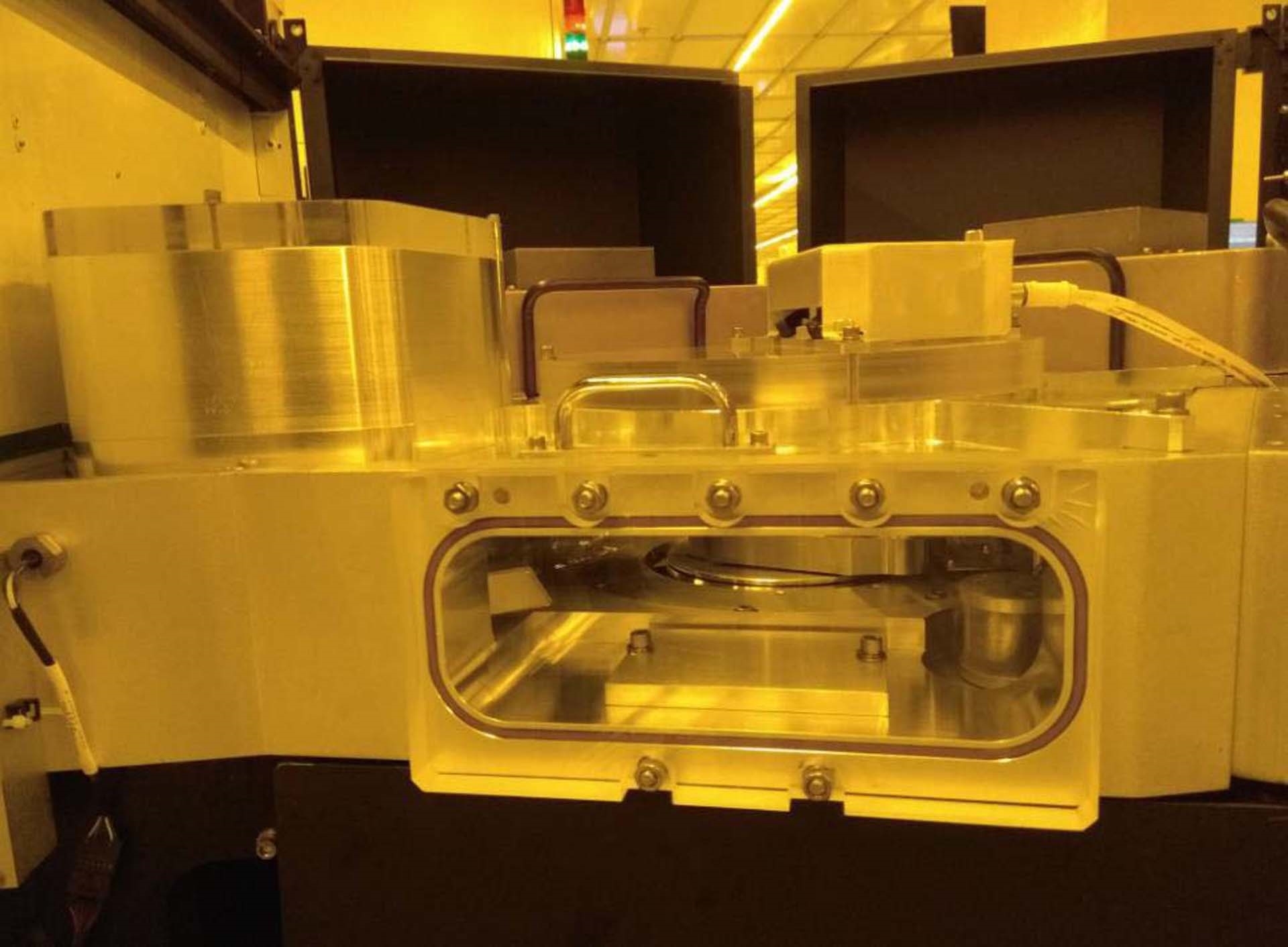

Used AMAT / APPLIED MATERIALS P5000 #9236969 for sale

URL successfully copied!

Tap to zoom

ID: 9236969

Wafer Size: 8"

Vintage: 1998

PECVD System, 8"

Process: Passivation

Chamber type: DLH

CIM Linked

Main frame

Load lock

SMIF System: ASYST ARM-2200 V111S

Handler system: Robot assembly

Process chamber:

(3) CVD Deposition chambers A, B & C

(3) Primary generators

(3) RF2 Generators & matches

(4) Ebara pumps

Heat exchanger

Mini SBC board

SBC Board

SEI Board

(2) AI Boards

(2) AO Boards

VGA Board

(4) Stepper driver boards

(2) Digital I/O boards

Buffer I/O board

(2) Optical sensor boards

(4) Chopper driver boards

(3) Baratrons

LAMDA Power supply

Hard Disk Drive (HDD)

Wiring distribution board

Pneumatic board

Loader interconnect board

(2) TC Gauge boards

+12V DC Power supply

+15V DC Power supply

-15V DC Power supply

AI MUX Board

(3) RF Generators

Controller distribution board

Encoder interface board

System electronic back plane

Robot blade assembly

Facility:

A10S Loadlock pump

A70W Process pump

Incoming power: 208 VAC

Heat exchanger temperature set point: 65

Buffer:

LPT / Indexer: ARM-2200 H112S

Center finder

Storage elevator: (8) Slots

LL Robot type: Metal

Load lock actuator: IO Door

Chamber actuator: 0010-70162

CDA Pressure for buffer: 60 psi

Process chamber:

RF 1 Generator: ENI OEM-12B

RF 2 Generator: RFPP 7520572050

RF Match: AMAT / APPLIED MATERIALS Automatch 0010-09750

Pressure manometer: MKS 10T (122BA-001000EB-S)

Throttle valve / PCV Model: VEXTA PX245-02AA-C4

TC Part number: 3310-01074

Chuck type: P-Chuck

Chuck part number: 0010-38437

Process temperature: 400°C

MFC Gases:

C2F6: 10 SLM

SIH4: 3000scc

NH3: 300scc

N2: 10 SLM

N20: 3000 SCC

N20 (G): 200 SCCM

PH3: 300 SCC

DPA Included

Endpoint: 0190-09472

CDA Pressure for chamber: 60 psi

1998 vintage.

AMAT / APPLIED MATERIALS P5000 is a reactor that is used to manufacture semiconductor devices. It uses advanced technology to provide precise thermal control and a platform for chemical vapor deposition (CVD). The reactor is designed to ensure uniform temperatures and reduce non-uniformity throughout the growth of the material or device. AMAT P-5000 is a single-wafer reactor that encompasses three key characteristics: uniformity, temperature control, and substrate flexibility. The reactor consists of several components: a quartz chamber, a susceptor mount, a control equipment, a heating element, and a cooling system. The quartz chamber allows the oxidation or deposition of a film onto the substrate under controlled Conditions. The susceptor mount holds the wafer during the processing, and is designed to provide a uniform temperature distribution. The control unit enables precise temperature control and a platform for CVD. The heating element is designed to provide uniform temperature through the entire wafer. The cooling machine is used to reduce substrate temperature and enable process stability. APPLIED MATERIALS P 5000 reactor has a wide range of advantages, such as enhanced performance, high repeatability, increased throughput, and improved yields. It is also capable of producing devices at high temperatures, with excellent uniformity and repeatability. Additionally, P5000 reactor is ideal for wafer bonding, as it ensures a very uniform temperature and greater precision in the handling of the bonds. In conclusion, AMAT P5000 reactor is a crucial component of the semiconductor manufacturing process. Its ability to provide uniform temperatures and reduce non-uniformity throughout the growth of the material or device makes it extremely useful and cost-effective. As technology advances, it is expected that P 5000 reactor will become even more advanced and efficient in producing semiconductor devices.

There are no reviews yet