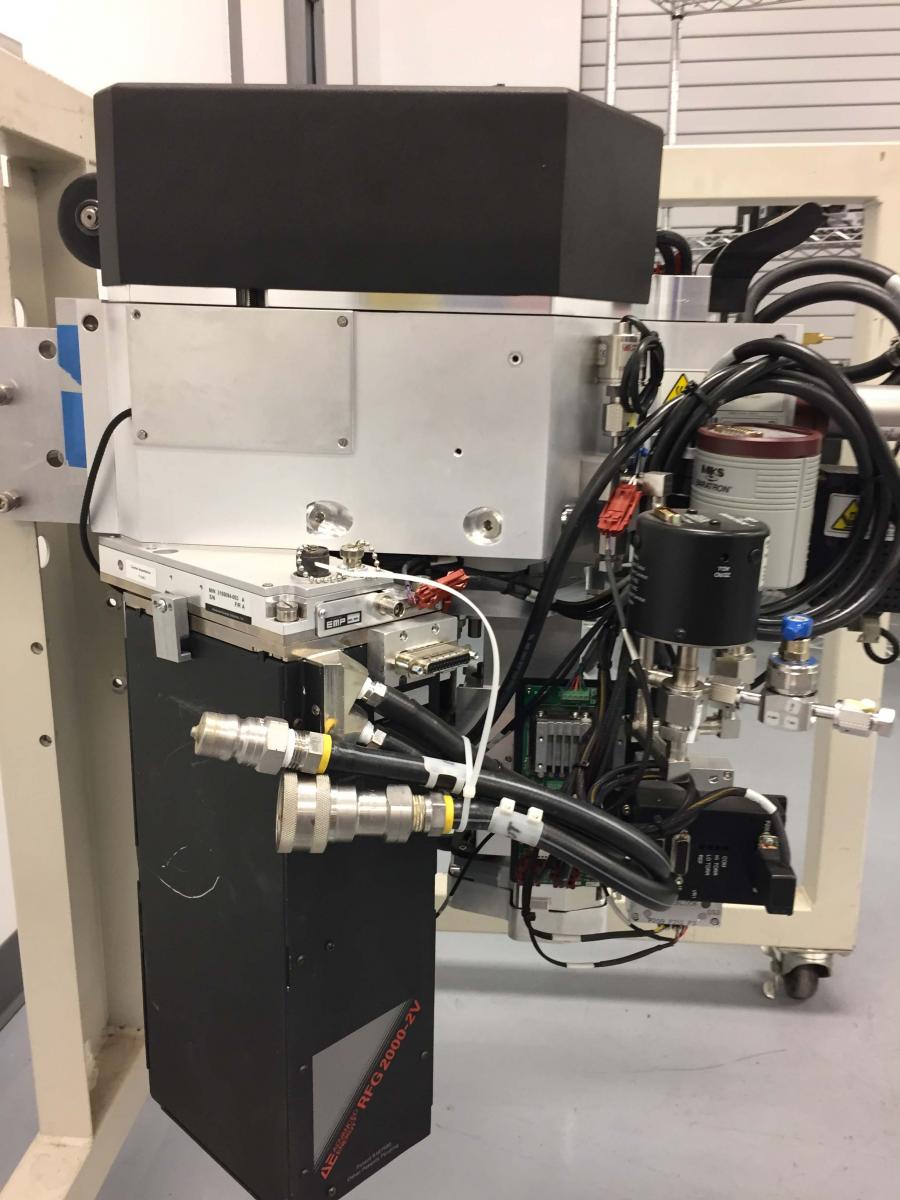

Used AMAT / APPLIED MATERIALS P5000 #9181885 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS P5000 is a silicon-based deposition equipment that is used to deposit thin films onto semiconductor substrate wafers. The system is designed specifically to meet the demands of advanced semiconductor manufacturing processes. The unit is capable of controlling the thickness, coverage and uniformity of the deposited thin films with unprecedented precision. AMAT P-5000 features the industry's highest vacuum performance and process control capabilities. The machine is outfitted with a robust capacitively-coupled plasma source, enabling optimal control of film deposition parameters. This plasma source works in tandem with the tool's advanced closed-loop control, allowing users to accurately and precisely regulate thin film parameters. In addition, APPLIED MATERIALS P 5000 includes pre-installed deposition recipes, and numerous pneumatic components are available to customize the asset operation and optimize thin film deposition. These components ensure that AMAT P5000 is consistently performing up to the highest standard. P5000 also features real-time in-situ monitoring, allowing users to quickly and accurately assess thin film formation and changes in deposition parameters from start to finish. Additionally, the model includes a corrosion shield, helping to extend the equipment's life span by protecting heaters and gas lines from contaminants. P-5000 operates at a maximum temperature of 1050 degrees Celsius and can accommodate substrates up to eight inches in size. Its standard chamber design accelerates throughput rates and reduces cycle times with a patented reticle pattern, which eliminates the need for extra equipment. Overall, AMAT / APPLIED MATERIALS P-5000 is a robust, reliable, and precise deposition system solution used to create thin films with exacting levels of accuracy. This unit's robust capabilities, efficient design and innovative features make it the ideal choice for any advanced semiconductor manufacture process.

There are no reviews yet