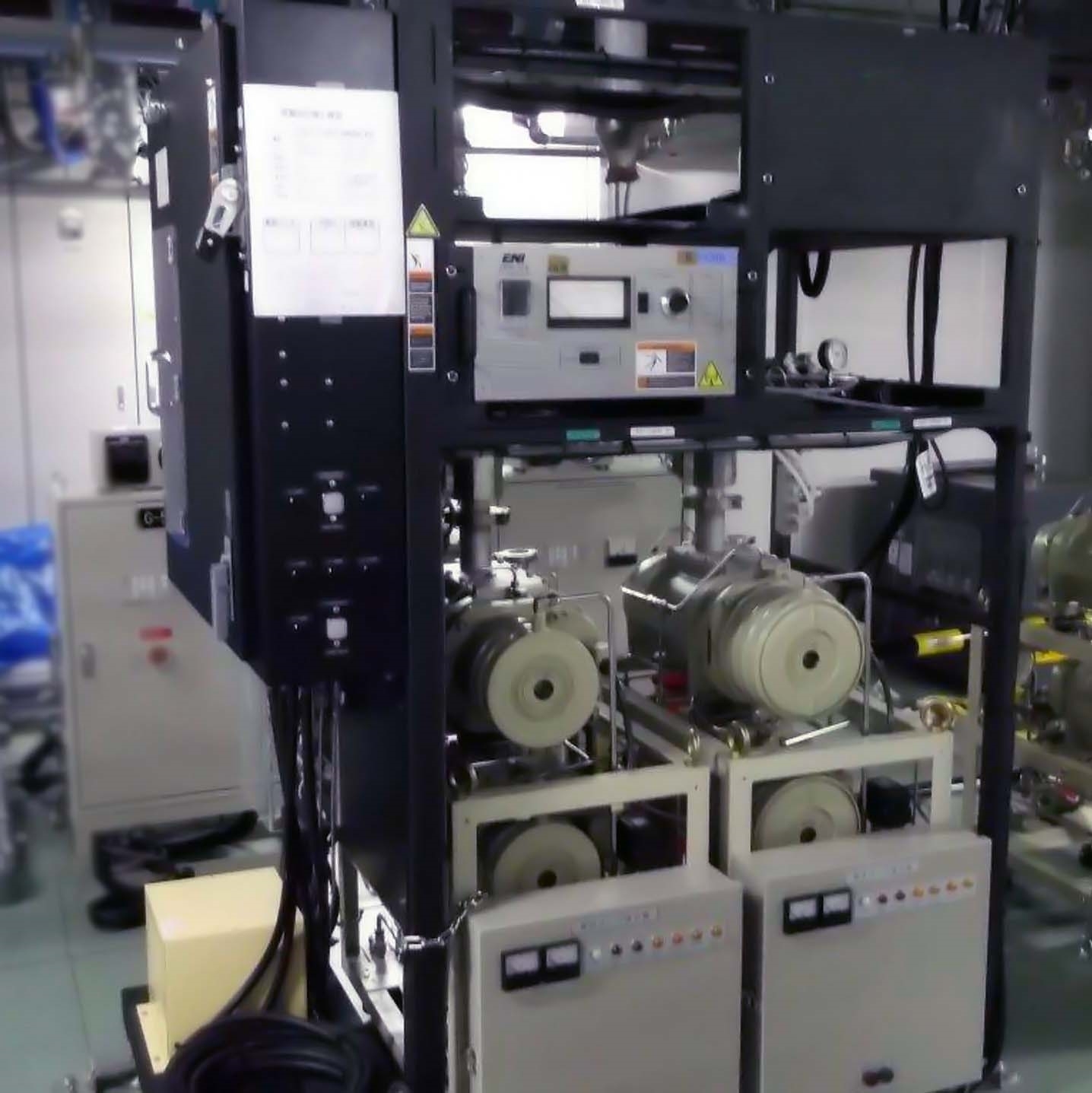

Used AMAT / APPLIED MATERIALS P5000 #9217907 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9217907

Wafer Size: 8"

Vintage: 1996

CVD System, 8"

Process: SIO

Process chamber:

Chamber A & B: SIO

Chamber D: ETCH

Chamber version:

Chamber A & B: VAT ISO Valve

Chamber D: Standard

RF Generator type:

Chamber A & B: OEM-12B

Dry pump type:

Chamber A, B, D & L/L: EBARA 50x20 UERR 6M-J

Throttle valve type:

Chamber A, B & D: Non heated

VME System:

20 Slots

CPU: Synergy

Video: VGA

SEI

AI

AO

(4) DI/DO

(4) Steppers

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD), 3.5"

Manometer type:

Chamber A & B: MKS 122B 11441

Chamber D: MKS 127

RF Matching box type:

Chamber A & B: 0010-09750D DR

Chamber D: 0010-09416

Turbo pump type:

Chamber D: LEYBOLD NT340M

System electronic type:

(2) TC Gauges

Buffer I/O

AI MUX

(2) OPTO

(4) Choppers

+12VPS

+15VPS

-15VPS

Storage elevator: 8 Slots

Cassette handler: Phase III, Top clamp

Robot: Phase III

Blade: Phase III

I/O Wafer sensor

Load lock purge

Heat exchanger:

AMAT0:

Connect to chamber A, B & D: Wall / LID

Main frame front type: Through-the-wall

Standard remote frame

TC Gauge type:

Chamber-A Rough: VCR

Chamber-B Rough: VCR

Chamber-D Rough: VCR

L/L Rough: VCR

L/L Chamber: VCR

Lamp module type:

Chamber A & B: STD 0010-09337

Mini-con

Magnet driver type:

Chamber A & B: P/N 0015-09091

Chamber D: P/N: 0015-70060

Signal tower

Gas panel type: (28) Gases

MFC Type (Main):

Chamber / Flow Gas / Flow size / Calibration gas / Maker / Model

B / SIH4 / 500 / N2 / STEC / SEC-4400

B / N2 / 5000 / N2 / STEC / SEC-4400

B / CF4 / 5000 / N2 / STEC / SEC-4400

B / N2O / 300 / N2 / STEC / SEC-4400

A / SIH4 / 500 / N2 / STEC / SEC-4400

A / N2 / 5000 / N2 / STEC / SEC-4400

A / CF4 / 5000 / N2 / STEC / SEC-4400

A / N2O / 300 / N2 / STEC / SEC-4400

D / O2/ 100 / N2 / STEC / SEC-4400

D / CF4 / 500 / N2 / STEC / SEC-4400

D / AR / 100 / N2 / STEC / SEC-4400

MFC Type (Remote):

Chamber / Flow Gas / Flow size / Calibration gas / Maker / Model

A / NF3 / 1000 / N2 / STEC / SEC-4400

A / N2O / 3000 / N2 / STEC / SEC-4400

B / NF3 / 1000 / N2 / STEC / SEC-4400

B / N2O / 3000 / N3 / STEC / SEC-4400

1996 vintage.

AMAT / APPLIED MATERIALS P5000 is a full-featured automated processing tool designed for high-volume semiconductor manufacturing. It is precision-engineered for superior performance and offers a range of process recipes and configurable capabilities for maximum versatility. AMAT P-5000 provides a powerful processing chamber that can handle a large volume of substrates with higher throughput. It has a five-zone cassette-style loadlock and substrate transfer equipment that ensures stable thermal cycling and repeatable process conditions. The system also offers digital and analog loadlock sensors for monitoring temperature, pressure, and other environment parameters. The reactor has an enhanced automation platform that provides integrated DataBoss and Primus software to simplify programming and equipment management. DataBoss Explorer software provides advanced optics and ergonomic features to quickly configure recipes and optimize process results. Primus software allows users to preset recipes and access multiple process controllers to optimize recipe progression and substrate throughput. APPLIED MATERIALS P 5000 is equipped with a Suite 200 ultra-high-vacuum cluster station that offers rapid cycle times and excellent control accuracy. The unit is also provided with a VacGenEx dual-gun, single-liner deposition capability that provides superior deposition quality and throughput. AMAT / APPLIED MATERIALS P-5000 features a wide range of plasma technologies, including inductively coupled plasma (ICP), radio frequency (RF) bias, microwave plasma, and remote-plasma-source plasma. All of these plasma technologies are designed to increase process flexibility and yield. The machine also has integrated heating and cooling capabilities for precise temperature control. APPLIED MATERIALS P5000 can void process gases for maximum maintenance cost savings and supports up to eight reactors for enhanced throughput capabilities. It is compatible with a variety of substrates and substrates types, including crystalline silicon, GaAs, and glass. AMAT P5000 is equipped with integrated safety features, including Argon gas pressure monitoring, inertial sensors, and anti-static grounding systems. It also comes with advanced reporting and analysis capabilities to empower users to quickly analyze data and identify performance trends that may affect device yields.

There are no reviews yet