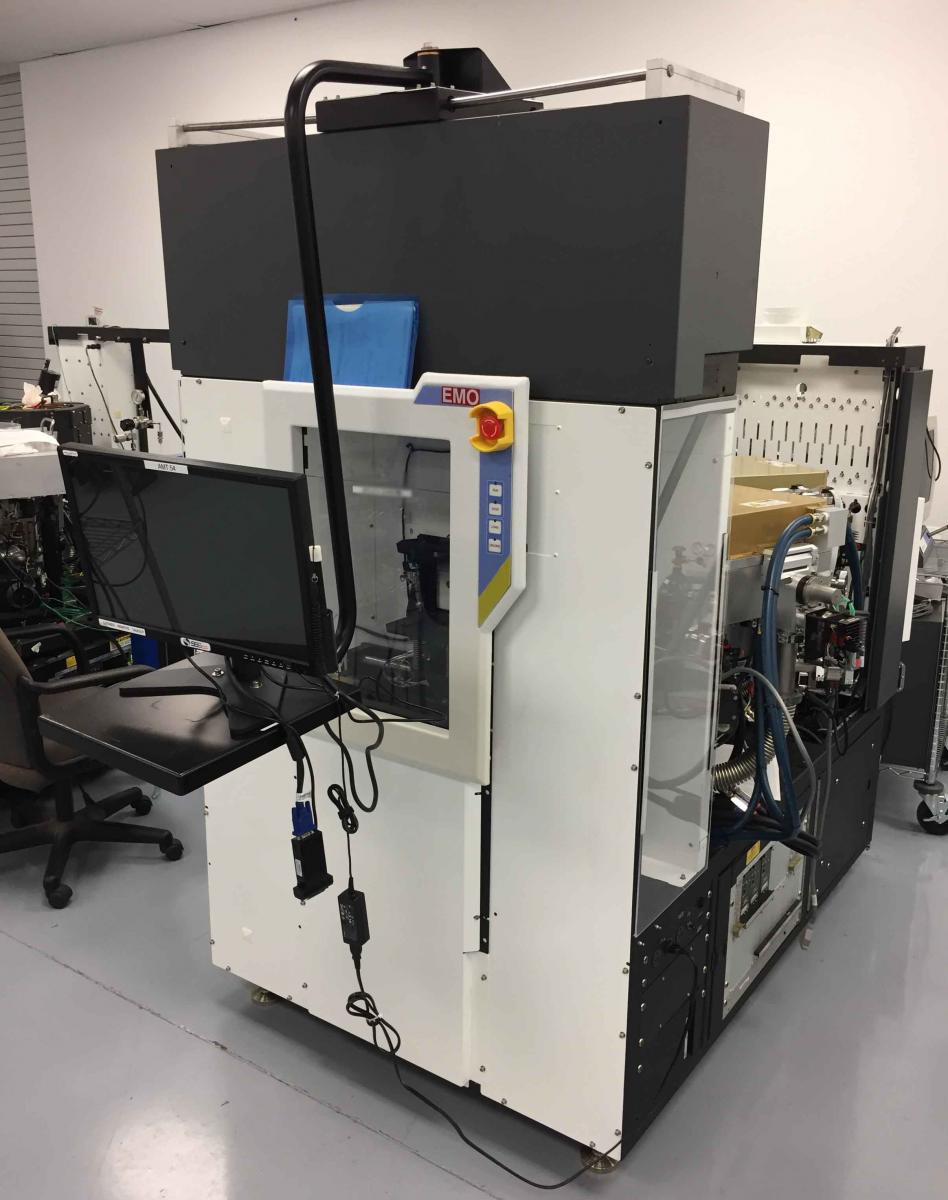

Used AMAT / APPLIED MATERIALS P5000 #9103153 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9103153

Wafer Size: 6"

CVD Nitride system, 6"

(4) Chambers

15 Slot storage elevator

Phase III robot

VAT ZA Style slit valves rectangular insert

Penulator flat screen monitor

Solid state hard drive

28 Slot gas panel

Mini controller with remote gas control

(28) Horriba STEC Z500 digital MFC’s

Modular AC rack

Load lock lid hoist

Chamber A,B,C,D:

Silane nitride giant gap chamber

Thick plate gas box with teflon insulator

Direct drive cluster throttle valve

Nupro gas valve, filter, manifold

MKS 627B Dual 10-100 torr baratron heated

Includes:

Lift hoop

Fingers

Susceptor

Not included:

RF Matches

Generator

Heat exchanger

Currently de-installed.

AMAT / APPLIED MATERIALS P5000 is a state-of-the-art research and development reactor which is used for production of ultra-thin silicon and other materials for electronic chip technologies. It is capable of producing device layers of less than 10nm and is suitable for fabrication of semiconductor devices, such as graphene and photovoltaics products. AMAT P-5000 utilizes a single wafer processing chamber, consisting of a short dielectric lining, and a number of powerful components, including heating element, gas evacuation equipment, and injector. The heating element is a resistive ceramic heat exchanger, capable of heating up quickly and maintaining stable temperatures. The gas evacuation system is designed to remove any unwanted gases, while the injector is used to inject process gases into the chamber. The chamber is supported by a power supply unit, which delivers continuous electrical power to the various components, while a gas purification machine is used to clean up the process gases. APPLIED MATERIALS P 5000 is designed to selectively etch silicon, metals and other materials through the application of radio frequency sputtering, or other energy- or charge-based processes. The reactor is able to achieve higher precision and finer patterns than traditional lithography-pattern-based processes, such as those used in chip fabrication. The reactor typically operates at plasma pressures between 0.5 and 5mTorr, and is capable of producing dielectric layers, metals, and other materials. AMAT P5000 supports a range of process parameters and options, such as temperature range, deposition time, and total process cycle time. This allows for the production of complex 3D microstructures and other intricate chip designs. The reactor is capable of producing a uniform surface for the application of electrical circuitry and back end processes, and is used in the microelectronics industry for fabrication of ultra-thin integrated circuits. P5000 has proven to be a reliable and efficient device, allowing users to achieve accurate, high-performance devices in a fraction of the time required by traditional lithography-based processes. With its fine-tuned control capabilities and superior performance, P-5000 has become an invaluable tool for researchers in the microelectronics industry.

There are no reviews yet