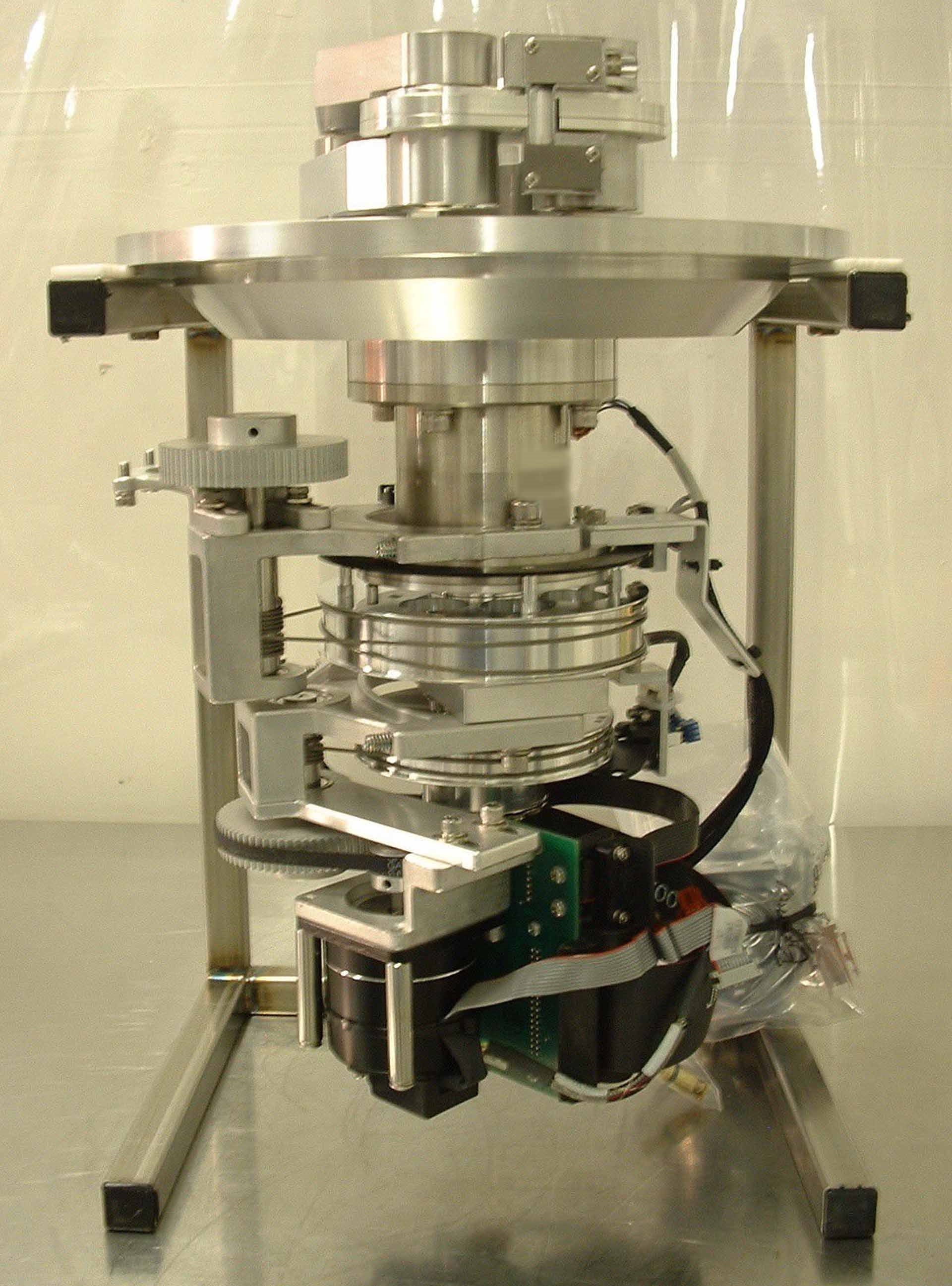

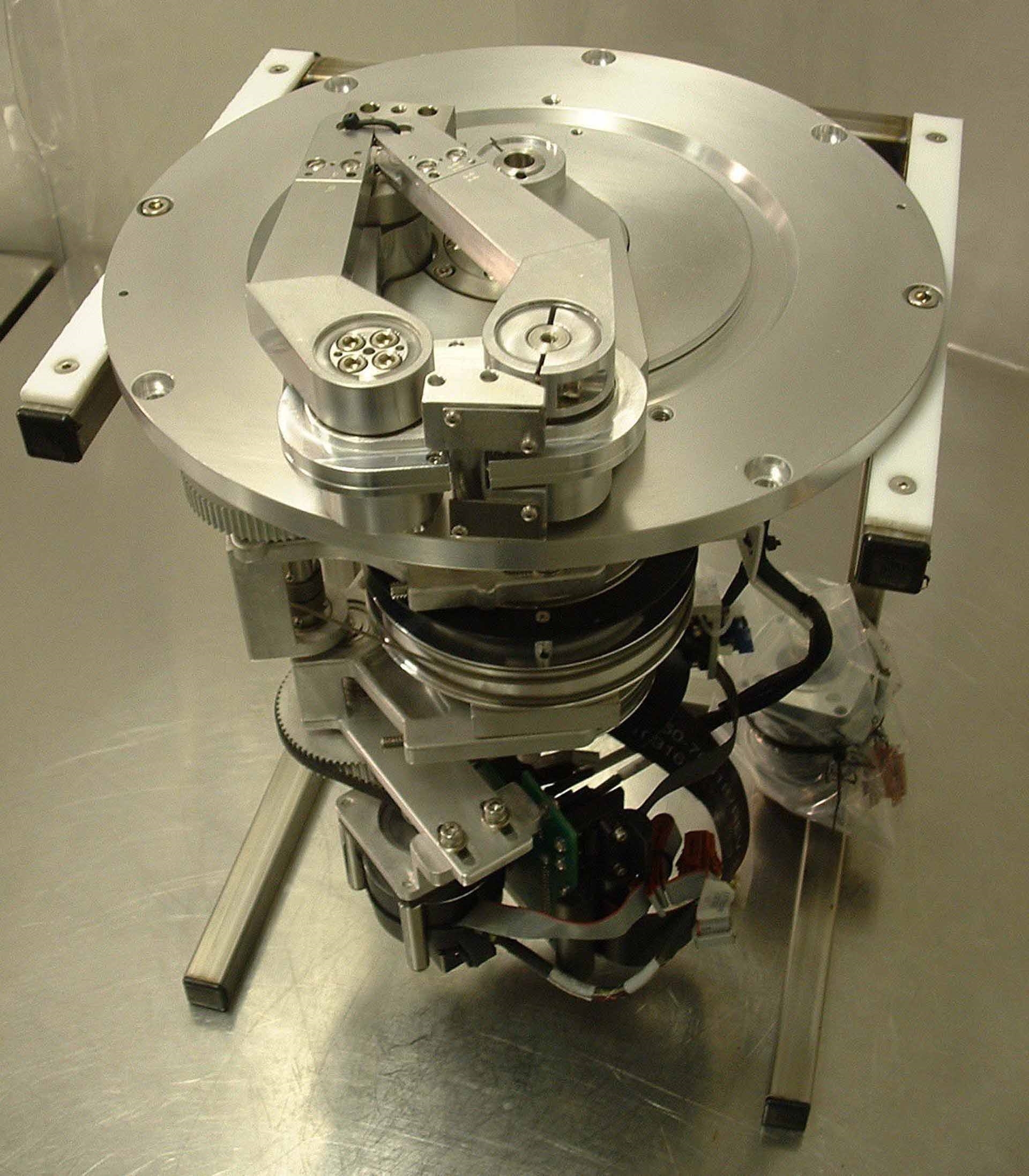

Used AMAT / APPLIED MATERIALS P5000 #9193401 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS P5000 reactor is a fully-integrated, multi-chamber etch equipment designed for a variety of applications, including advanced chip fabrication, memory device fabrication and solar cell manufacturing. The system is composed of three main components: AMAT P-5000 etch reactor, the PX nozzle and the outboard vacuum unit. APPLIED MATERIALS P 5000 etch reactor is equipped with advanced plasma and vacuum technology to provide precise control and uniformity of processing parameters. This reactor is configured with a tri-torus chamber design, which allows for efficient plasma generation and patterned etching processes. The overall chamber design also creates short and shallow process times, making the machine suitable for high-throughput applications. The tool also provides a range of processable gas and gas mixtures, allowing for the etching of a variety of material systems. The PX nozzle is the asset's primary delivery model for both etch and deposition processes. This arrangement provides a wide range of flexibility for process development and execution, allowing for the introduction of gases, mixtures and etch/deposition materials in a precisely controlled manner. This nozzle also performs temperature and pressure control, as well as reactor temperature monitoring and uniformity. This ensures that critical process conditions are maintained throughout the chamber. The outboard vacuum equipment is an external system equipped with throttling valves, pressure transducers, high-vacuum pumps, and other components. This unit is responsible for directly controlling the working pressure in the chamber, high-pressure gas introduction, loading and delivery of gases, and process support. This ensures fast, efficient and reliable processing of working substrates. Overall, AMAT / APPLIED MATERIALS P-5000 reactor is an advanced etch machine designed to precisely regulate the production of advanced electronic devices, memory devices, and solar cells. The tool provides a high degree of process flexibility, uniform processing parameters and fast, efficient operation. This asset thus provides a reliable and effective platform for the etching of a diverse range of material systems.

There are no reviews yet