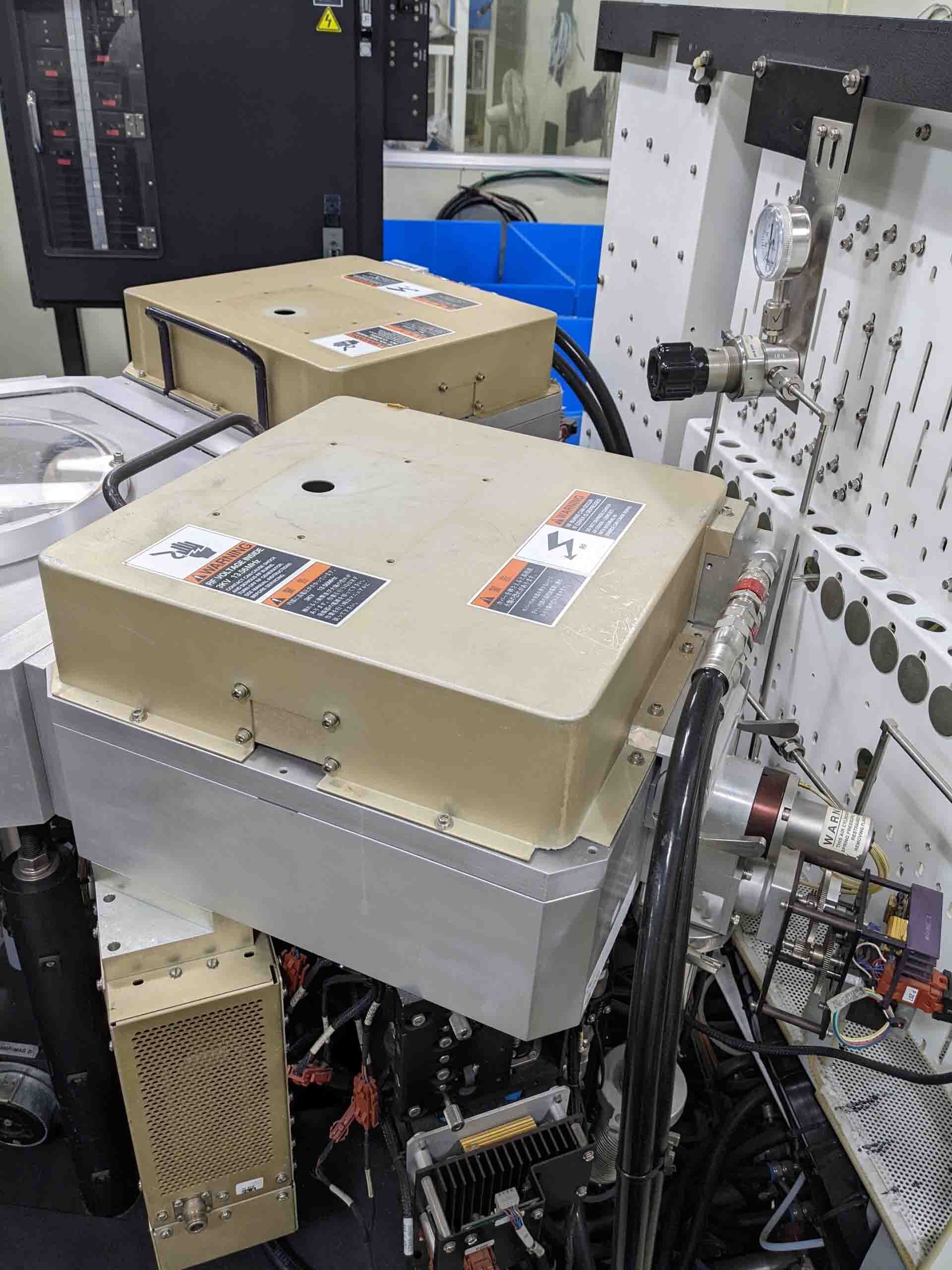

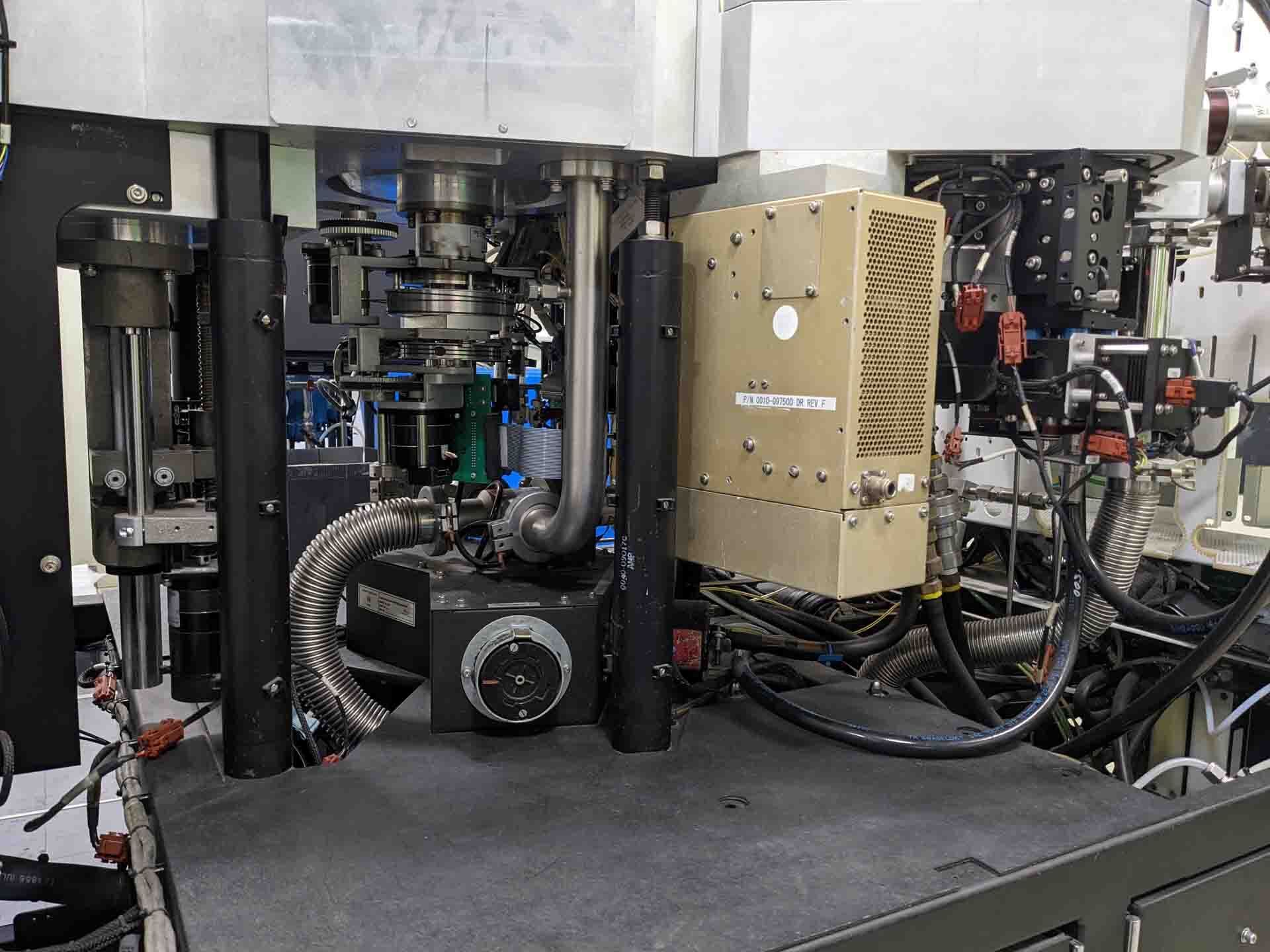

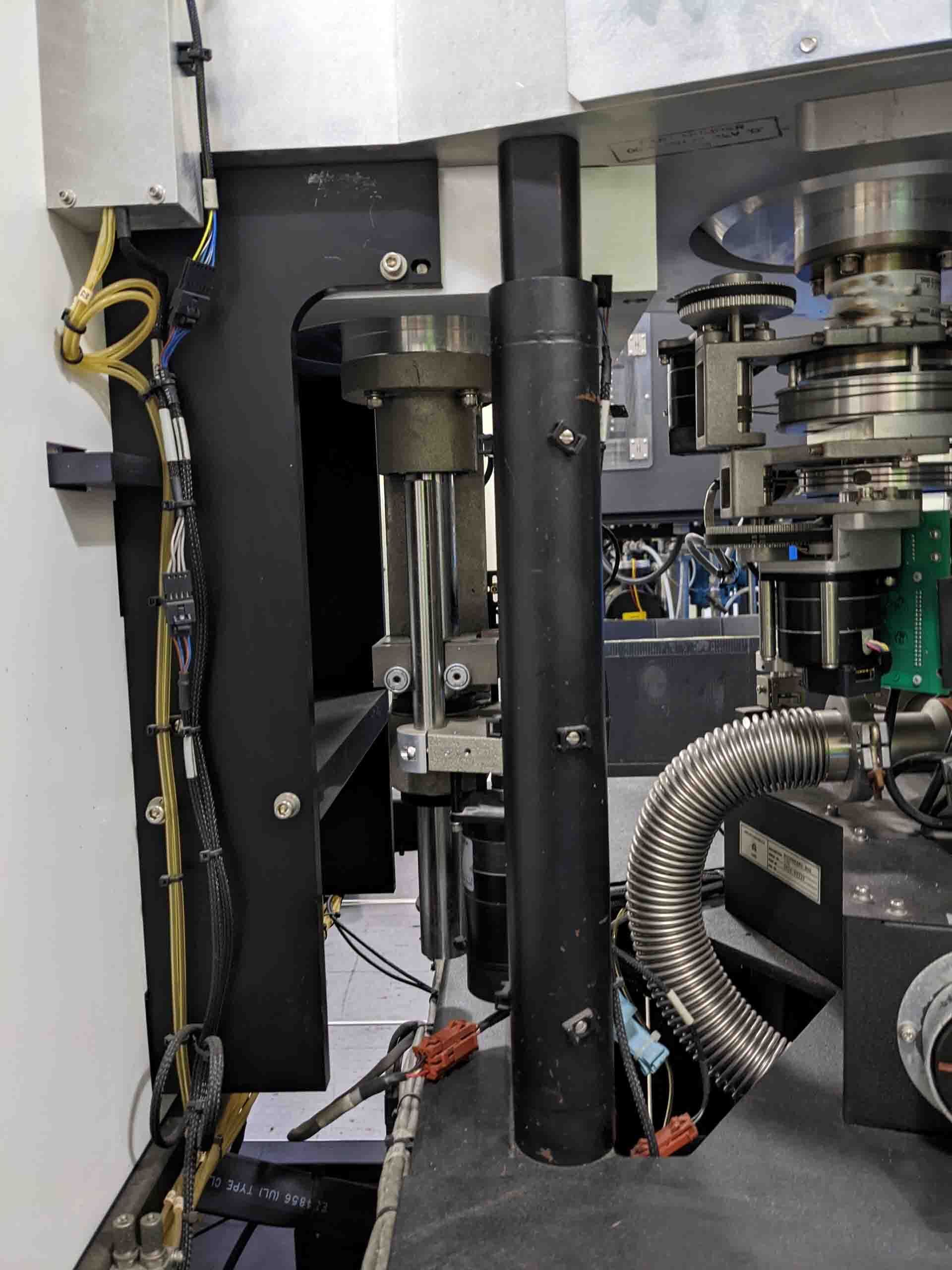

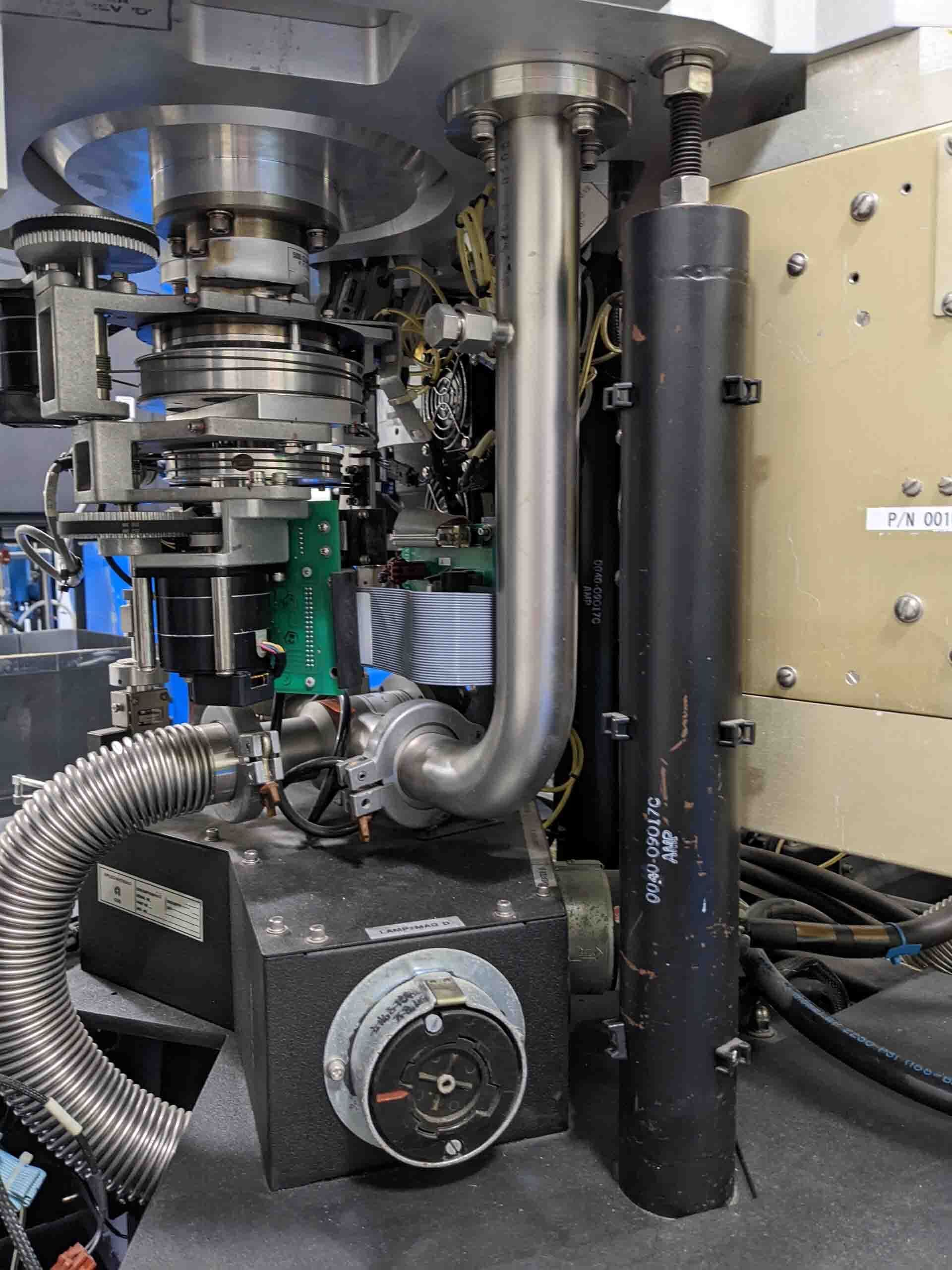

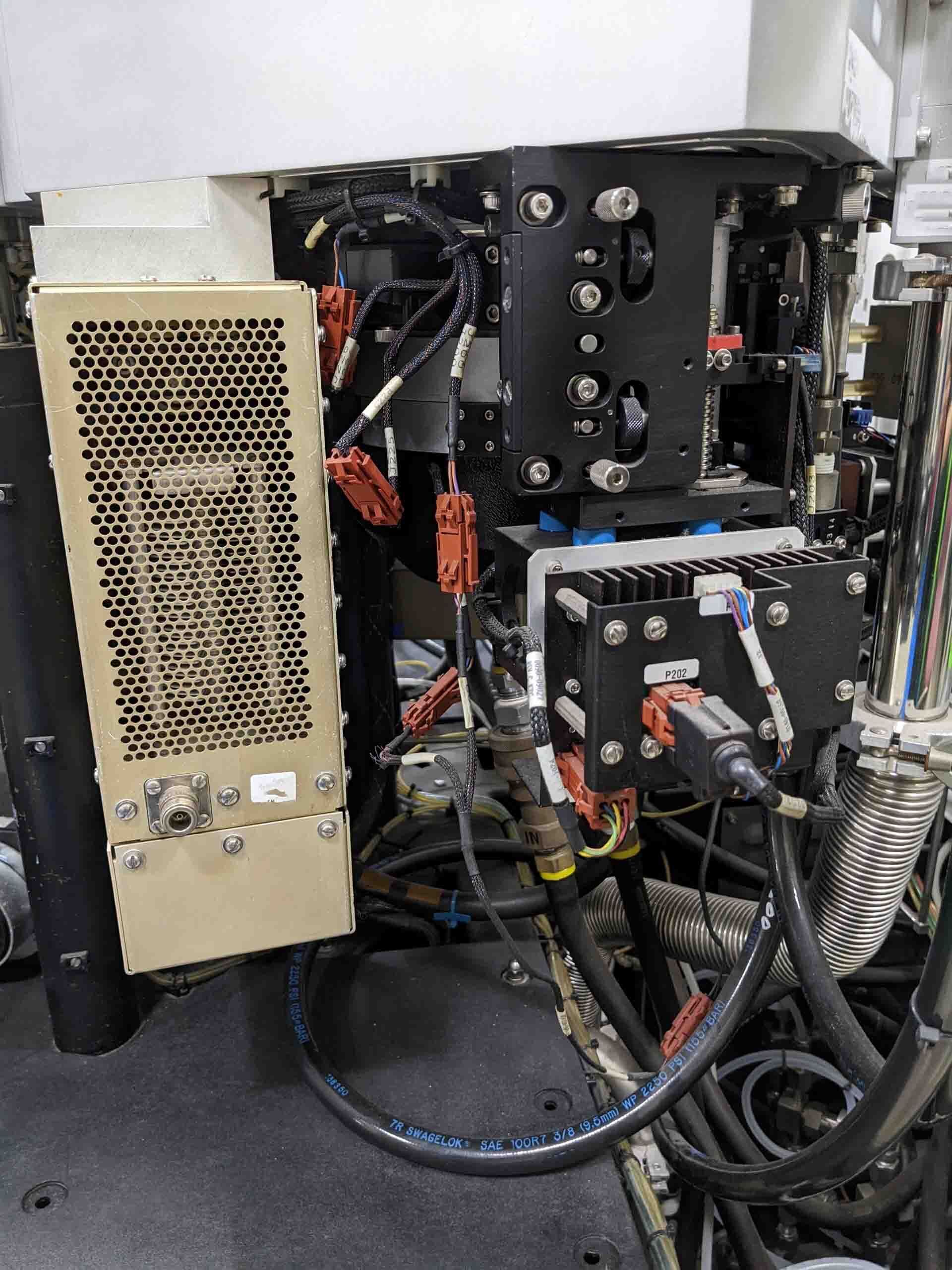

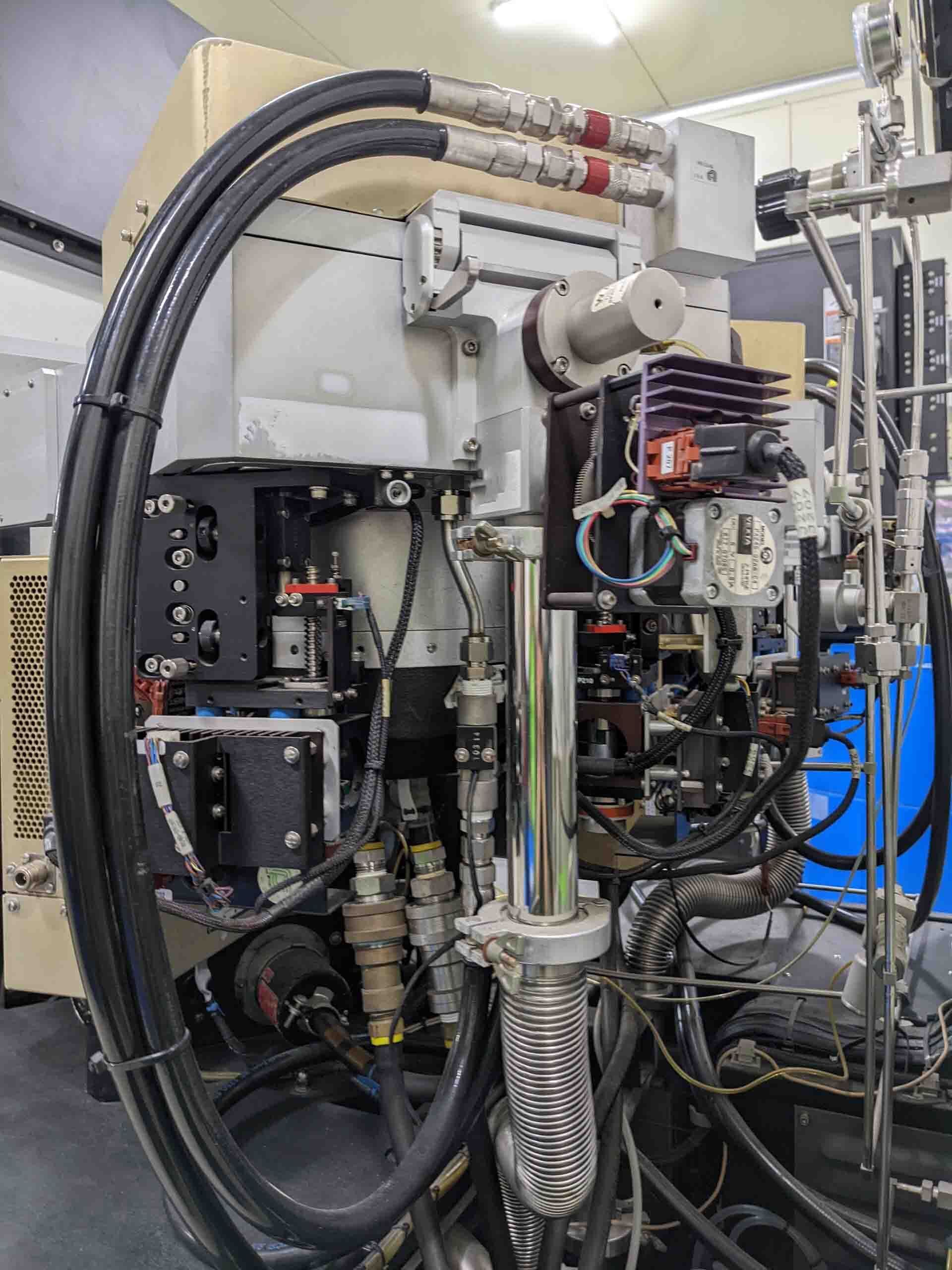

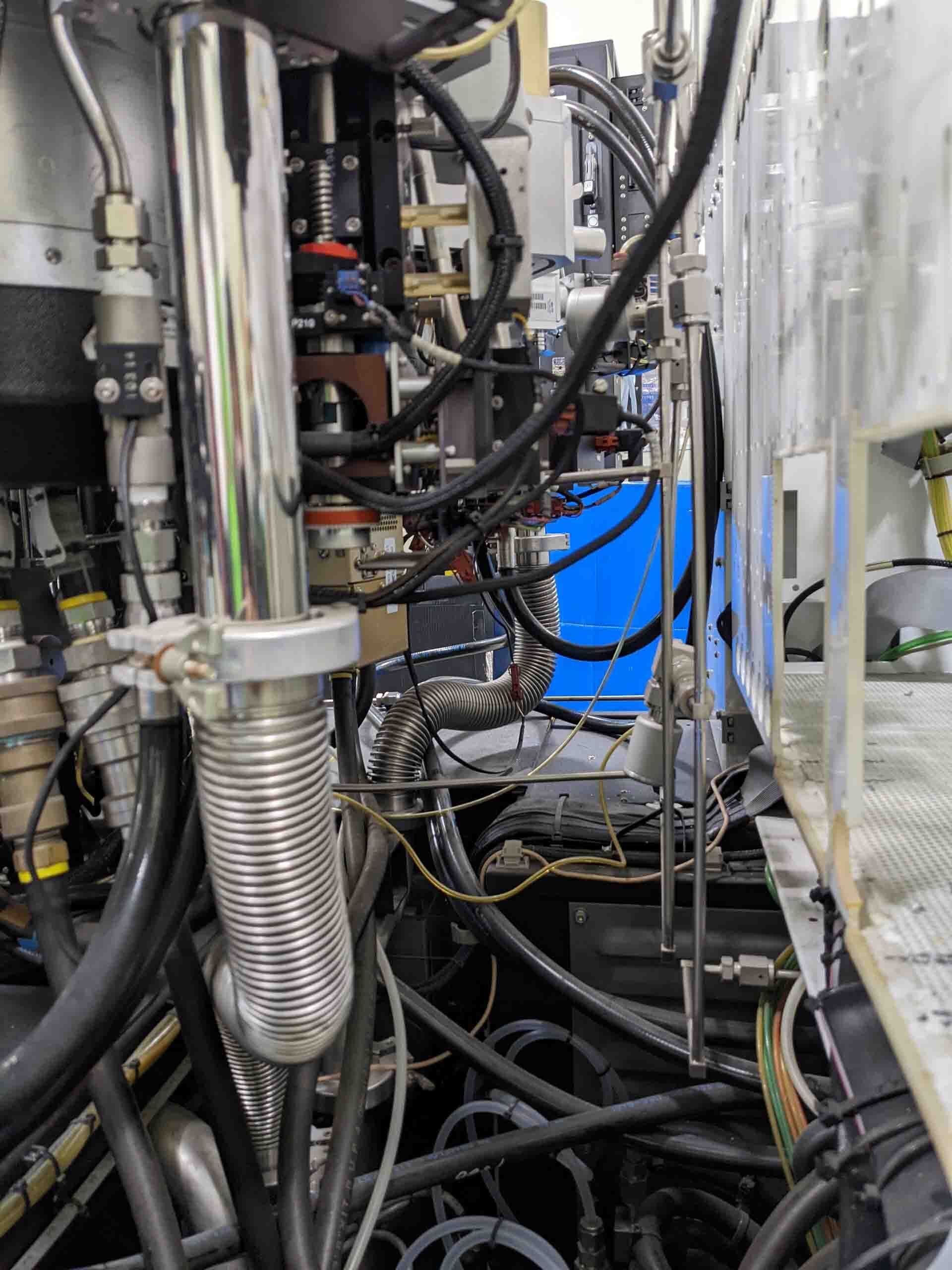

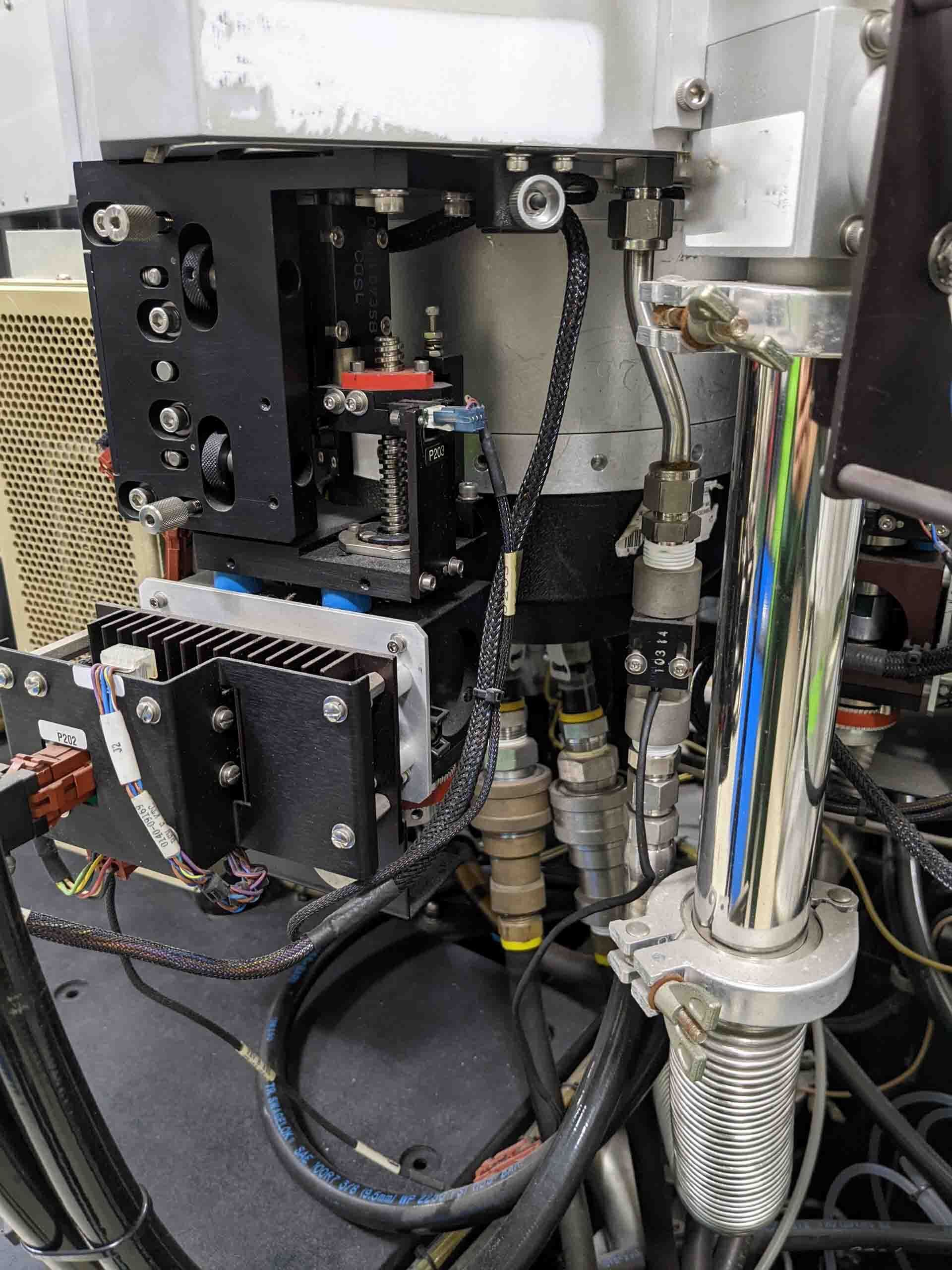

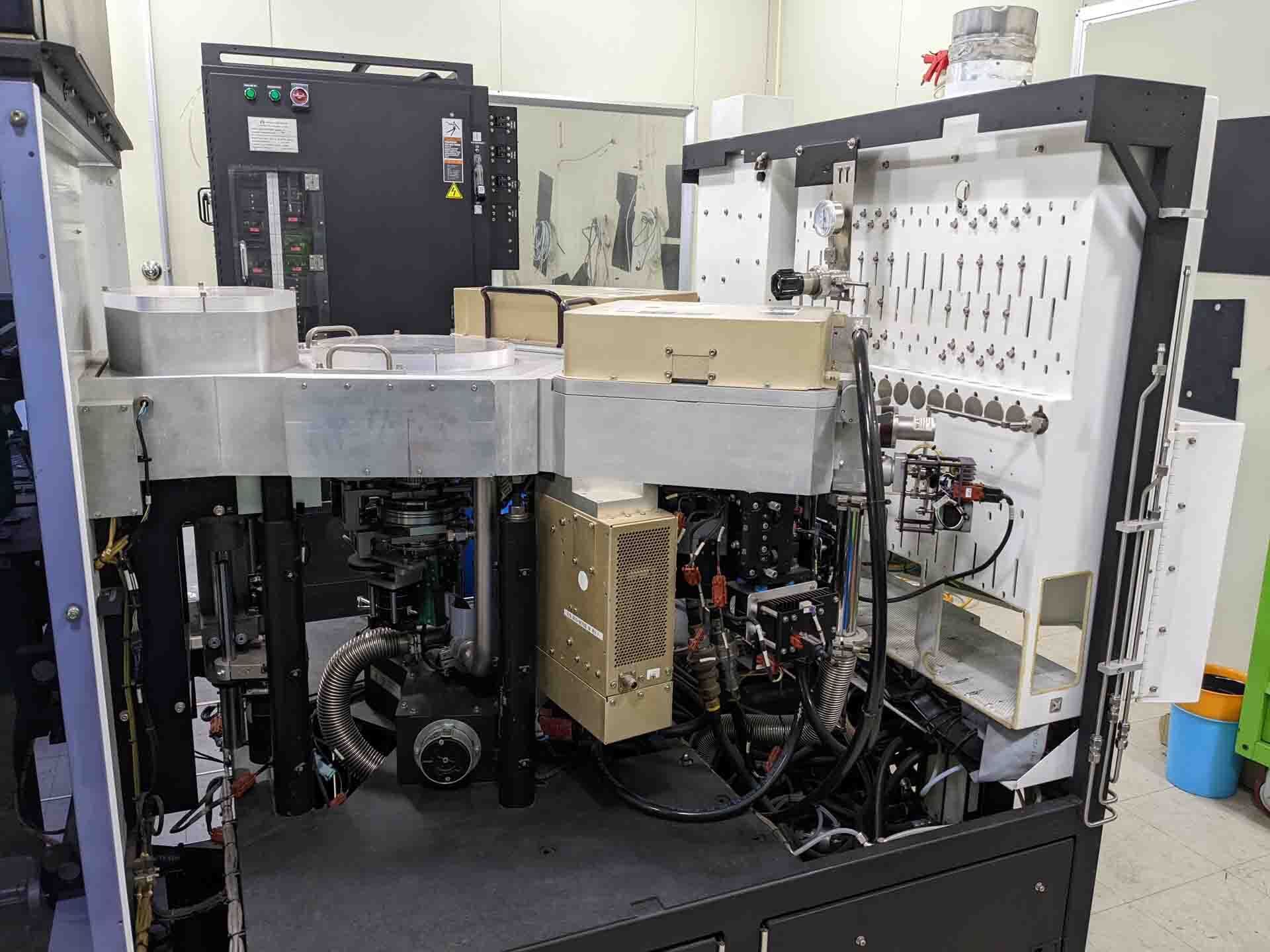

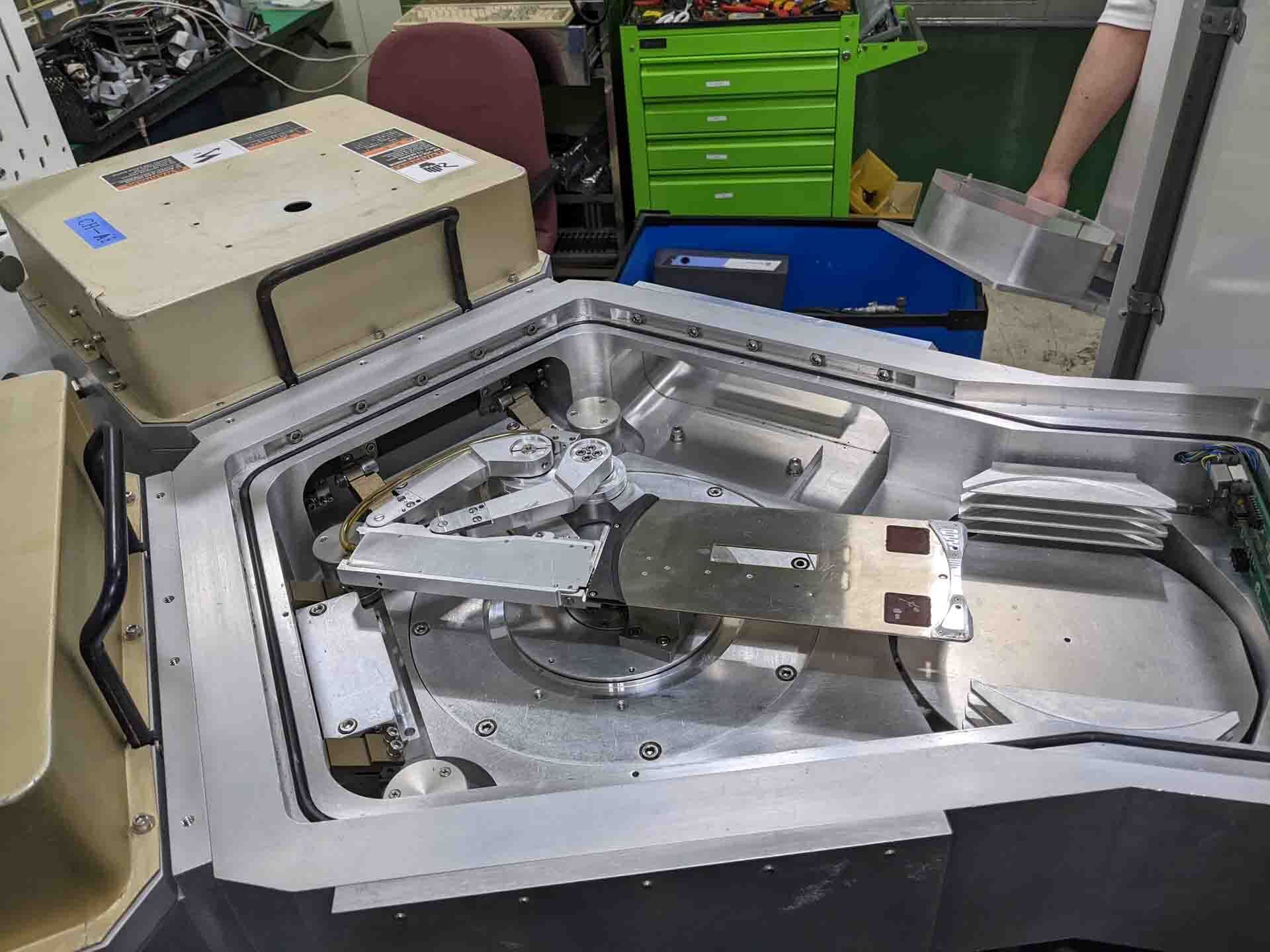

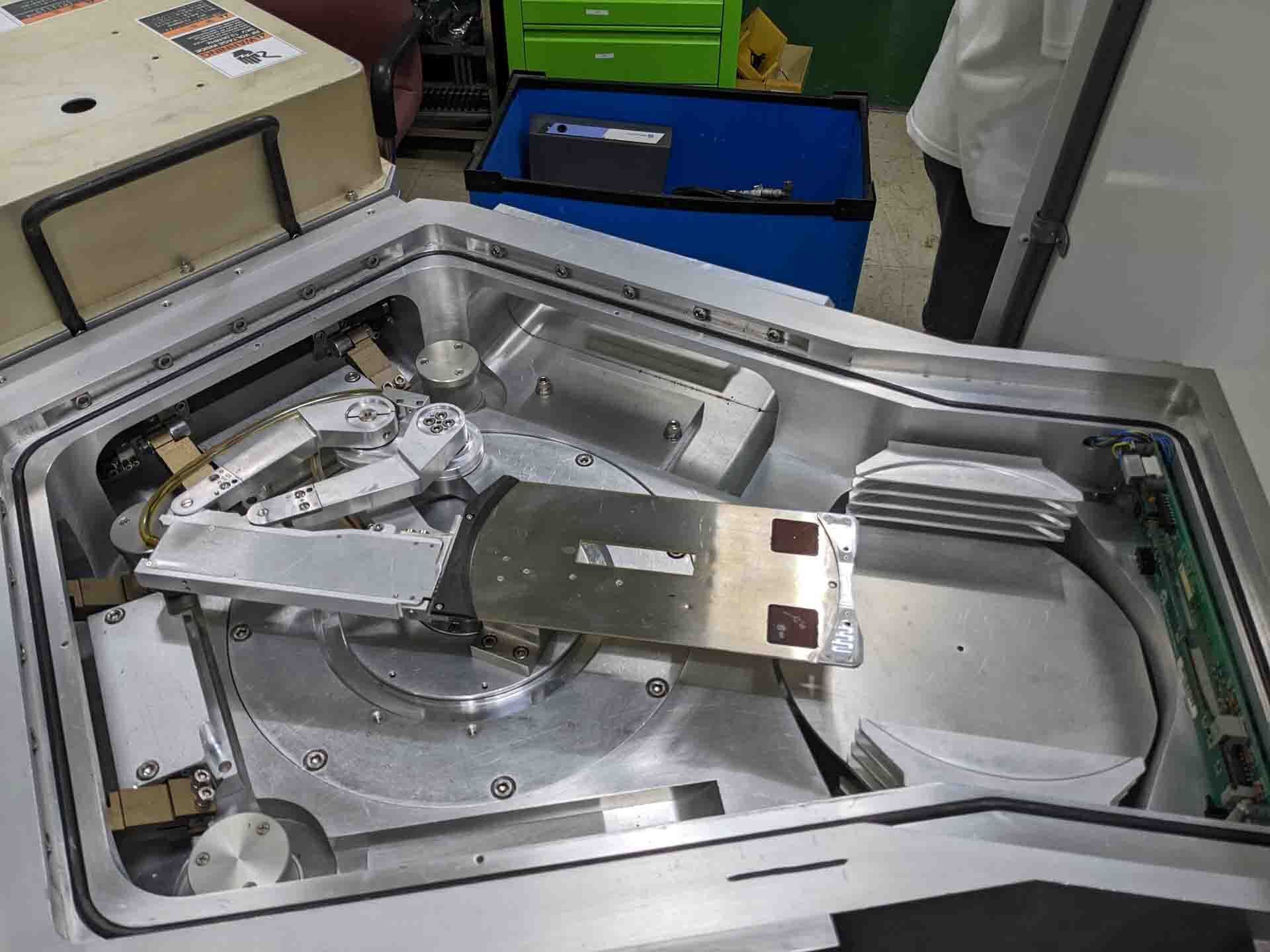

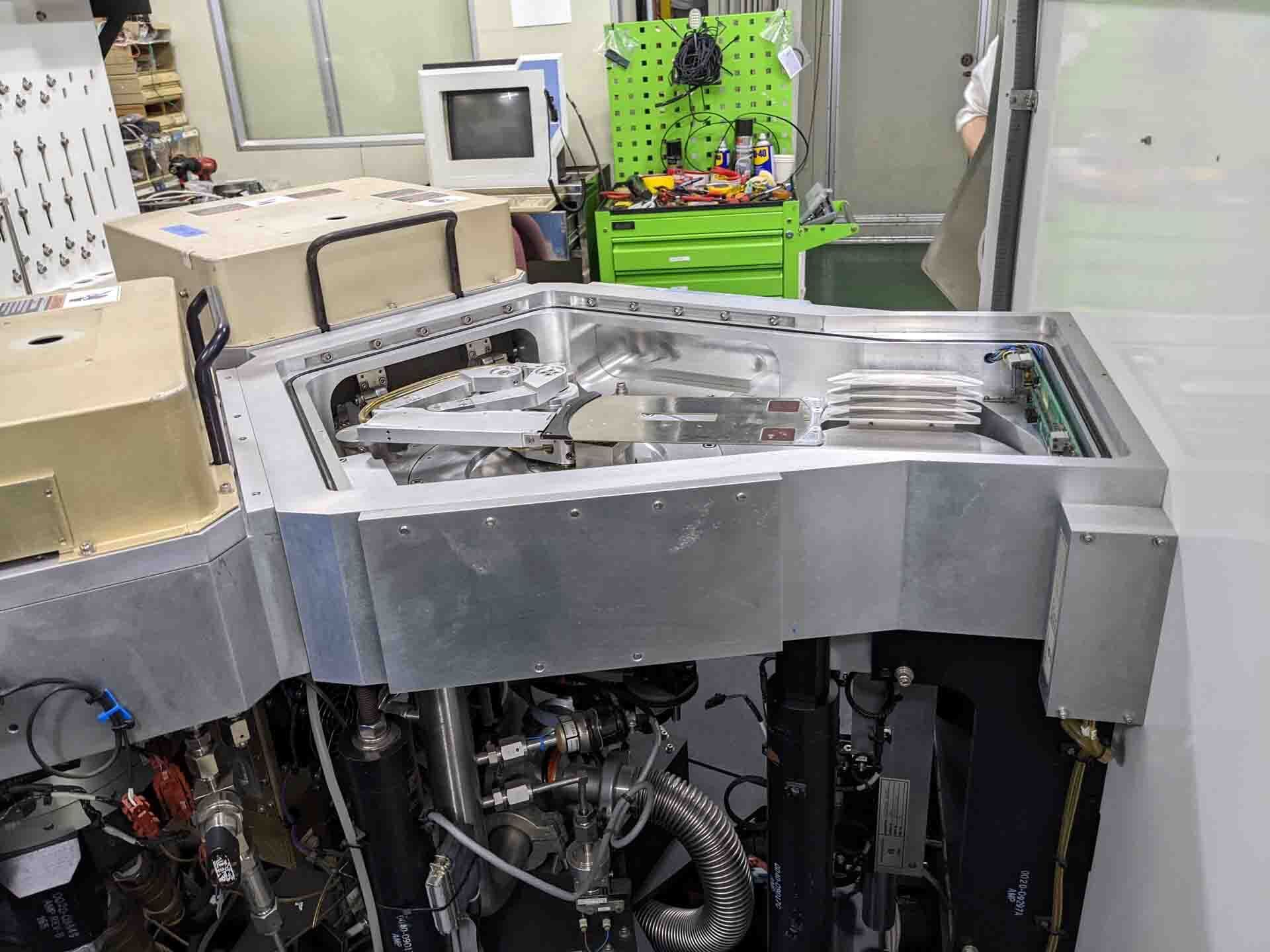

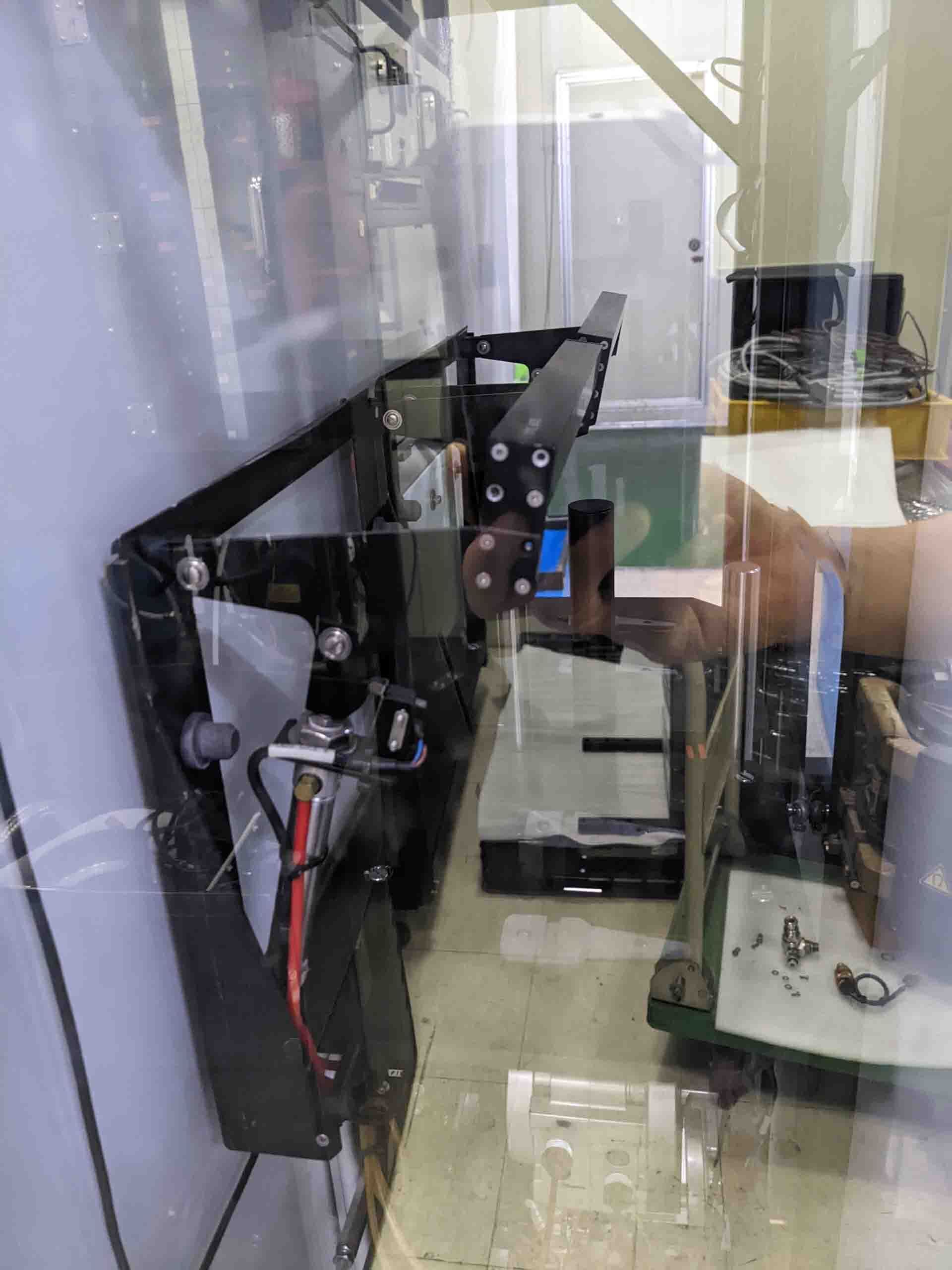

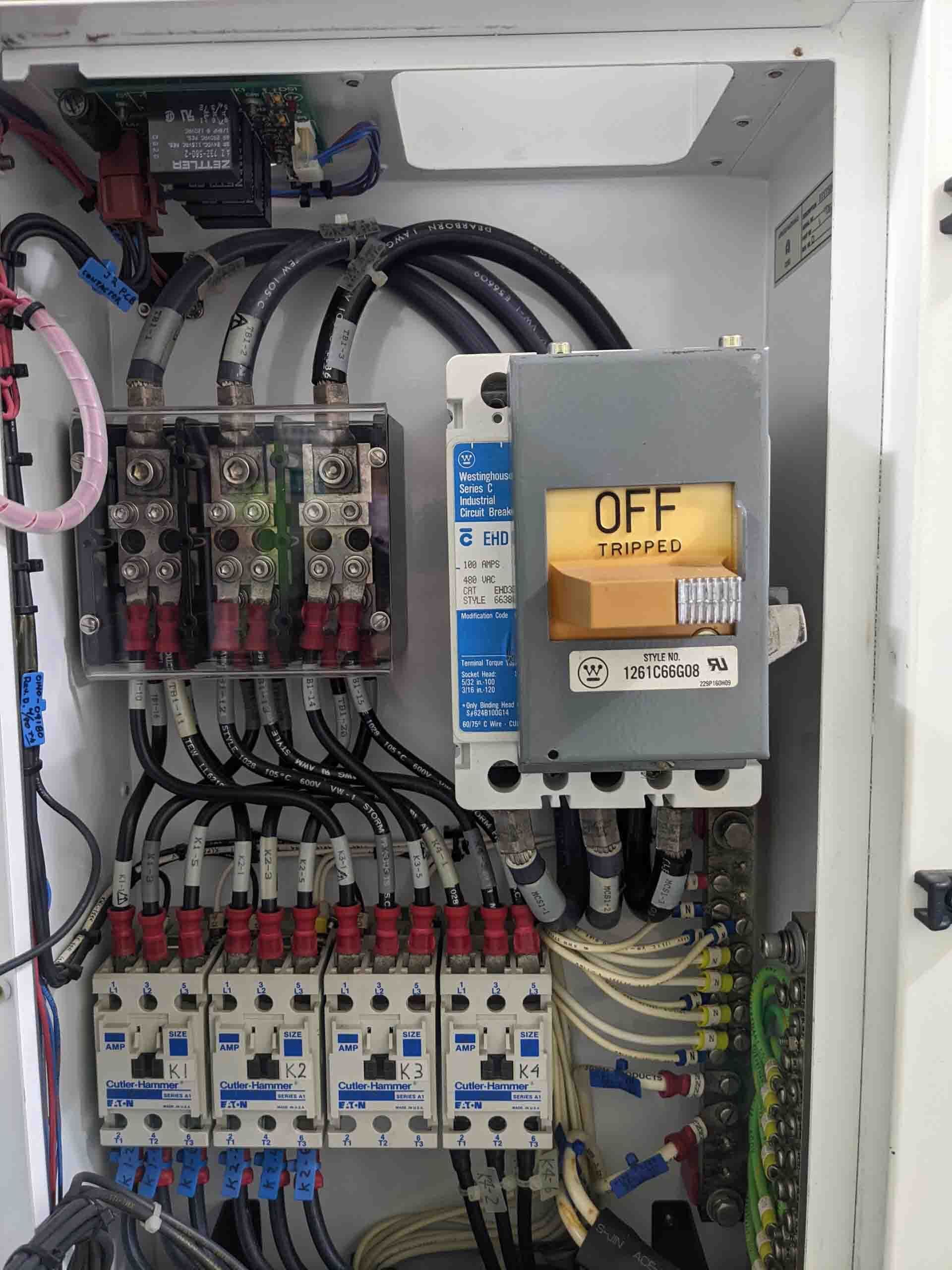

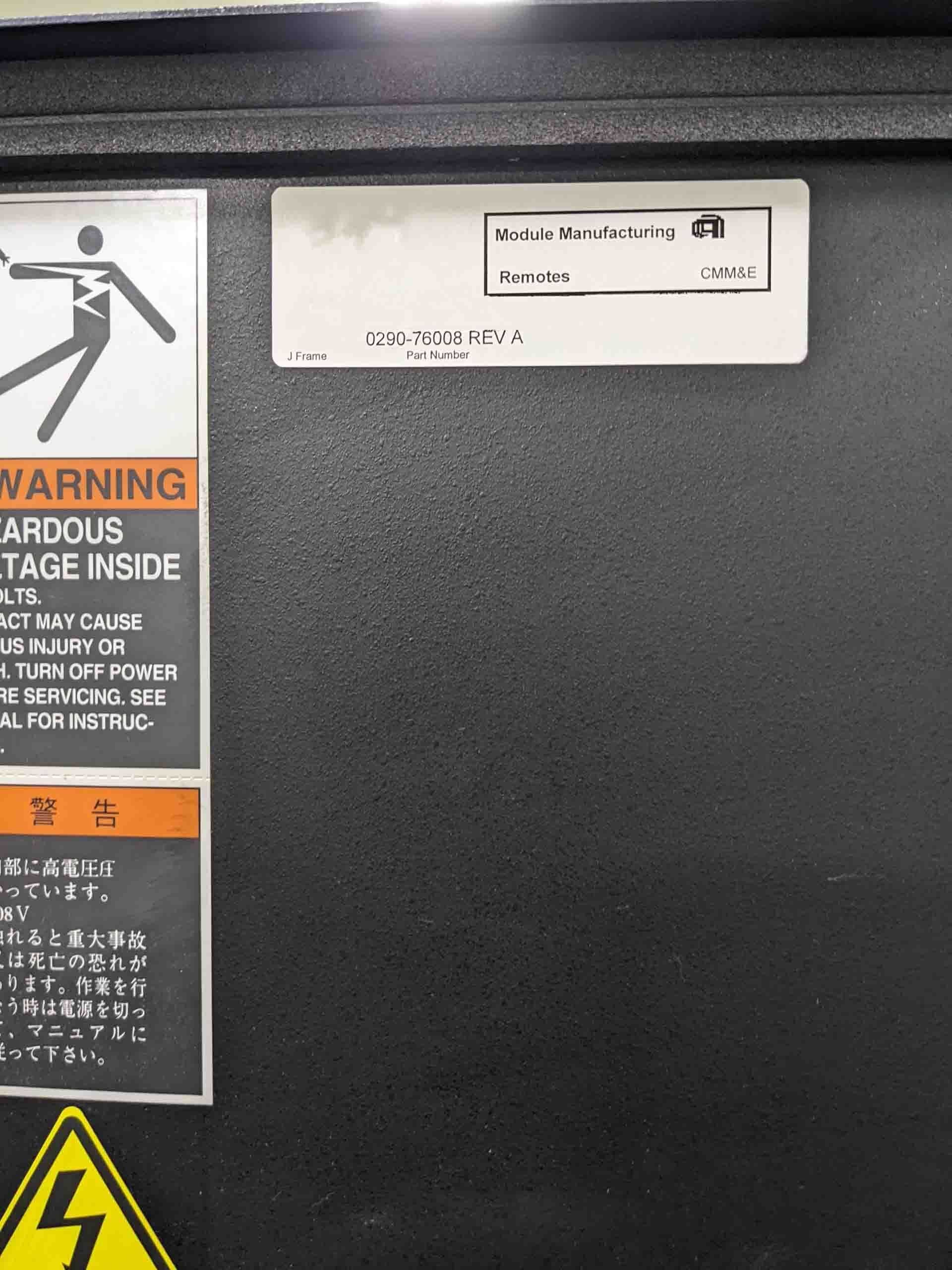

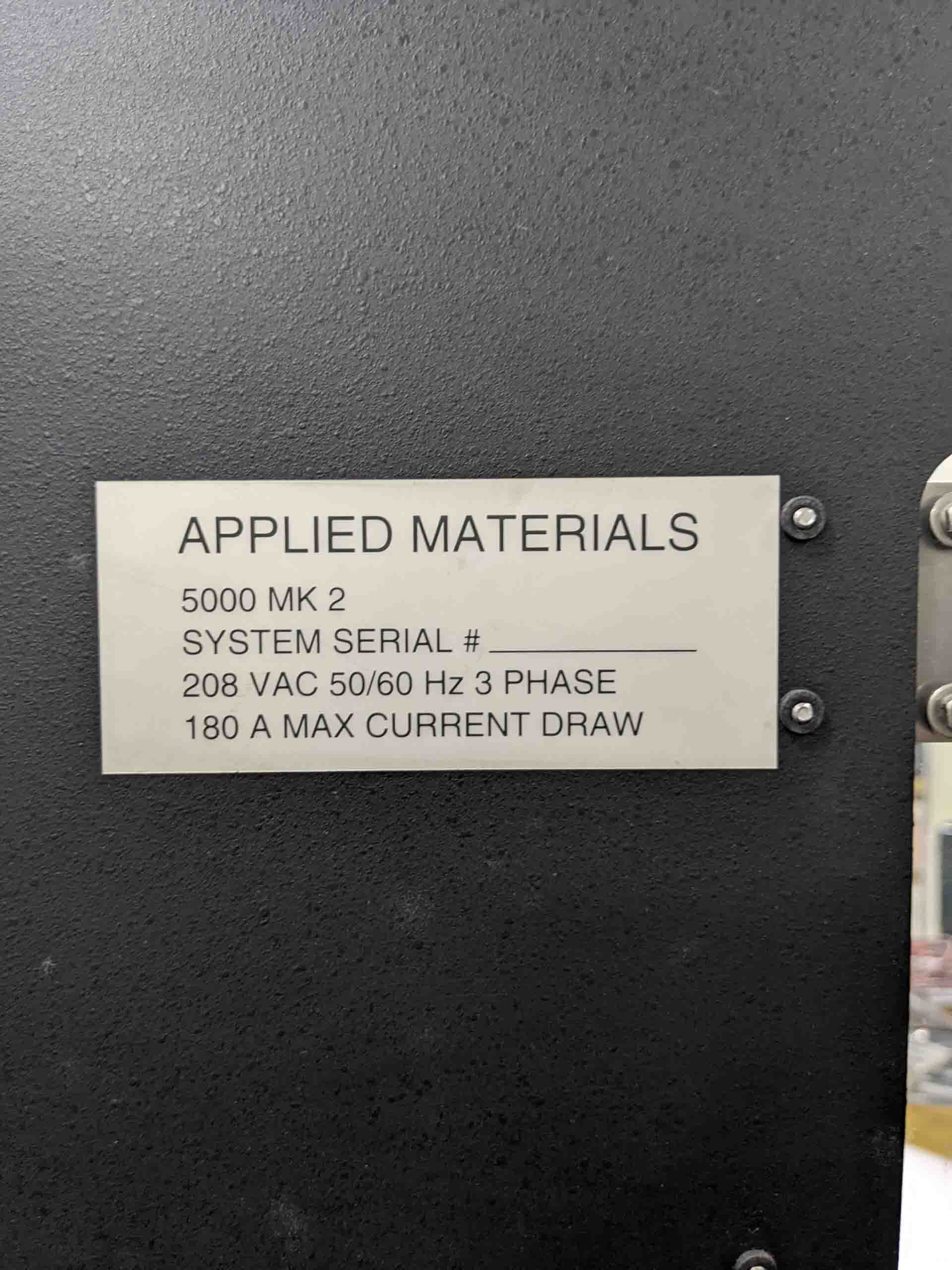

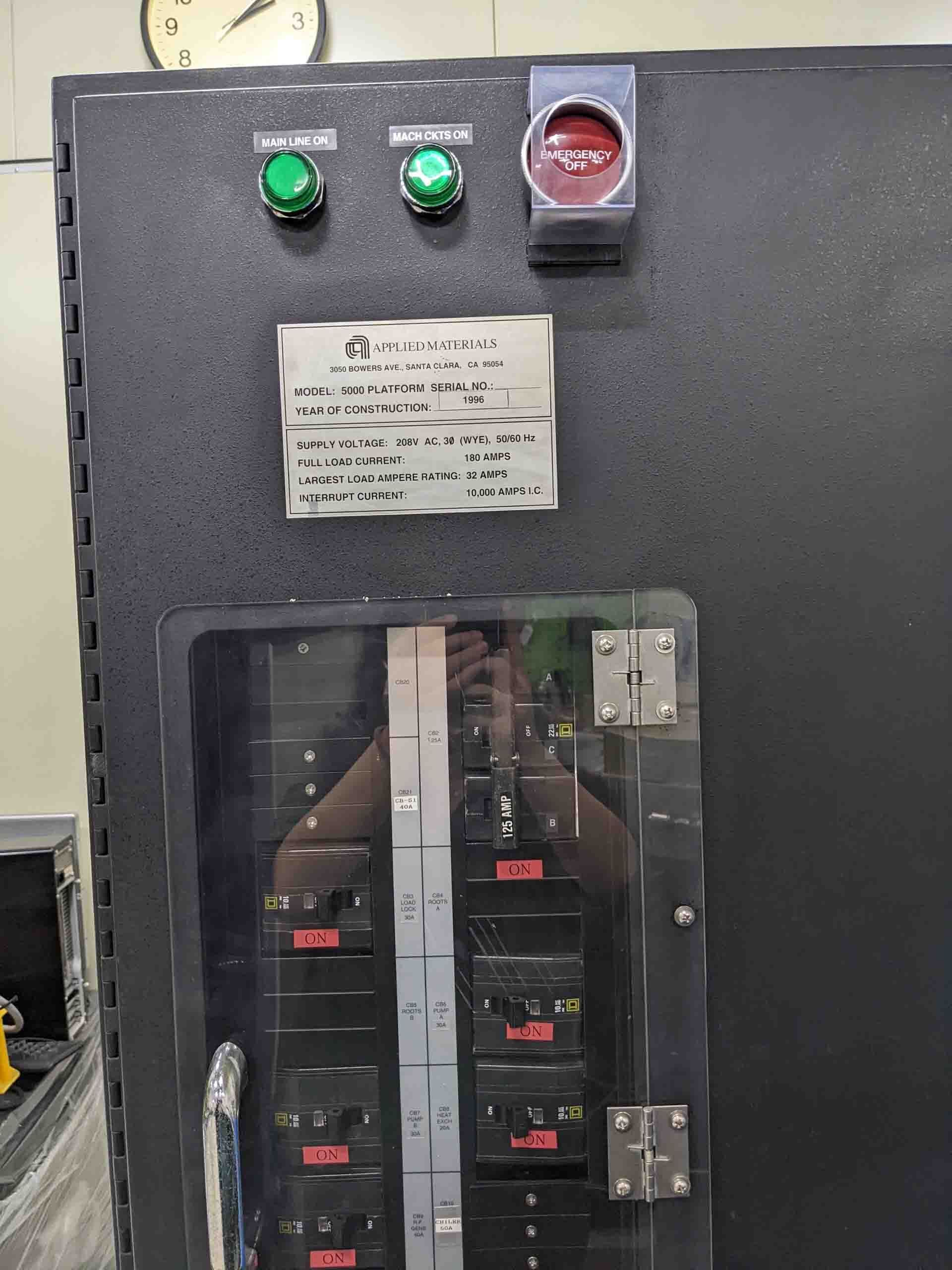

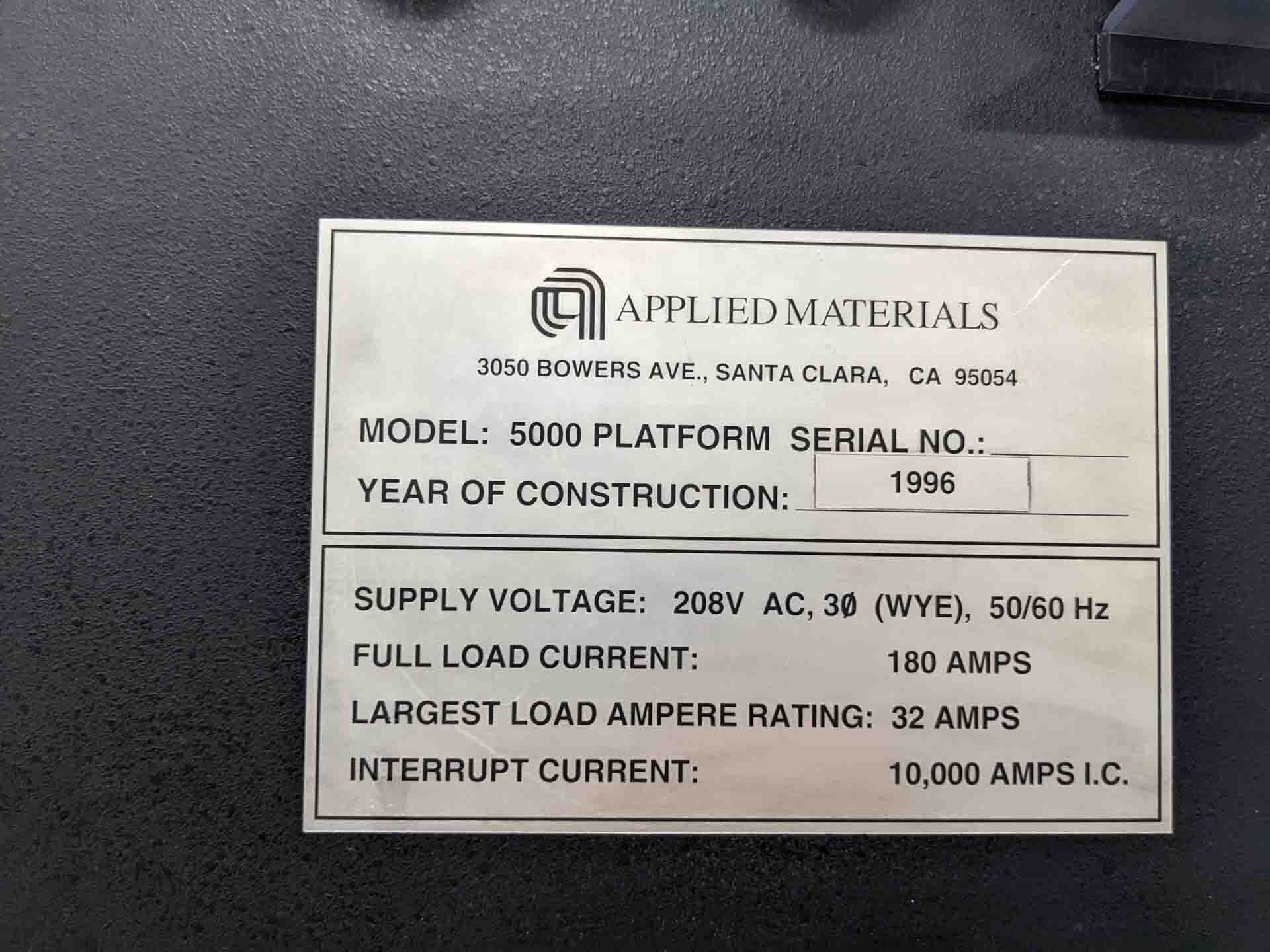

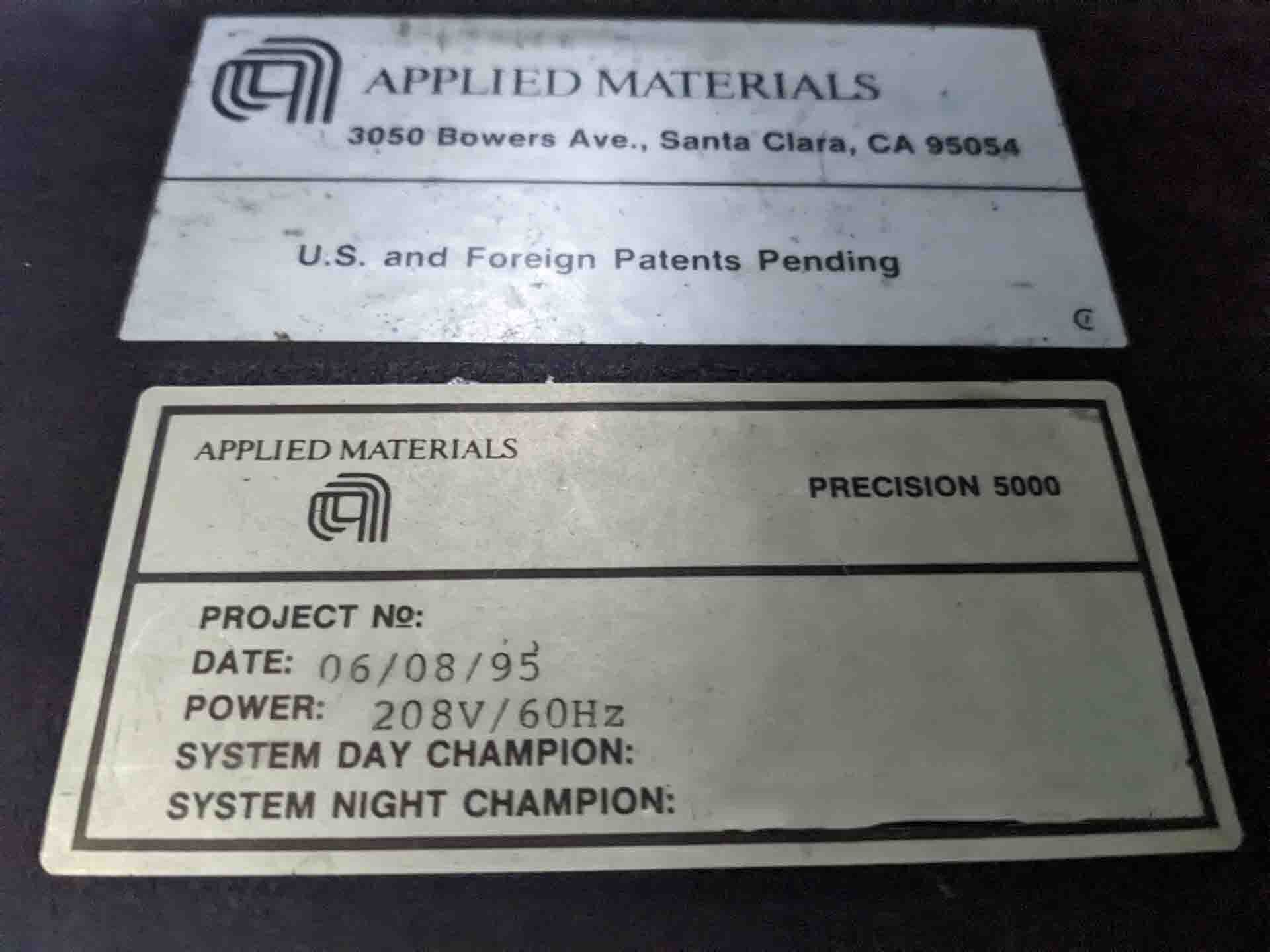

Used AMAT / APPLIED MATERIALS P5000 #293610620 for sale

URL successfully copied!

Tap to zoom

ID: 293610620

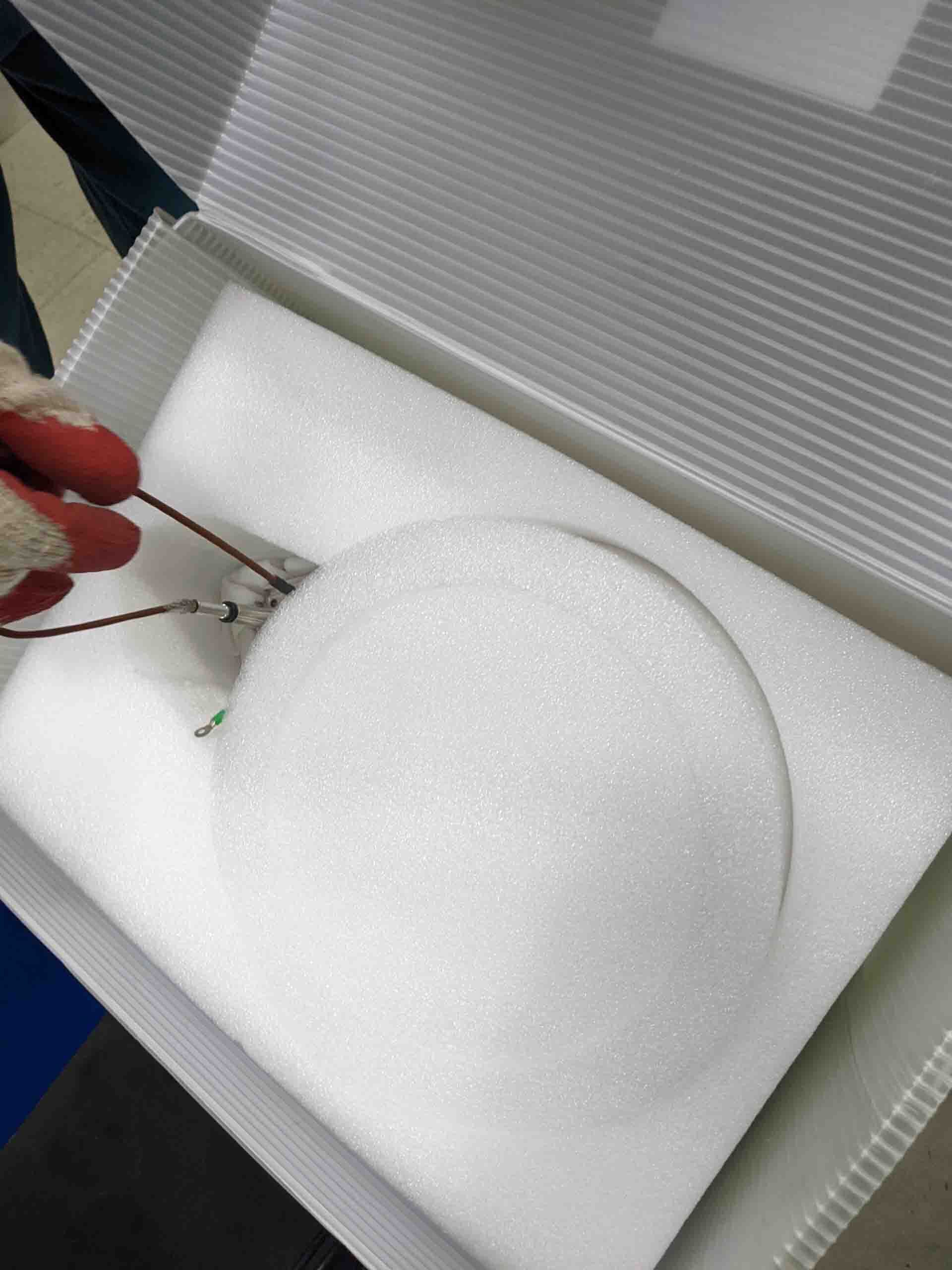

Wafer Size: 8"

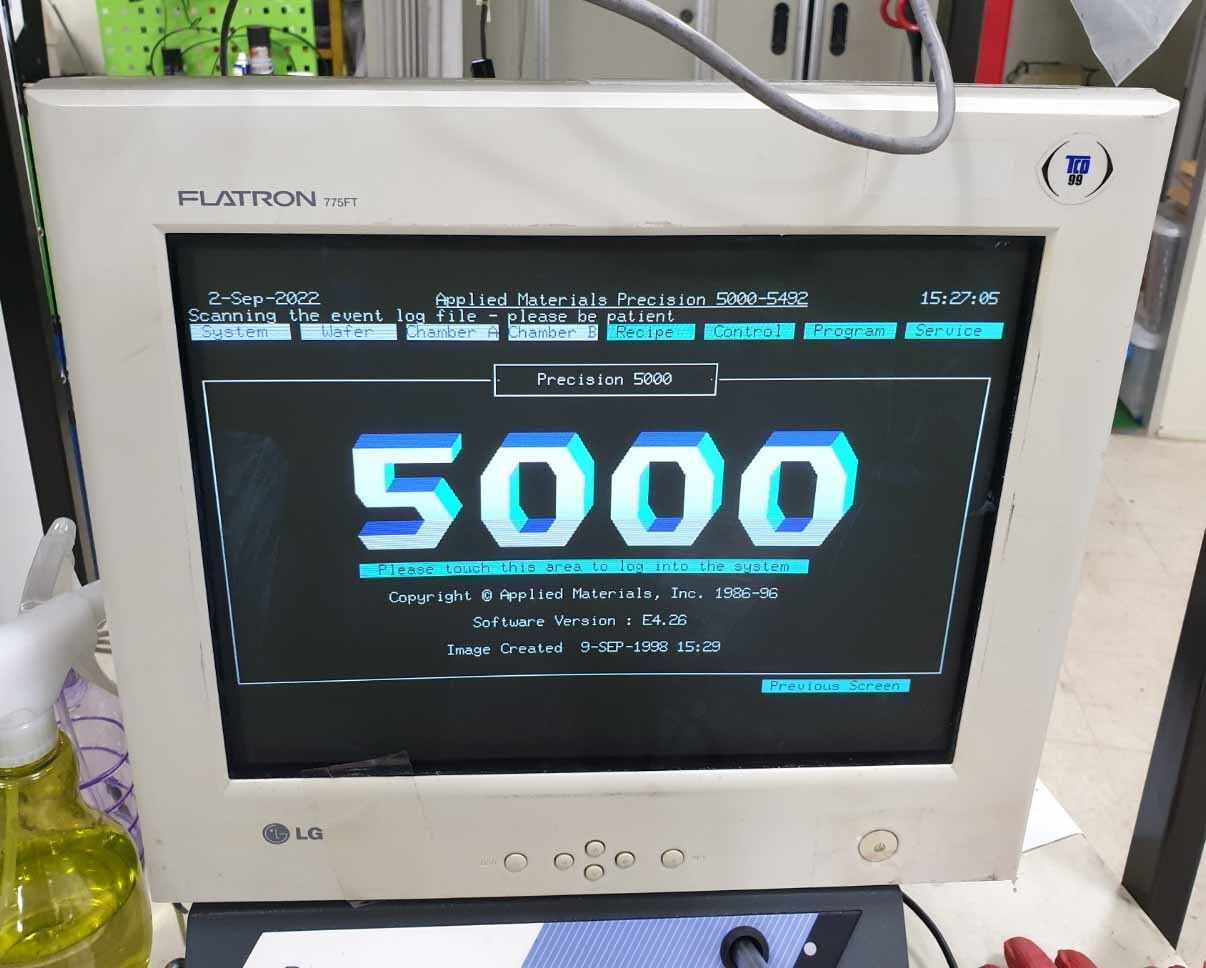

Vintage: 1995

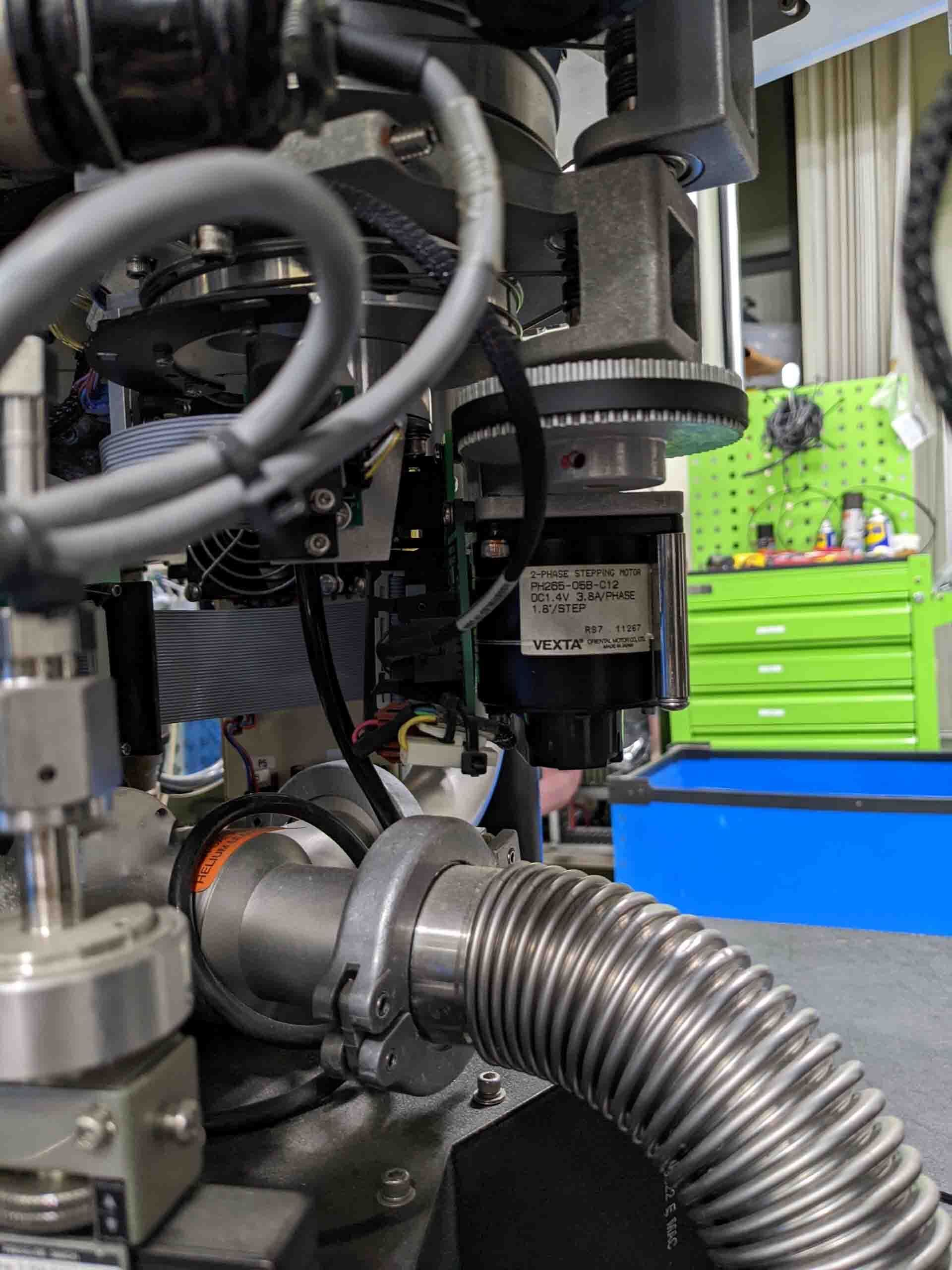

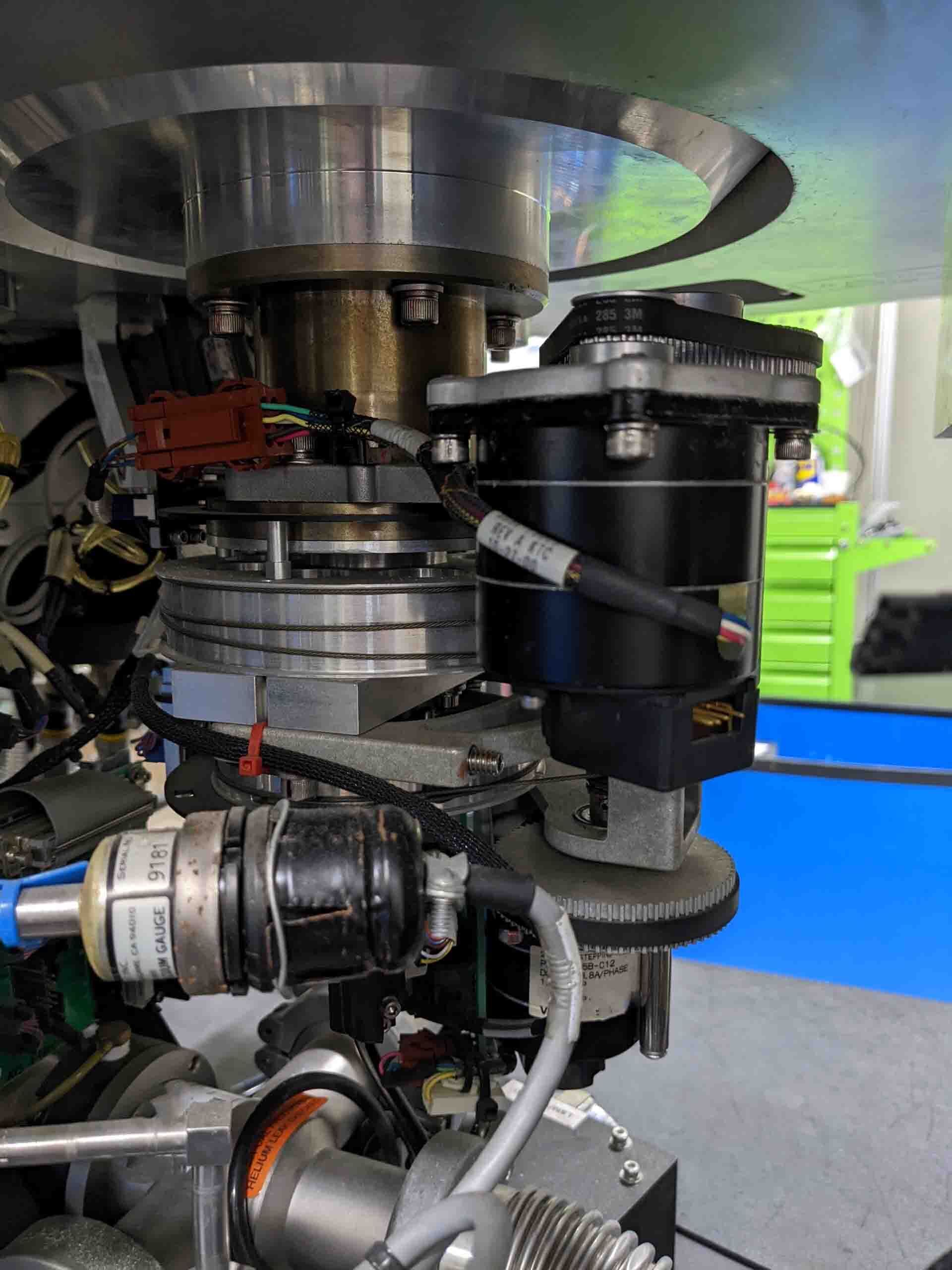

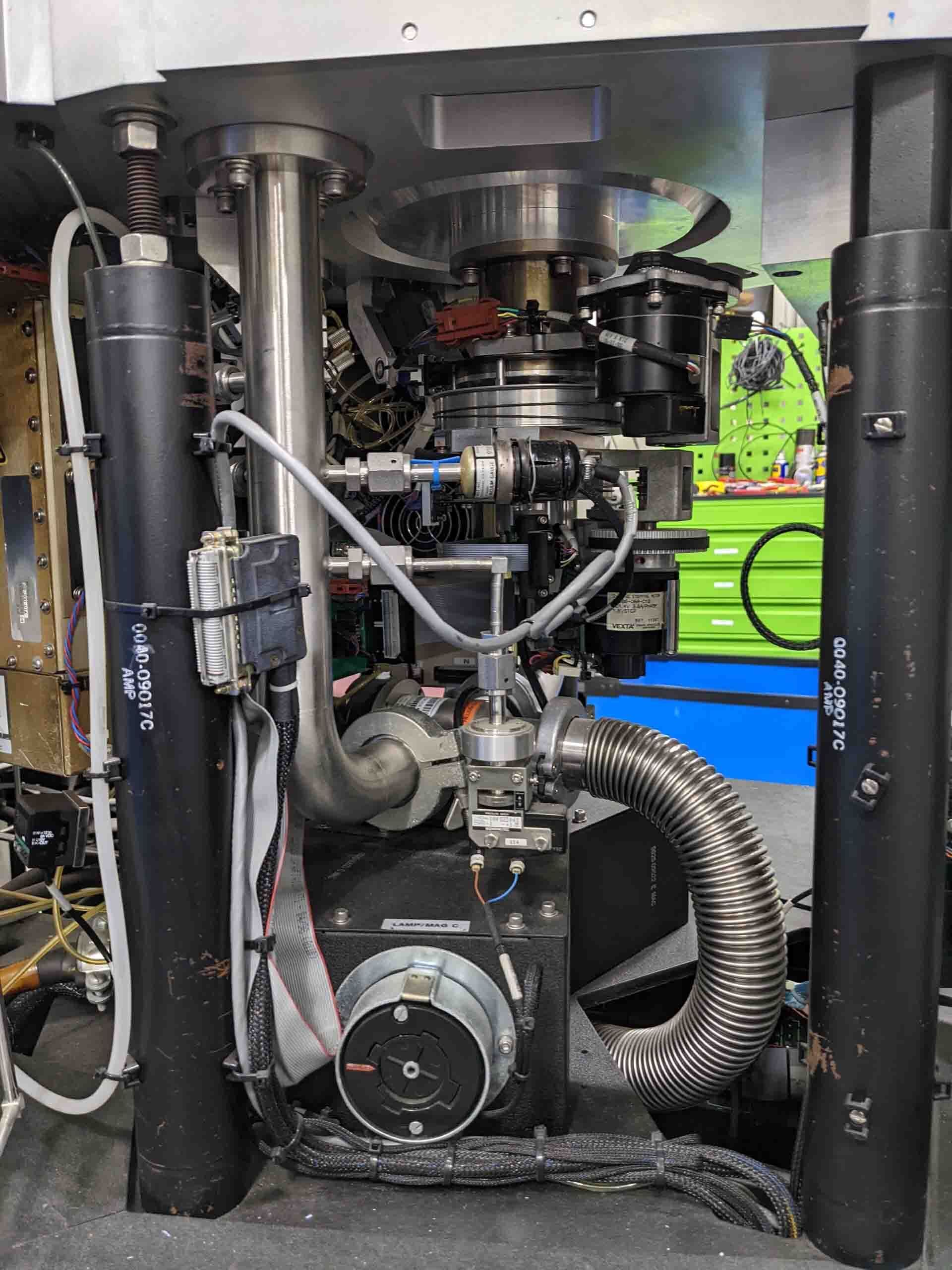

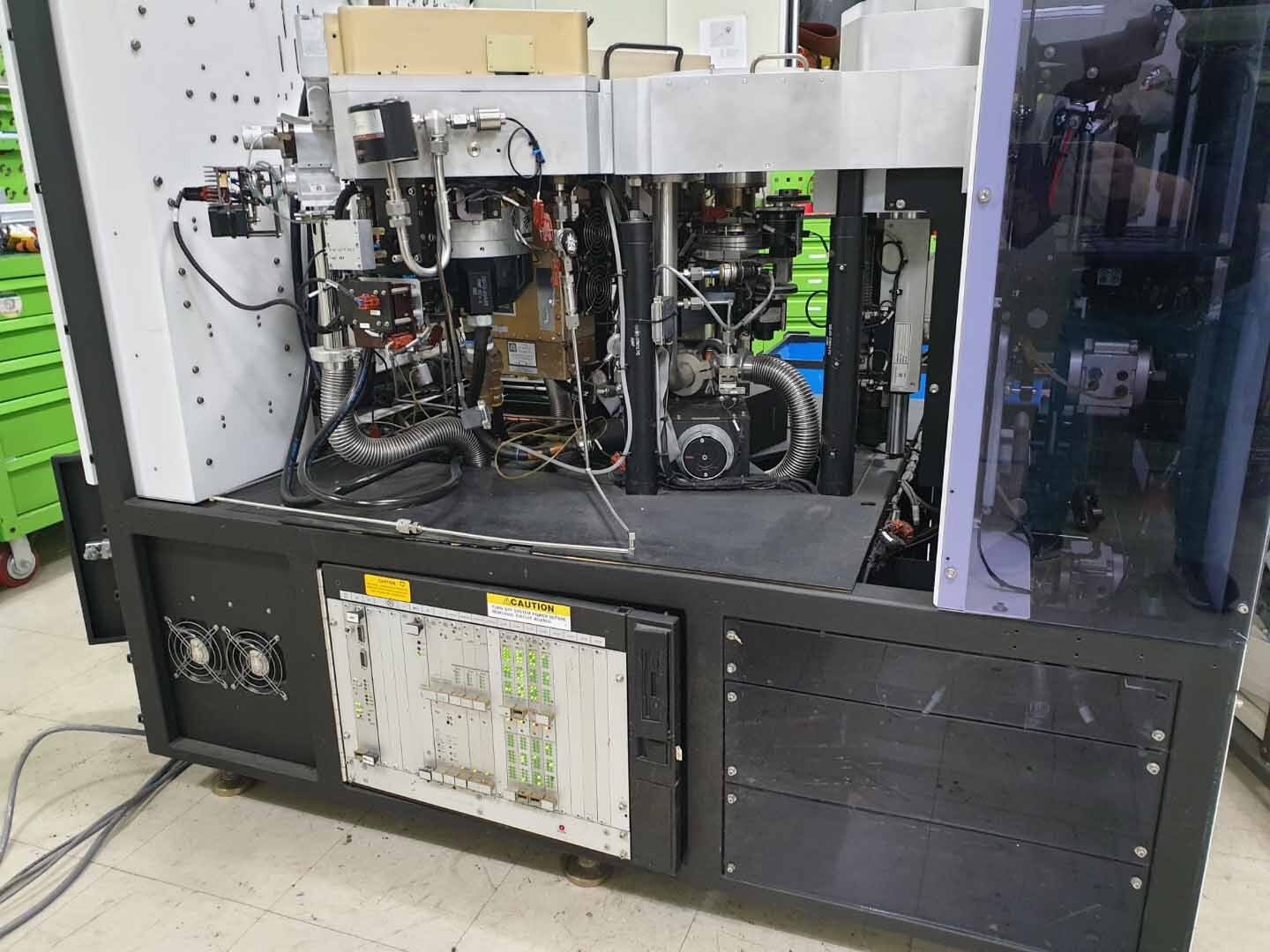

CVD System, 8"

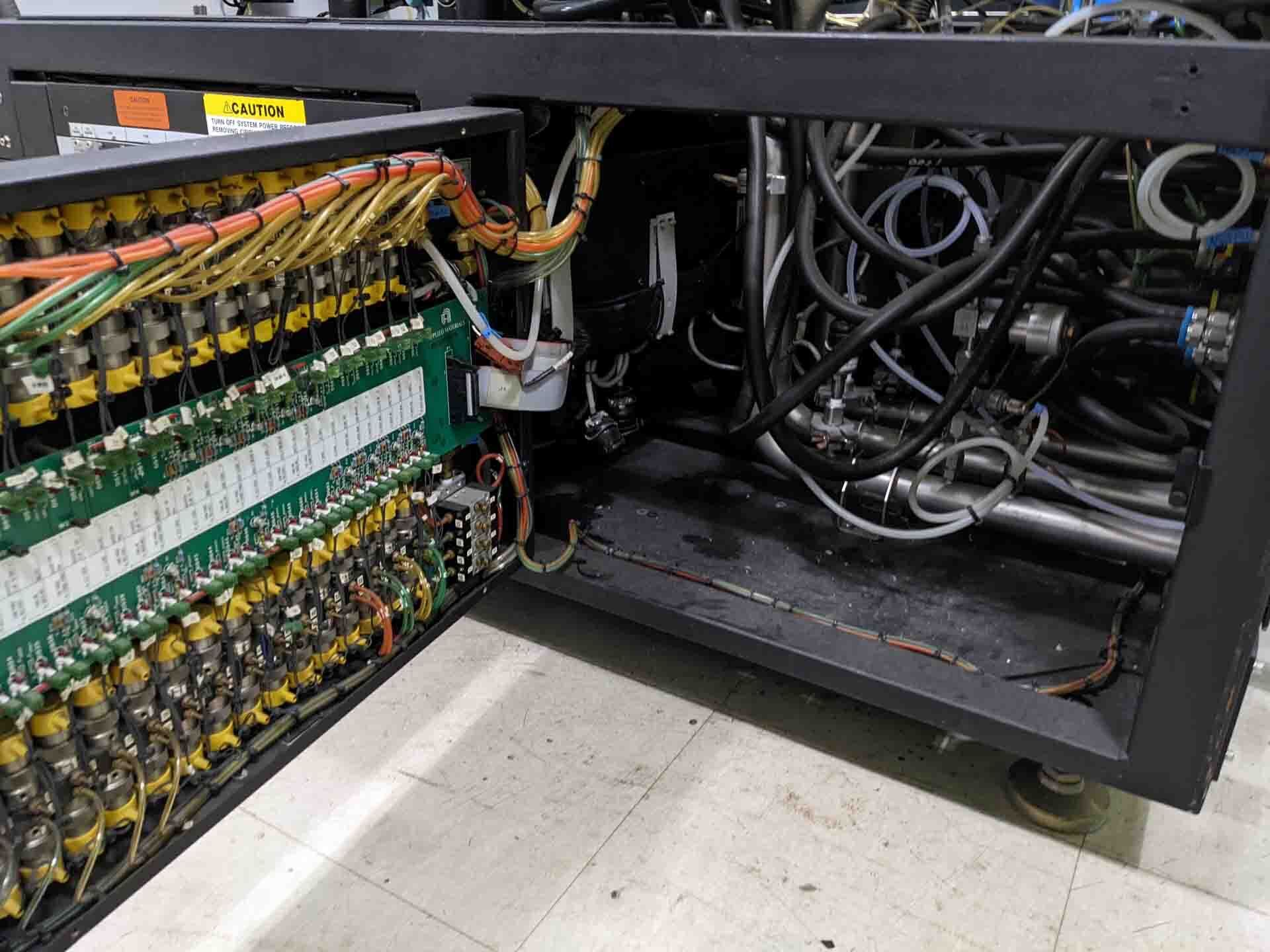

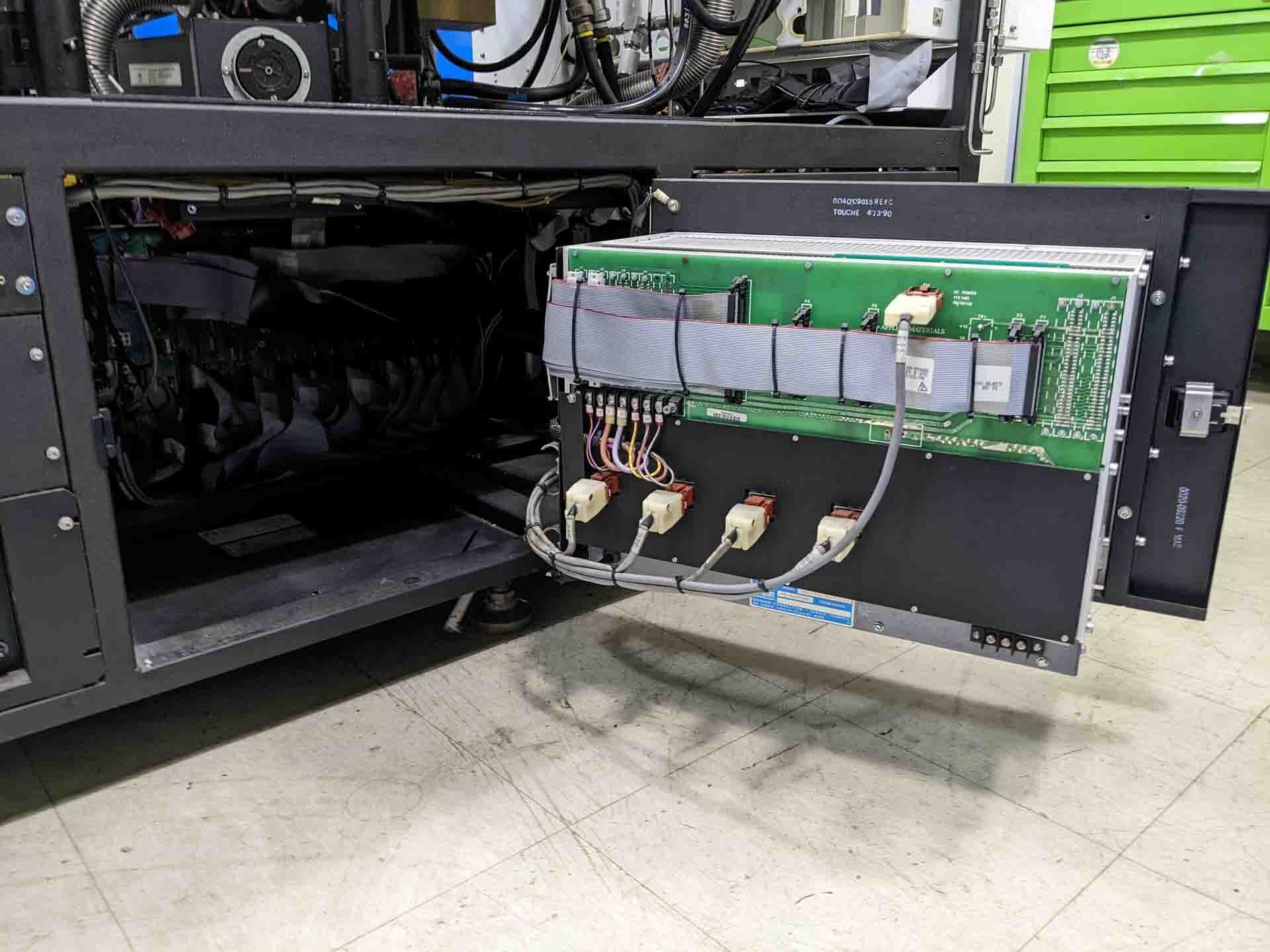

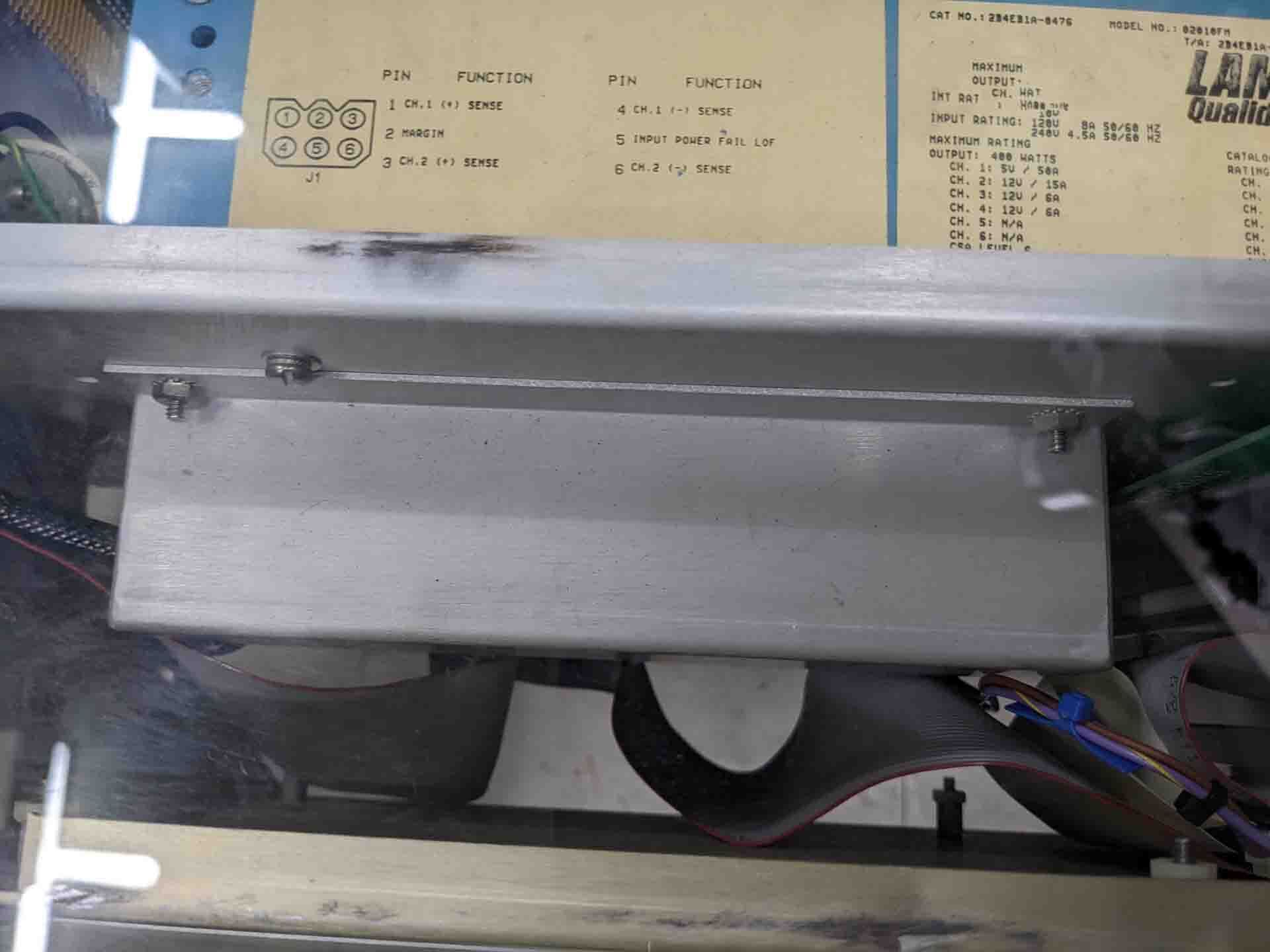

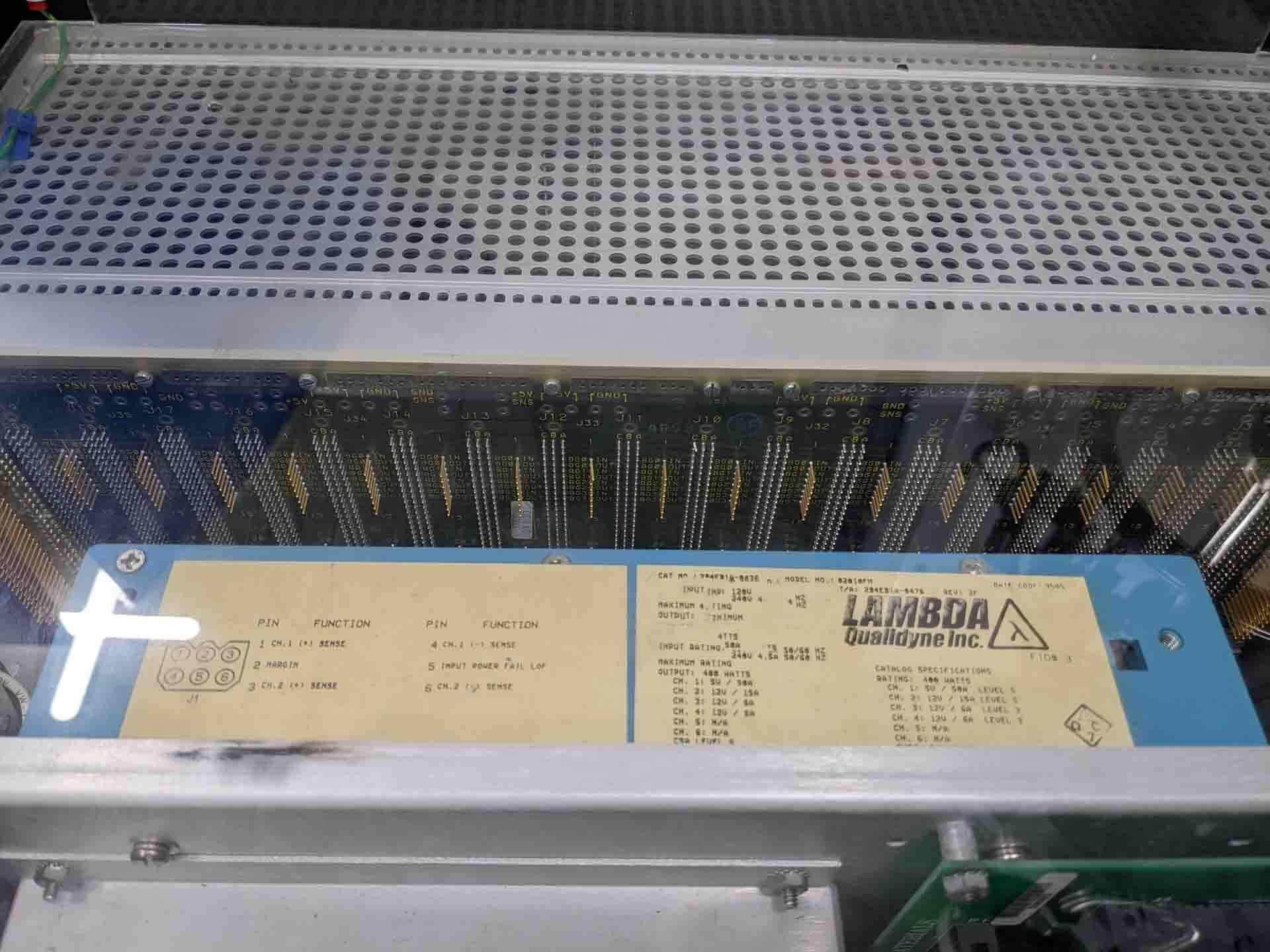

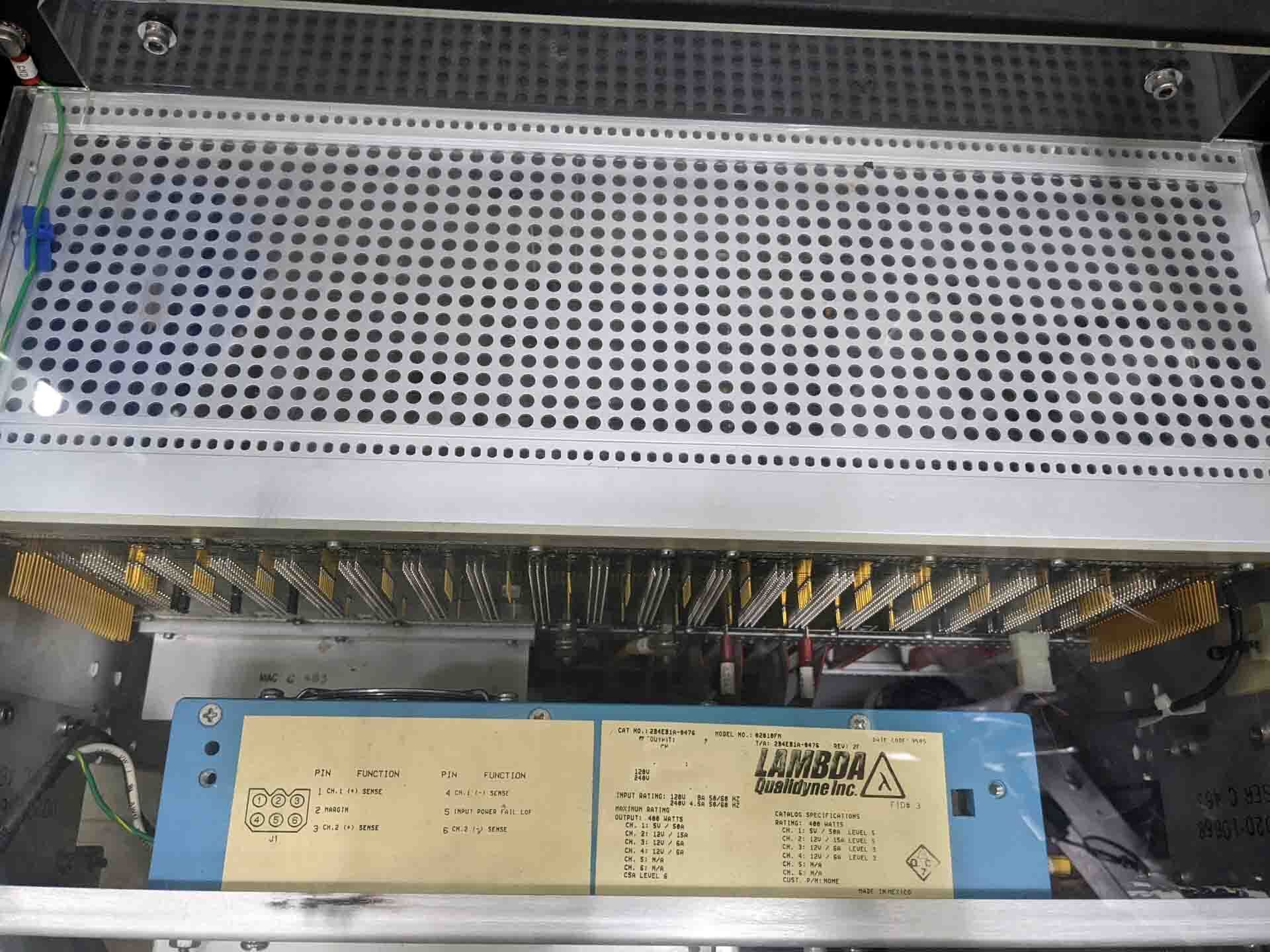

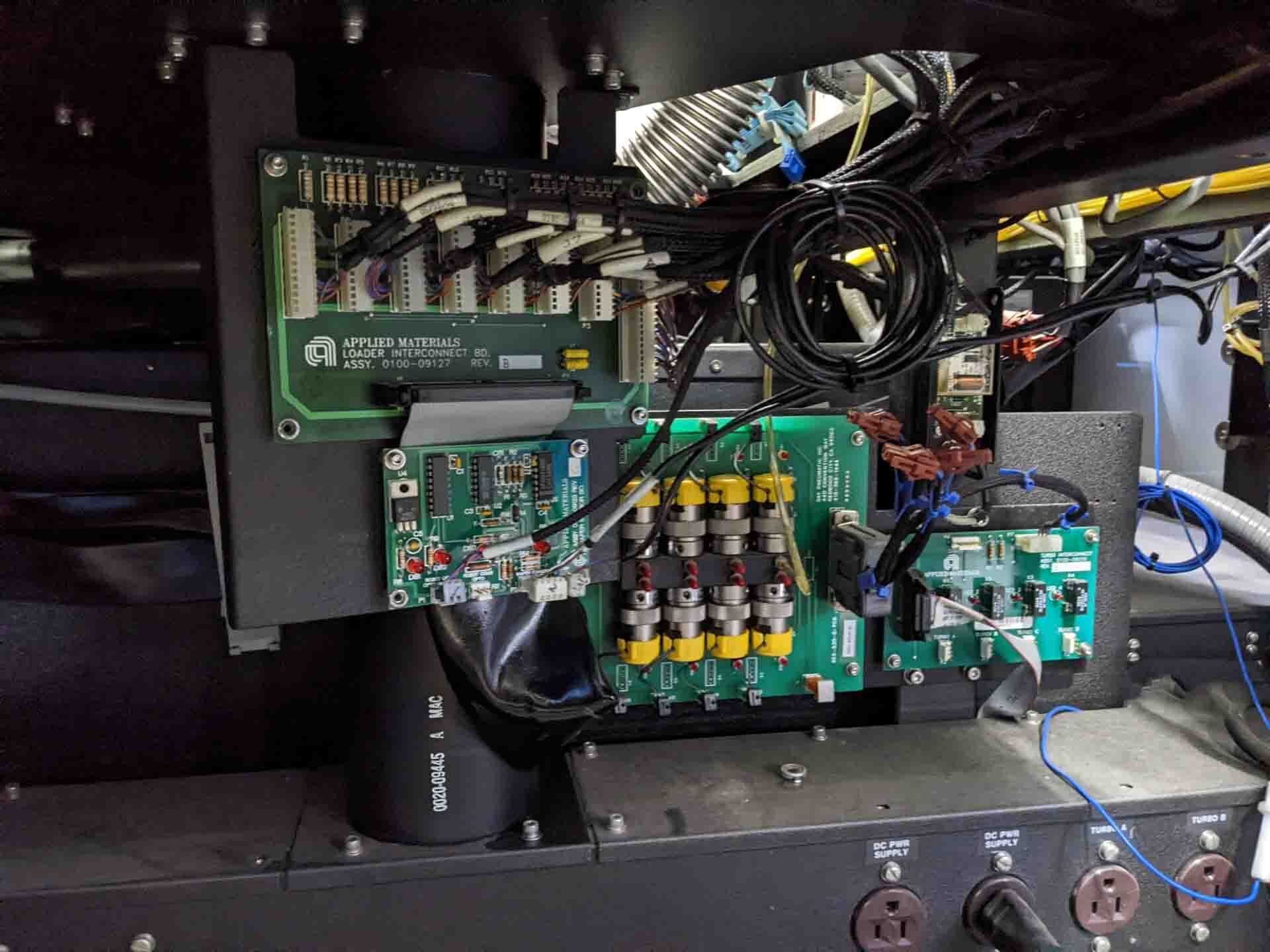

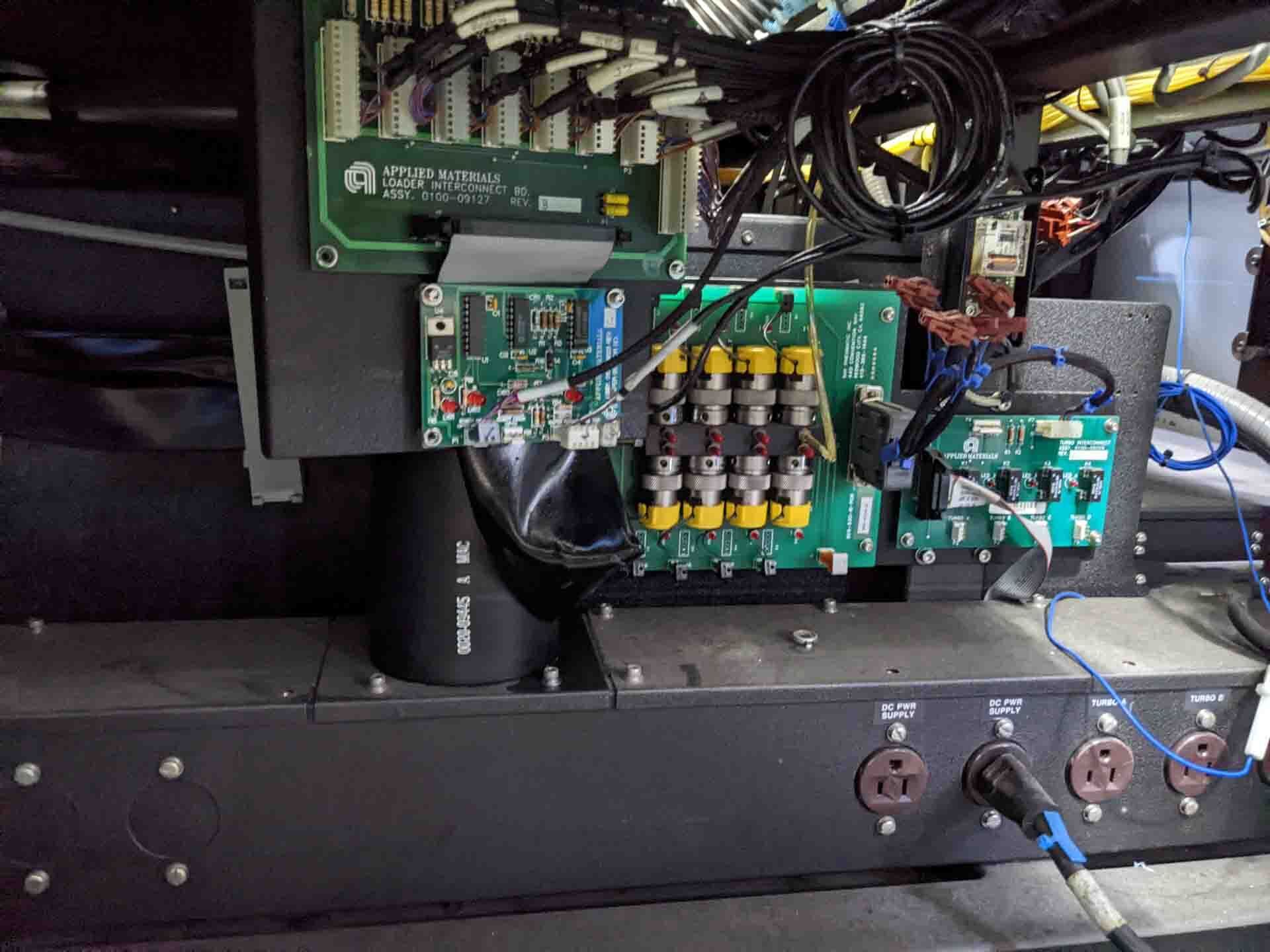

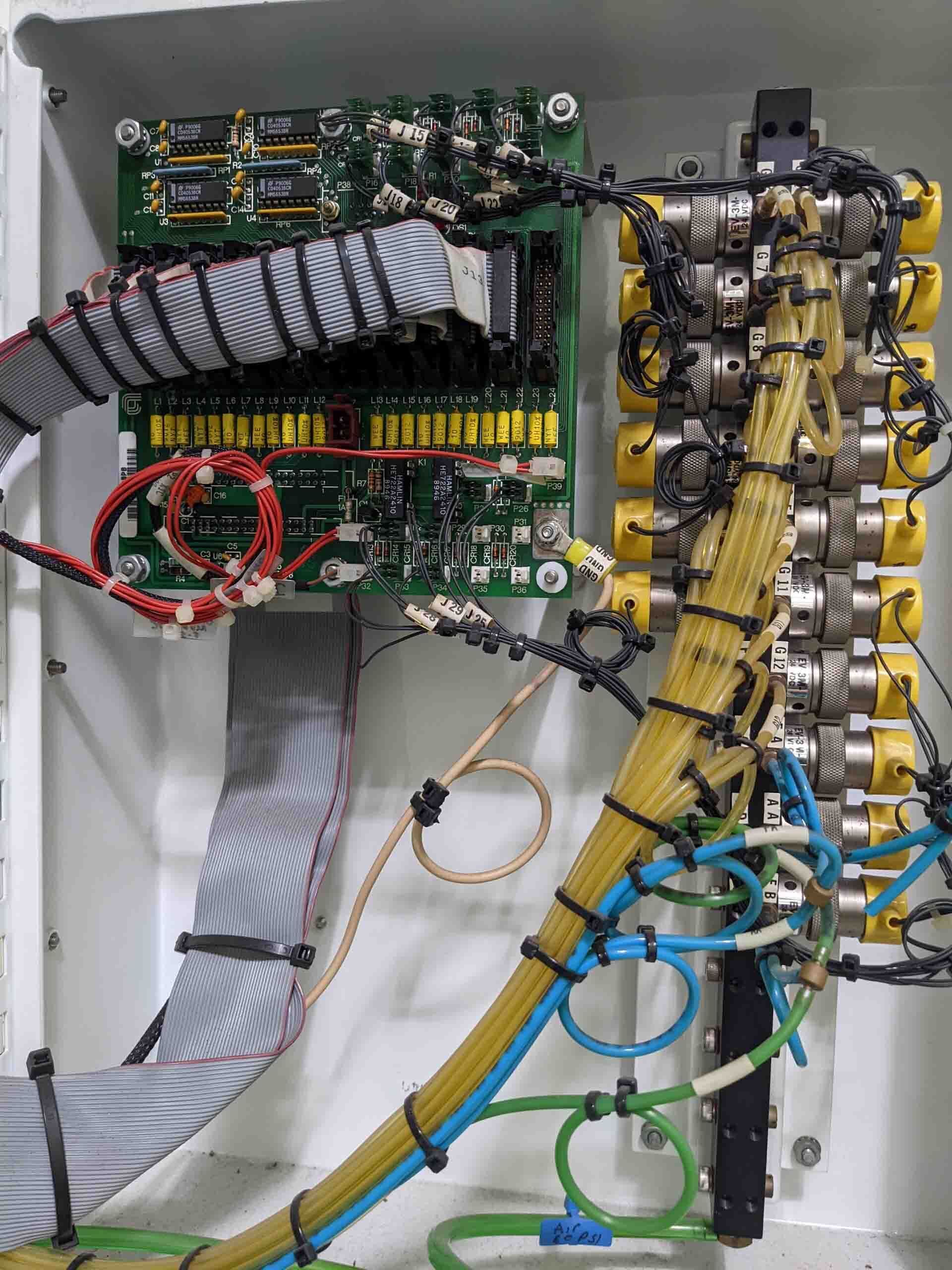

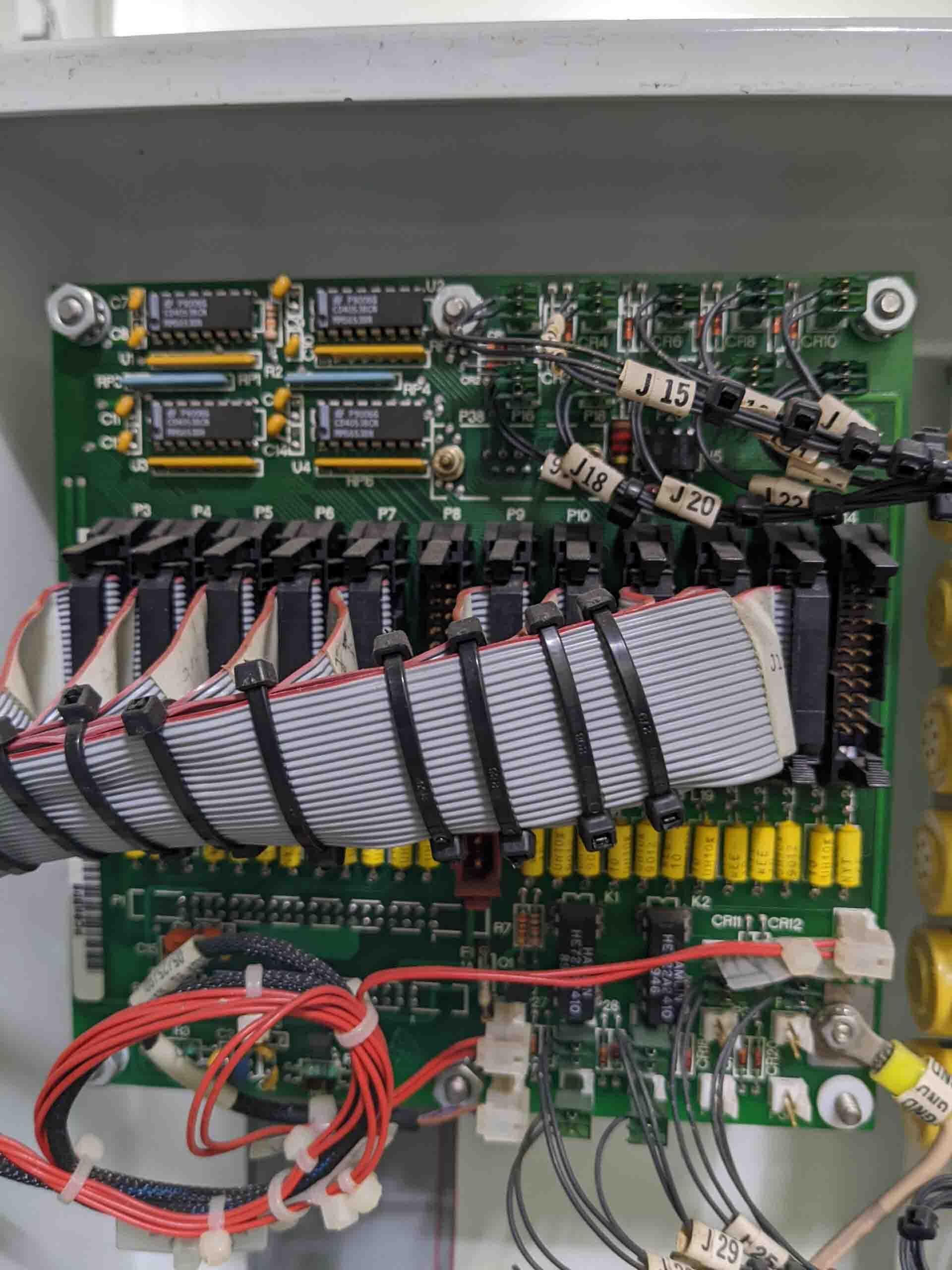

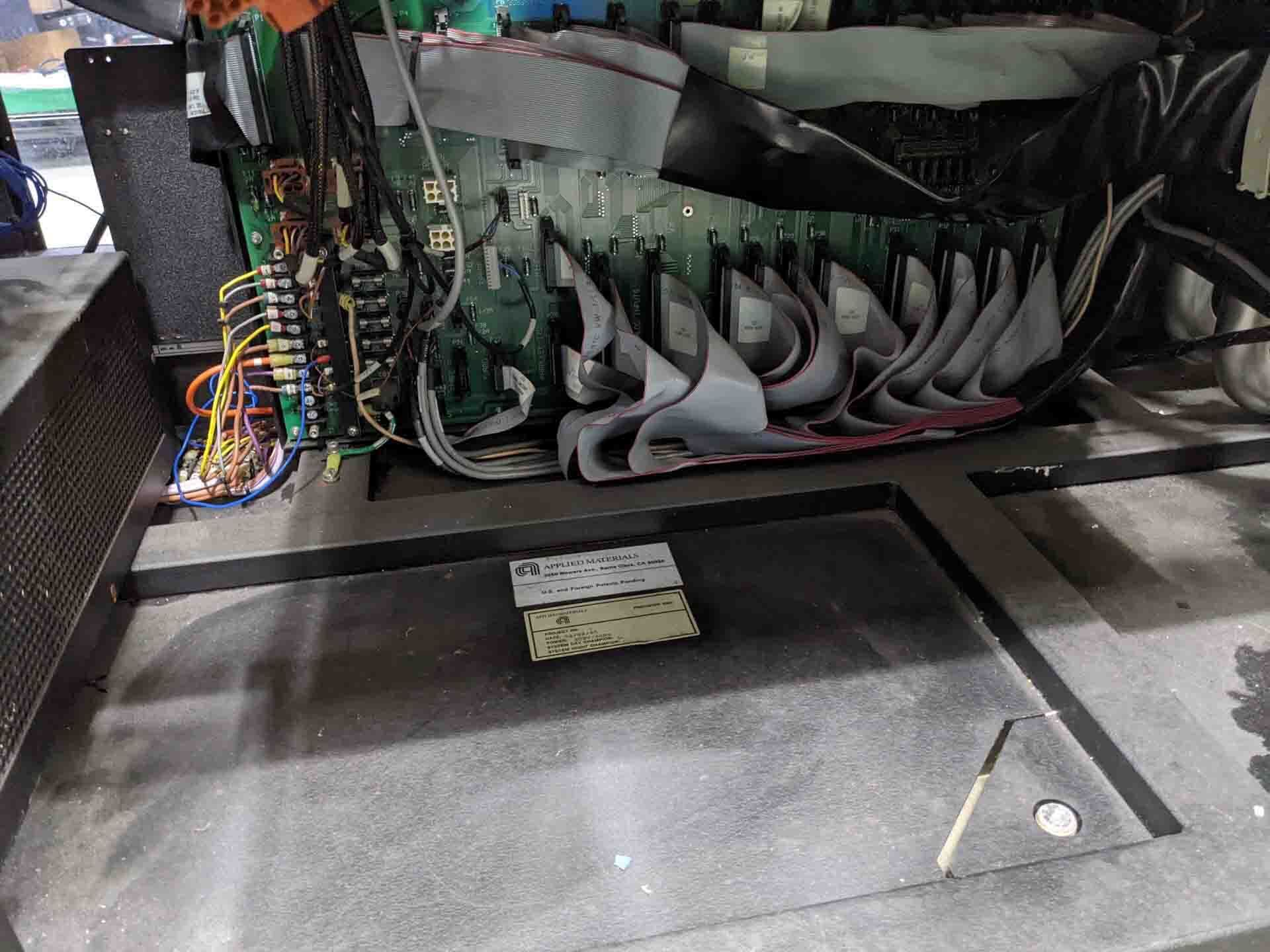

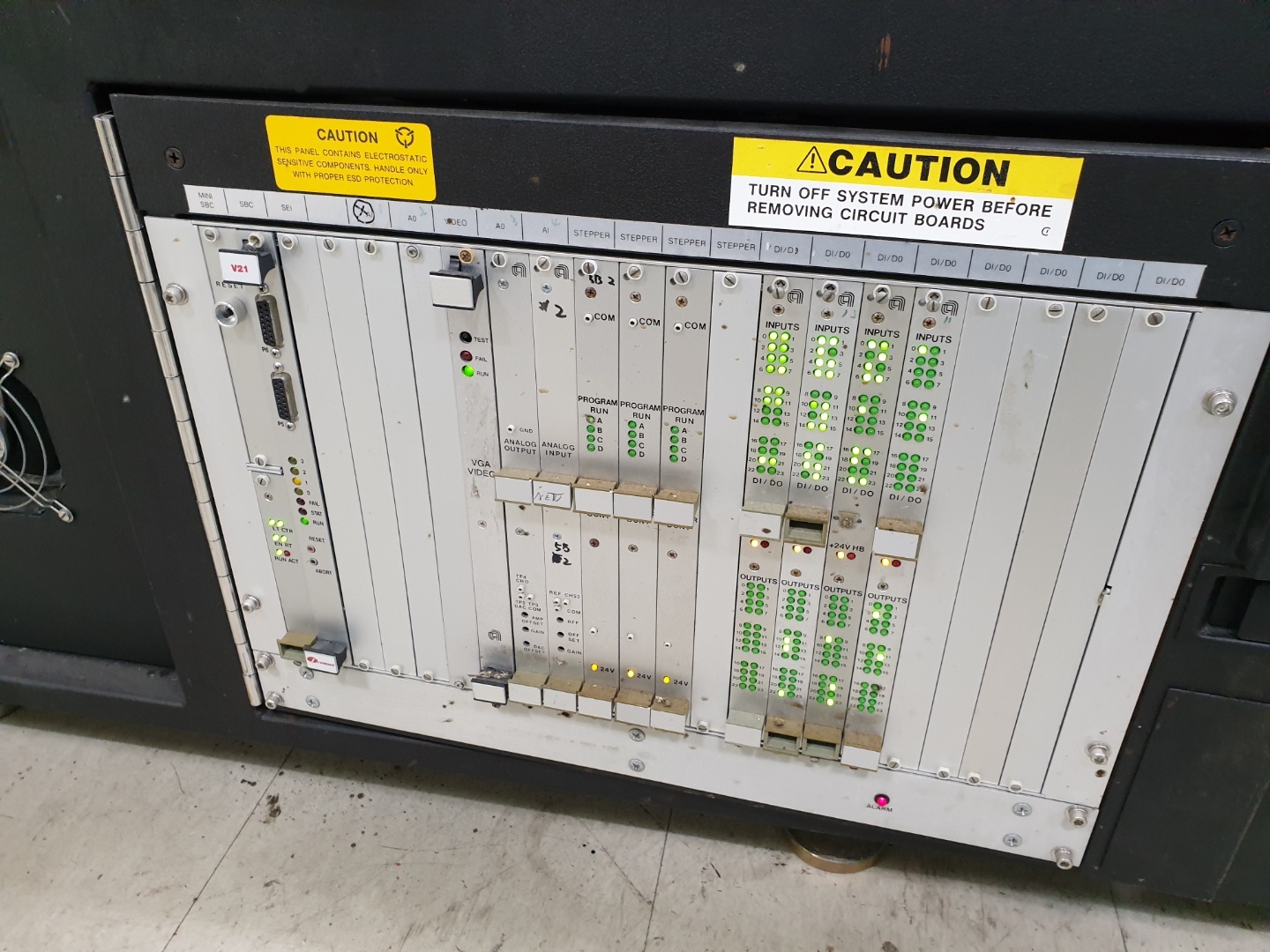

VME Type: Hard disk

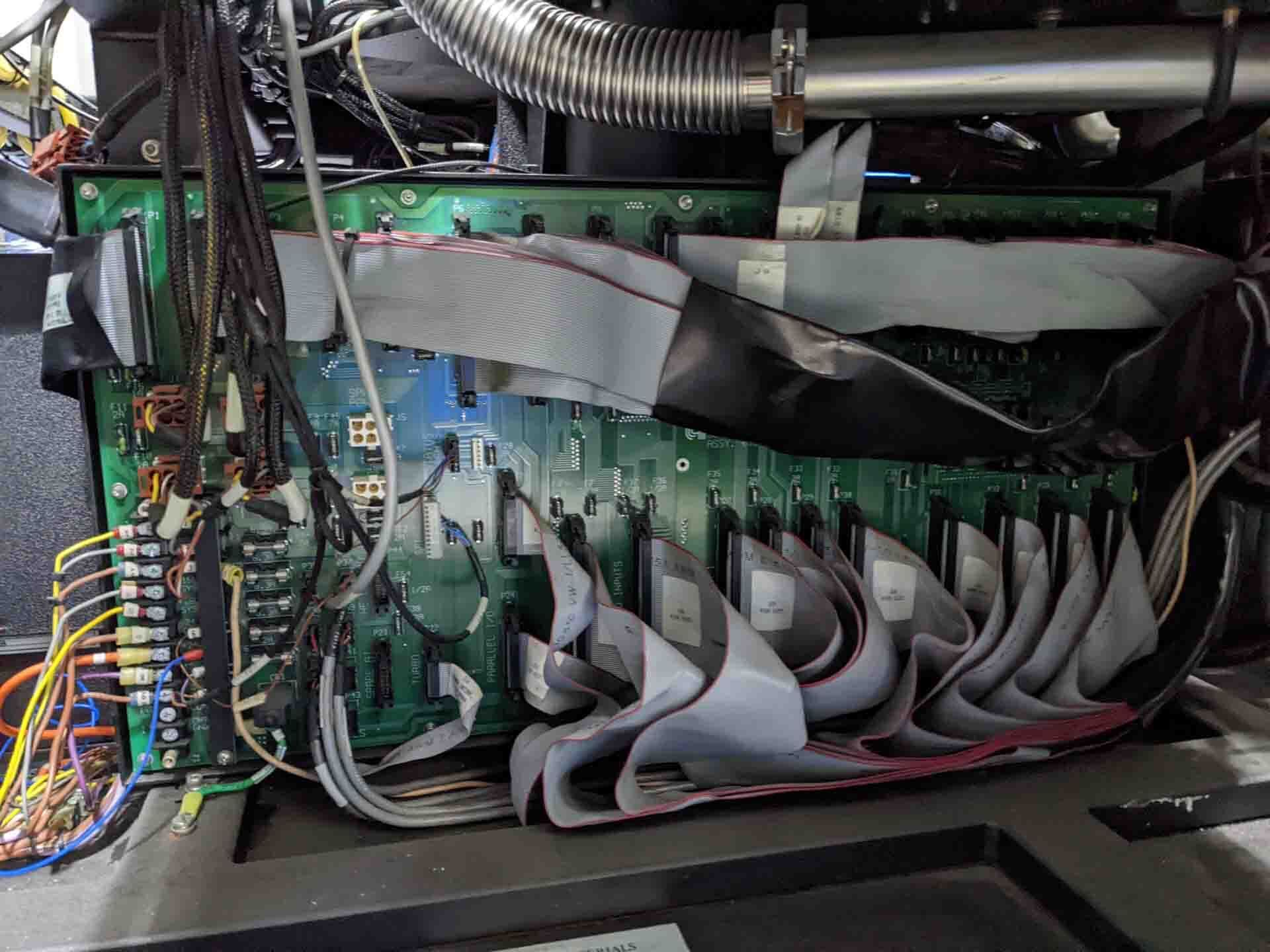

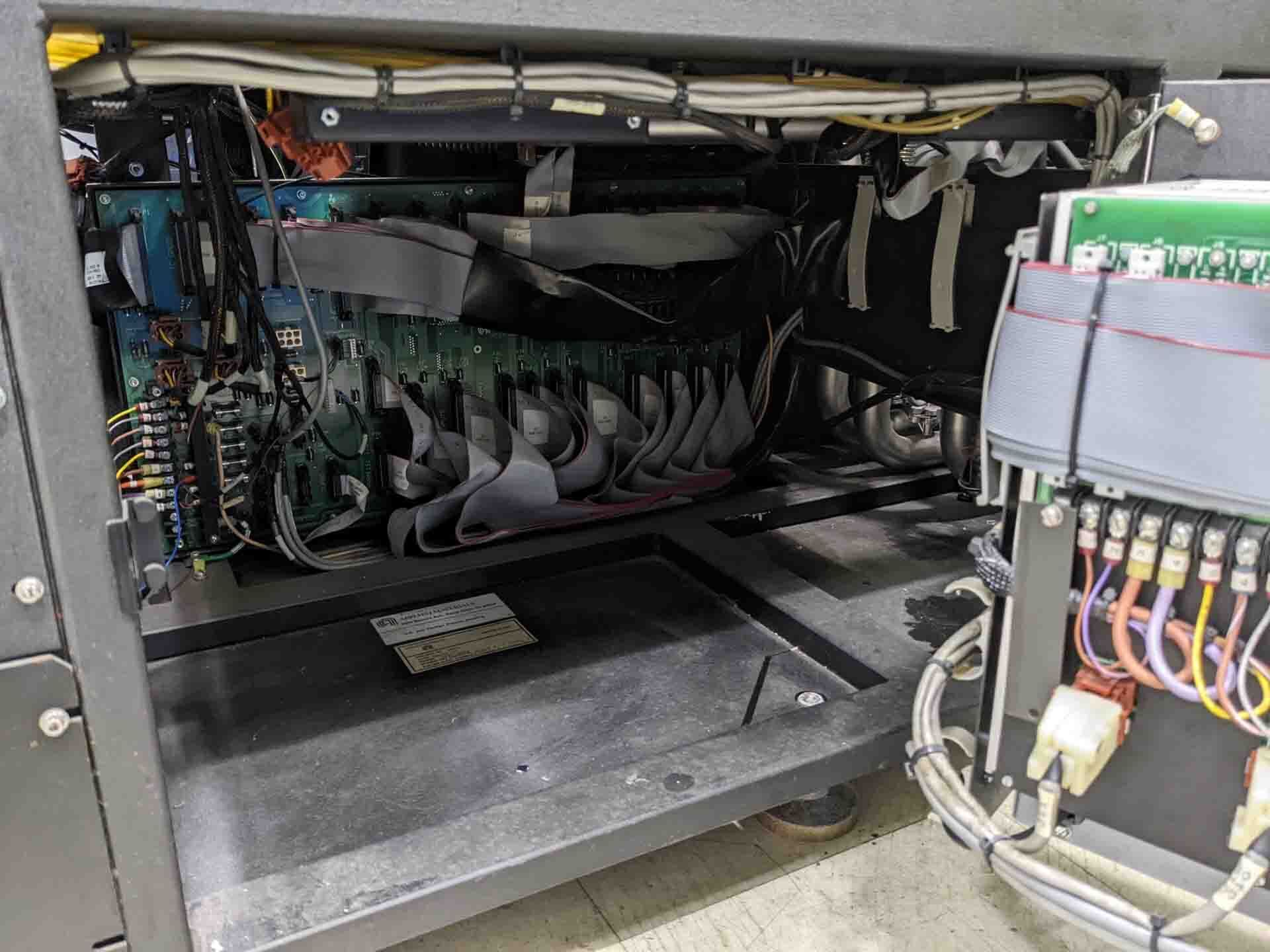

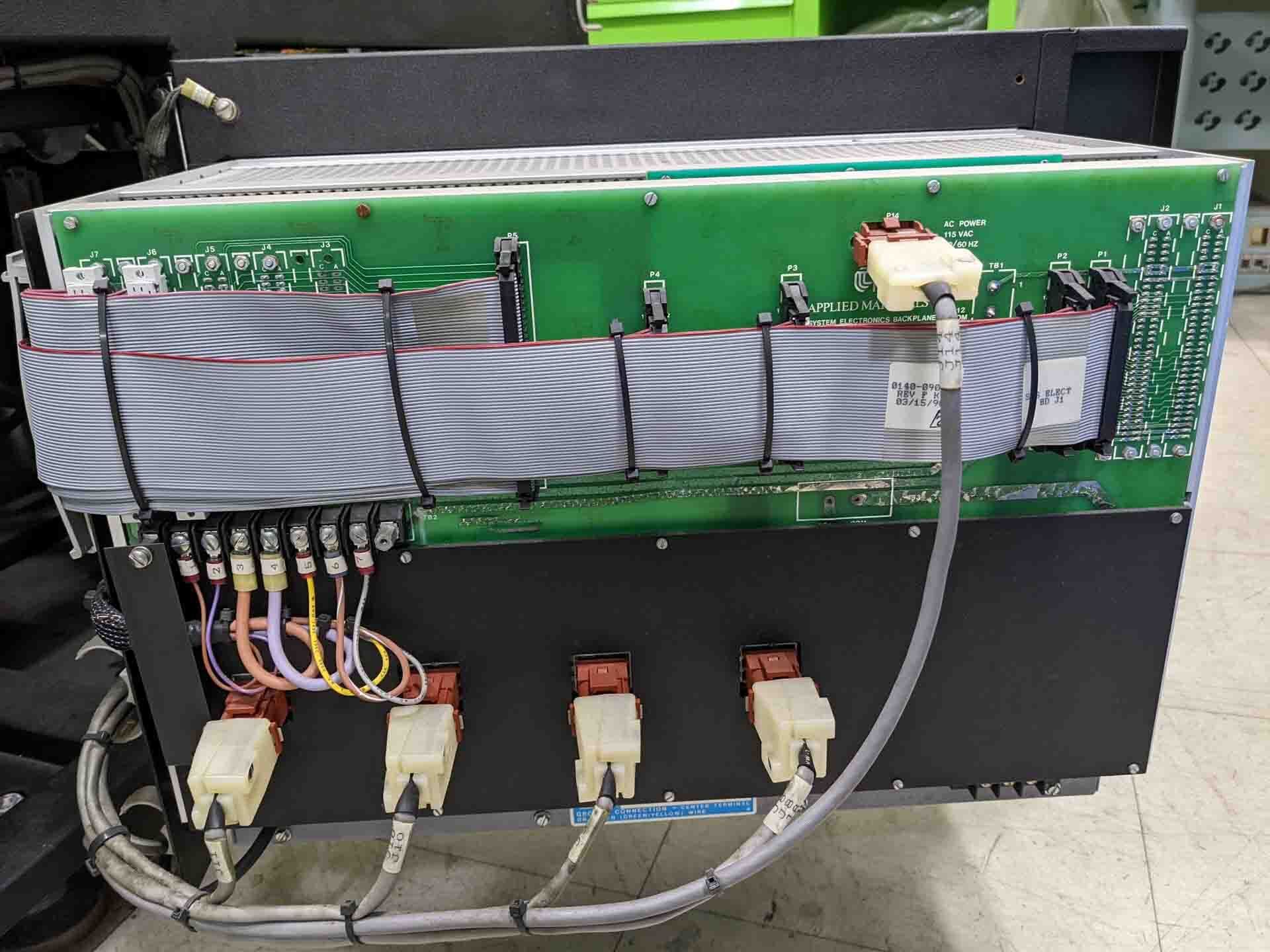

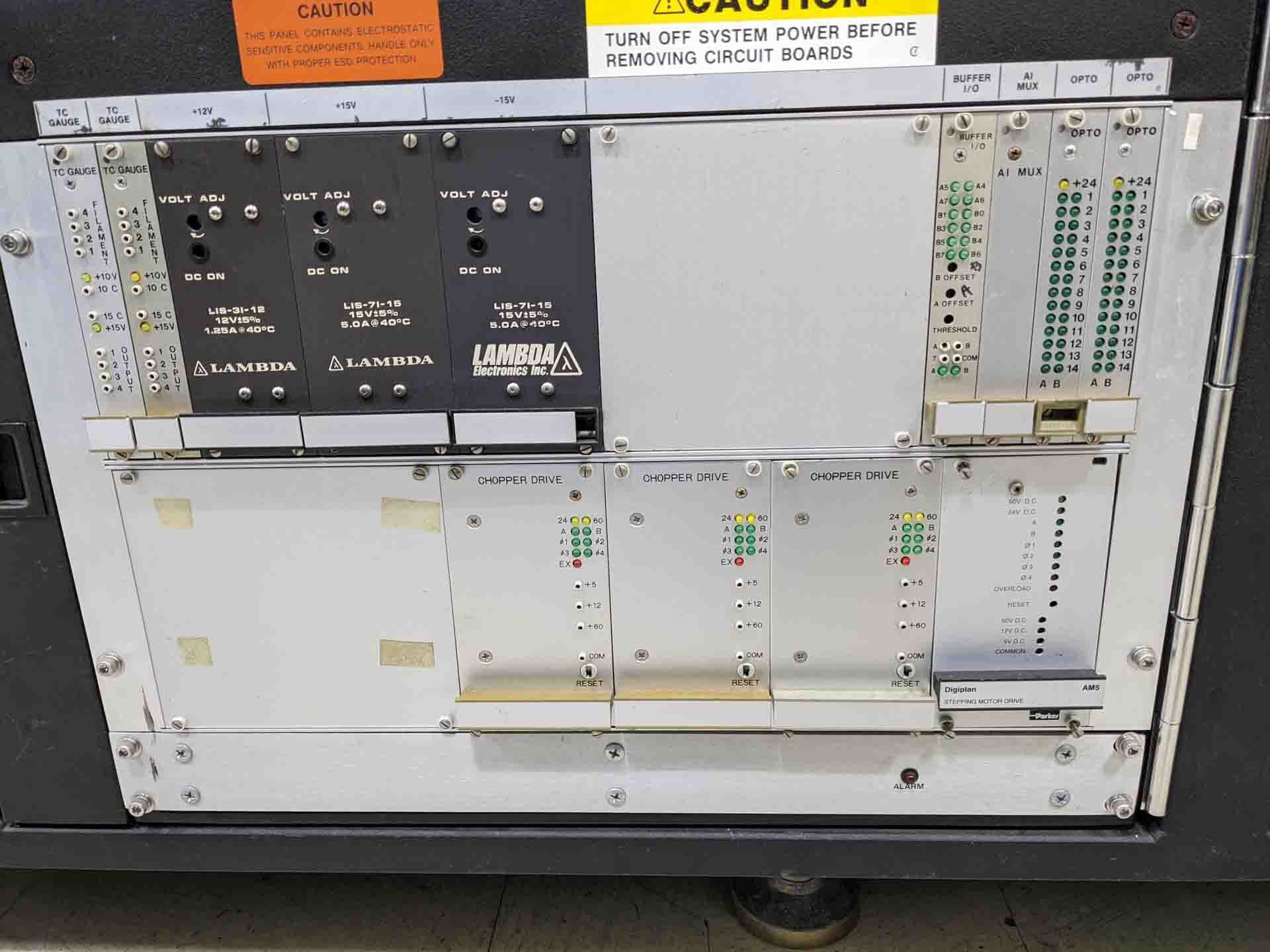

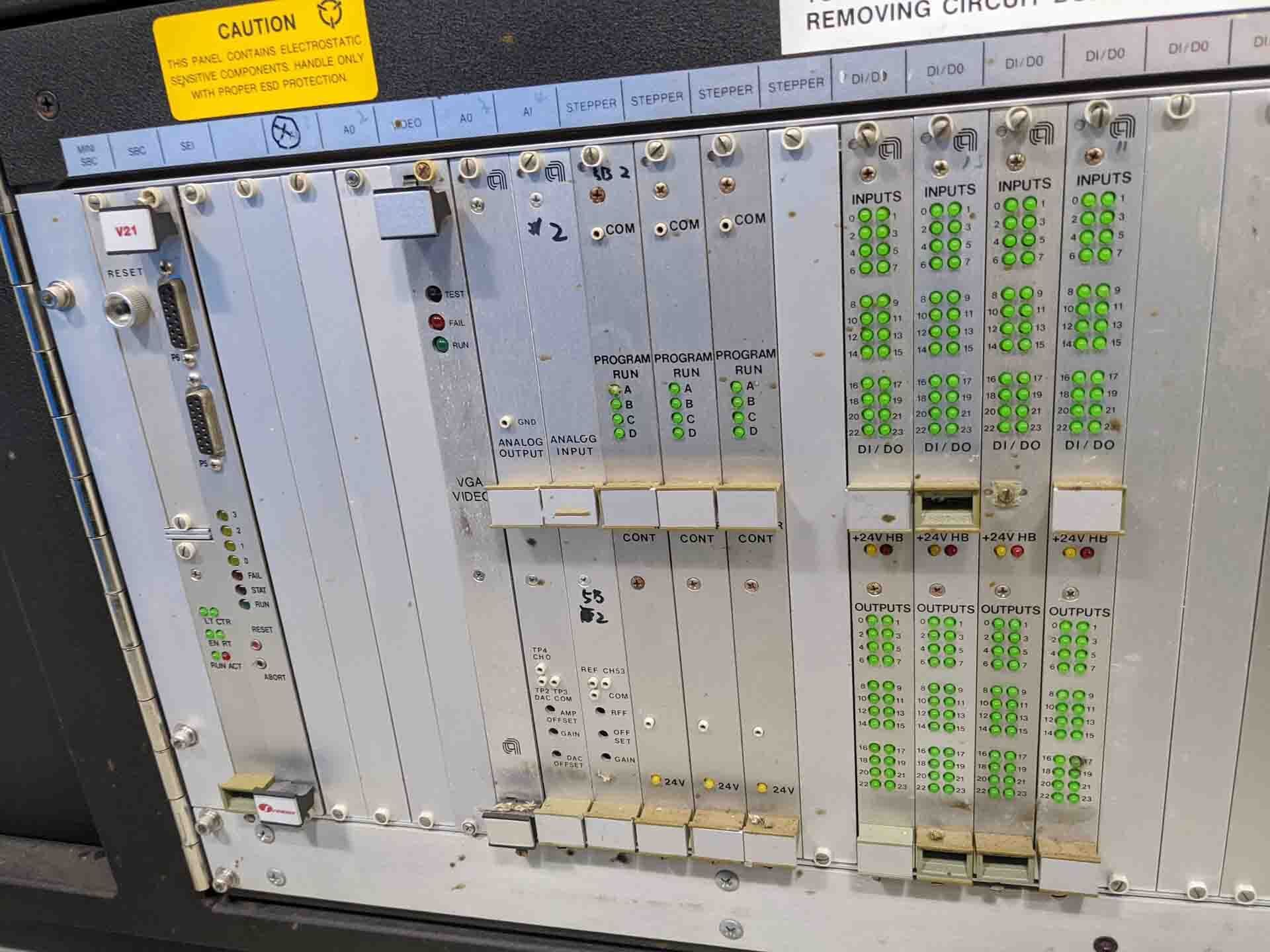

21-Slots controller

SBC Board type: V21 Synergy

VGA Video board

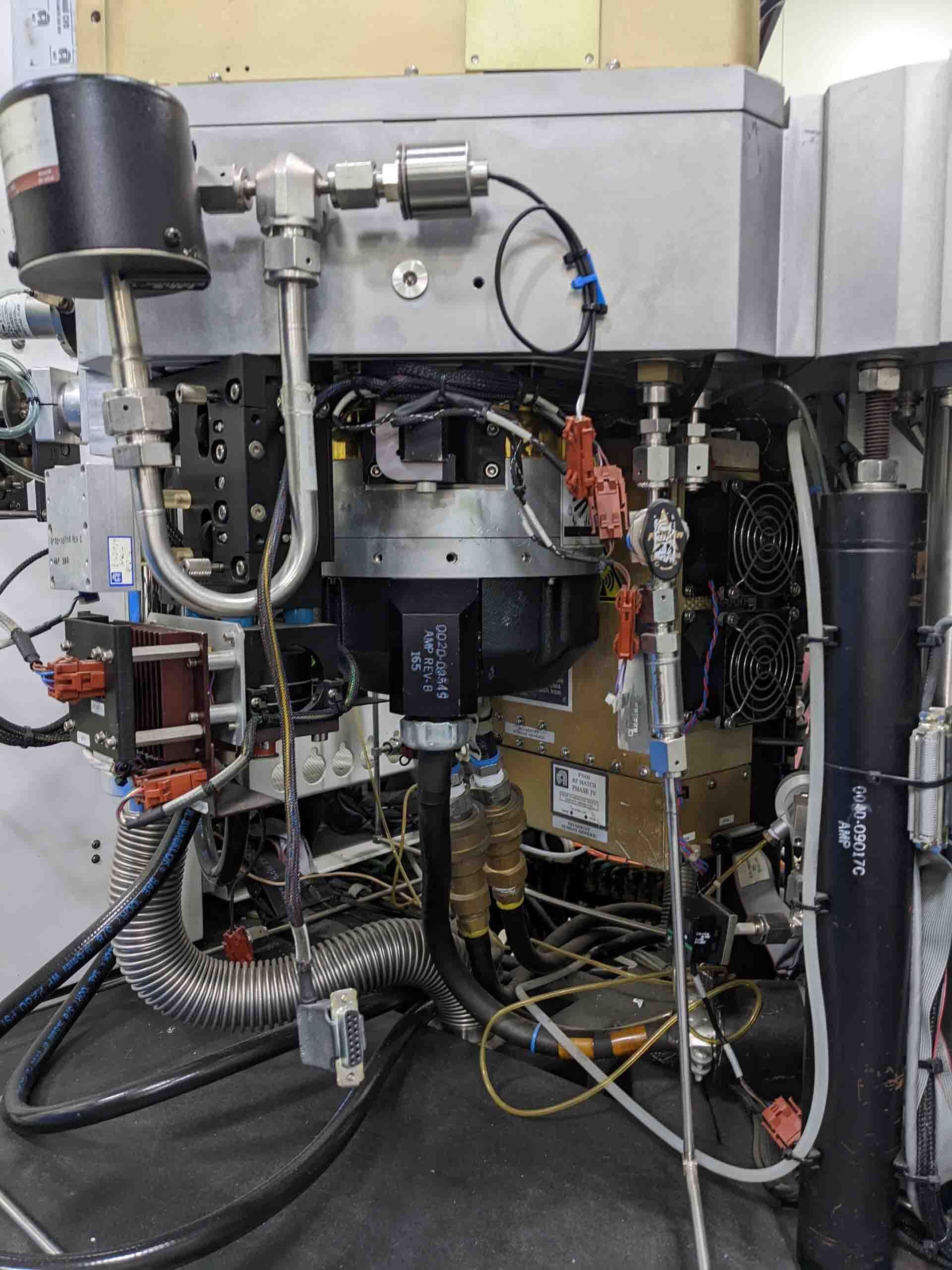

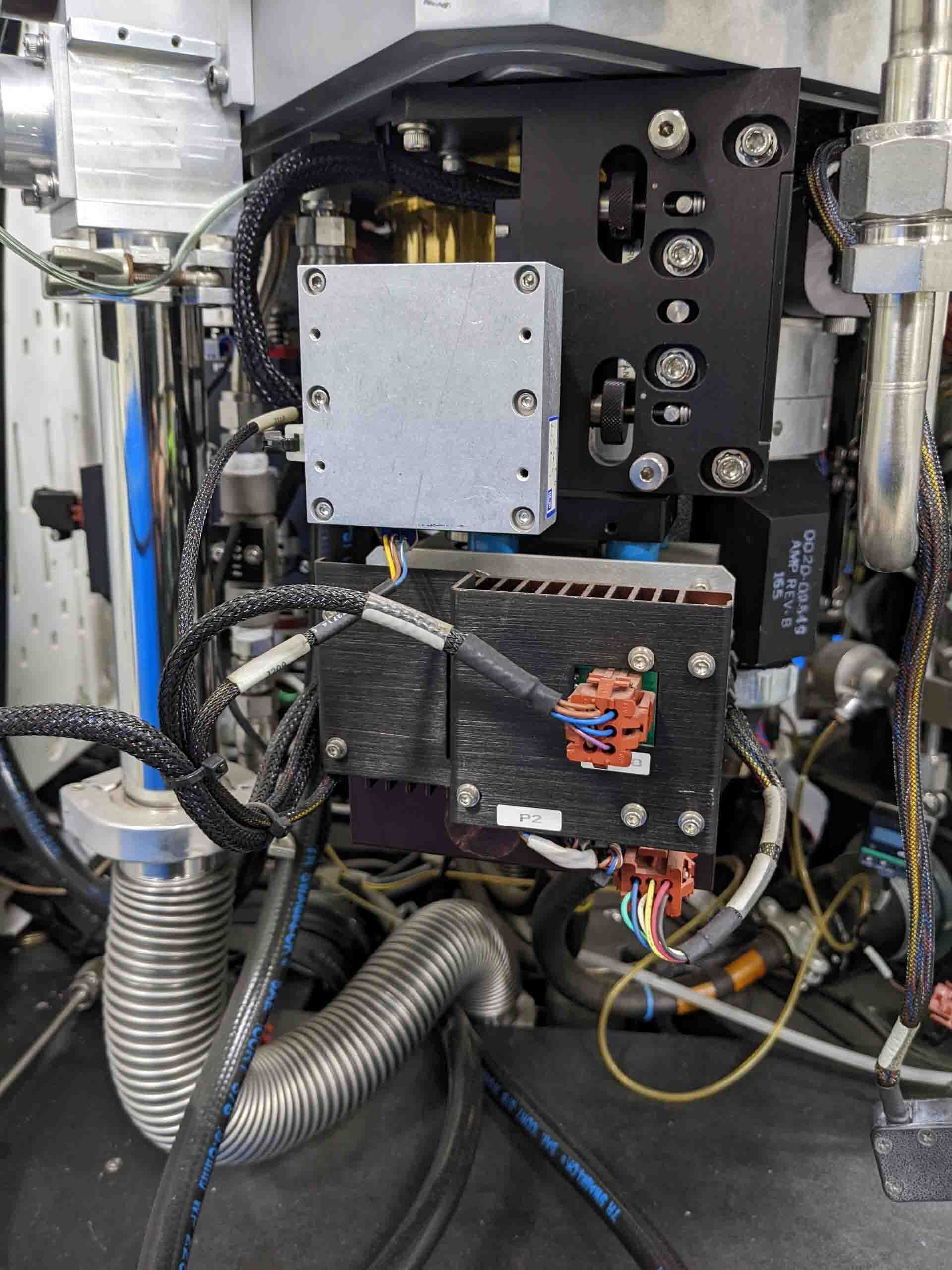

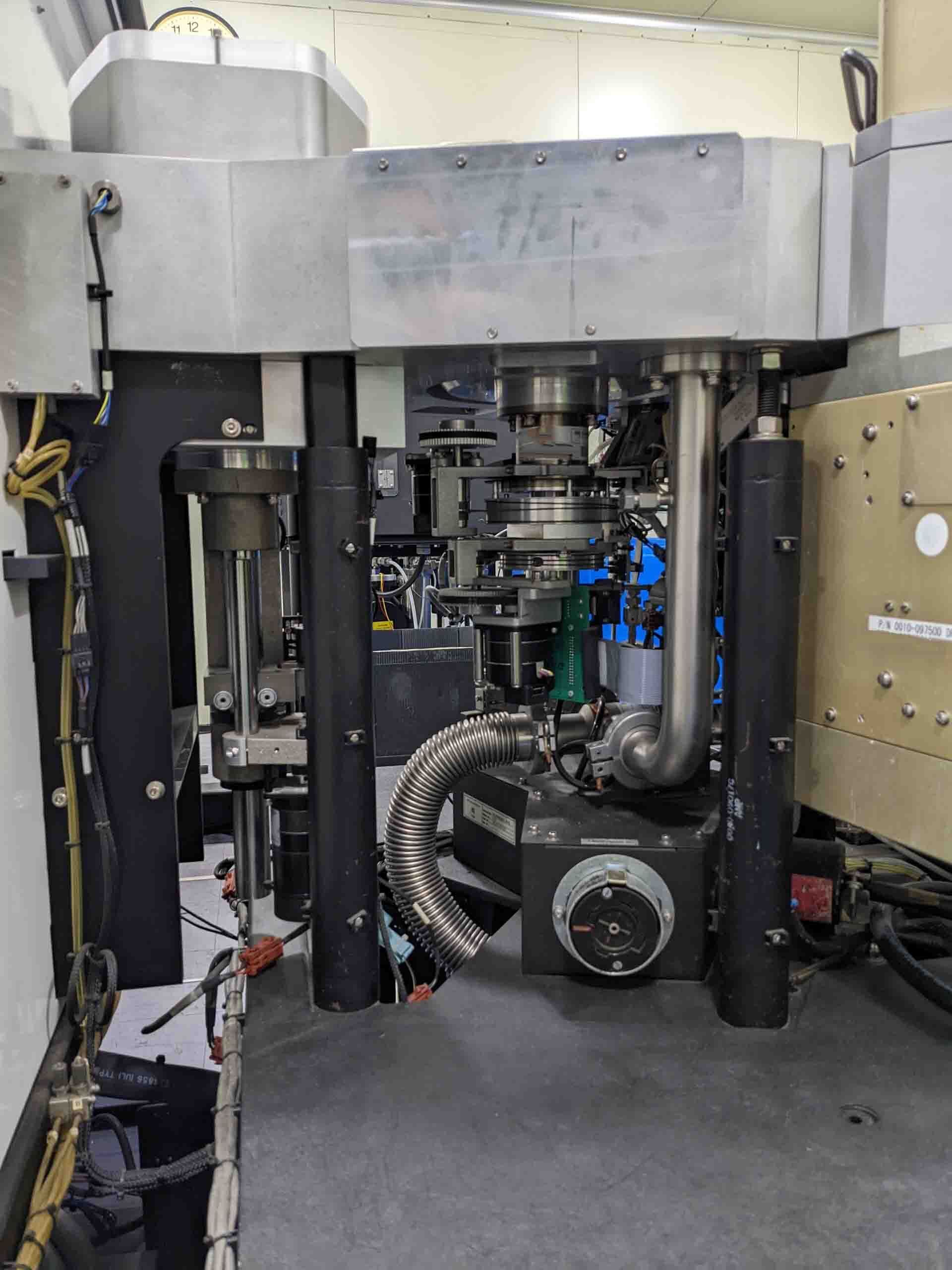

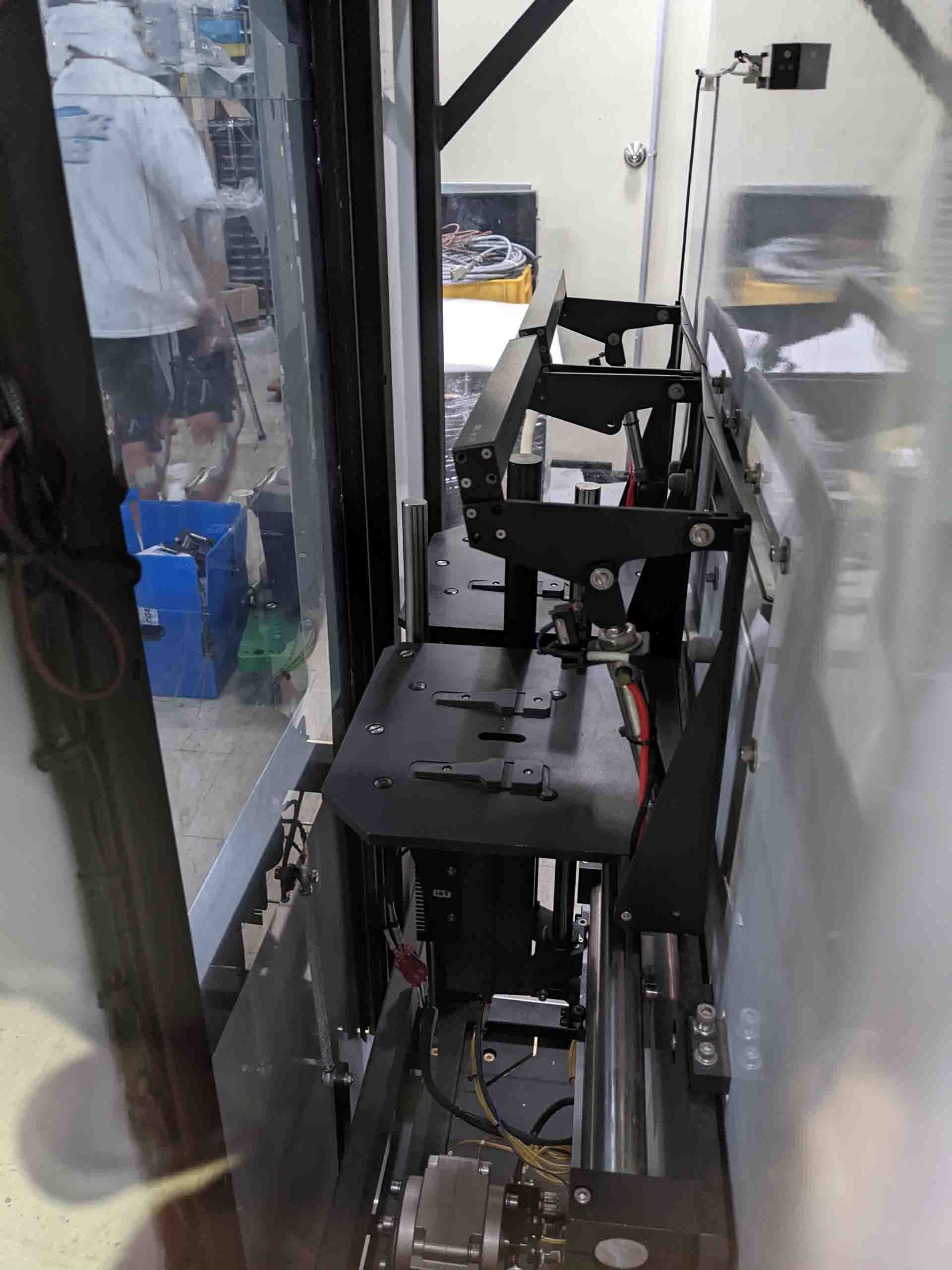

Robot type: Phase-III

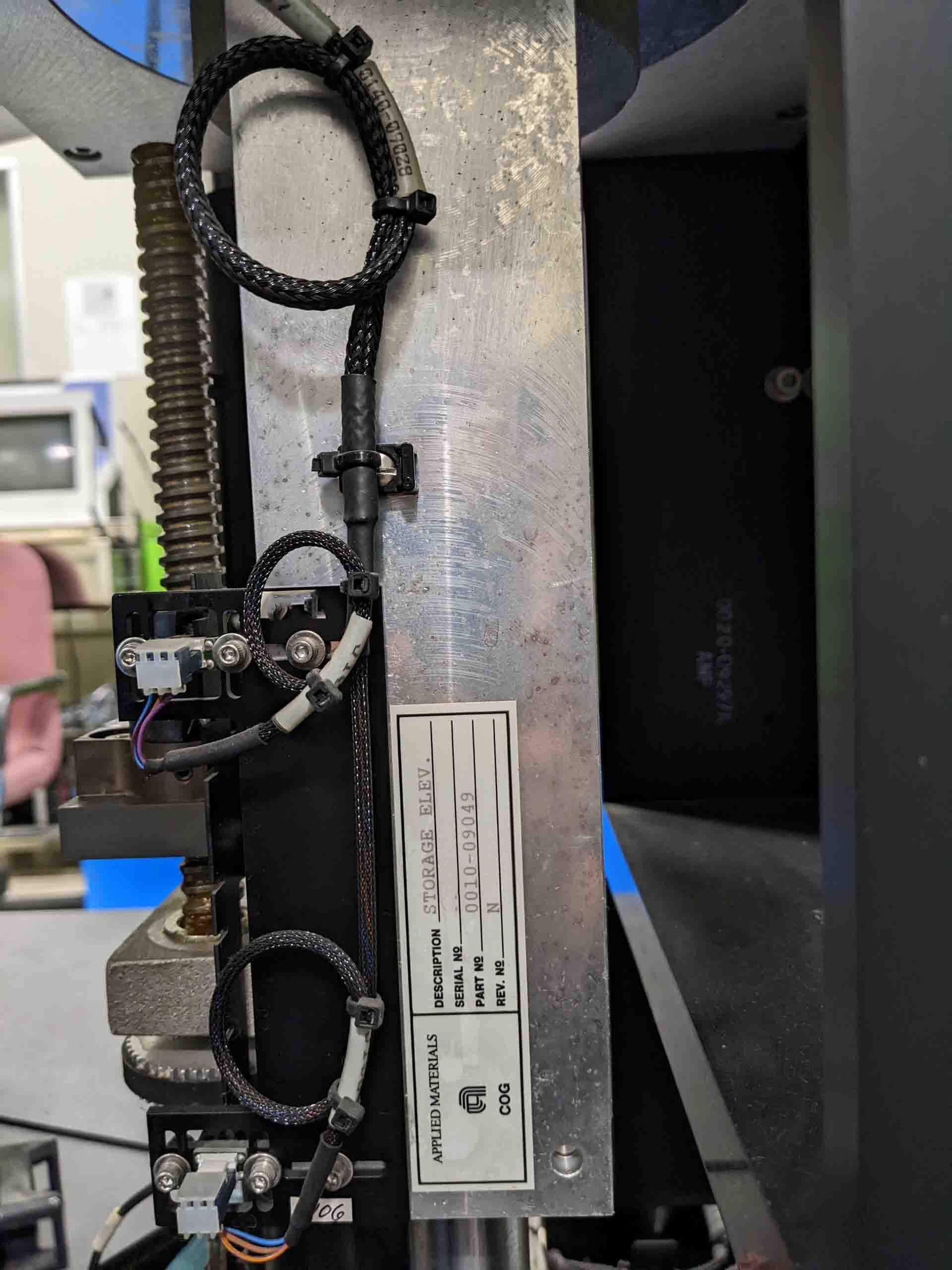

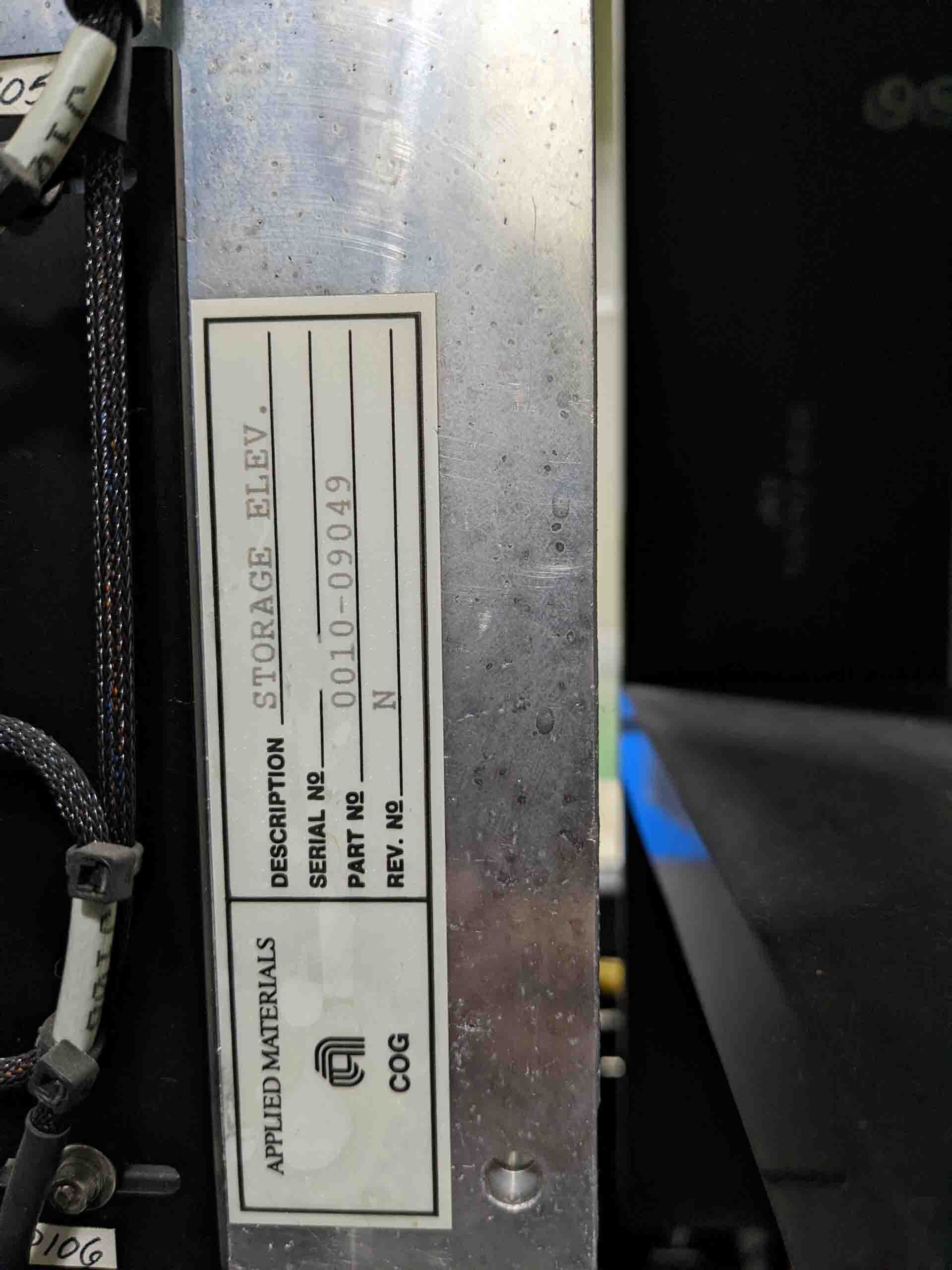

8-Slots storage elevator

No WPS sensor

Standard slit valve

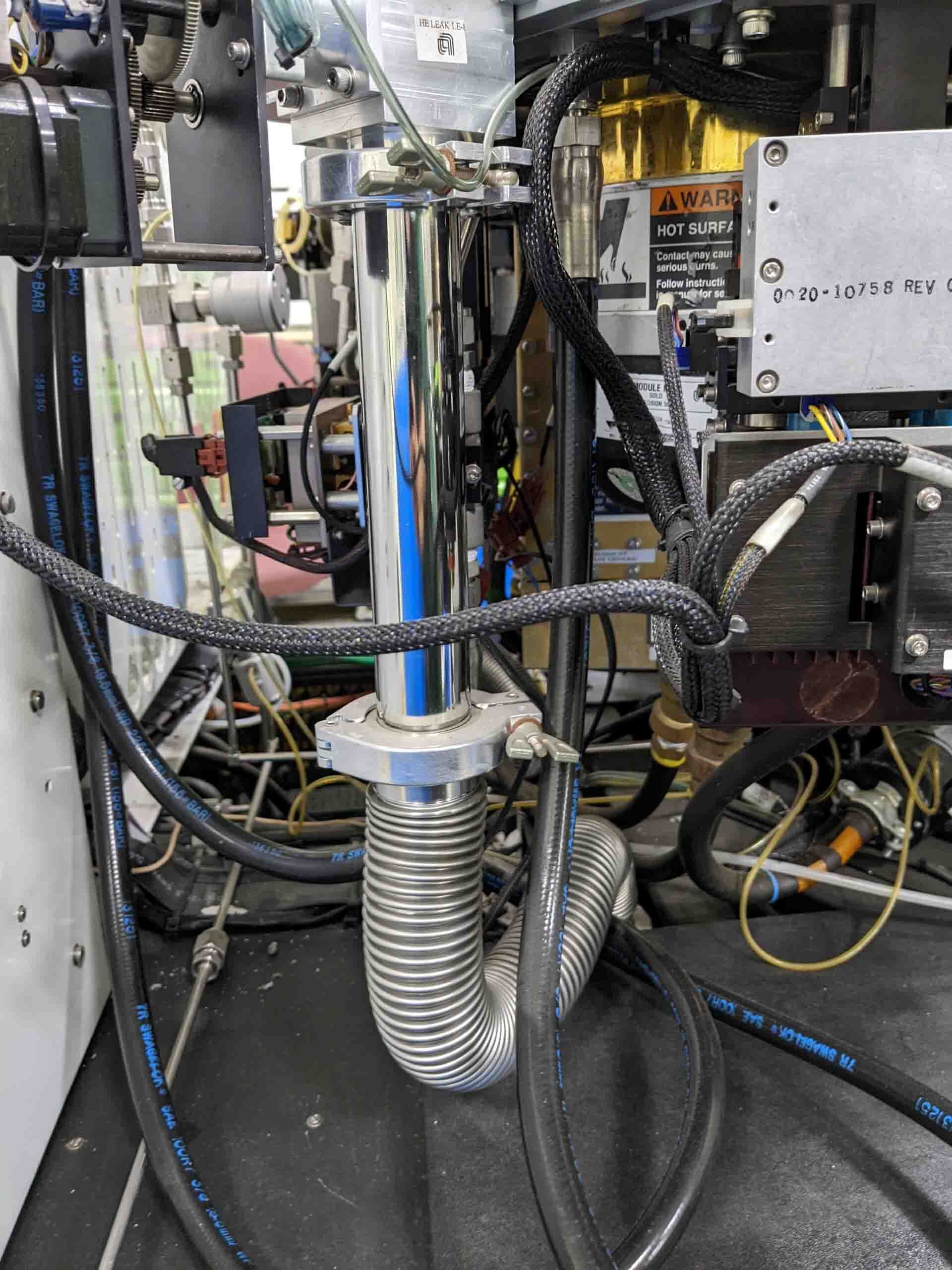

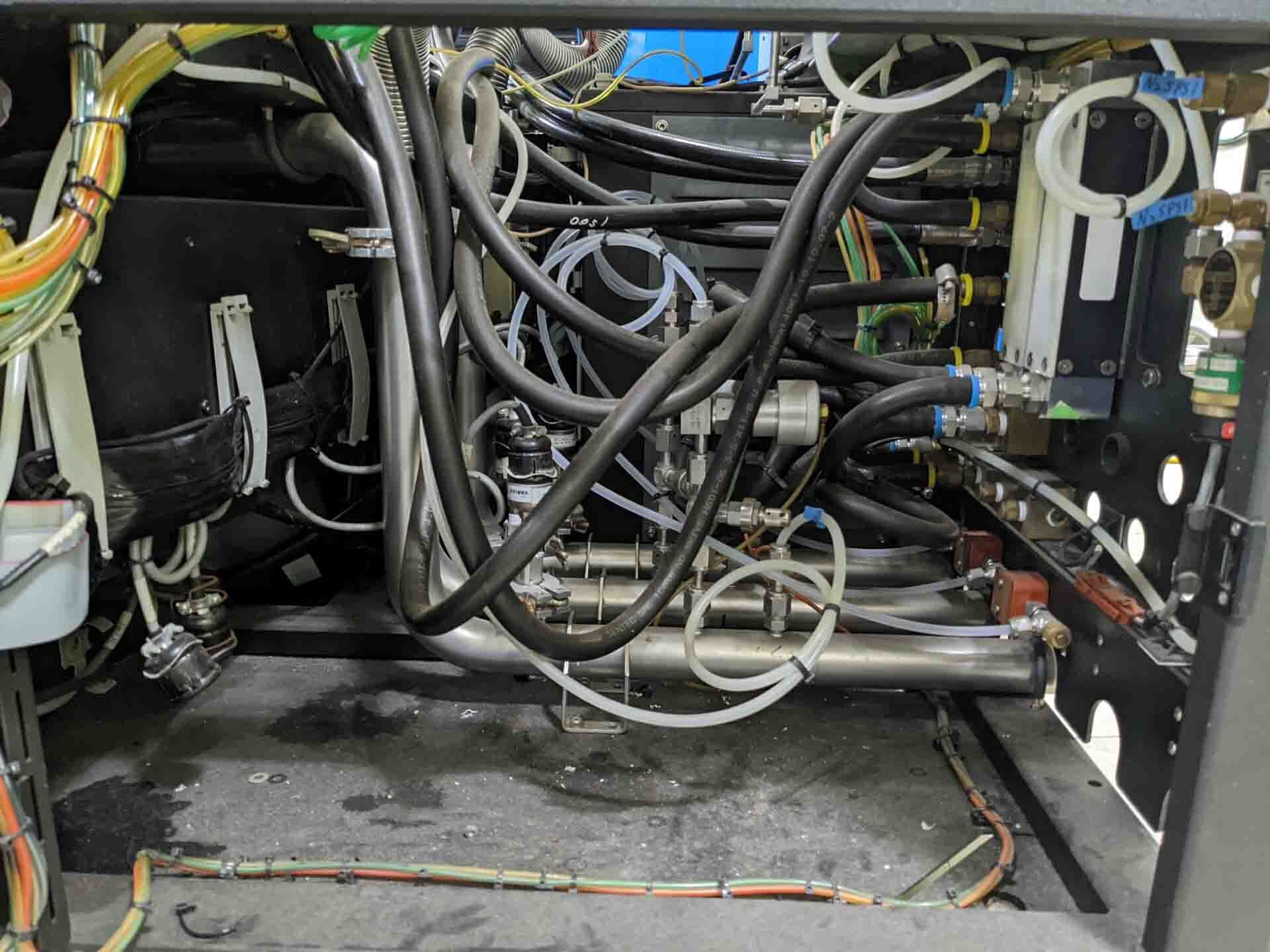

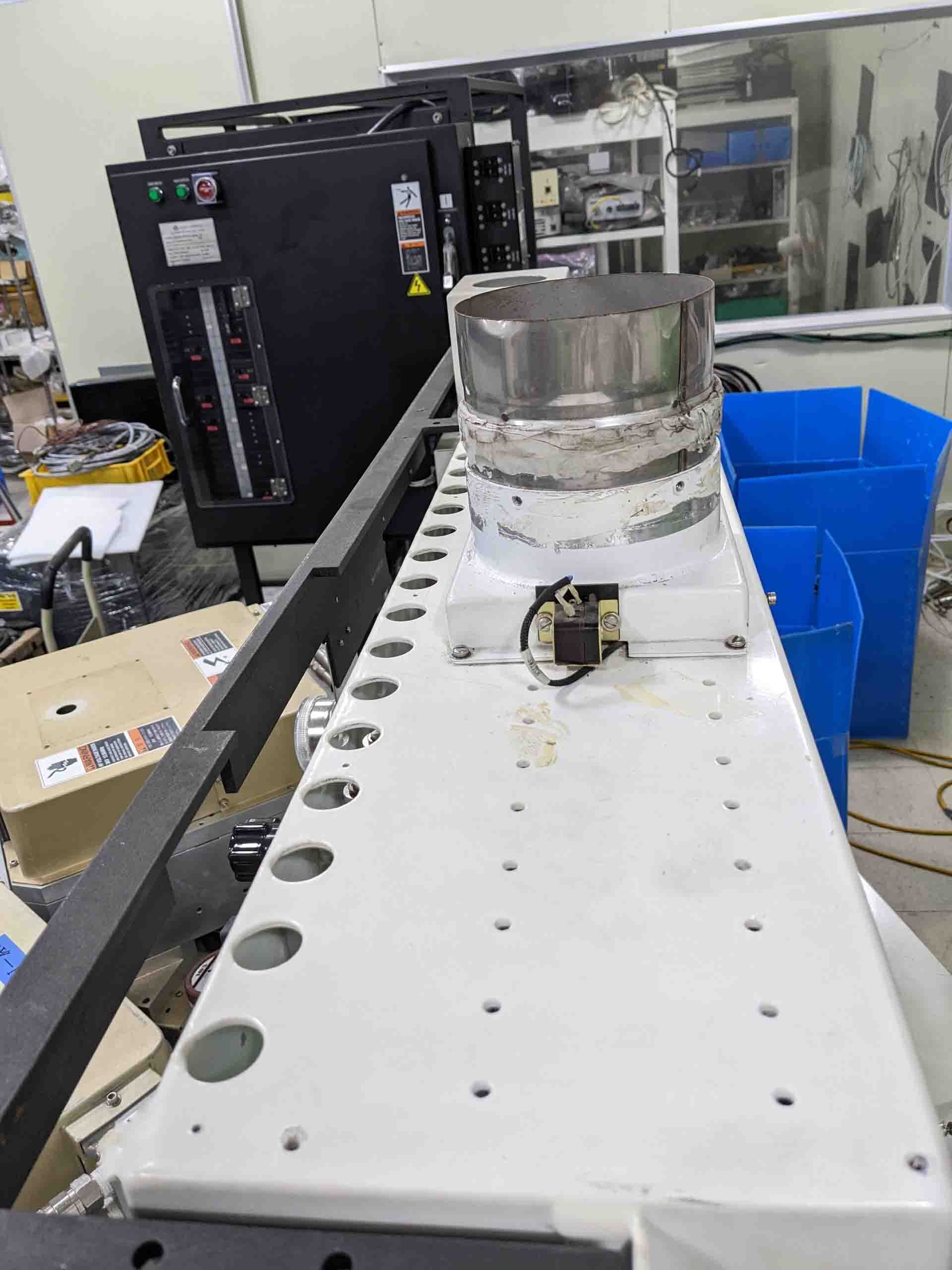

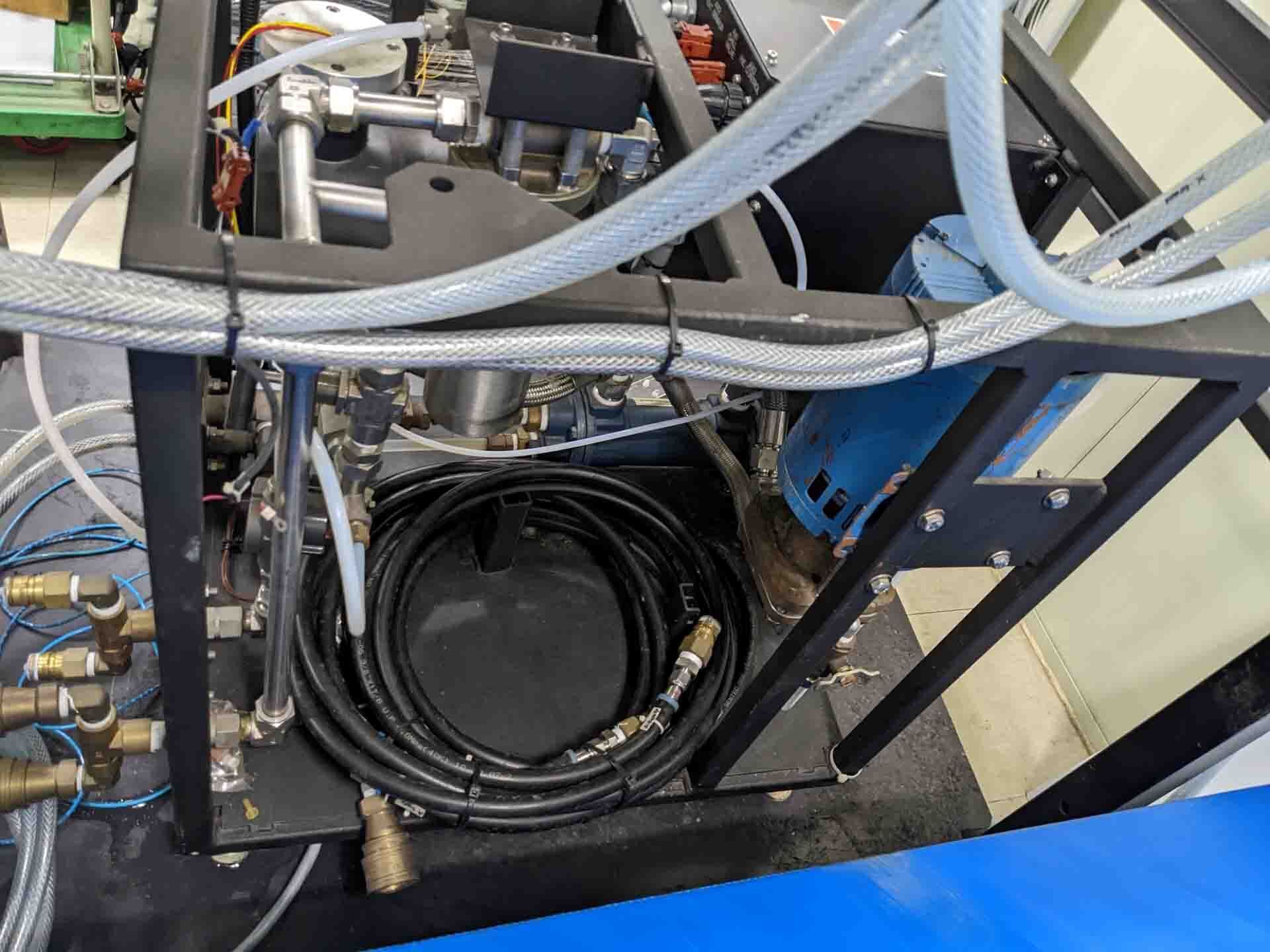

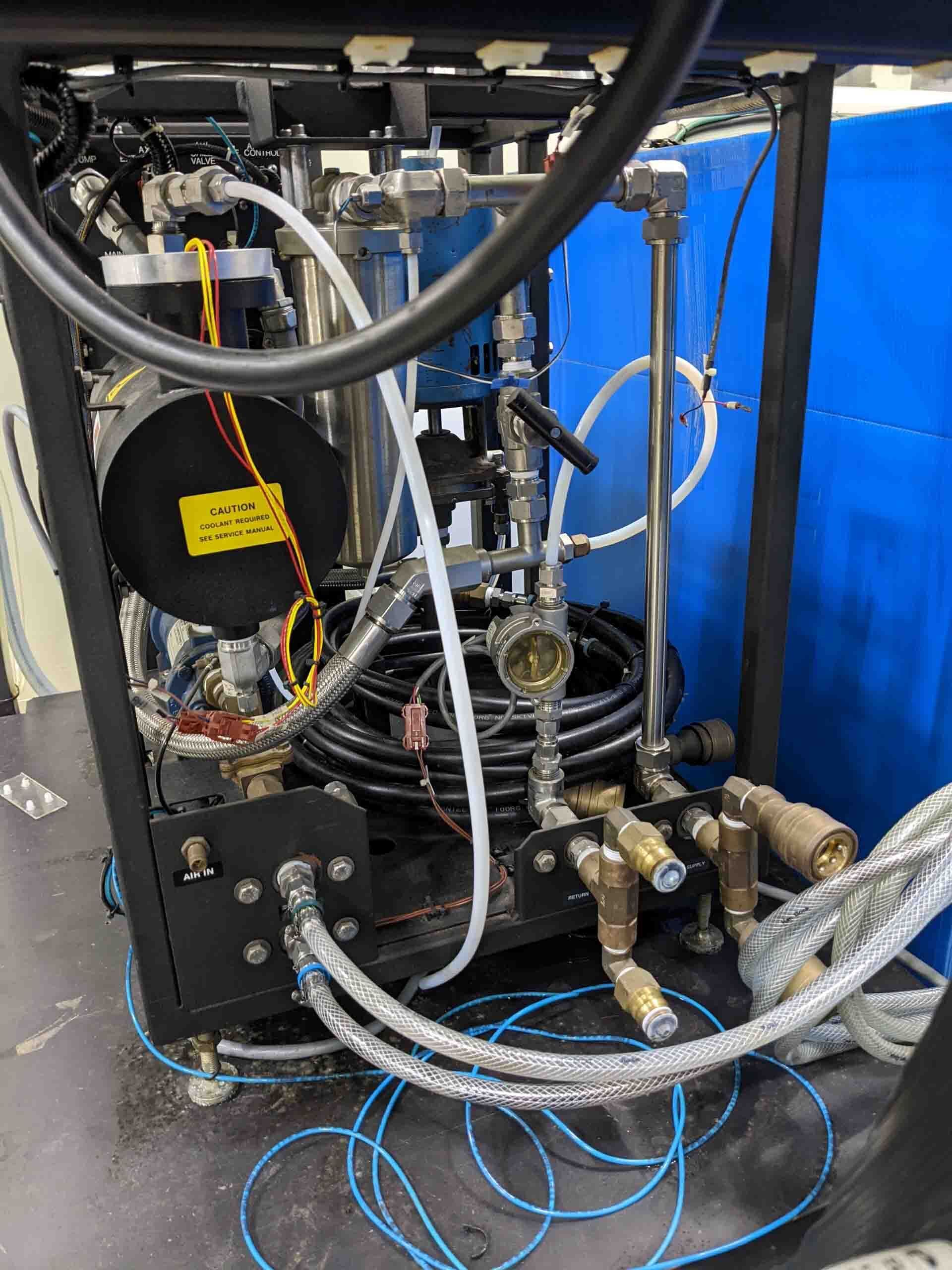

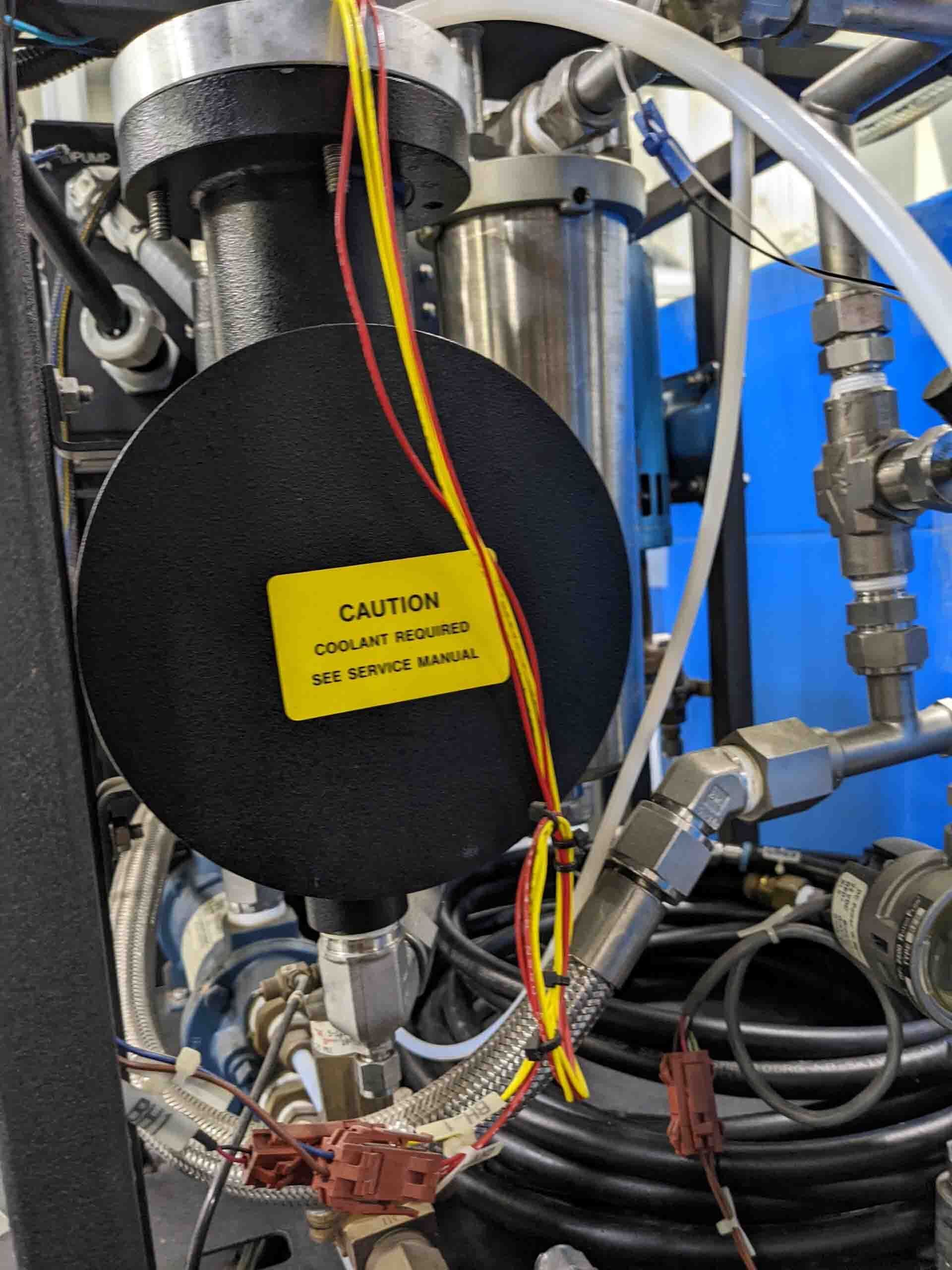

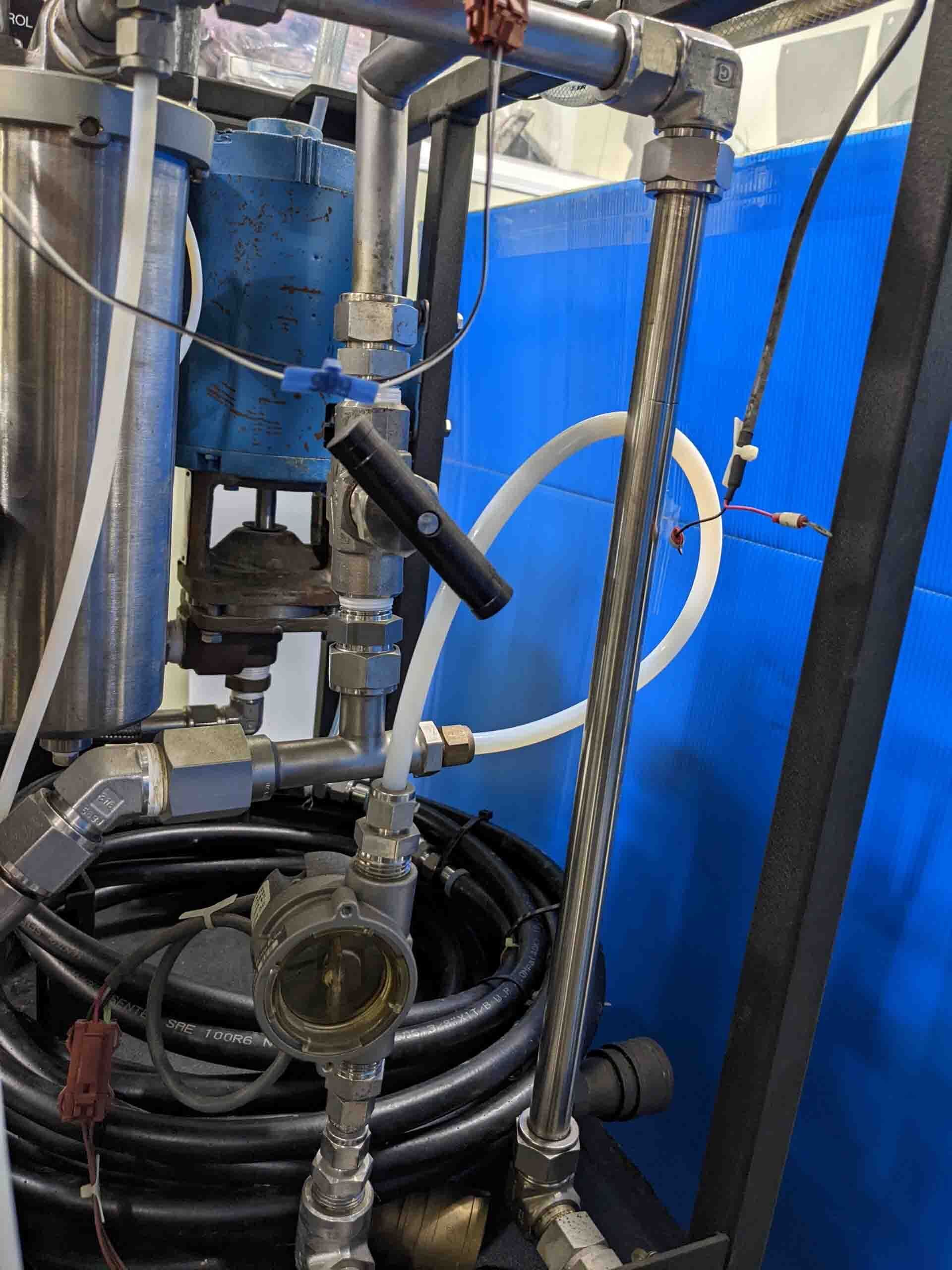

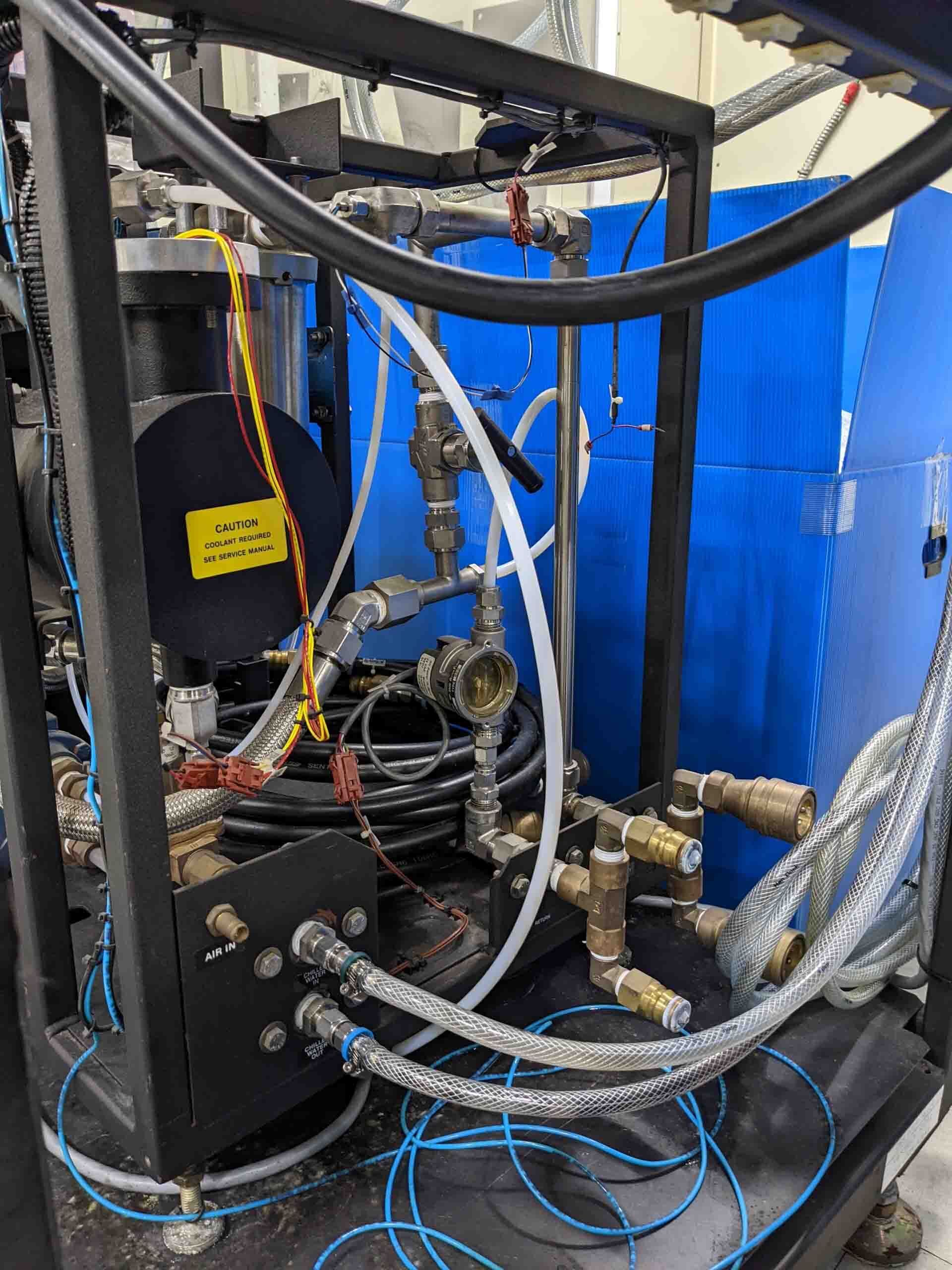

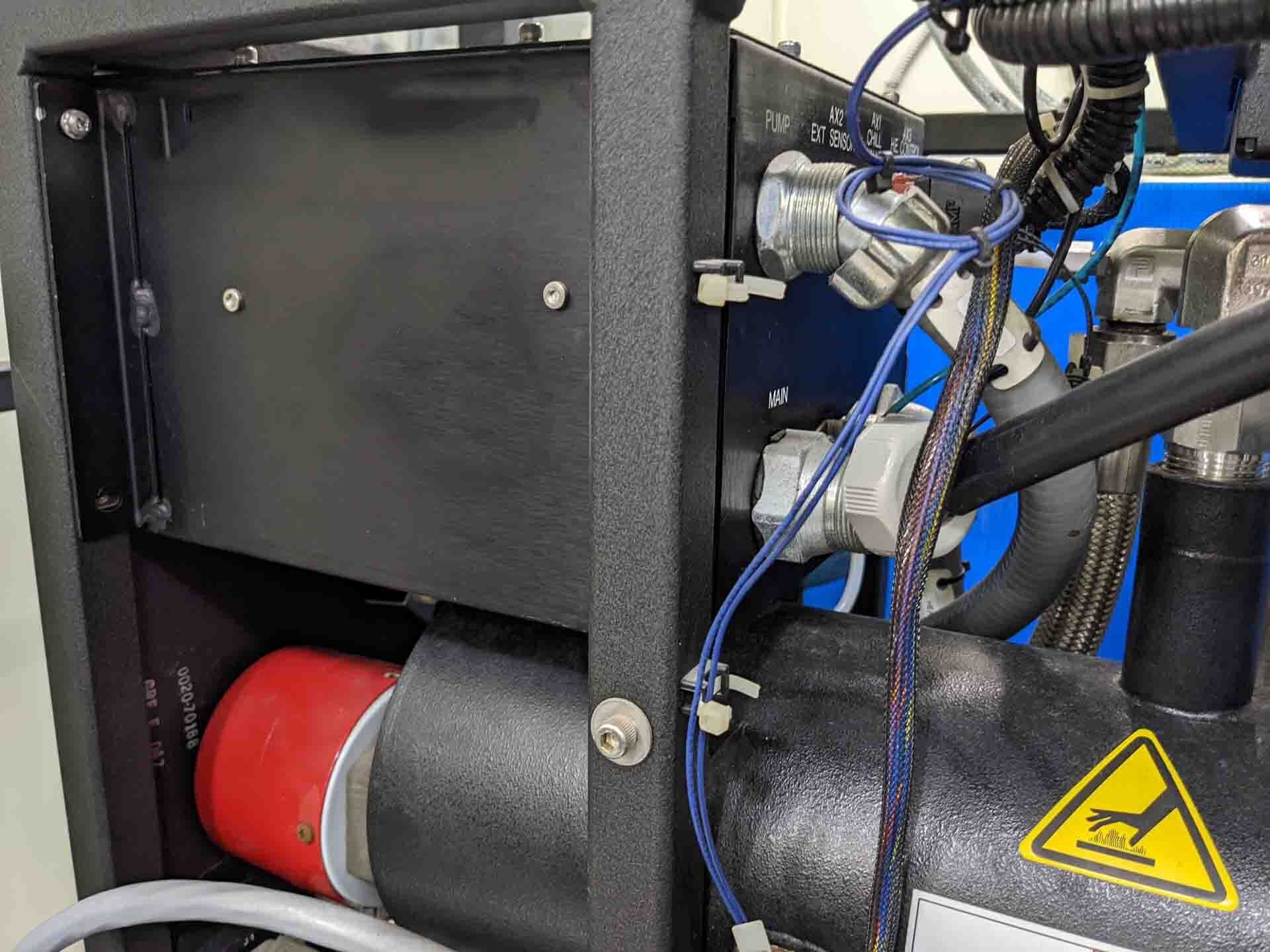

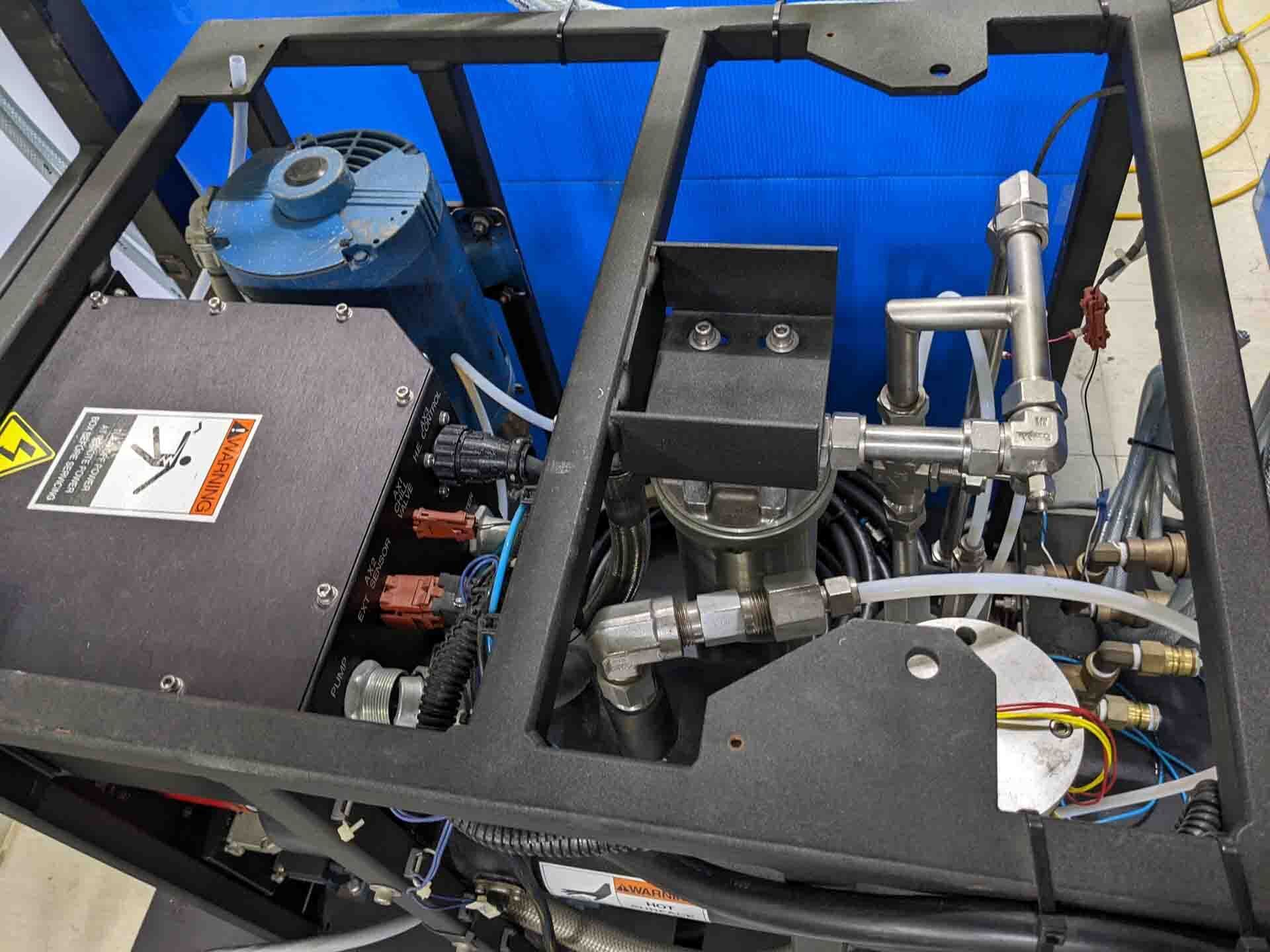

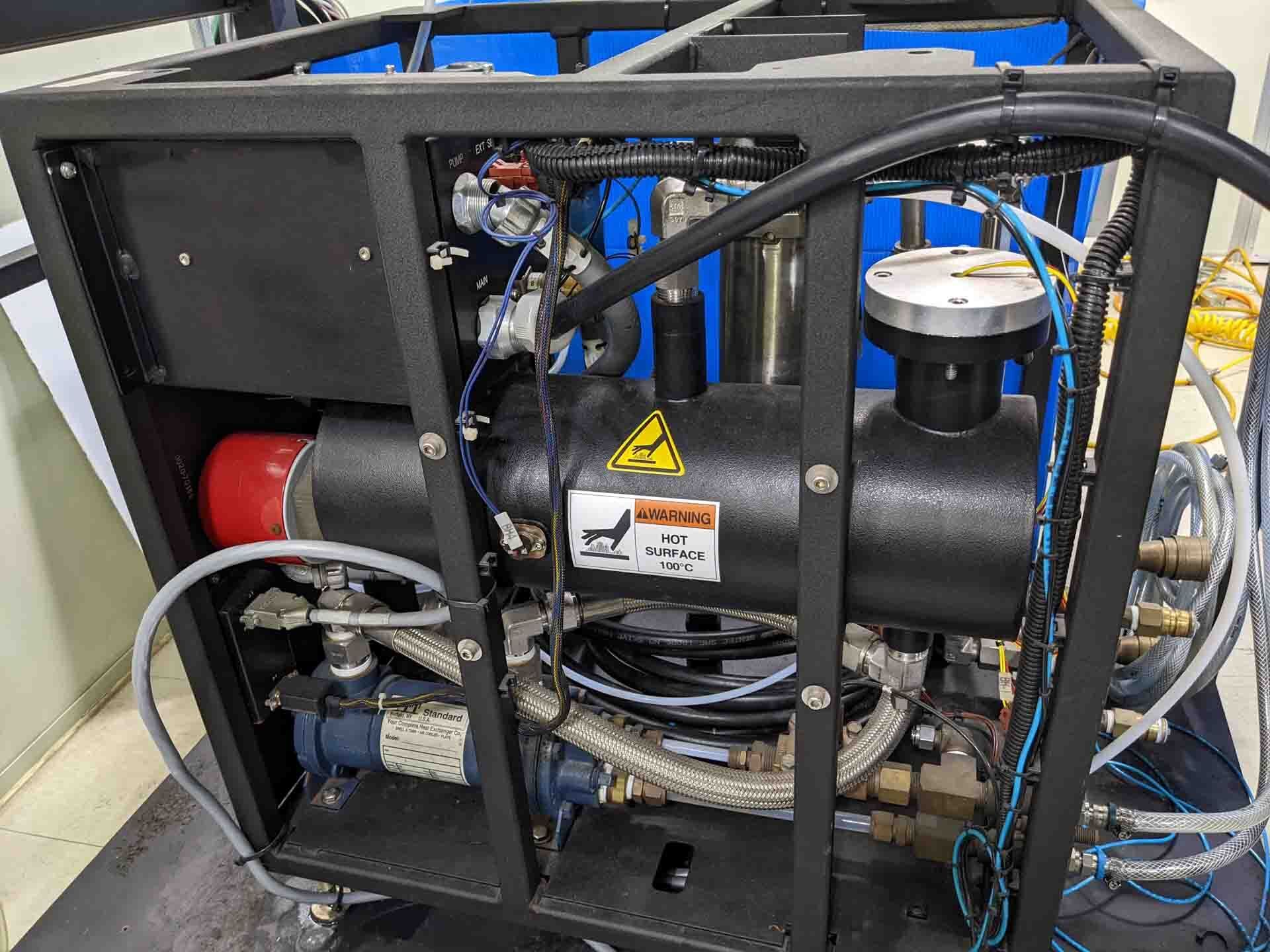

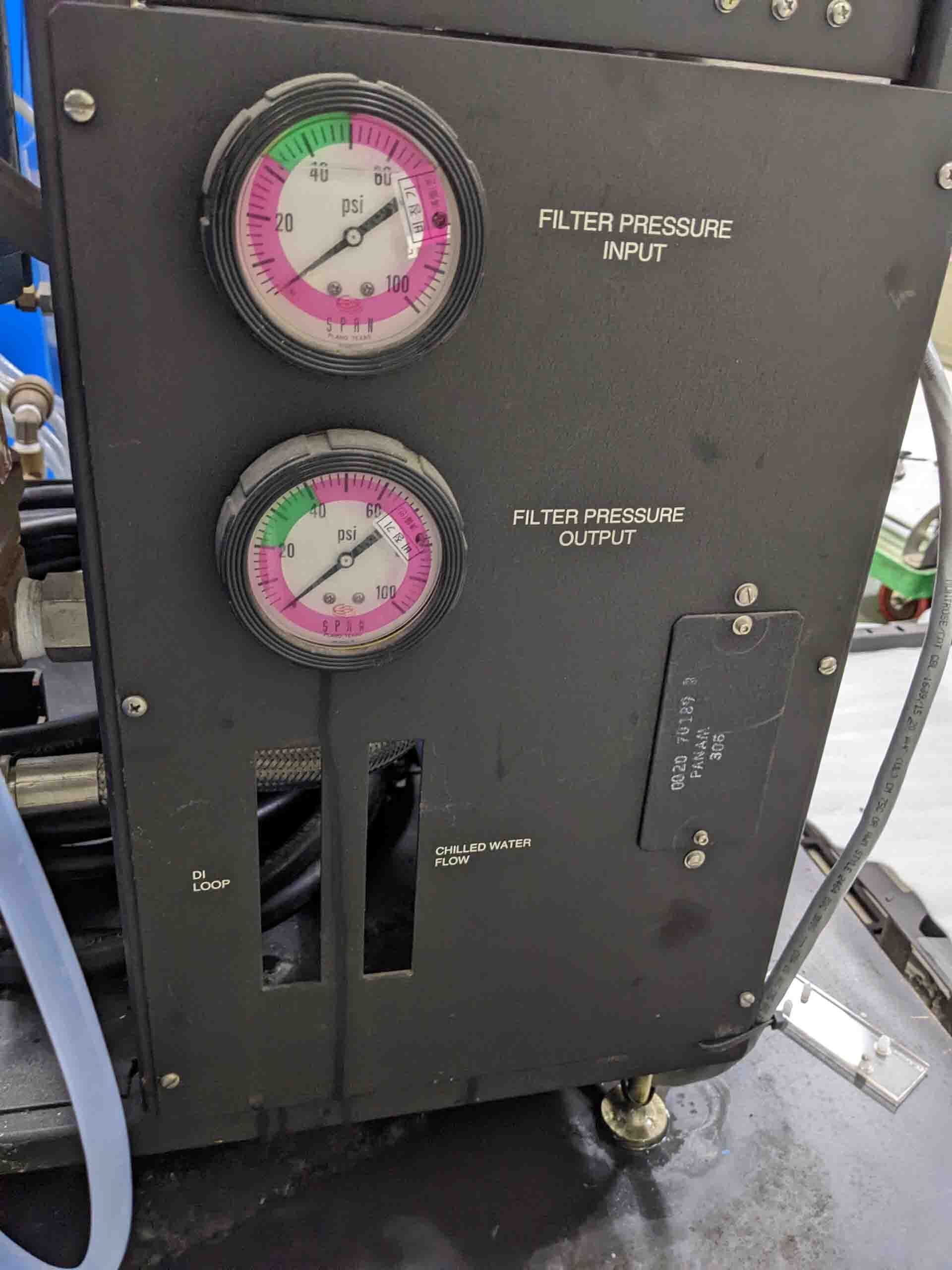

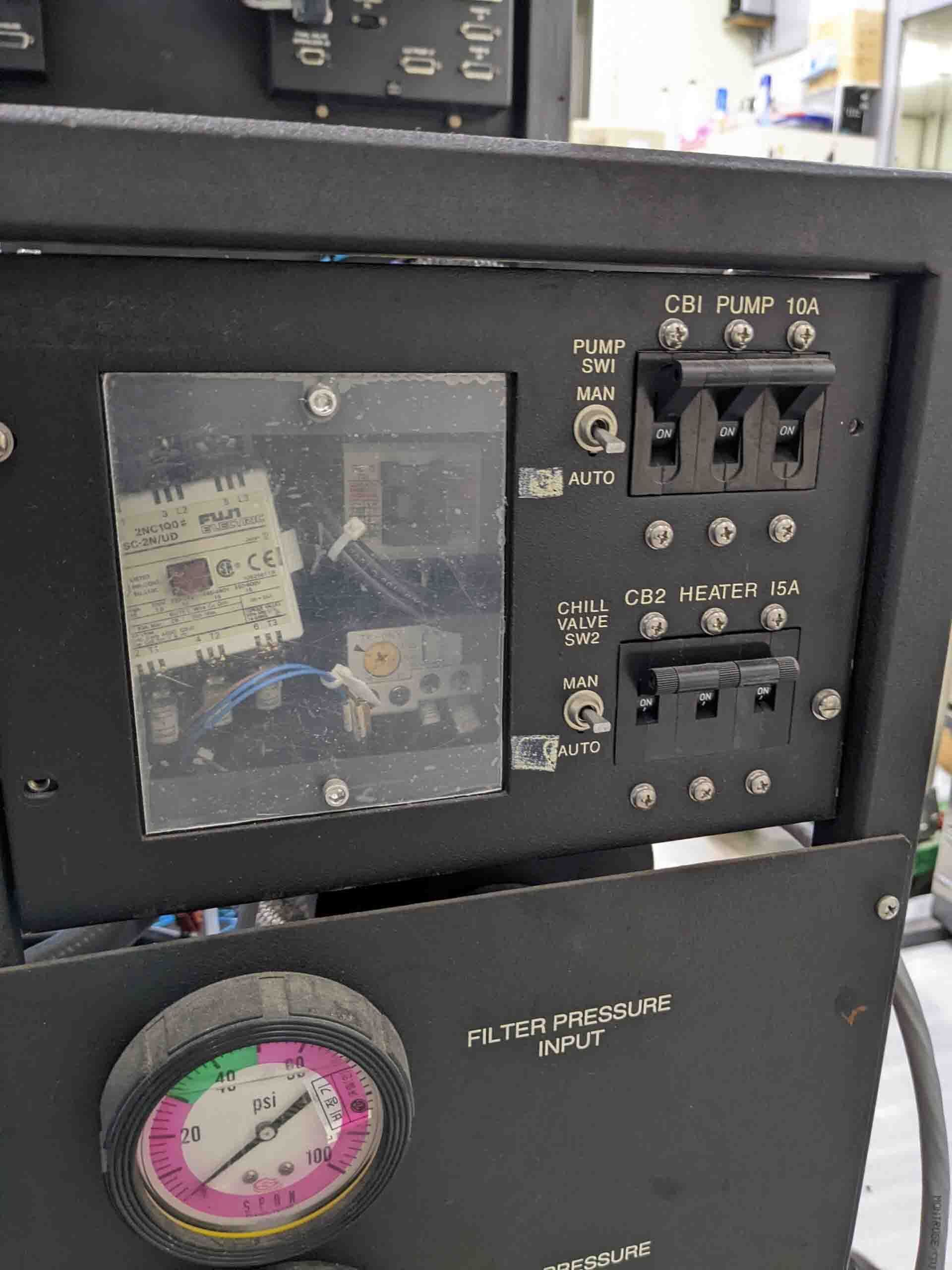

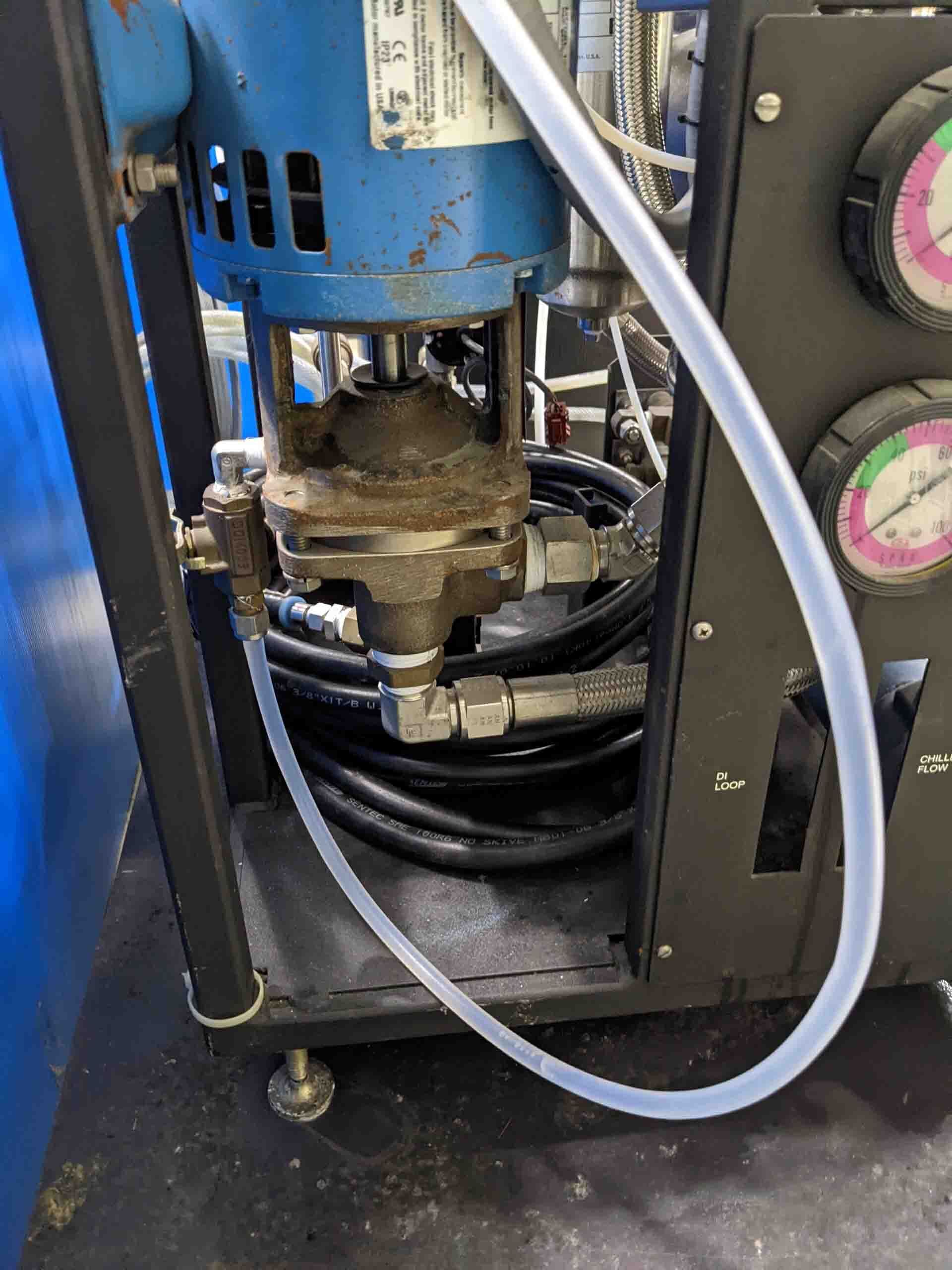

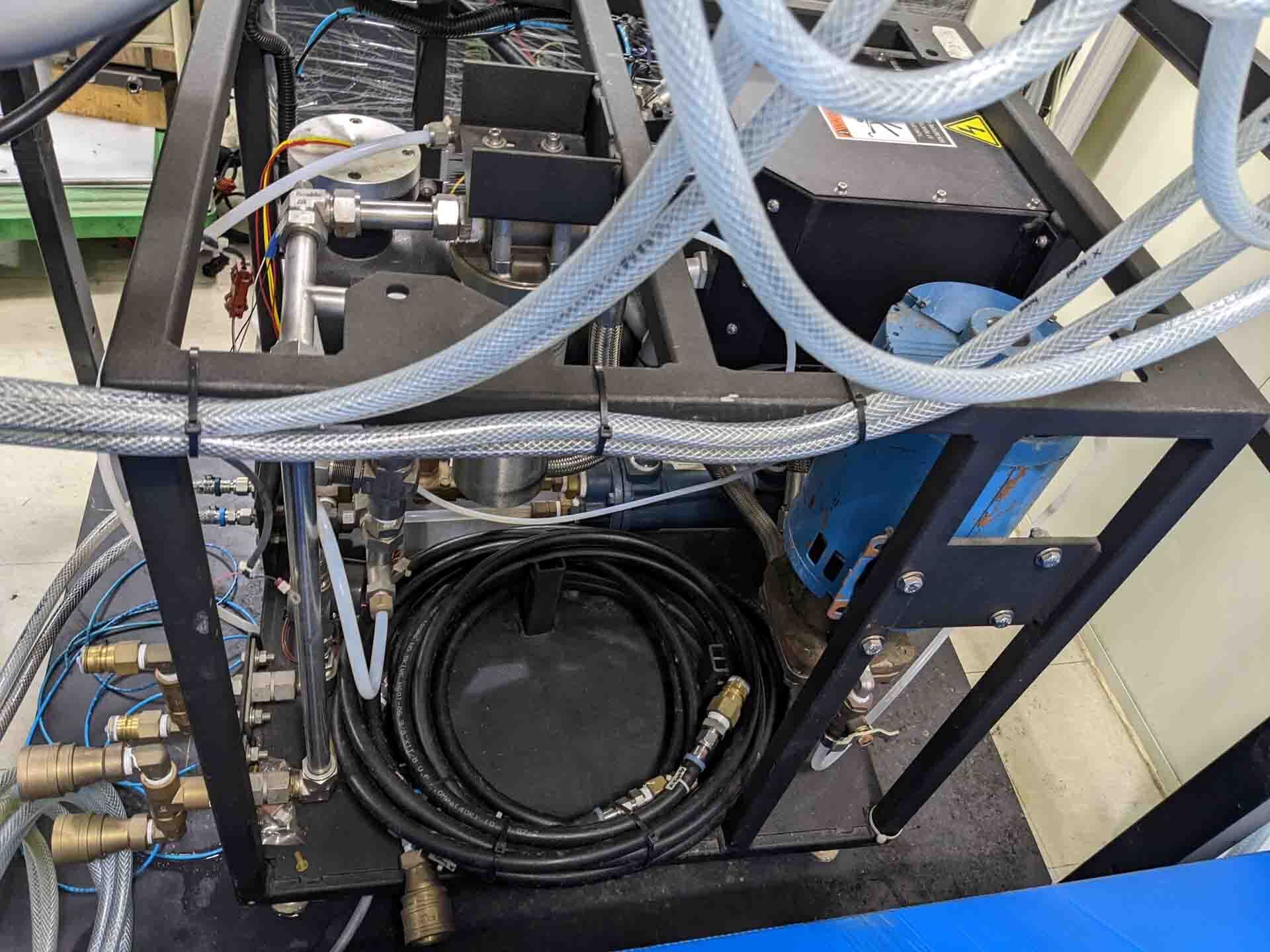

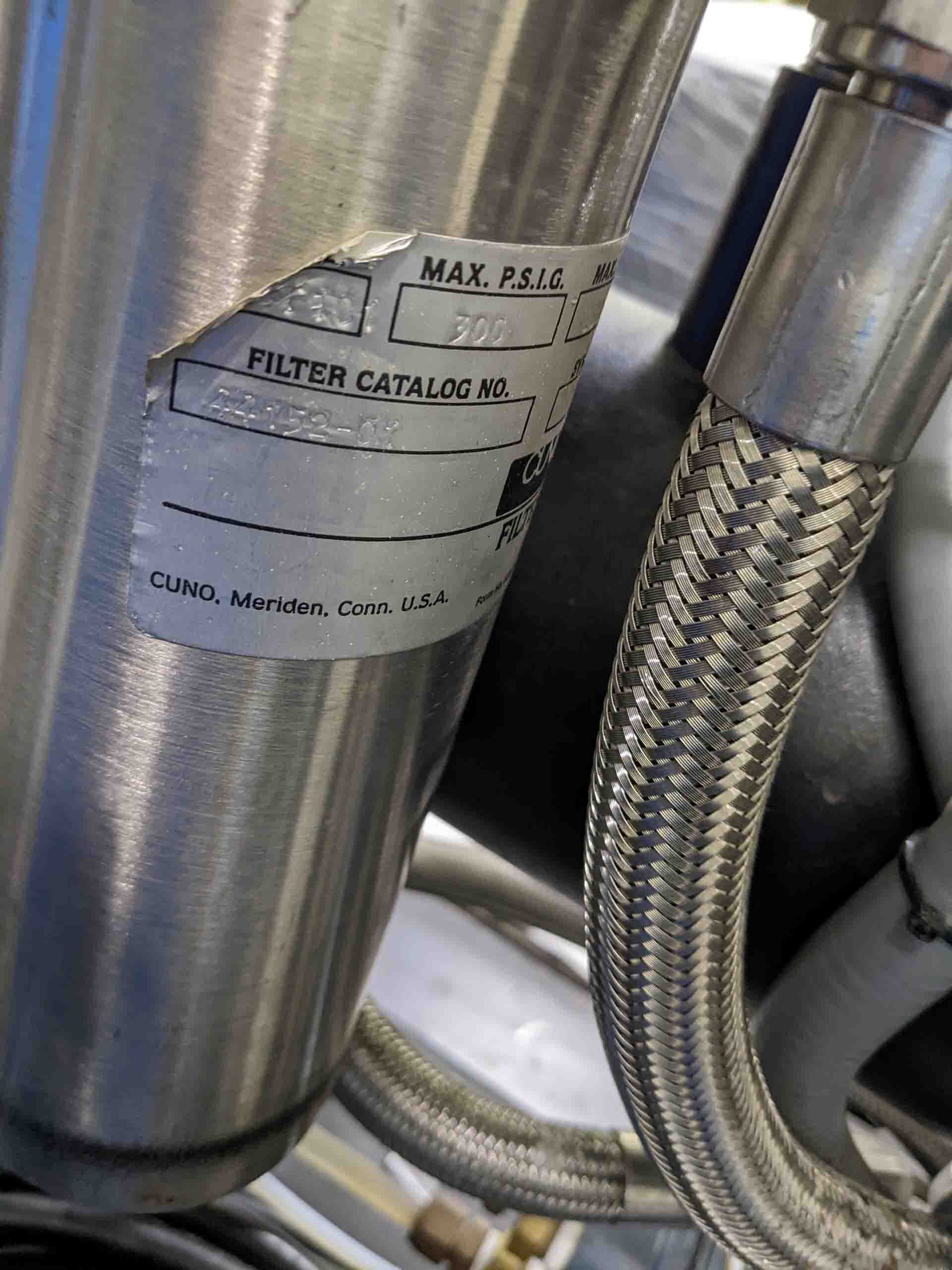

Heat exchanger

Floppy Disk Drive (FDD): 3.5"

Standard cassette handler

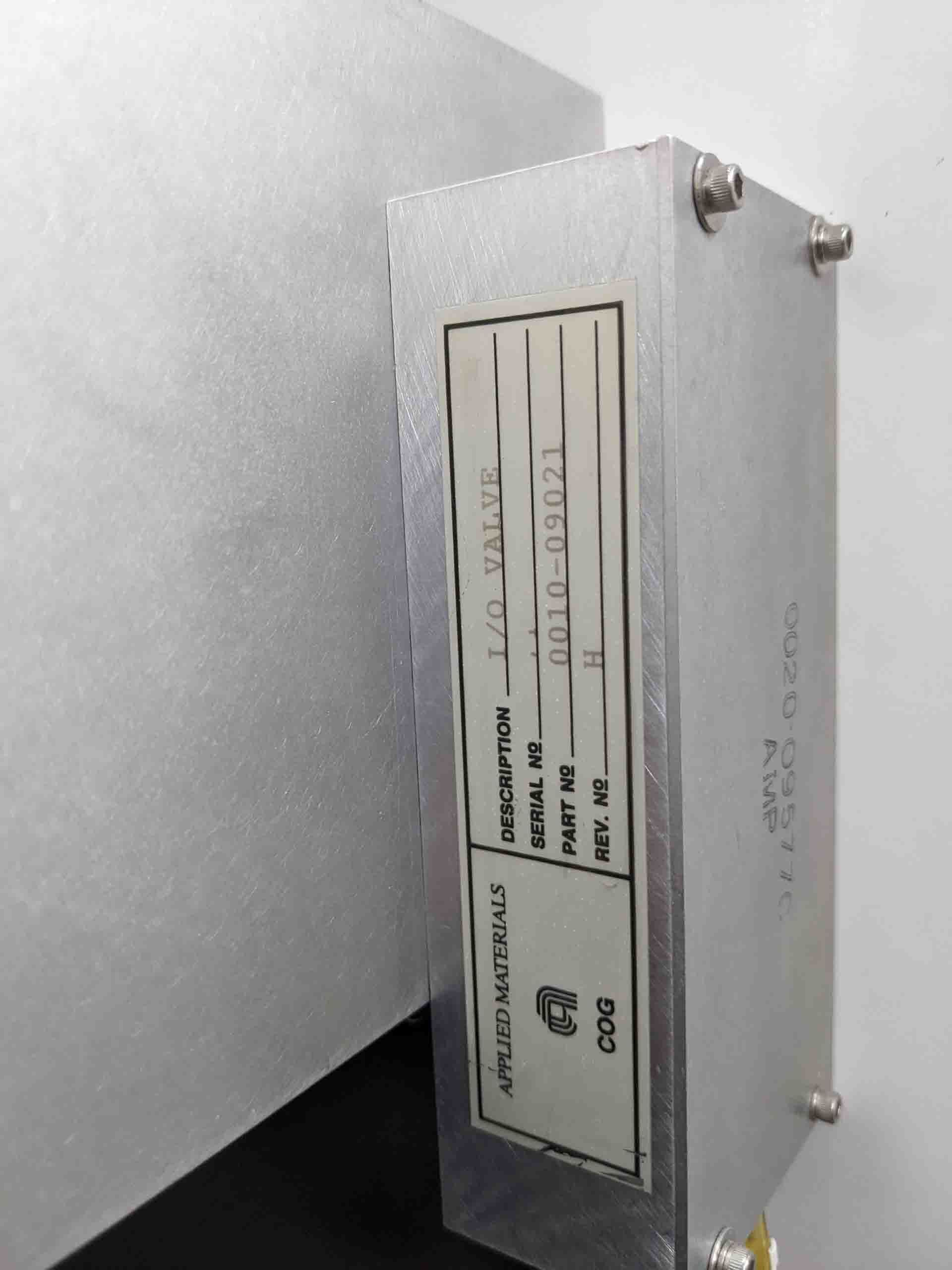

I/O Wafer sensor

No Load lock slow vent

Load lock purge

Exhaust line type: Top, standard

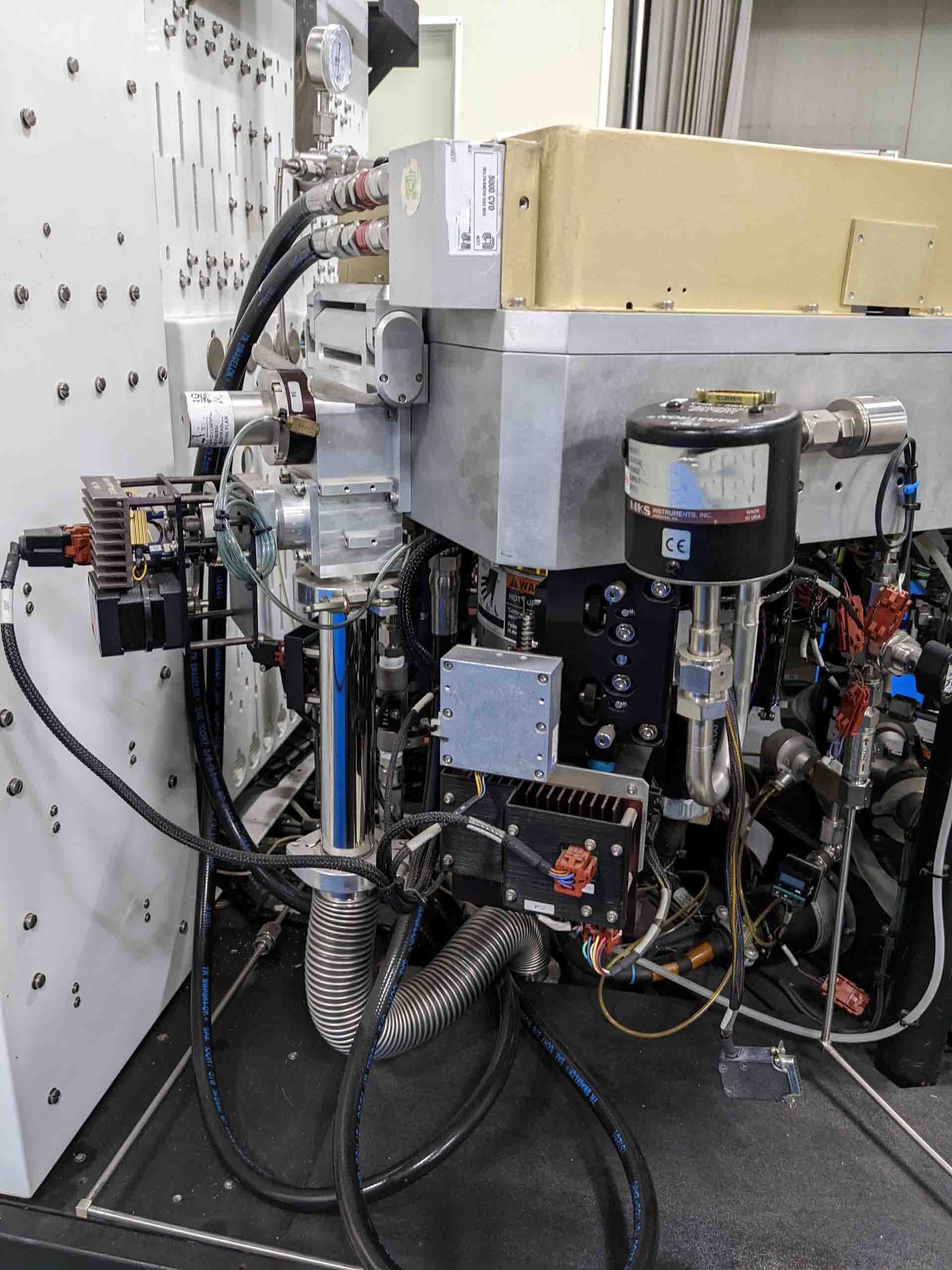

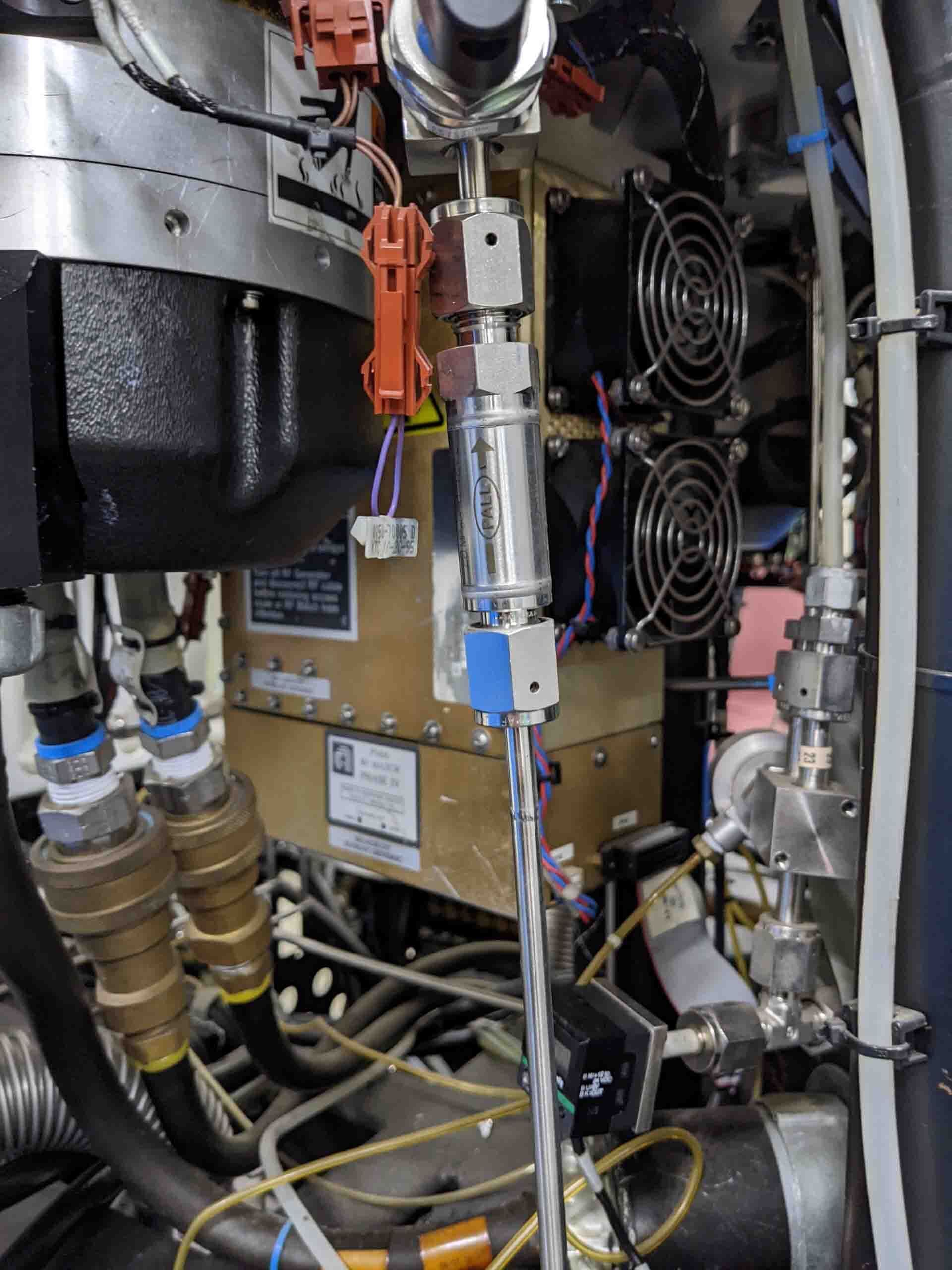

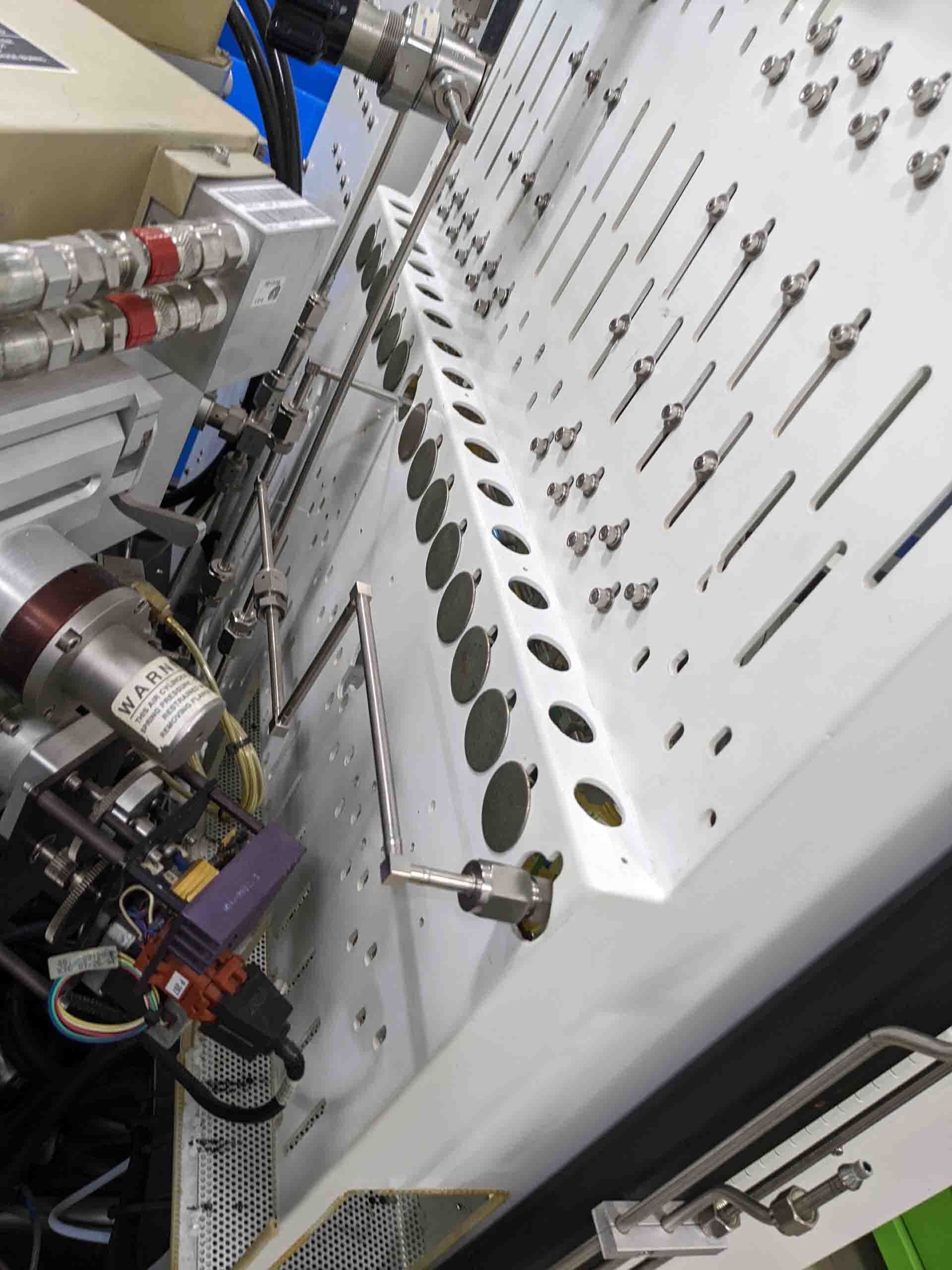

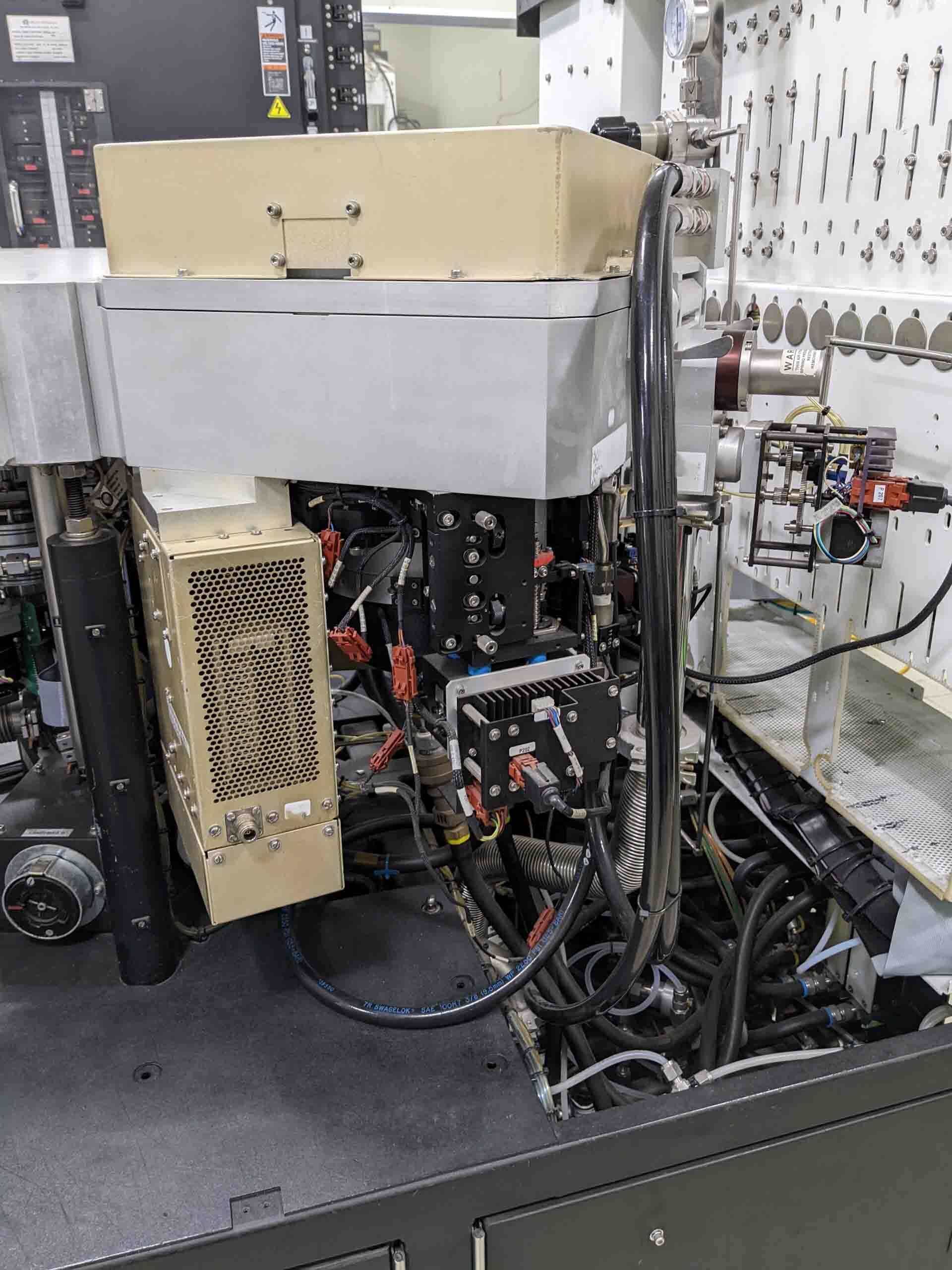

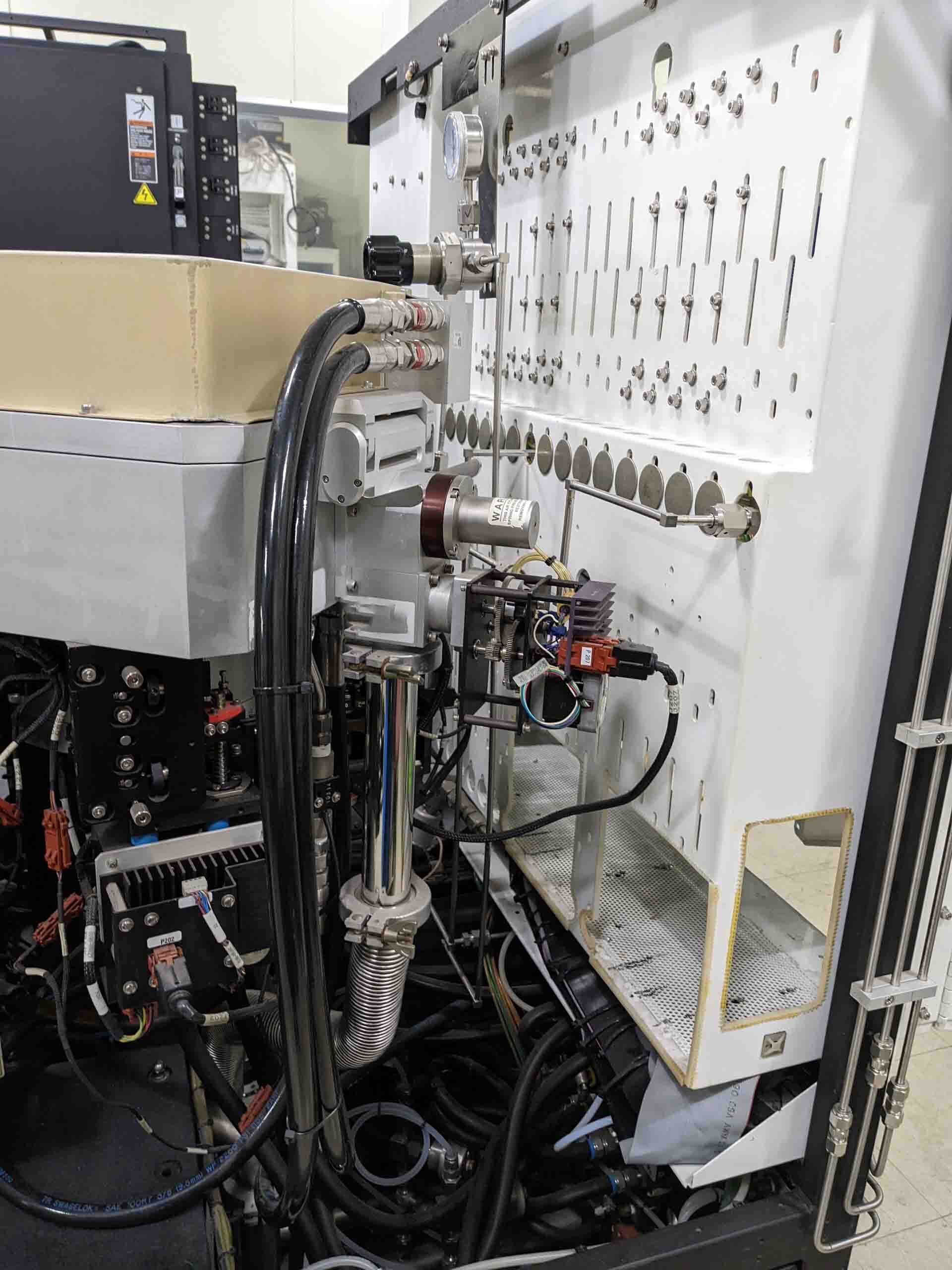

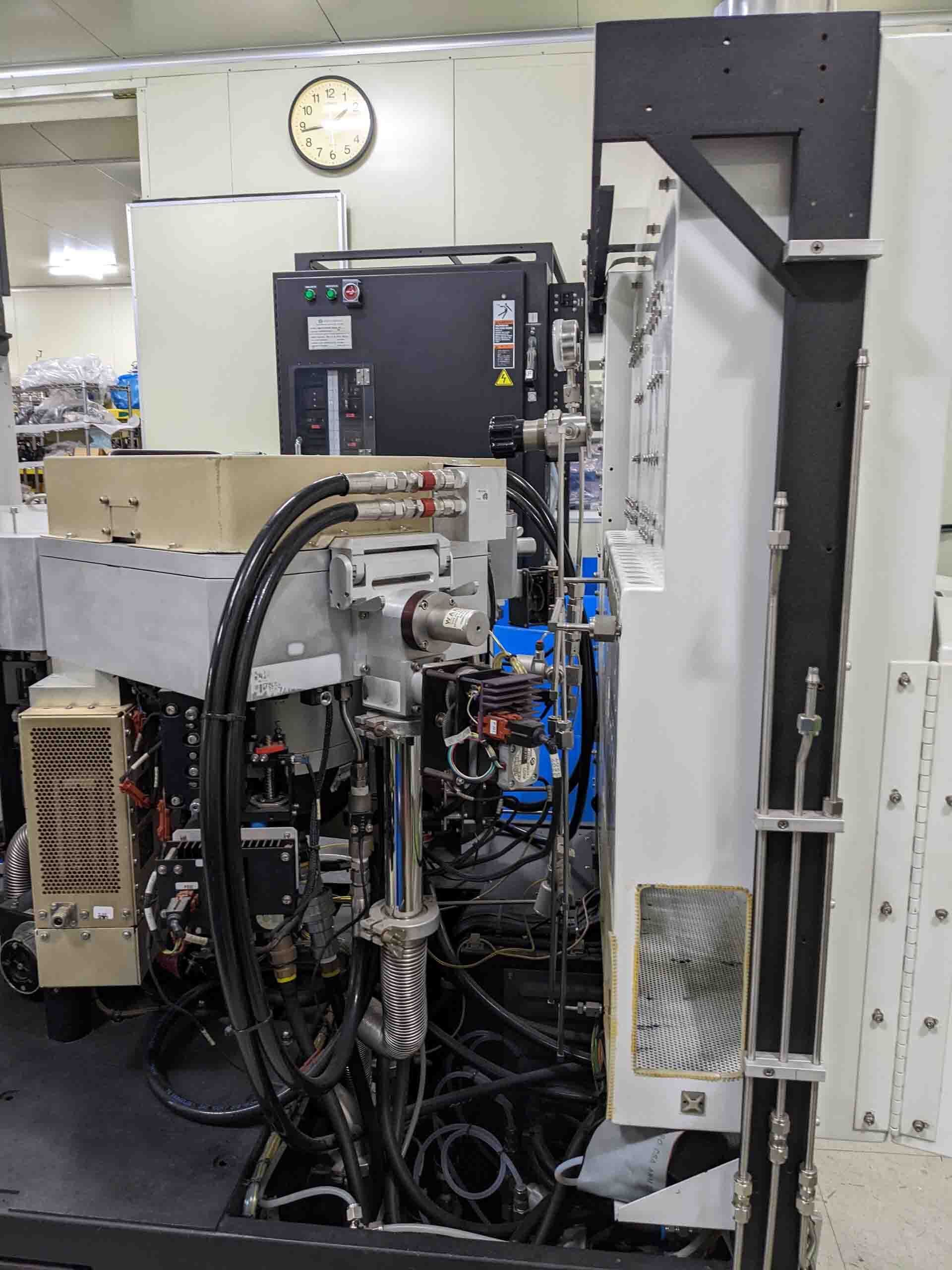

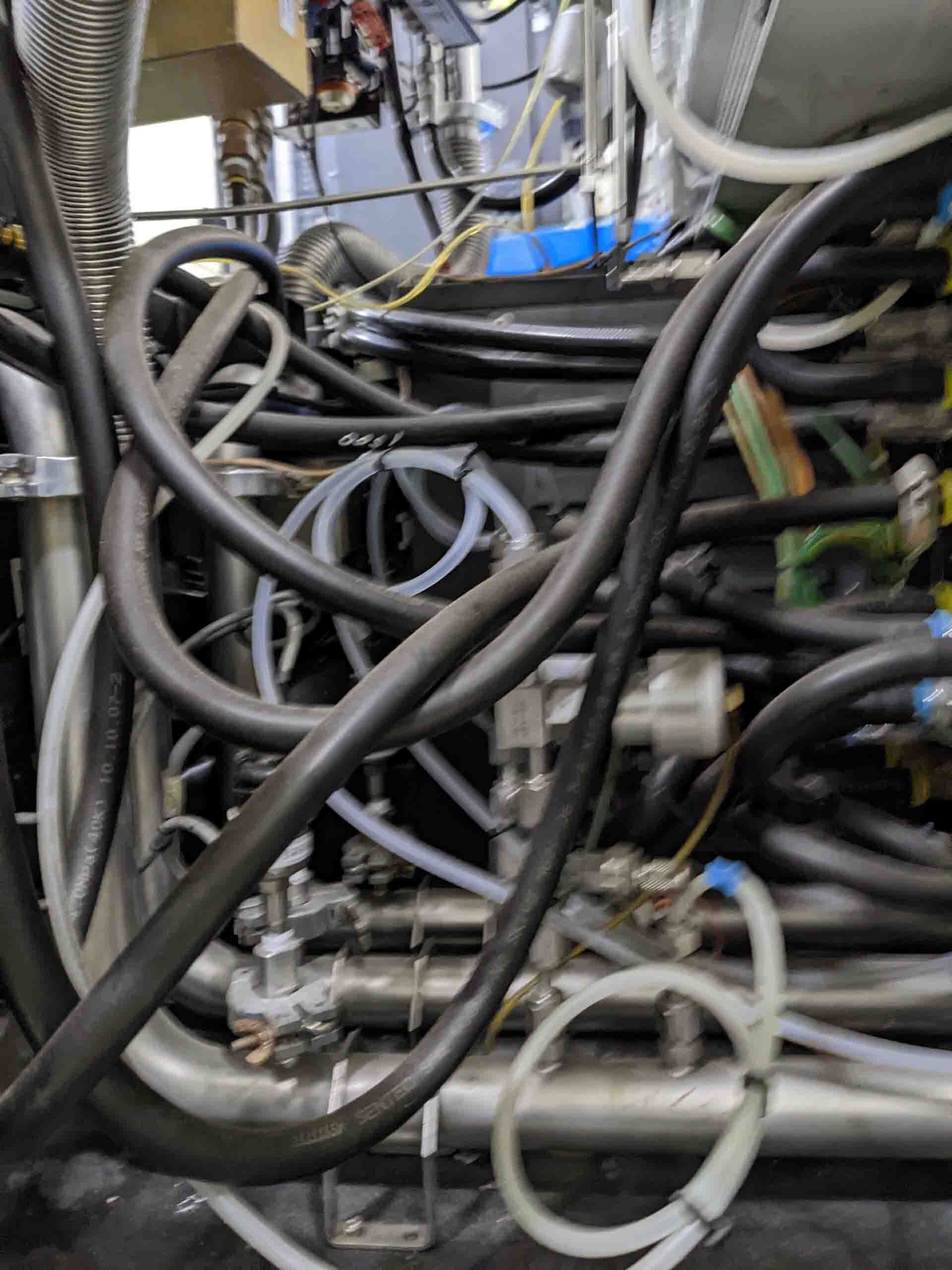

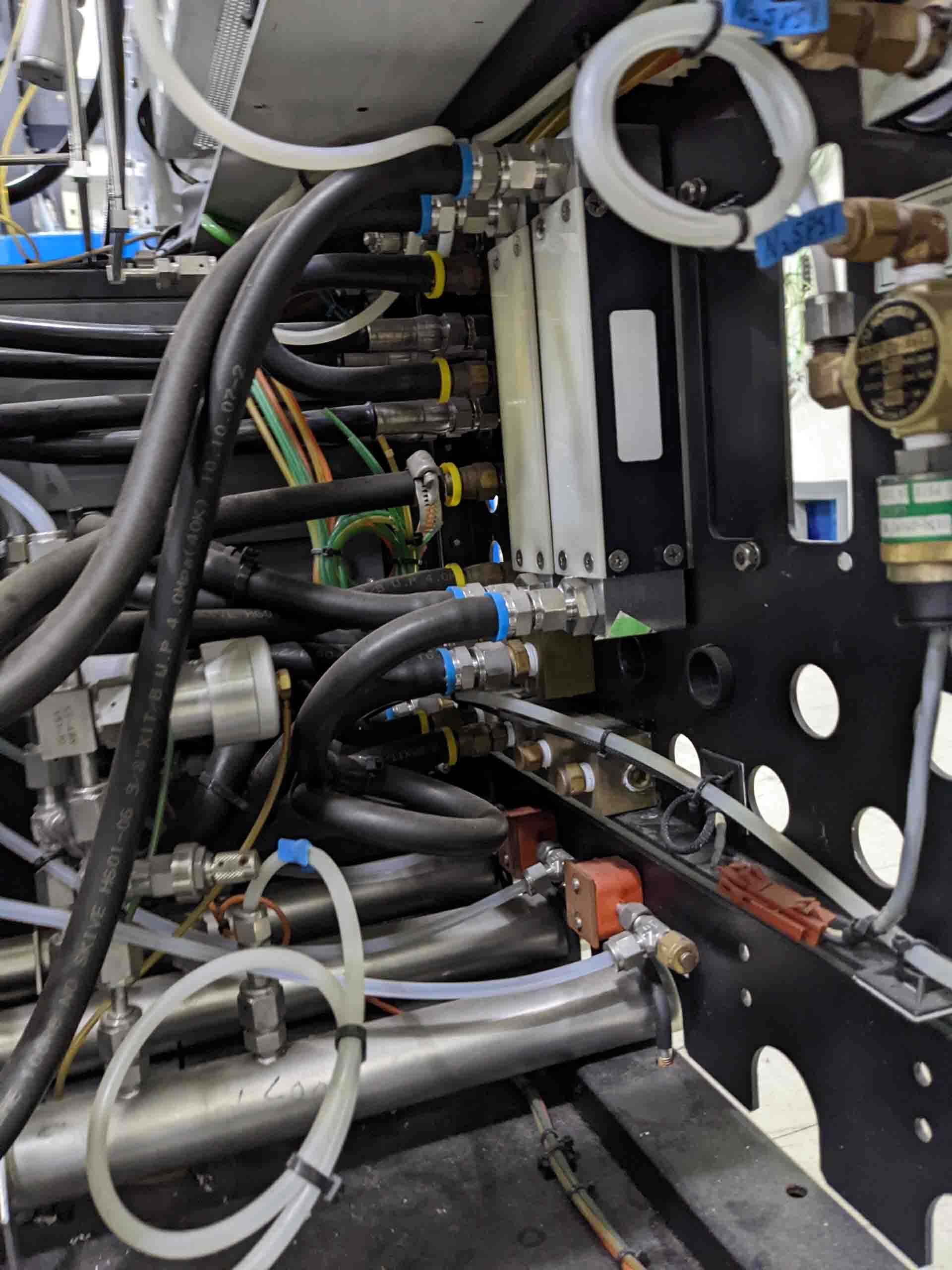

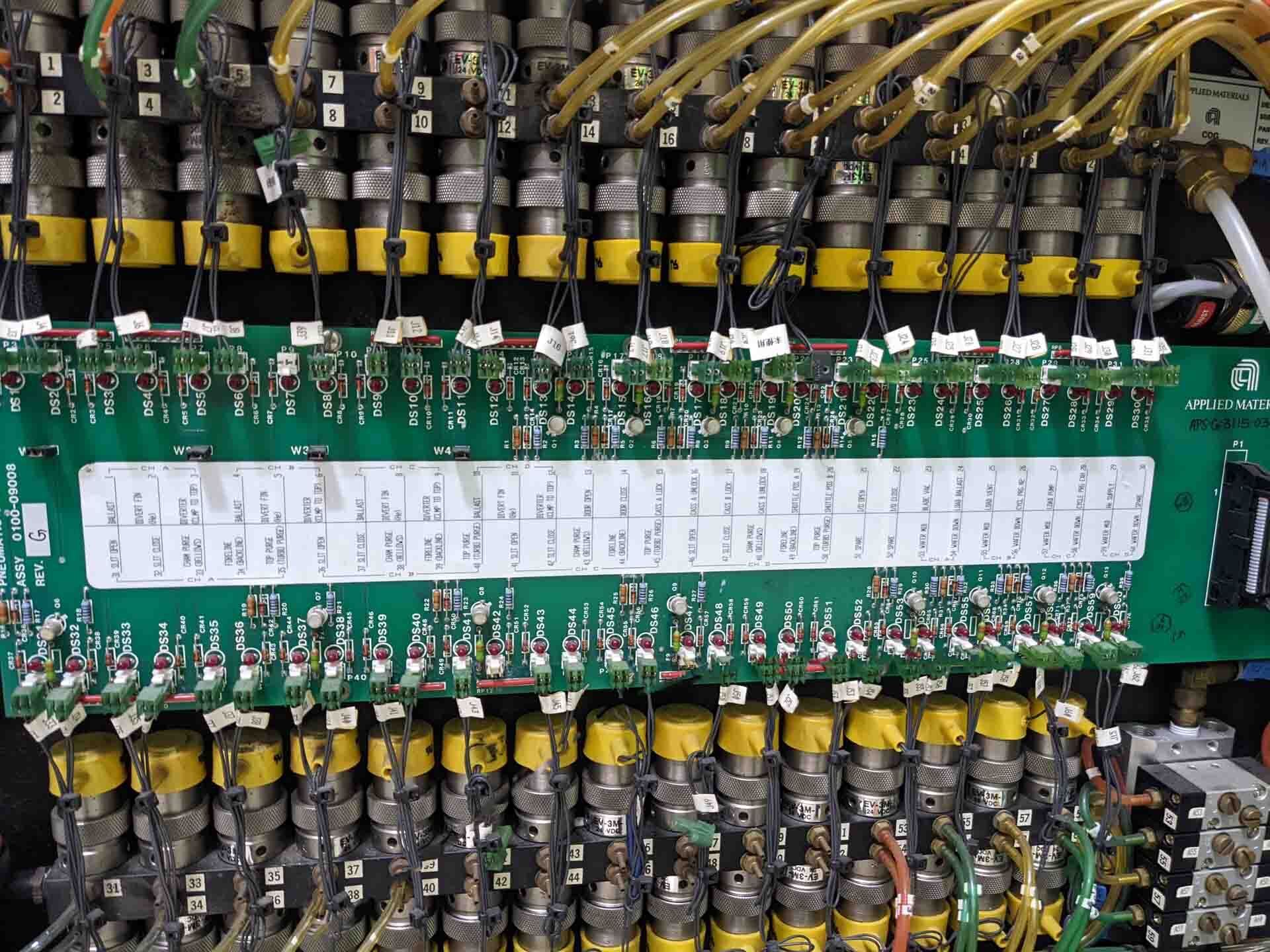

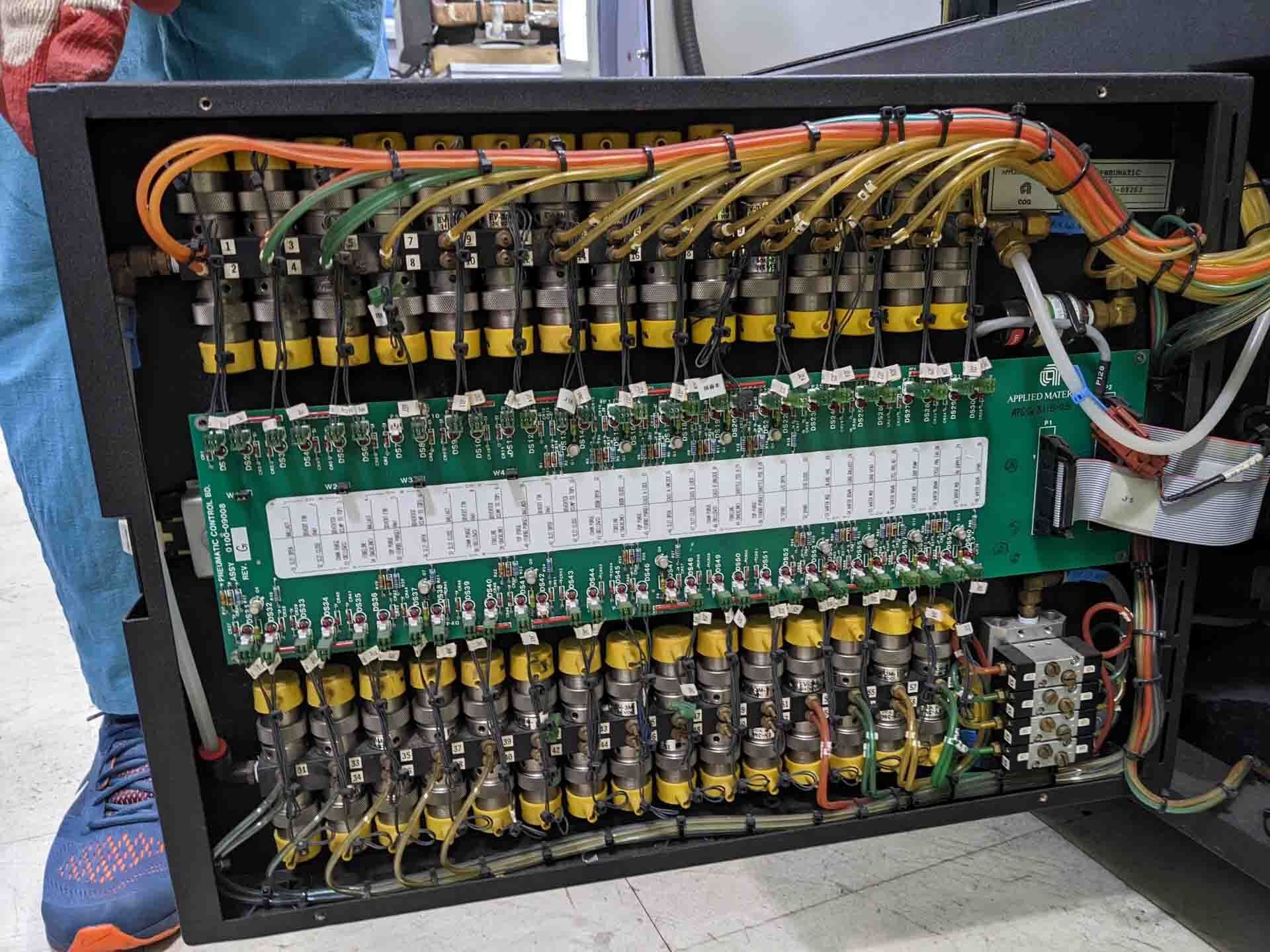

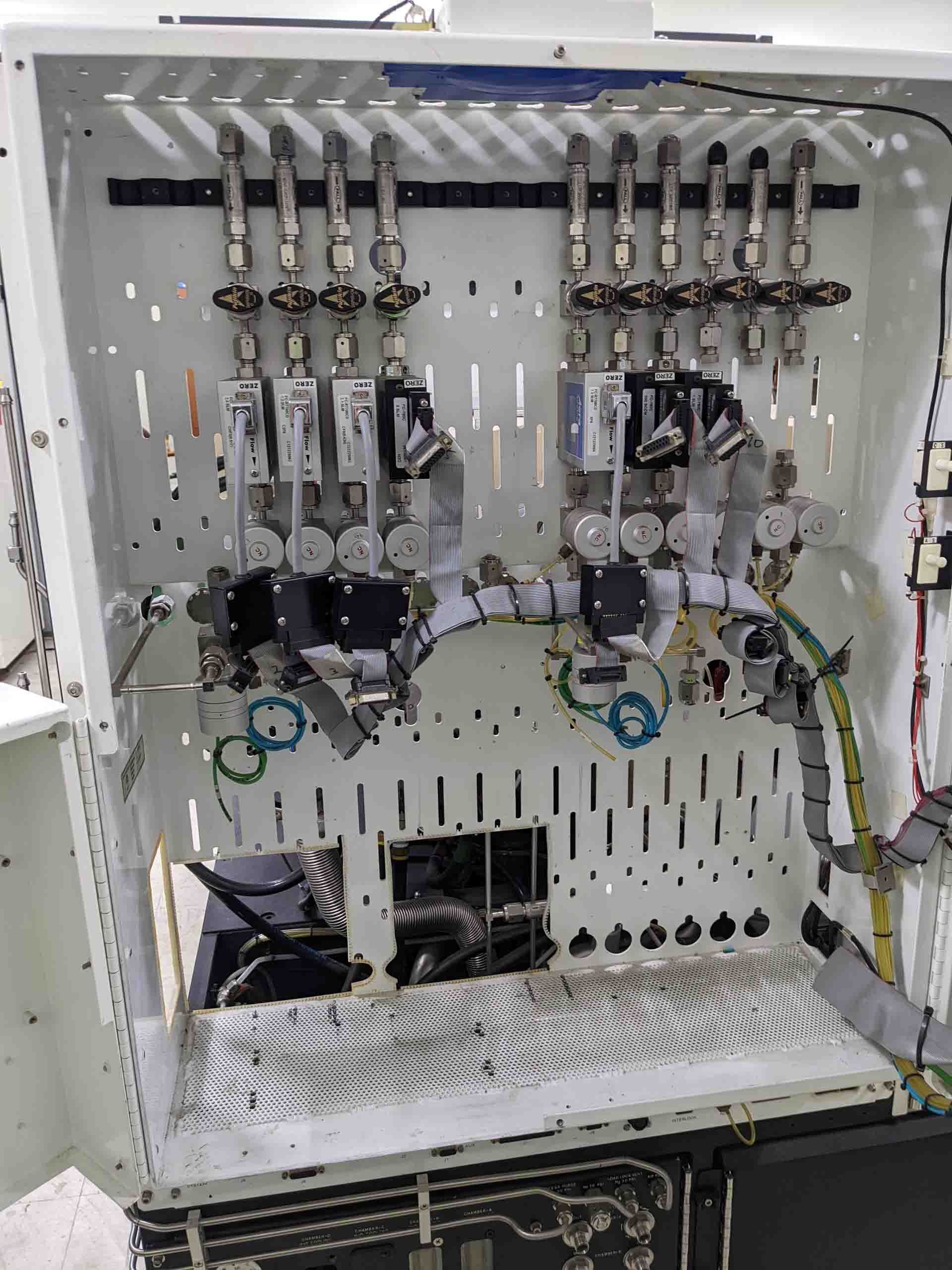

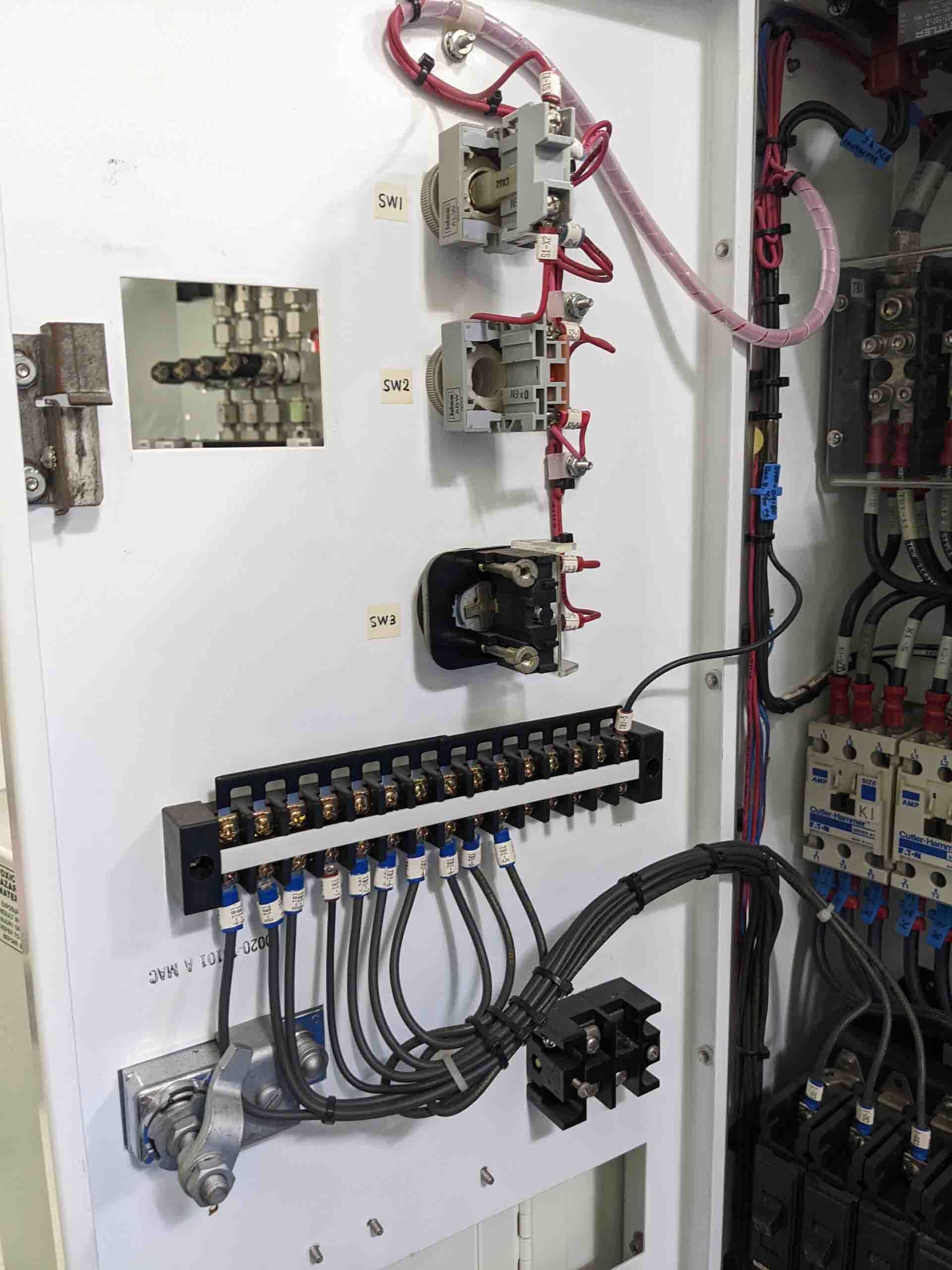

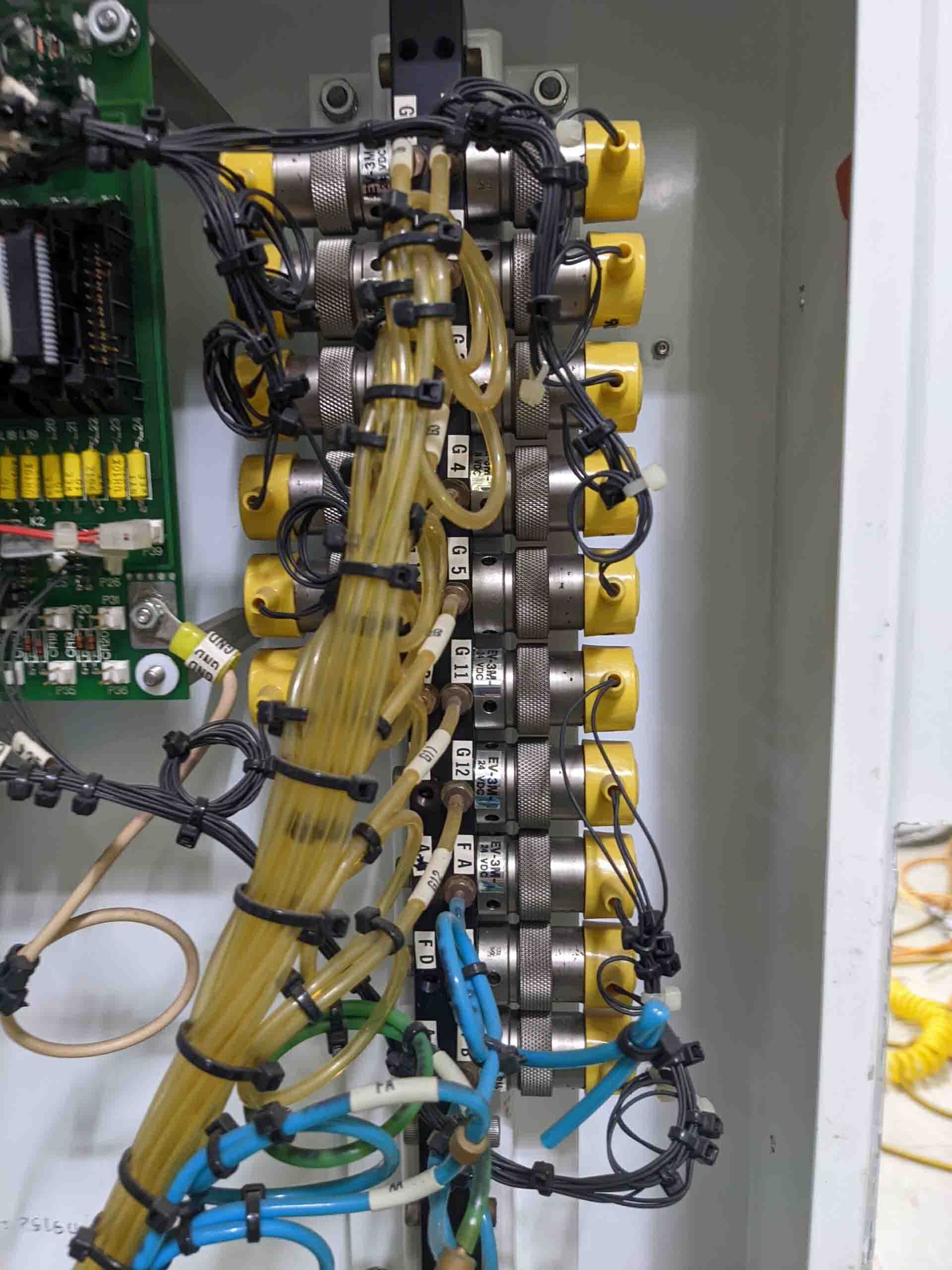

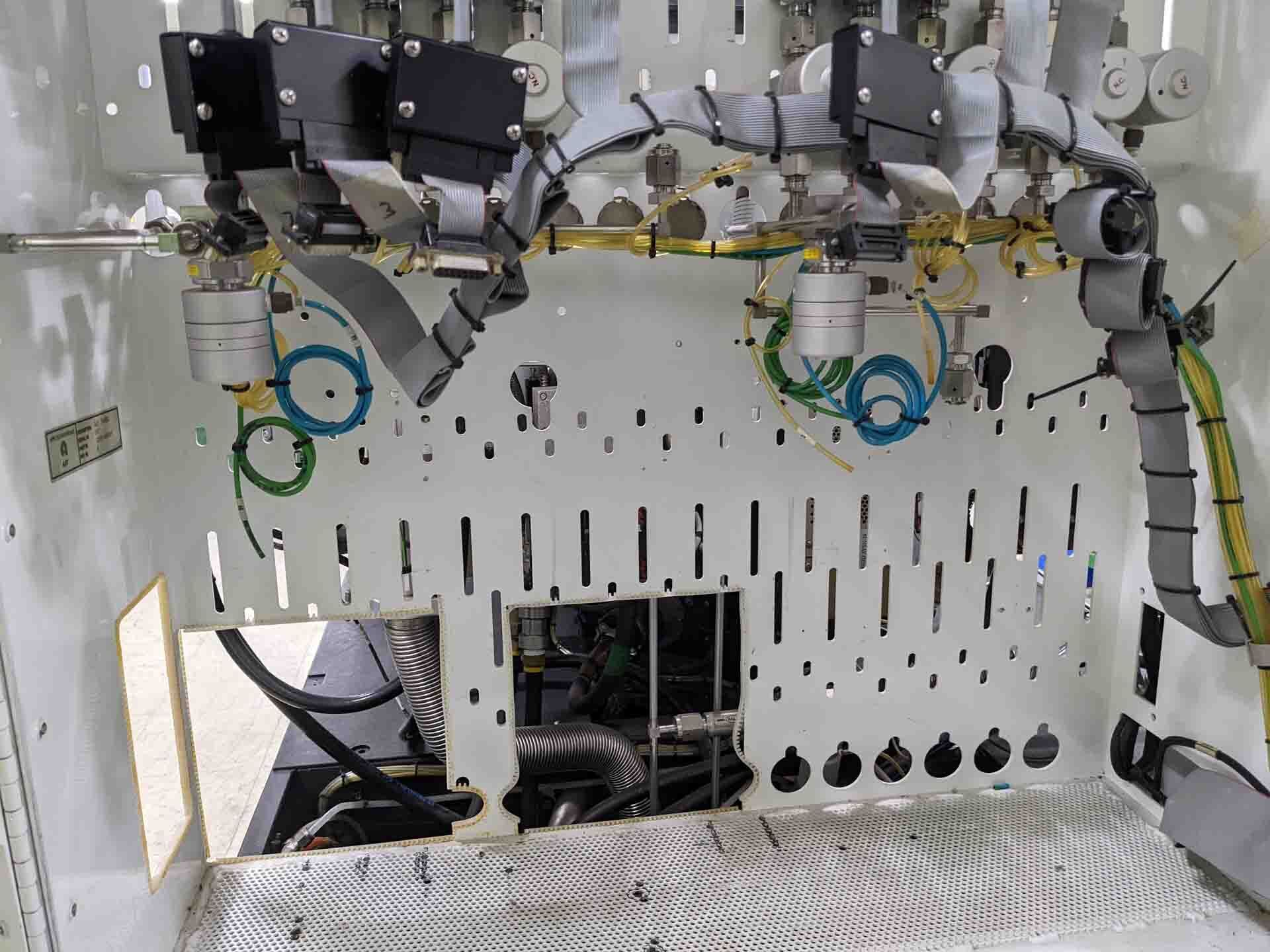

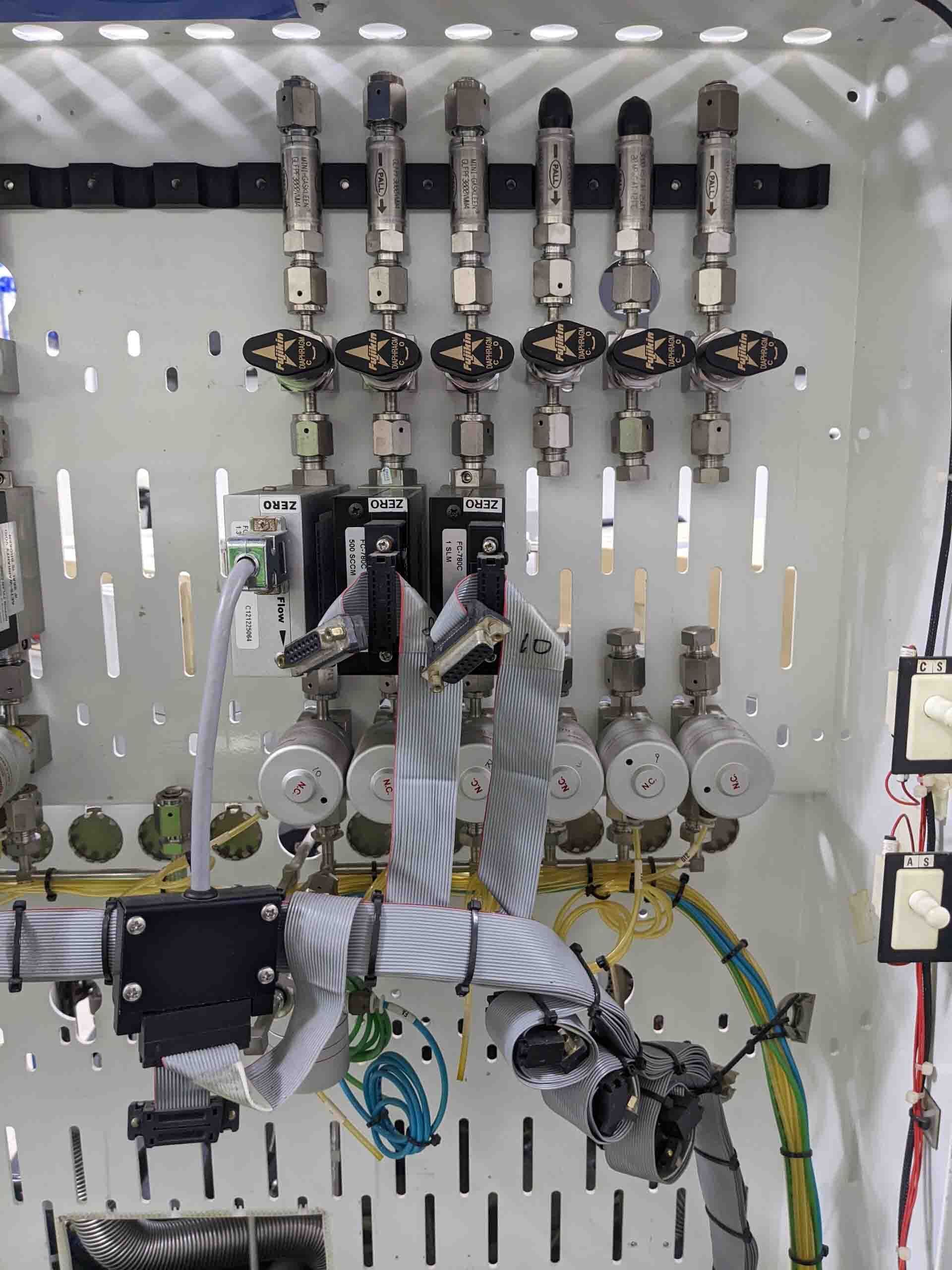

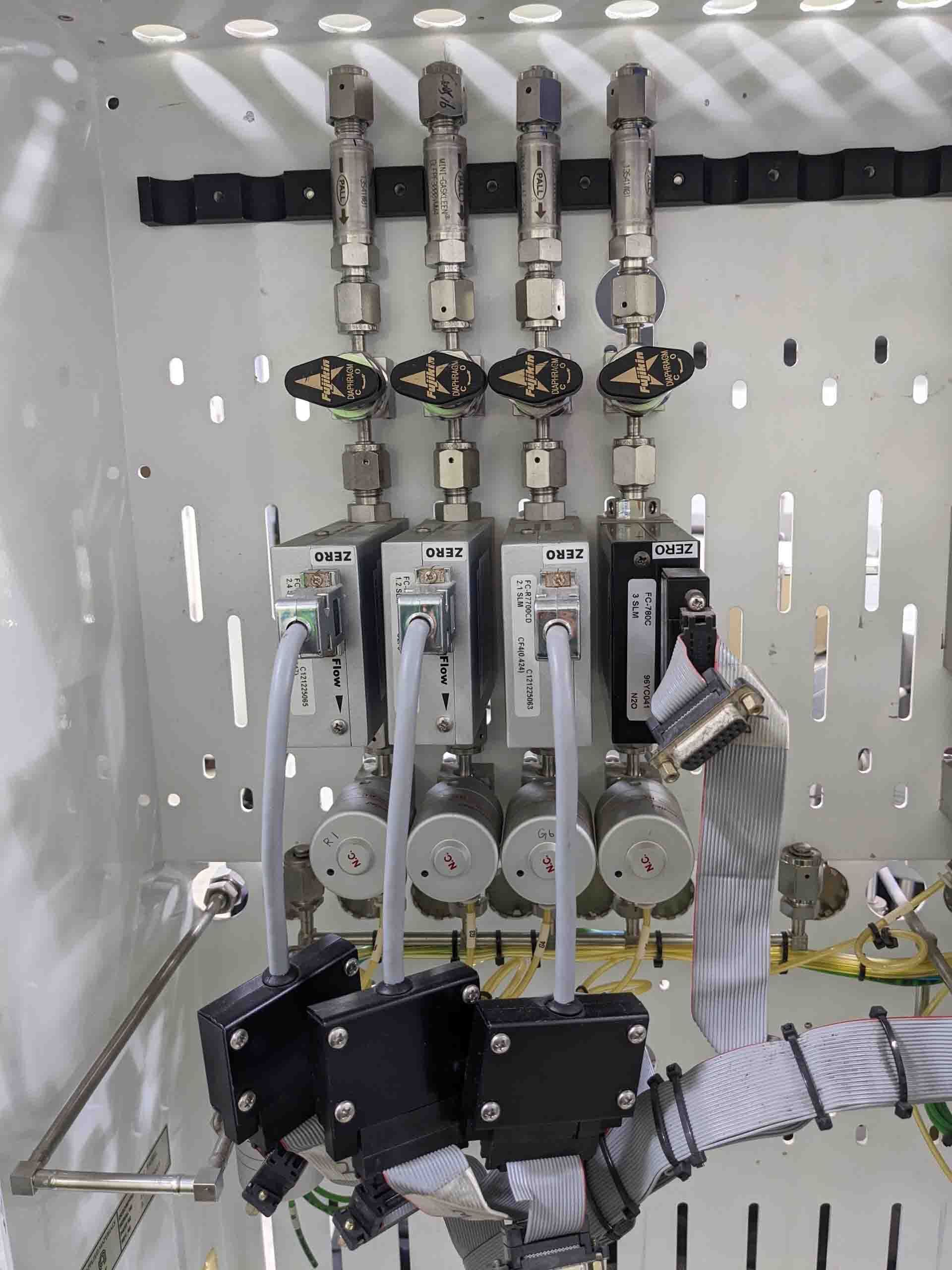

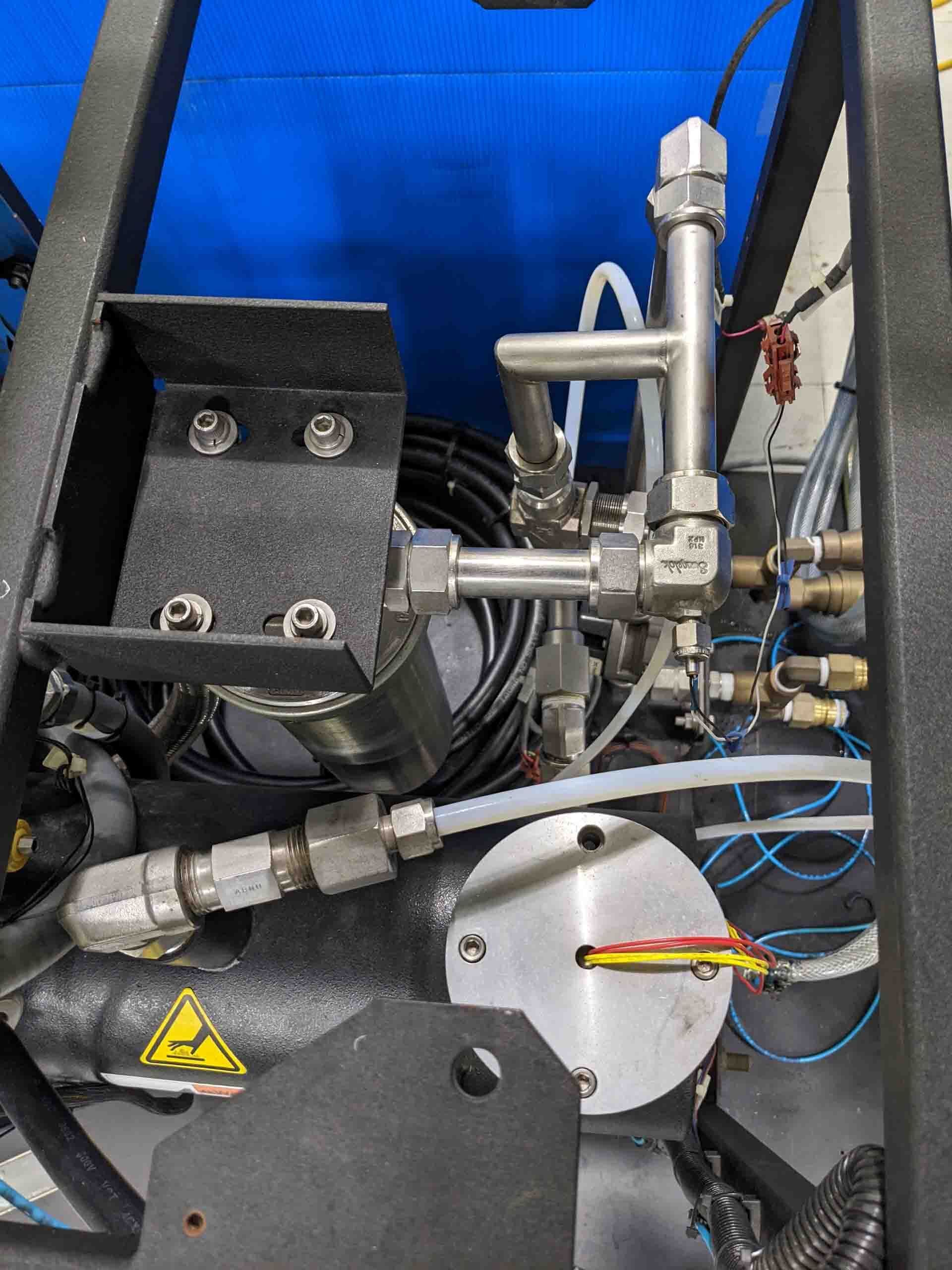

Gas panel: (28) Gas lines

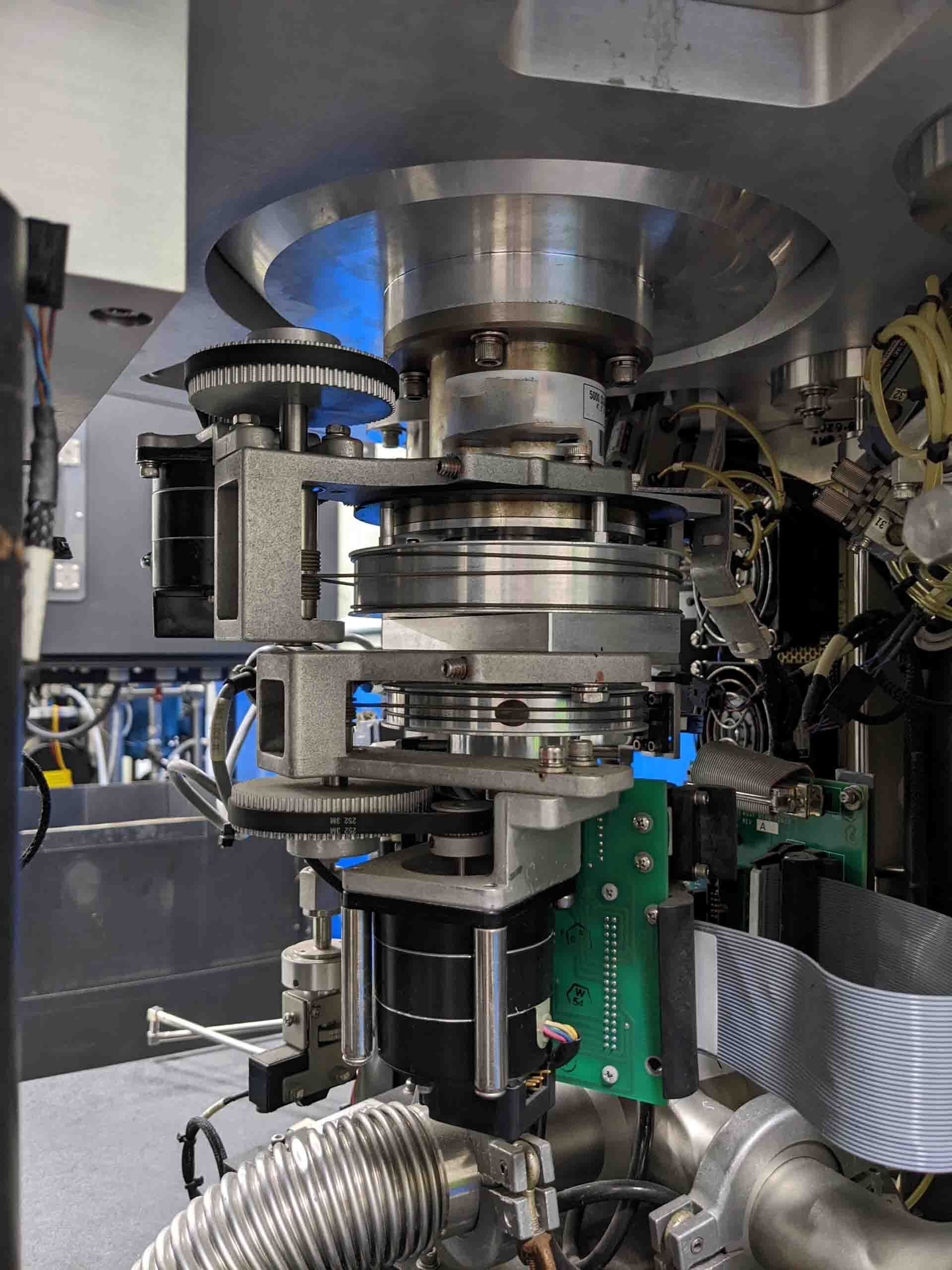

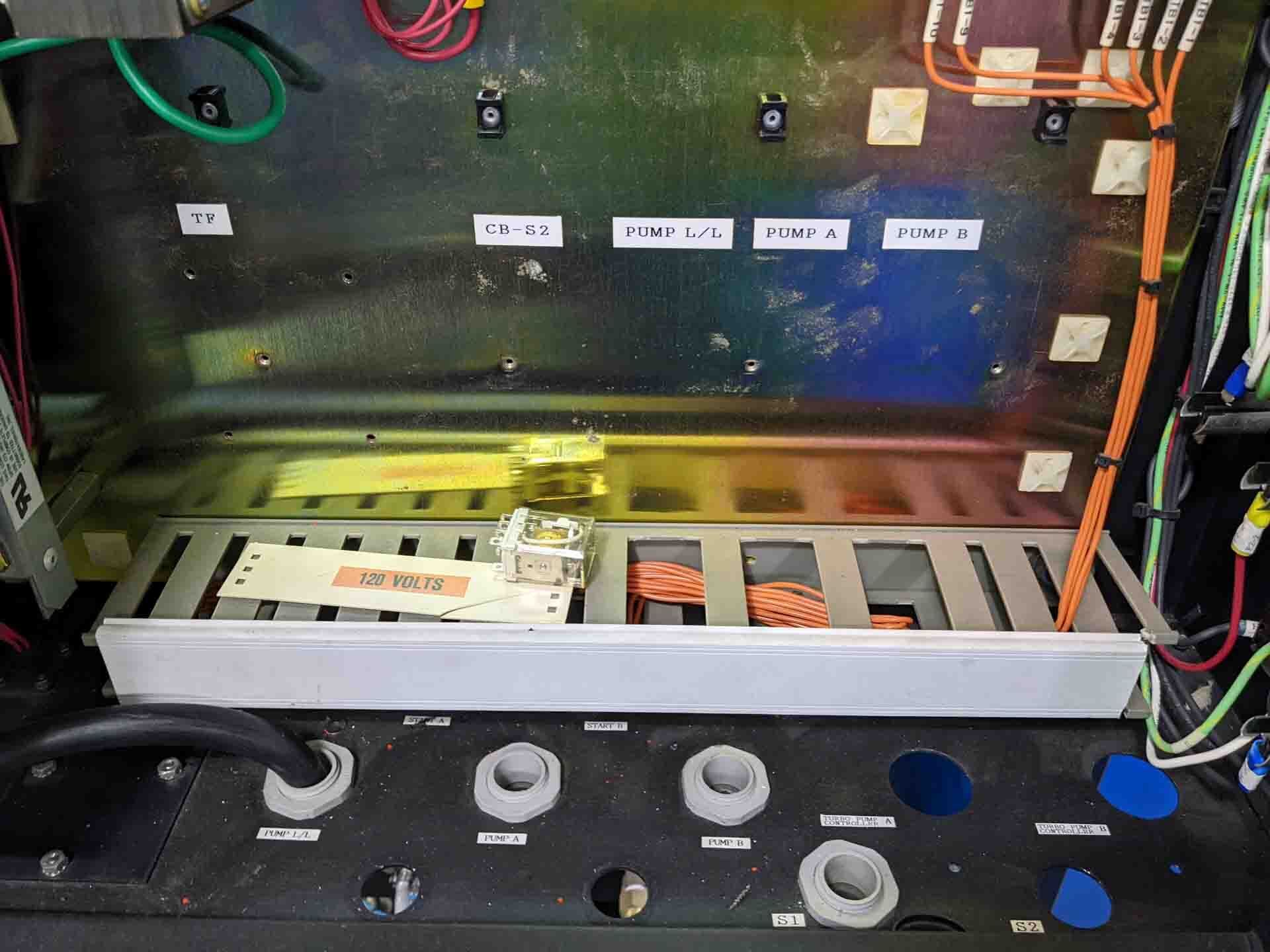

Chamber type:

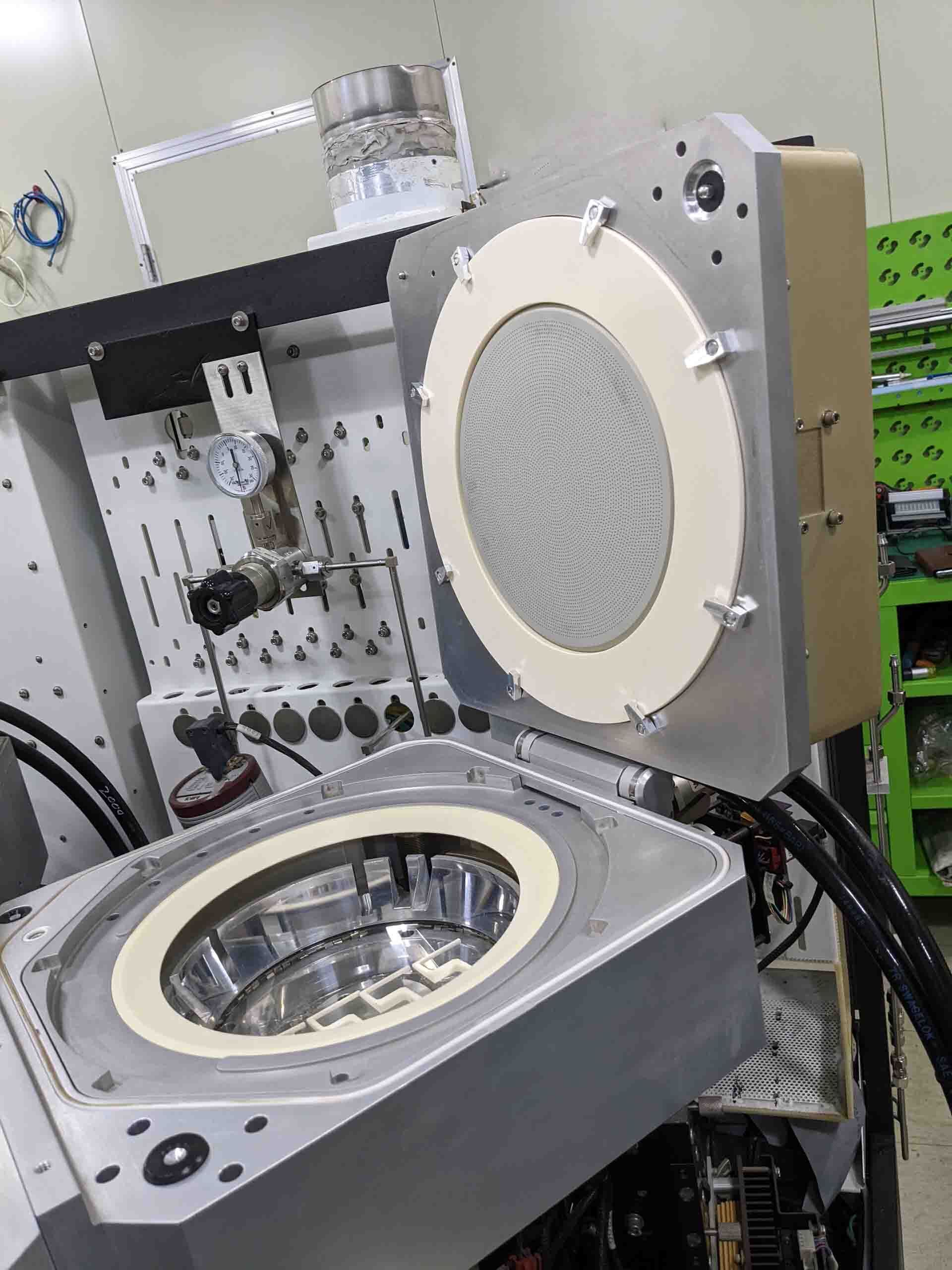

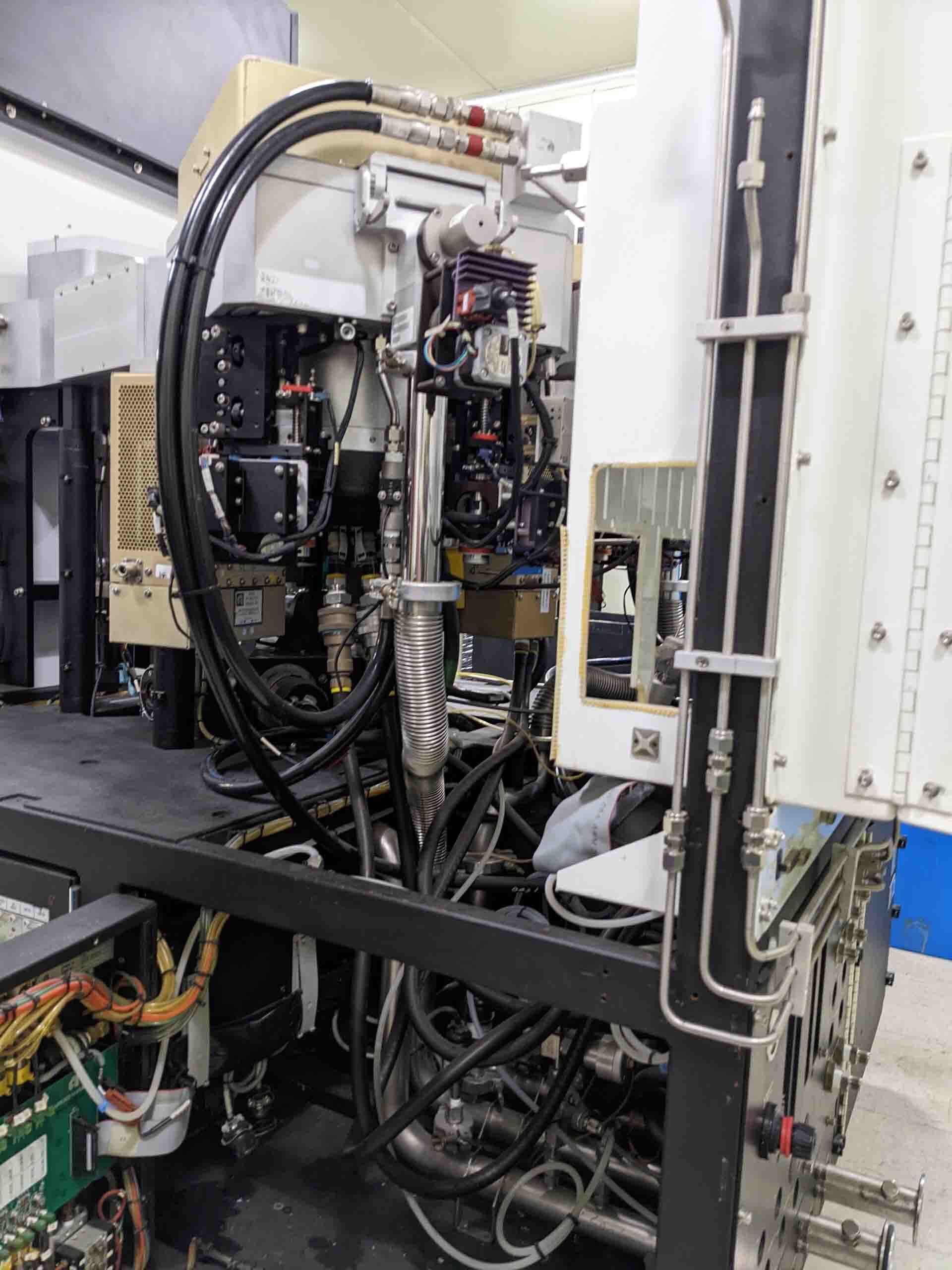

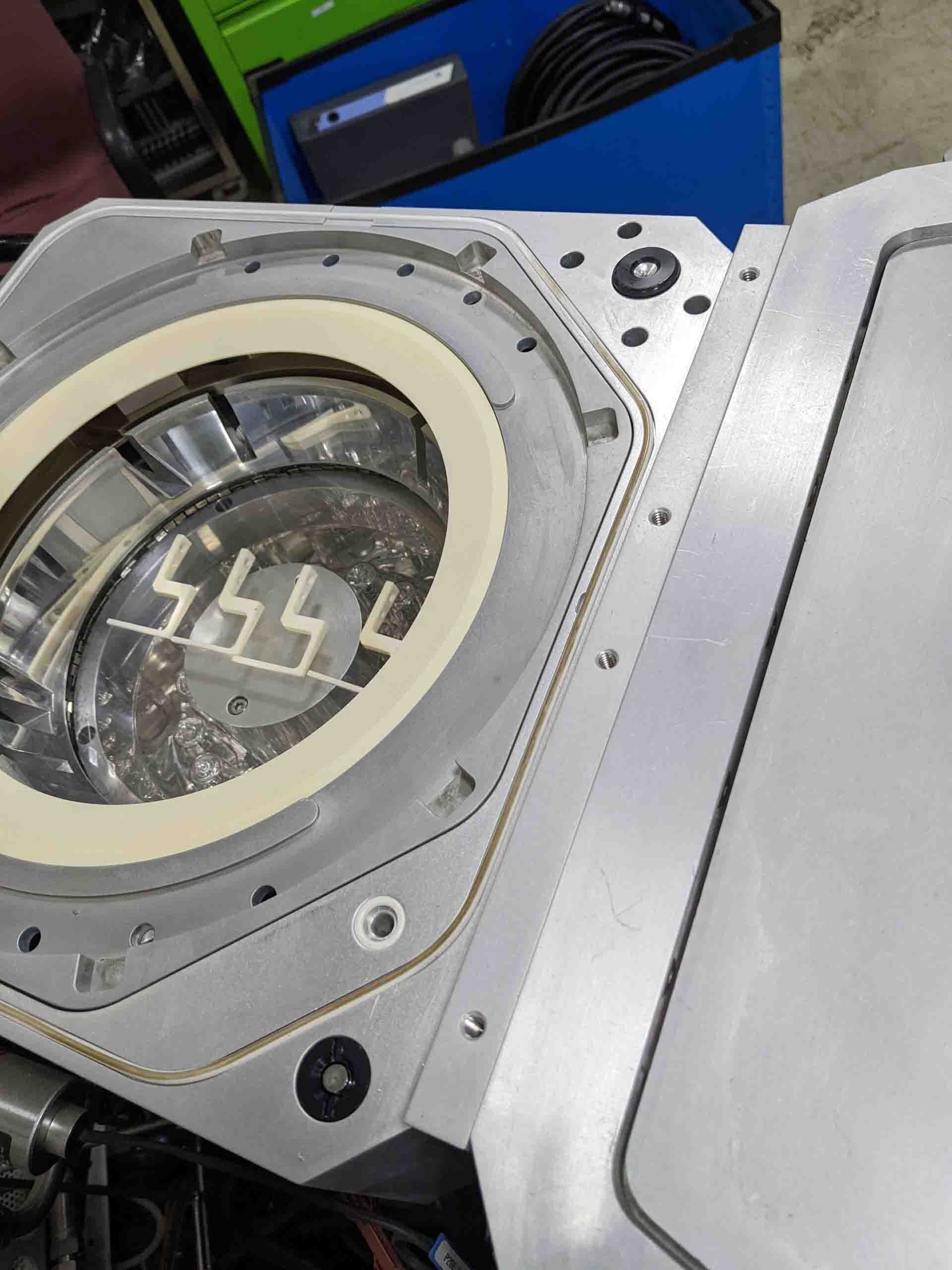

Chamber A: Universal CVD

Chamber B: Standard CVD

Chamber A, B:

Process: PECVD Oxide

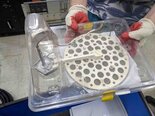

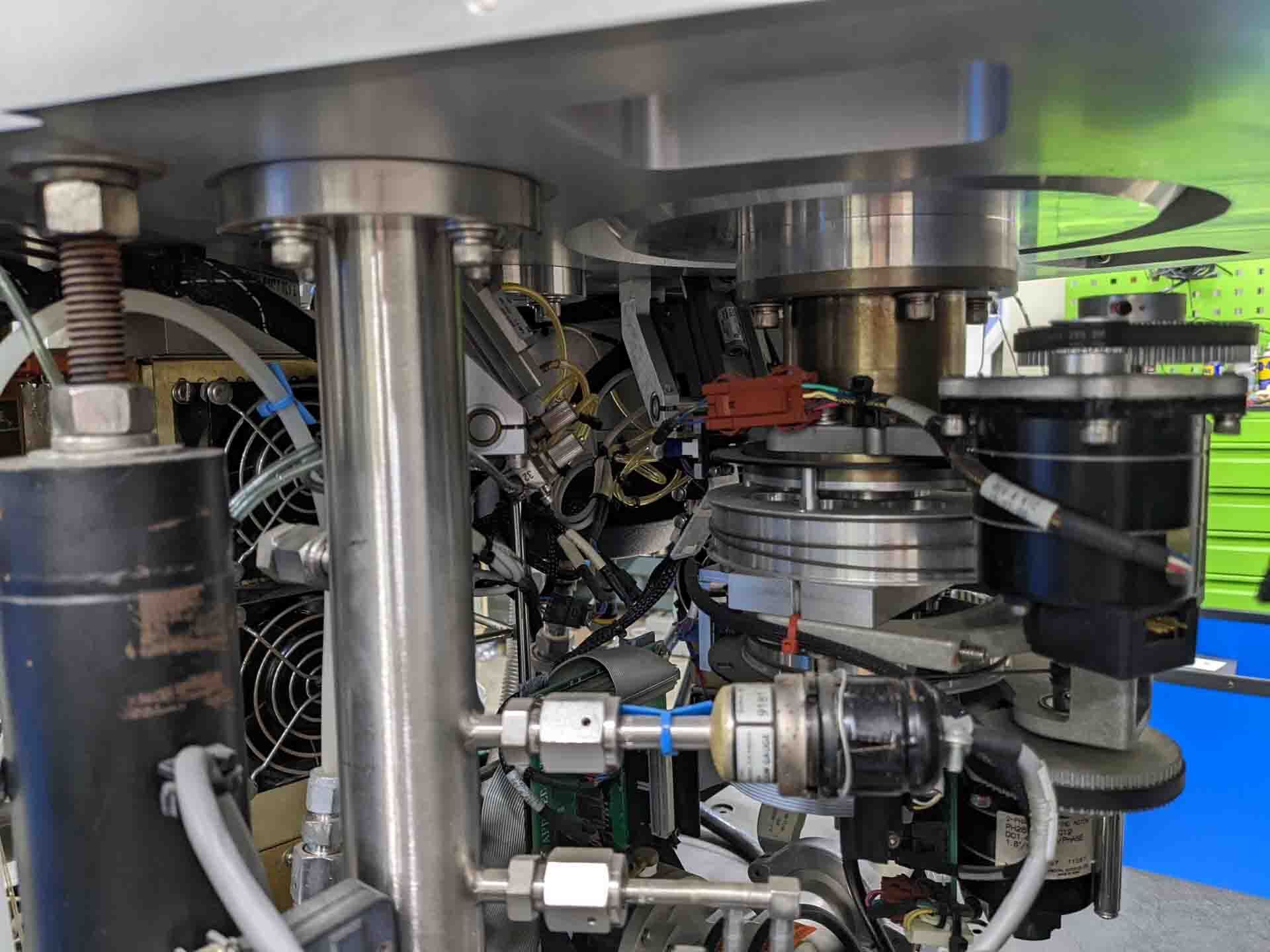

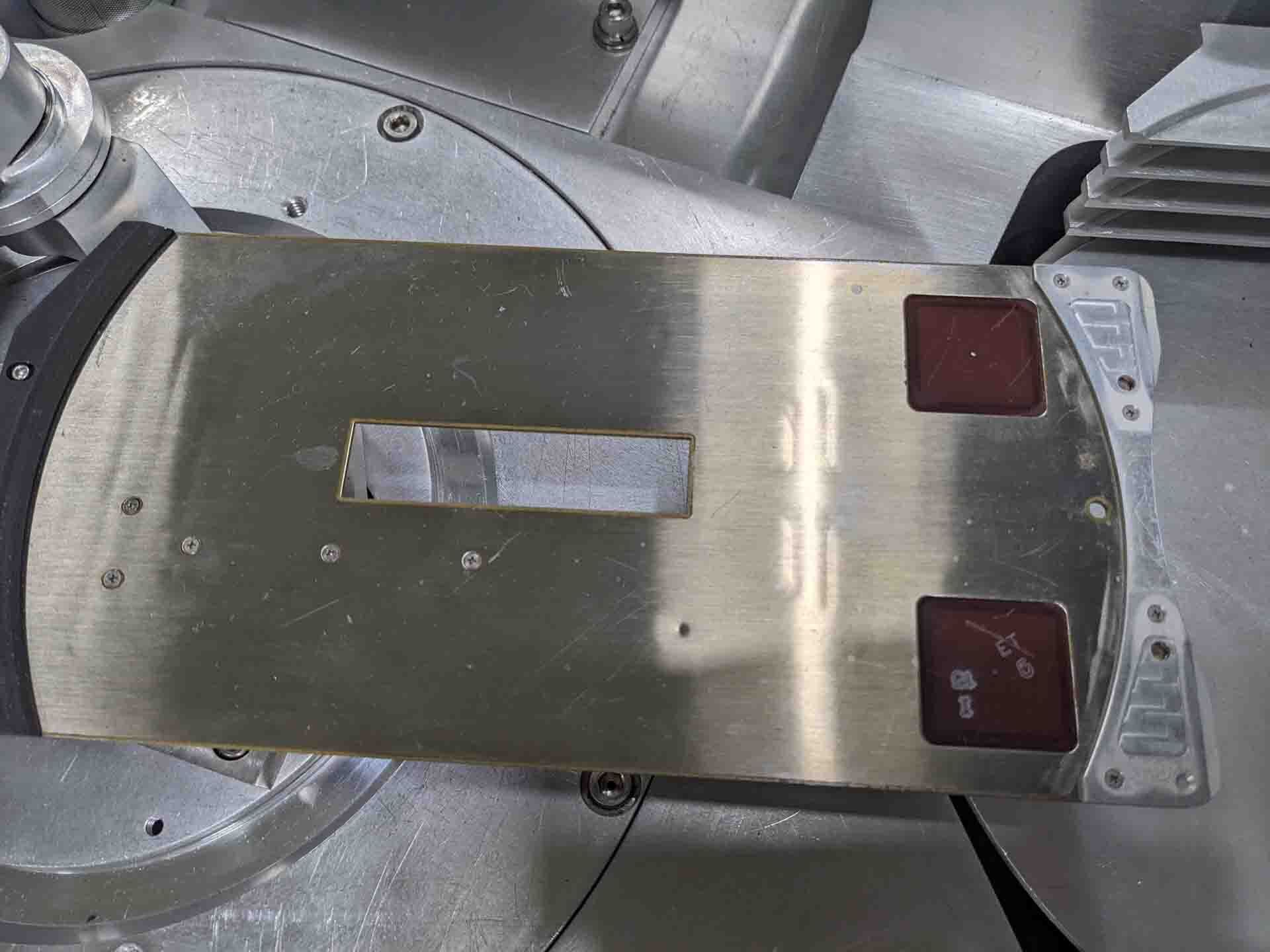

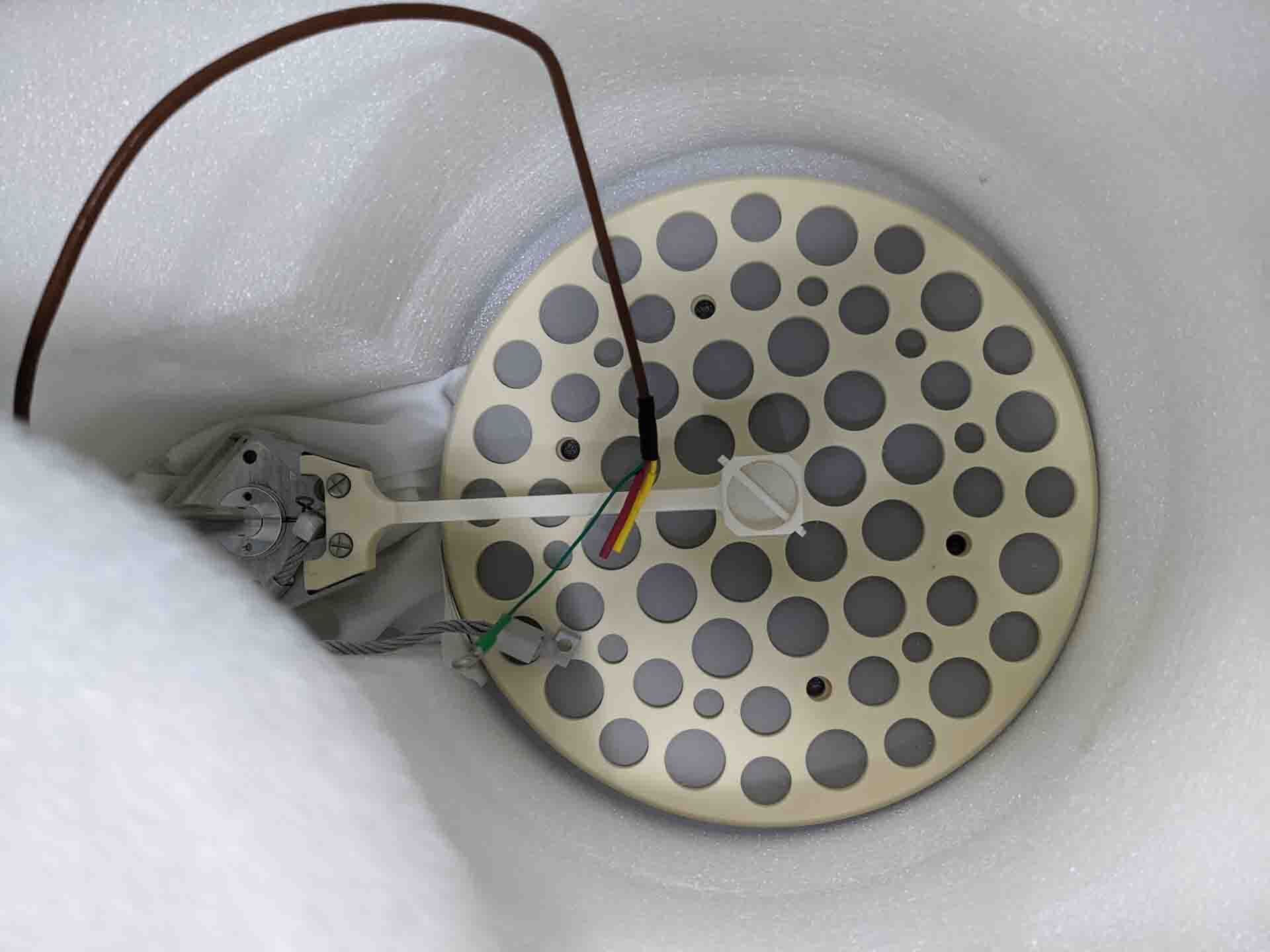

Process kit: Susceptor

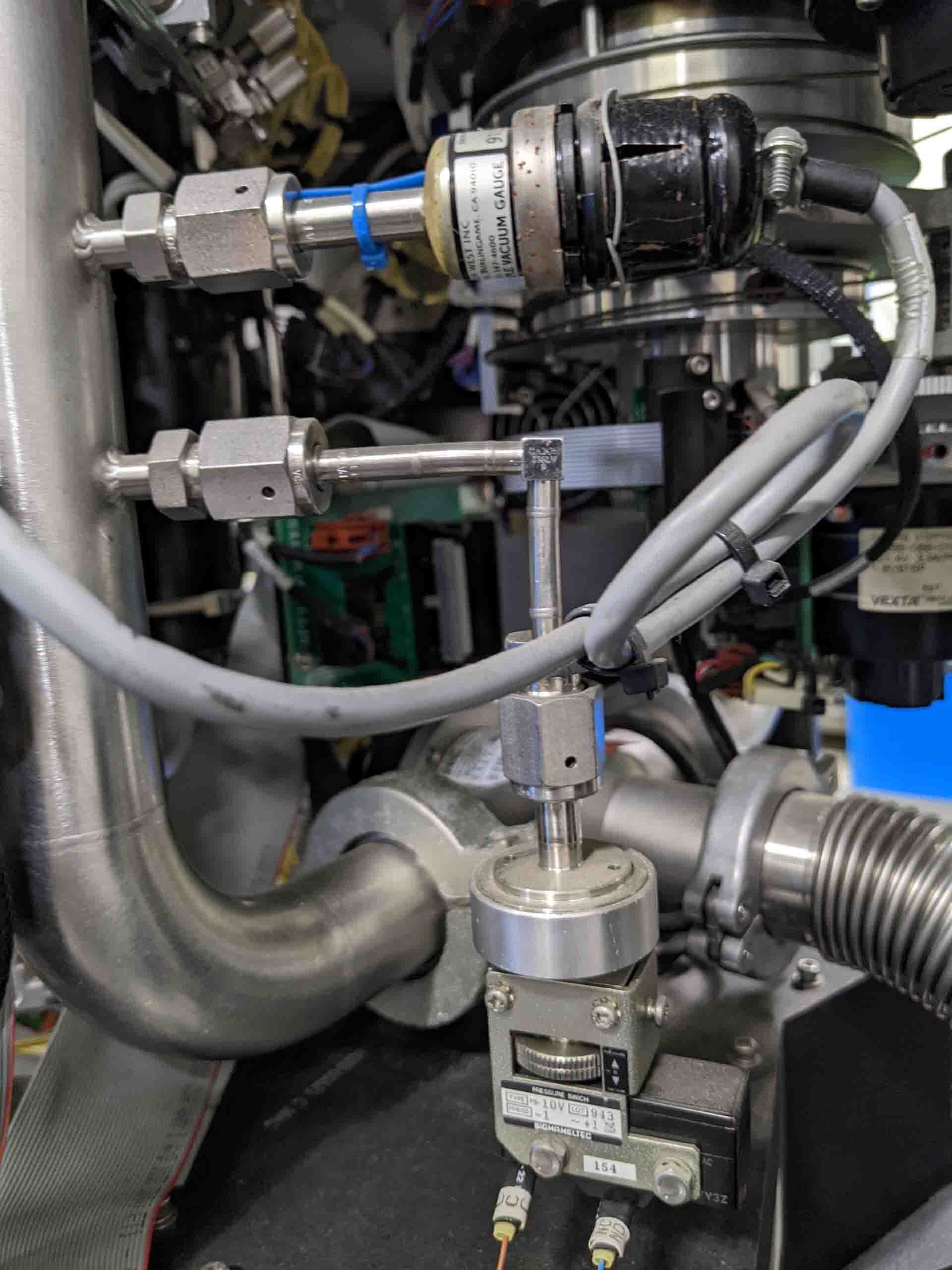

MKS Manometer, 100 Torr

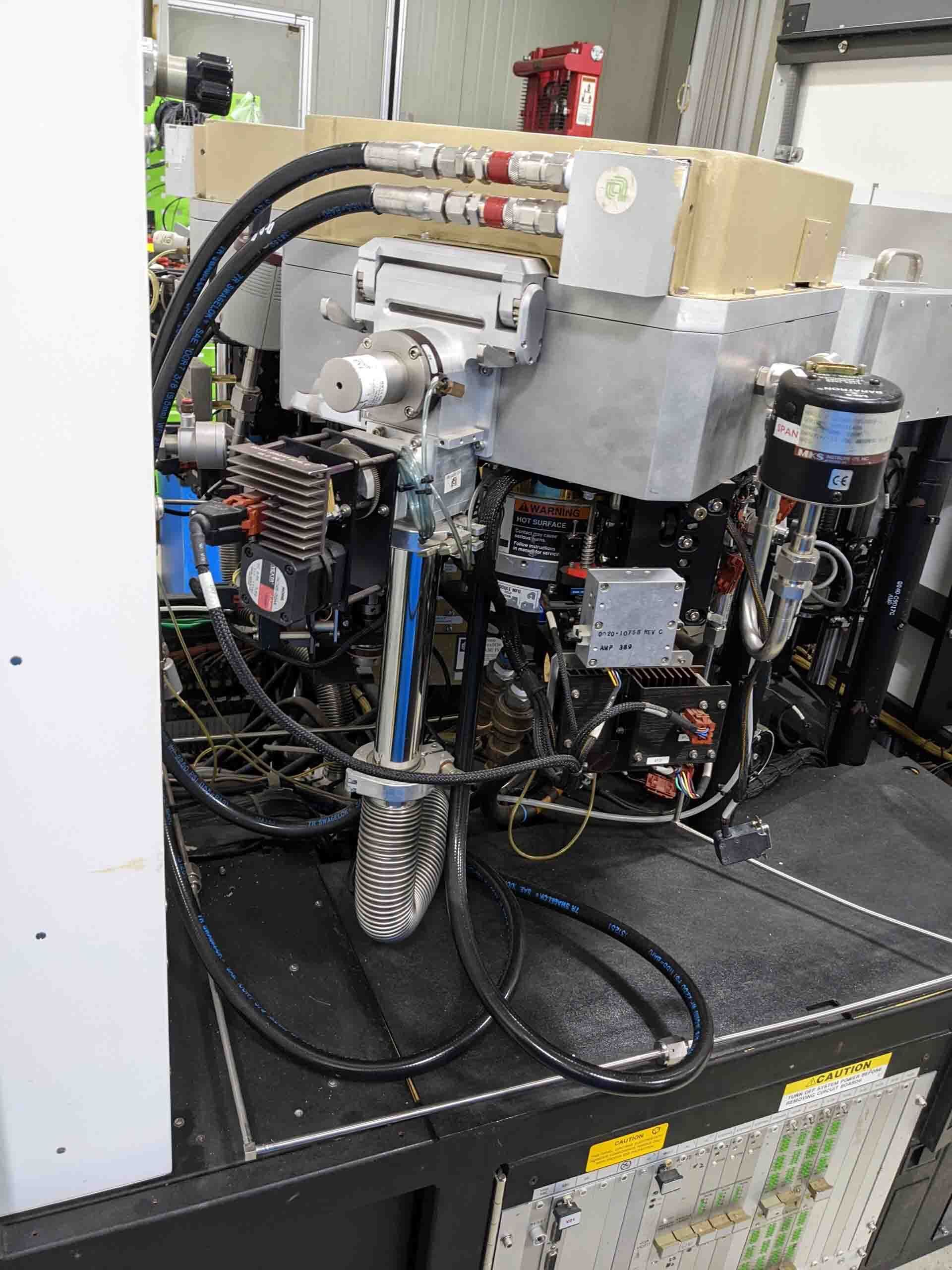

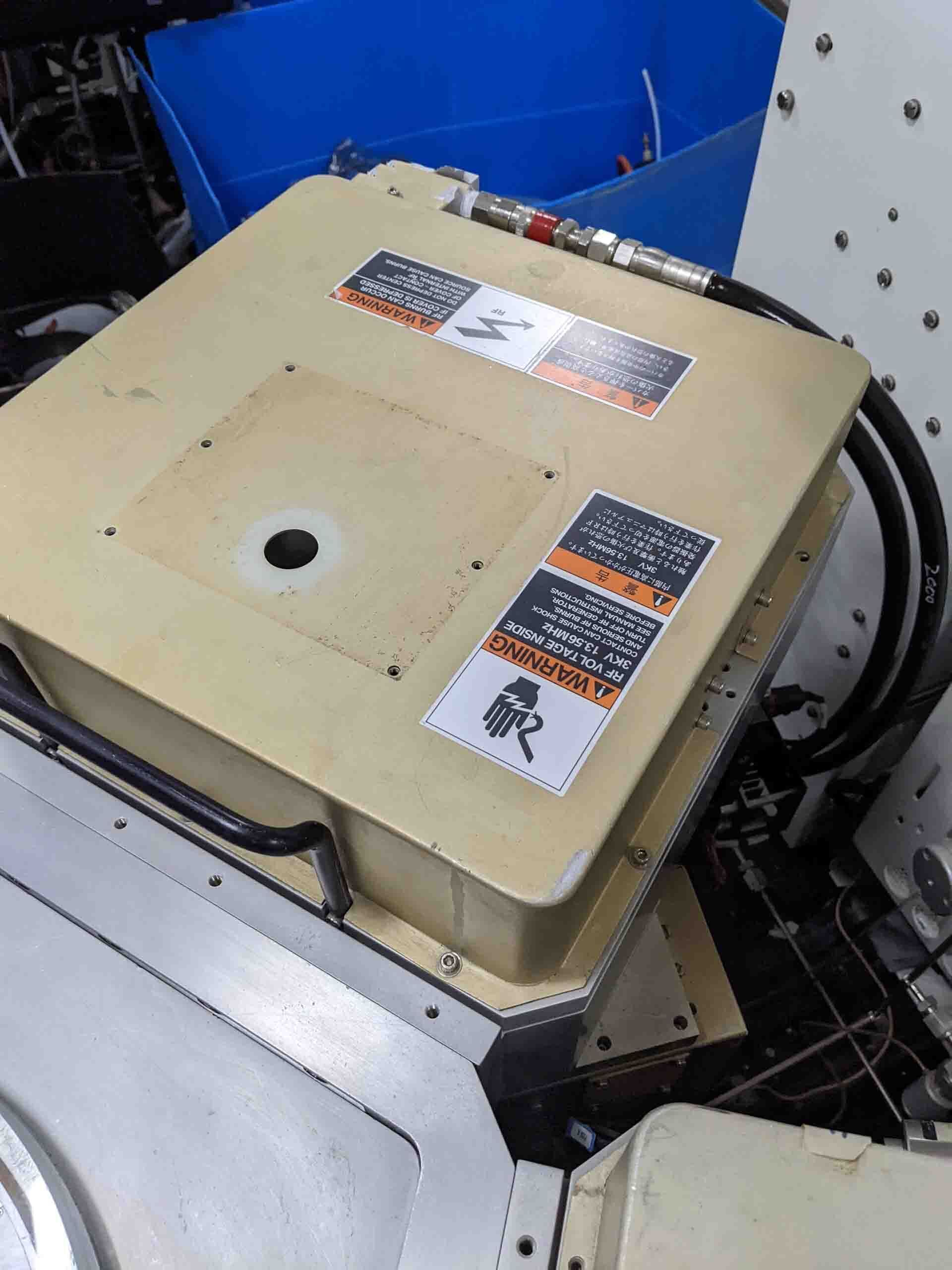

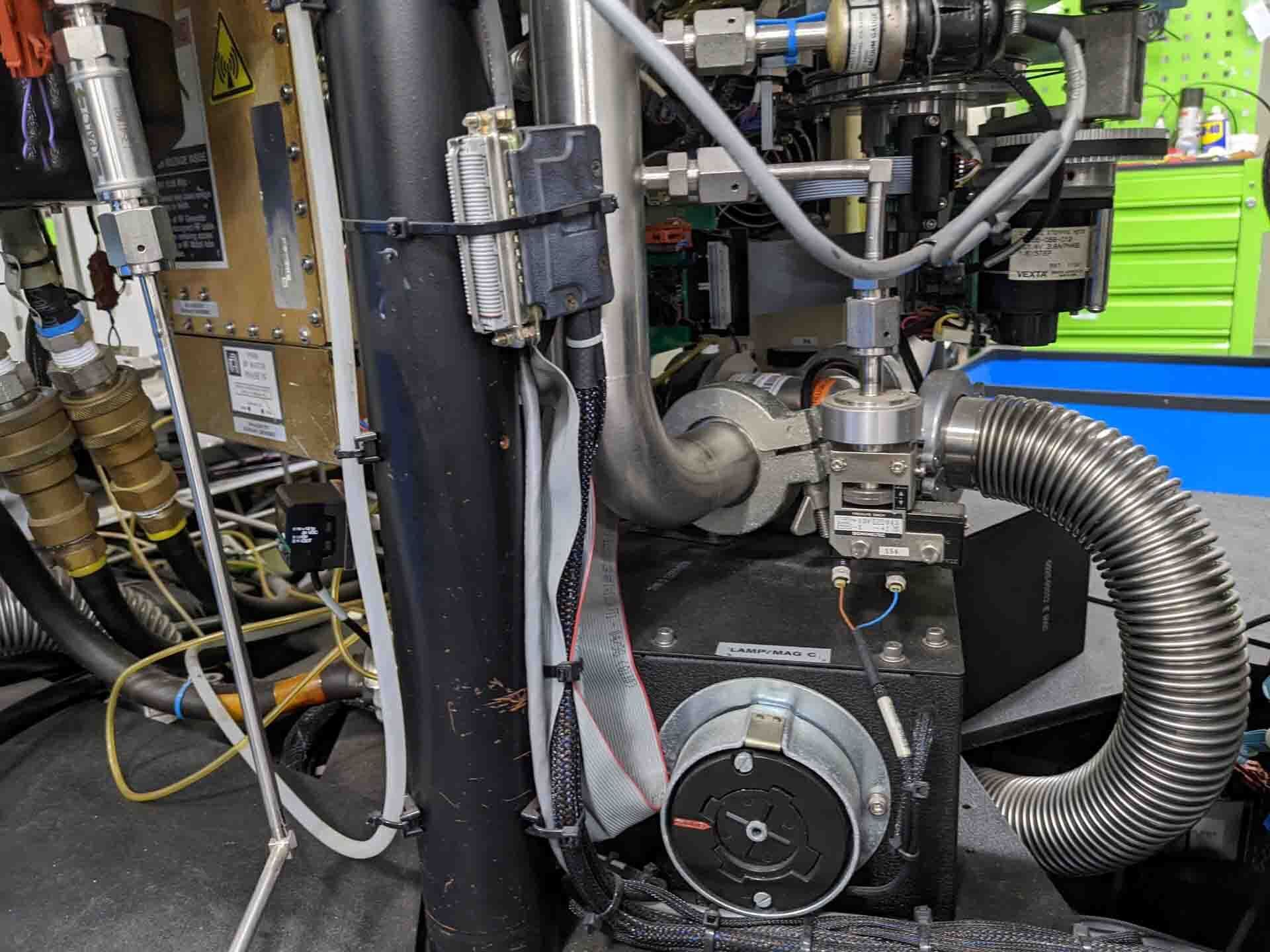

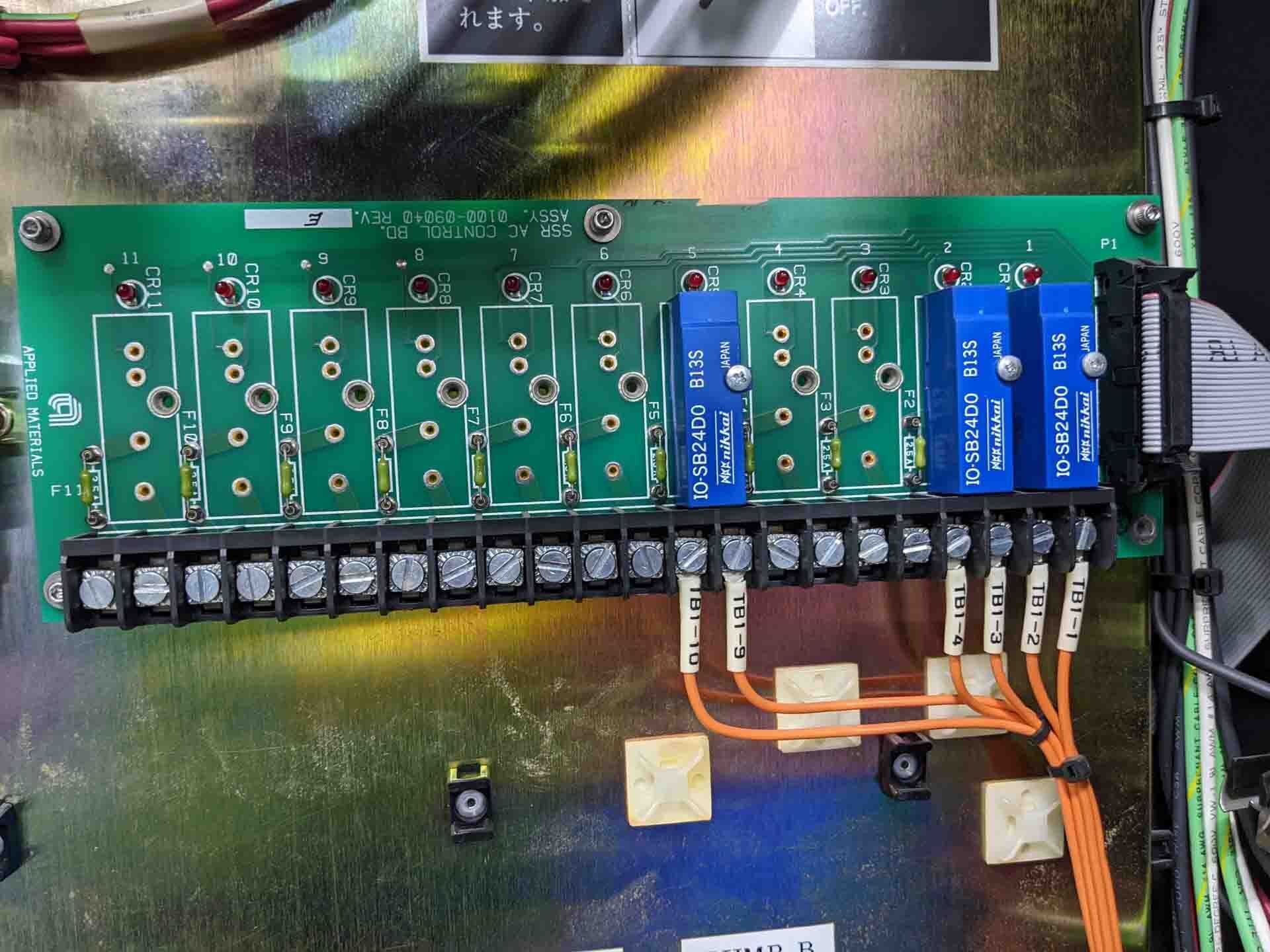

Clean method: RF Clean

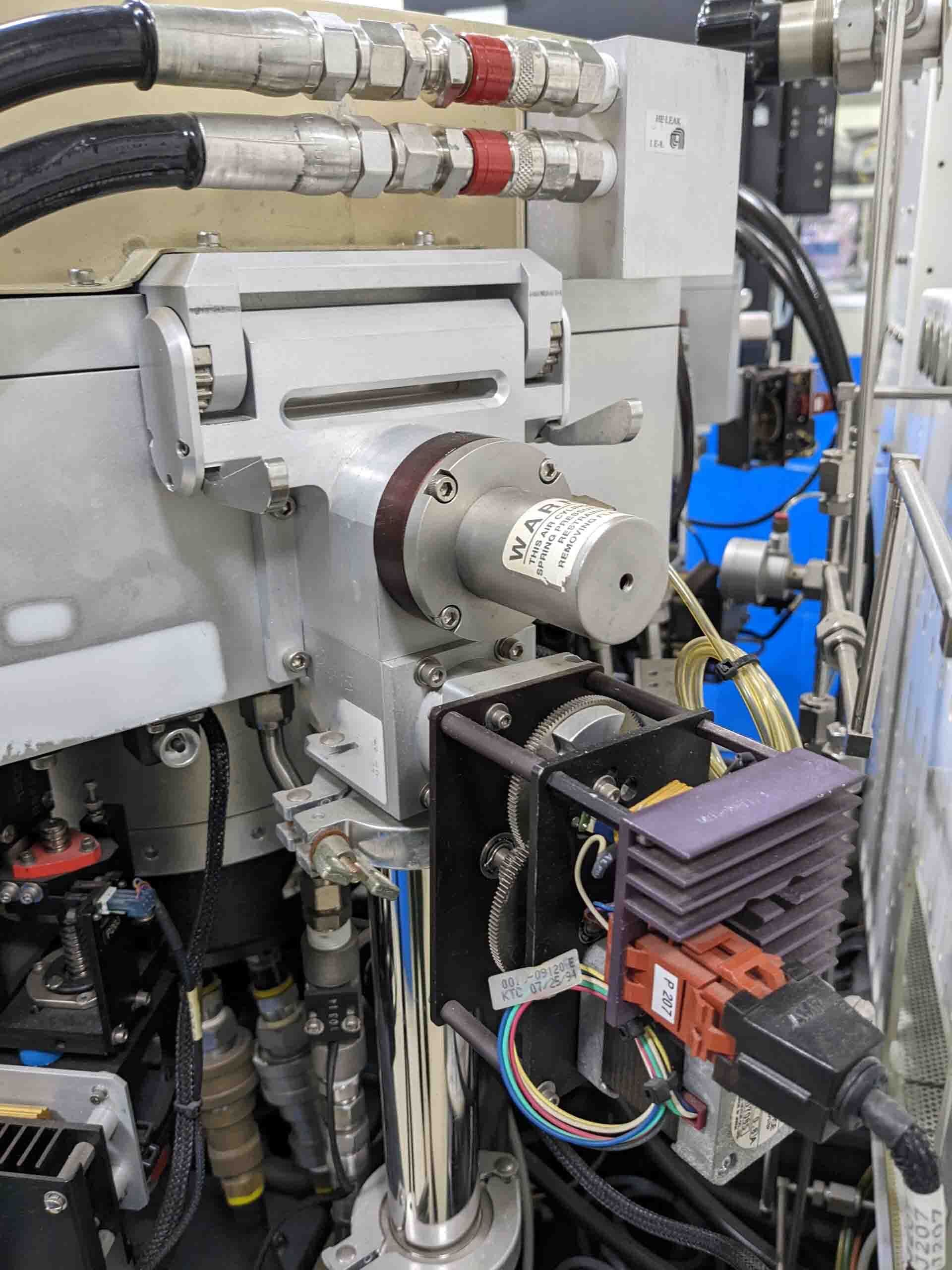

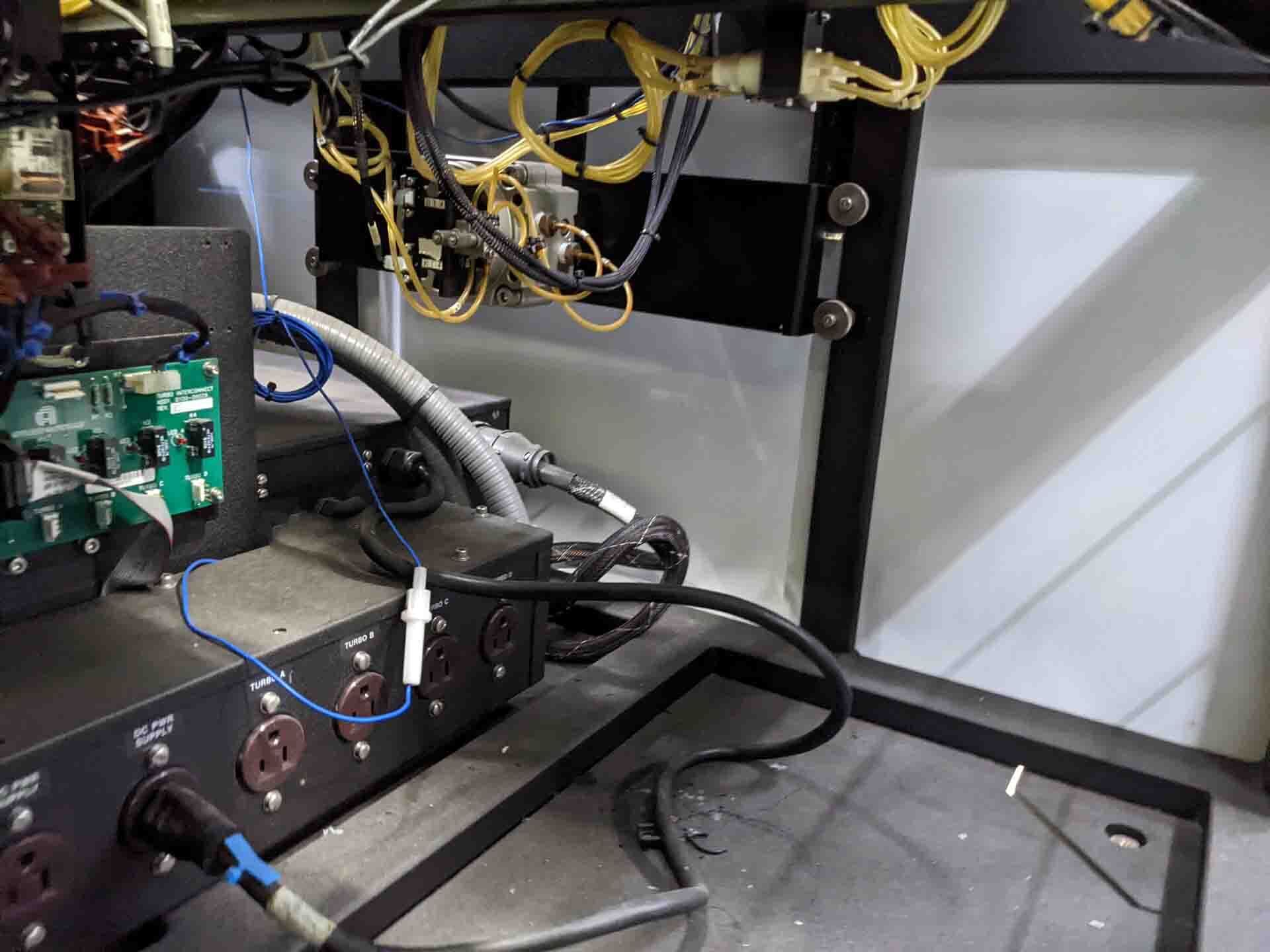

Throttle valve: Direct drive dual spring W/C plug

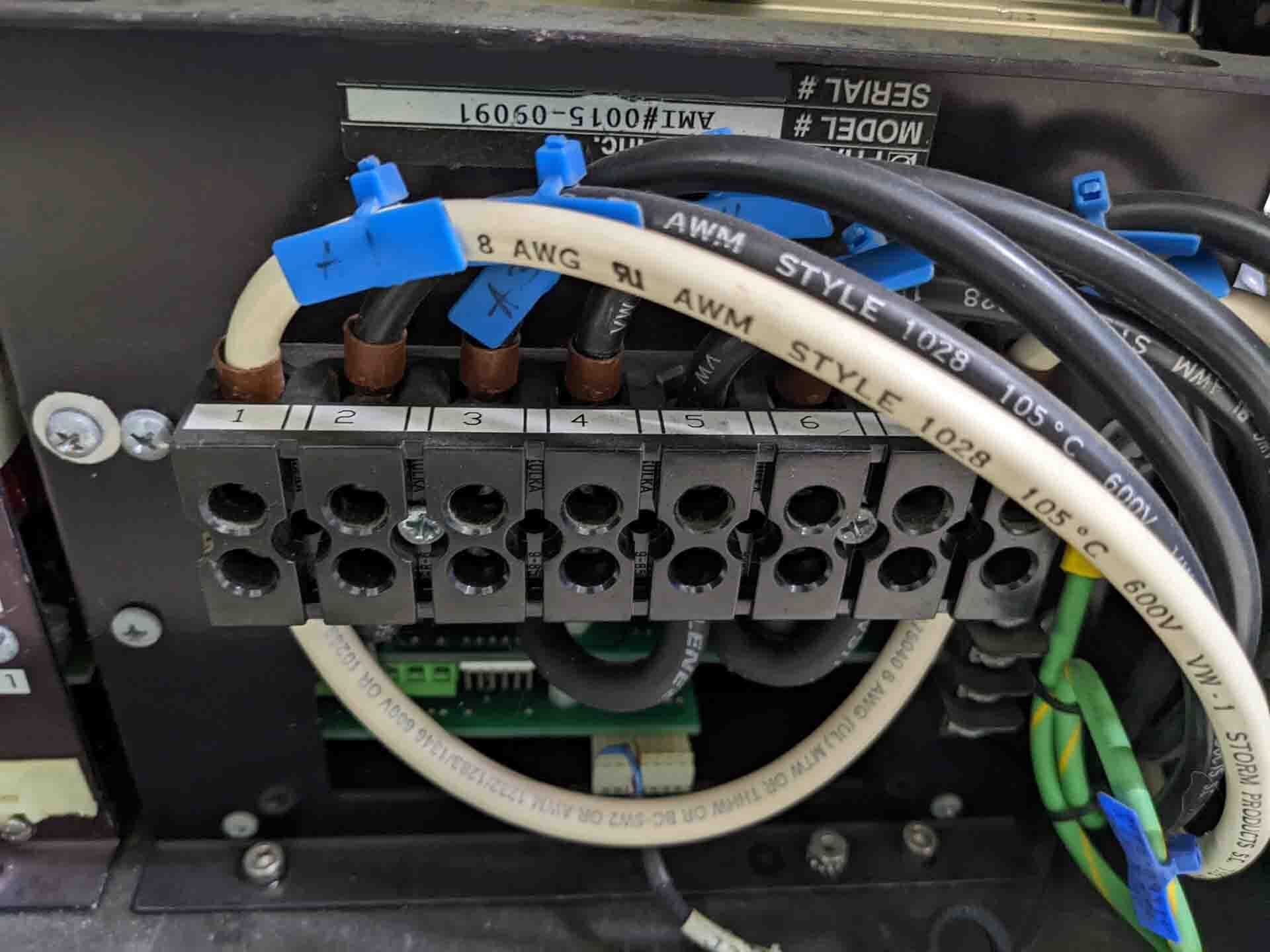

Gas box MFC: AERA

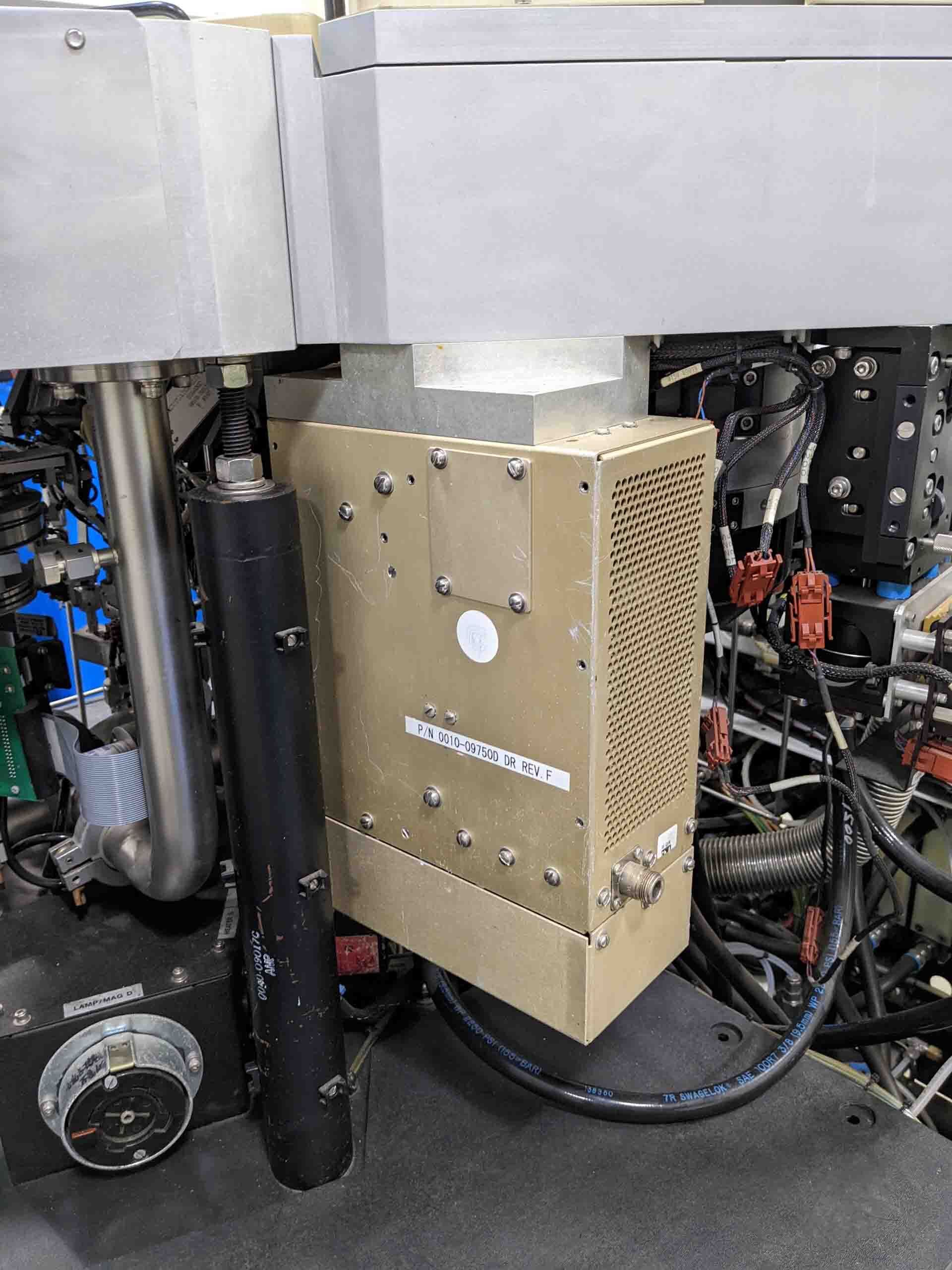

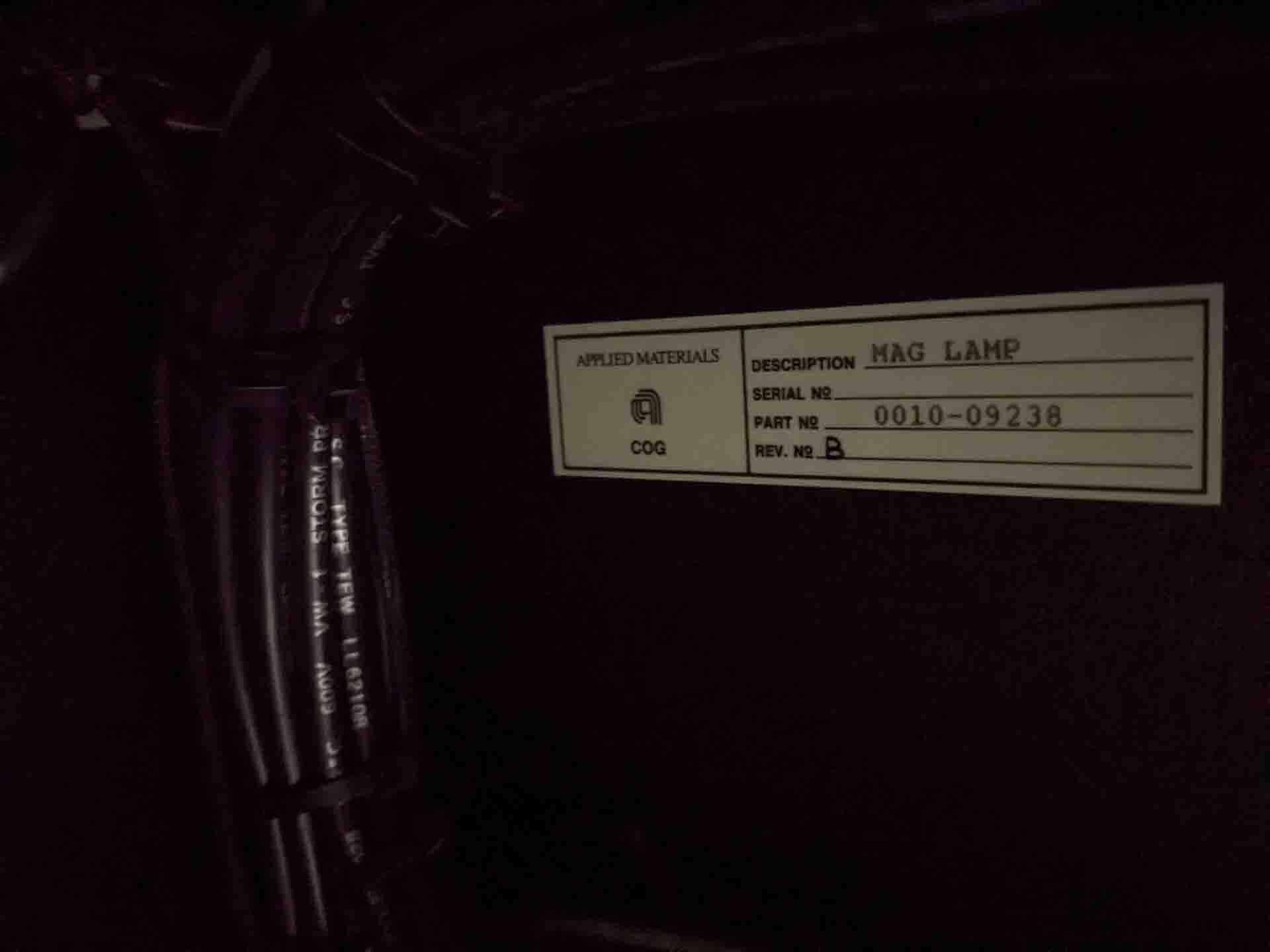

Lamp driver

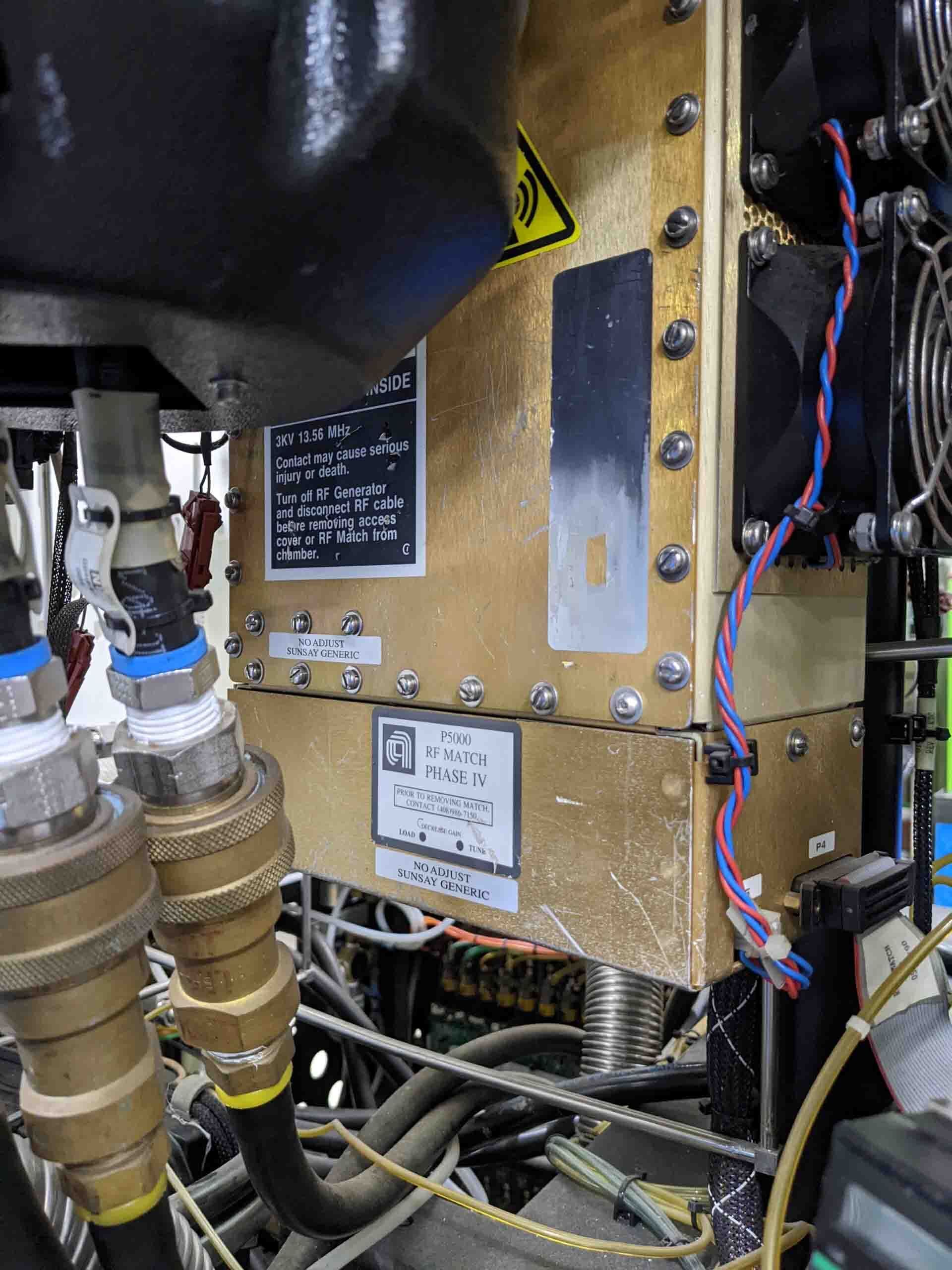

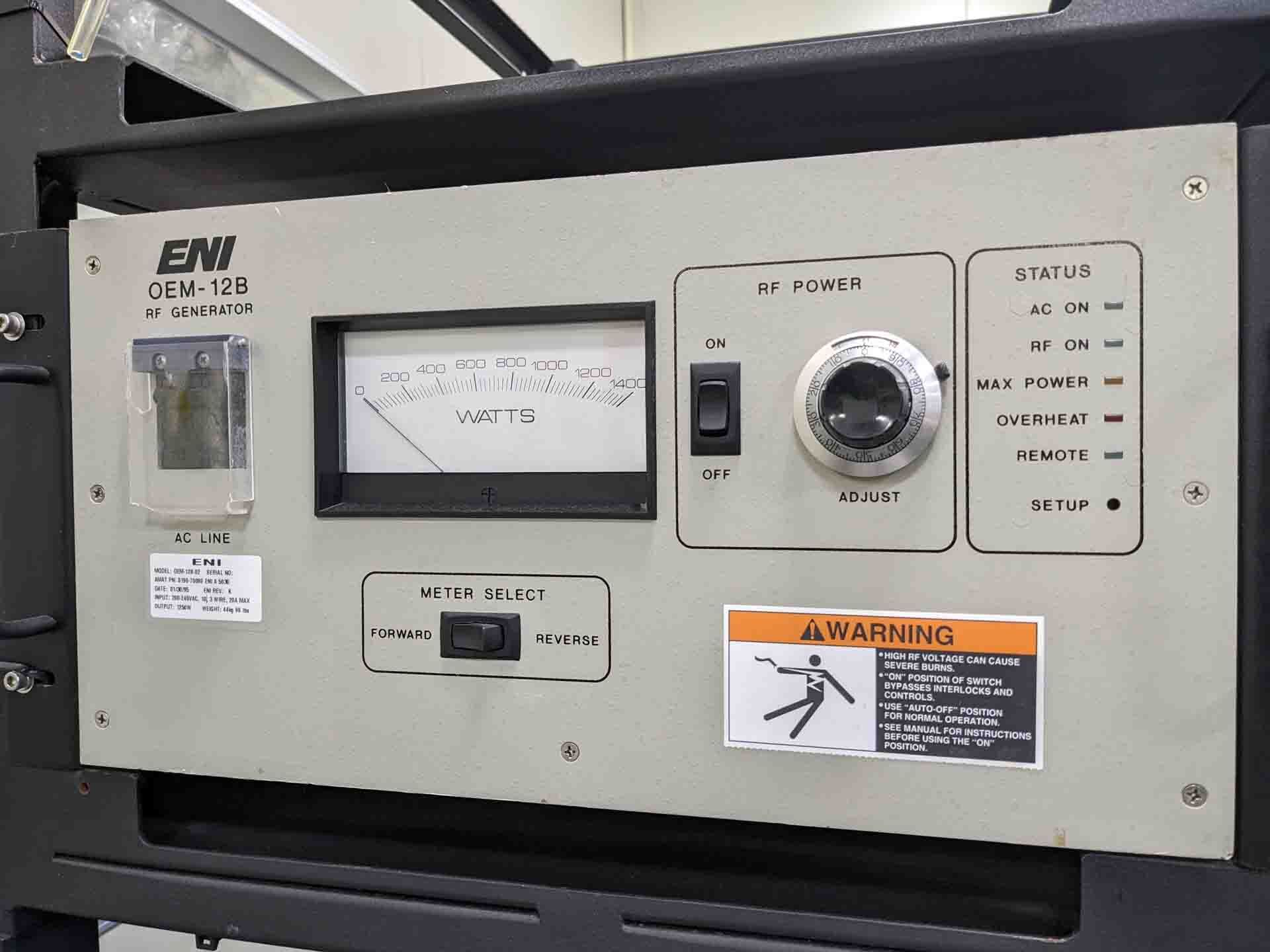

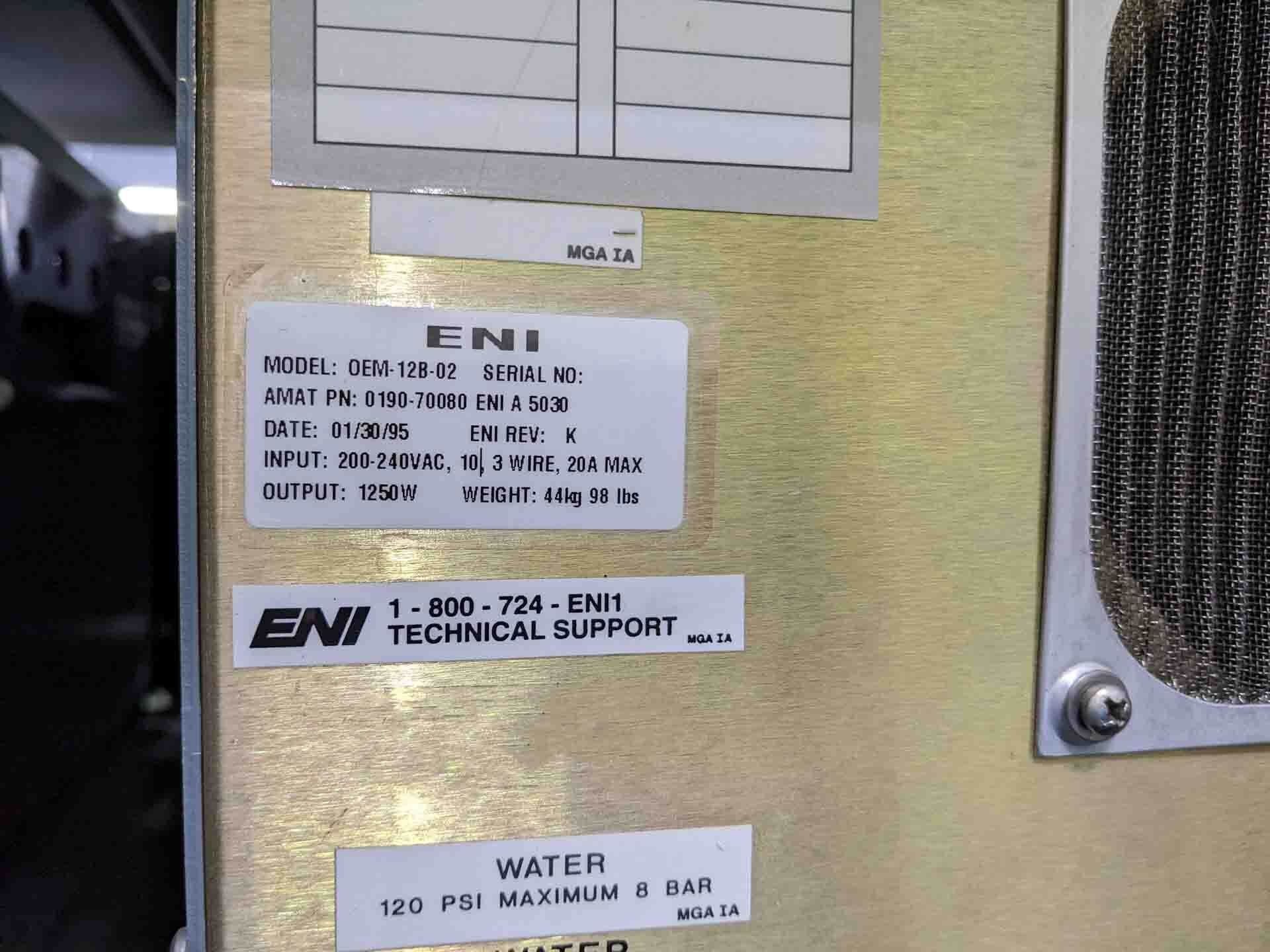

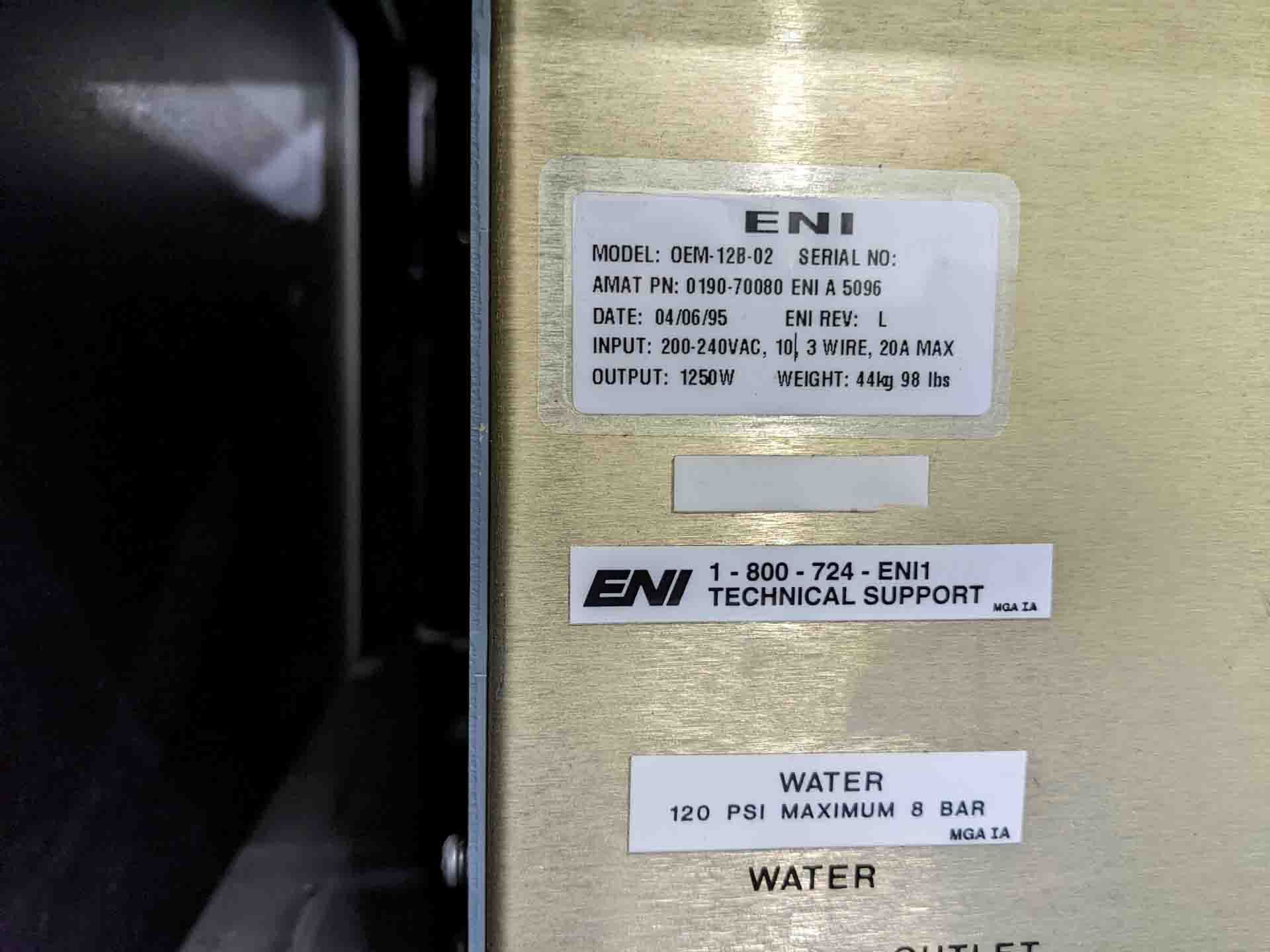

ENI OEM-12B RF Generator

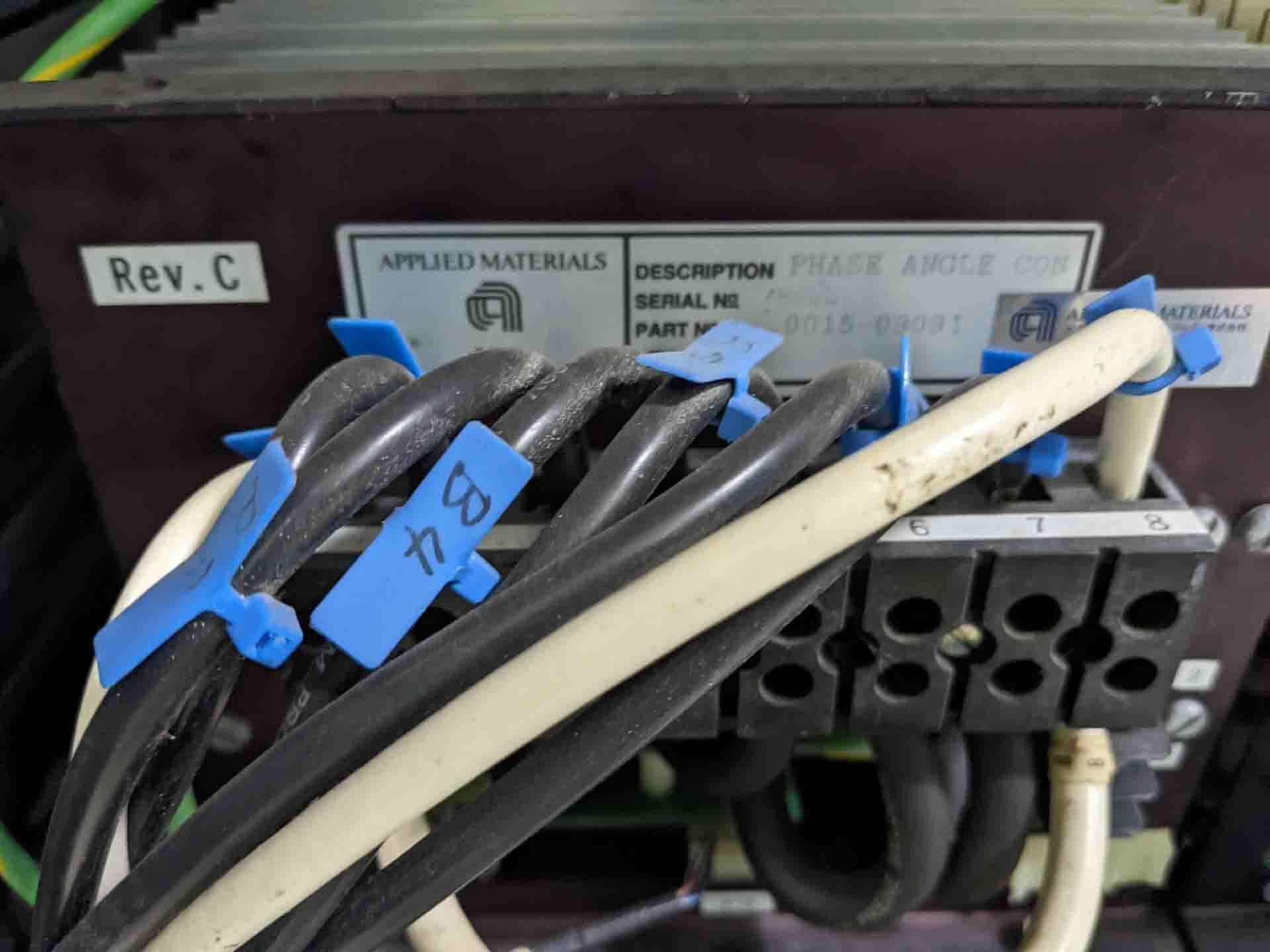

RF Match: Phase-IV

1995 vintage.

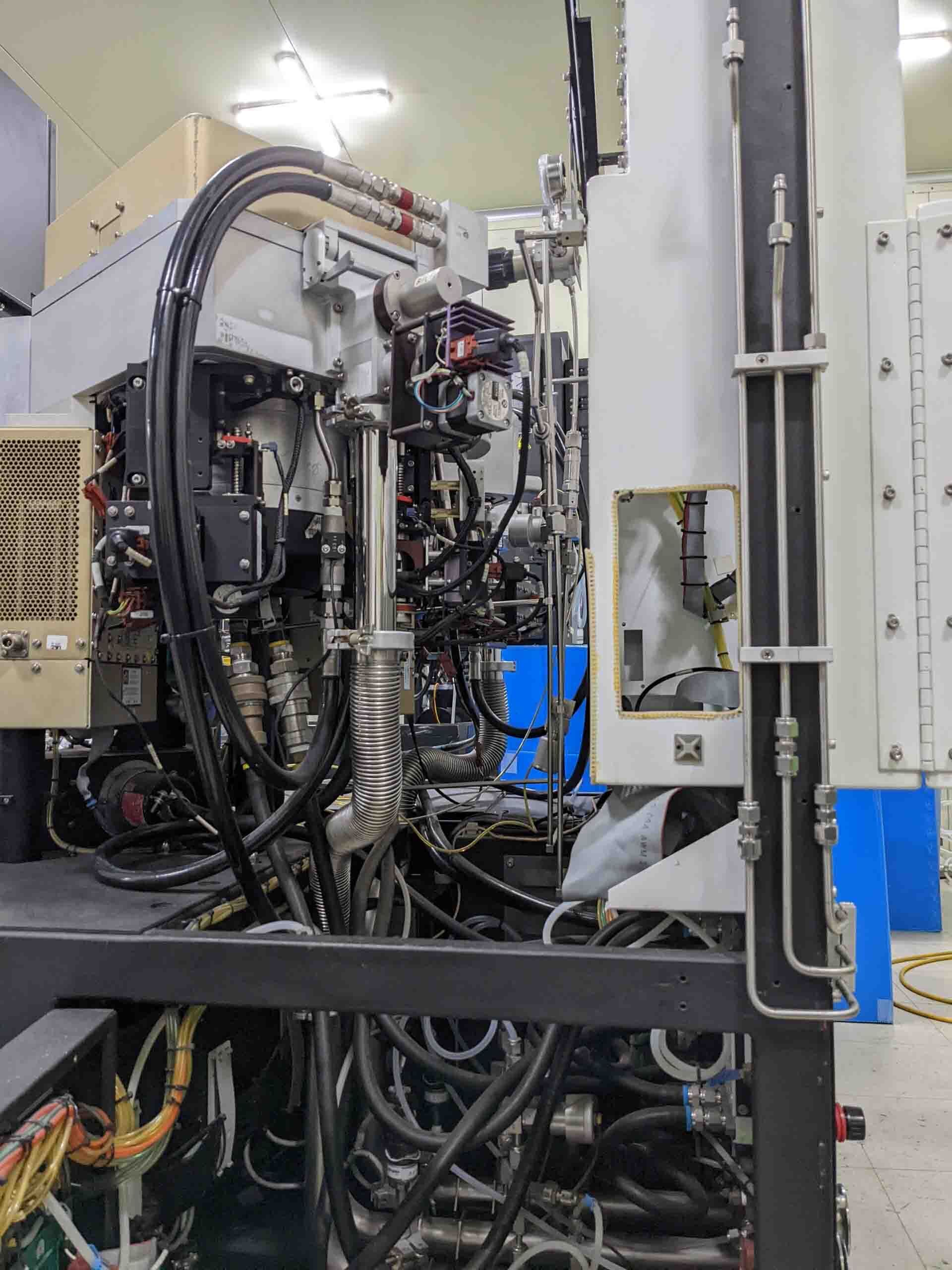

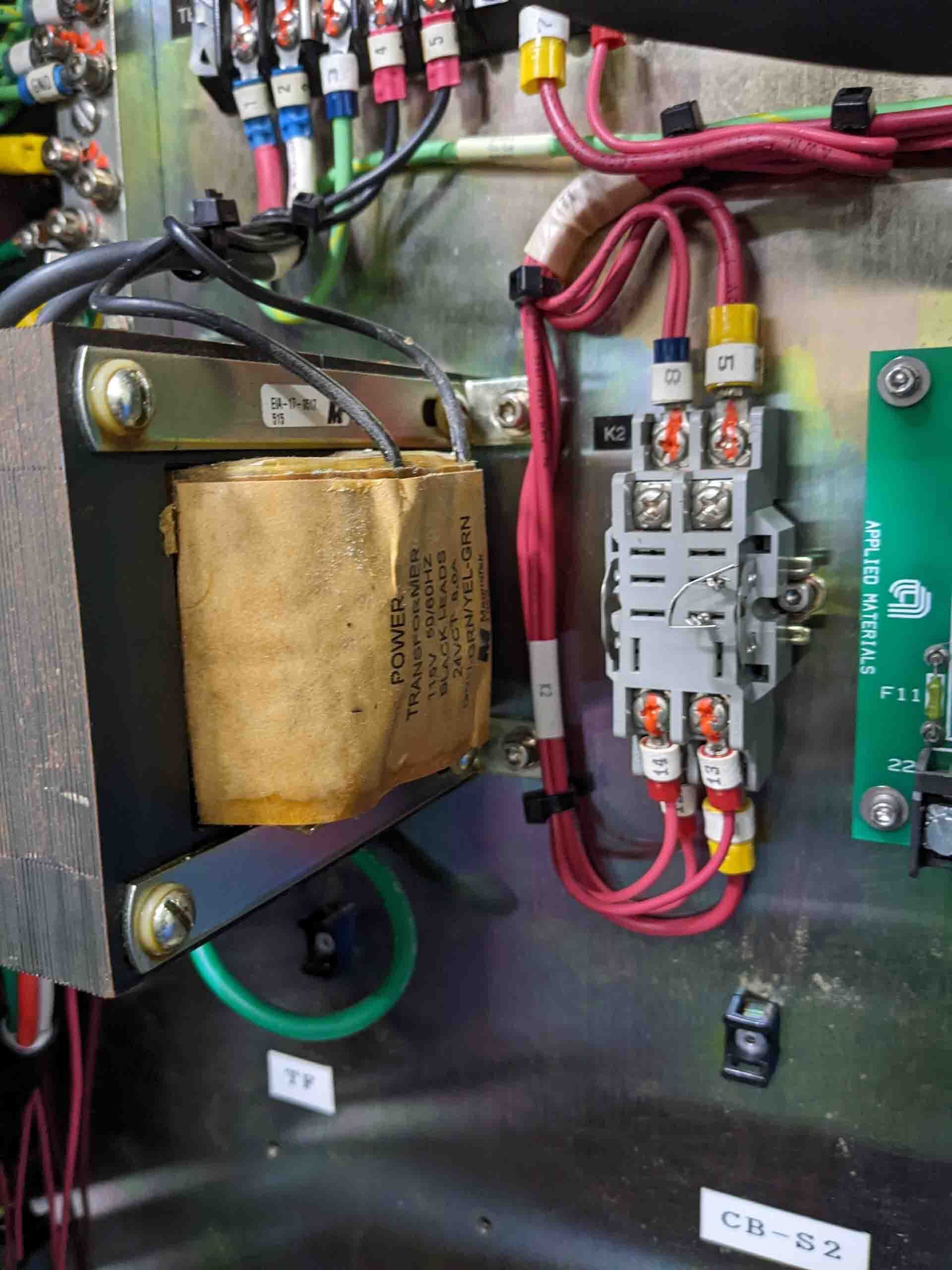

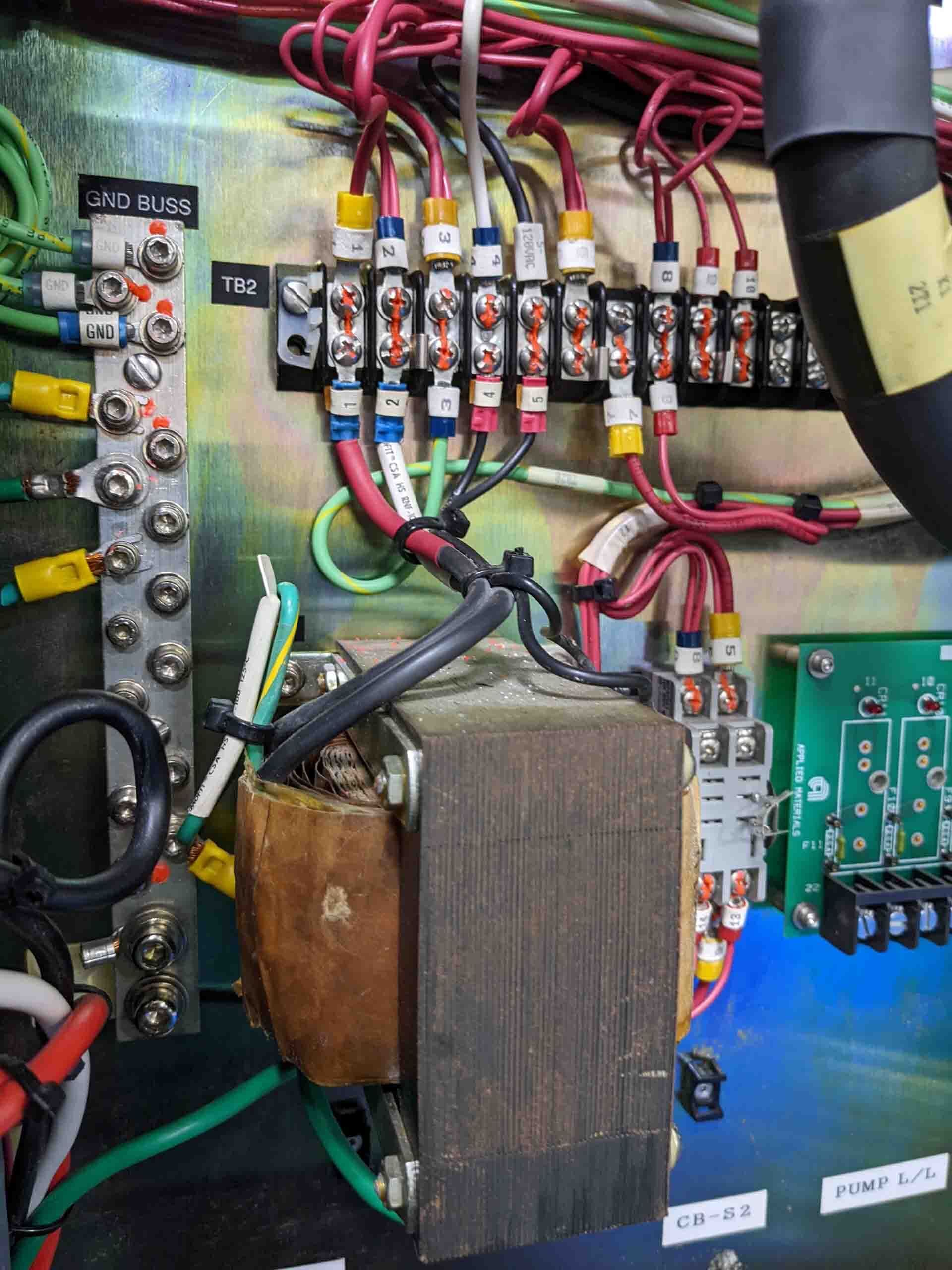

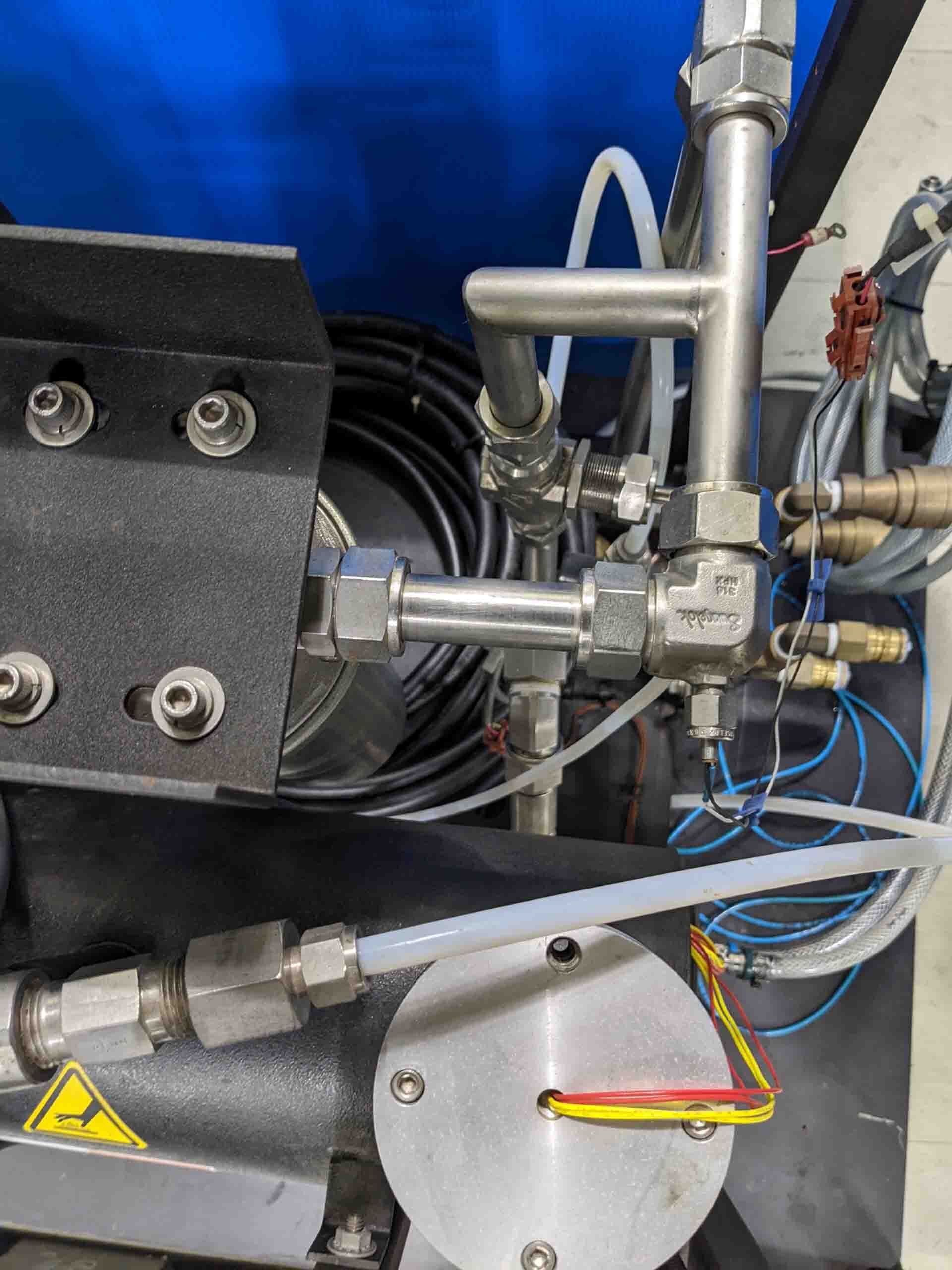

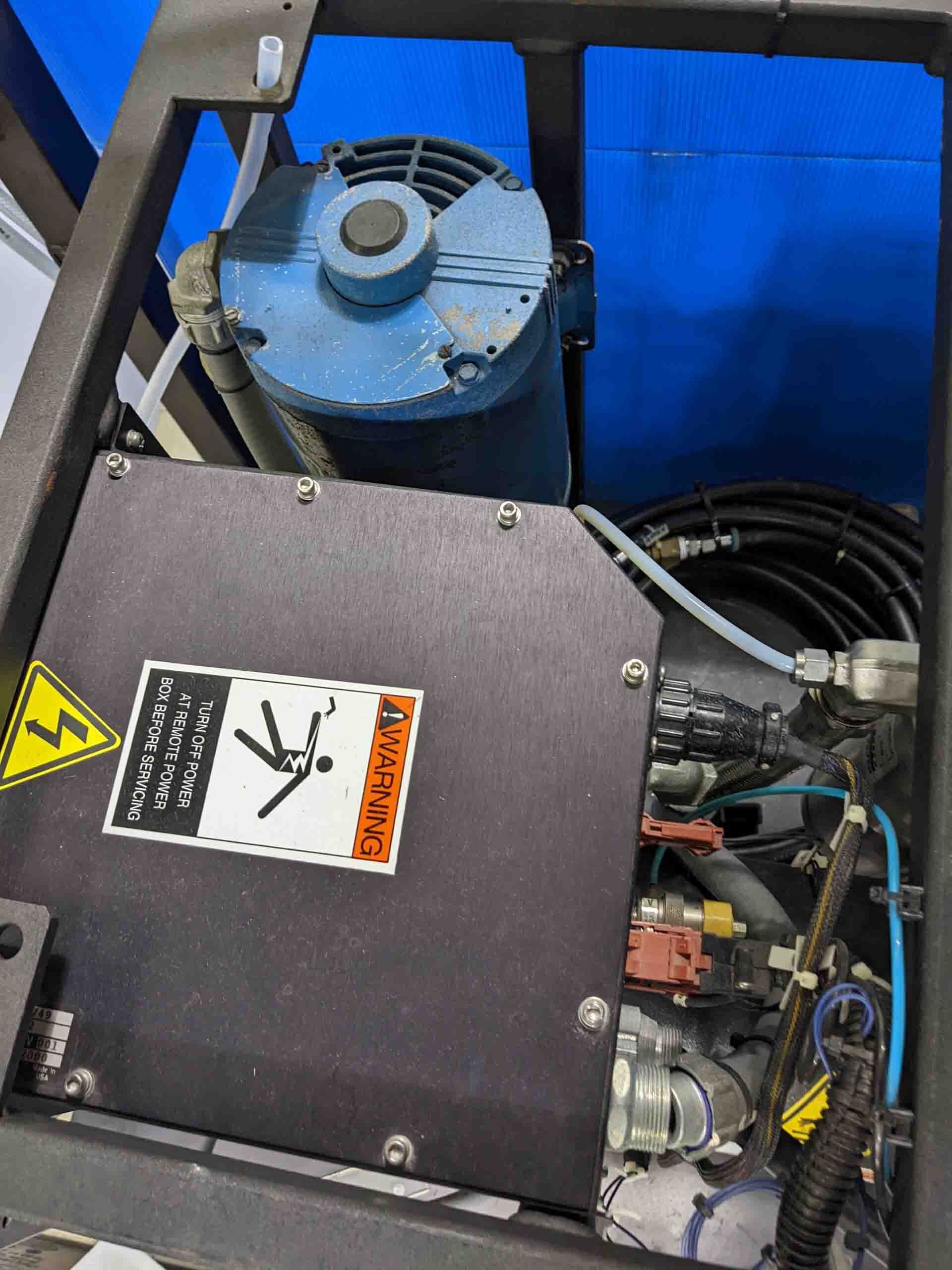

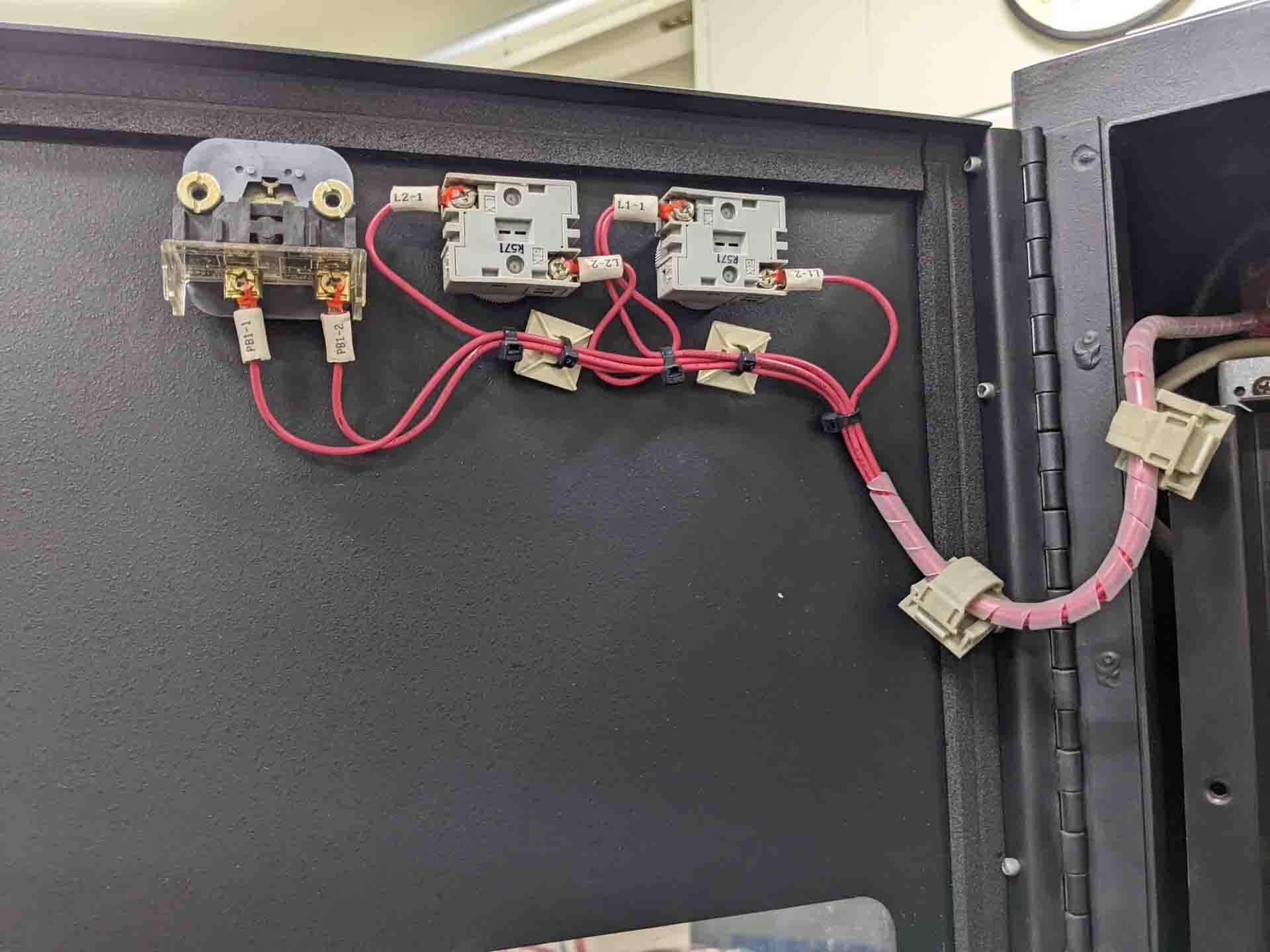

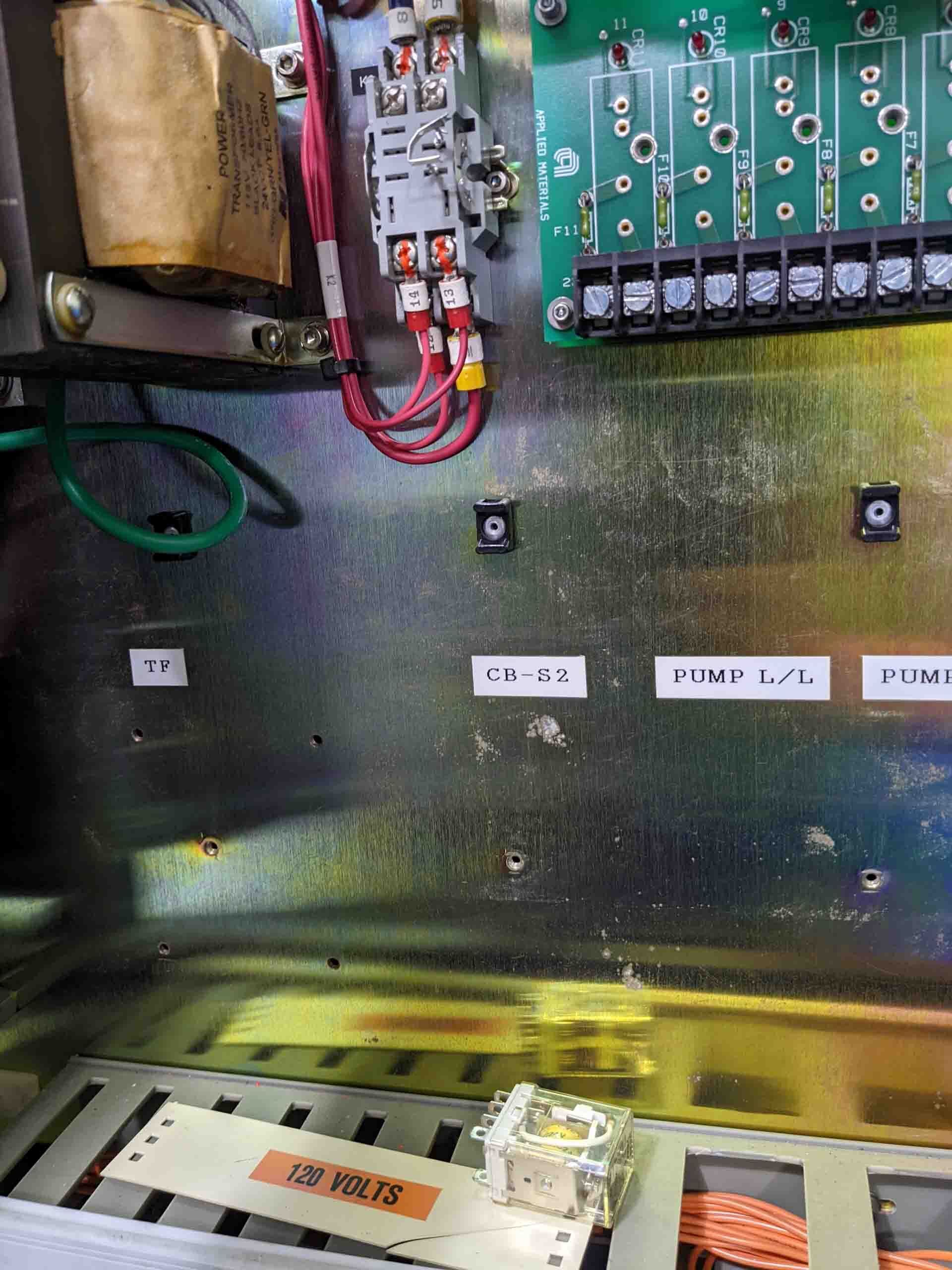

AMAT / APPLIED MATERIALS P5000 is an advanced reactor chamber specifically designed for semiconductor process applications. This reactor chamber offers a wide range of features that enable it to deliver superior performance and control in a variety of applications. The reactor chamber is made of high quality stainless steel and is nitride treated for corrosion protection. The chamber is configured for AMAT P-5000 wafer processing with a radius of 30.7cm, a chamber width of 45.7cm and a chamber height of 39cm. APPLIED MATERIALS P 5000 reactor chamber utilizes a completely automated process control system that can be set up to allow a wide range of user-defined parameters such as chamber pressure, temperature, substrate temperature, thermal cycle and gas flow. The process control system also includes an embedded data logger that stores process information and may be retrieved to analyze trends and determine the best parameters for a particular application. This allows for improved reliability and accuracy of processing results. The reactor chamber also includes a gas panel with two separate gas manifolds and regulators. The gas panel provides control over the gases being provided by each manifold, as well as the pressure and flowrate of the gases. This enables the user to adjust the process conditions to accomplish the desired results. AMAT / APPLIED MATERIALS P 5000 reactor chamber is designed to be installed into a work environment that is free from environmental debris, dust and other particles. The chamber is equipped with a static discharge cable to help minimize static electricity build-up within the chamber. The chamber is equipped with an automated nitrogen purge system and an inlet port. The inlet port is designed to allow for the delivery of heated nitrogen and other process gases into the chamber. This helps maximize the process efficiency and consistency. In addition, P 5000 reactor chamber is designed for easy and straightforward maintenance. The chamber includes removable top and bottom seals within the chamber that can be easily removed to allow for periodic cleaning and servicing of the chamber. This reduces downtime and allows the user to continue processing without interruption. AMAT P5000 reactor chamber is an advanced and reliable tool for the semiconductor processing applications. Its features make it suitable for a variety of applications and its maintenance is straightforward and efficient. With proper operation and maintenance, this reactor chamber can help ensure high-quality results and reliable long-term operation.

There are no reviews yet