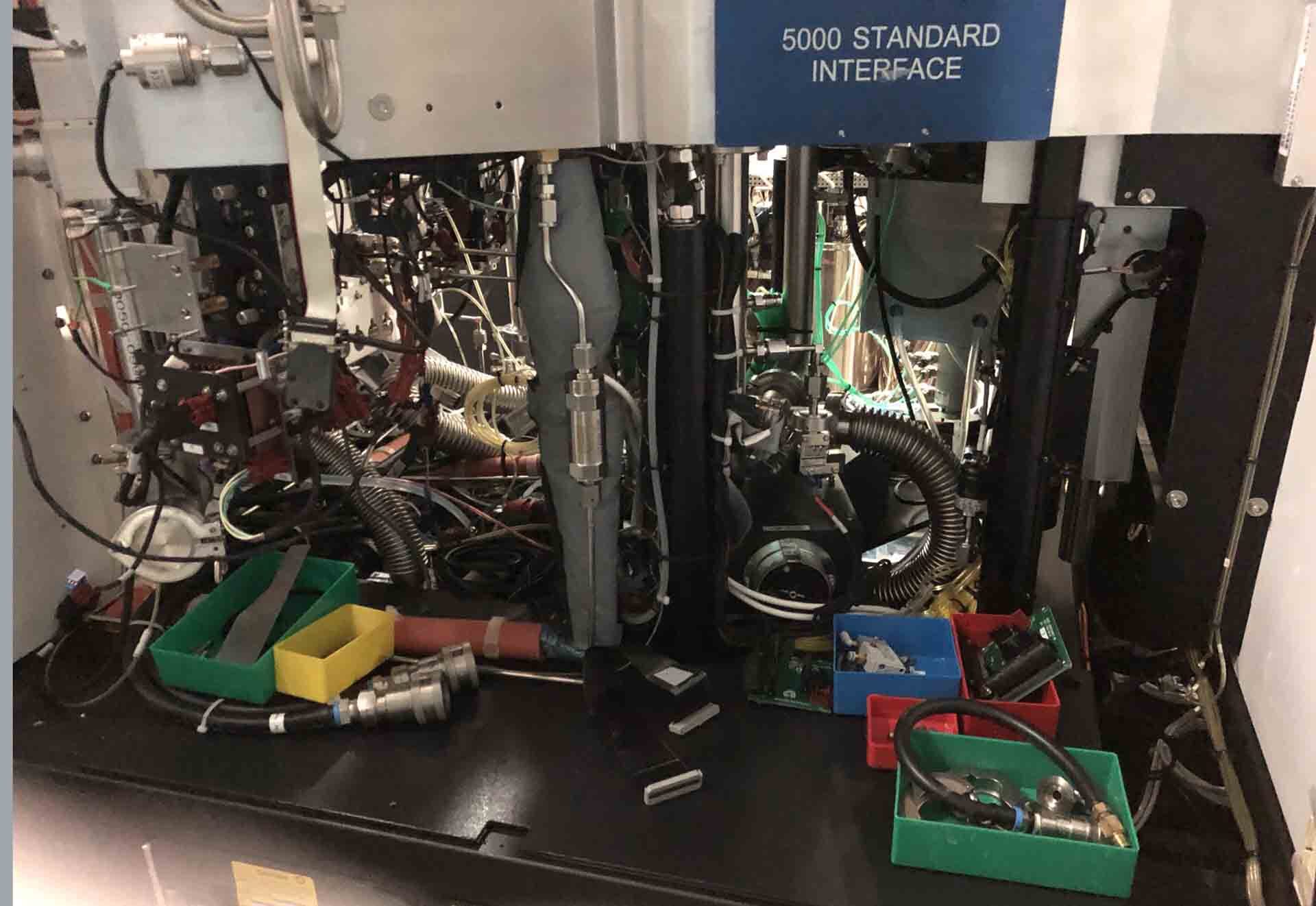

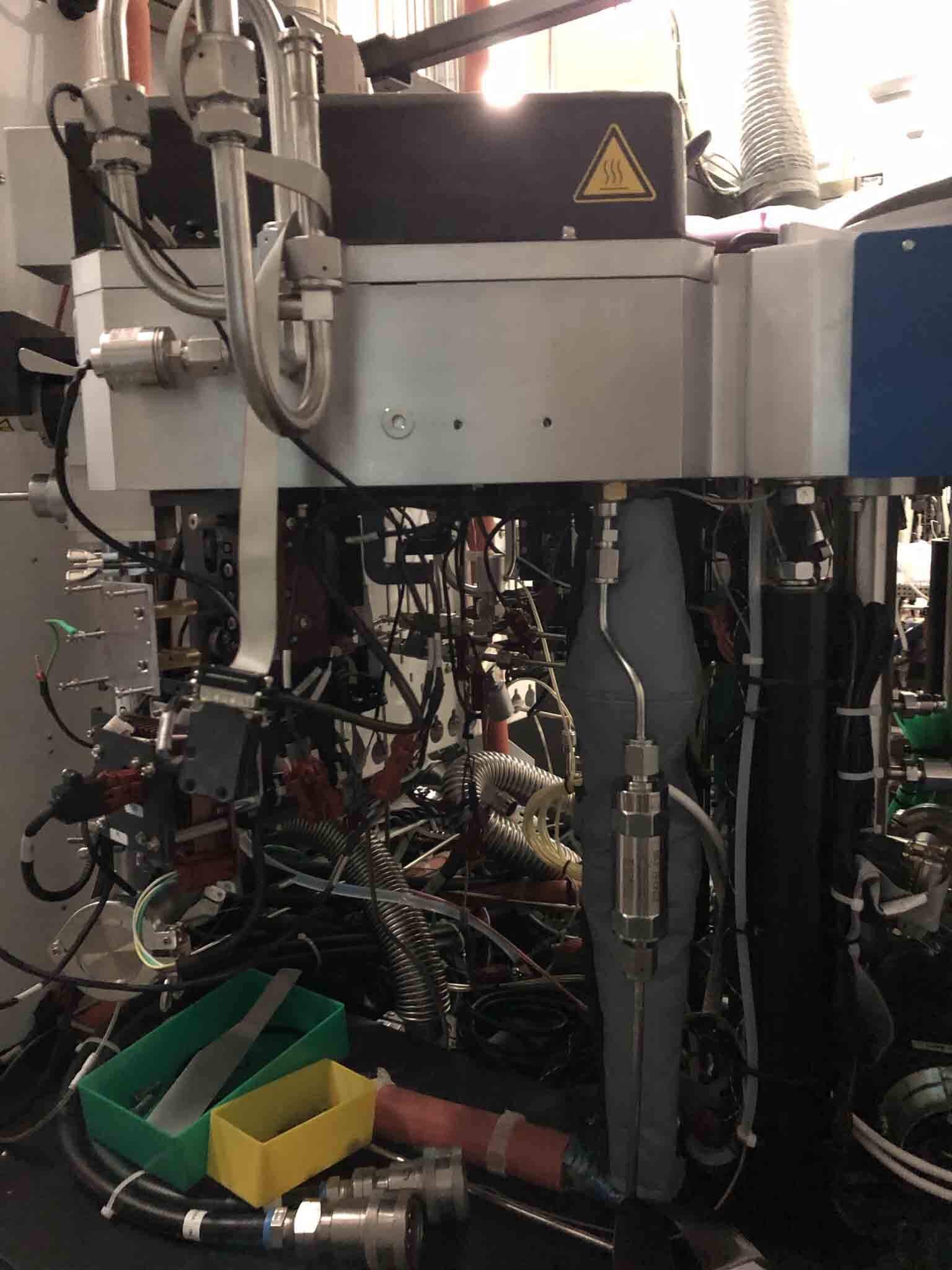

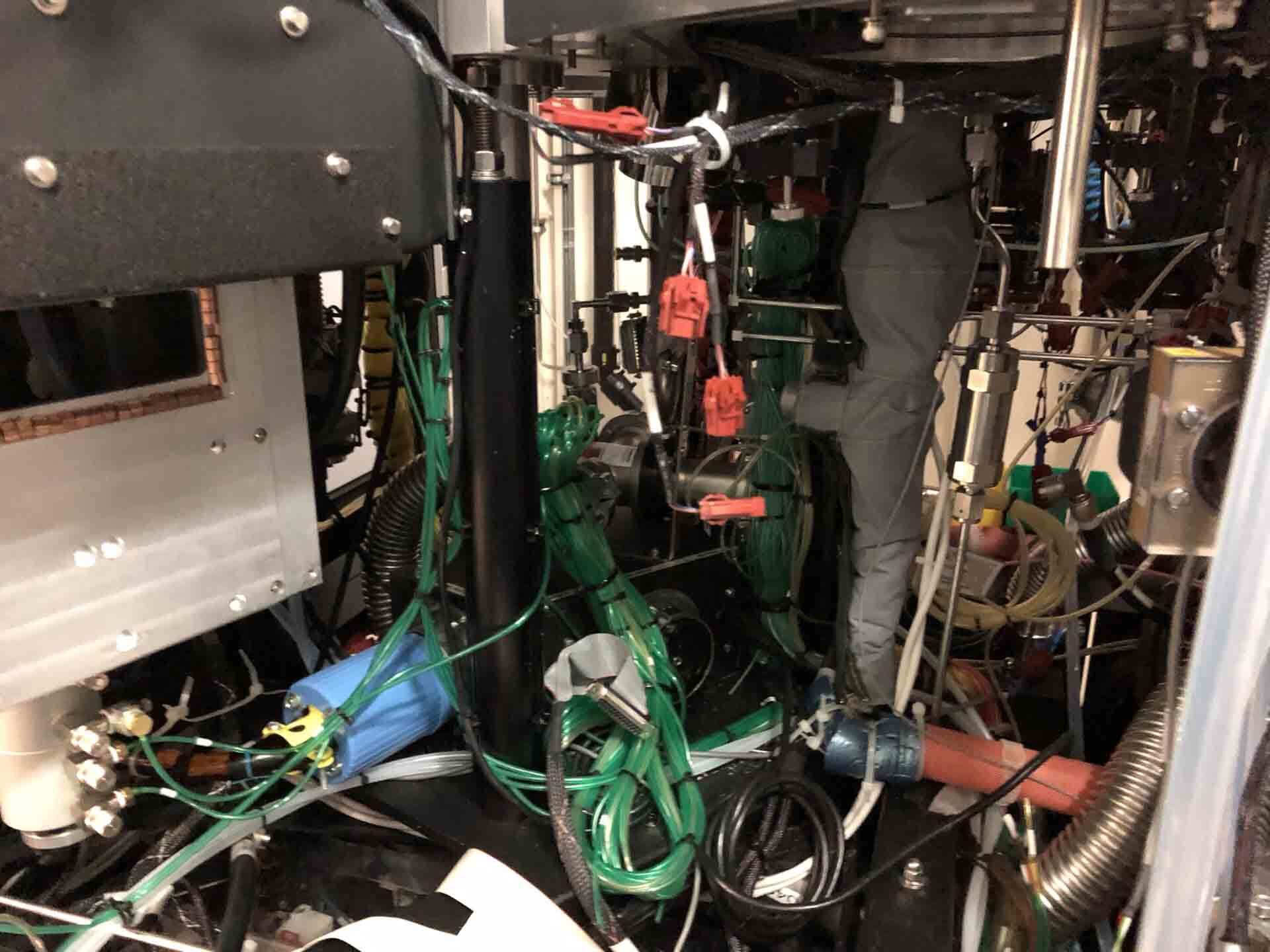

Used AMAT / APPLIED MATERIALS P5000 #293594320 for sale

URL successfully copied!

Tap to zoom

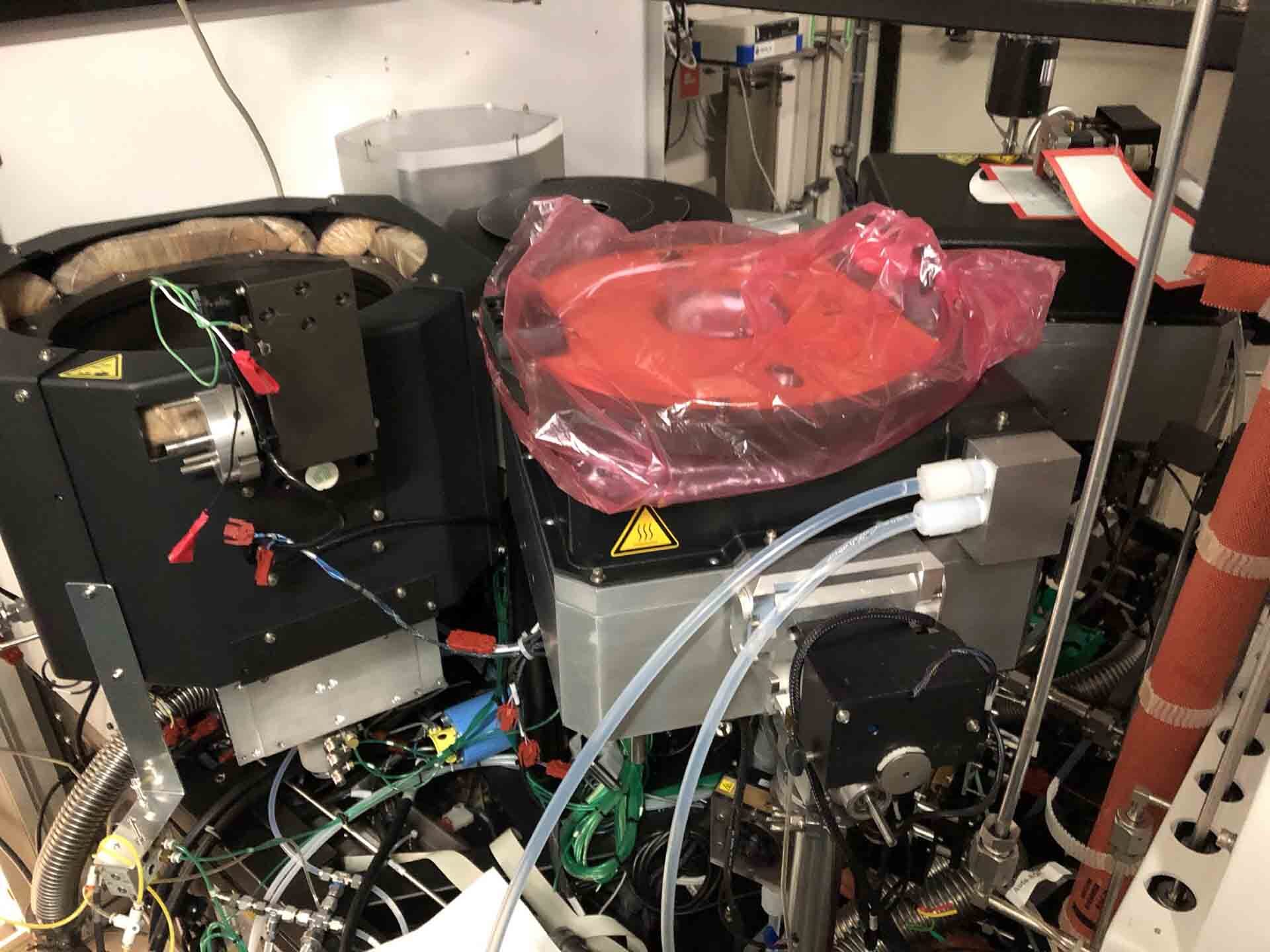

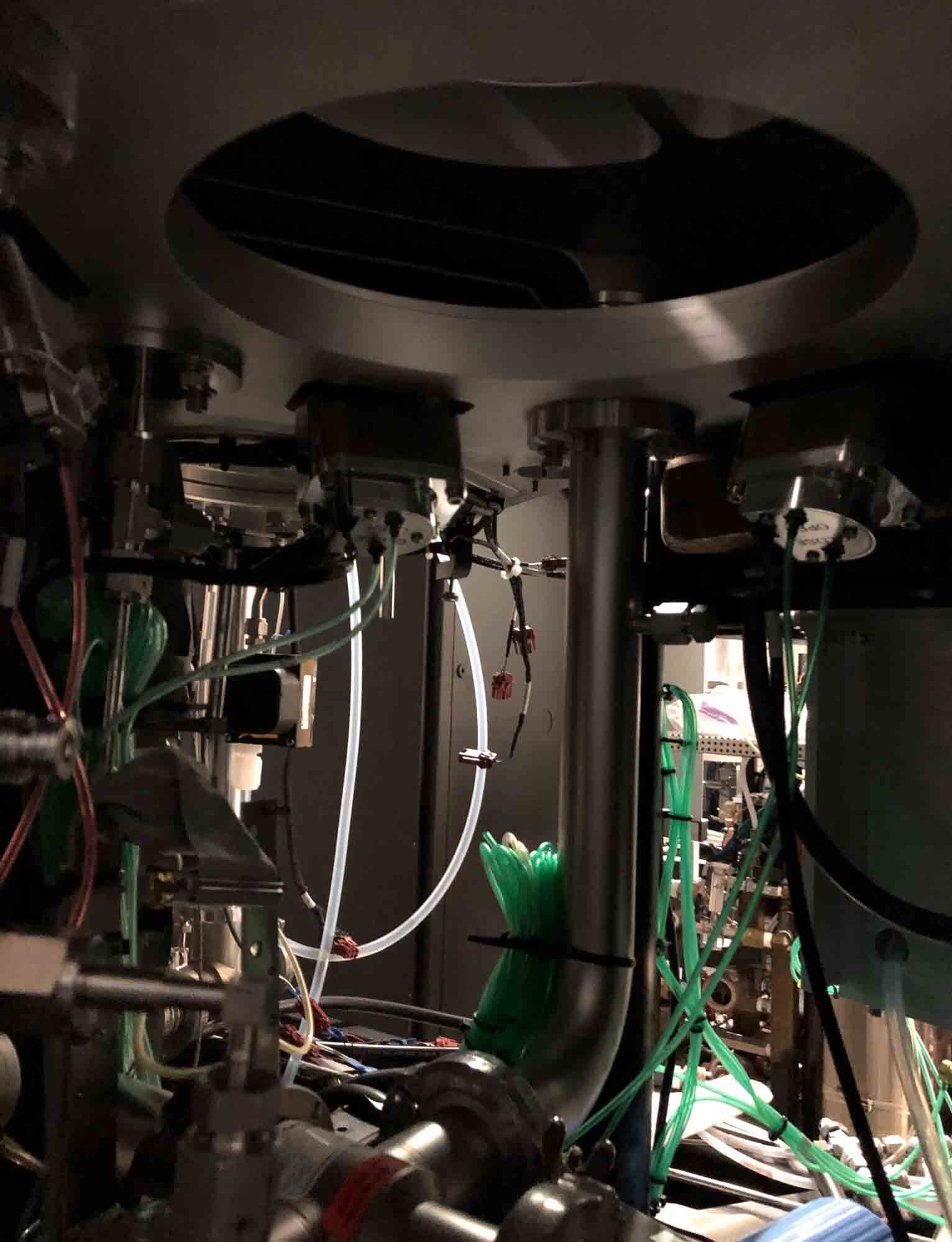

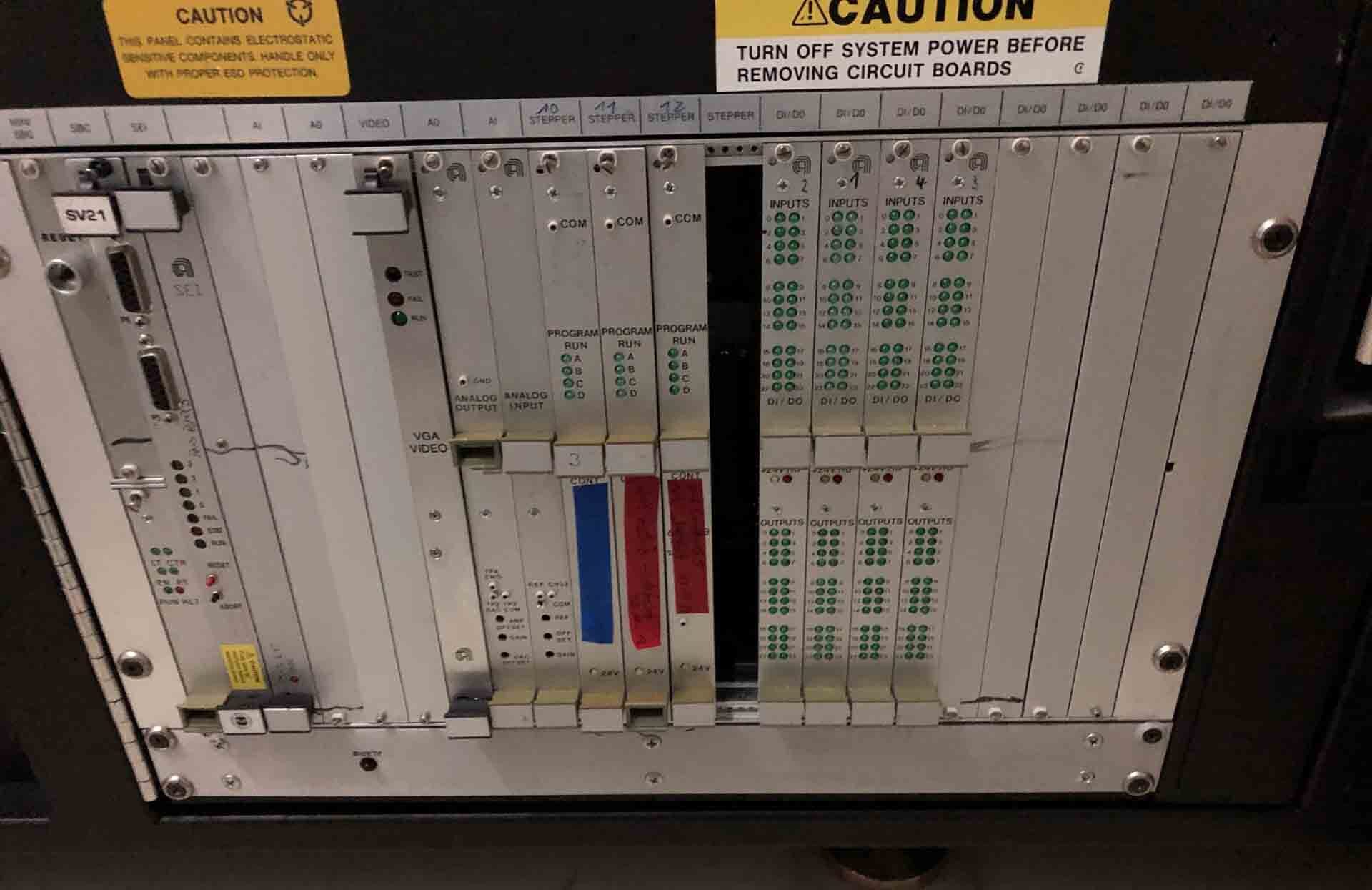

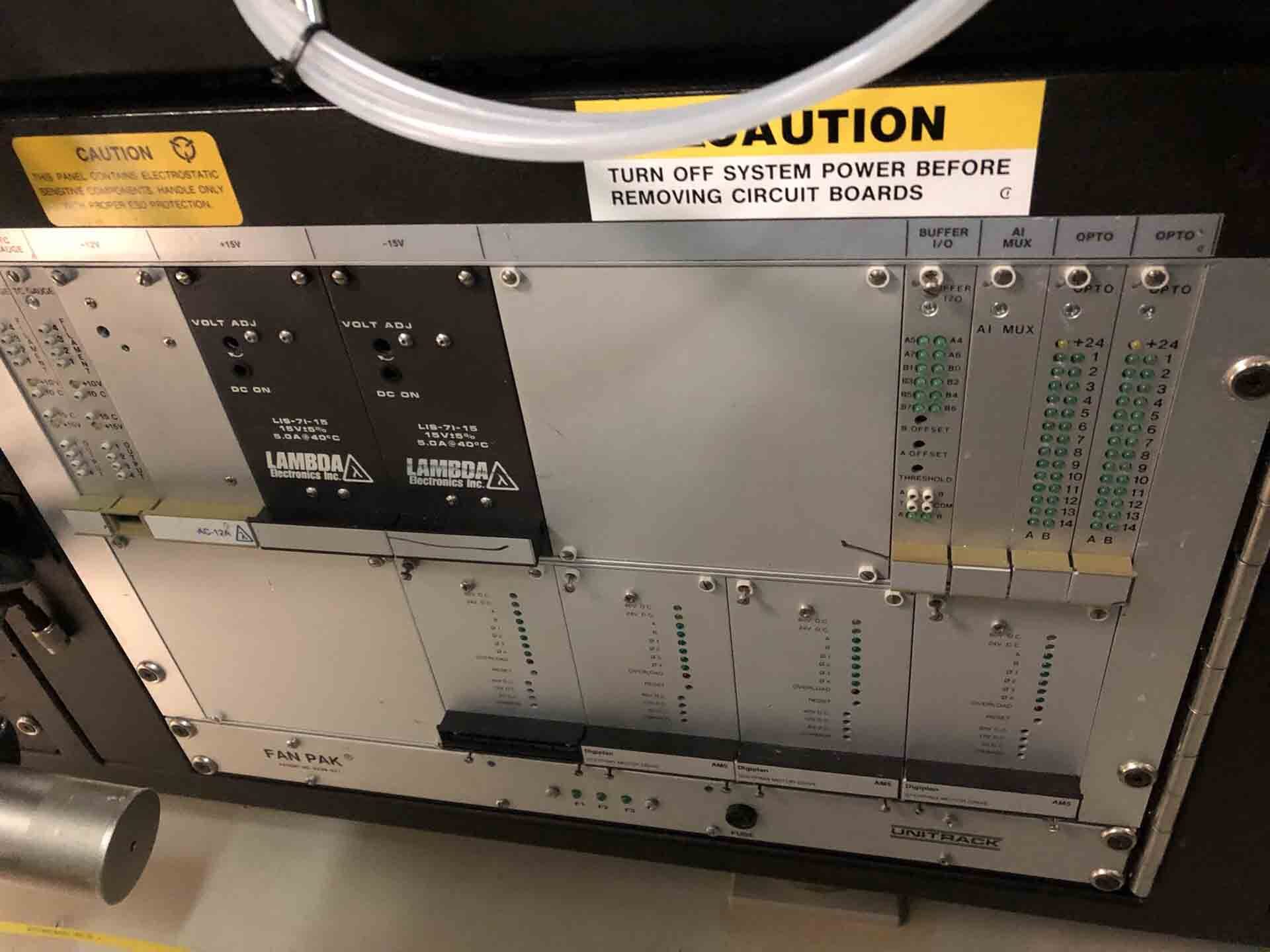

AMAT / APPLIED MATERIALS P5000 is a production scale reactor designed to provide a highly consistent and repeatable fabrication environment to process a wide range of materials. Its features, including a 200mm chamber with a five-wafer batch loading capability, make it an attractive choice for semiconductor process control. Its construction includes an optical window assembly, which houses a large, flat quartz window connected to the 200mm chamber. This window allows for better optical analysis and provides a means of inspecting process wafers before and after processing. Additionally, AMAT P-5000 has an integrated temperature control module. This module utilizes a combination of crucible, filament, and wafer temperature monitoring, as well as precision heater control for process consistency. The temperature control module can also be used to control and maintain the temperature of the reactor chamber. The power train added to APPLIED MATERIALS P 5000 allows for precise control of many process parameters, such as pressure, particle size, flow rate, and mixing. It also combines a resistive heating element to provide precise and repeatable heat input to the reactor chamber, as well as a programmable power station to facilitate loading and unloading of wafers. P-5000 utilizes a helium-based purge system to maintain a clean, contaminant-free environment in the reactor chamber. Its computer-controlled circulation system prevents both wafer contamination and the formation of a "shadow" on the wafer surface. For additional cleanliness, AMAT / APPLIED MATERIALS P-5000 can be vacuum loaded with an upstream controller and scrubbers. The positioner of AMAT P5000 uses a motion task program and a motion processor unit to allow for precise and repeatable positioning of the wafers. The positioner also works with the wafer observation ports of the optical window assembly for further optical analysis. APPLIED MATERIALS P-5000 reactor is an extremely versatile system, capable of performing a variety of processes in a reliable, reproducible environment. Its repeatable operation, along with its environmental control and positioner, make it a viable option for linear and non-linear scaling of device fabrication on the semiconductor industry.

There are no reviews yet