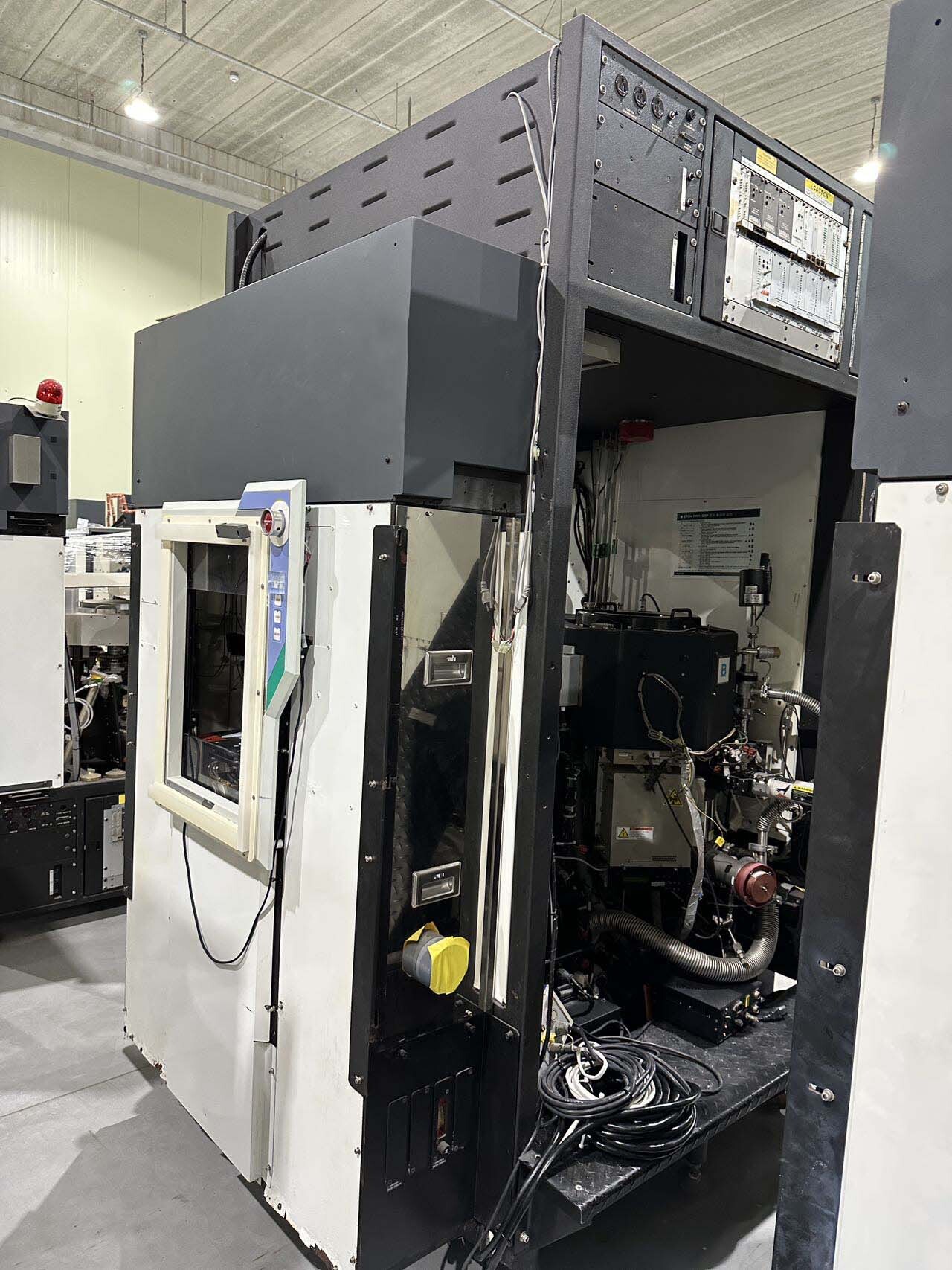

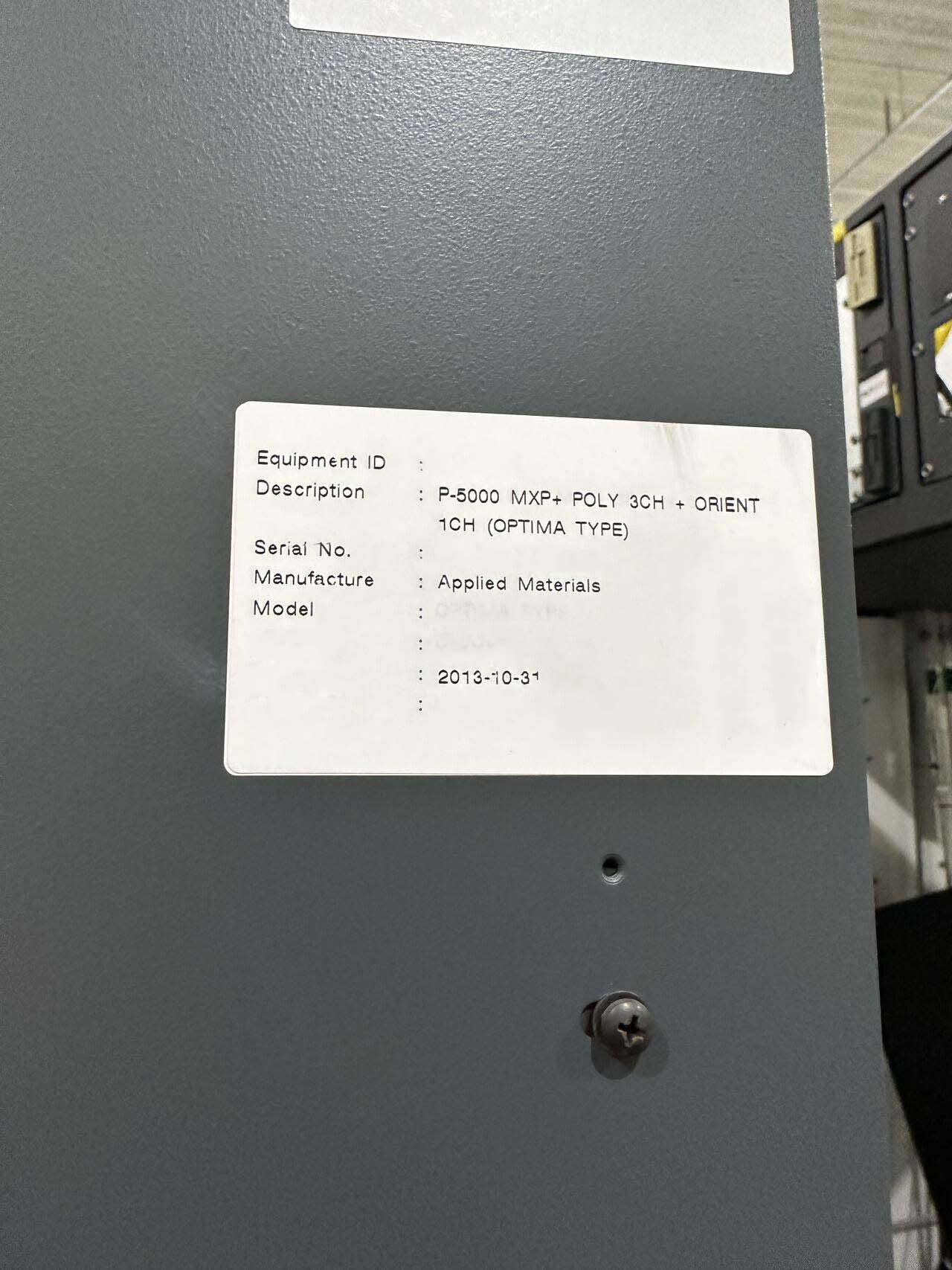

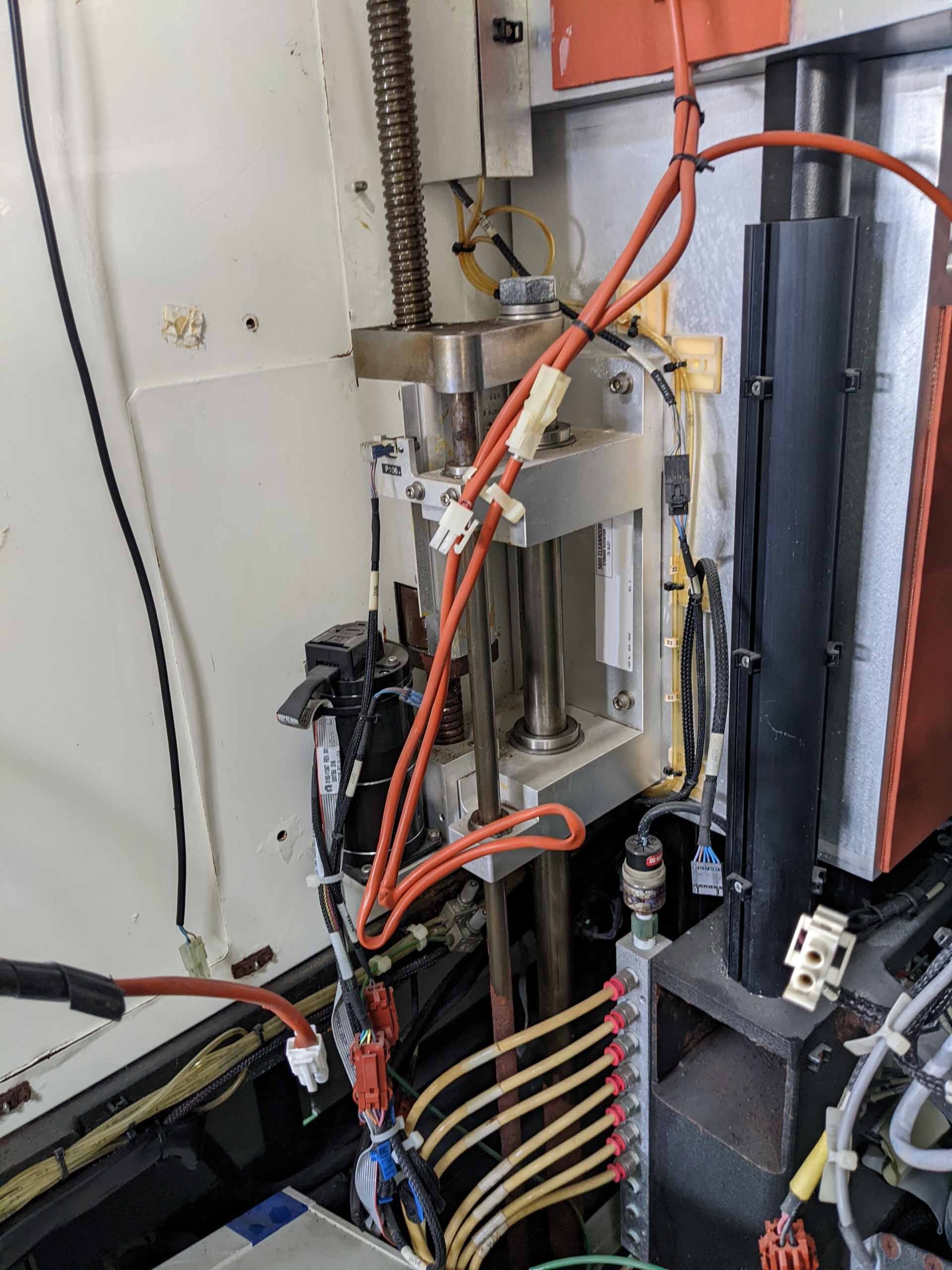

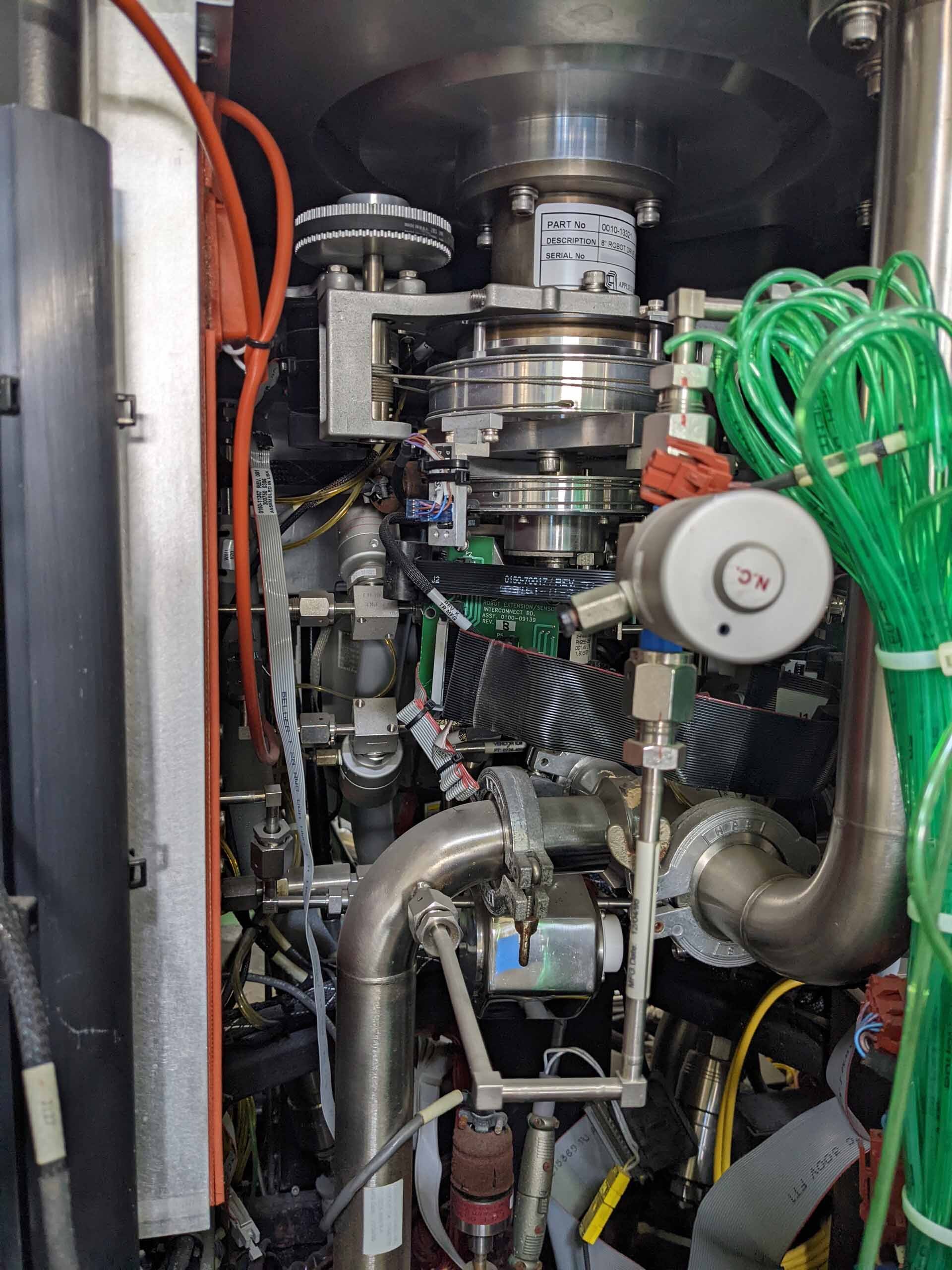

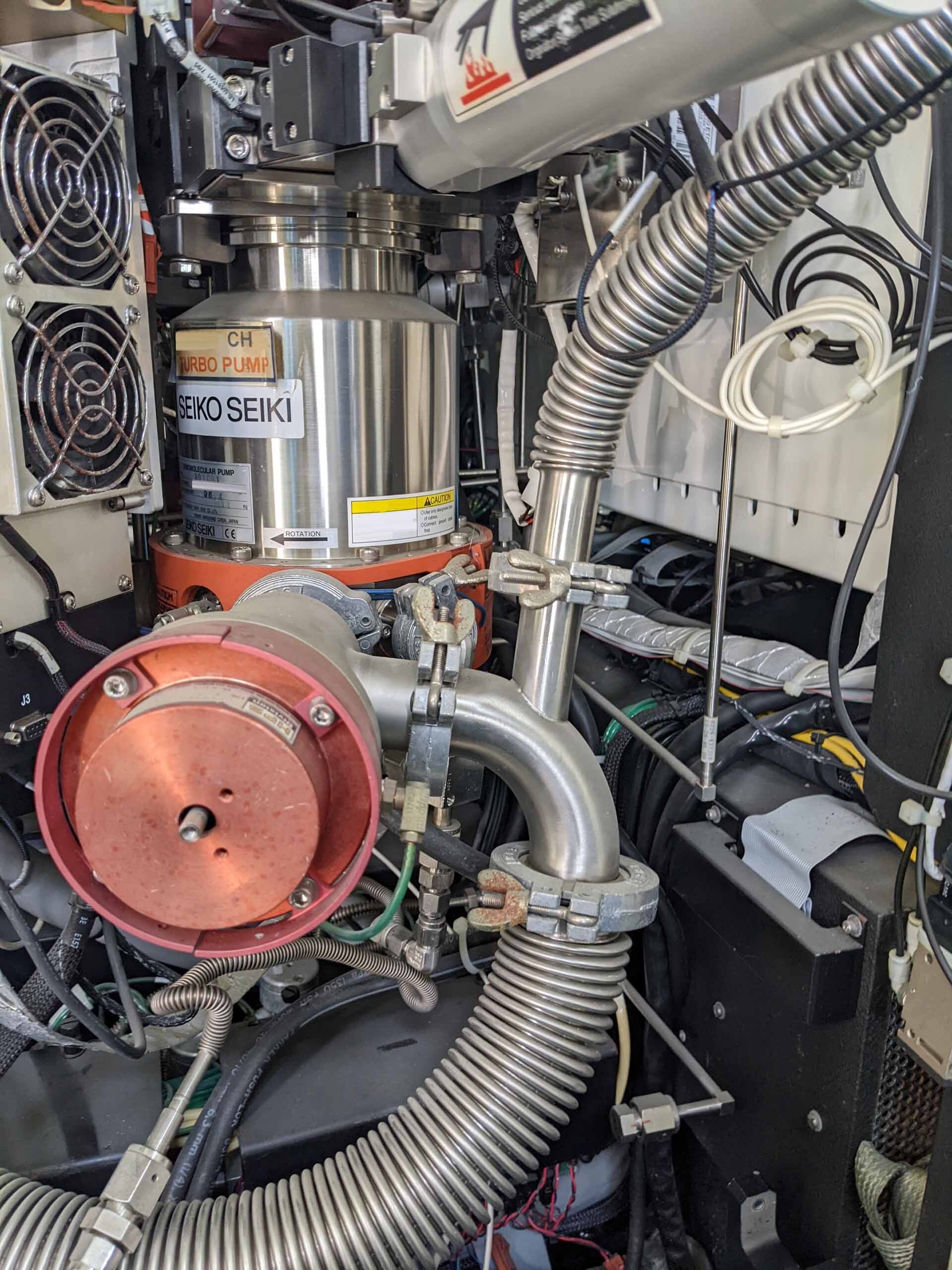

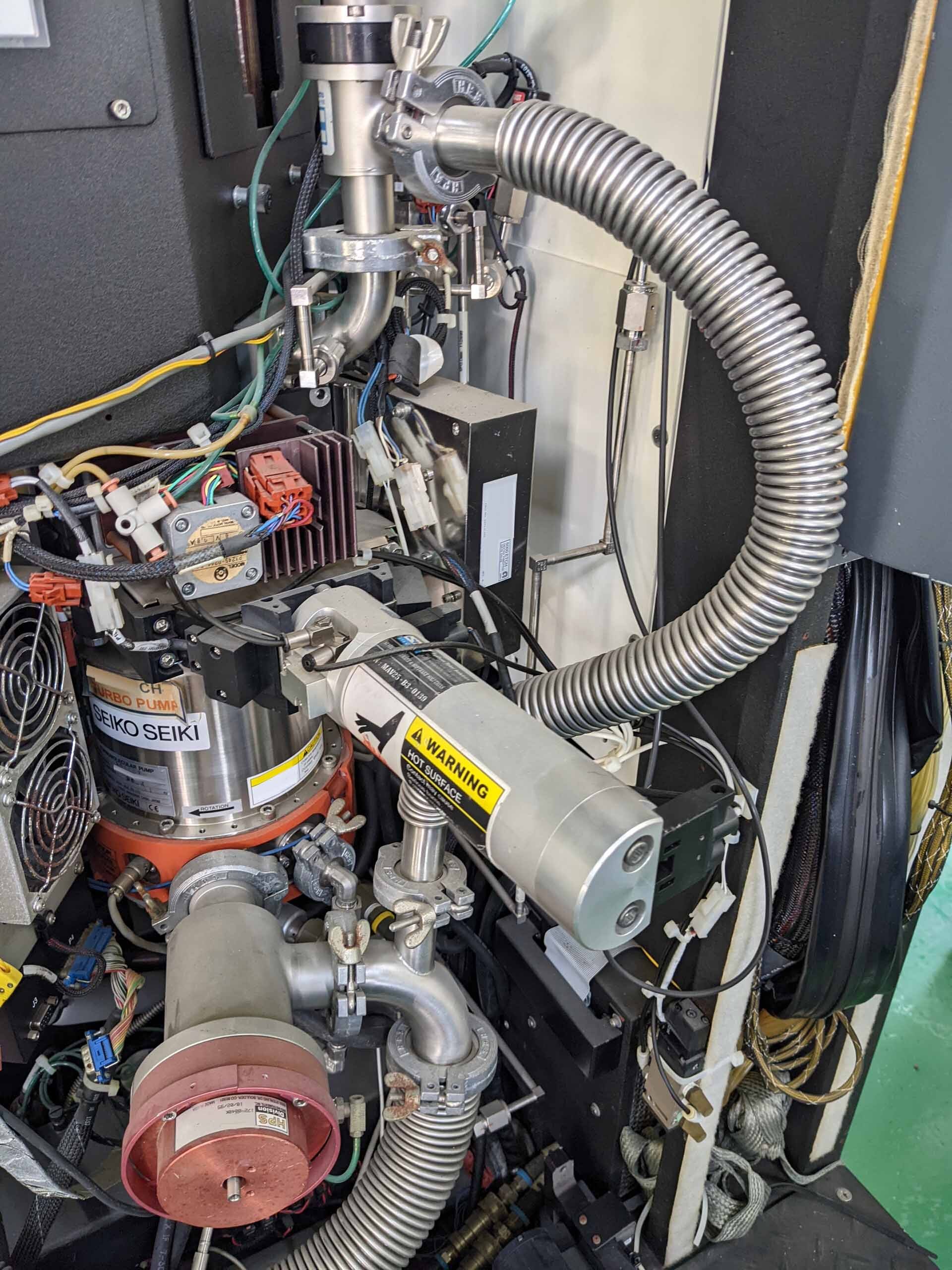

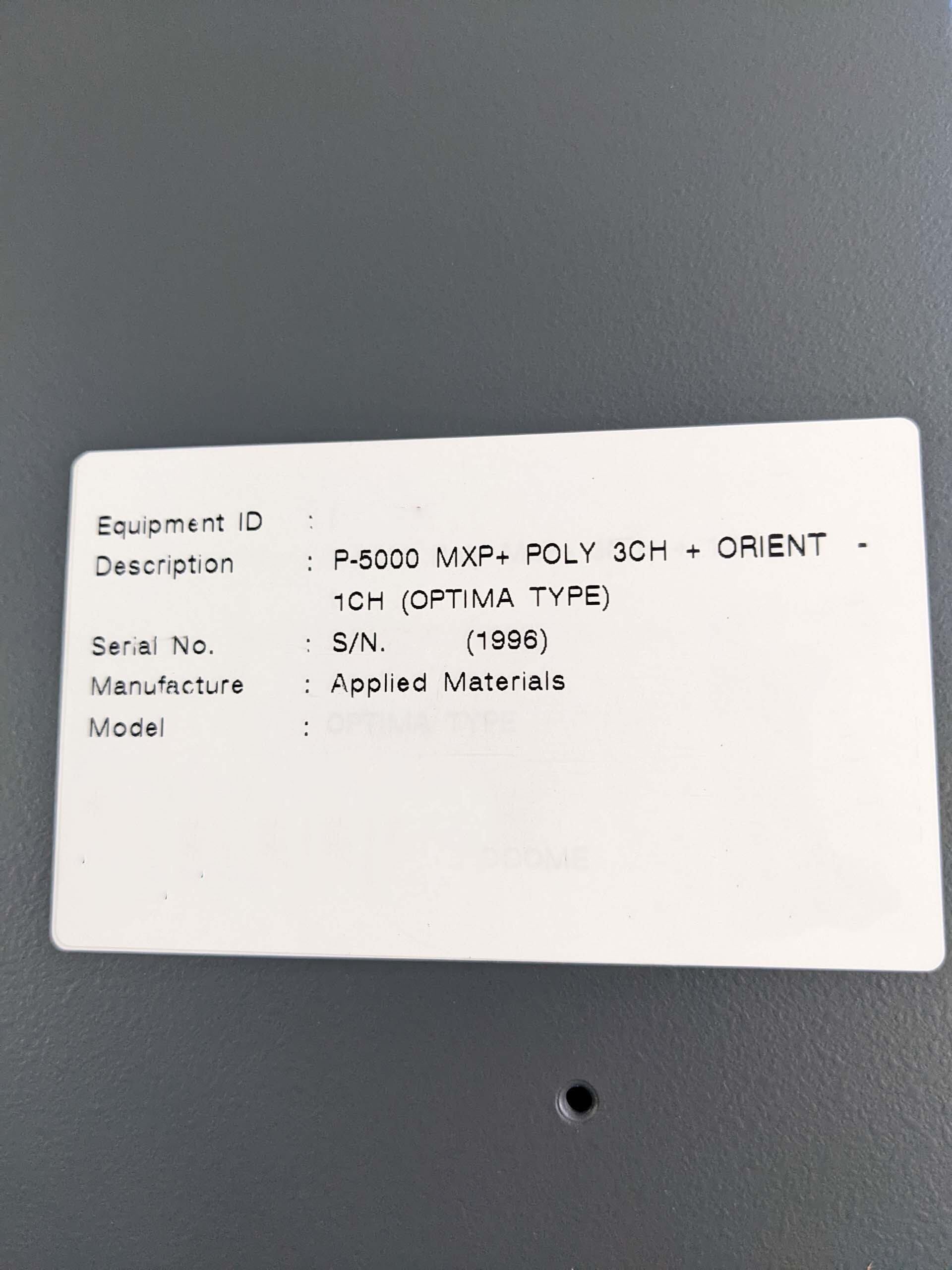

Used AMAT / APPLIED MATERIALS P5000 #293637028 for sale

URL successfully copied!

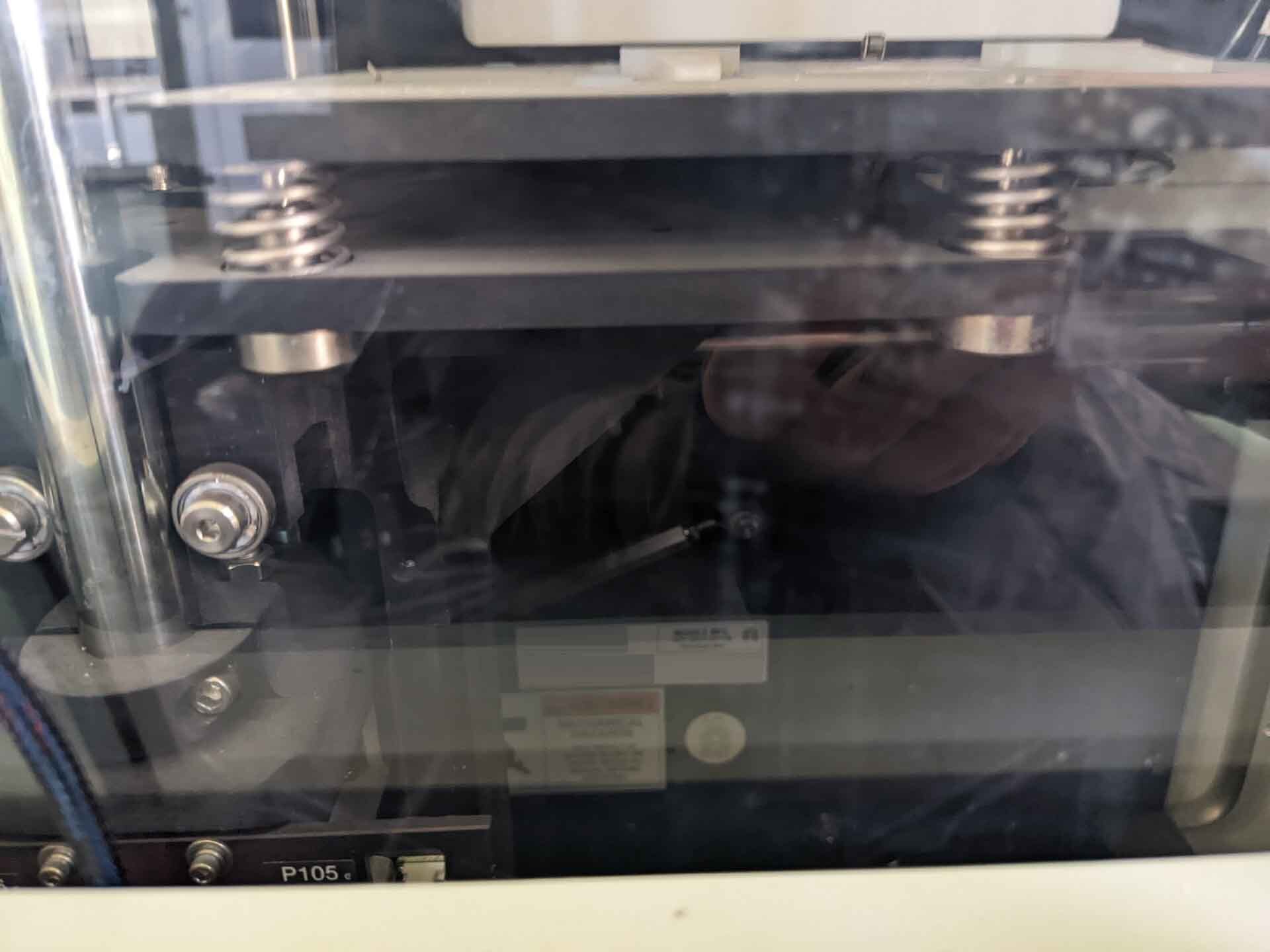

Tap to zoom

ID: 293637028

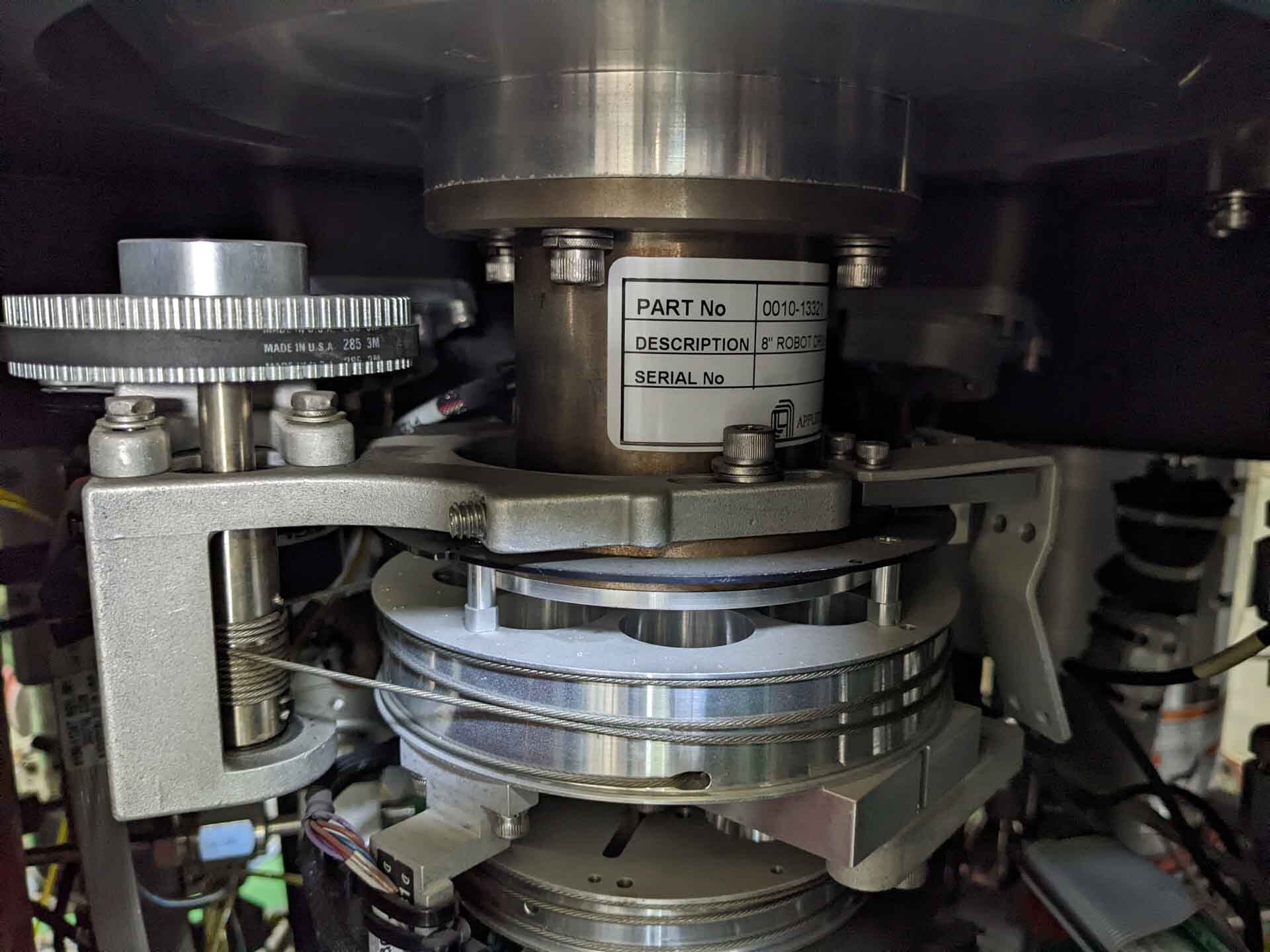

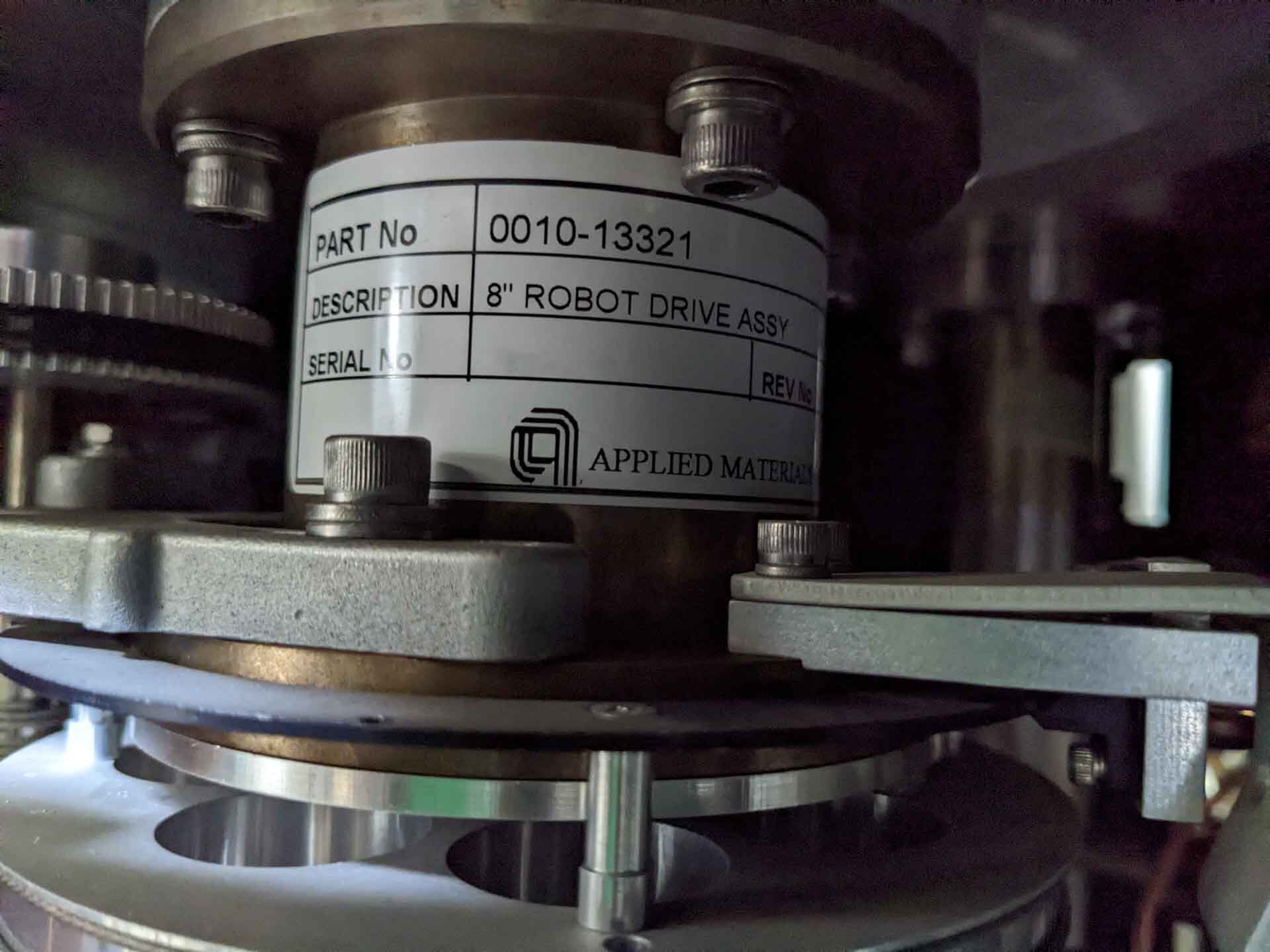

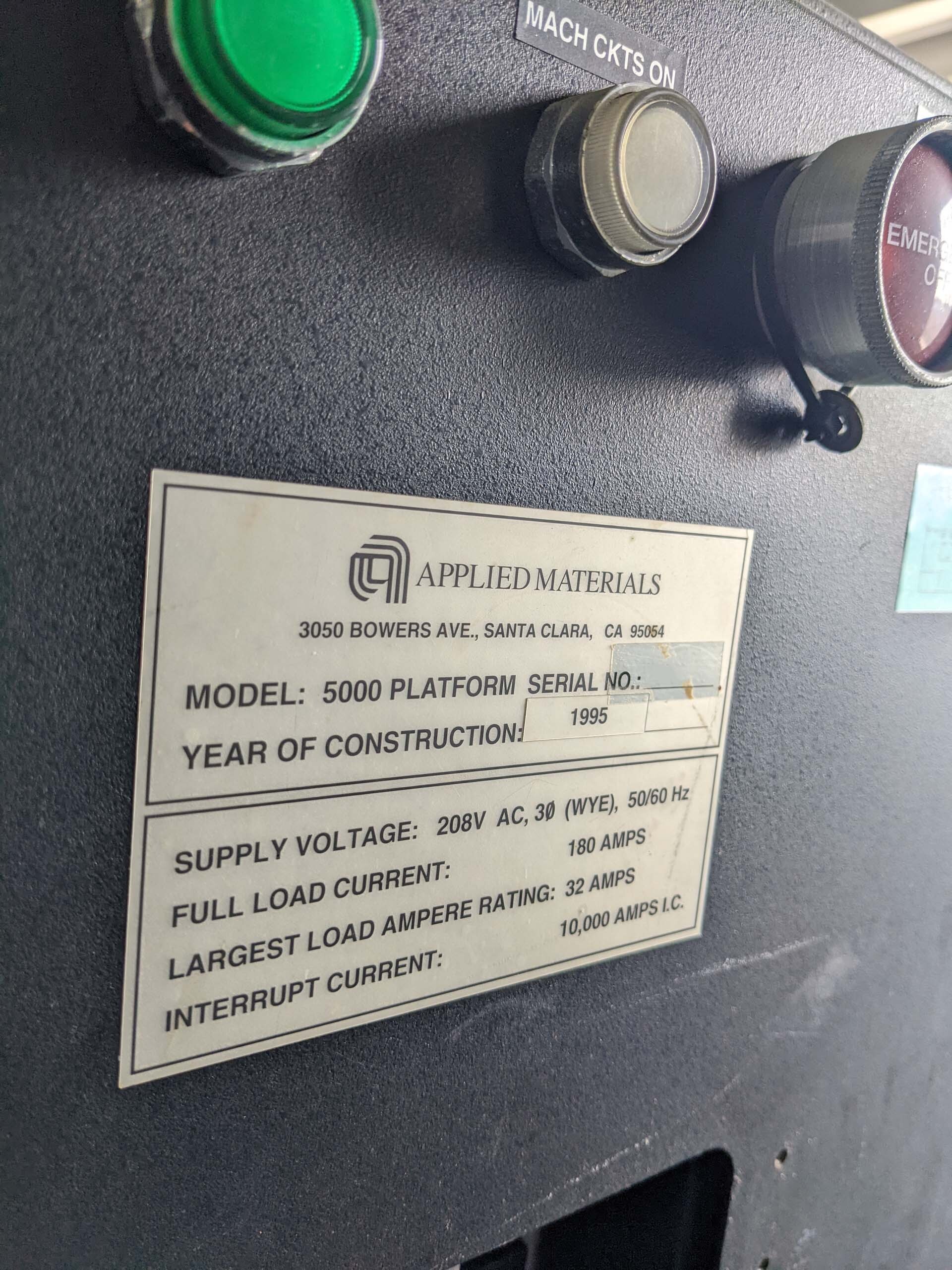

Wafer Size: 8"

Vintage: 2013

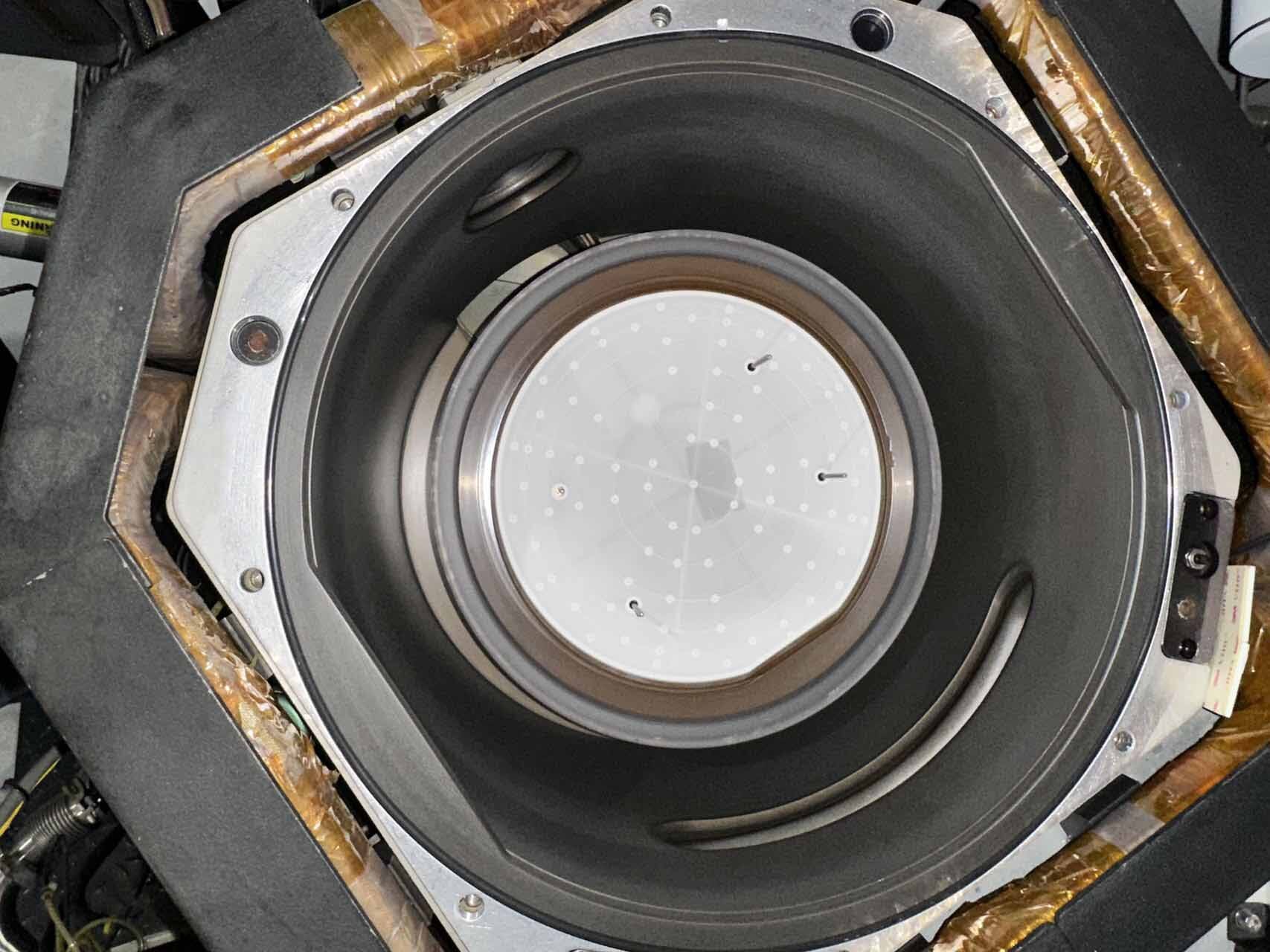

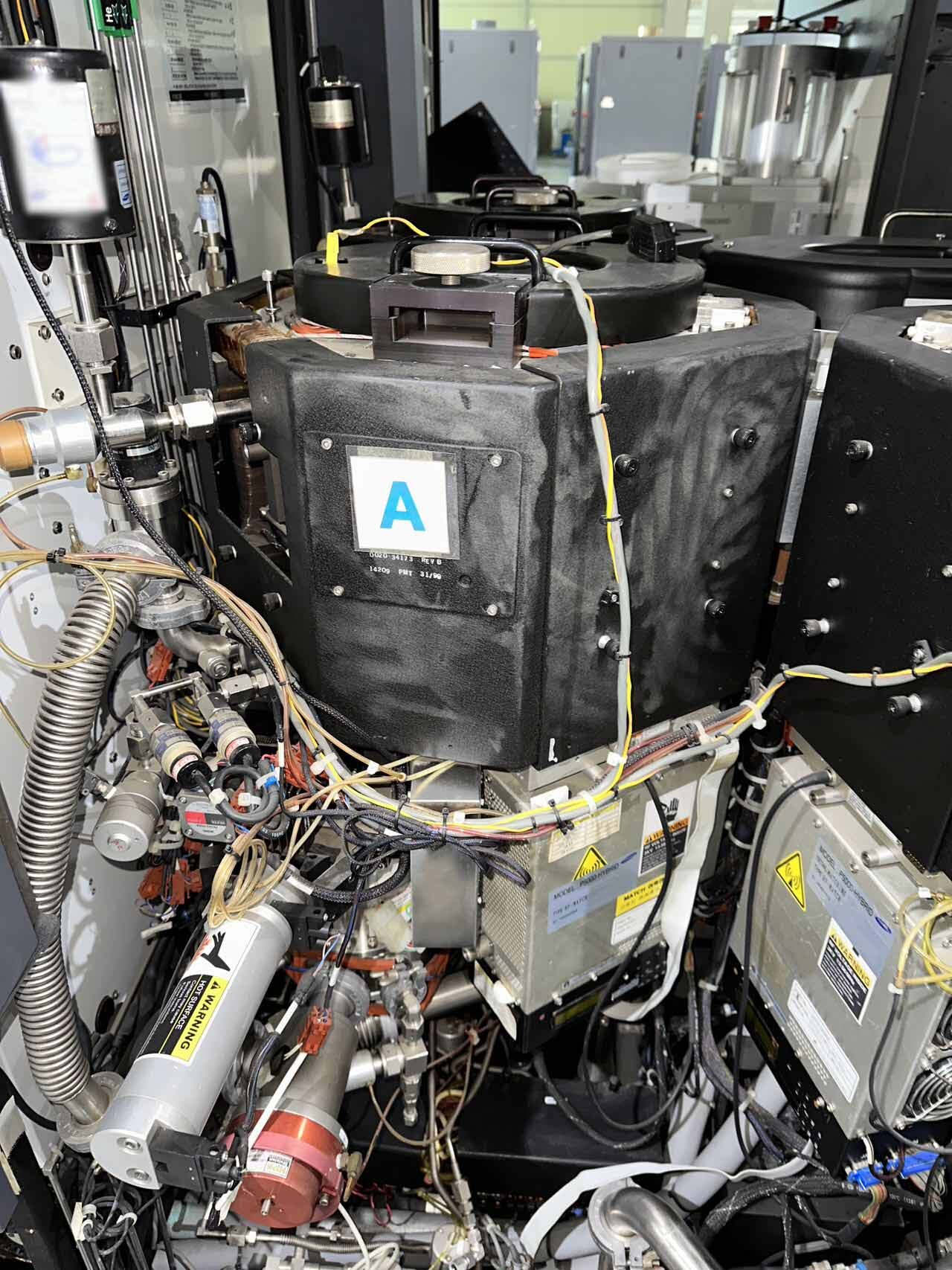

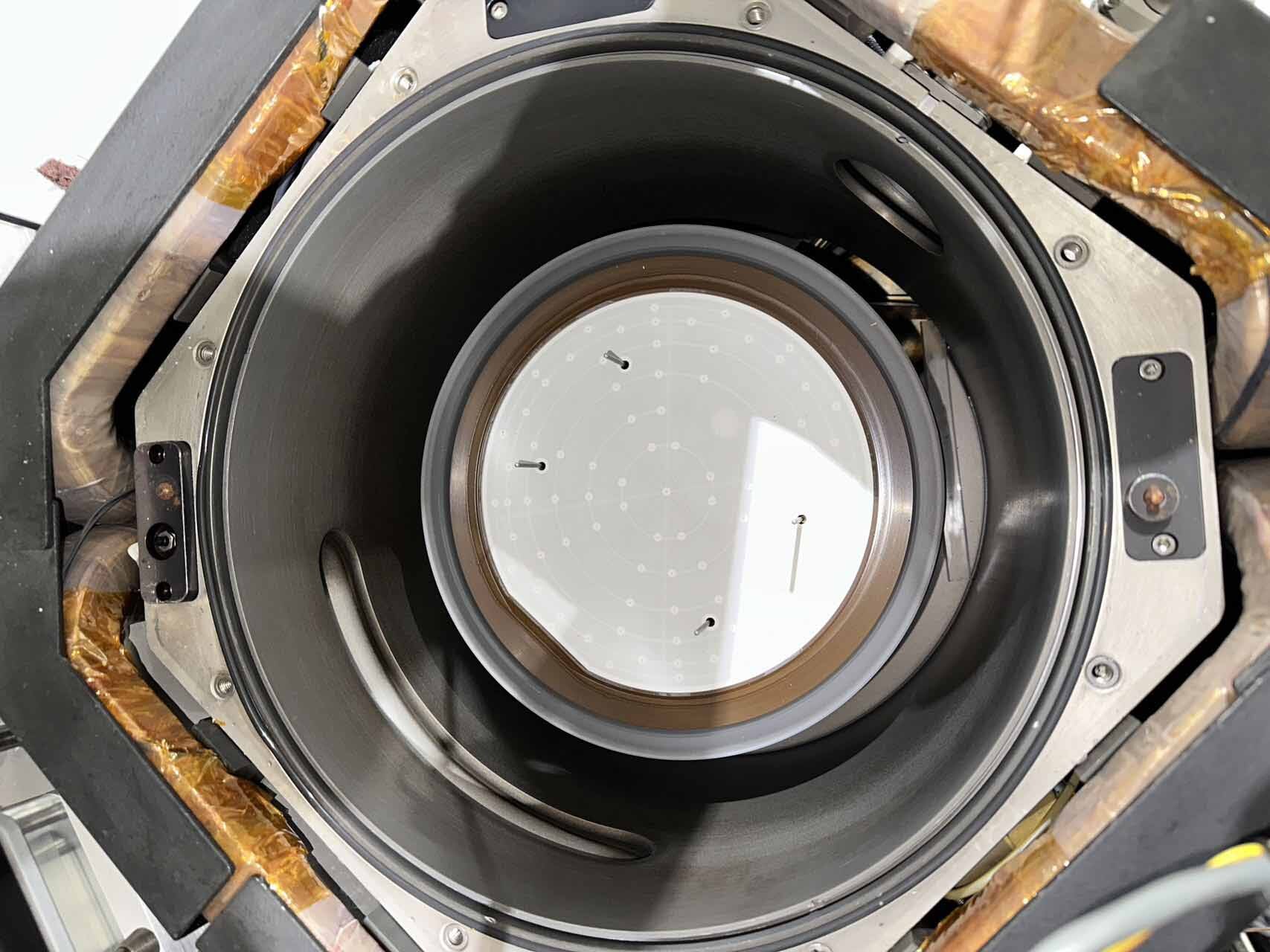

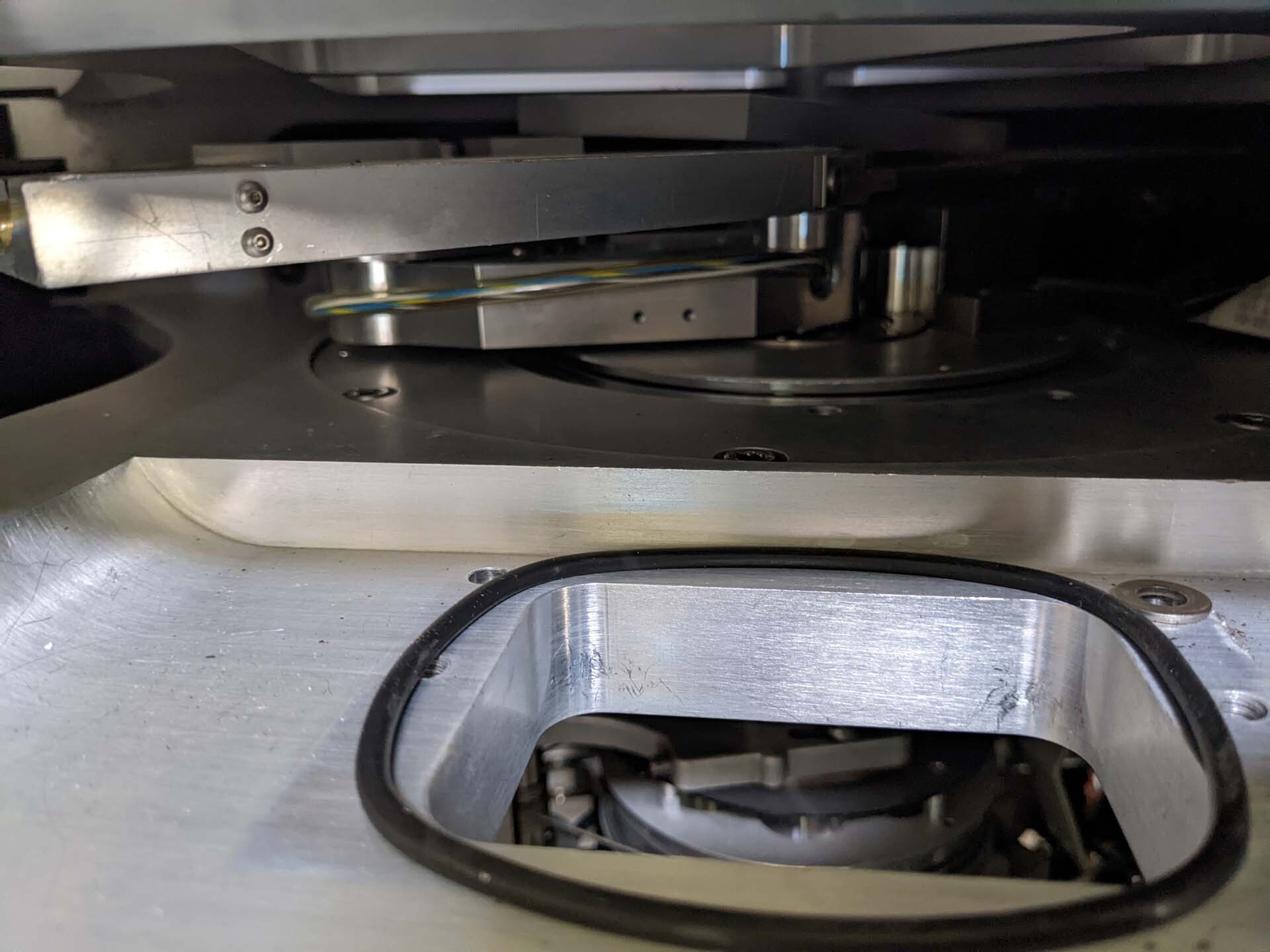

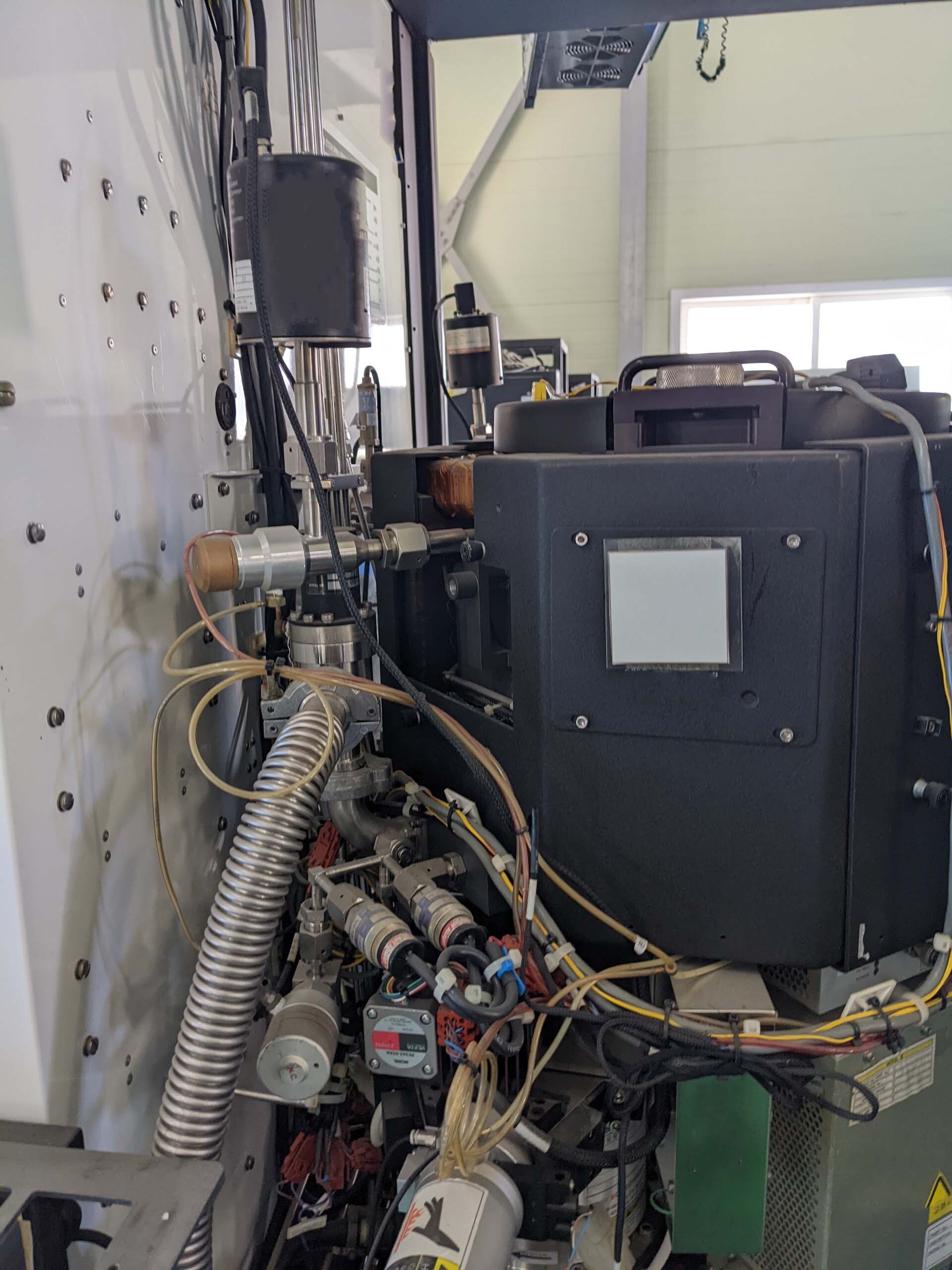

Etcher, 8"

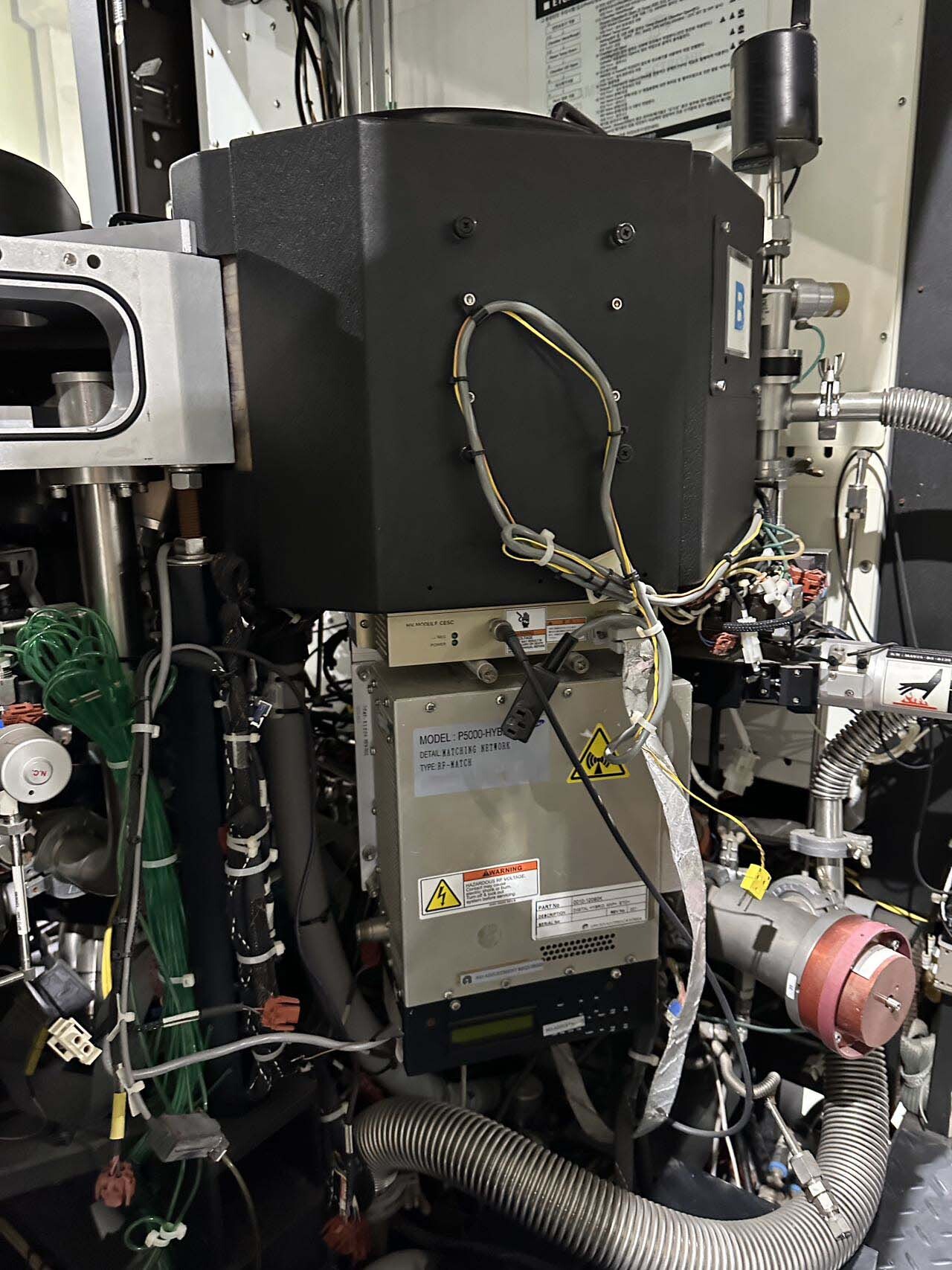

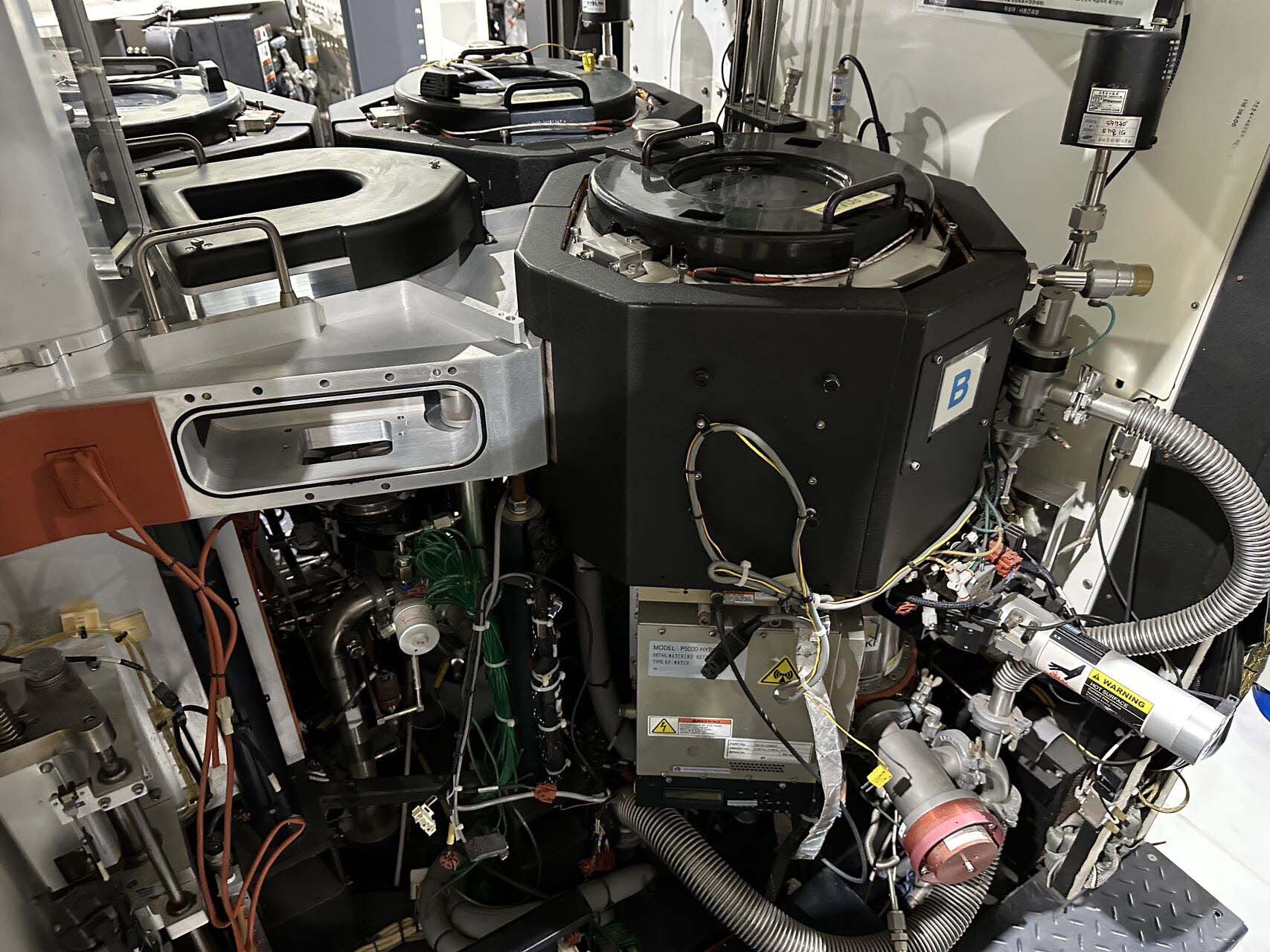

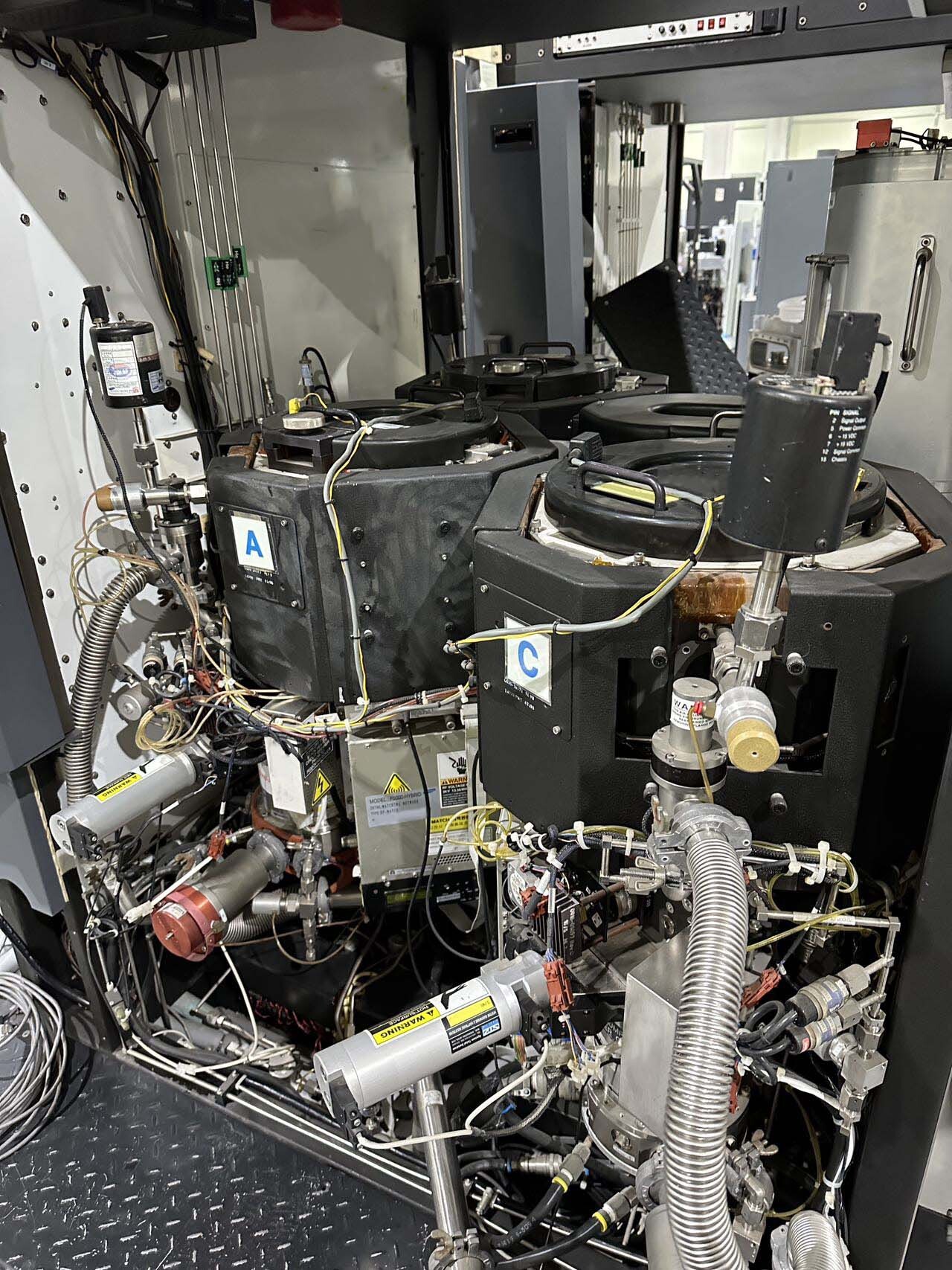

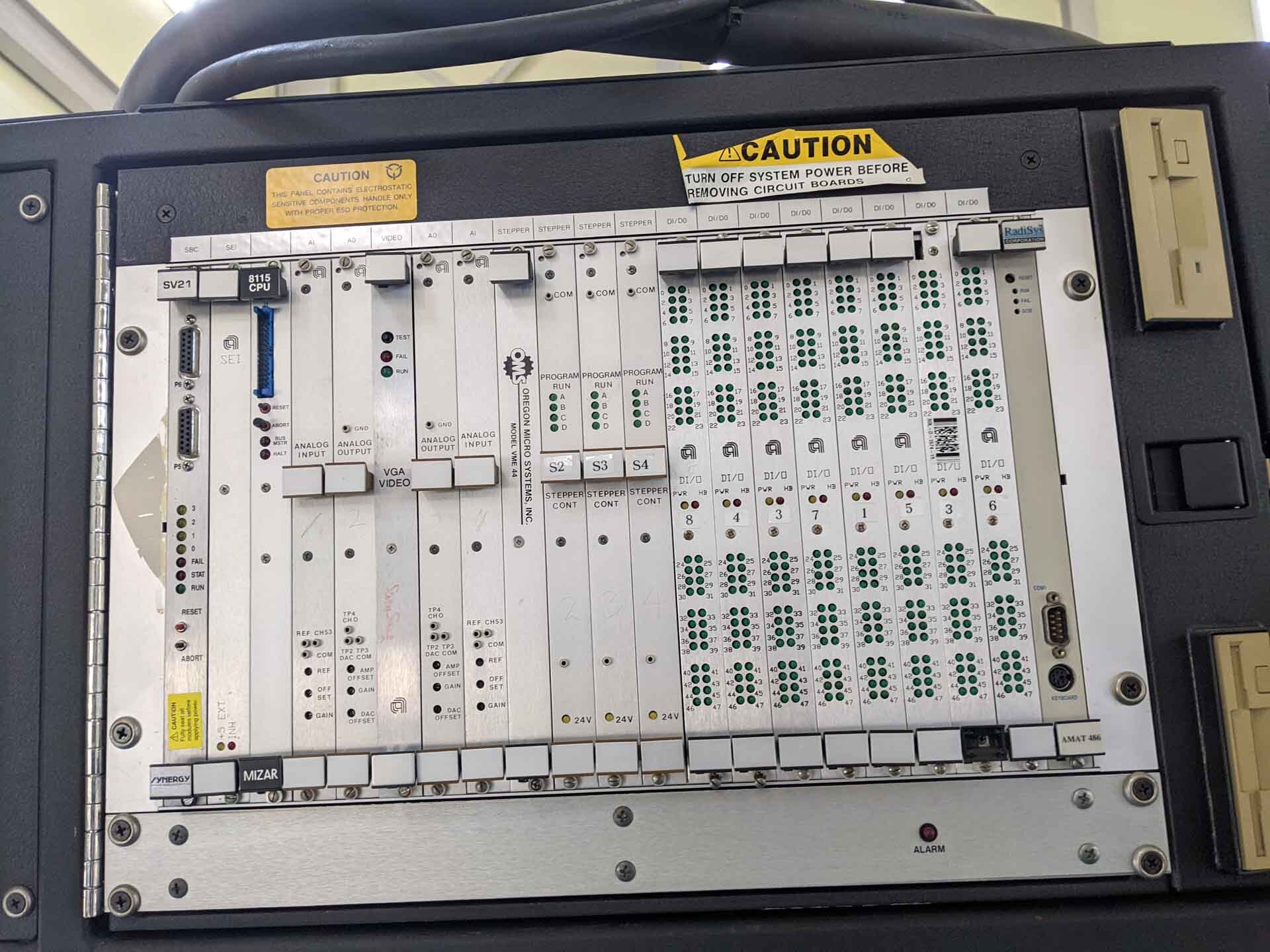

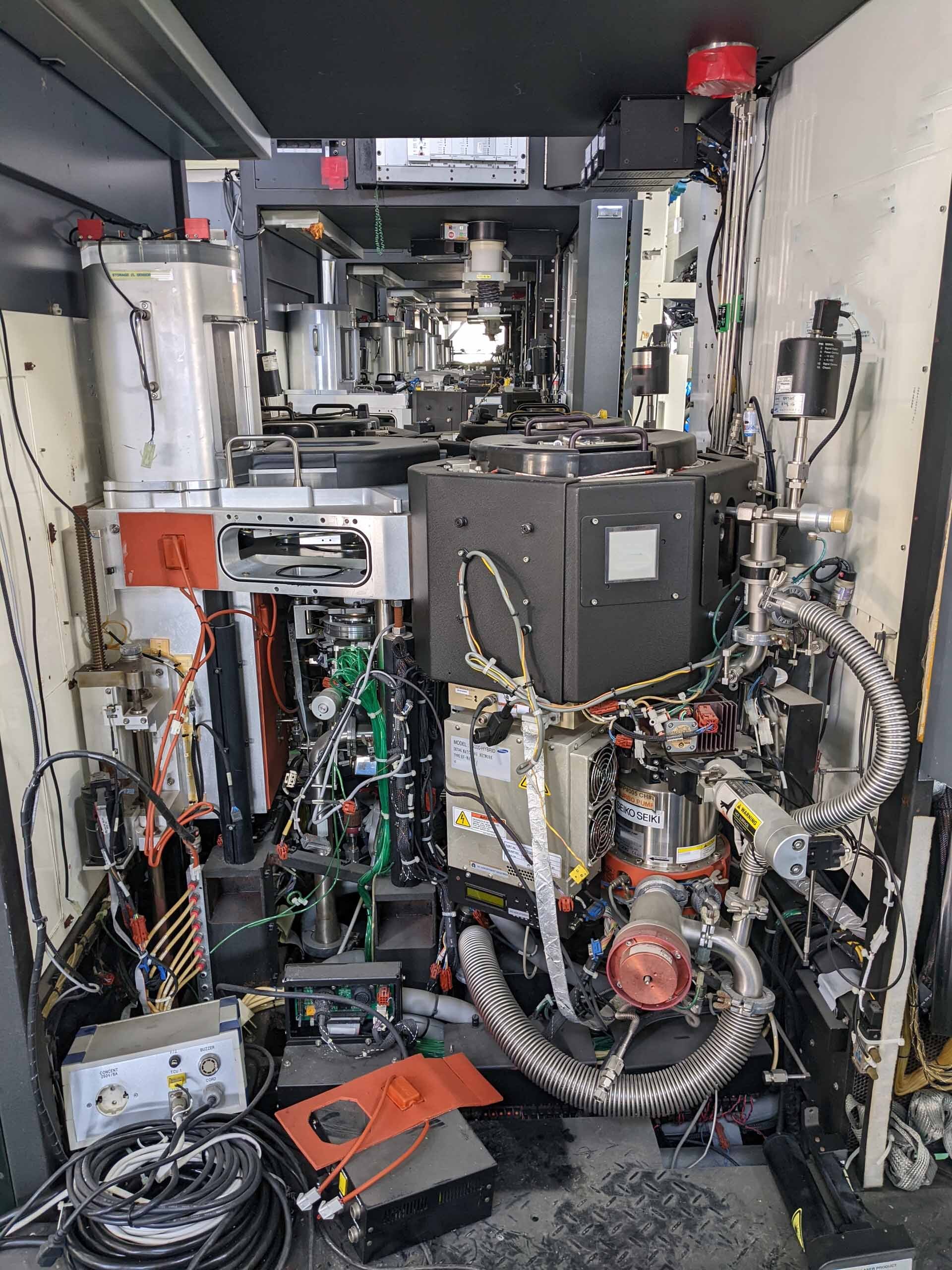

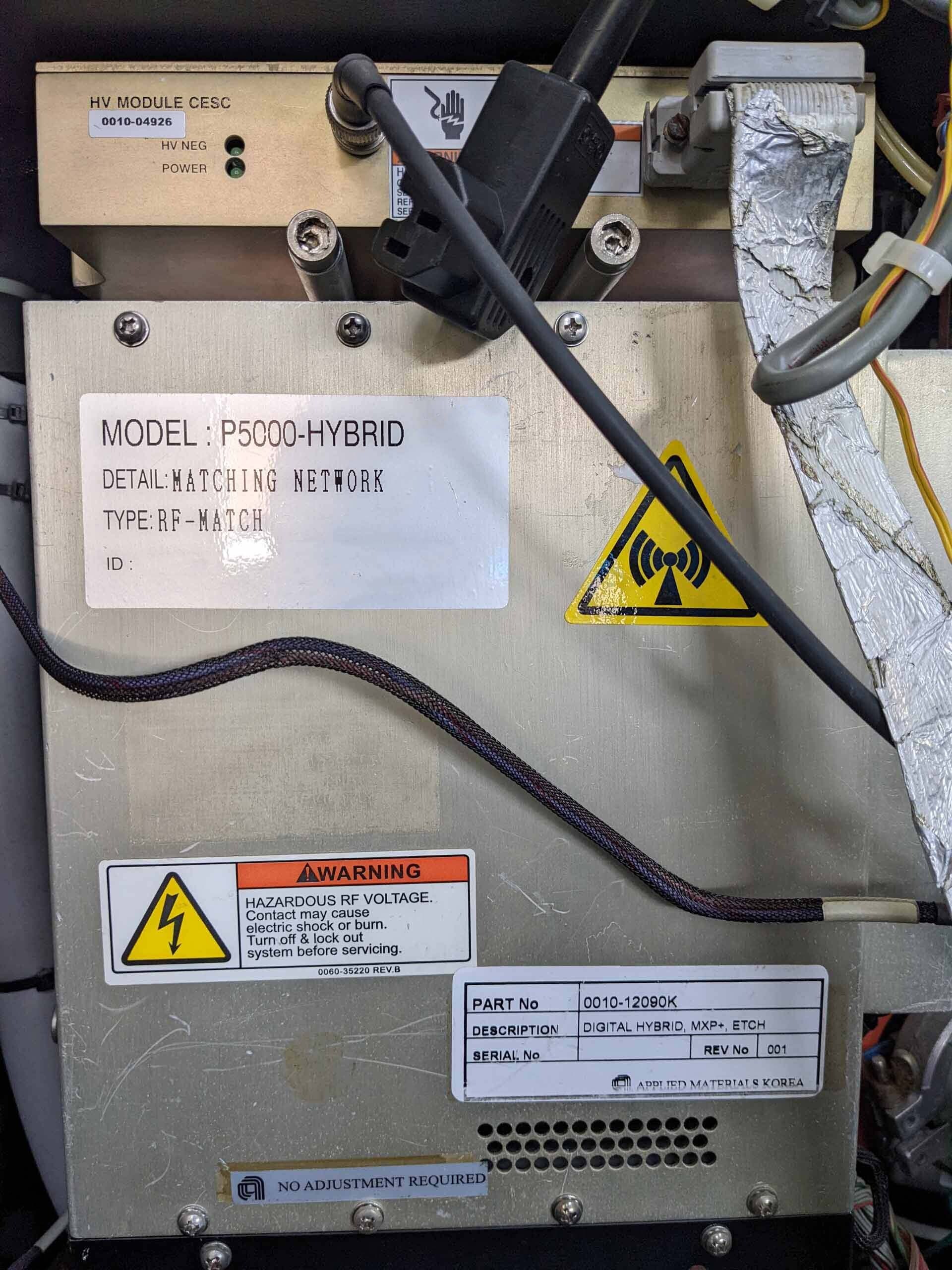

Orient MxP (Optima type)

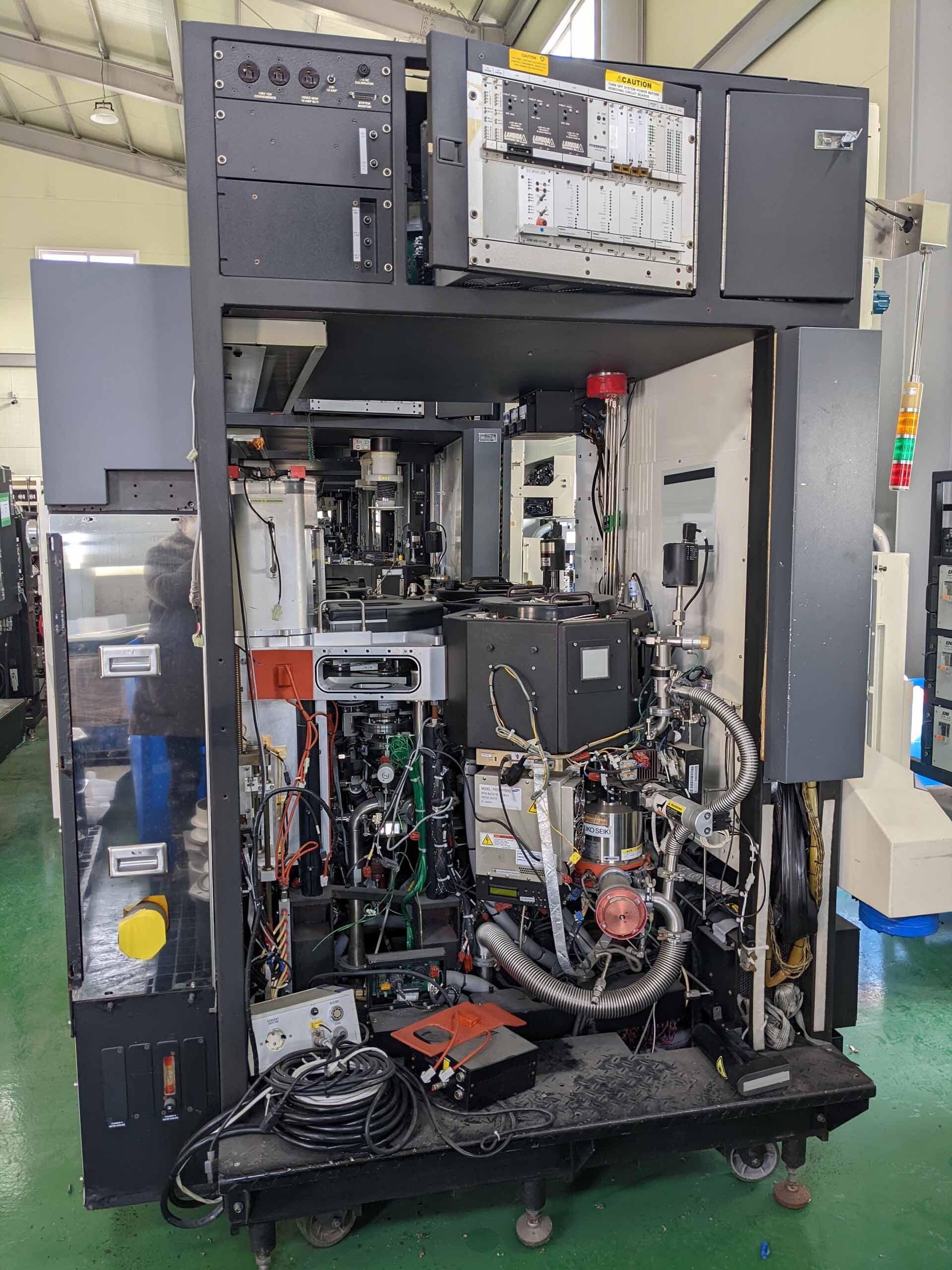

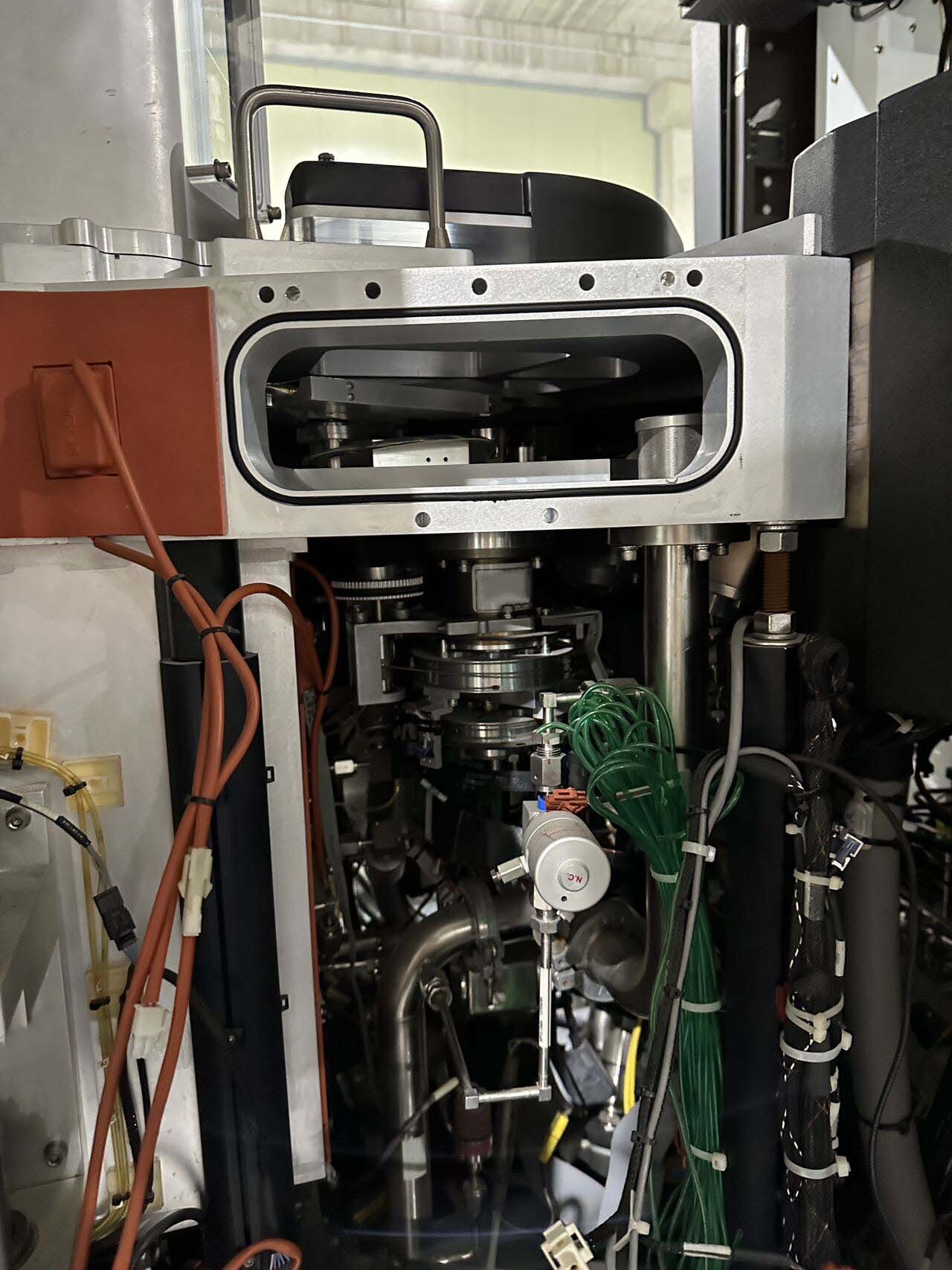

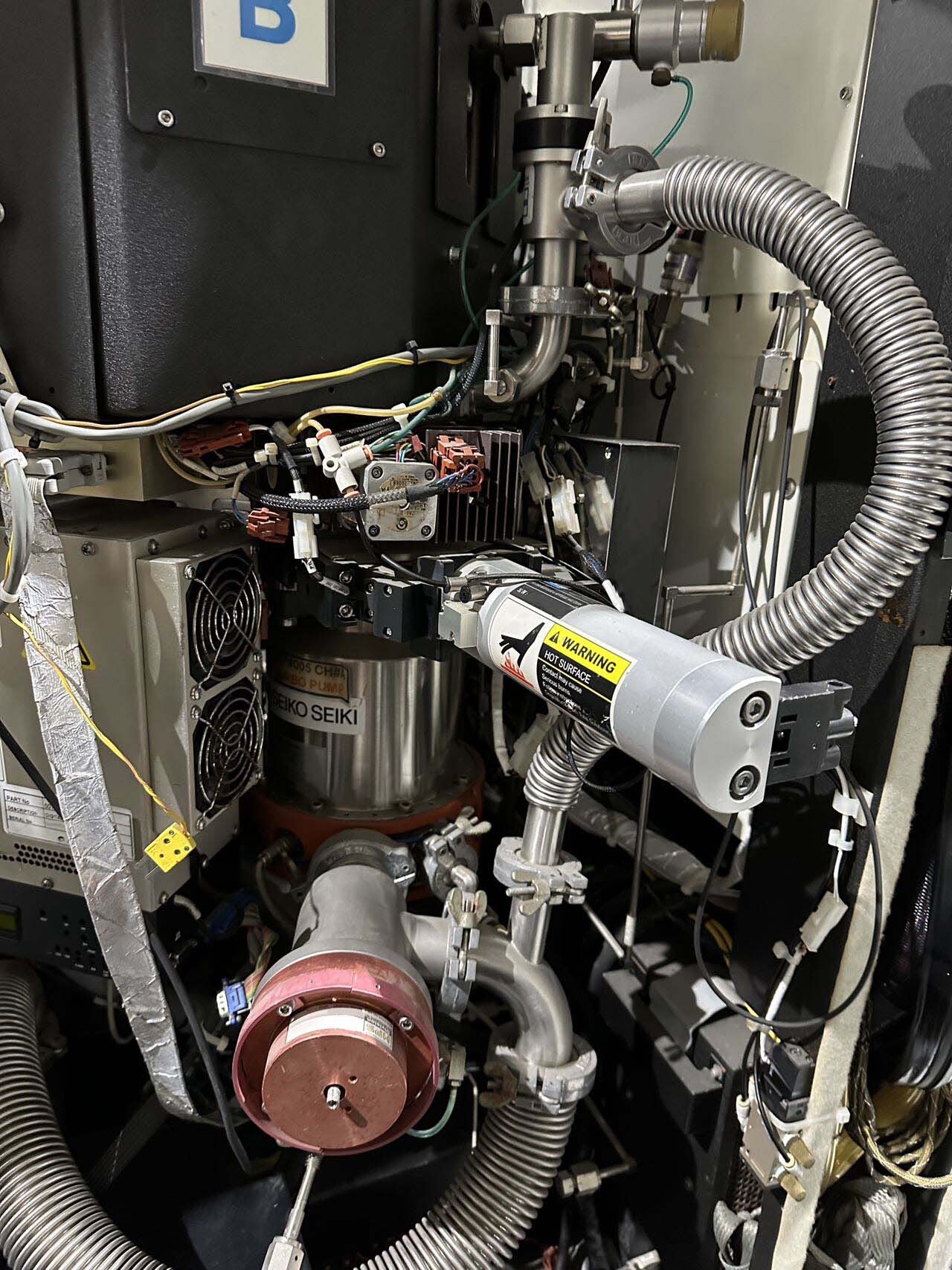

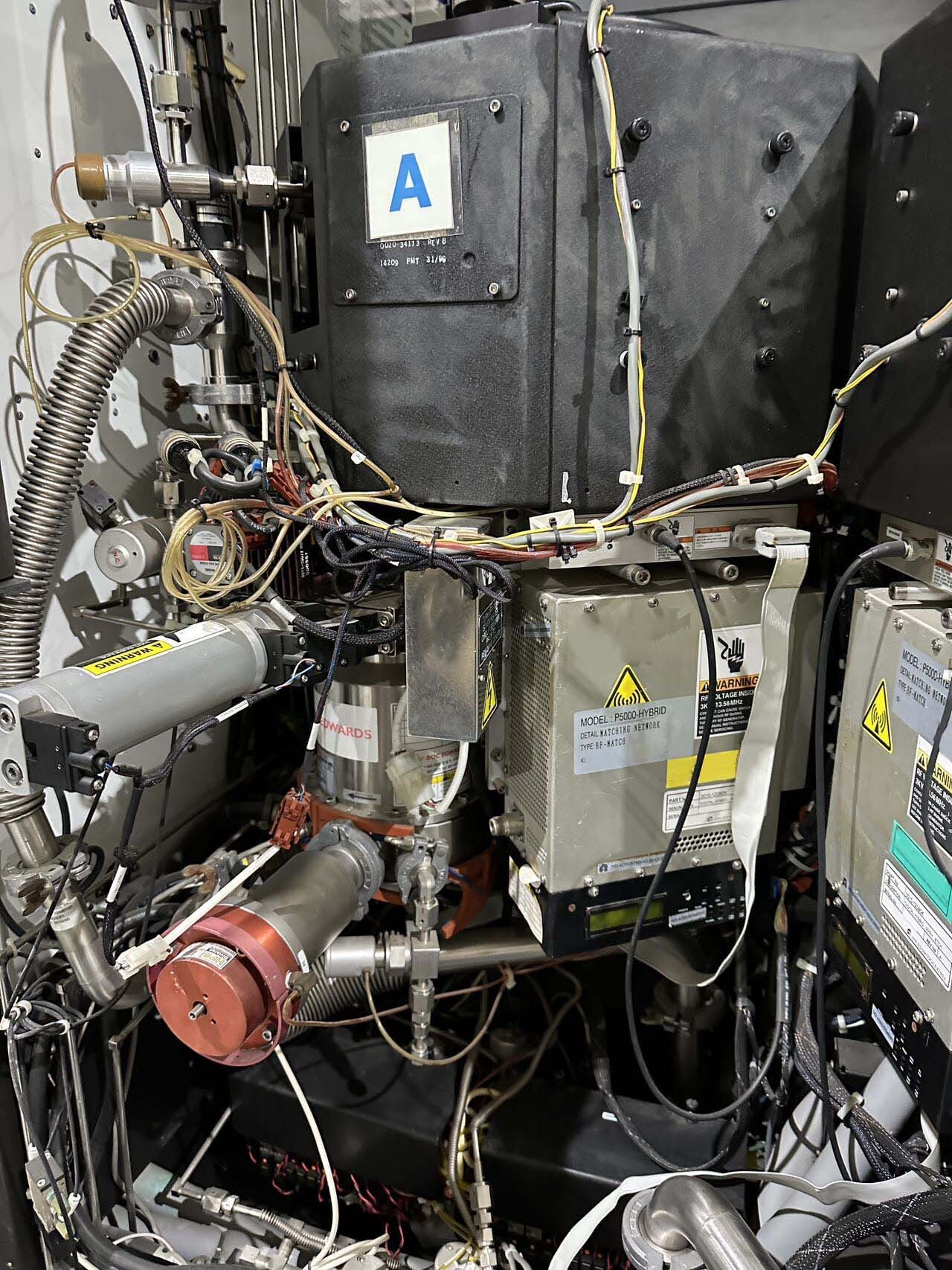

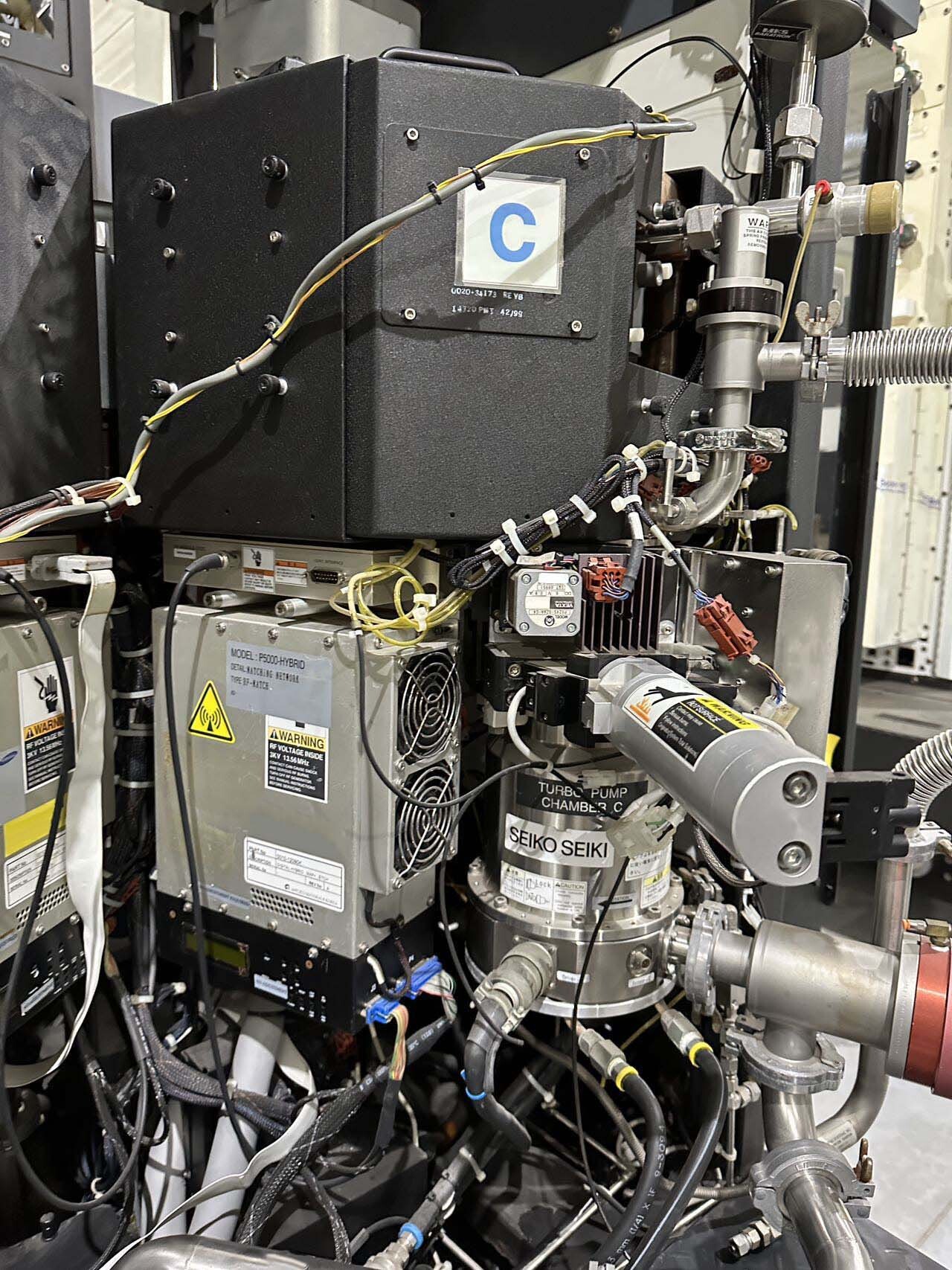

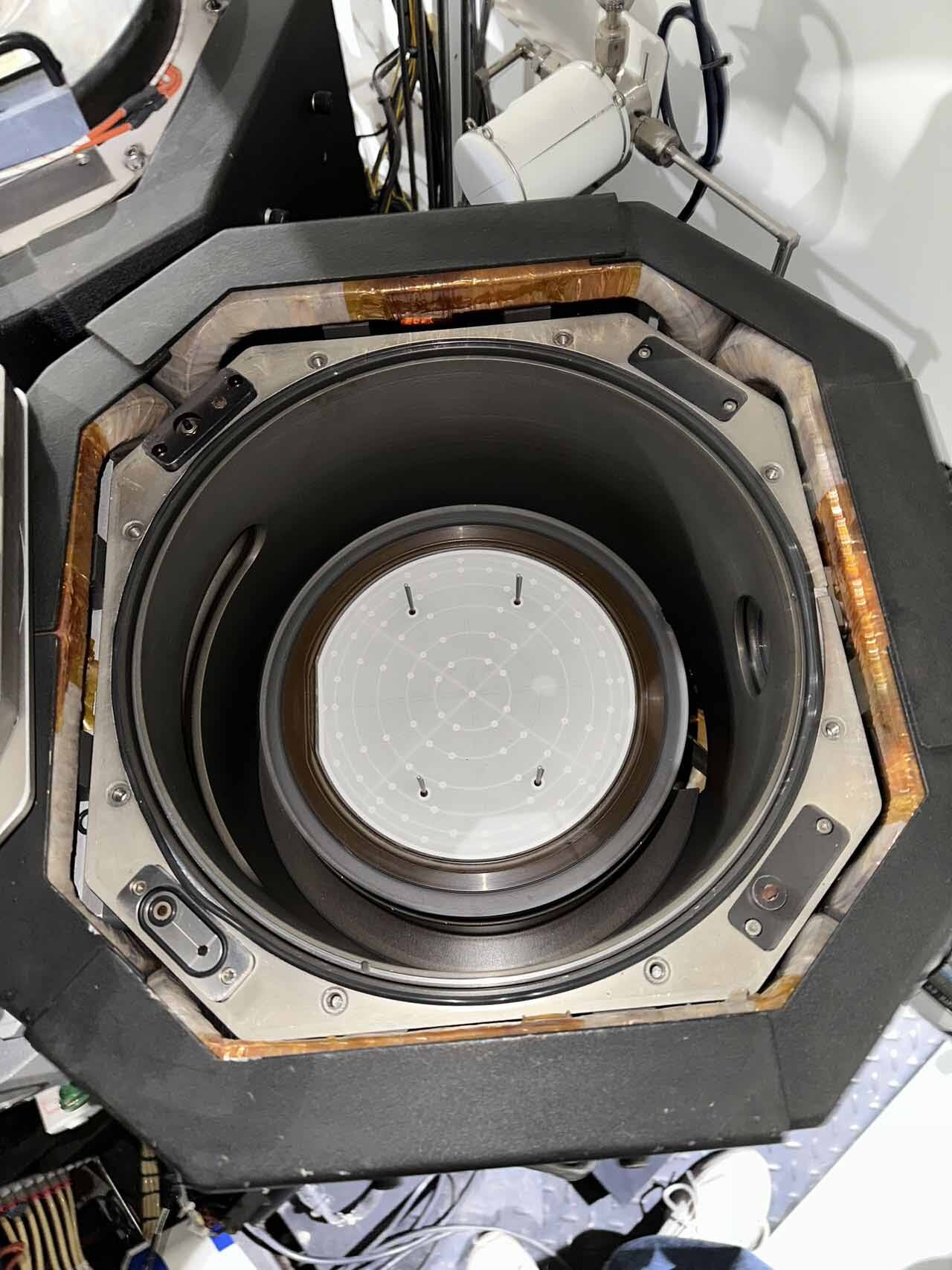

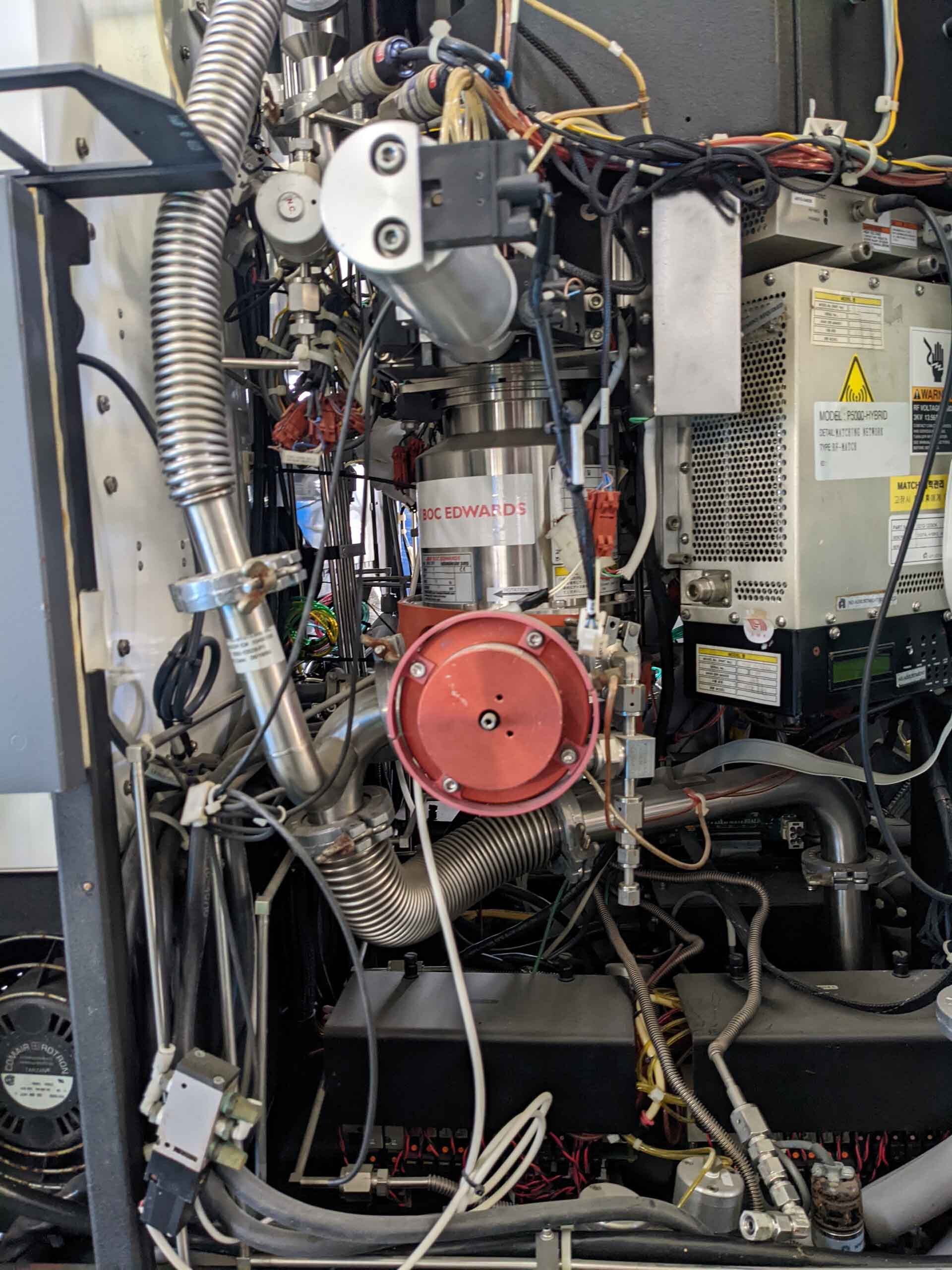

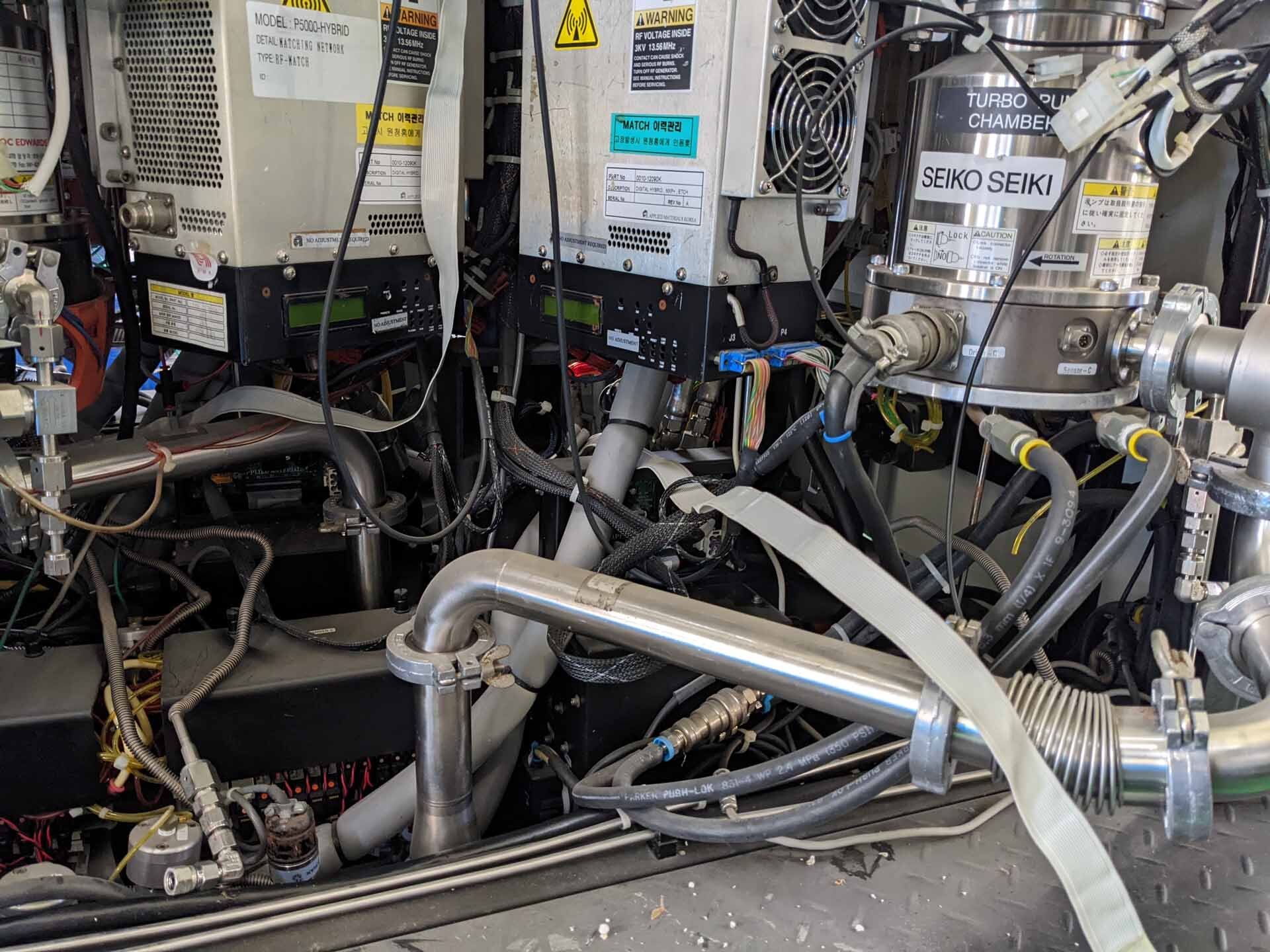

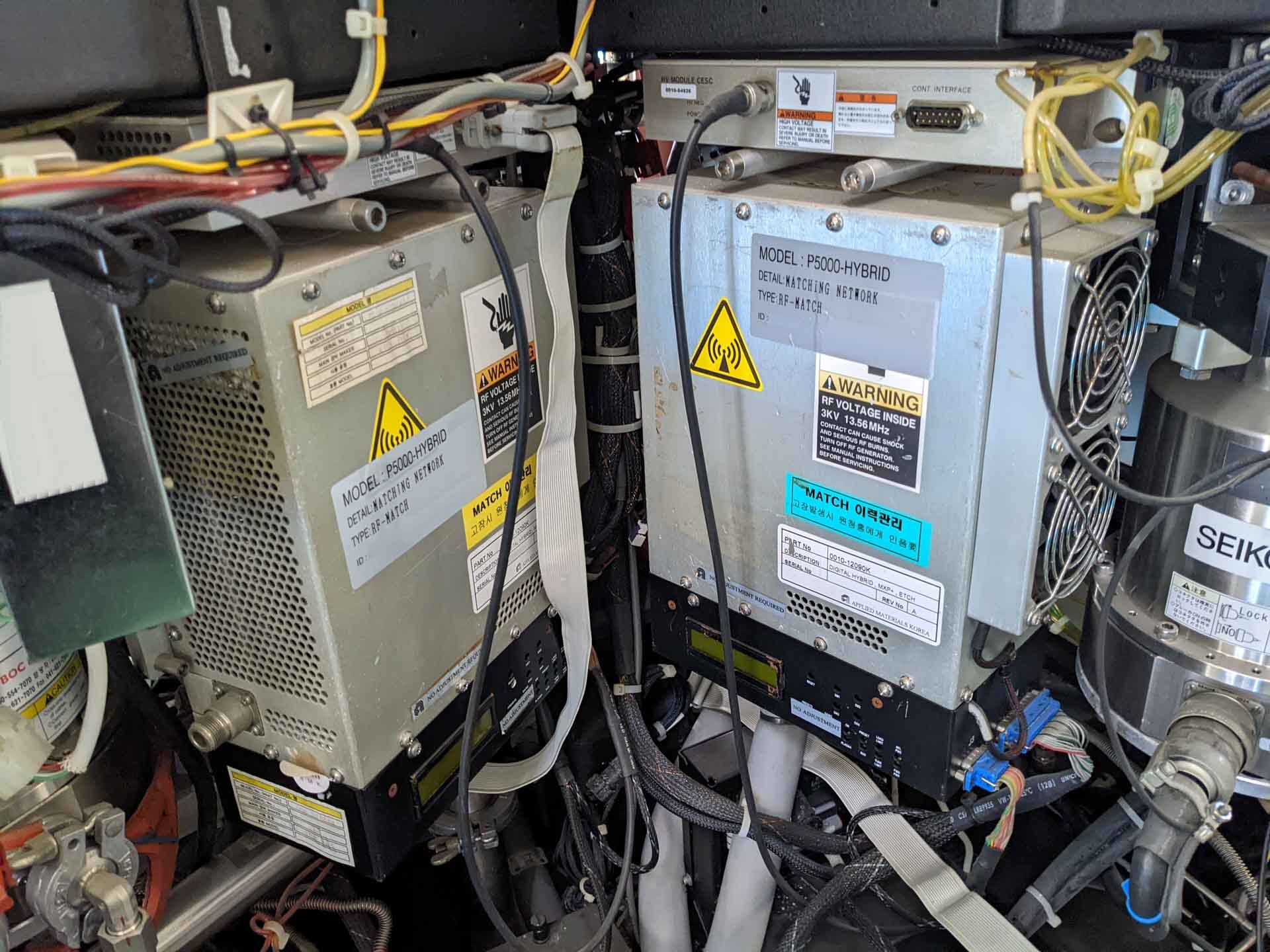

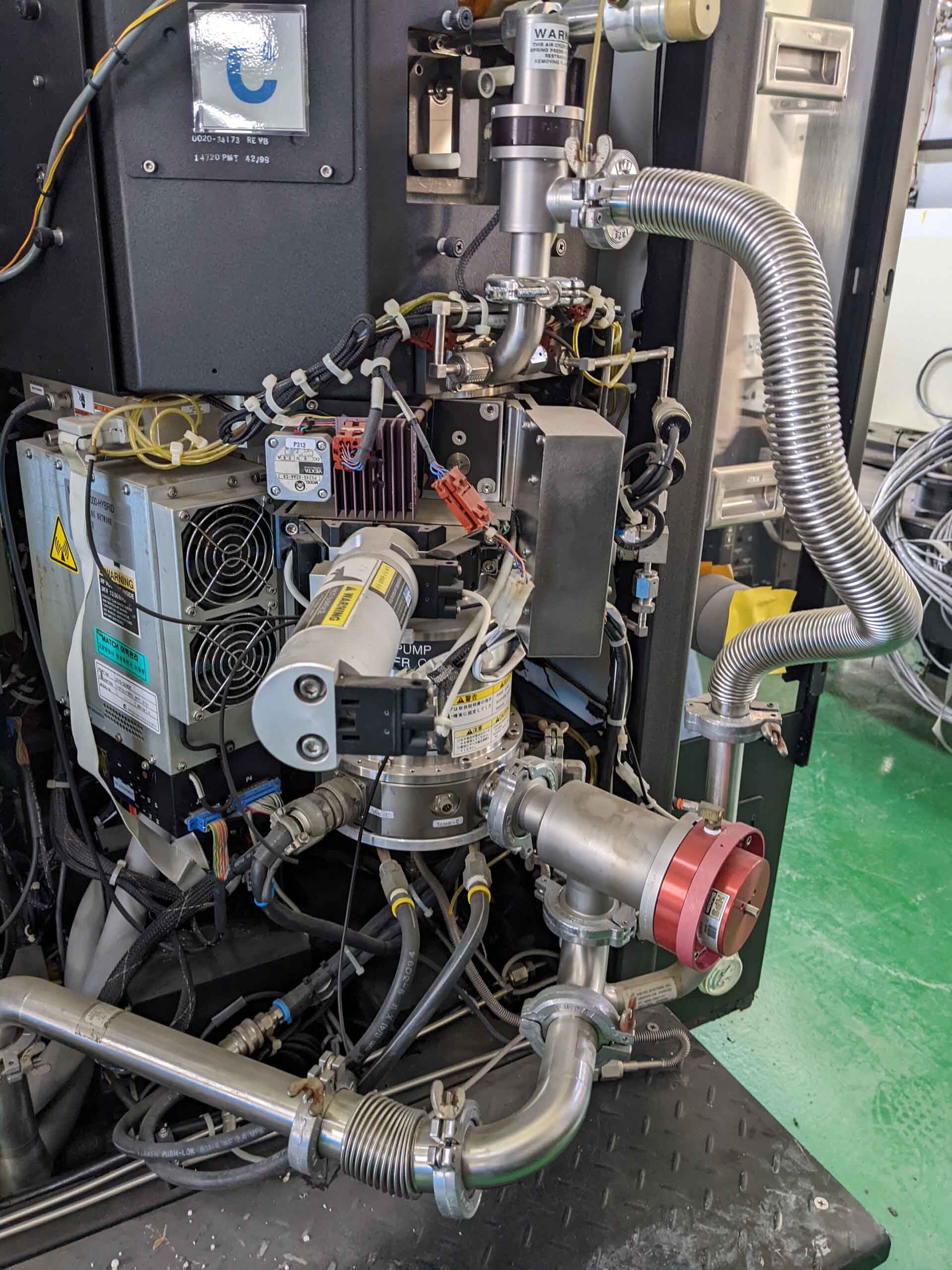

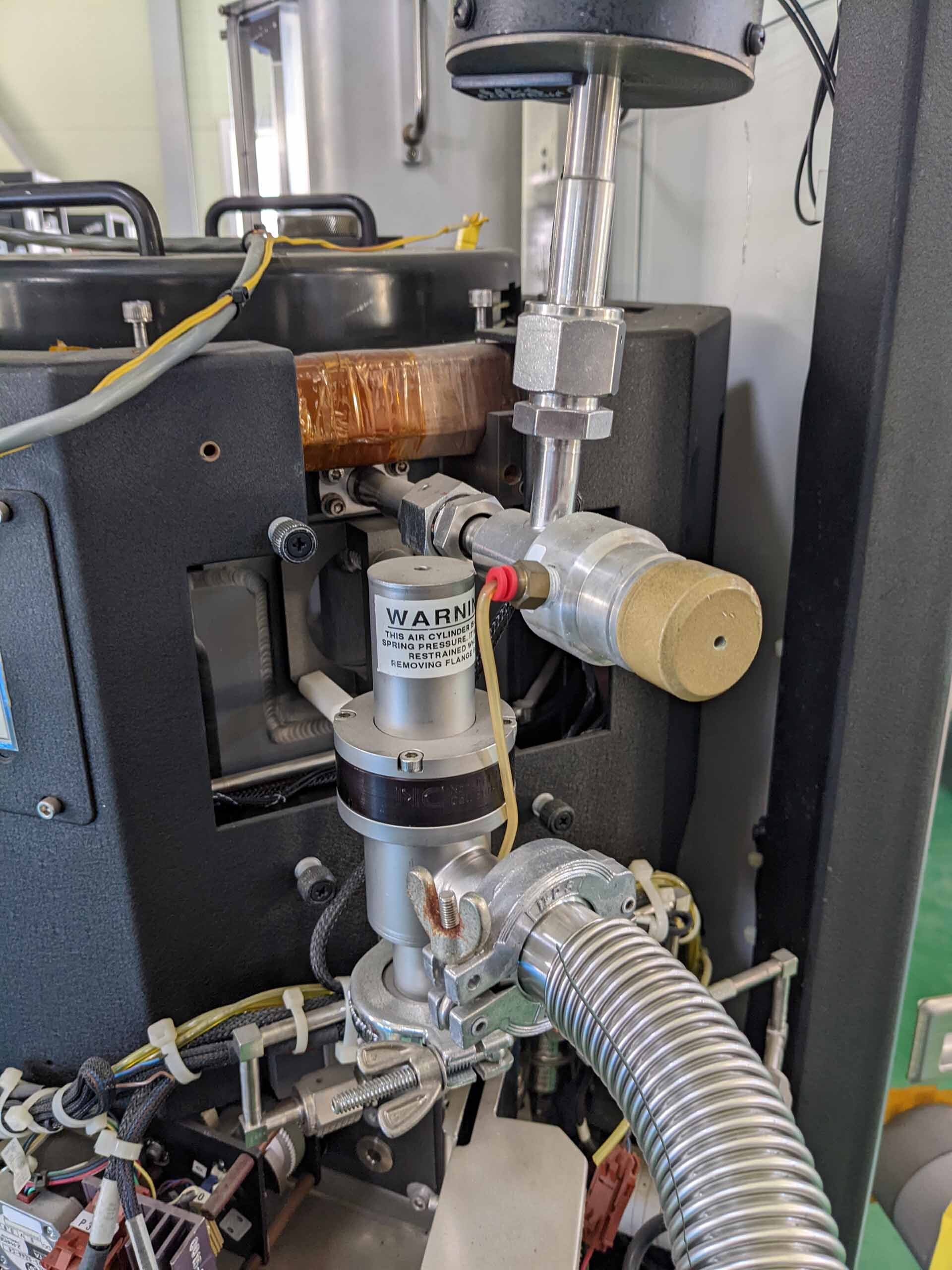

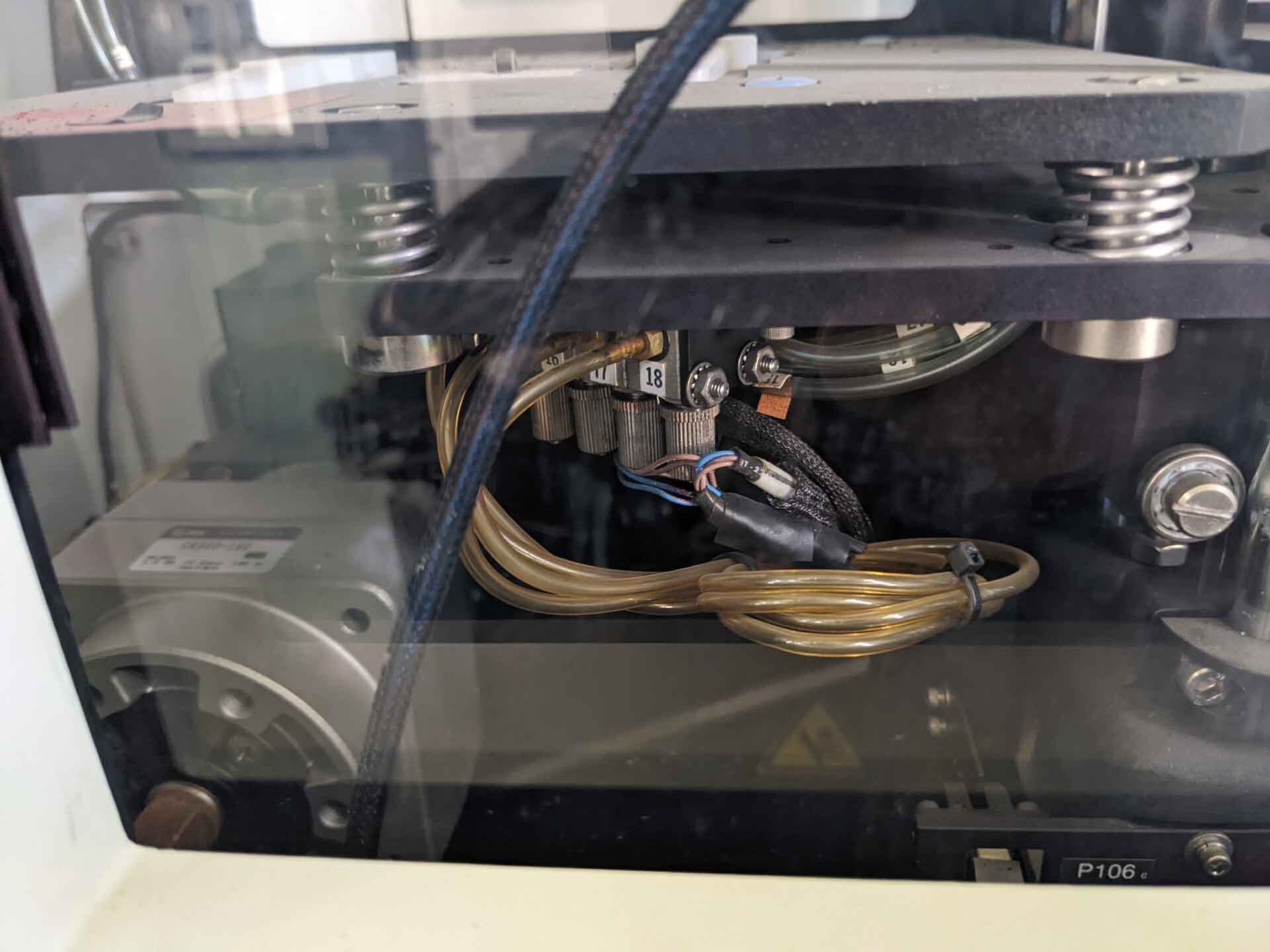

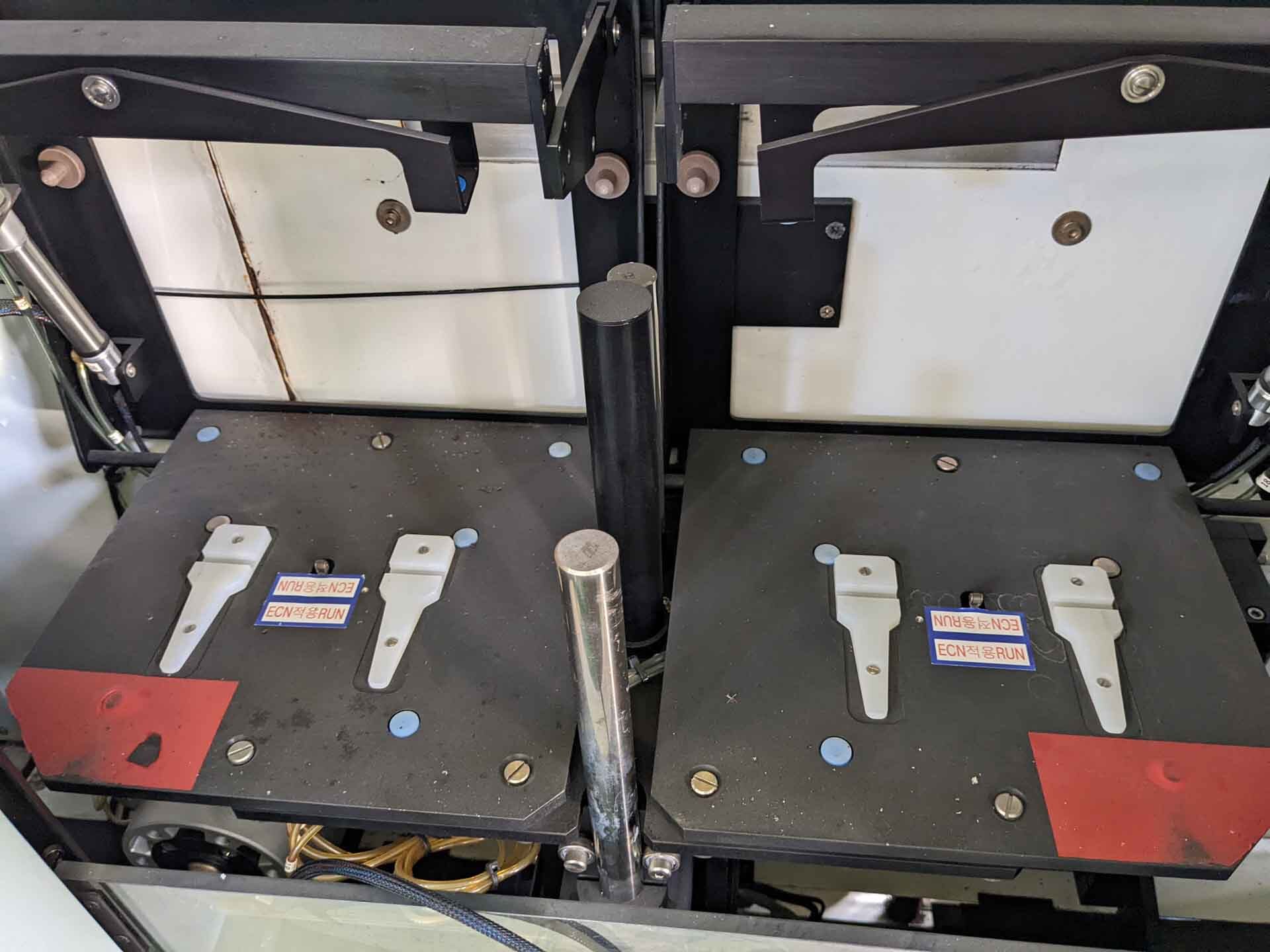

(3) Poly chambers

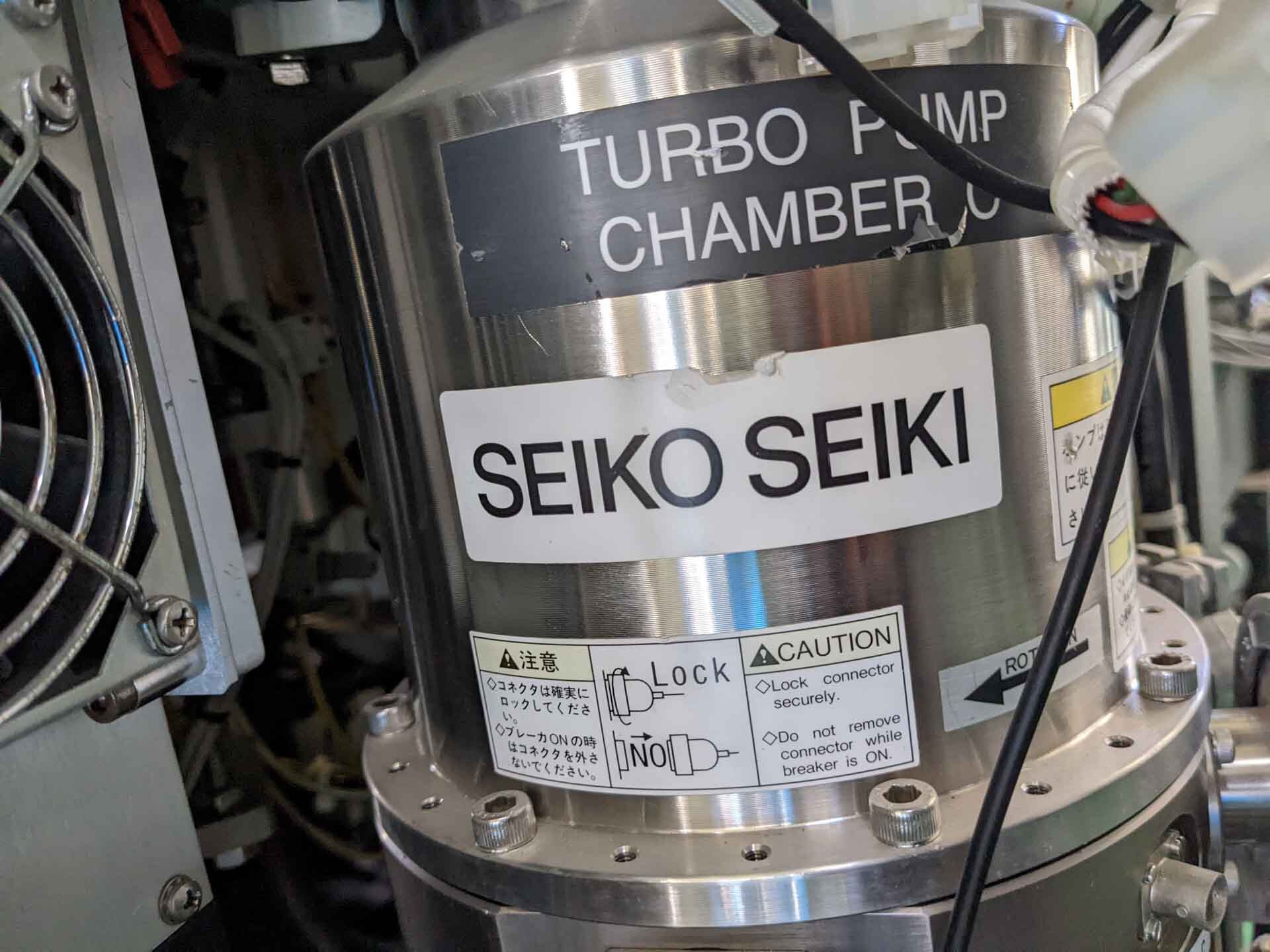

Does not include pump or chiller

2013 vintage.

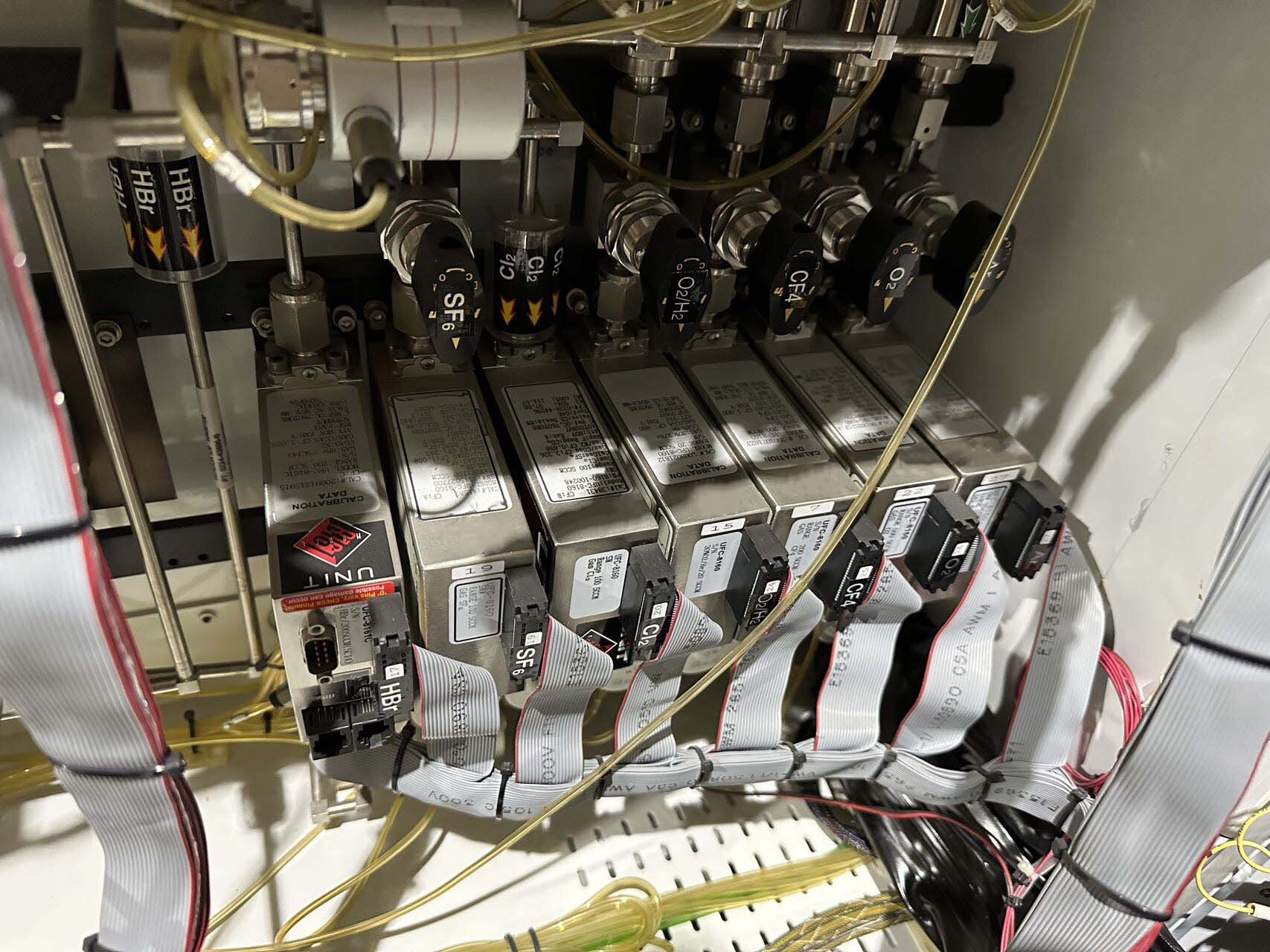

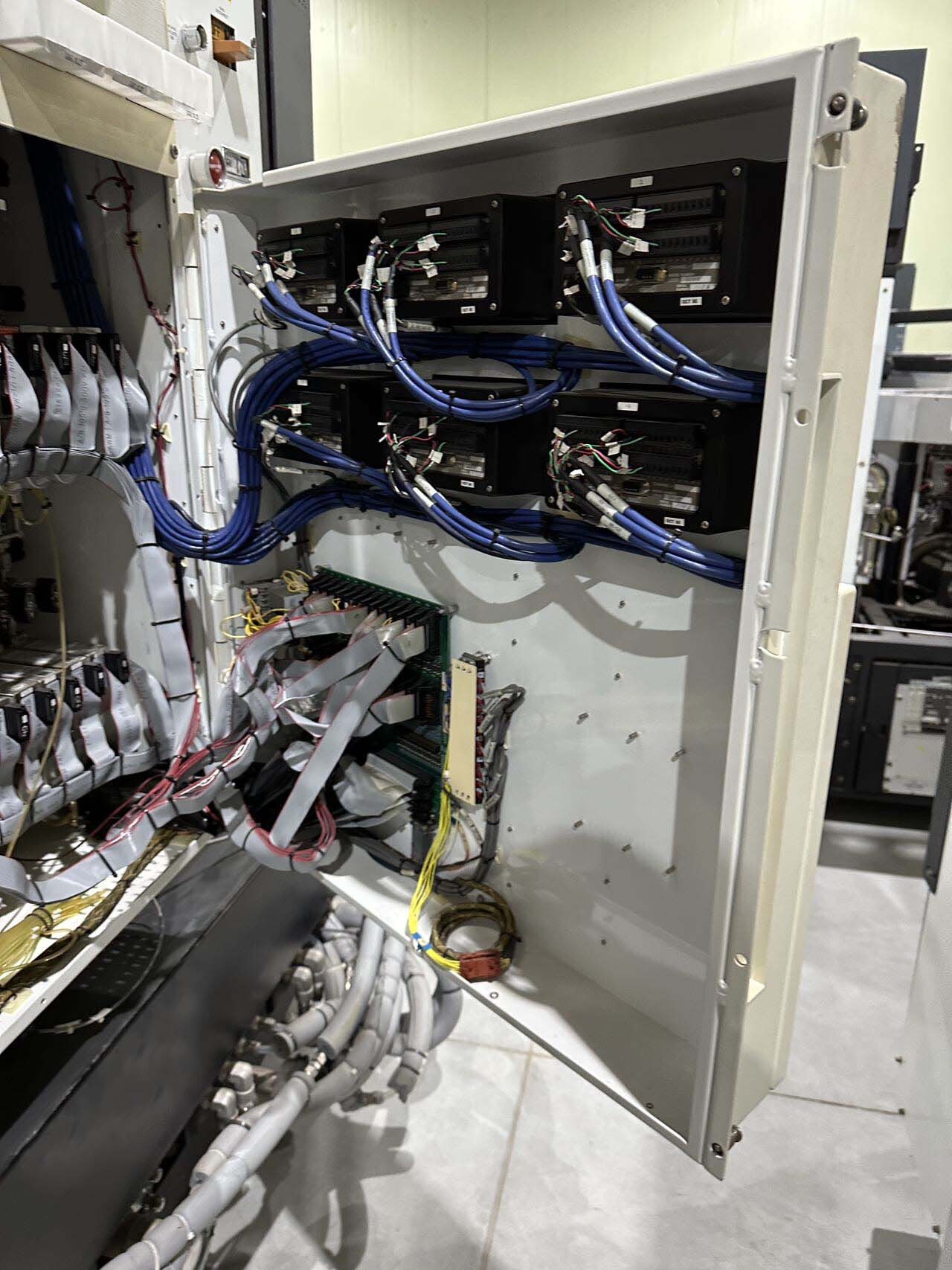

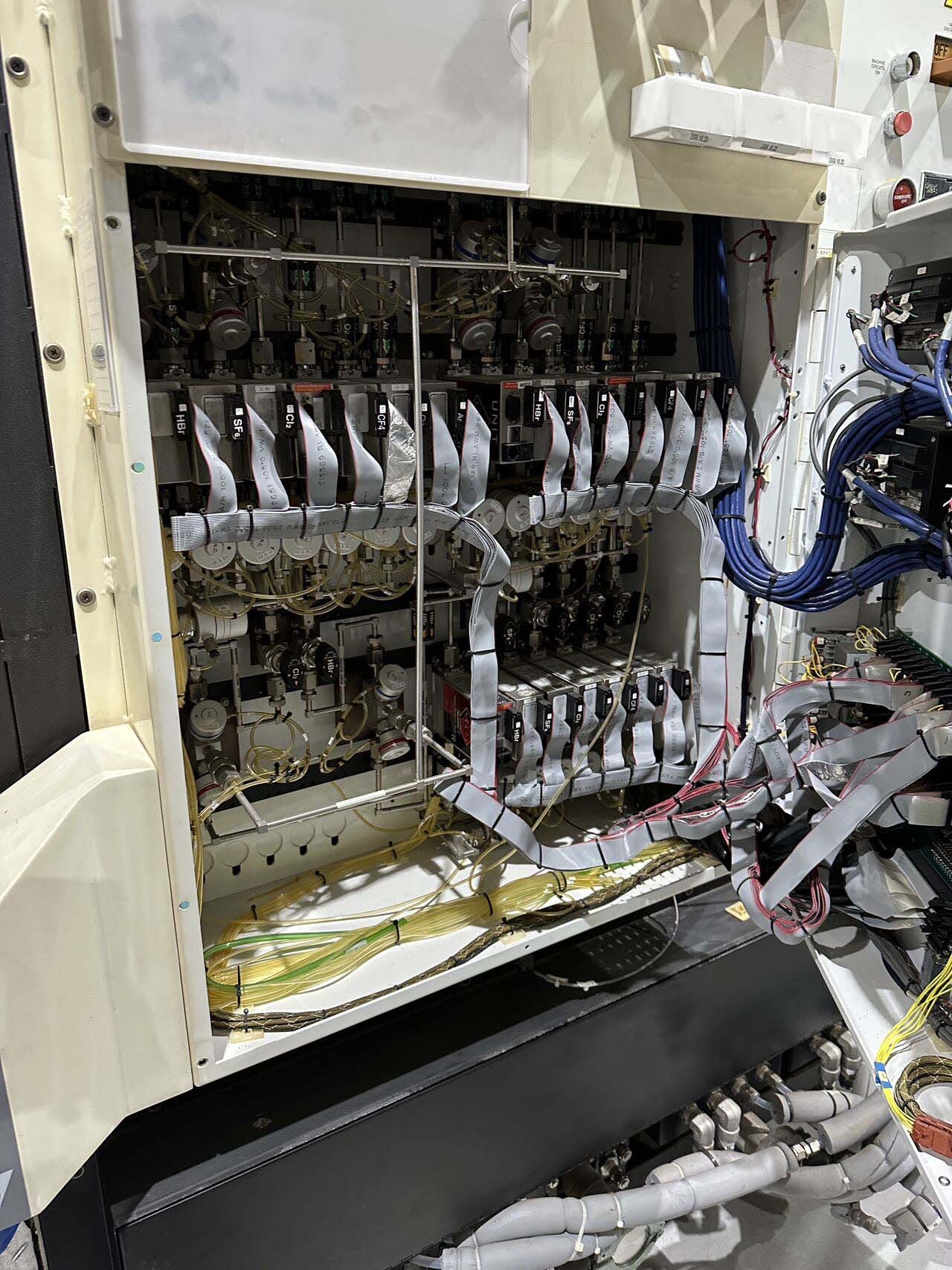

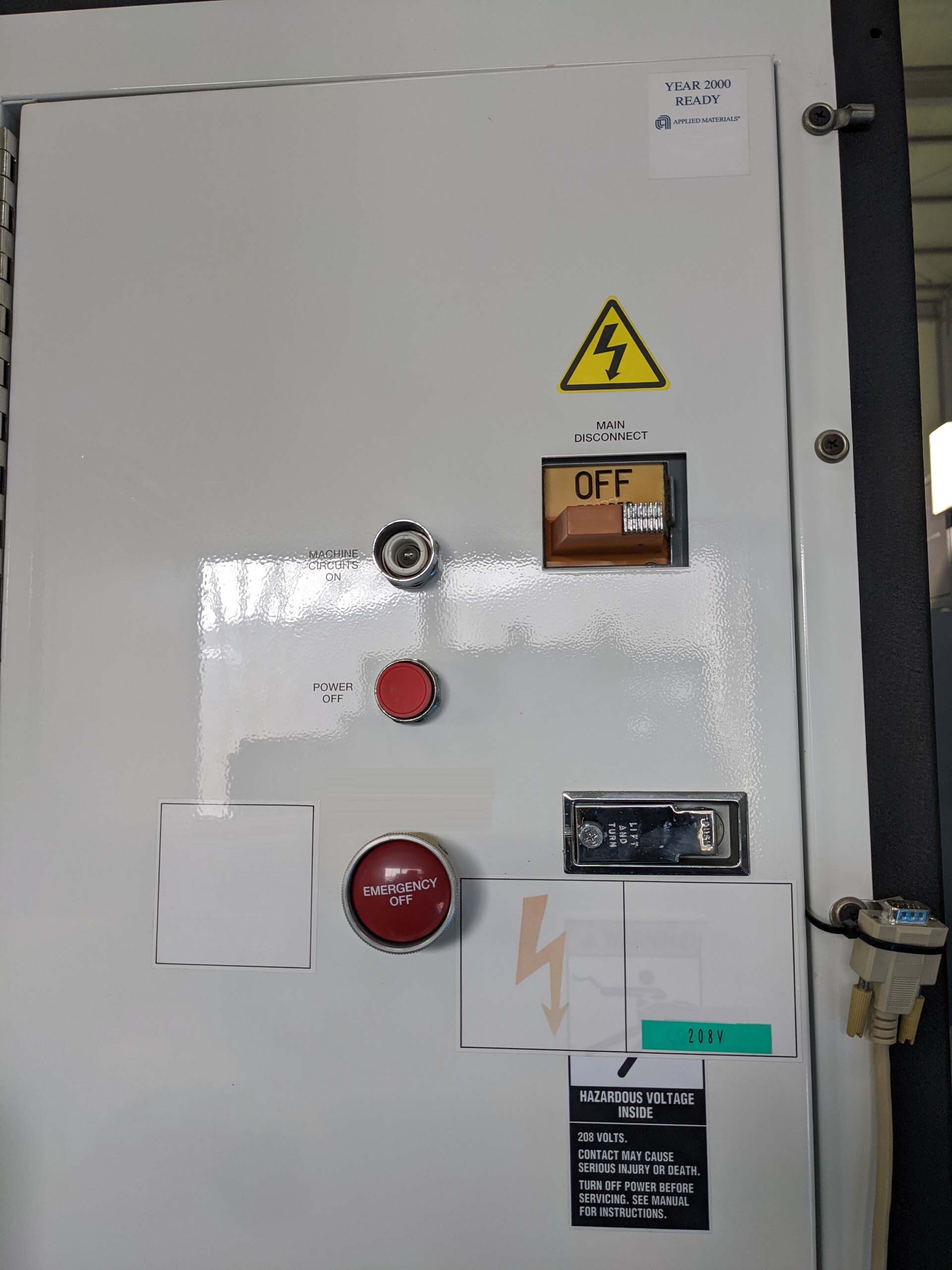

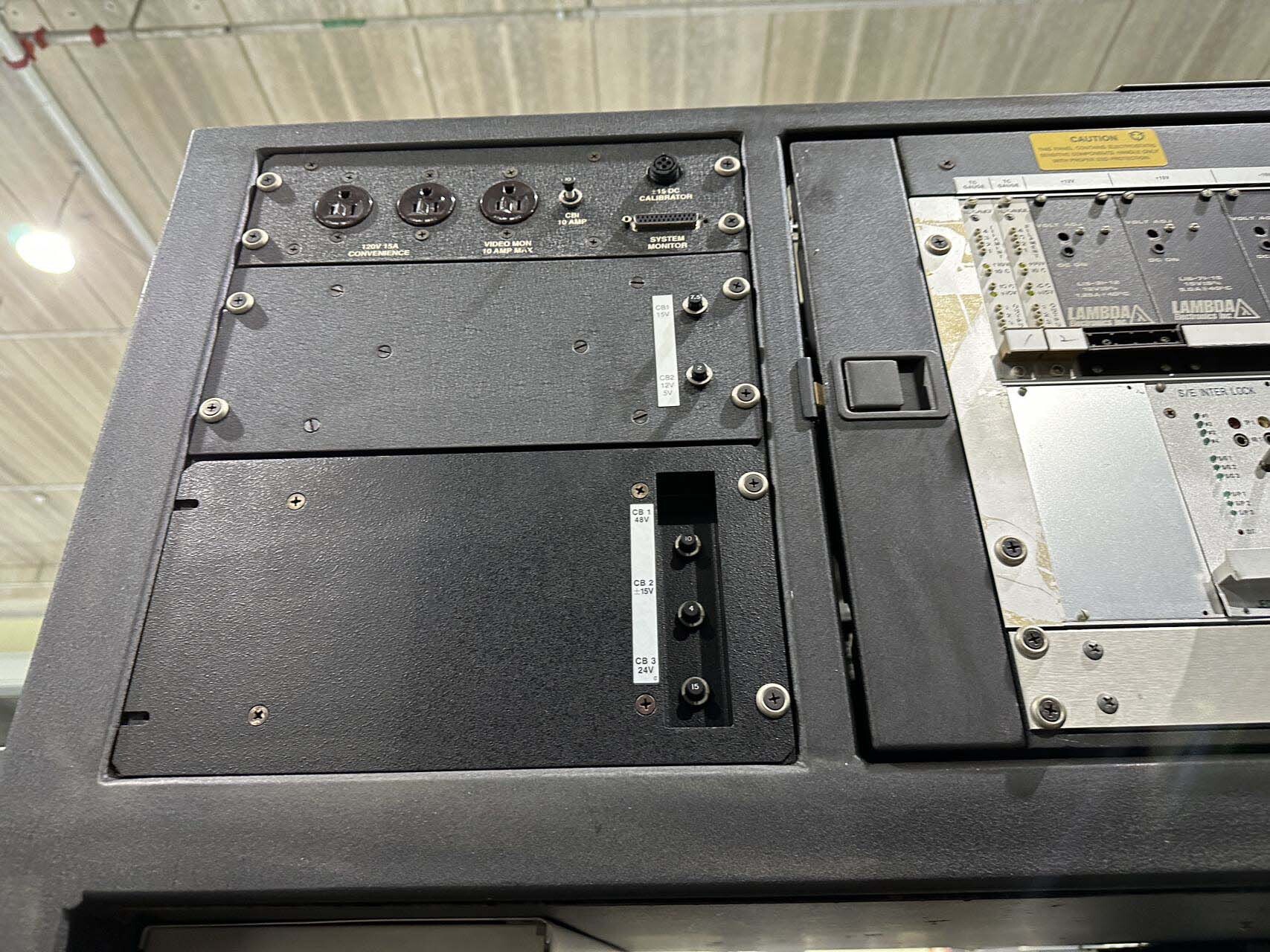

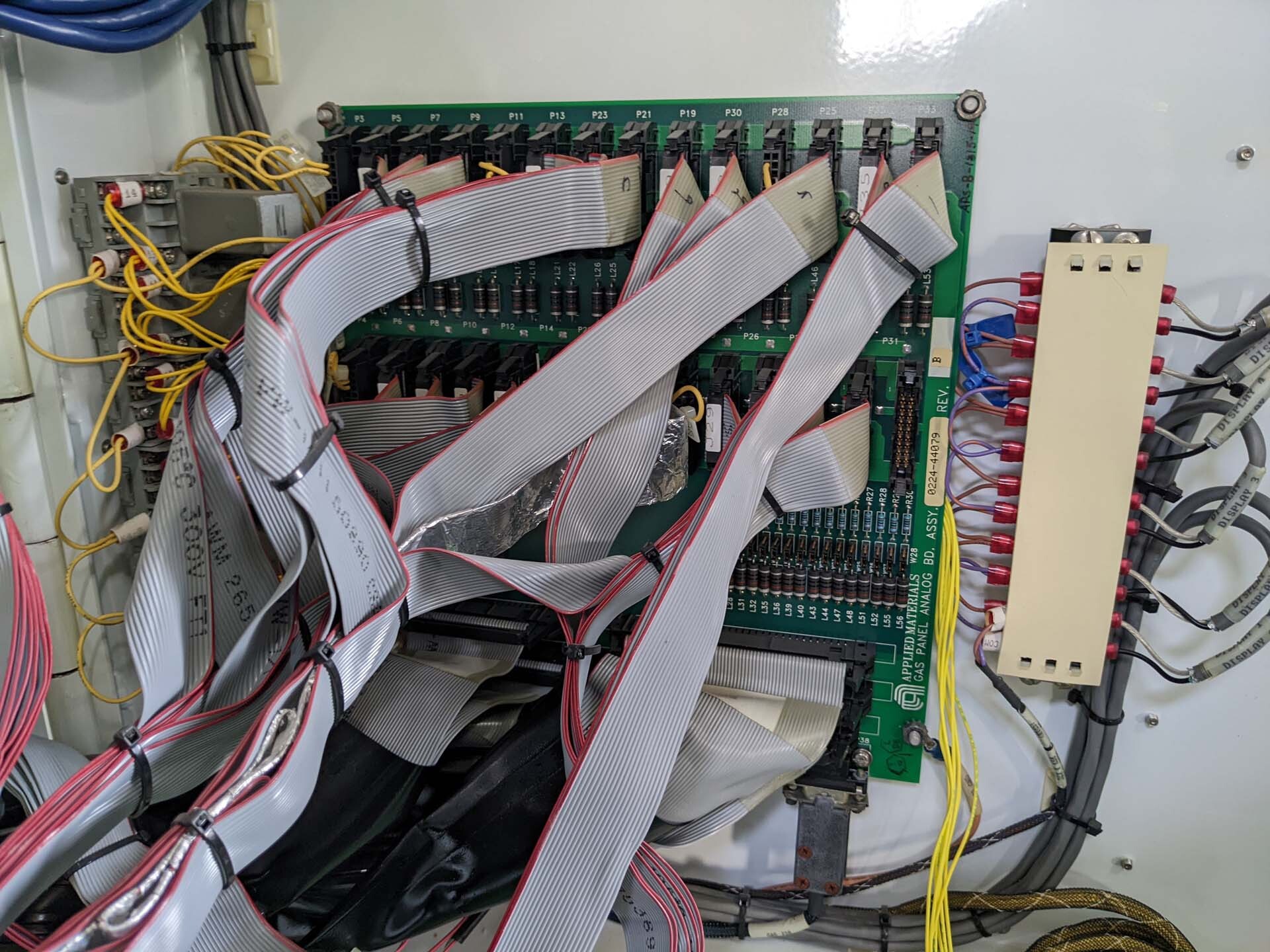

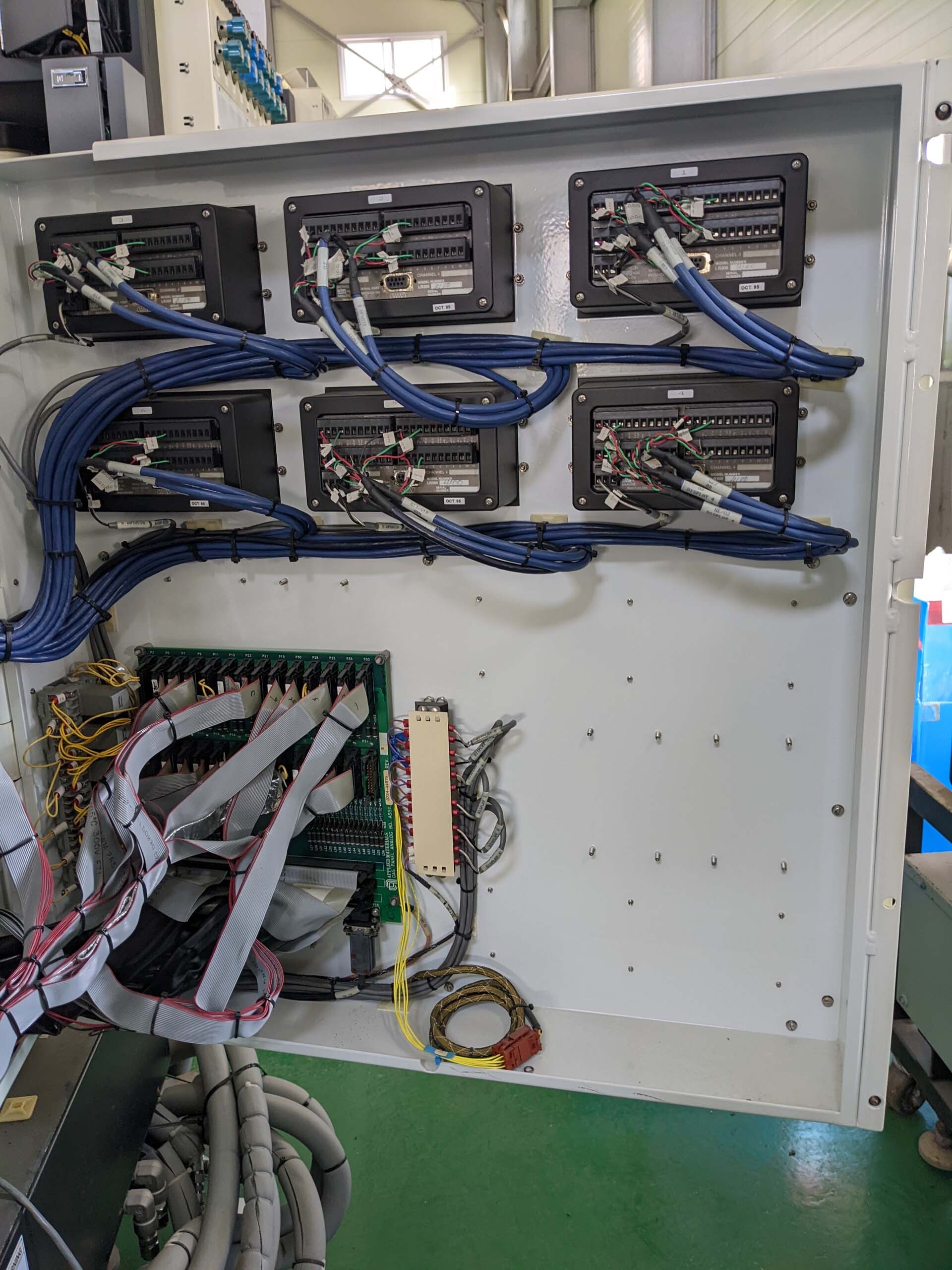

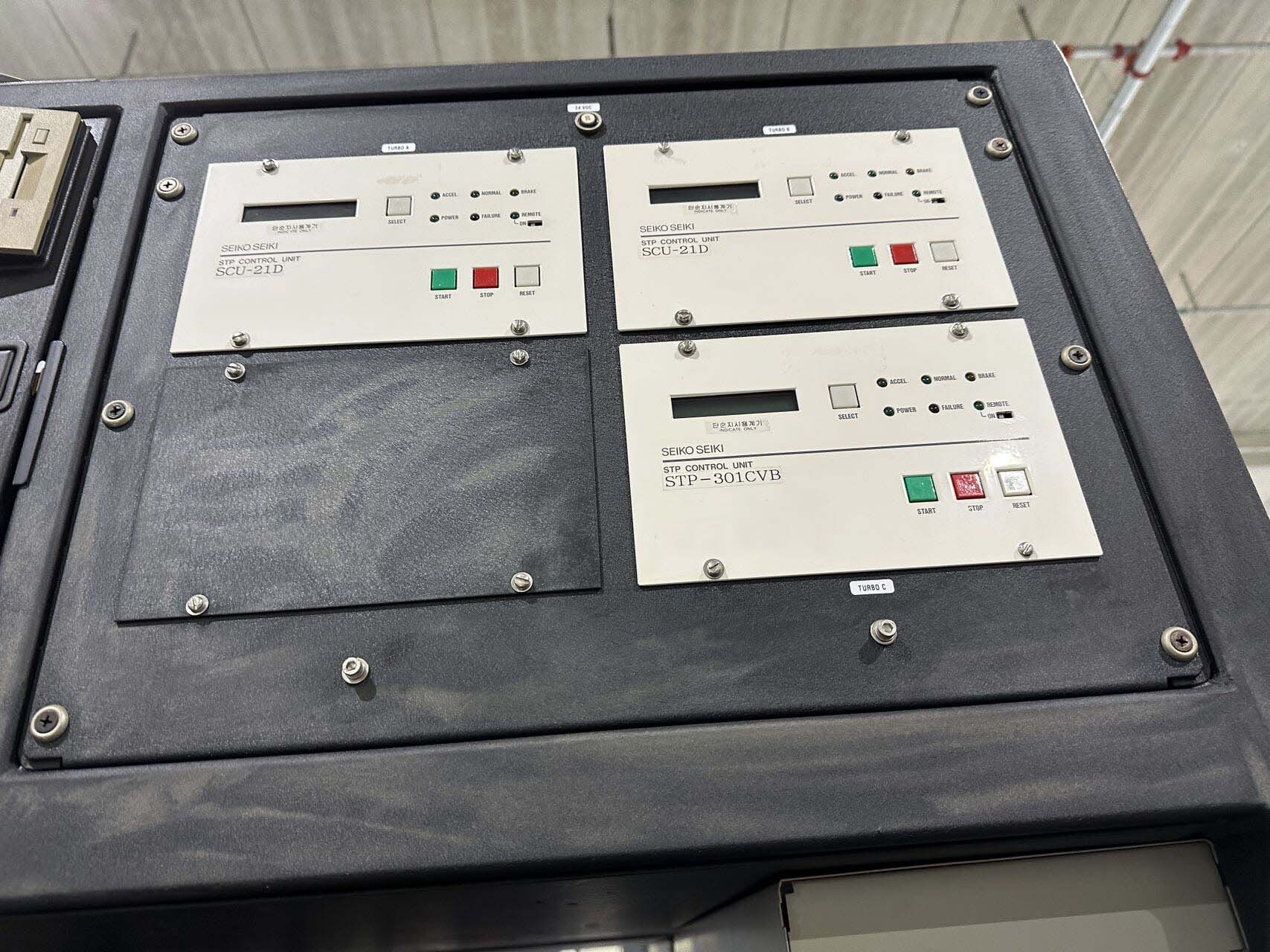

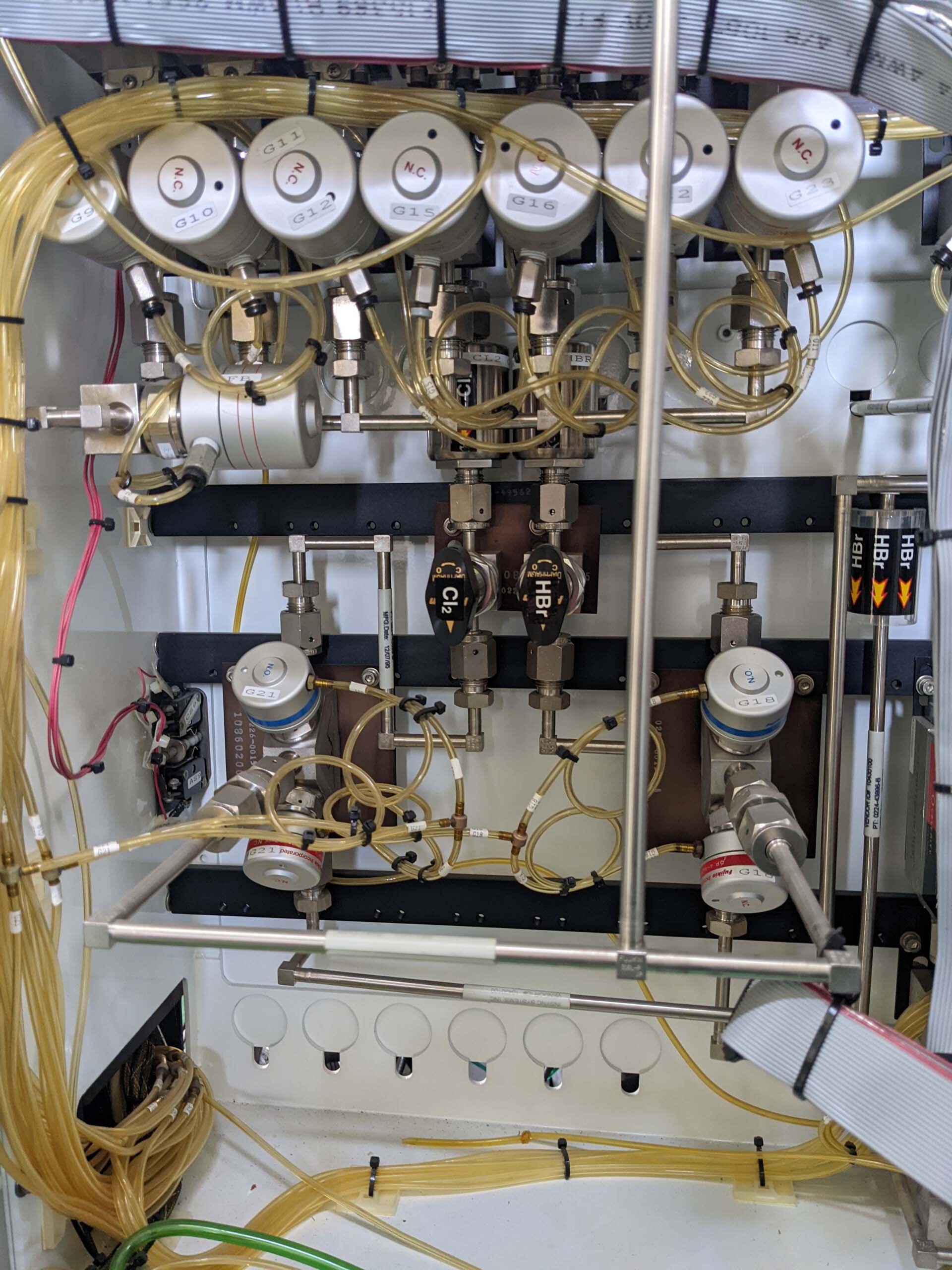

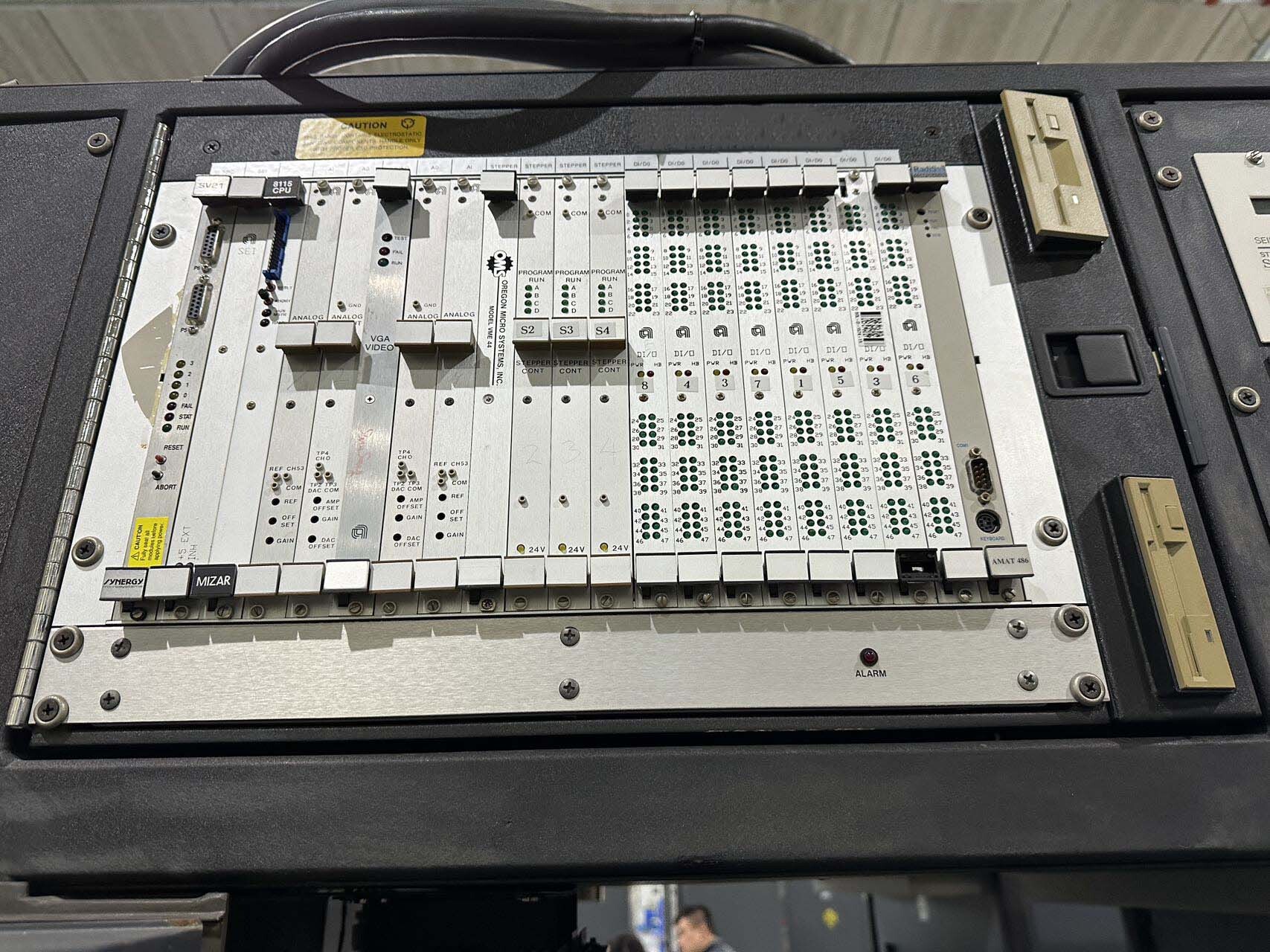

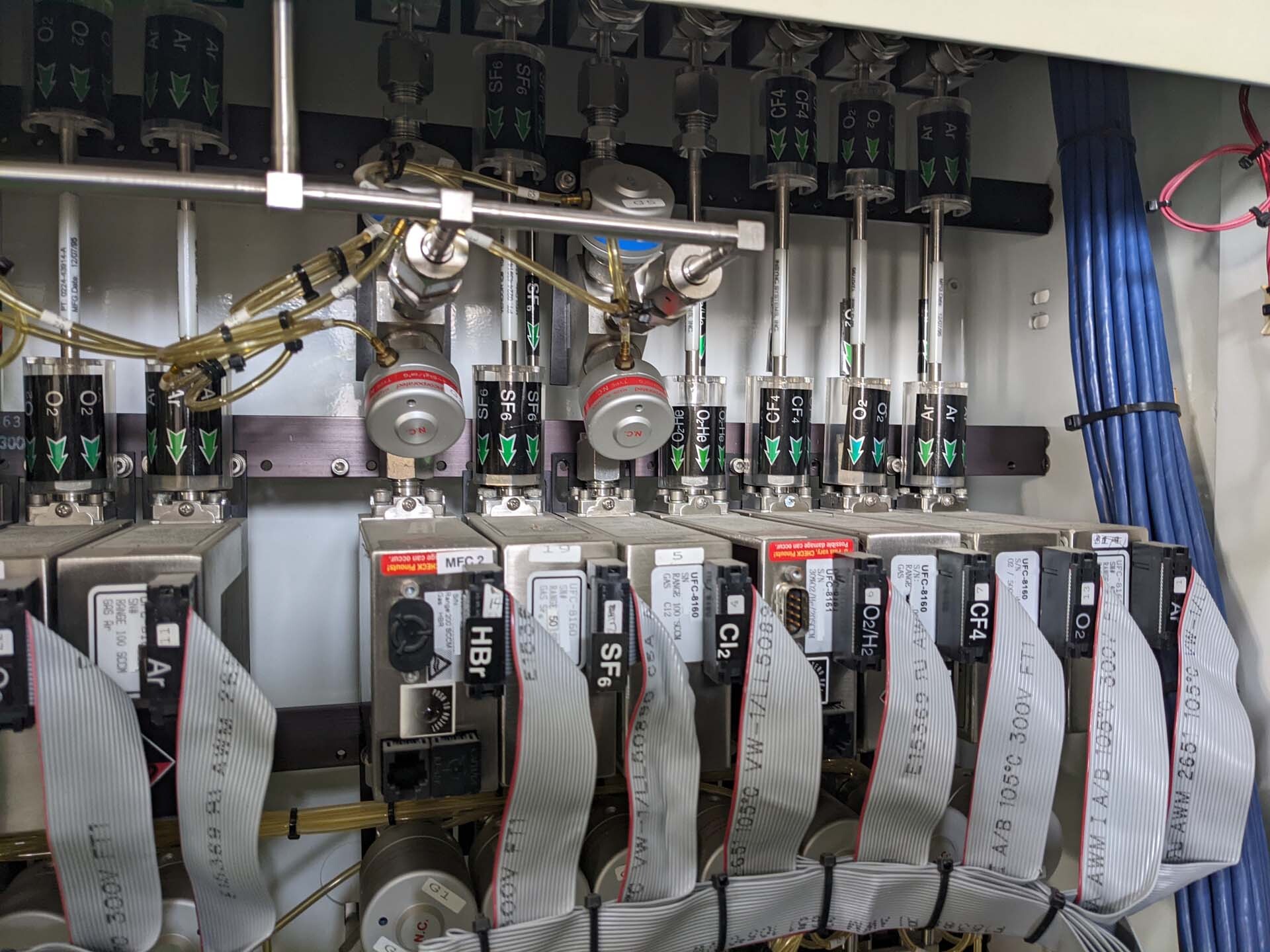

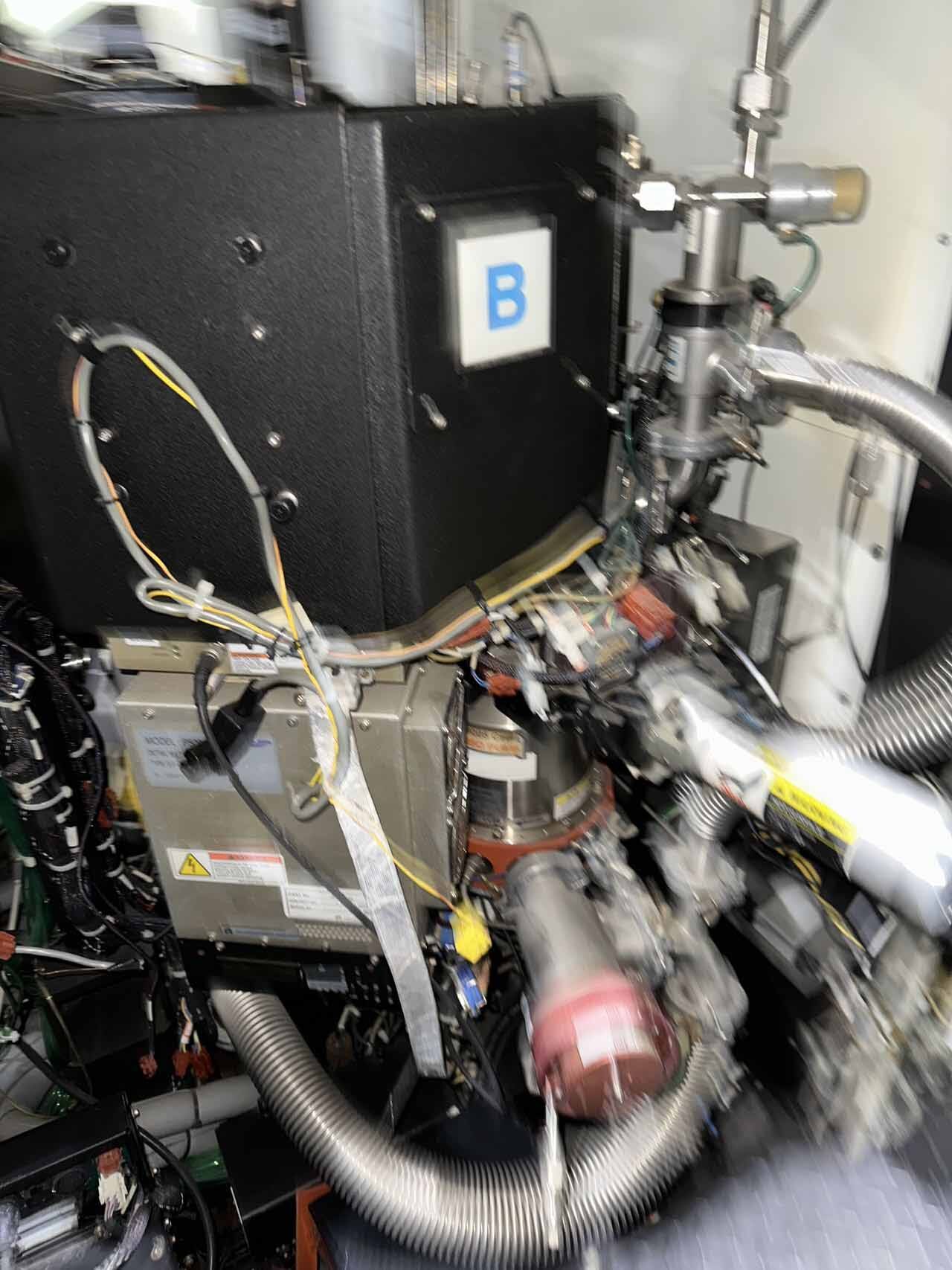

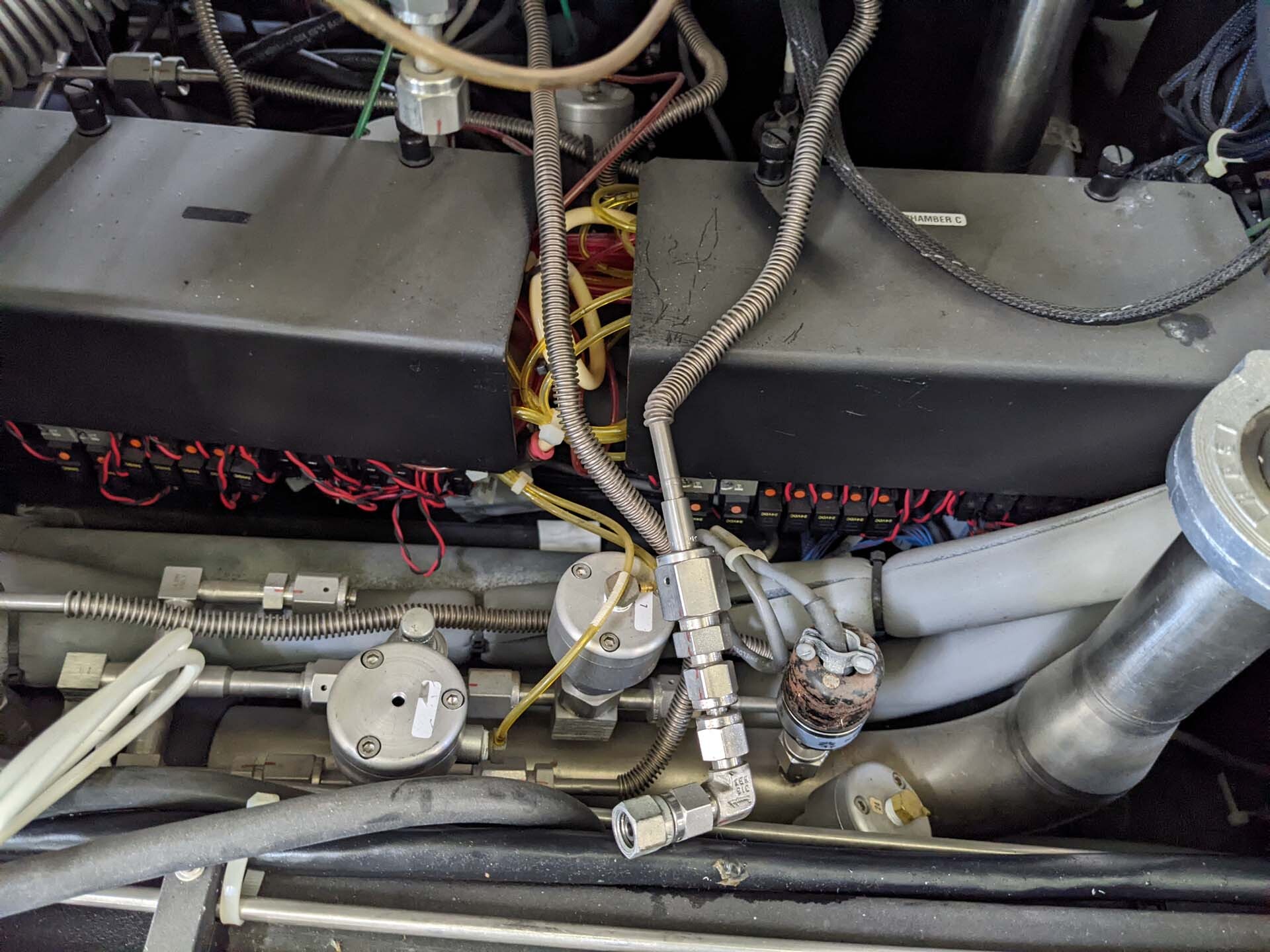

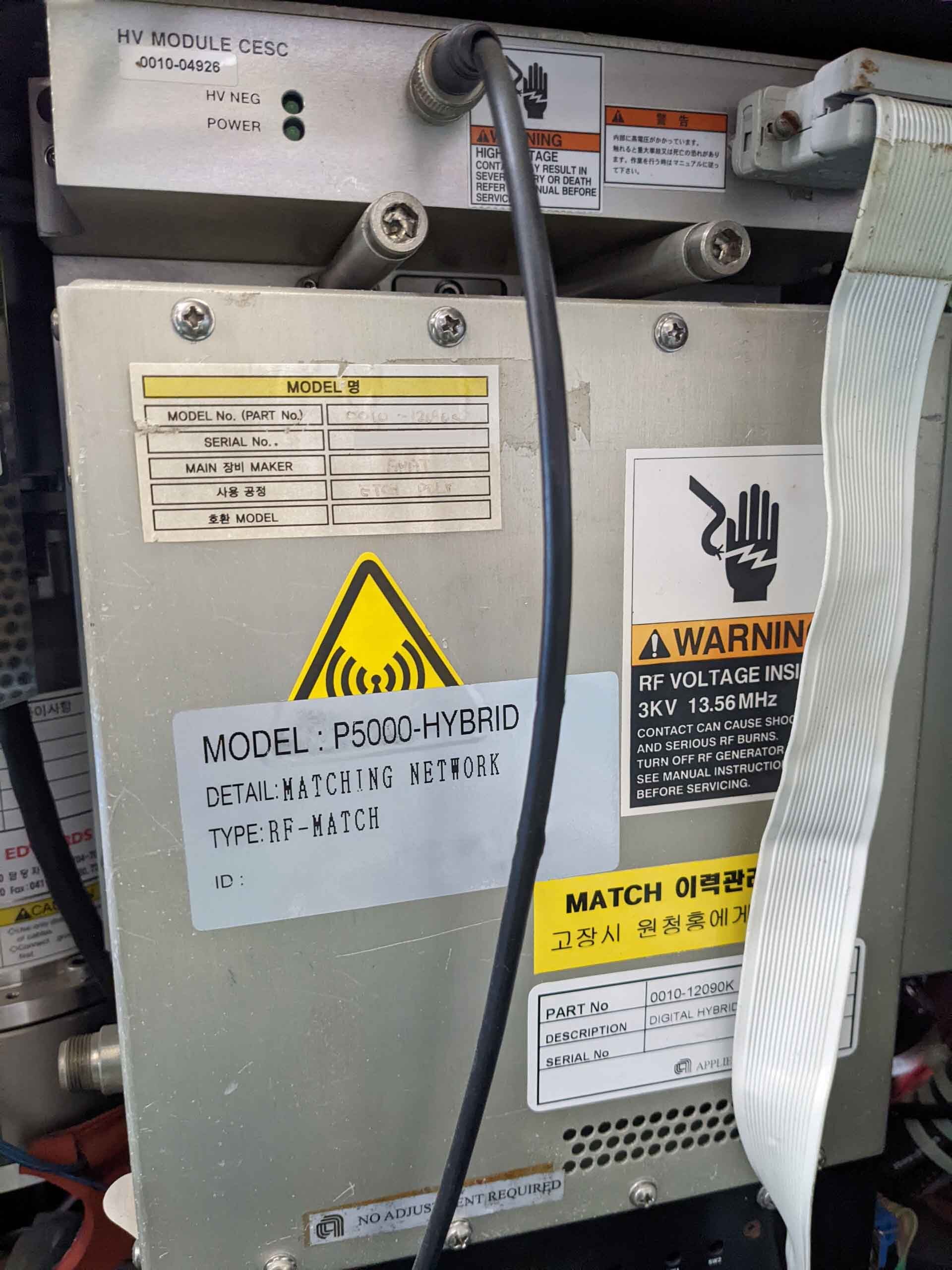

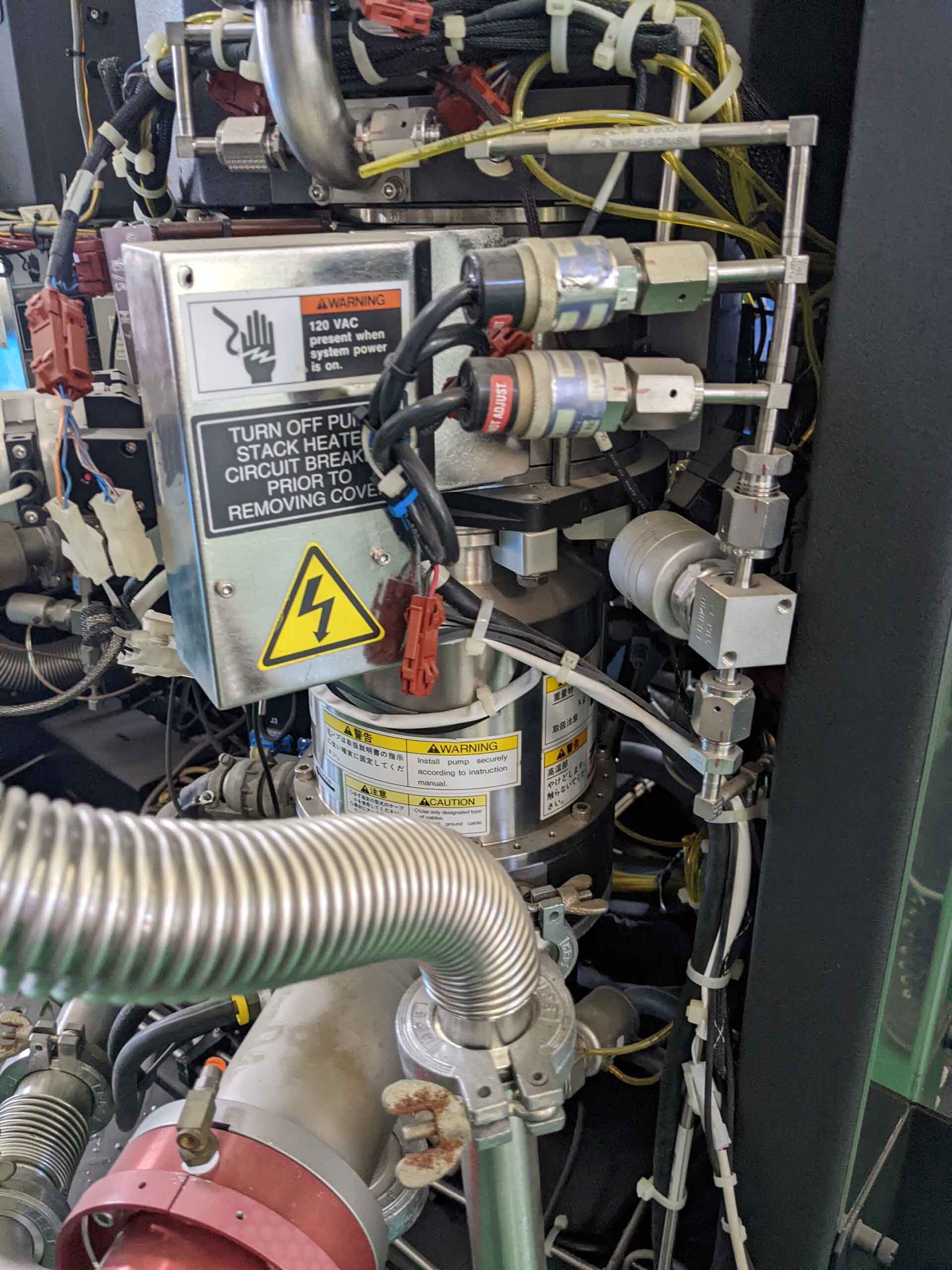

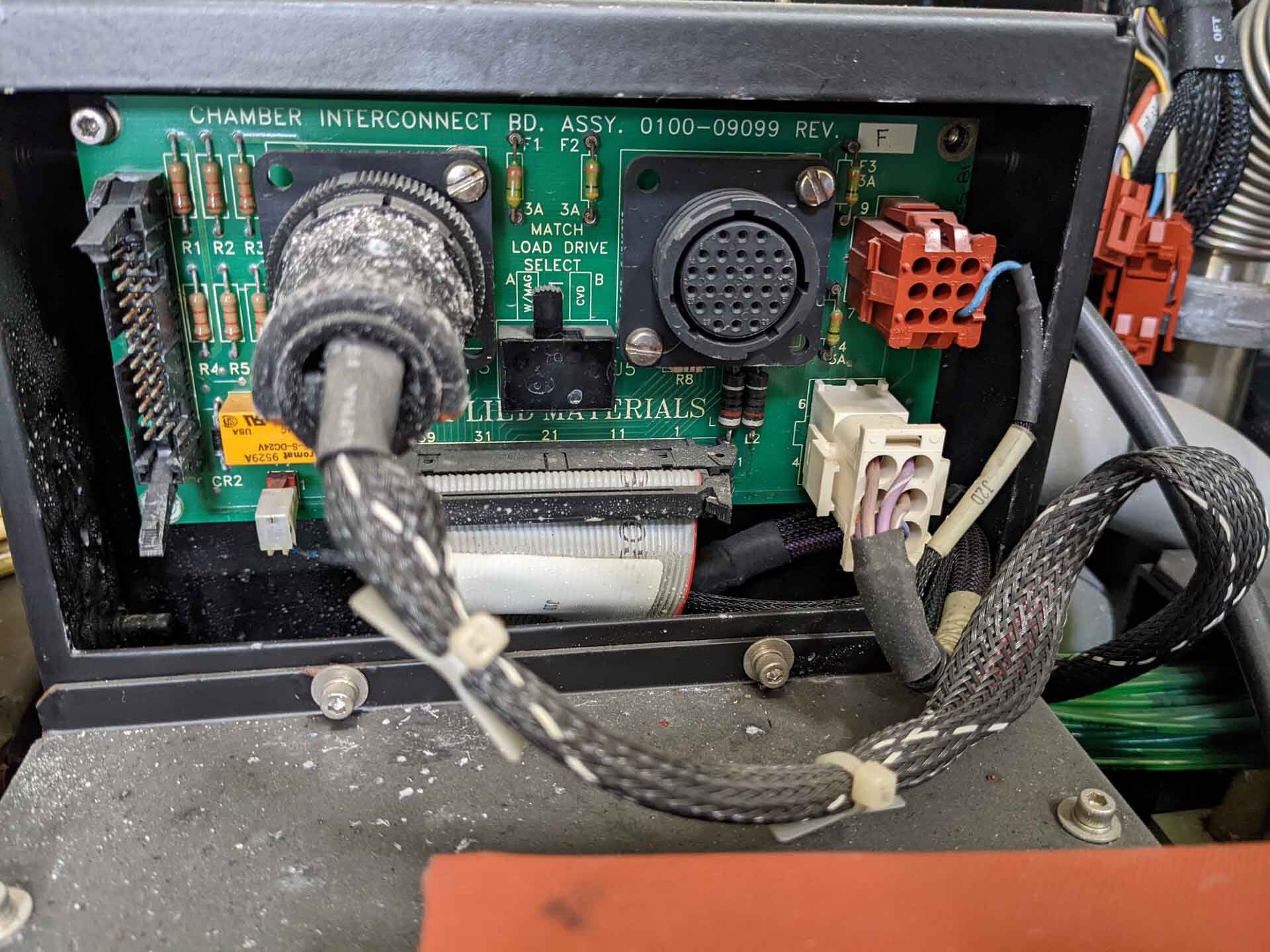

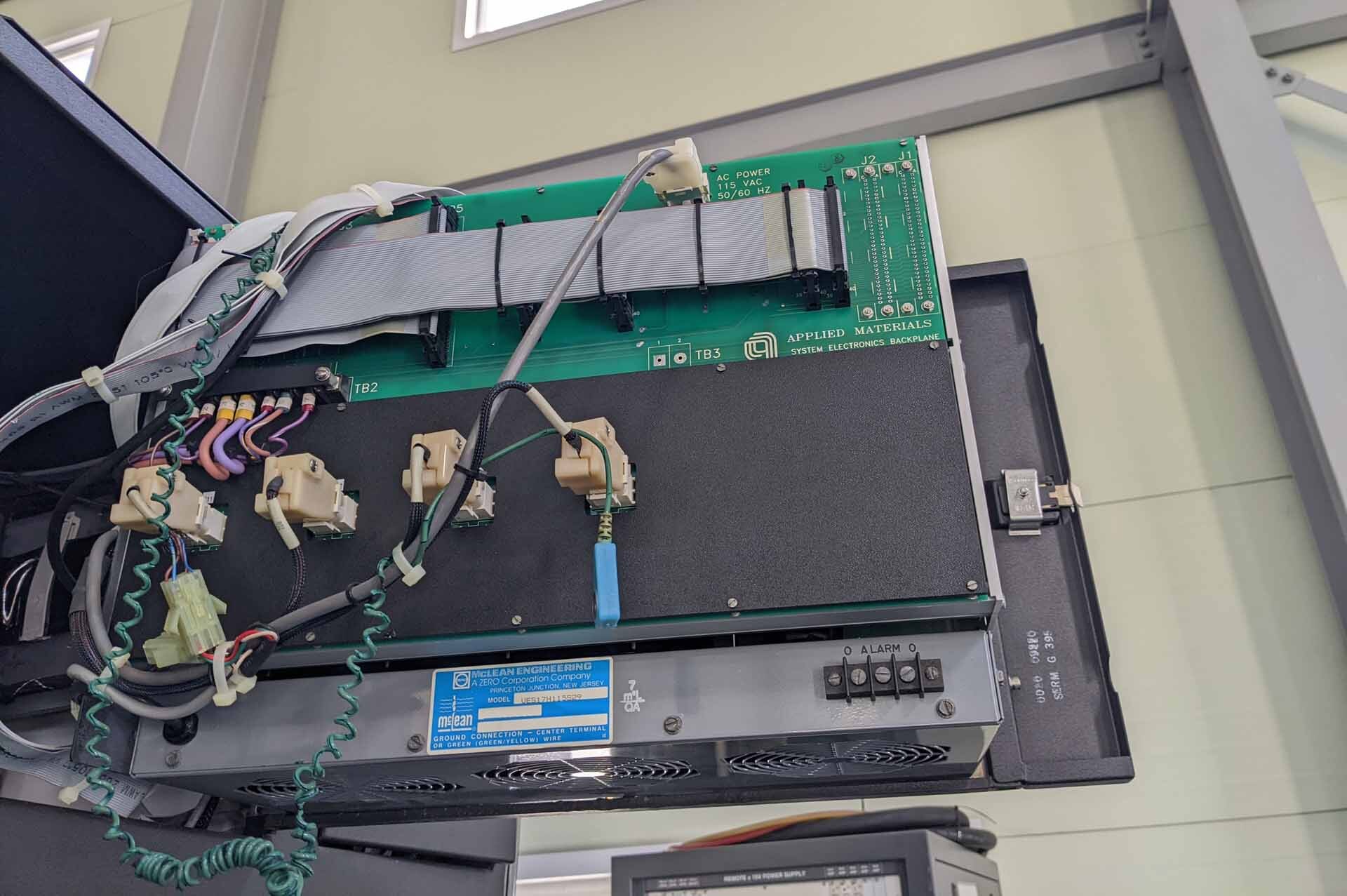

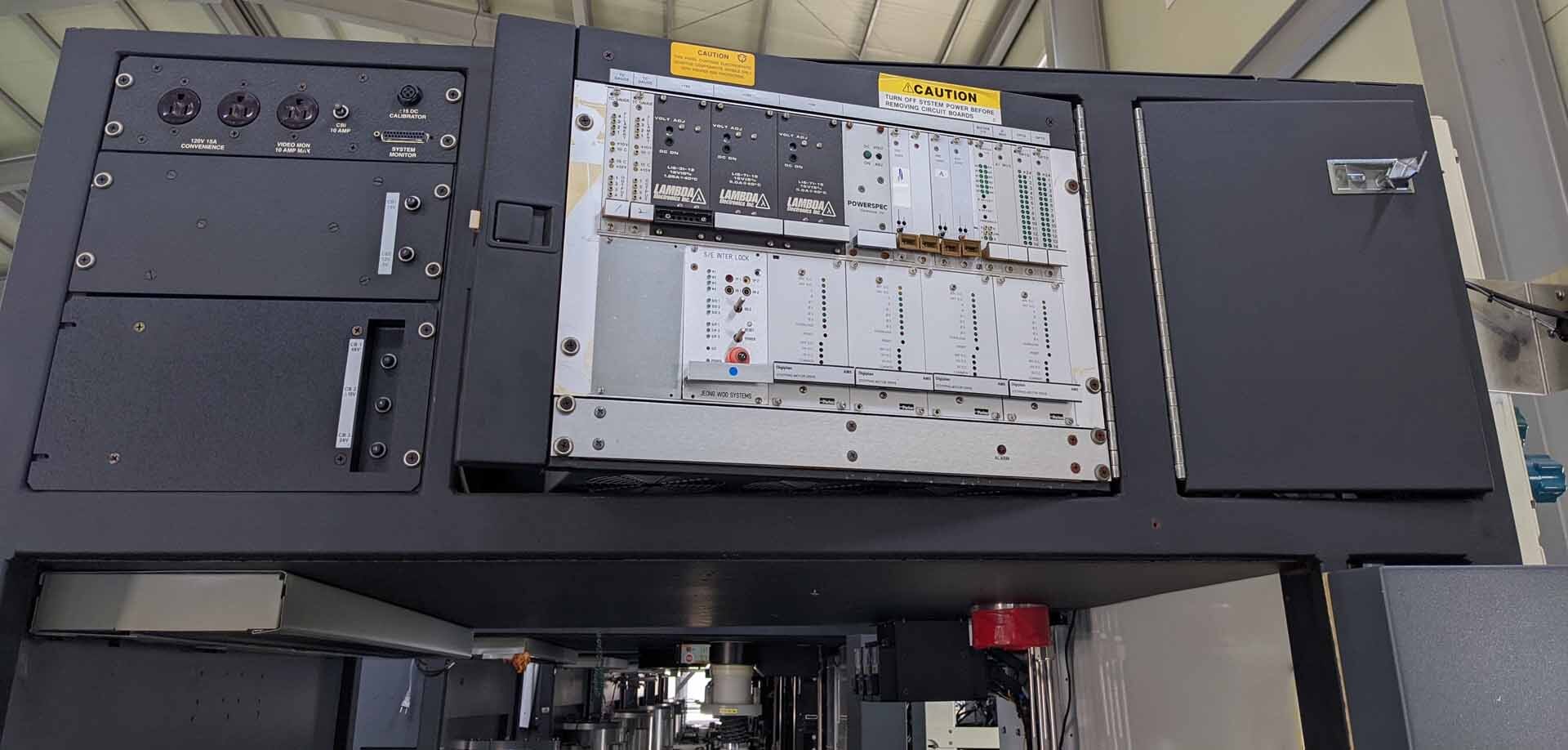

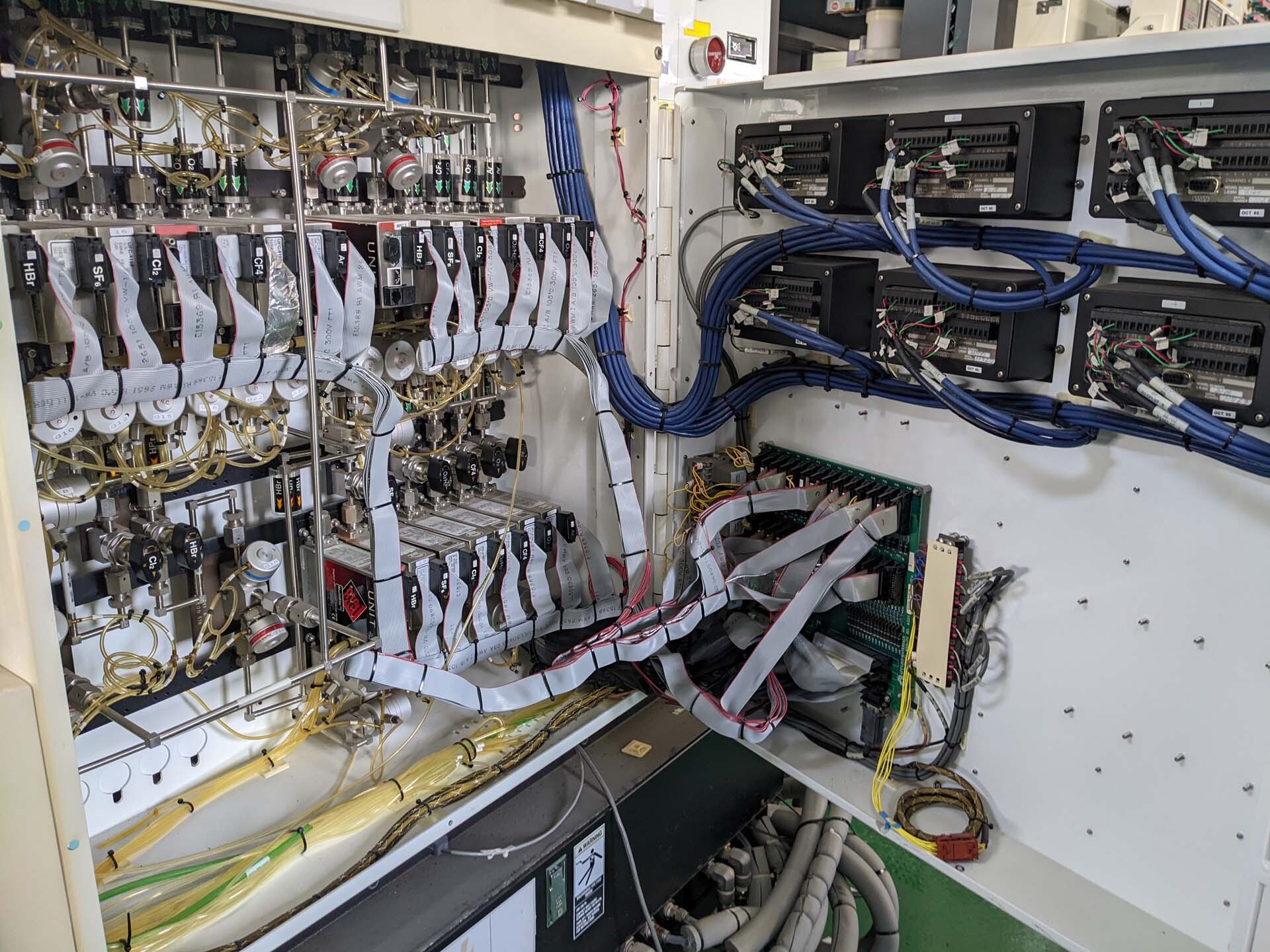

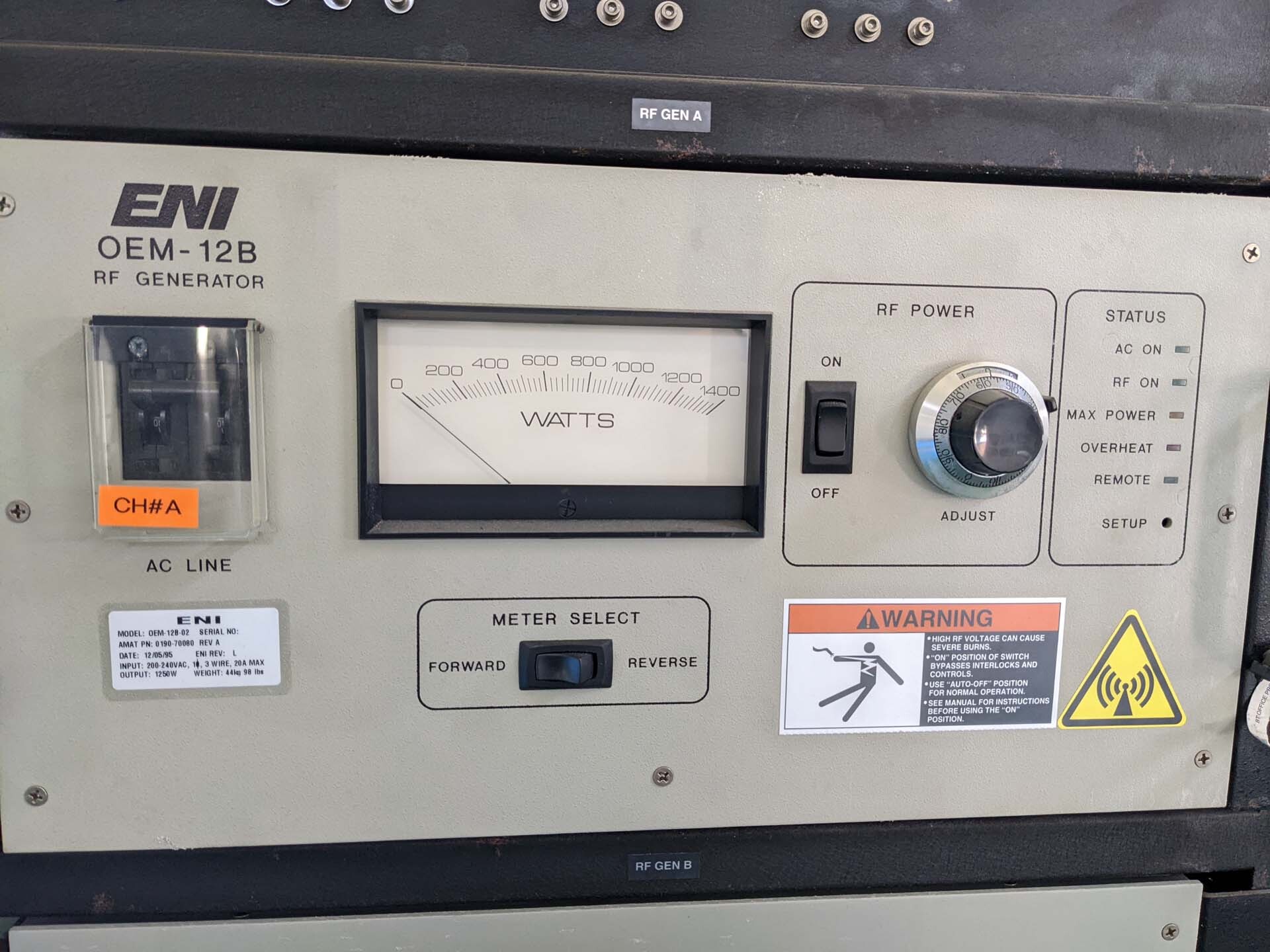

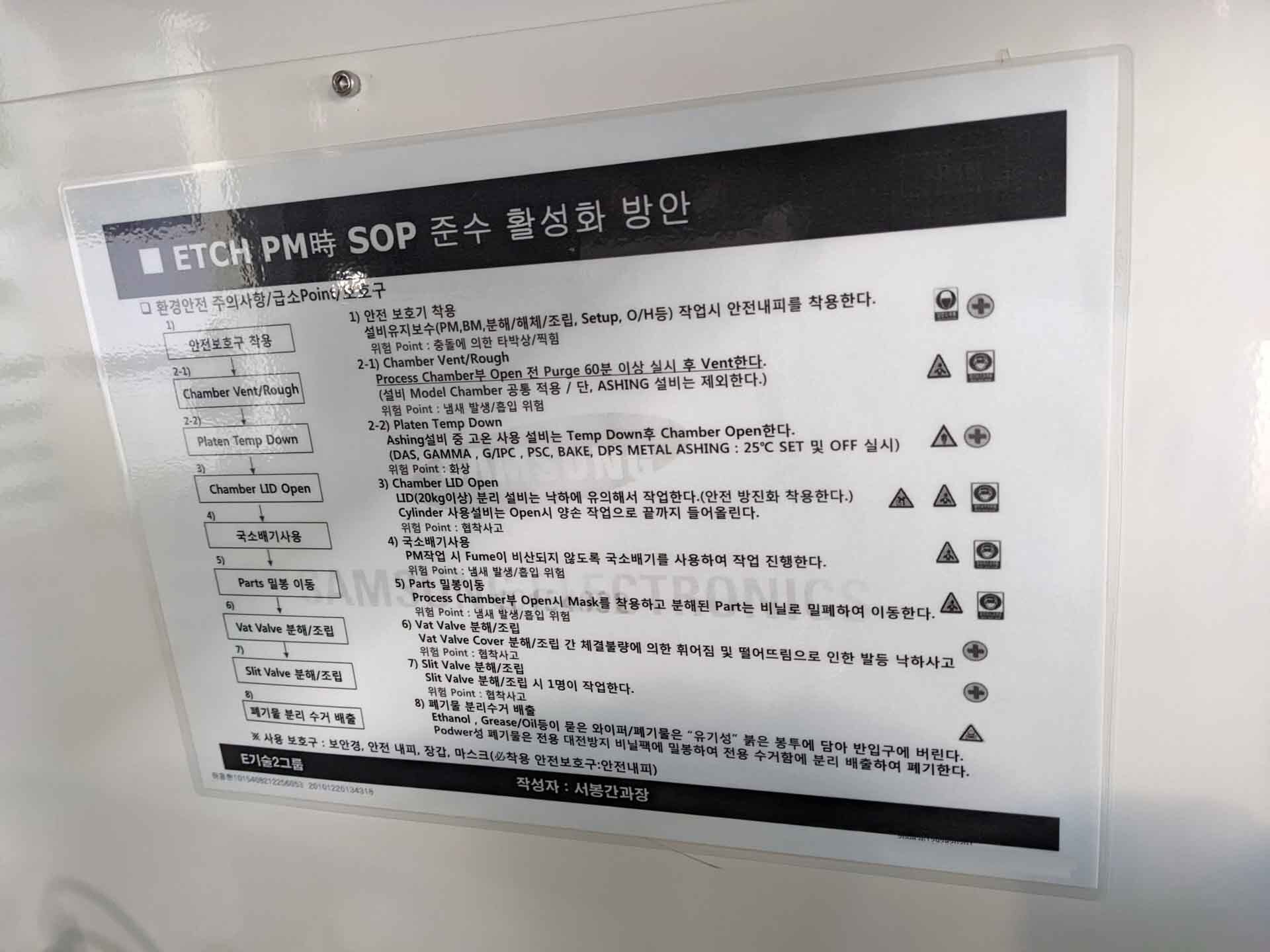

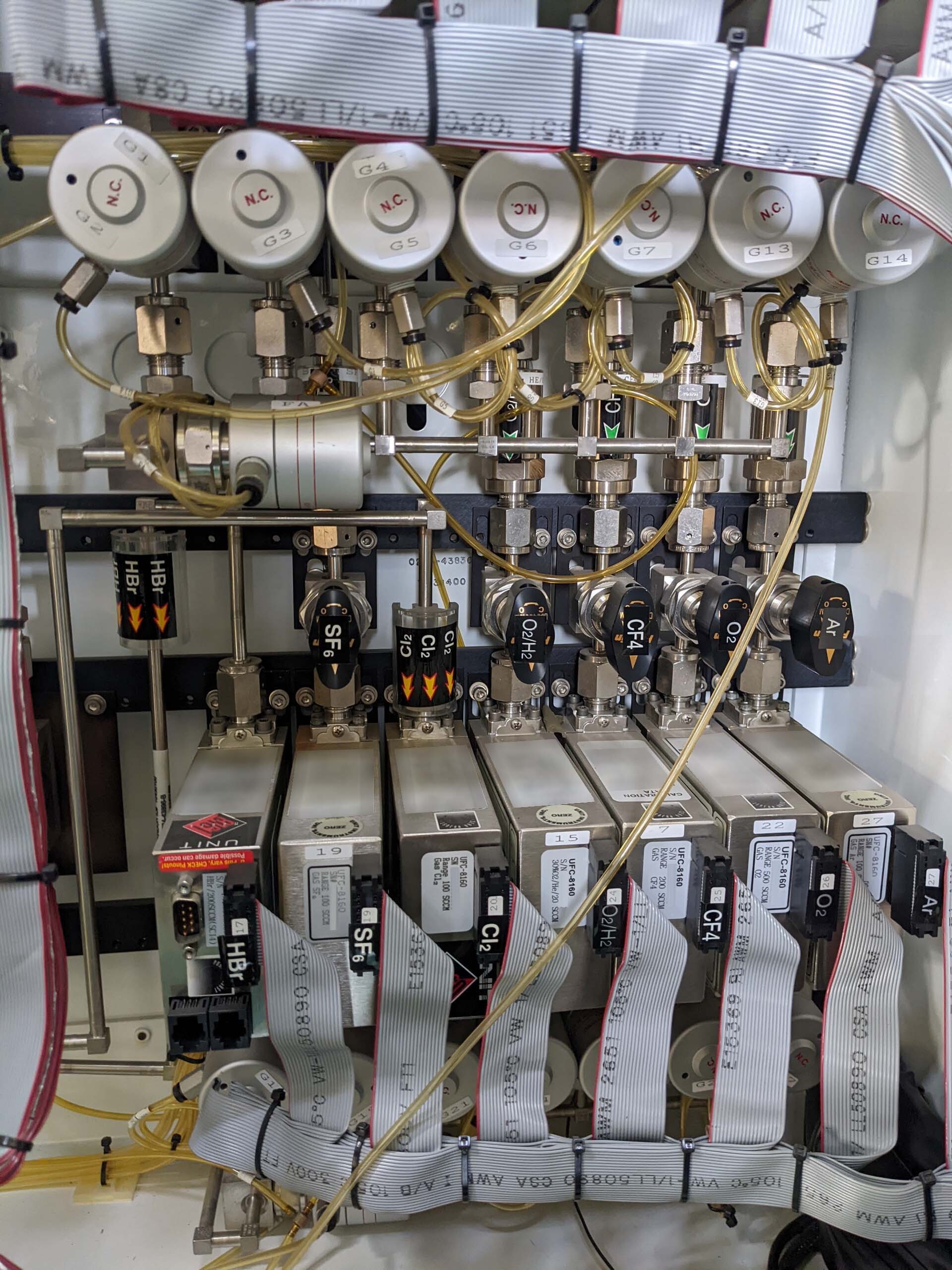

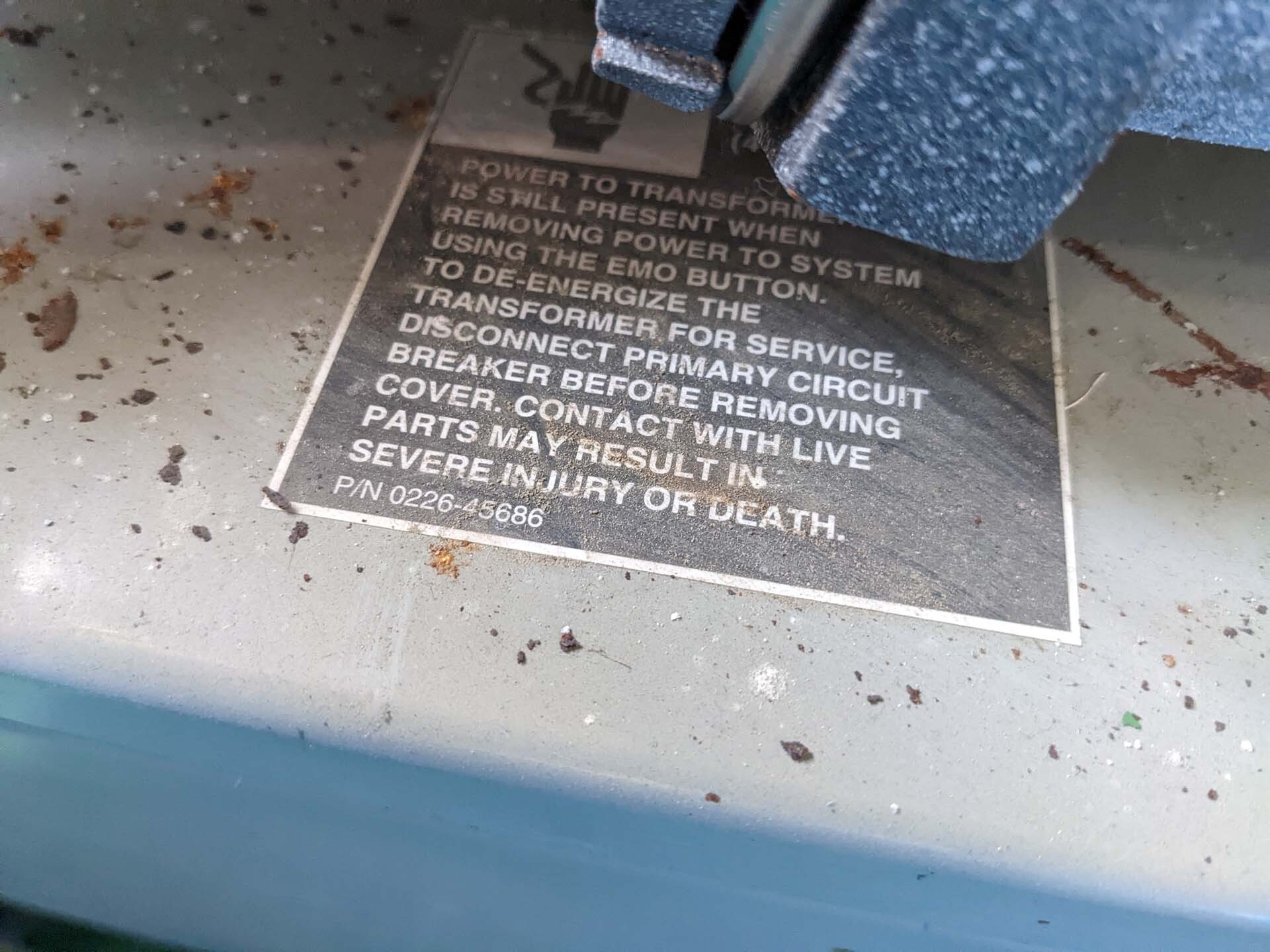

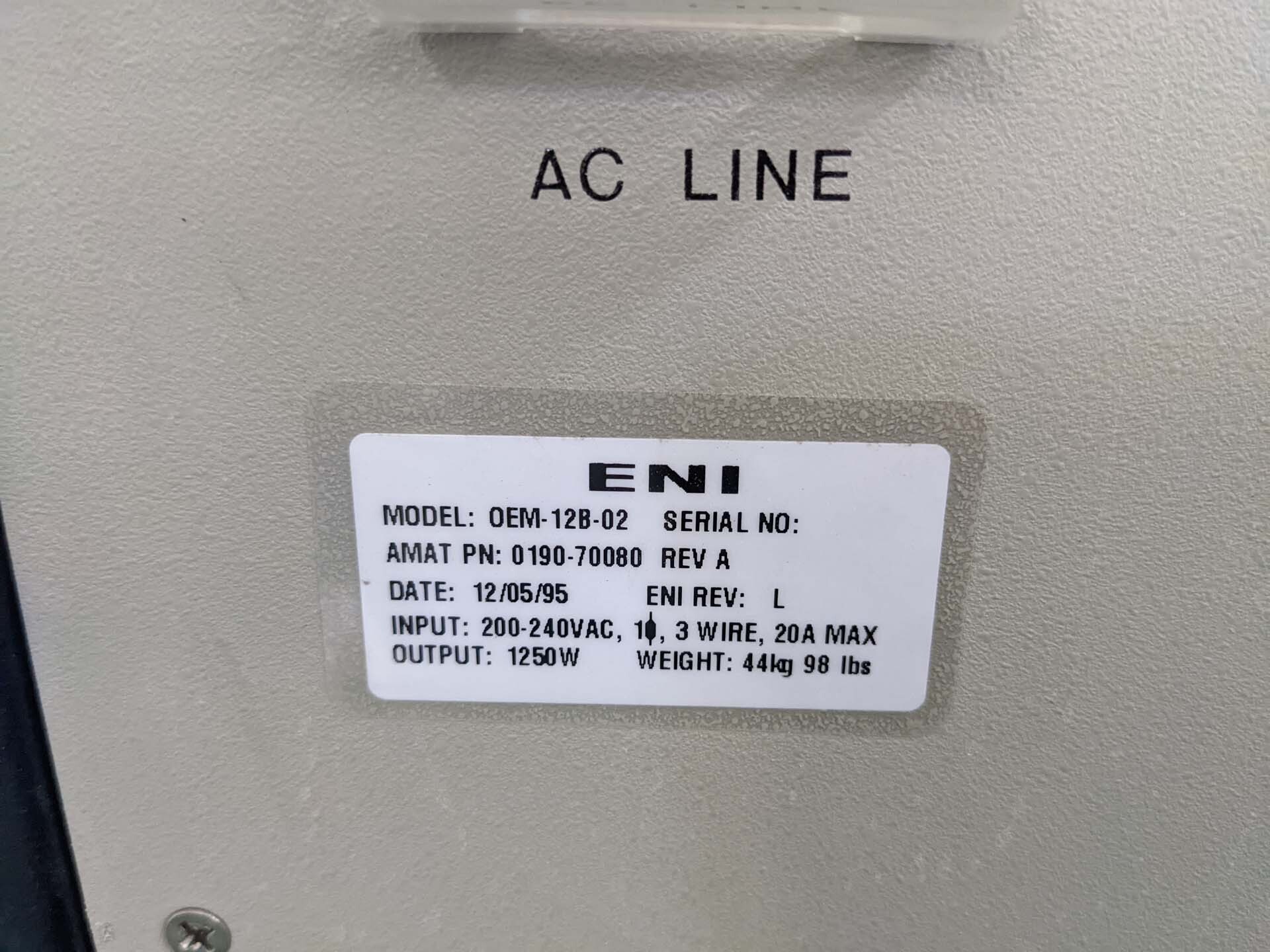

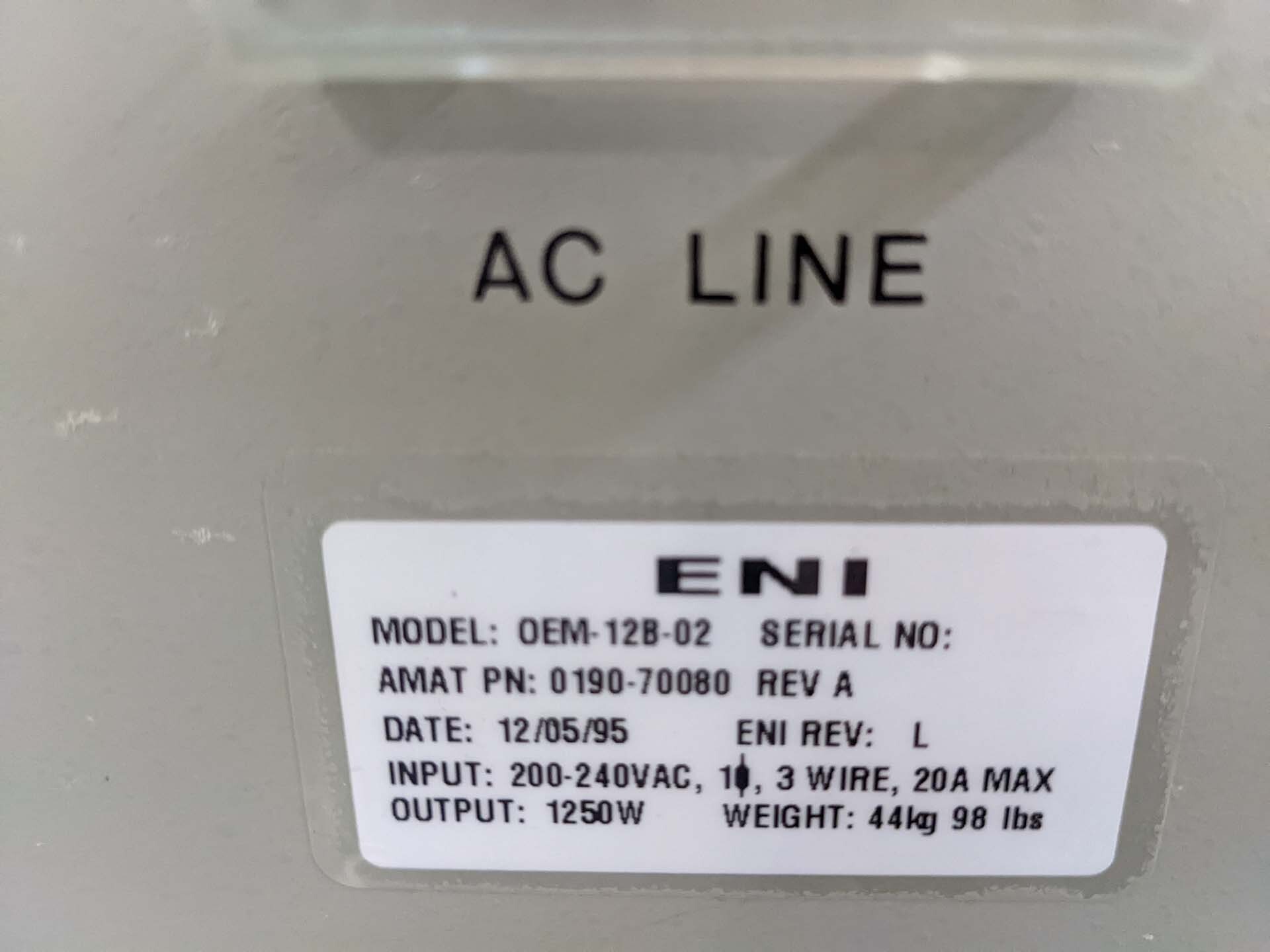

AMAT / APPLIED MATERIALS P5000 is a fully automated, mini-fabulator, single wafer advanced process control reactor equipment used for etch and deposition applications in the semiconductor industry. AMAT P-5000 is able to provide superior throughput with its combination of precision, repeatability, and high yield process control. It is capable of controlling the etching, oxidation, nitrocarbonizing and metal deposition parameters to fit a wide range of etch and deposition requirements. APPLIED MATERIALS P 5000 utilizes a combination of physical-mechanical and chemical processes to achieve chemical vapor etch (CVD) and chemical vapor deposition (CVD) of thin films. At the heart of the system lies its ability to precisely control the temperature, pressure, and chemical compositionality operating within the chamber while performing a multitude of etch/deposition processes. The unit includes a chemical gas delivery machine with multi-gas mixing capabilities, a chamber pressure delivery tool, as well as a physical-mechanical chamber cleaning asset. The model also includes a transportation and web handling equipment capable of supporting both thin and thick web products. P 5000 utilizes a RF plasma power source to pump photons into the chamber, enhancing the etching and deposition rates. The chamber temperature is kept constant through the use of a thermocouple in the power grounding system that adjusts the heating element element's power output and feedback control. A mass flow controller is then used to adjust the flow of the etch chemicals into the chamber and the CVD gasses are then brought in resulting in the deposition of the thin film. The reaction chamber of P-5000 is also utilized to etch with chemicals such as hydrogen peroxide, hydrofluoric and nitric acids. The chamber temperature is maintained using a thermocouple power control unit along with an on-board computer with embedded software to help control and monitor the process conditions. Additionally, AMAT / APPLIED MATERIALS P-5000 uses an optical emission spectrometer to help detect and measure gaseous species in the chamber during the etch and deposition processes. Overall, P5000 is an incredibly robust and reliable process control reactor machine for thin film etch/deposition and other semiconductor processes. The tool offers superior throughput, precision and repeatability, resulting in an average of 75-90% yield with consistent process results. By using AMAT / APPLIED MATERIALS P 5000, semiconductor process developers and engineers can be assured of getting high performance results while reducing the time and cost of fabrication cycles, leading to more reliable products.

There are no reviews yet