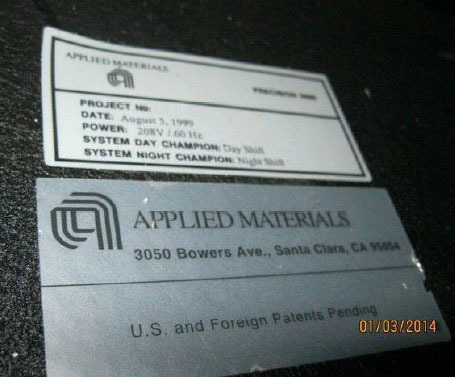

Used AMAT / APPLIED MATERIALS P5000 #9056702 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9056702

Vintage: 1999

PECVD System, 8"

Mark II P5000 mainframe

(4) Chambers

15 slot storage elevator

8” Cassette Handler

Bolt down load luck lid with purge

Phase III robot

Remote Rack with (2) ENI OEM 12B 13.56Mhz generators

Steelhead Heat Exchanger

Thru the wall interface with (2) monitors: (1) TTW, (1) stand alone

PLIS Cabinet

PLIS Minicontroller

DPS generator rack with ENI DPG-10 Generator and DPA Interlock board

Chamber A:

Universal PECVD chamber

Cluster Throttle valve

Gold Style Lamp module

Phase IV RF match

Dual manometers with 100/1000 Torr manometers

Unit 1660 MF calibrated to customer spec

STEC LF-410 LFM’s and 2410 injectors calibrated to customer spec

Chamber B:

Standard PECVD chamber

Cluster Throttle Valve

Gold Style Lamp Module

Phase IV RF Match

Dual manometers with 10/1000 Torr manometers

1660 MFC’s calibrated to customer spec

1999 vintage.

AMAT / APPLIED MATERIALS P5000 reactor is a high-performance processing equipment specifically designed for deposition, etching, and other related thin-film processing of semiconductor, thin film semiconductor and magnetic material. This tool is used for both volume production as well as R & D applications. AMAT P-5000 reactor has a laser & optical process module and a capable CPU/DSP based controller. The laser & optical process module is a 6-axis motion system, with a linear vacuum chamber mounted on a precision linear rail, allowing for accurate and repeatable movement. The laser & optical process module consists of a high-resolution laser unit, a focus camera, and fiber-optic and laser communications. The CPU/DSP based controller offers programmable control of parameters including gases and feedstock, RF and DC biasing, wafer temperature, time, energy, and acceleration. APPLIED MATERIALS P 5000 reactor also features a convection machine, which is capable of providing multiple temperatures over a large range of processing conditions. It is equipped with several gas distribution systems, such as a high-rate mass flow controller and a low-rate mass flow controller. The gas distribution tool helps to control the temporal and spatial distribution of the reactant species in the reactor. Radio Frequency (RF) and Direct Current (DC) biasing can also be applied during processing, allowing for the generation of active species in the reaction. AMAT / APPLIED MATERIALS P 5000 reactor also has a number of process-enhancing features. A high-vacuum exhaust asset is included in the model, allowing for fast, efficient evacuation of reaction by-products. Additionally, the equipment is designed to quickly take wafer samples, allowing for continual refinement and improvement of the process. AMAT / APPLIED MATERIALS P-5000 reactor is an effective tool for achieving superior performance in deposition, etching, and other related thin-film processing of semiconductor, thin film semiconductor and magnetic materials.

There are no reviews yet