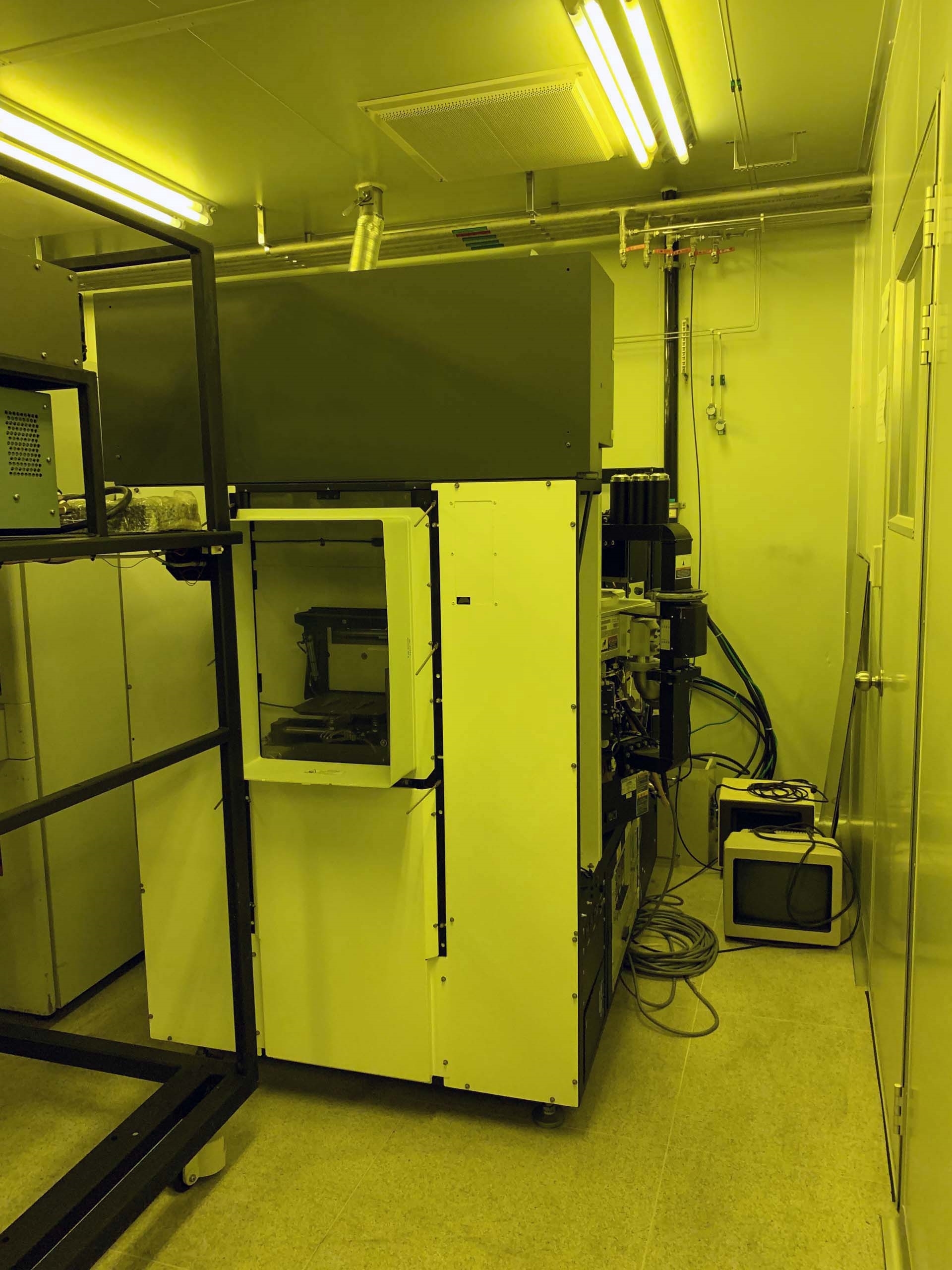

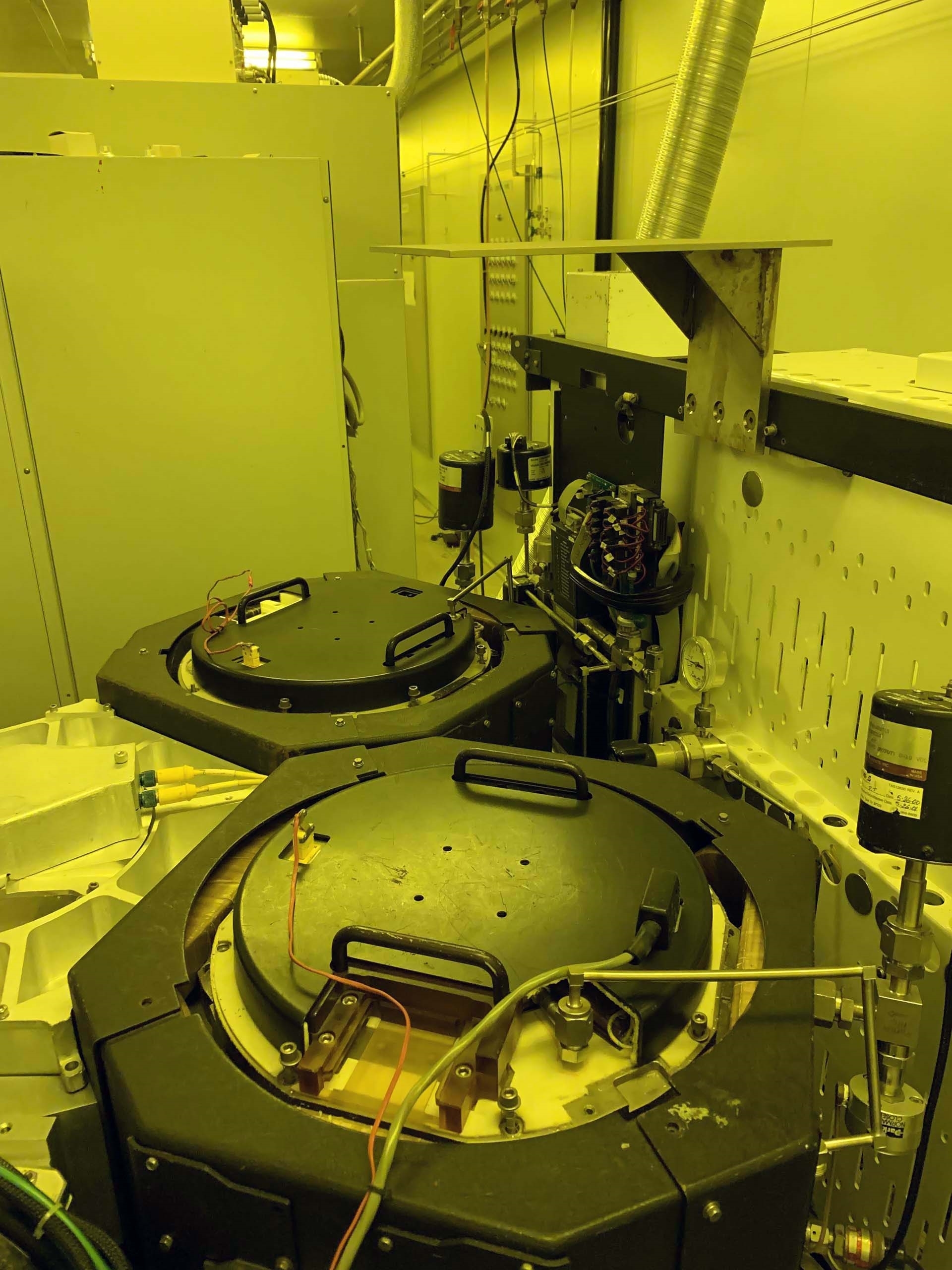

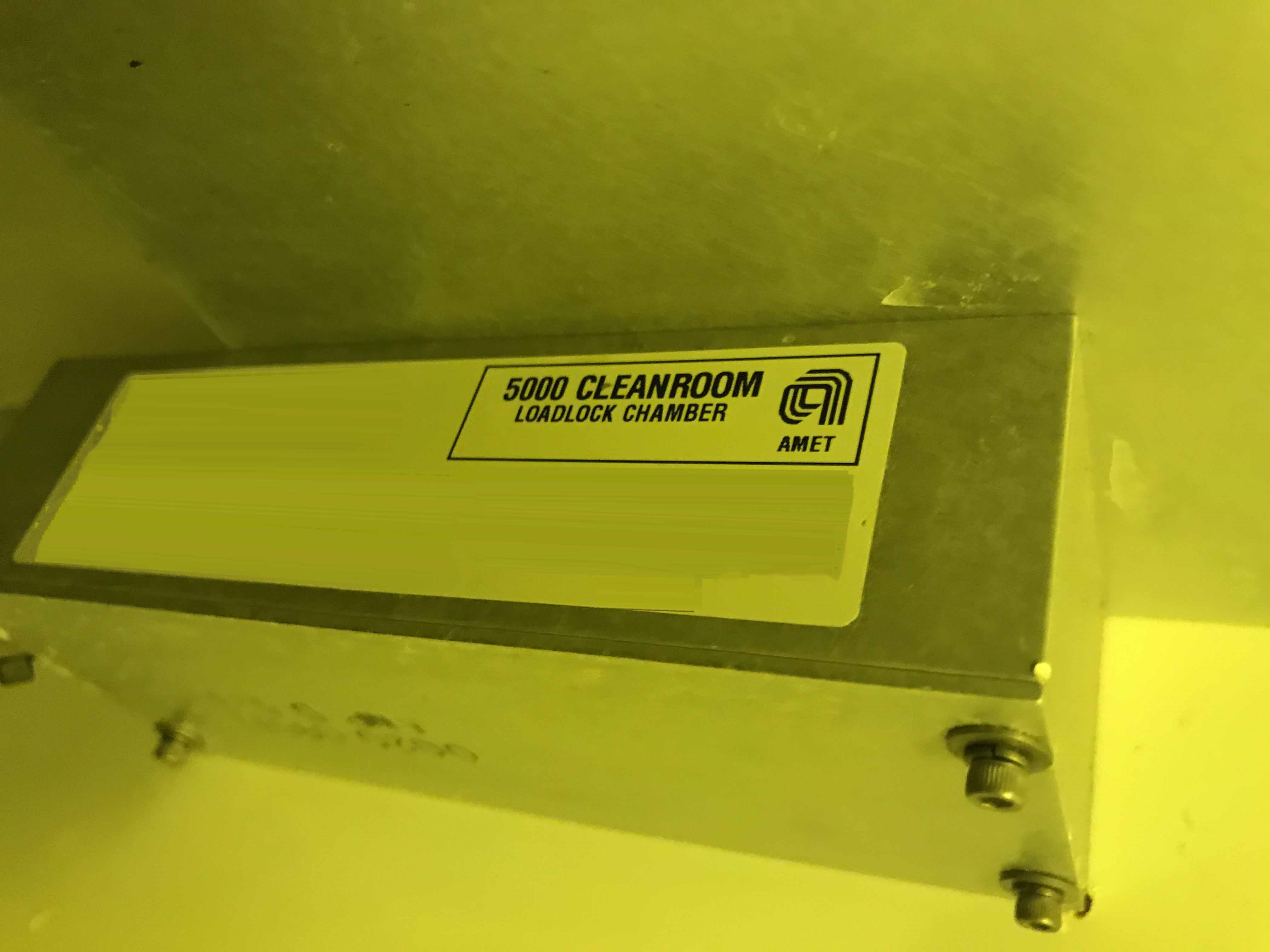

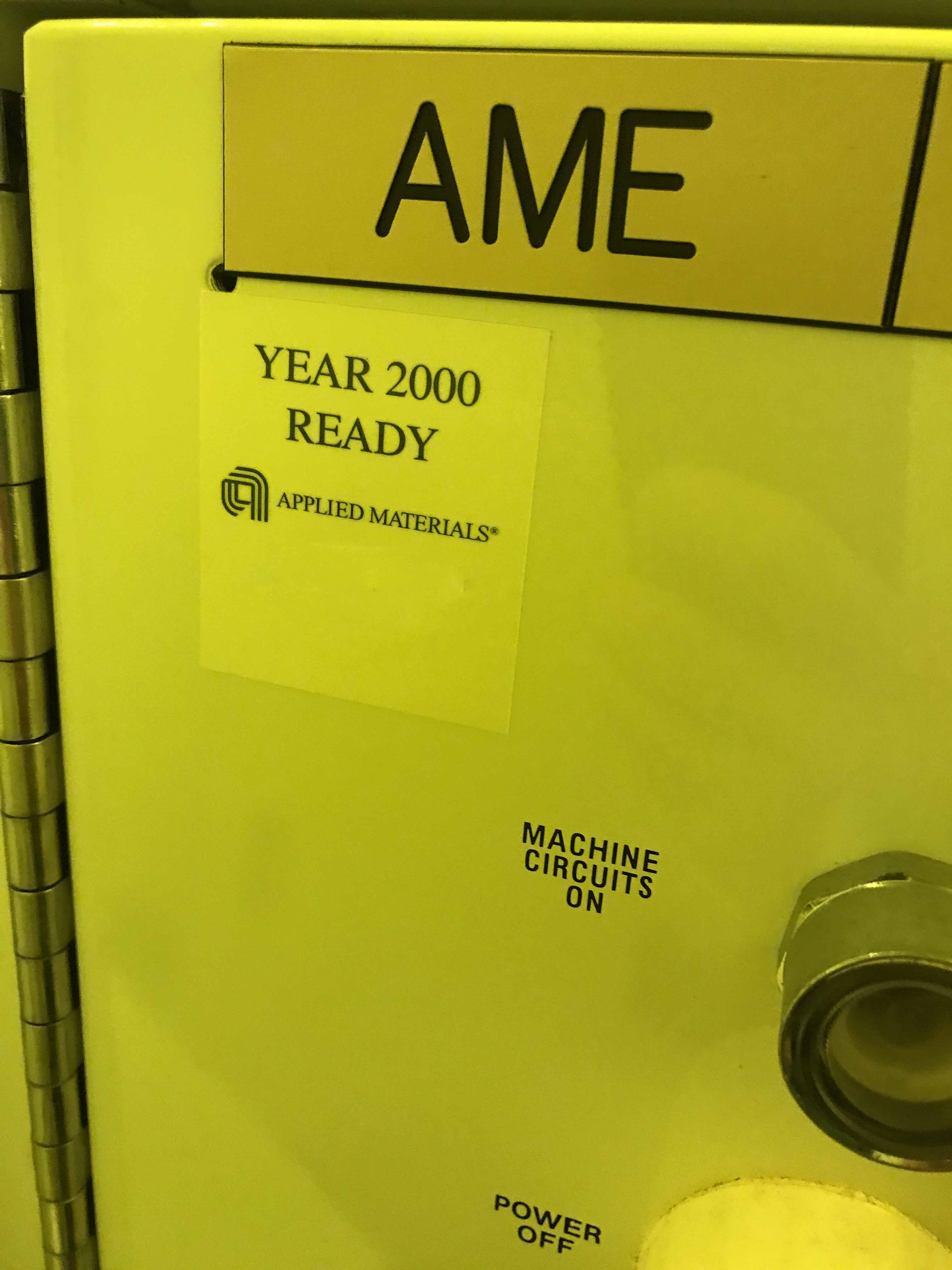

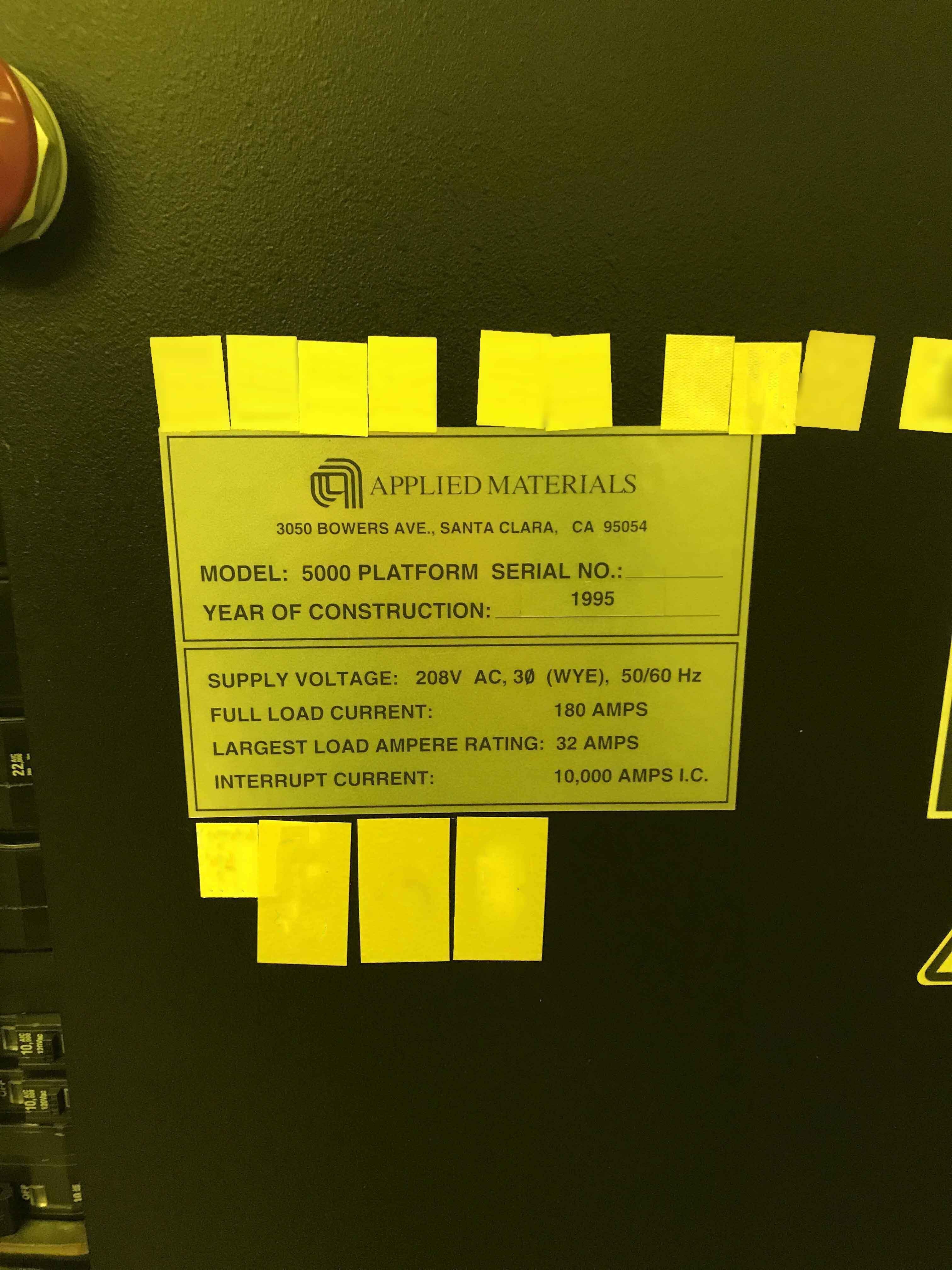

Used AMAT / APPLIED MATERIALS P5000 #9100769 for sale

URL successfully copied!

Tap to zoom

ID: 9100769

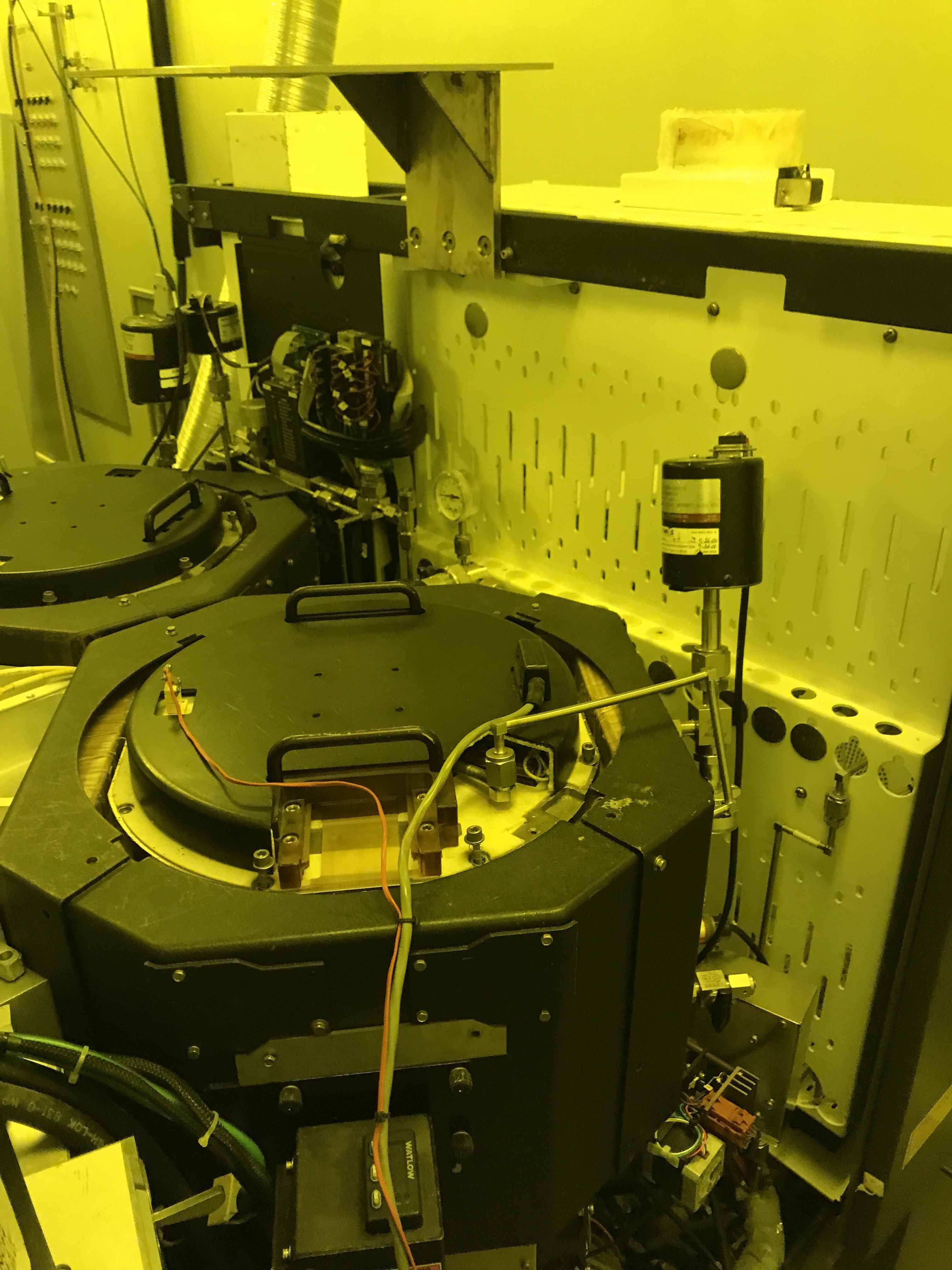

Wafer Size: 8"

Vintage: 1995

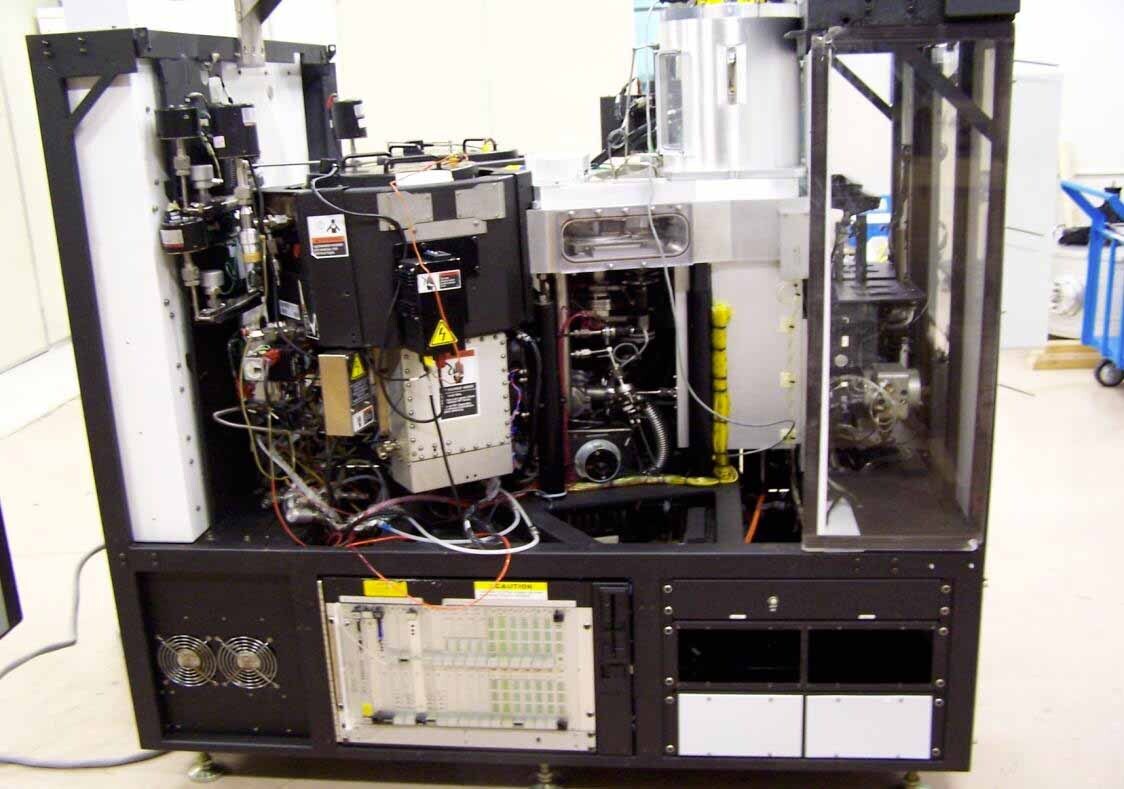

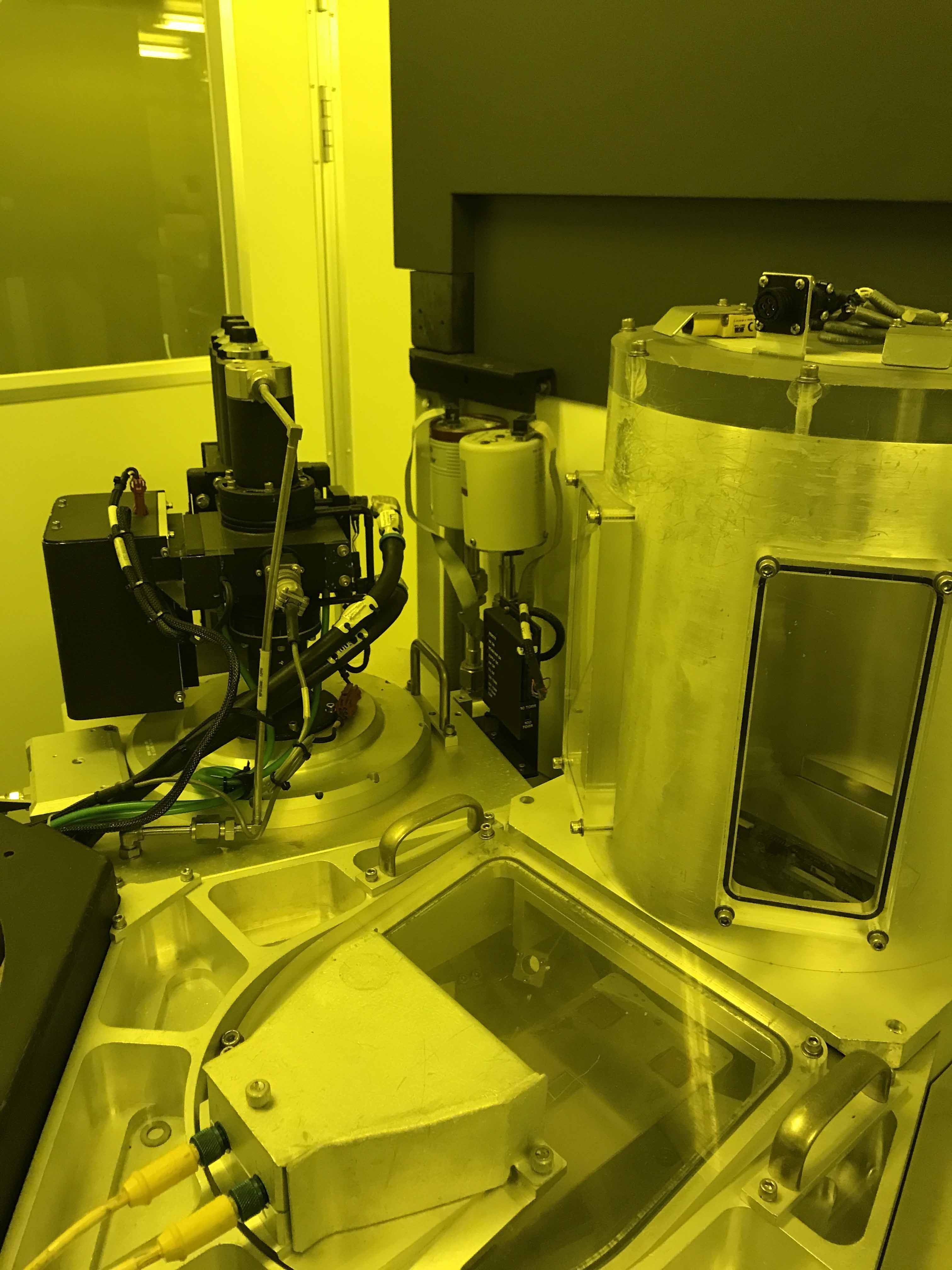

Metal etcher, 8"

Process: Al

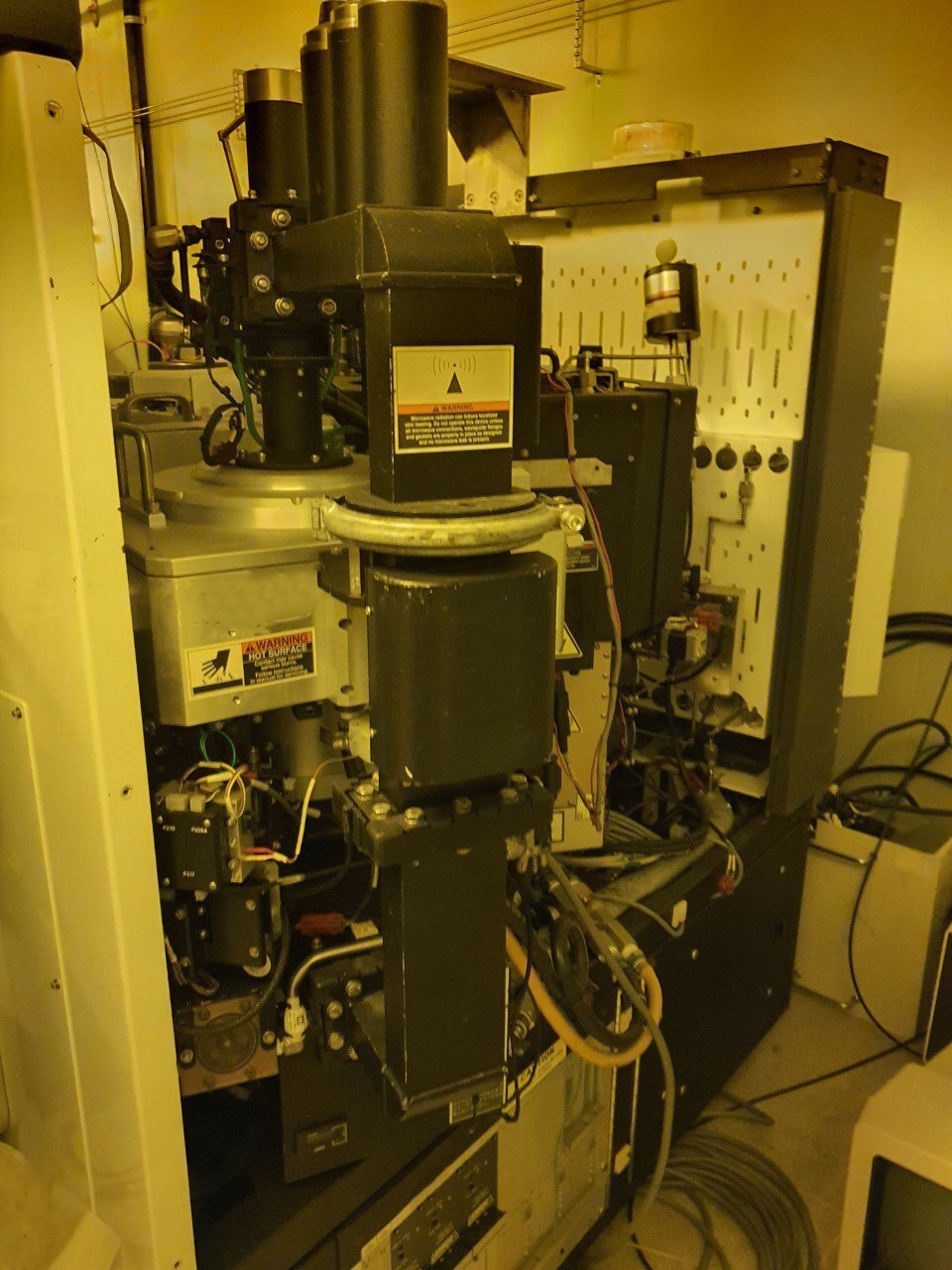

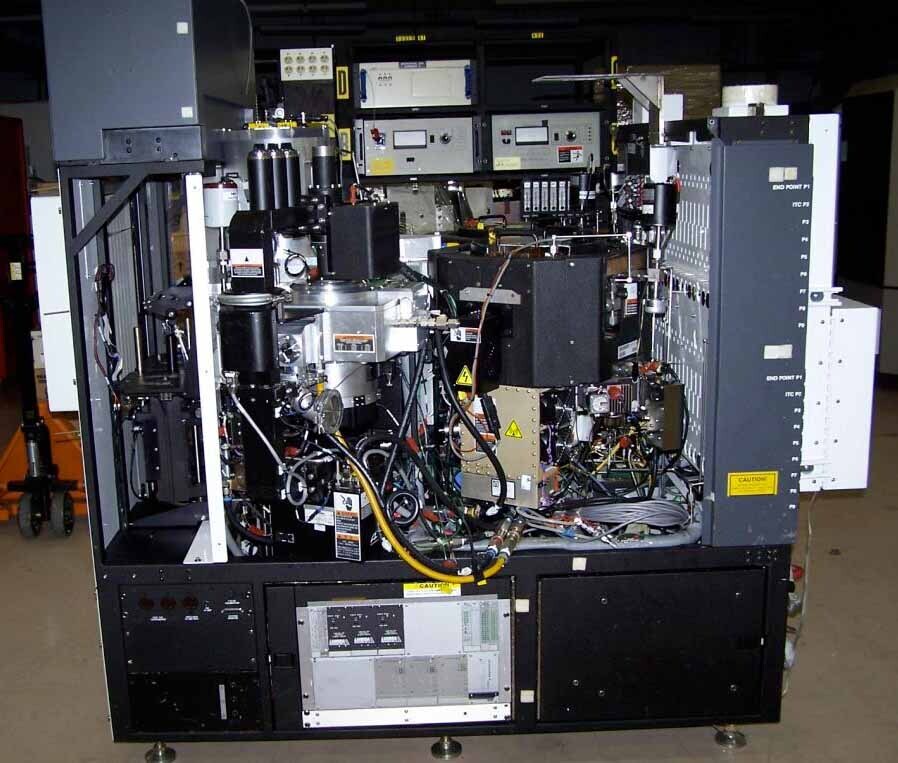

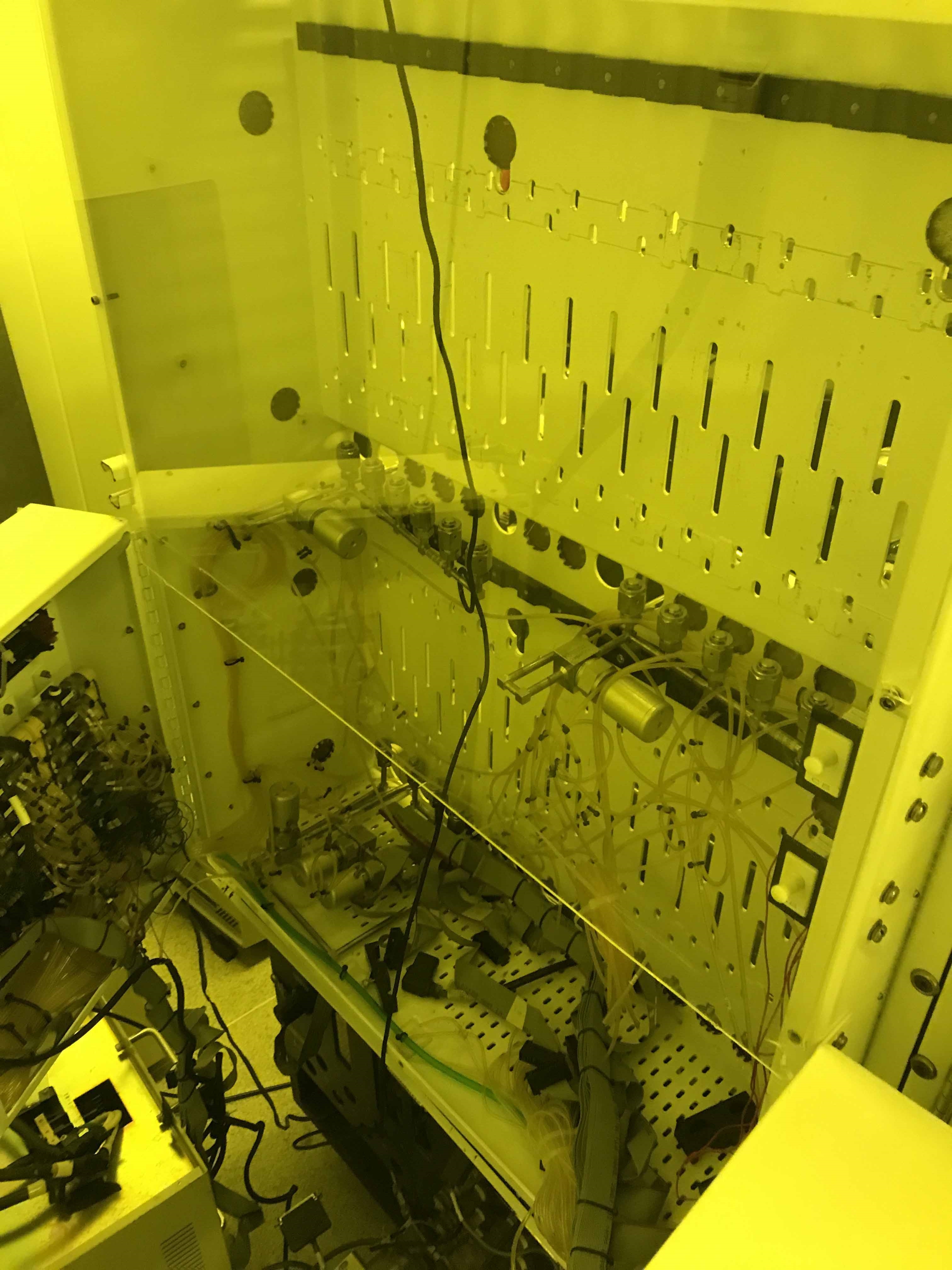

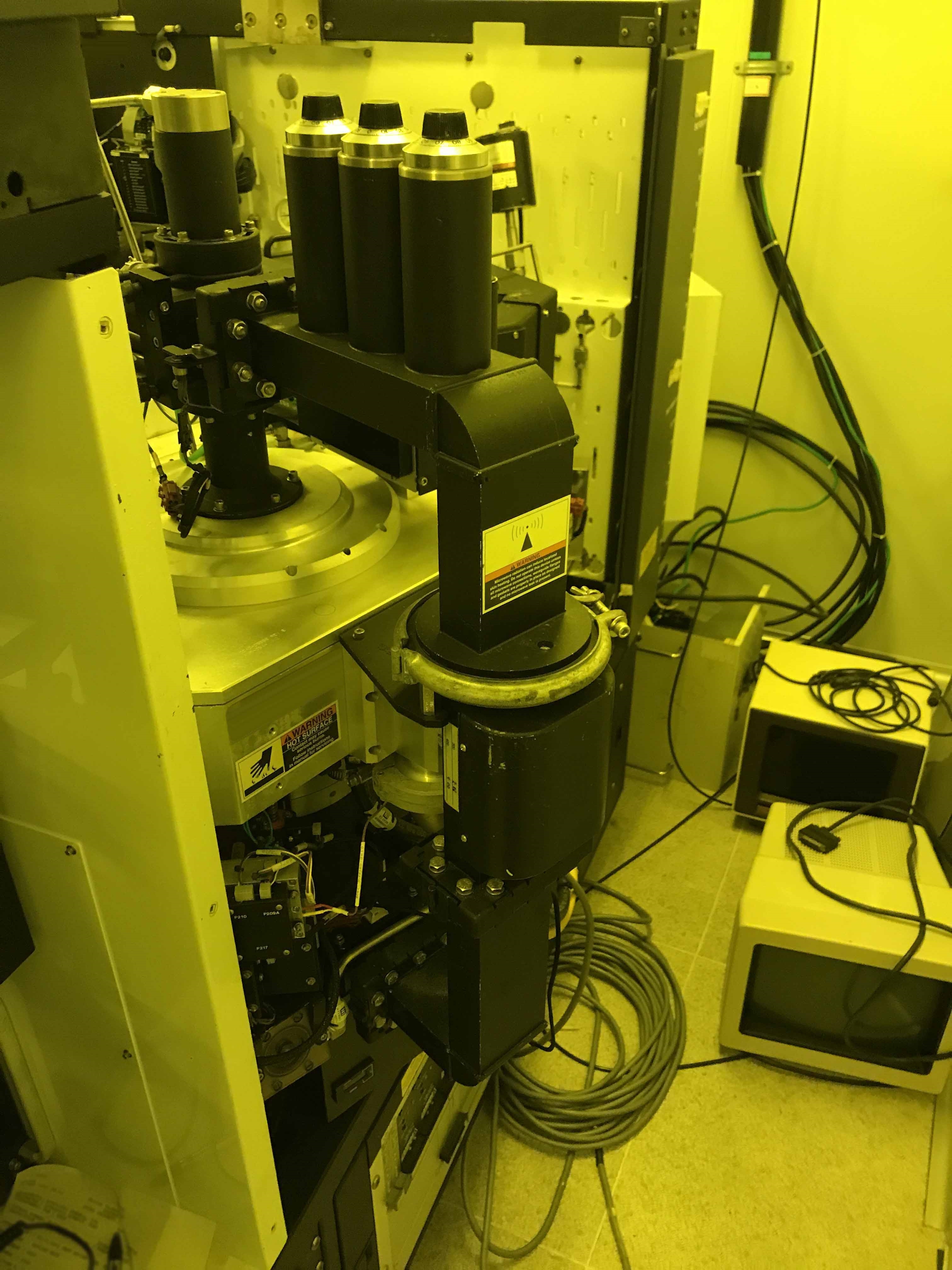

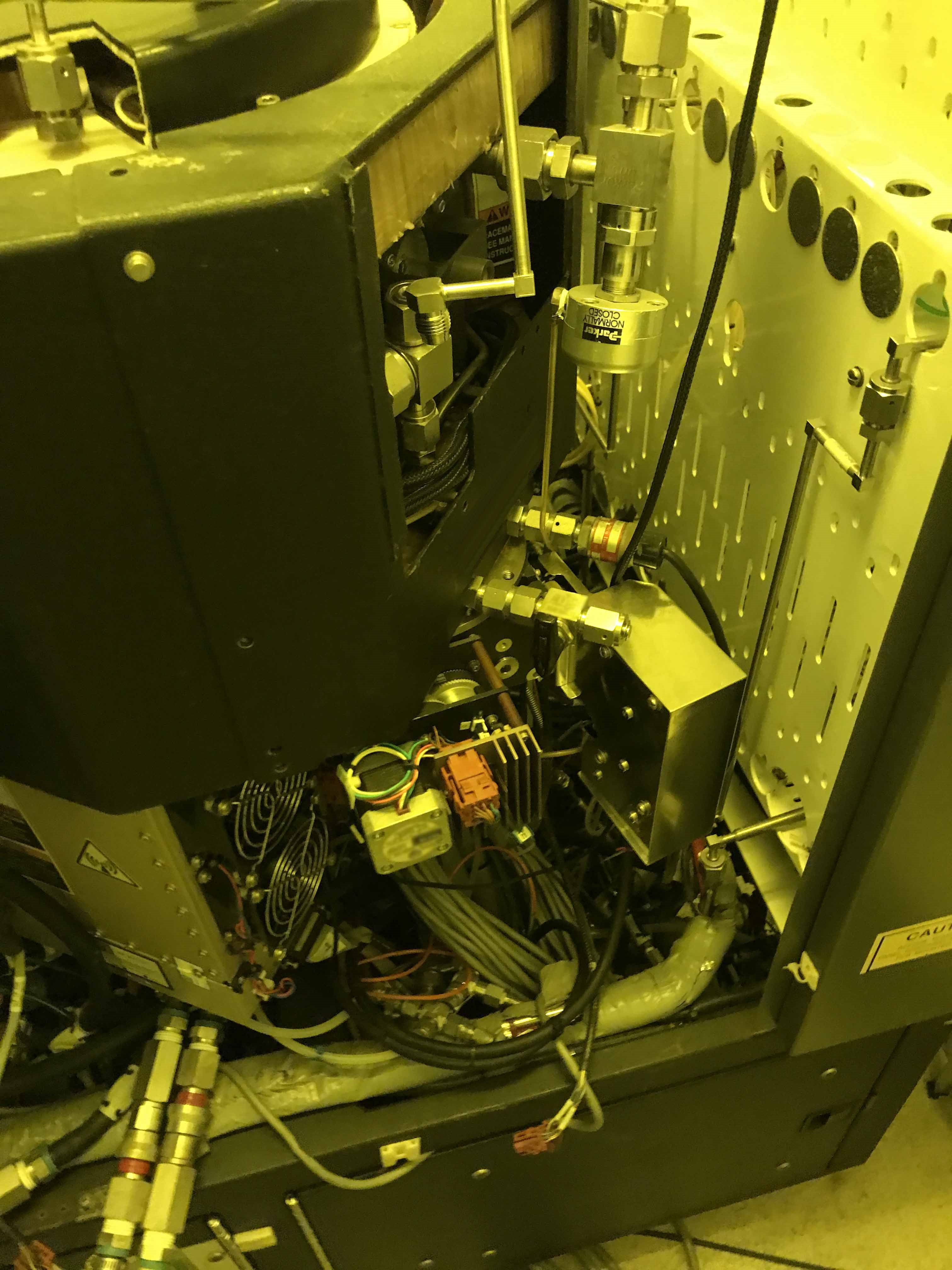

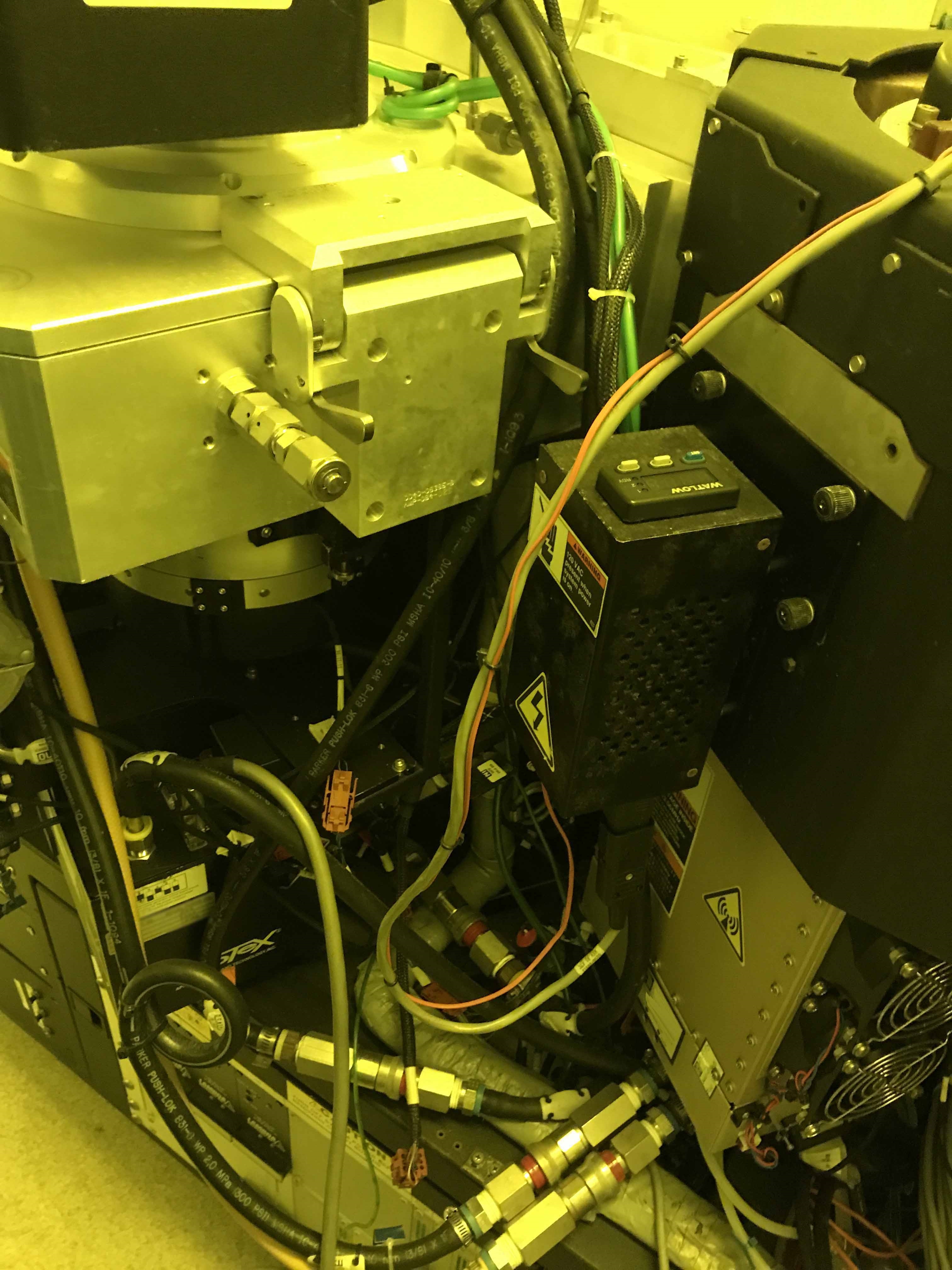

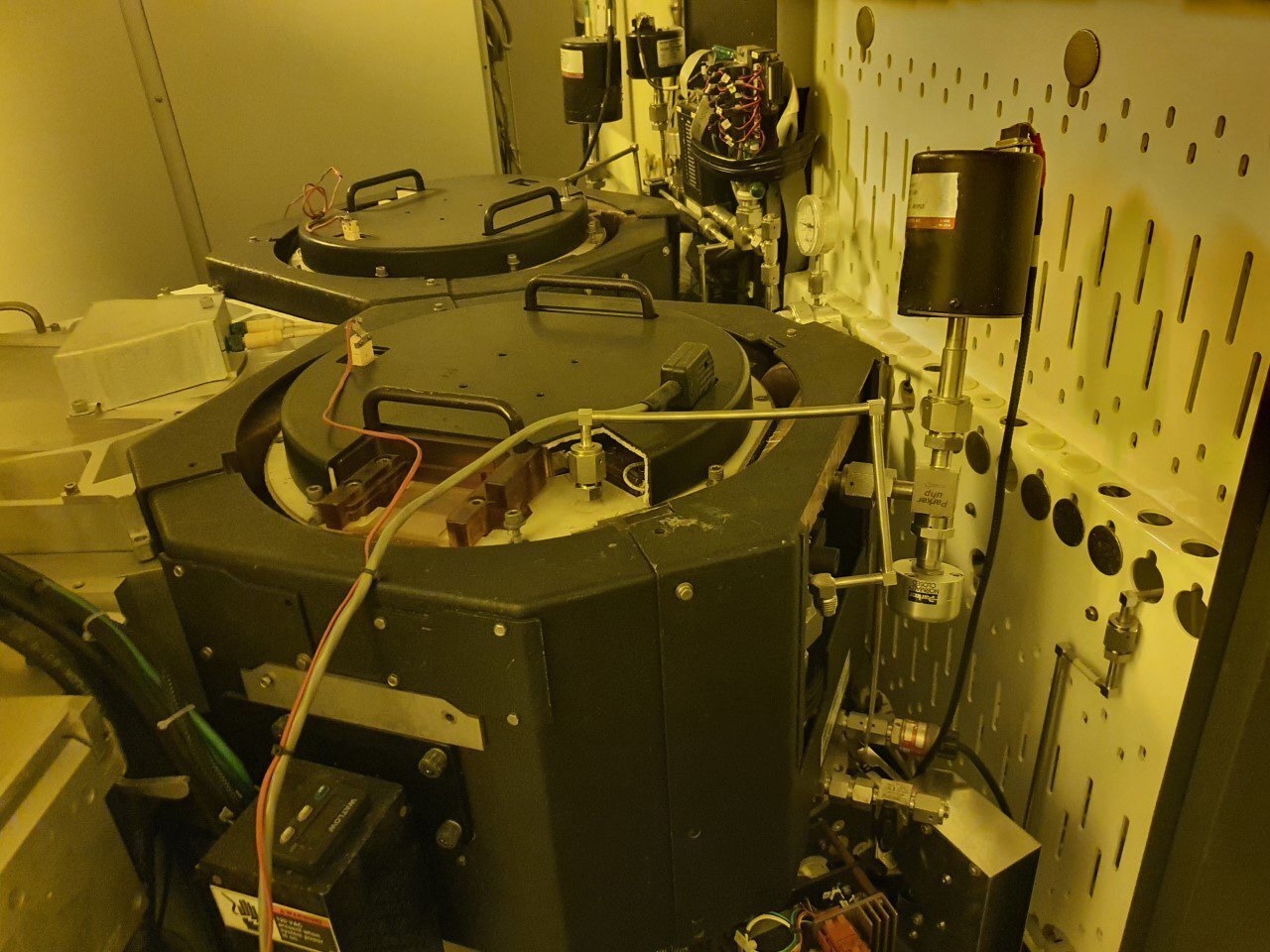

(2) MxP

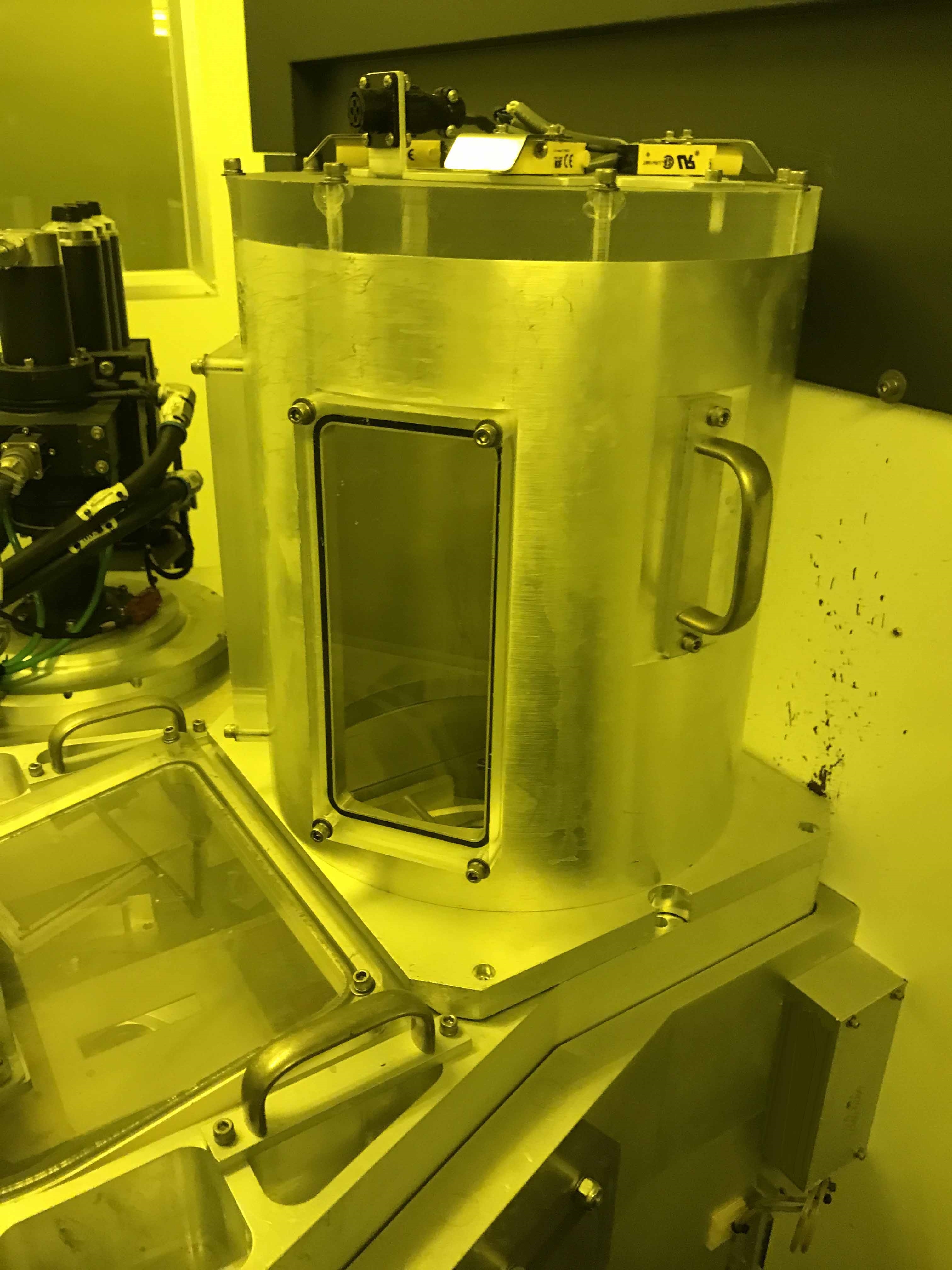

ASP Chamber

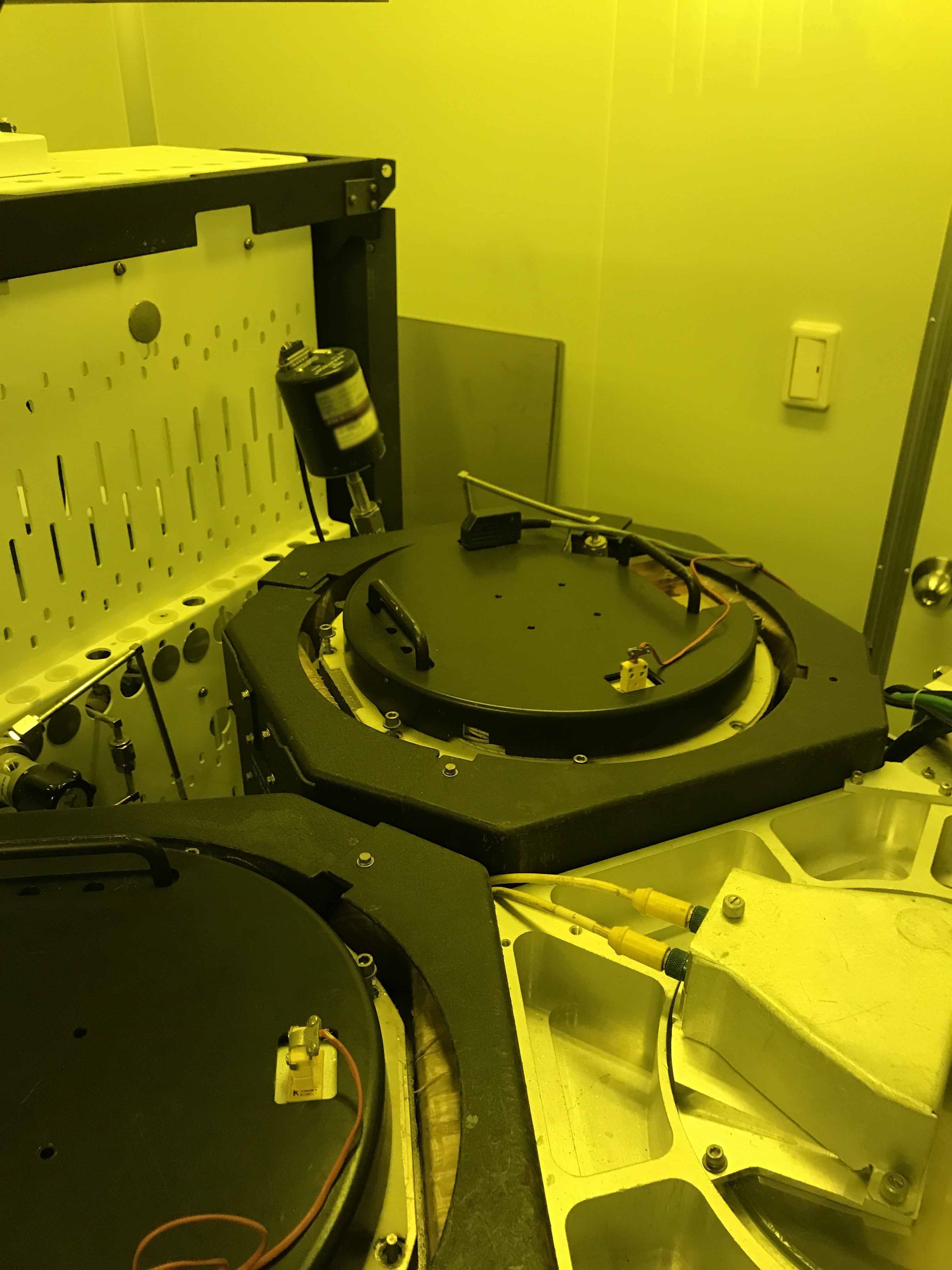

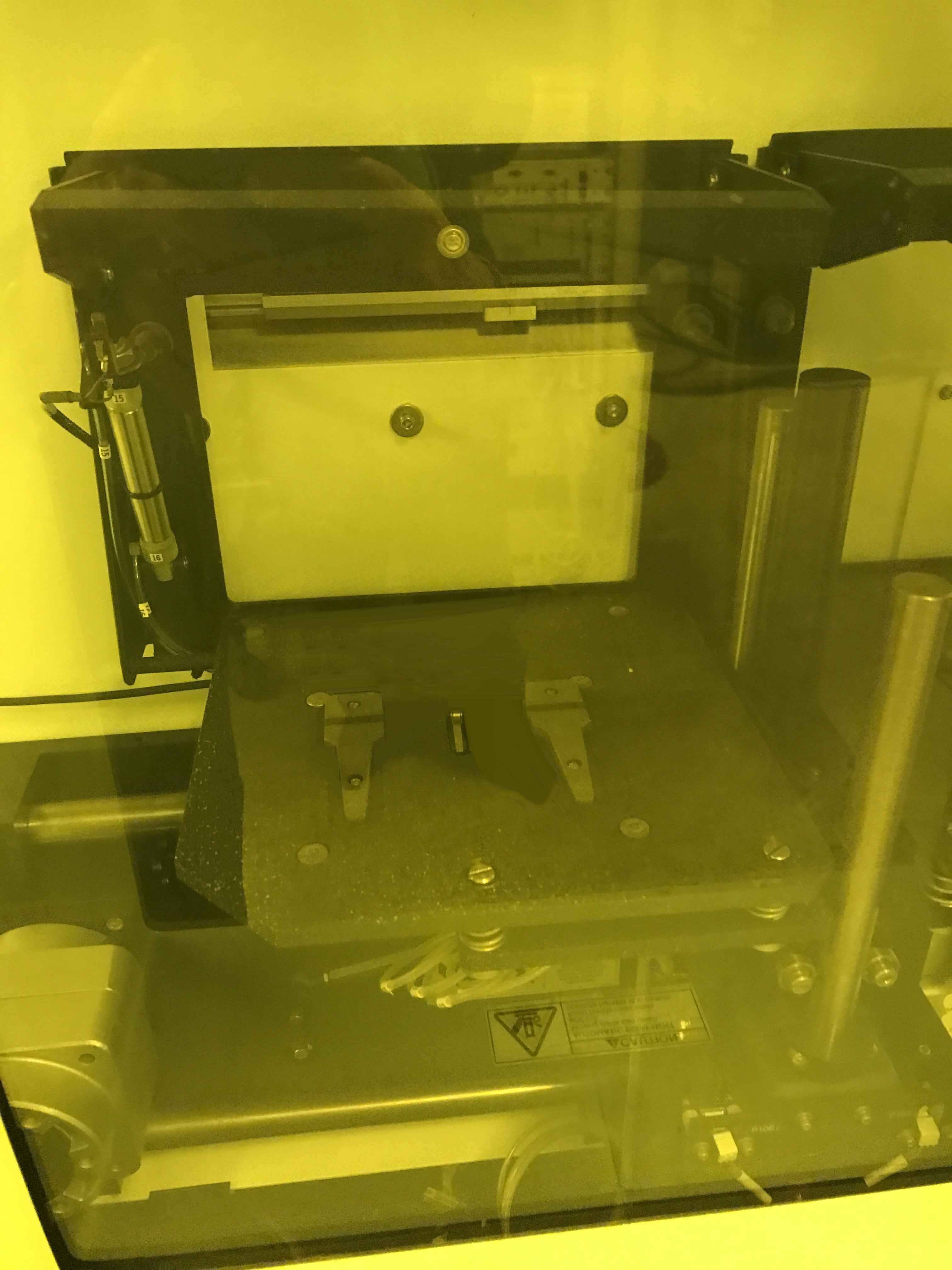

Wafer transfer system

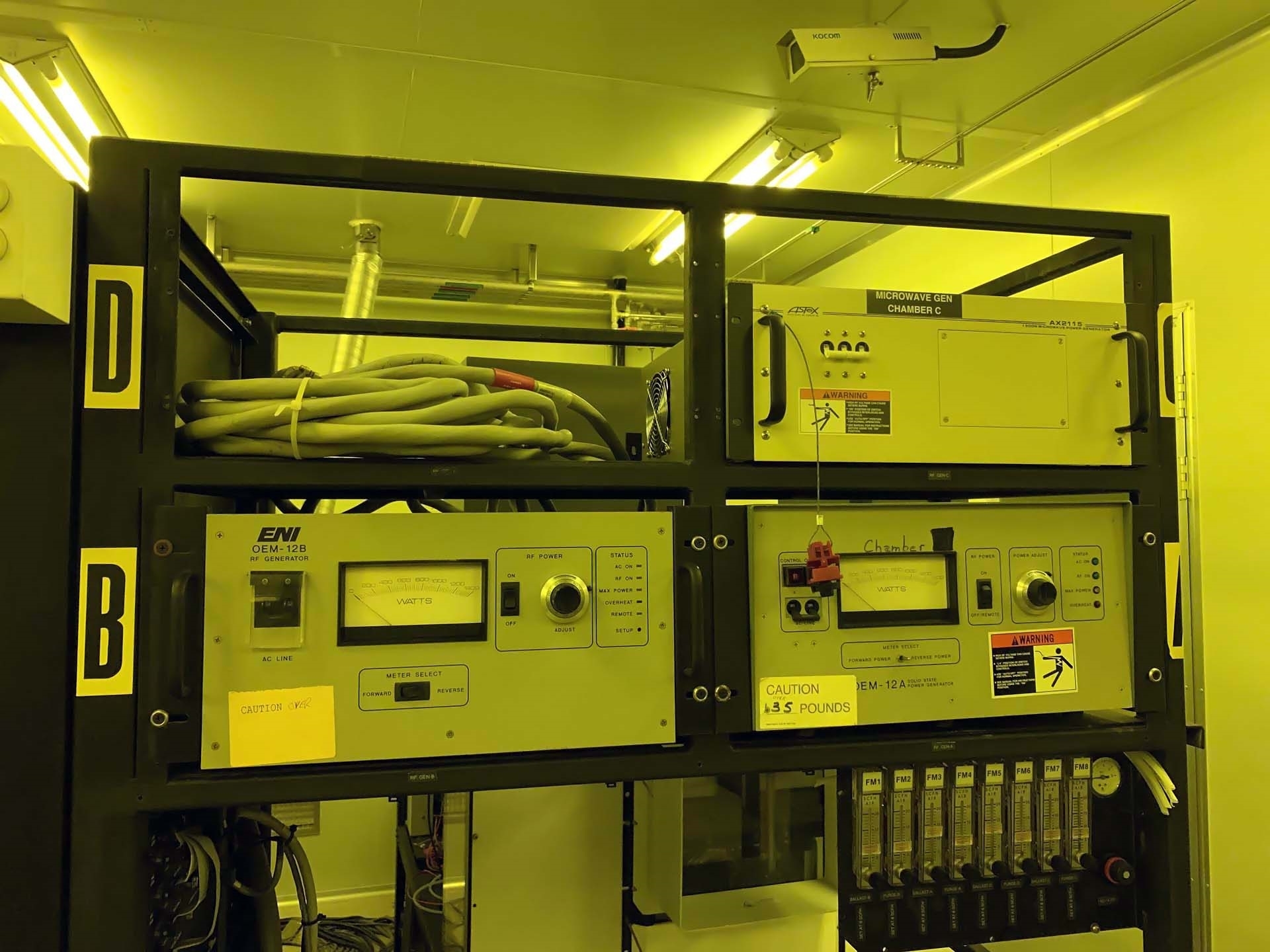

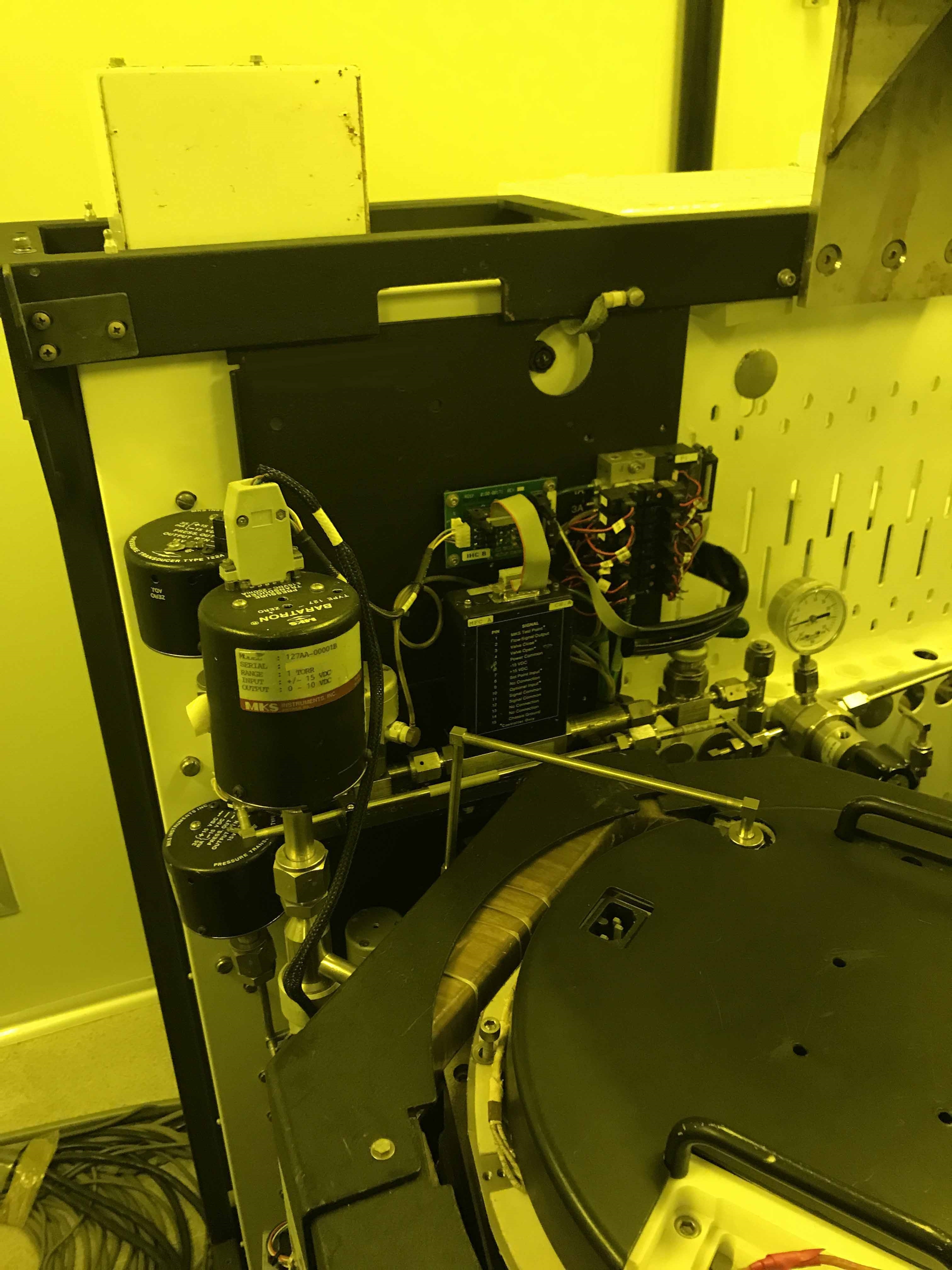

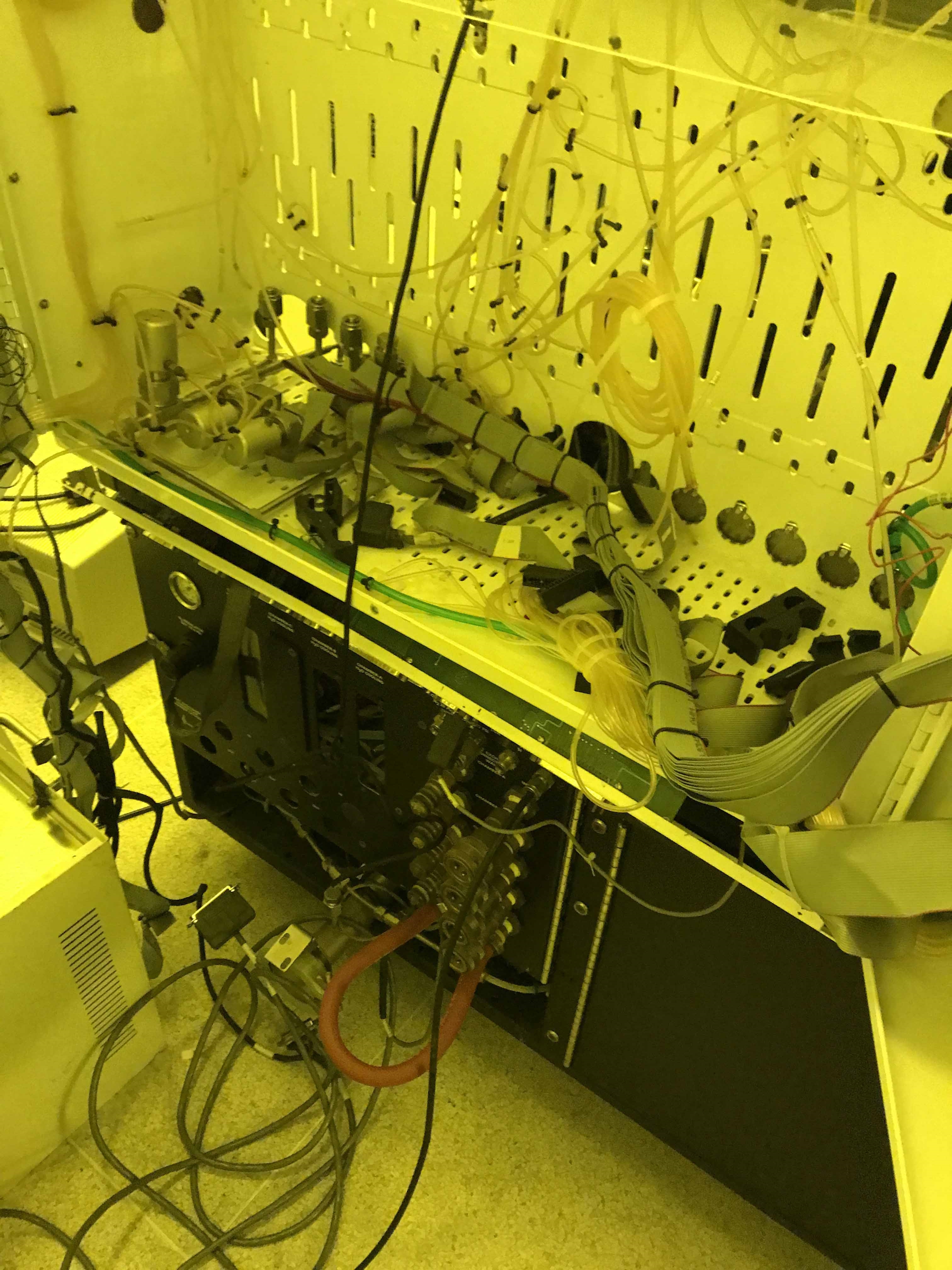

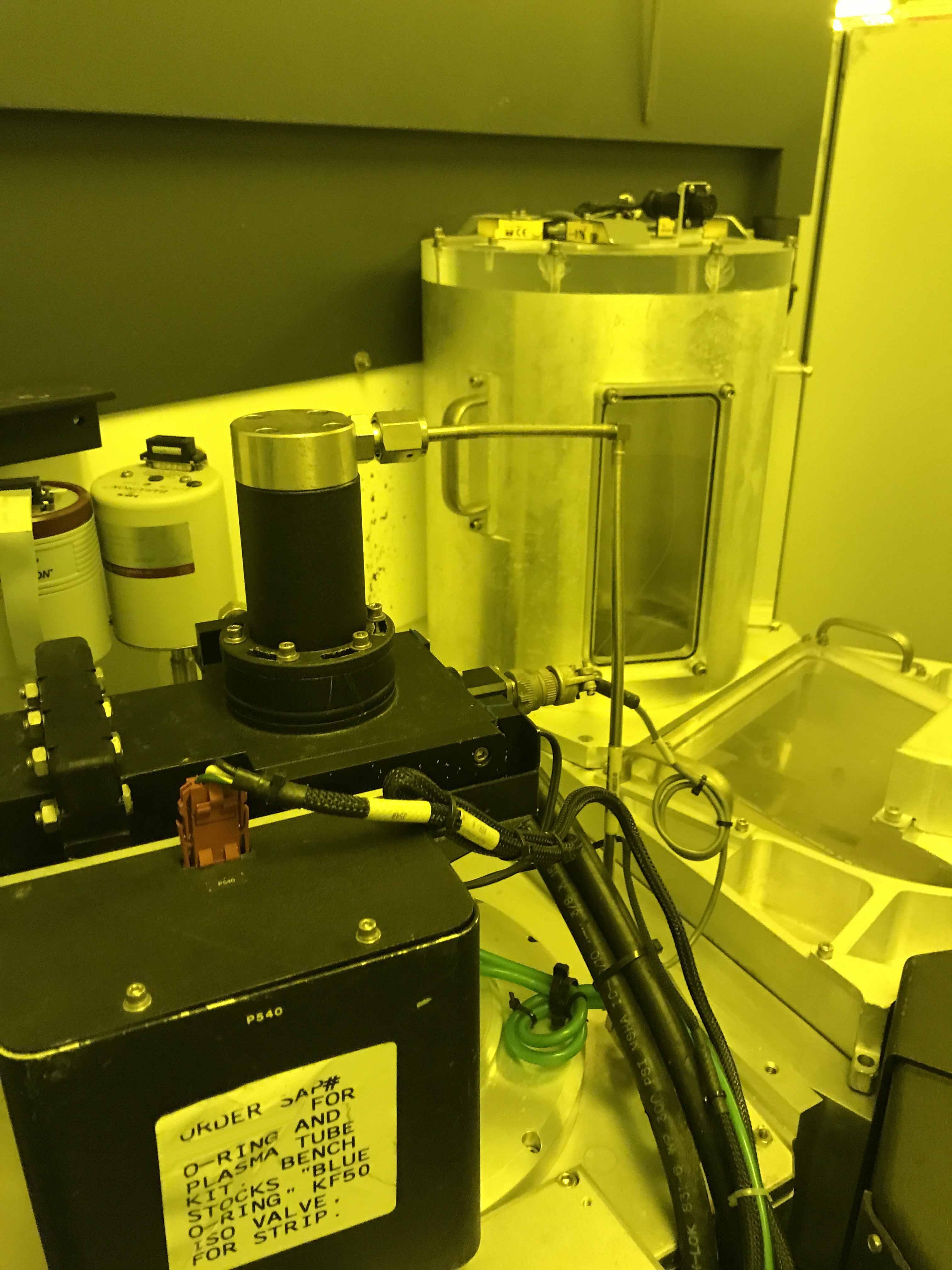

ASTEX Microwave power

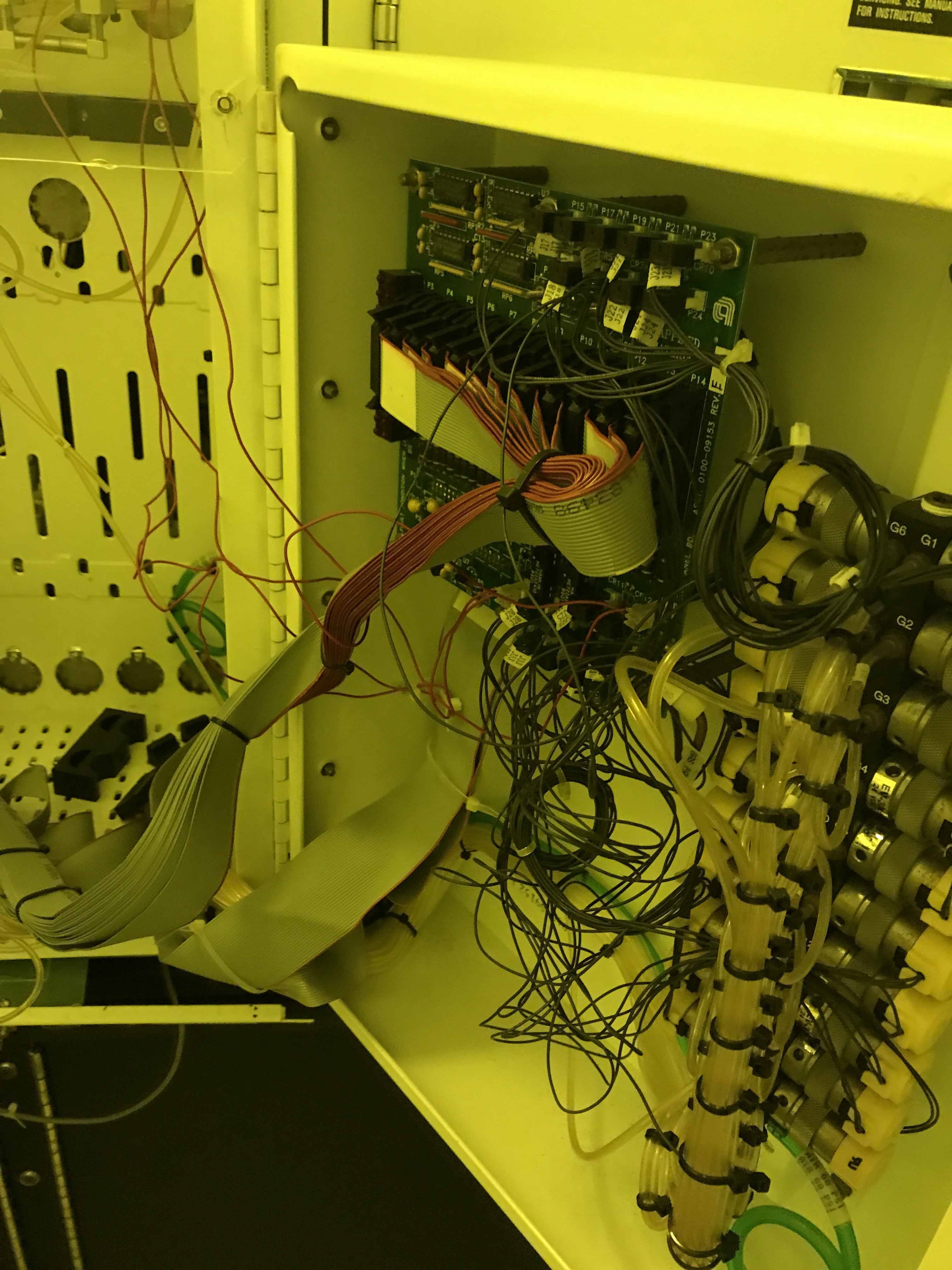

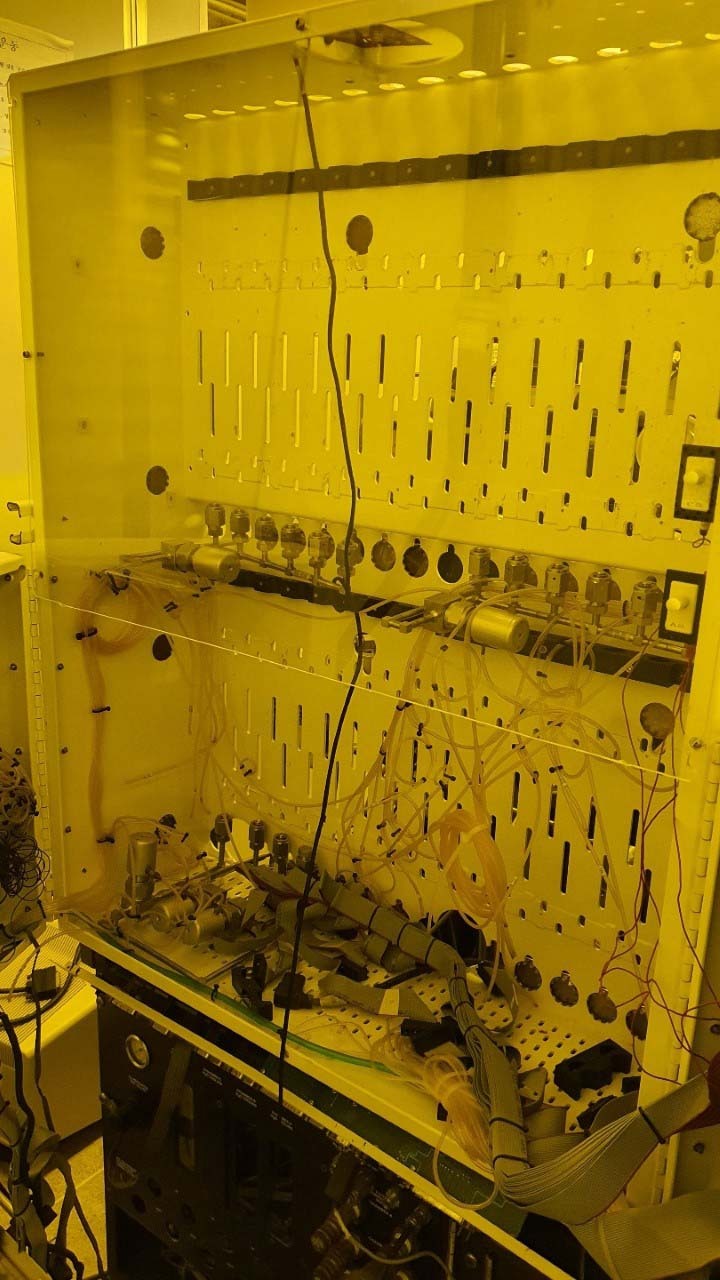

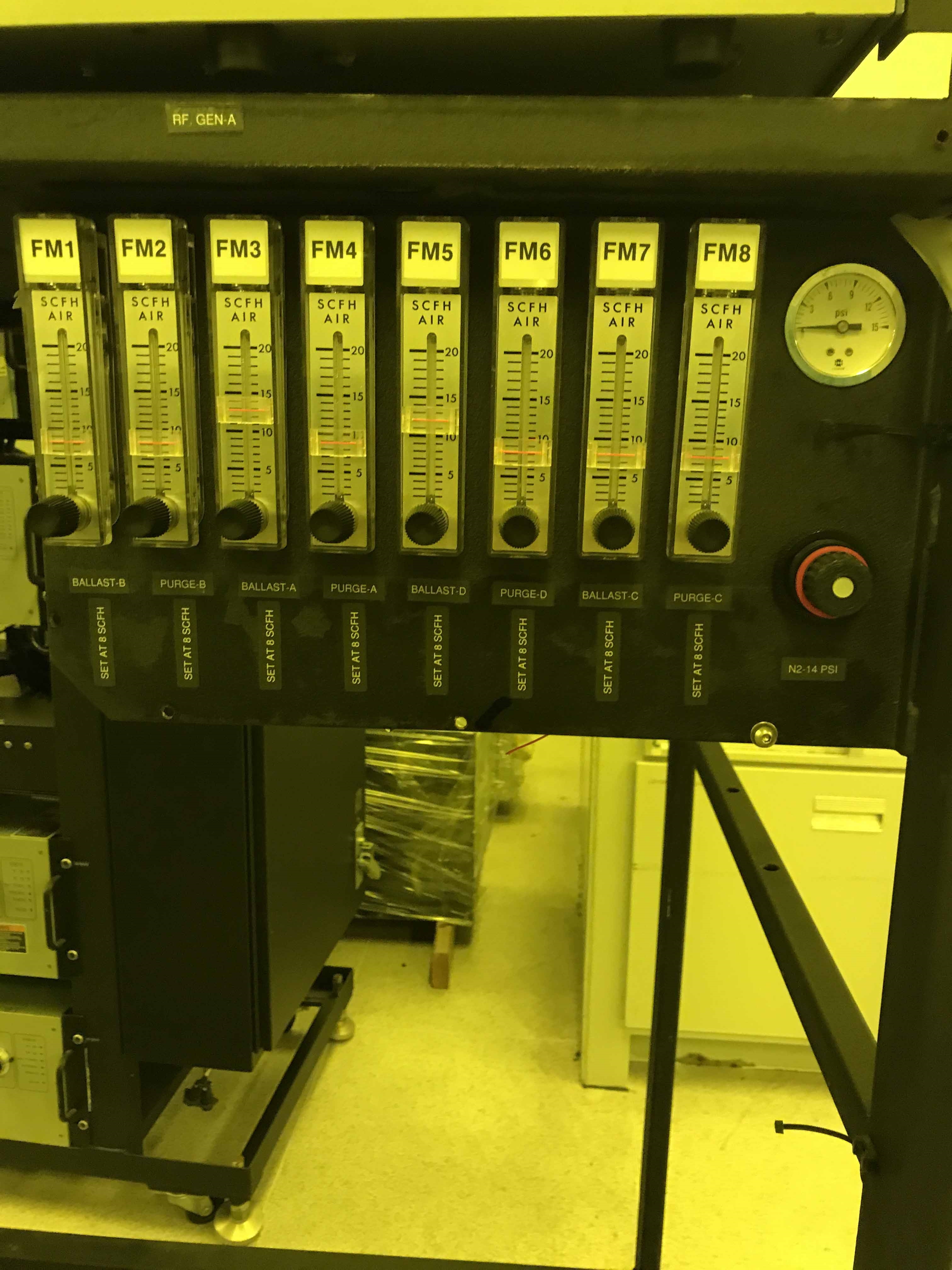

Gas lines

Hardware:

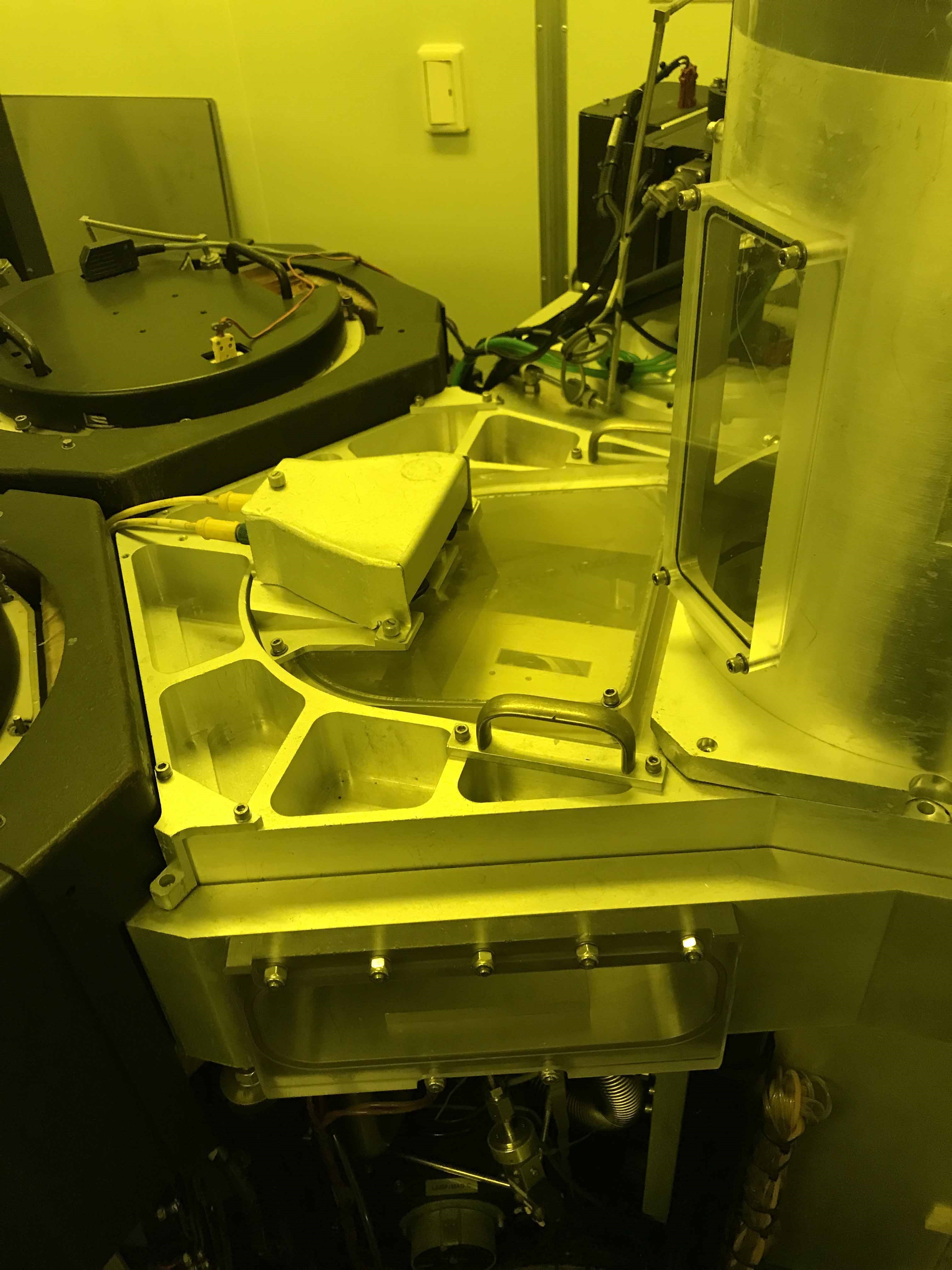

Main process modules:

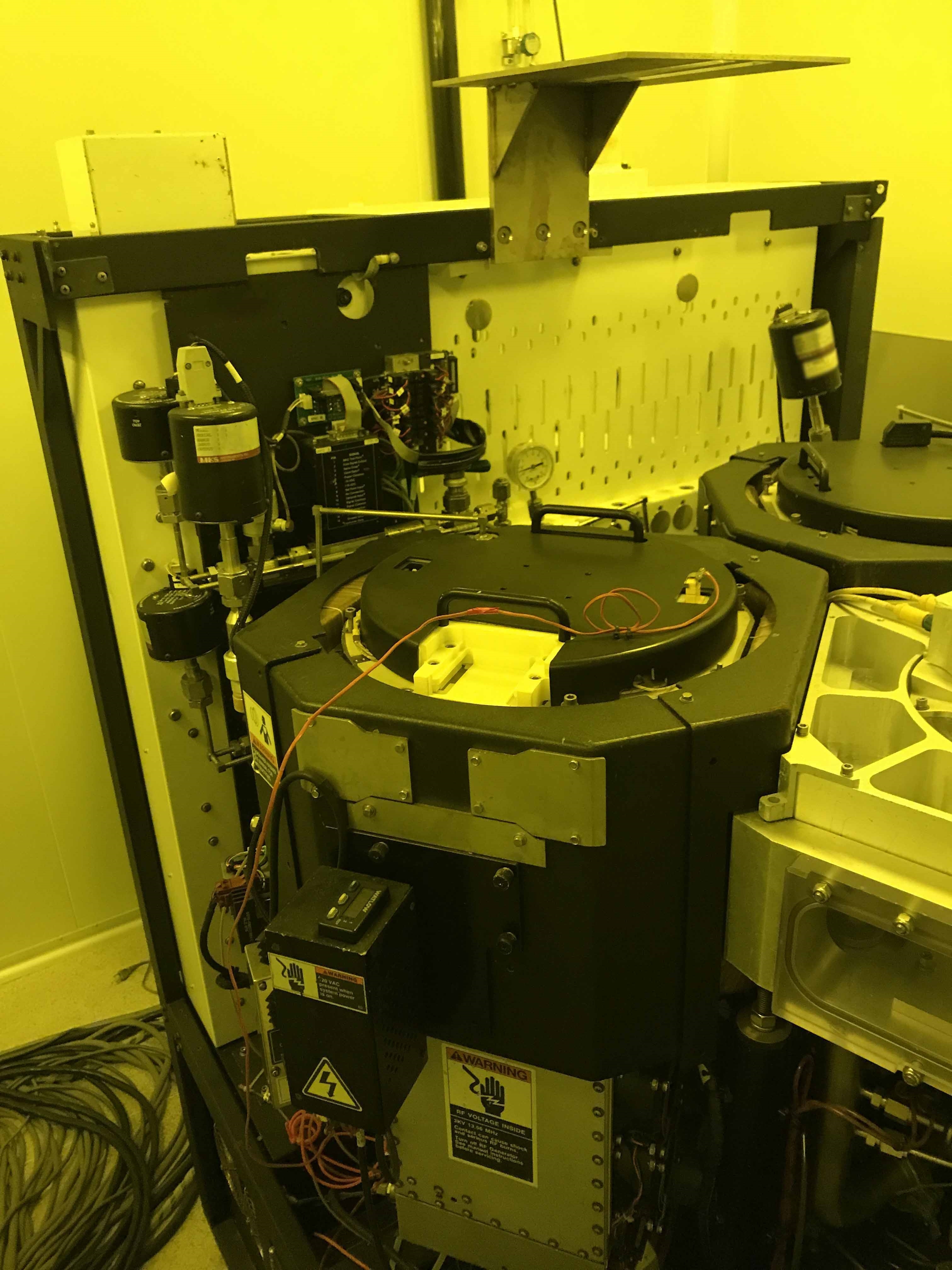

Chamber A

Metal etch B

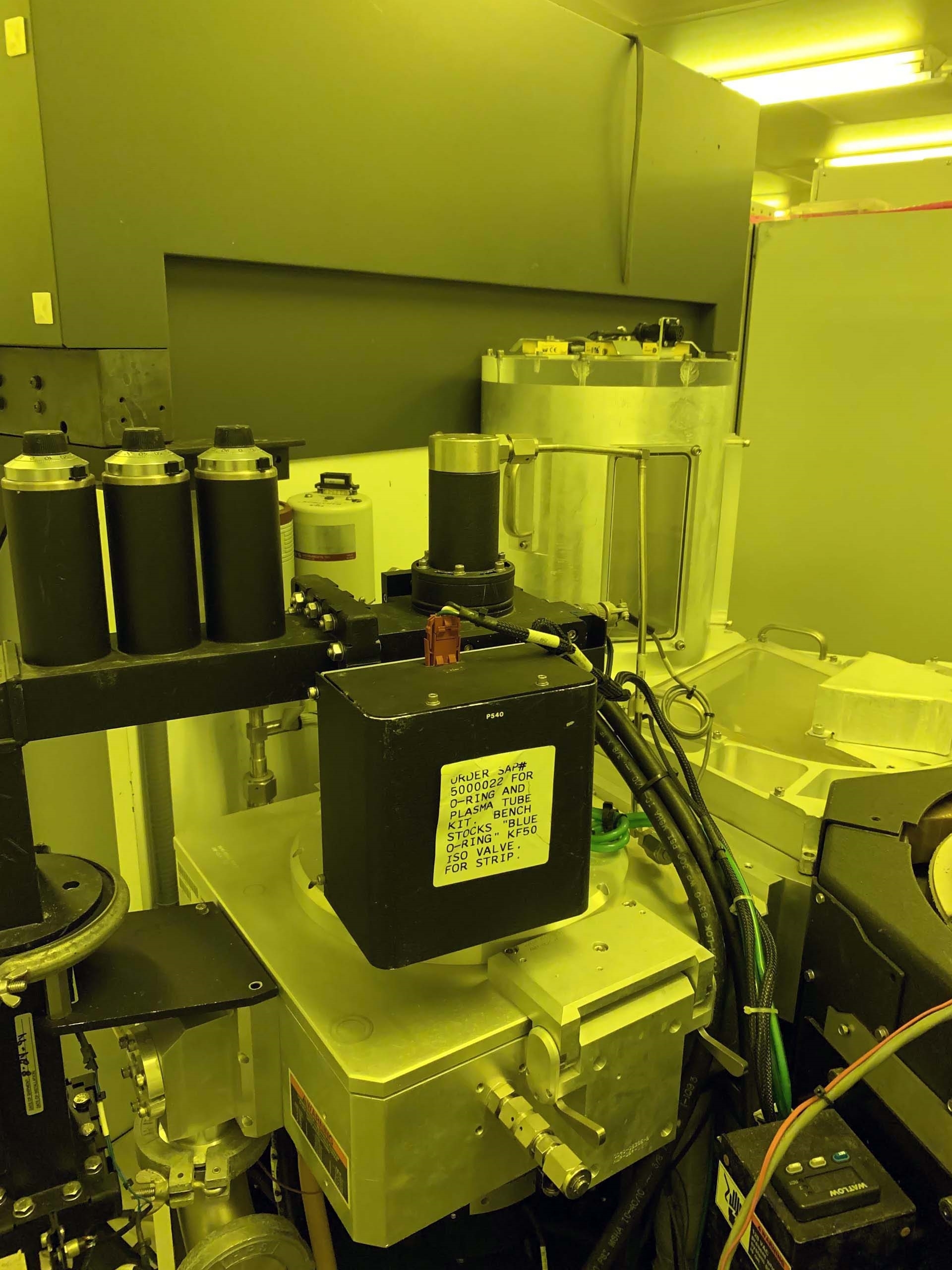

Strip D

Mark ll Main frame

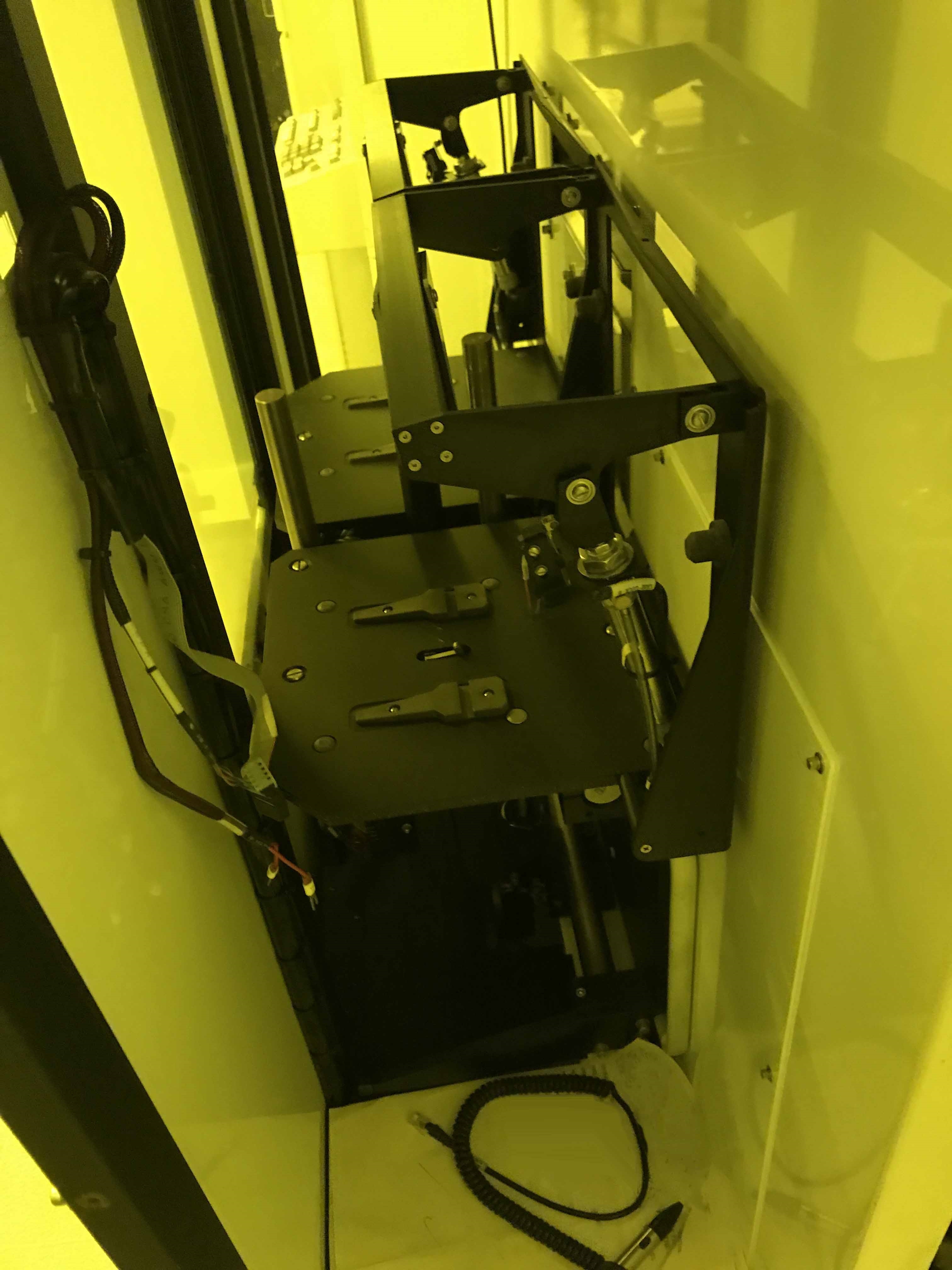

Storage elevator: 29 Slots

Independent helium cooling

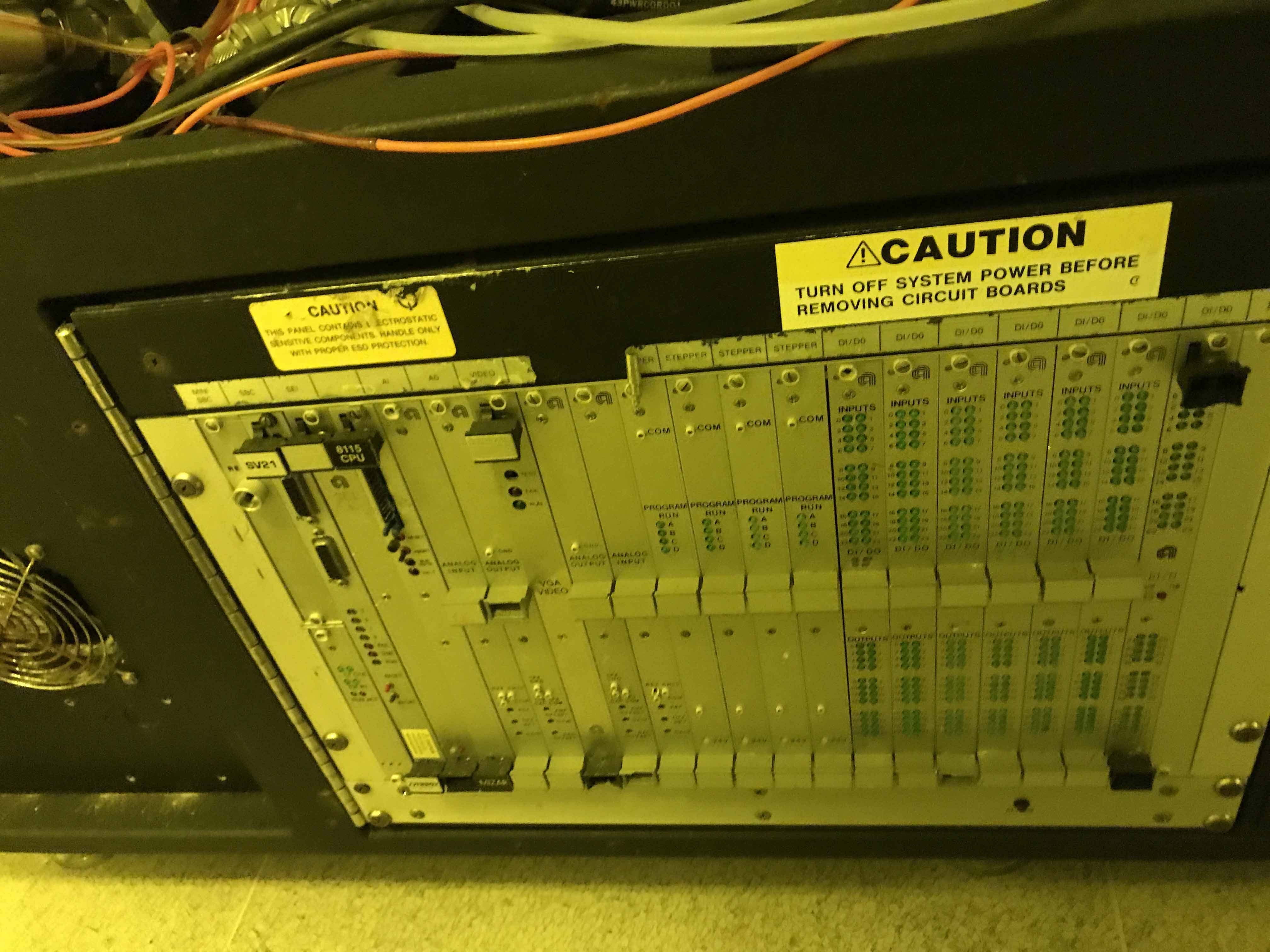

Expanded VME

Phase III robot

Phase II cassette

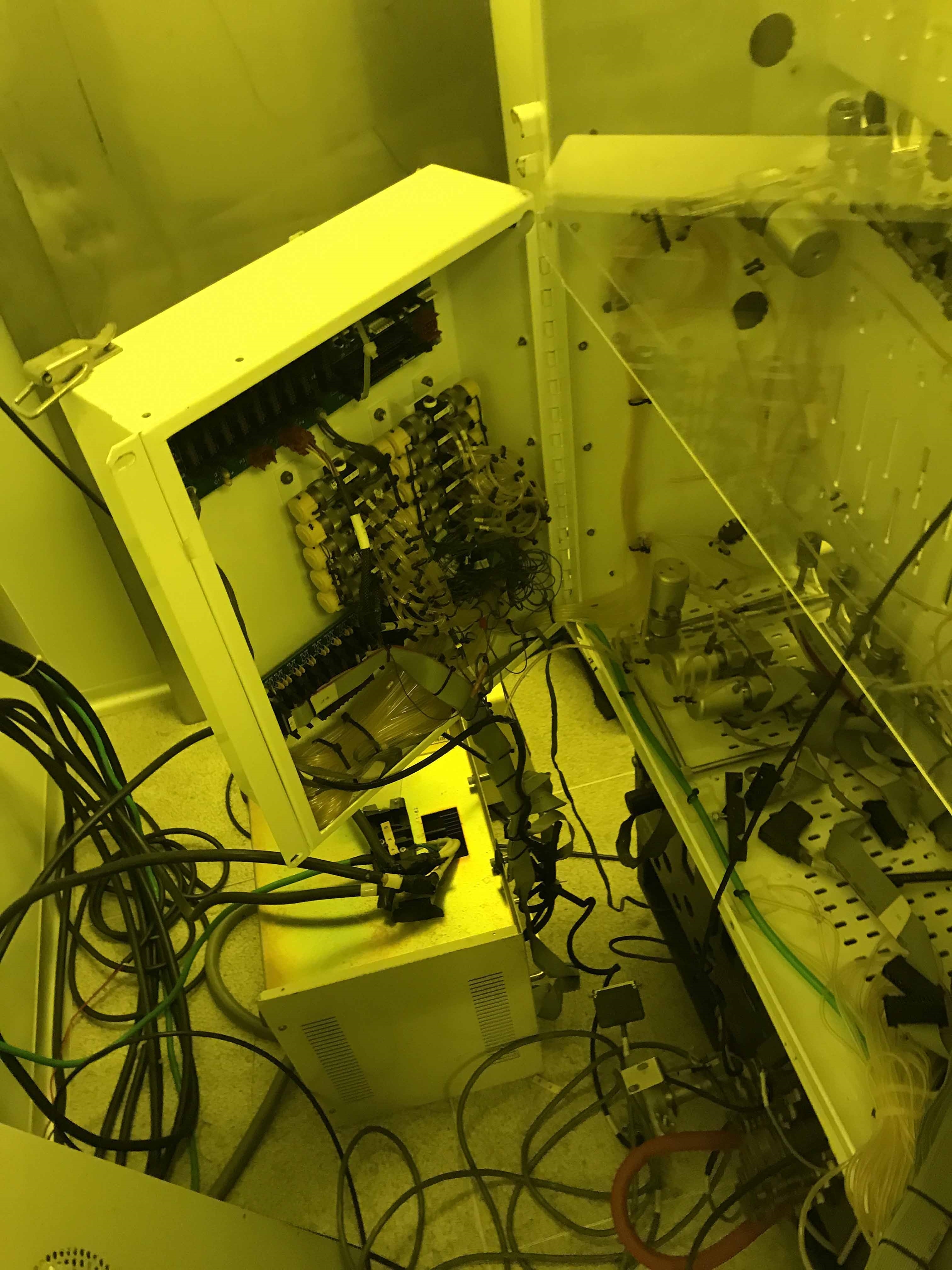

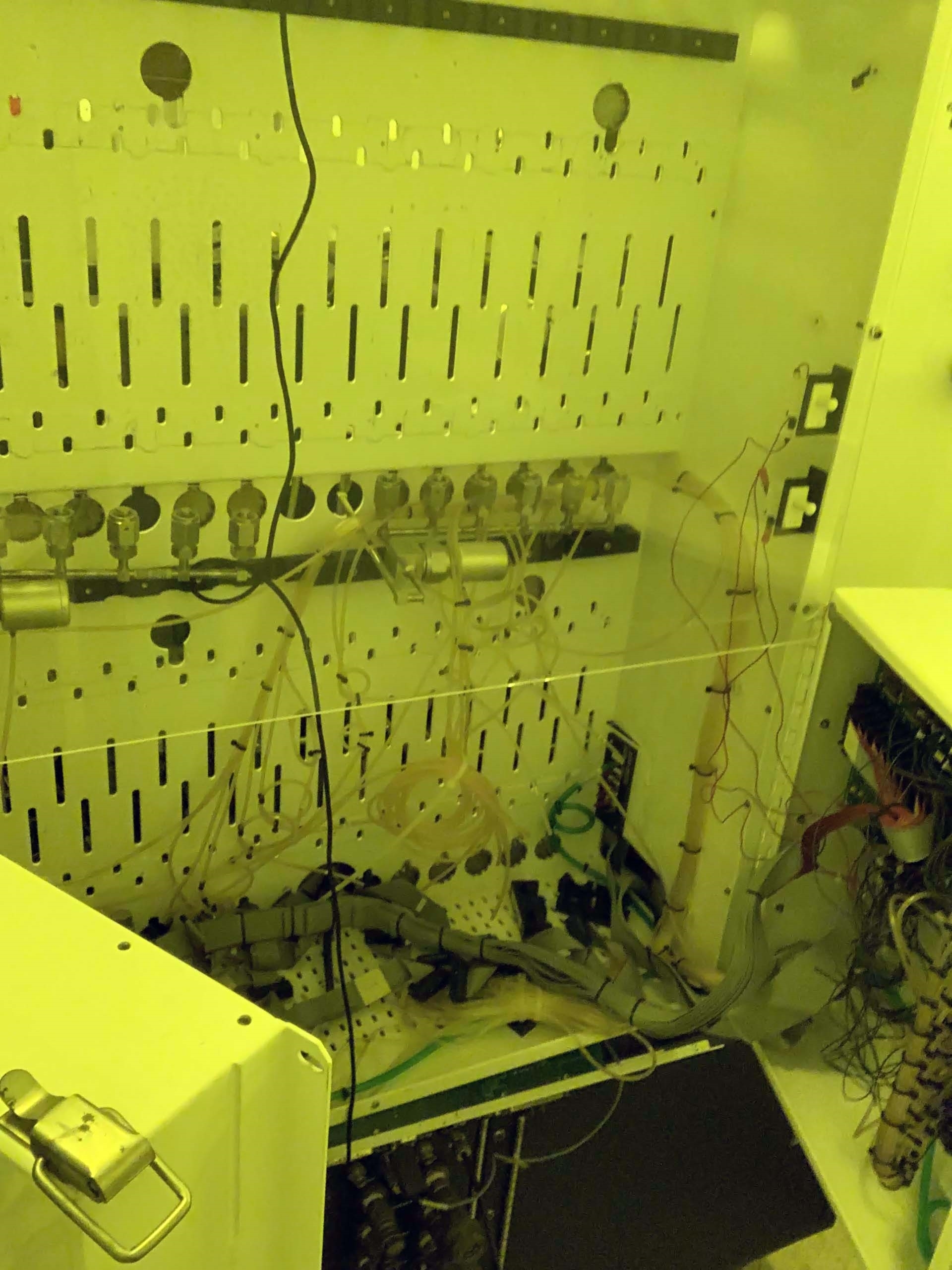

Sub modules:

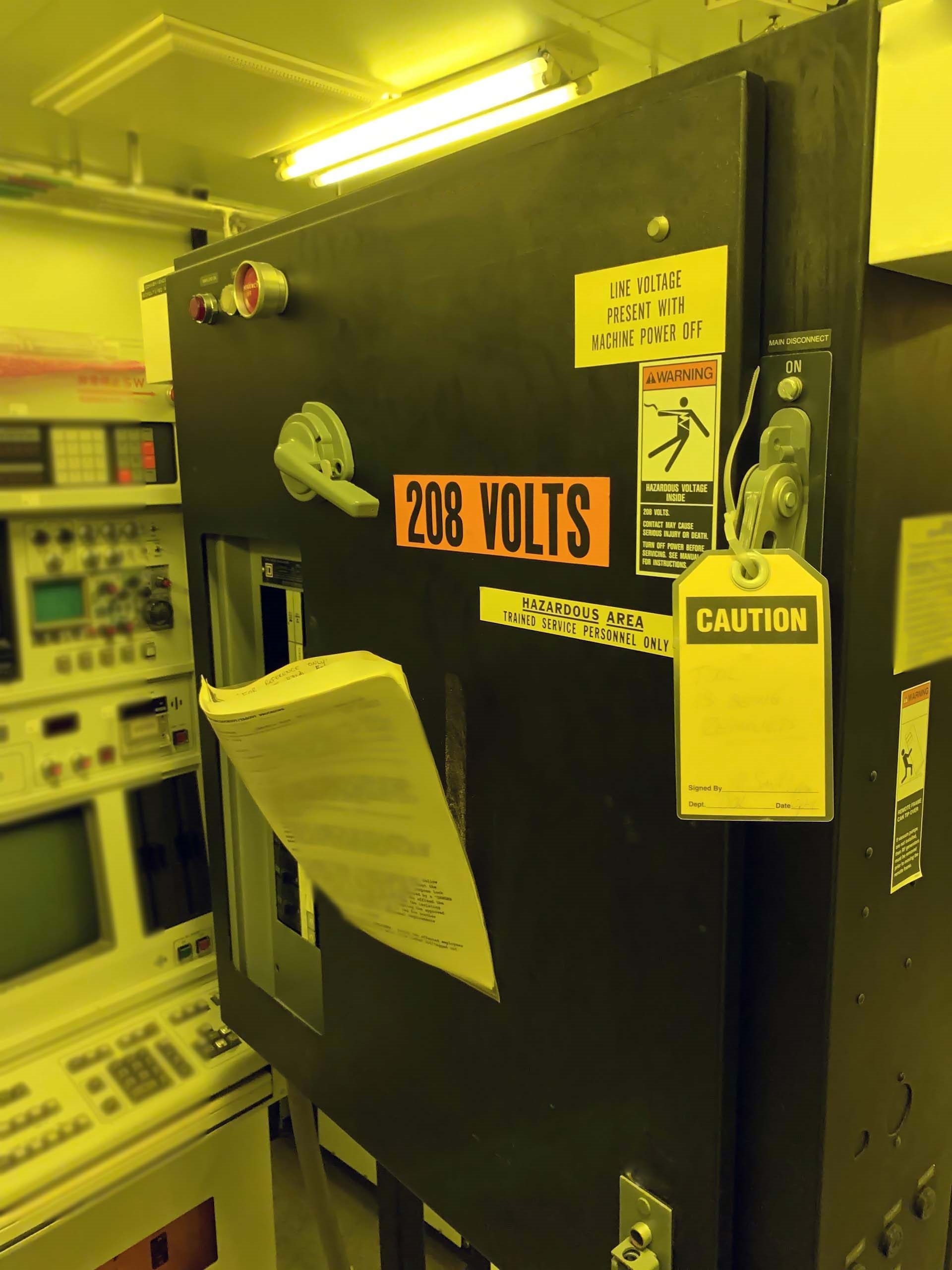

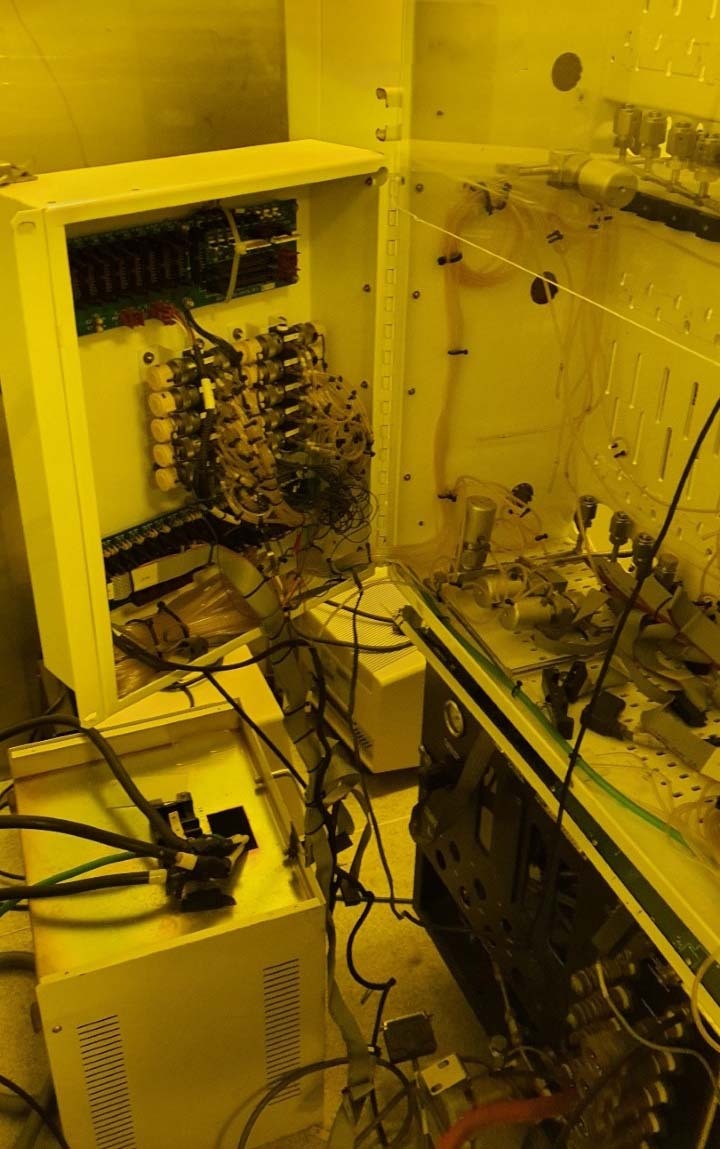

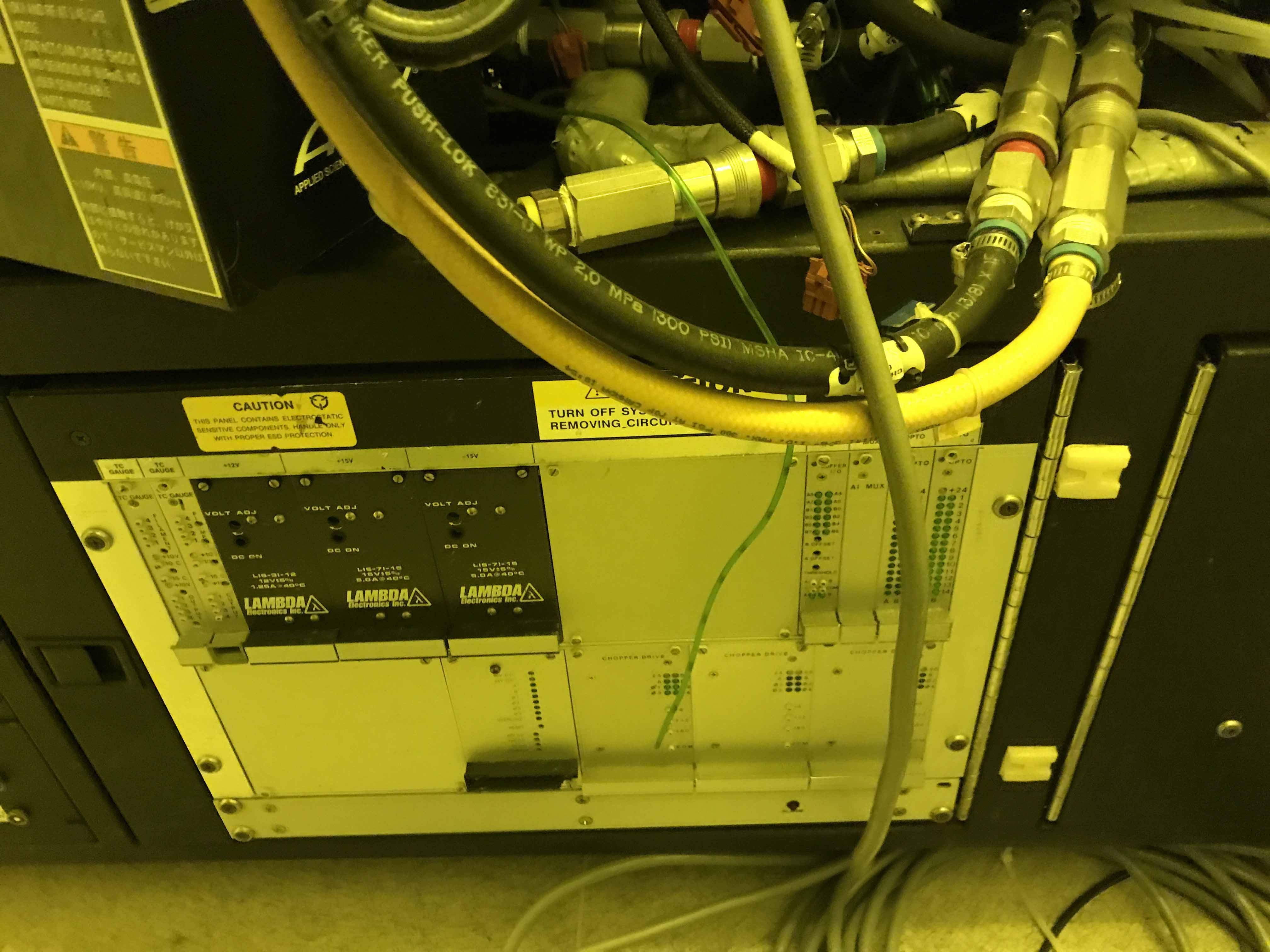

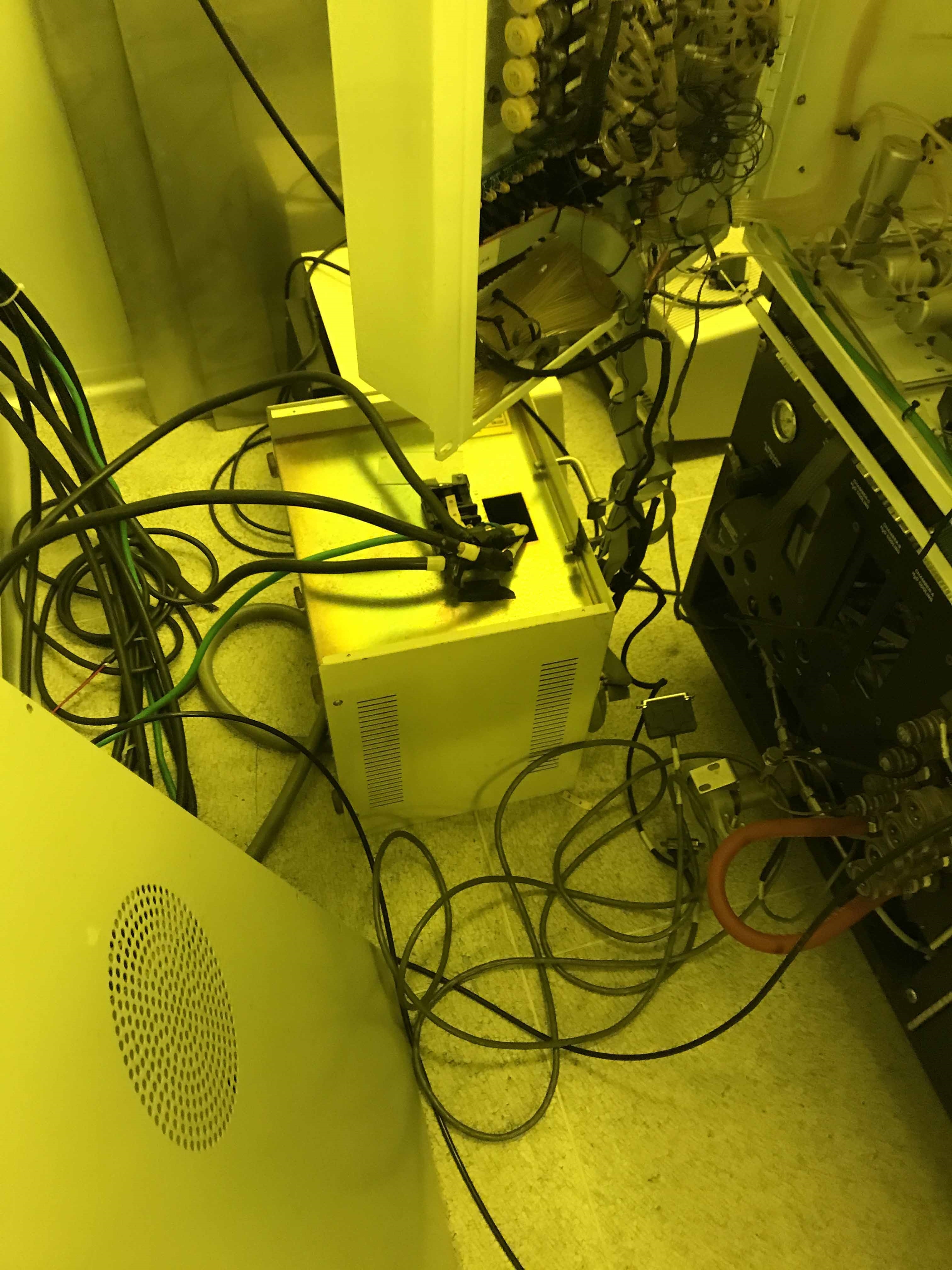

AC Remote frame

Digital cables

Analog cables

Emergency interlock cables

Heat exchanger

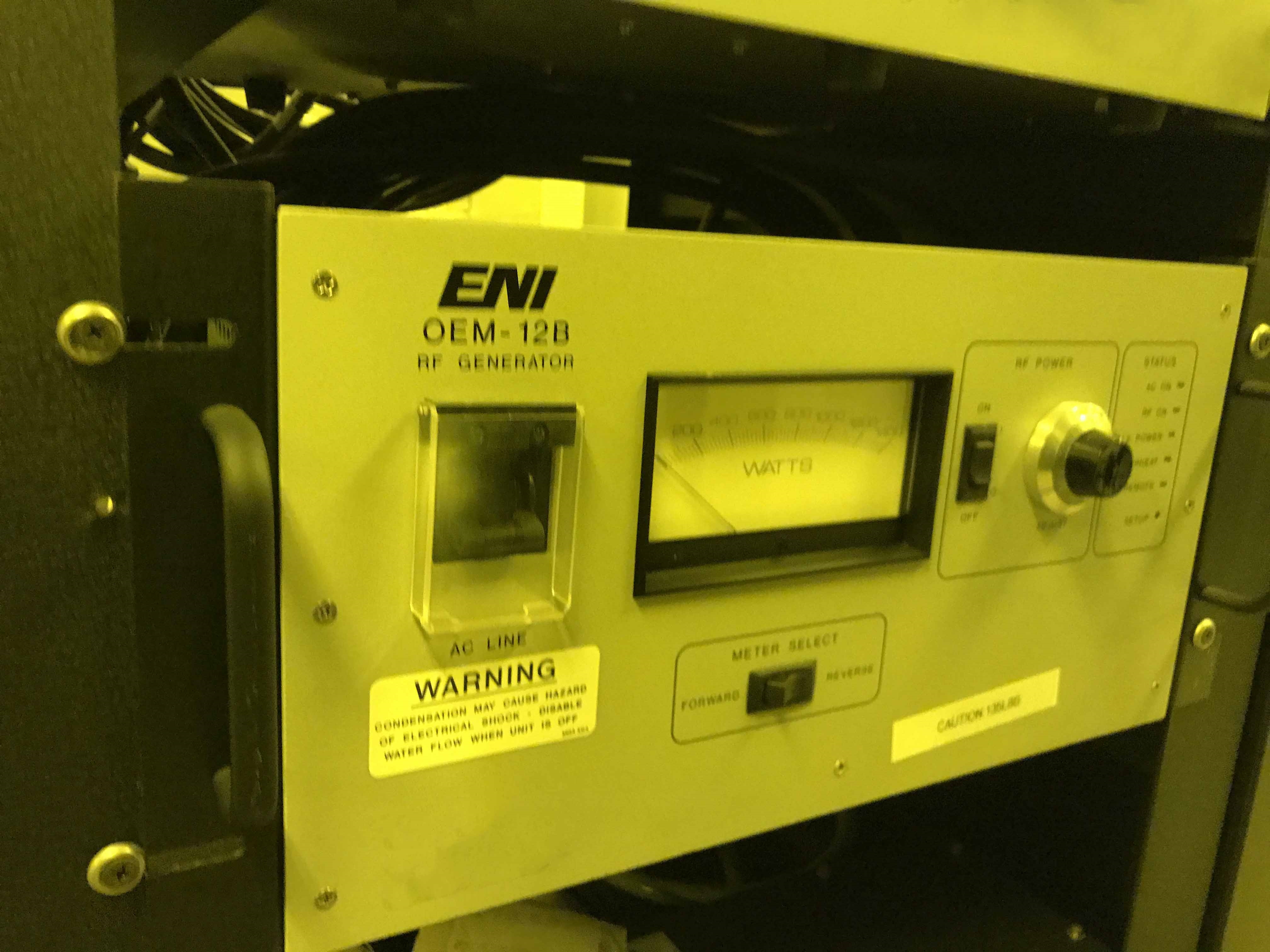

ENI OEM 12A RP Generator

ENI OEM 12B RP Generator

ASTEX Microwave

1995 vintage.

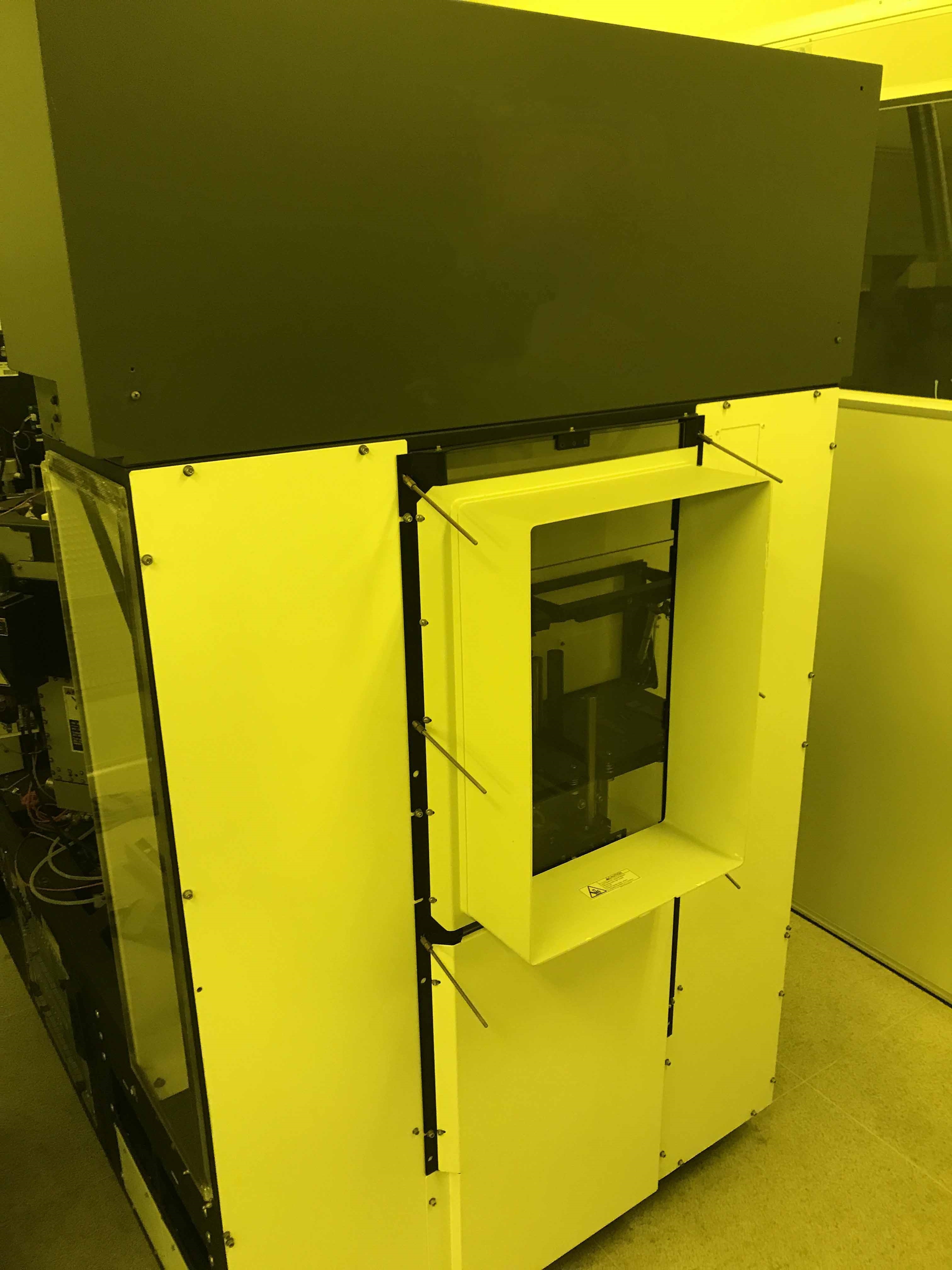

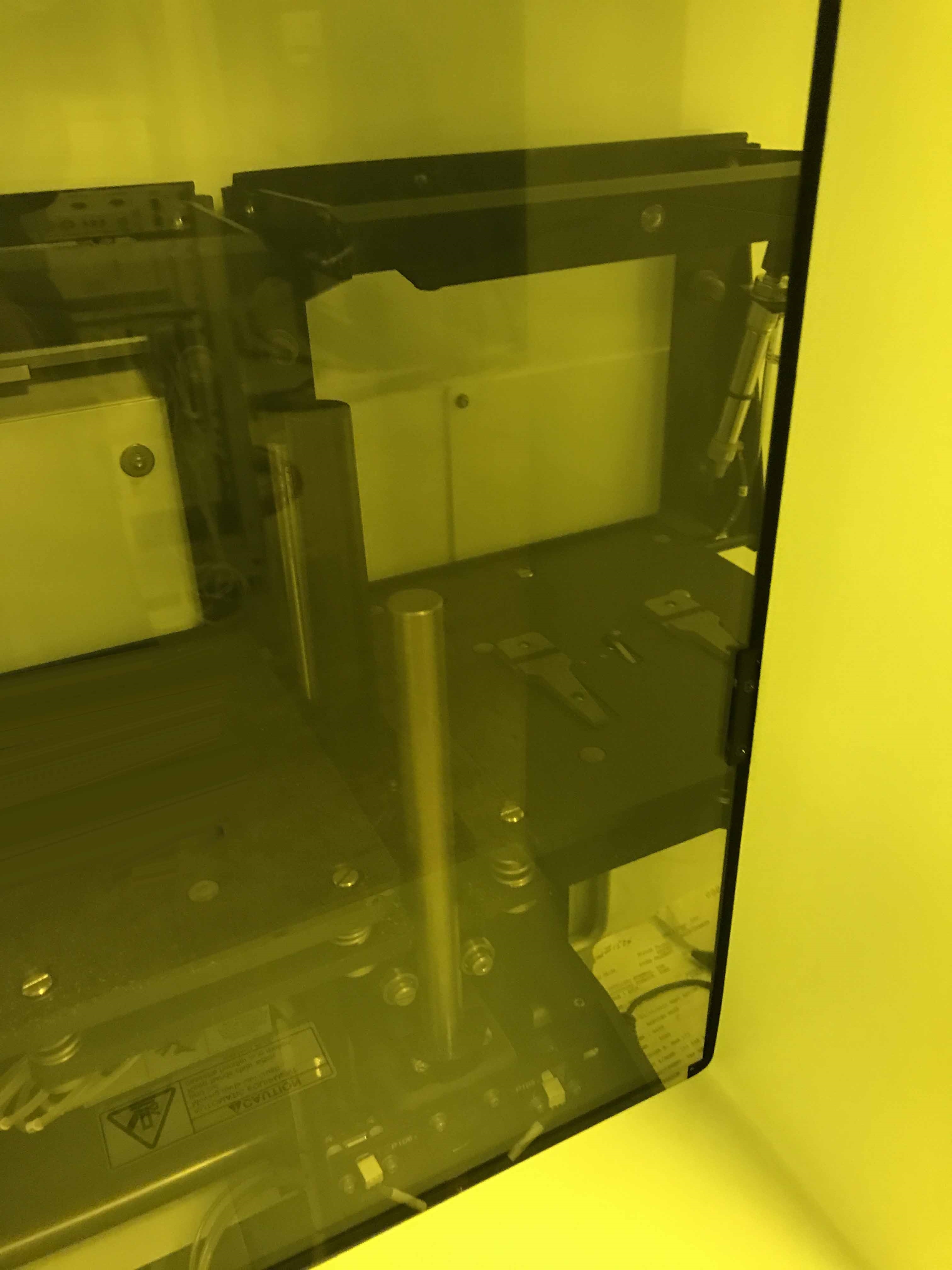

AMAT / APPLIED MATERIALS P5000 Reactor is a type of chemical vapor deposition (CVD) equipment developed by AMAT. This system is an advanced semiconductor deposition tool designed for high volume production. The reactor consists of several hardware components including a susceptor with wafer holders, a gas showerhead, a heater, and a gas delivery unit. The susceptor is a tall cylindrical chamber with a flat circular base, used to hold the wafer during the deposition process. Wafer holders are installed on the lid of the susceptor to arrange the wafers in a specified order. The gas showerhead is located inside the reactor. It is equipped with multiple nozzles which spray a specific quantity of the reactant gases from the delivery machine onto the wafer surface. A heater is included in AMAT P-5000 Reactor to control the temperature inside the reactor, allowing an accurate selection of reaction temperature and deposition rate. APPLIED MATERIALS P 5000 Reactor also includes an automatic gas delivery tool that provides the right mixture of gases at normal operating pressure. This asset also helps maintain a clean environment to prevent contamination of the wafer and the deposition process. Finally, P 5000 Reactor is equipped with a safety model which monitors the internal pressure, gas flow and temperature which ensures optimal deposition parameters and provides a safe working environment. The result of the CVD process in APPLIED MATERIALS P5000 Reactor is a high quality, consistent and uniform product. This equipment is ideal for manufacturers of semiconductor devices as it can handle high volume production and provide a high yield.

There are no reviews yet