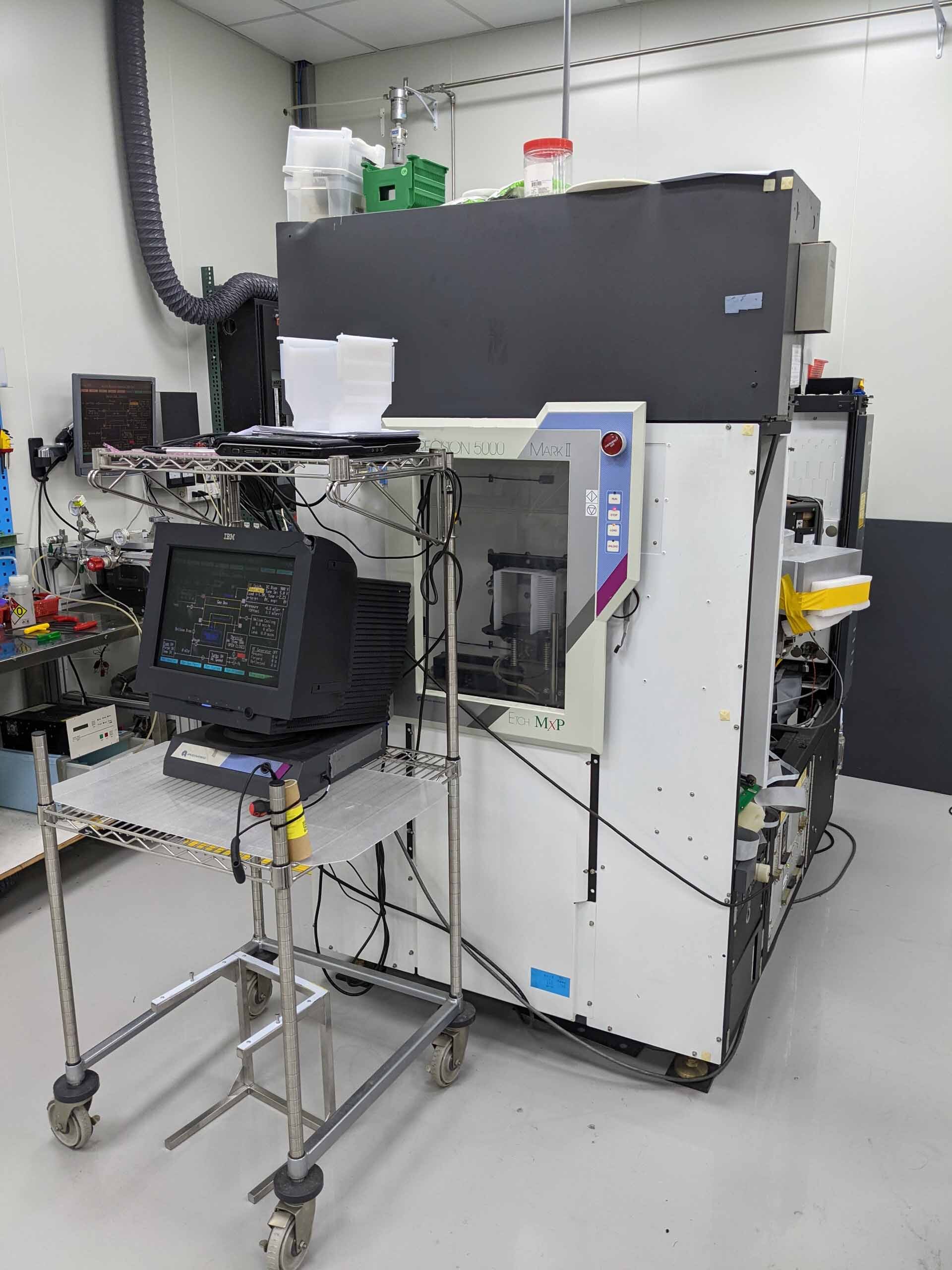

Used AMAT / APPLIED MATERIALS P5000 #293625726 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS P5000 is a vertical-type diffusion reactor widely used in the semiconductor industry for a variety of processes, such as oxidation, phosphorous diffusion, boron diffusion, and thermal annealing. This advanced reactor is designed to produce uniformity and repeatability while allowing for rapid and precise process execution. AMAT P-5000 reactor is designed with a vertical cylindrical geometry that has a height of 85 inches (2.15 meters), a diameter of 40.1 inches (102cm), and a volume of 45.7 cubic feet (1.3 cubic meters). The chamber is constructed of a quartz outer shell with a ceramic core, allowing for uniform and repeatable temperature compared to horizontal furnaces. The quartz shell also ensures that high temperatures, up to 2400°C or 4352°F, may be reached for high-temperature processes. APPLIED MATERIALS P 5000 features two quartz heating zones that meter the thermal requirements for critical processing steps. It may also be equipped with a variety of quartz and metalware components, such as alumina and tungsten baskets, for use in multiple process requirements. P-5000 reactor may be used for high temperature processes, such as phosphorus and boron diffusion, in the semiconductor industry. Such processes require accurate control of high temperature uniformity and repeatability, something AMAT / APPLIED MATERIALS P-5000 reactor is designed to meet. The quartz outer shell ensures uniform temperature on the wafers inside the reactor, while the ceramic core and quartz heating zones provide precise control of temperature. Furthermore, AMAT P5000 reactor's vertical geometry allows for fast, consistent process execution and cooling times, helping achieve short turn-around times. In addition, AMAT / APPLIED MATERIALS P 5000 reactor is designed with precise process control, something that is critical in producing top-level semiconductor products. It allows the user to select precise parameters such as time and temperature, increasing the accuracy of processes. Moreover, APPLIED MATERIALS P-5000 can be equipped with a PC-based control system, further expanding its process control capabilities. Overall, P 5000 is a versatile and reliable vertical-type diffusion reactor used in semiconductor industry owing to its precise temperature control , consistency in process repeatability and high-temperatures of up to 2400°C or 4352°F. It is designed to provide uniform heating of wafers while allowing rapid and precise process execution, allowing it to produce top-level semiconductor products.

There are no reviews yet