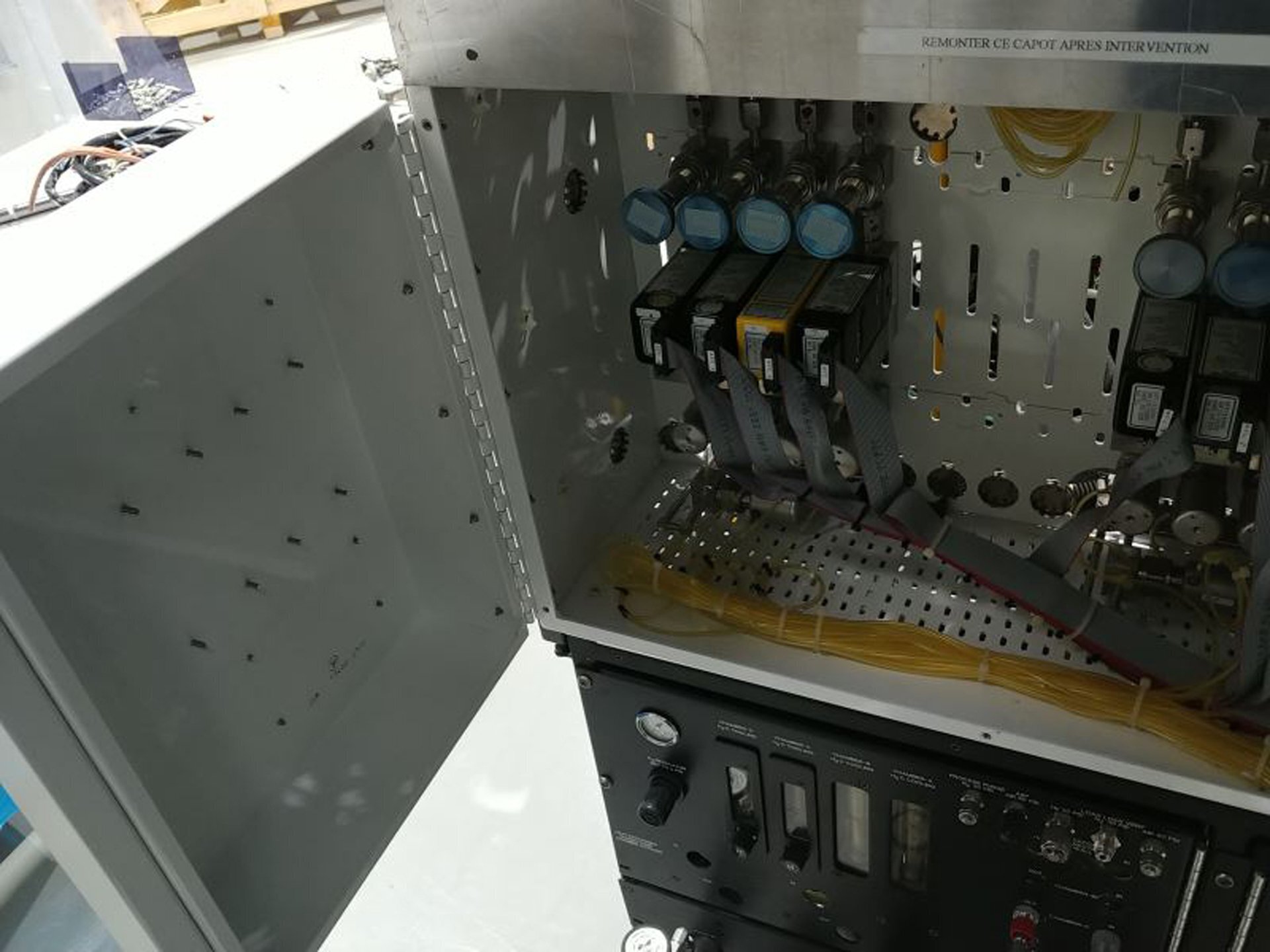

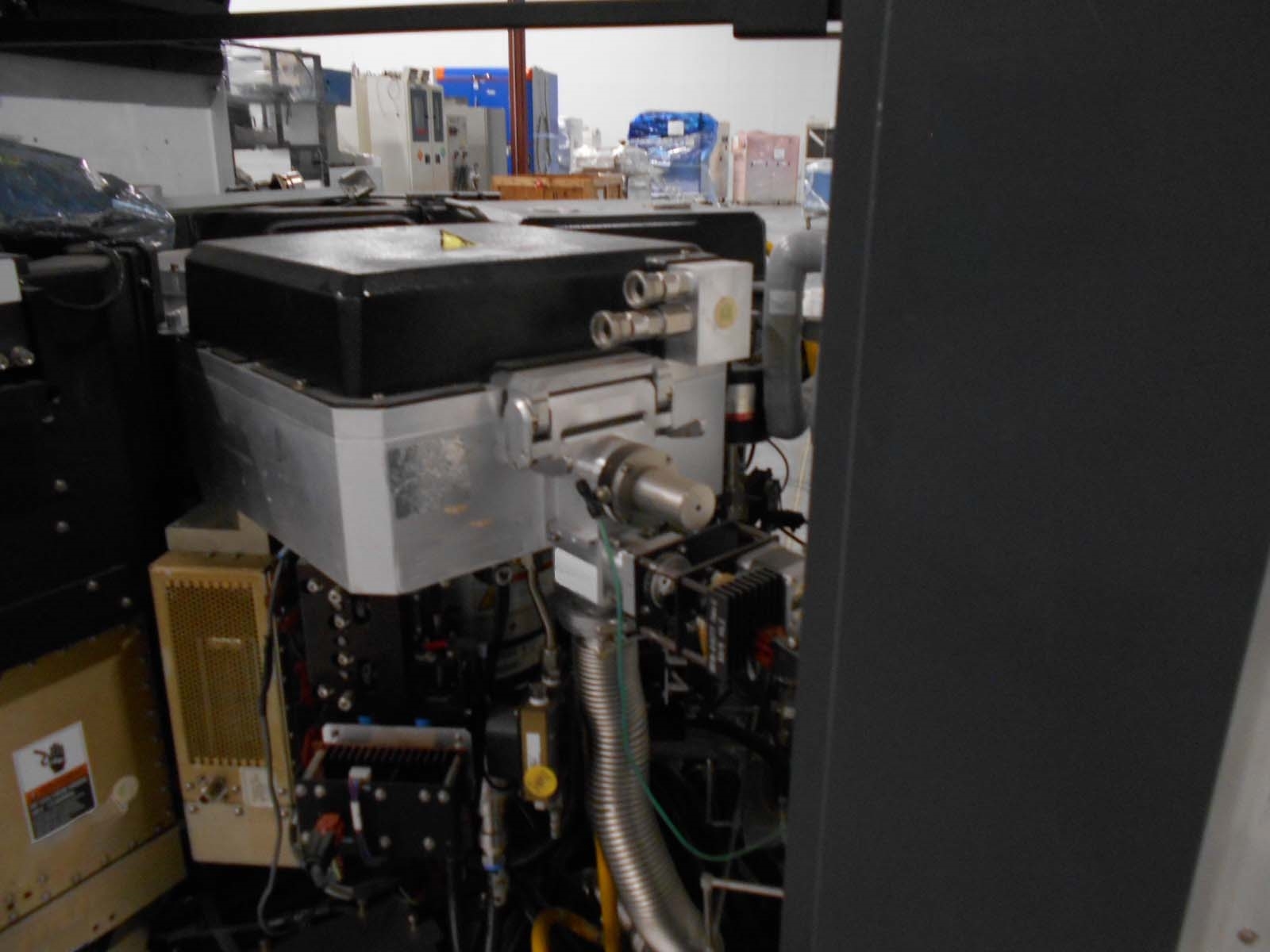

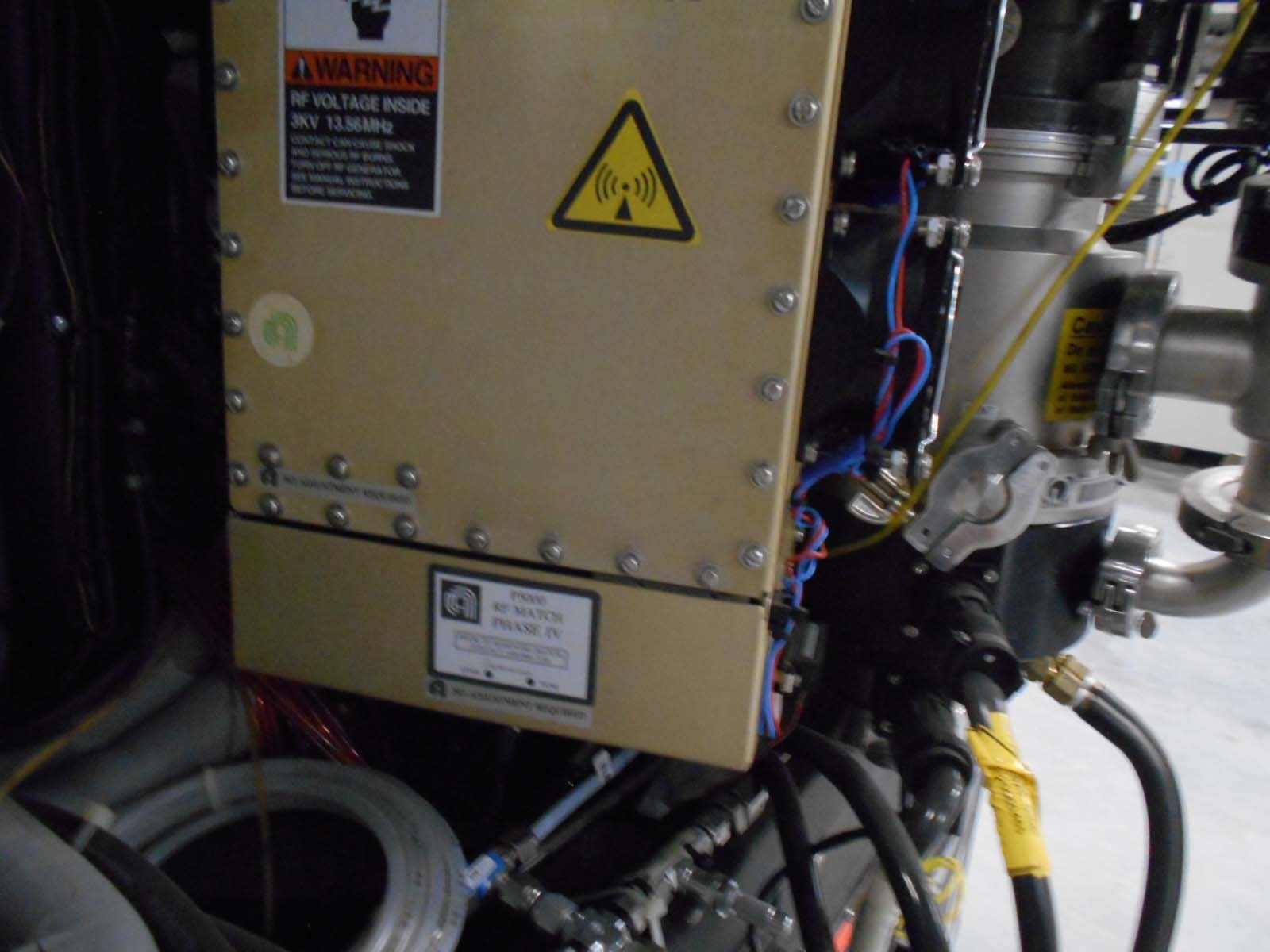

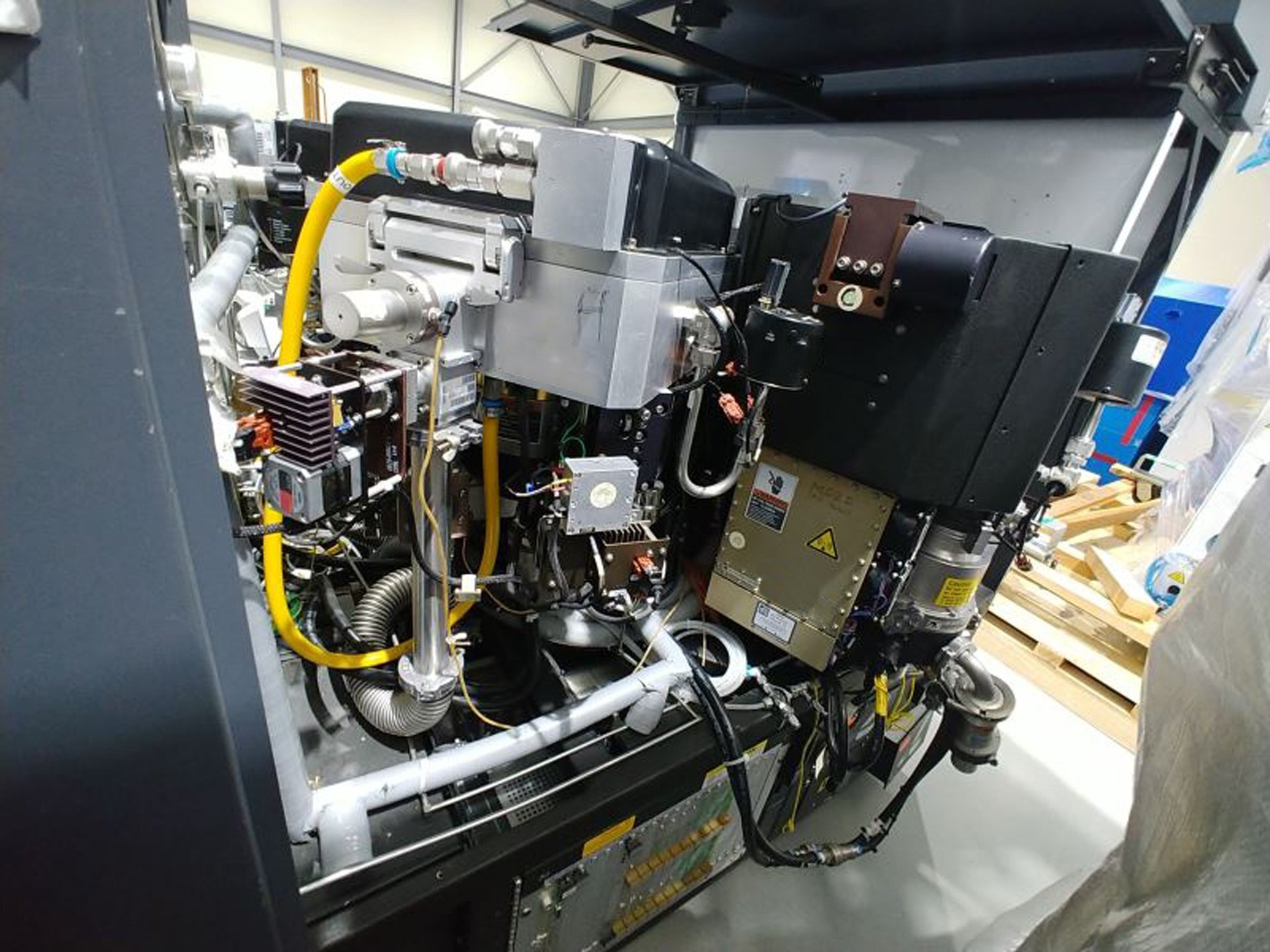

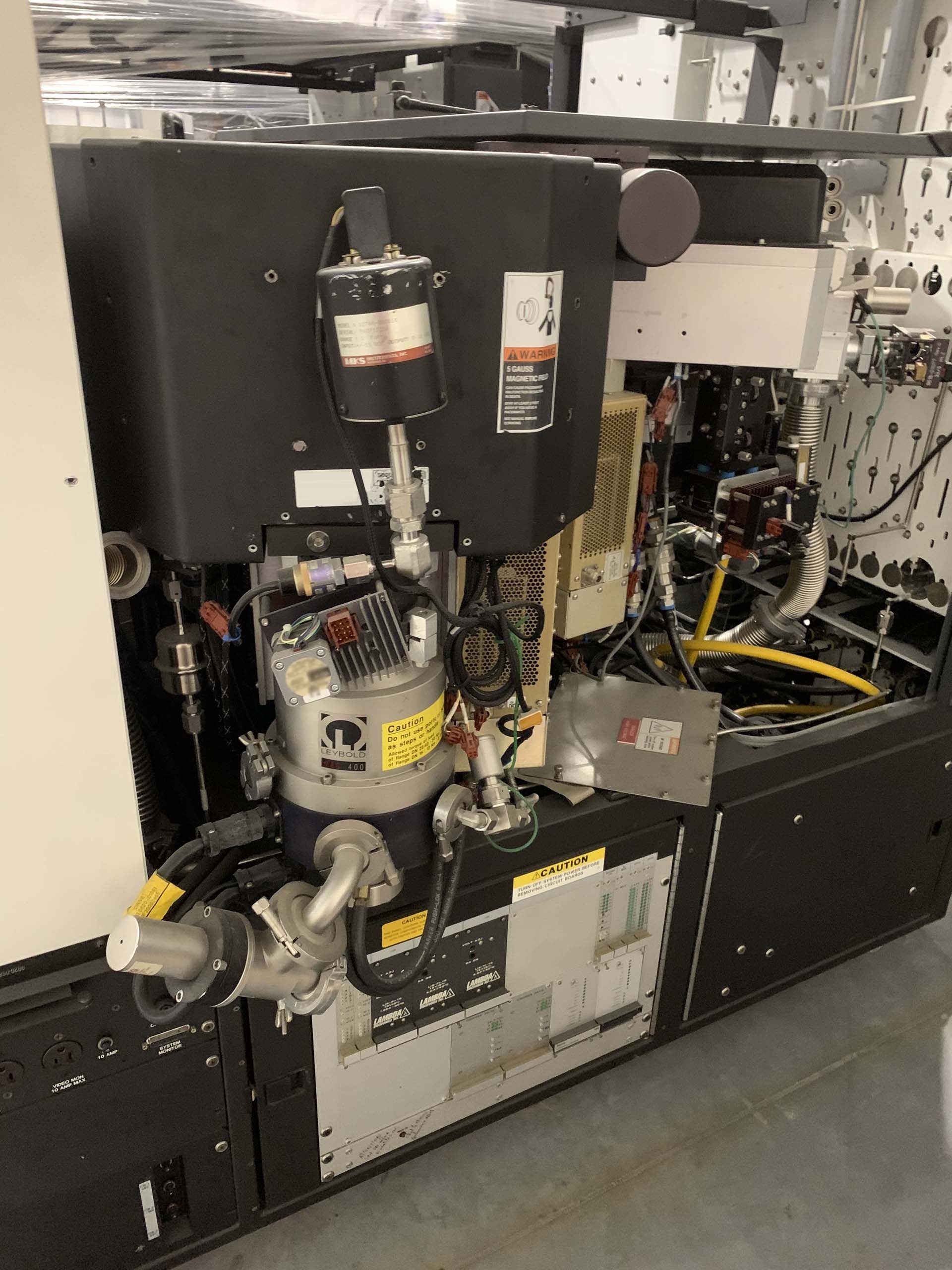

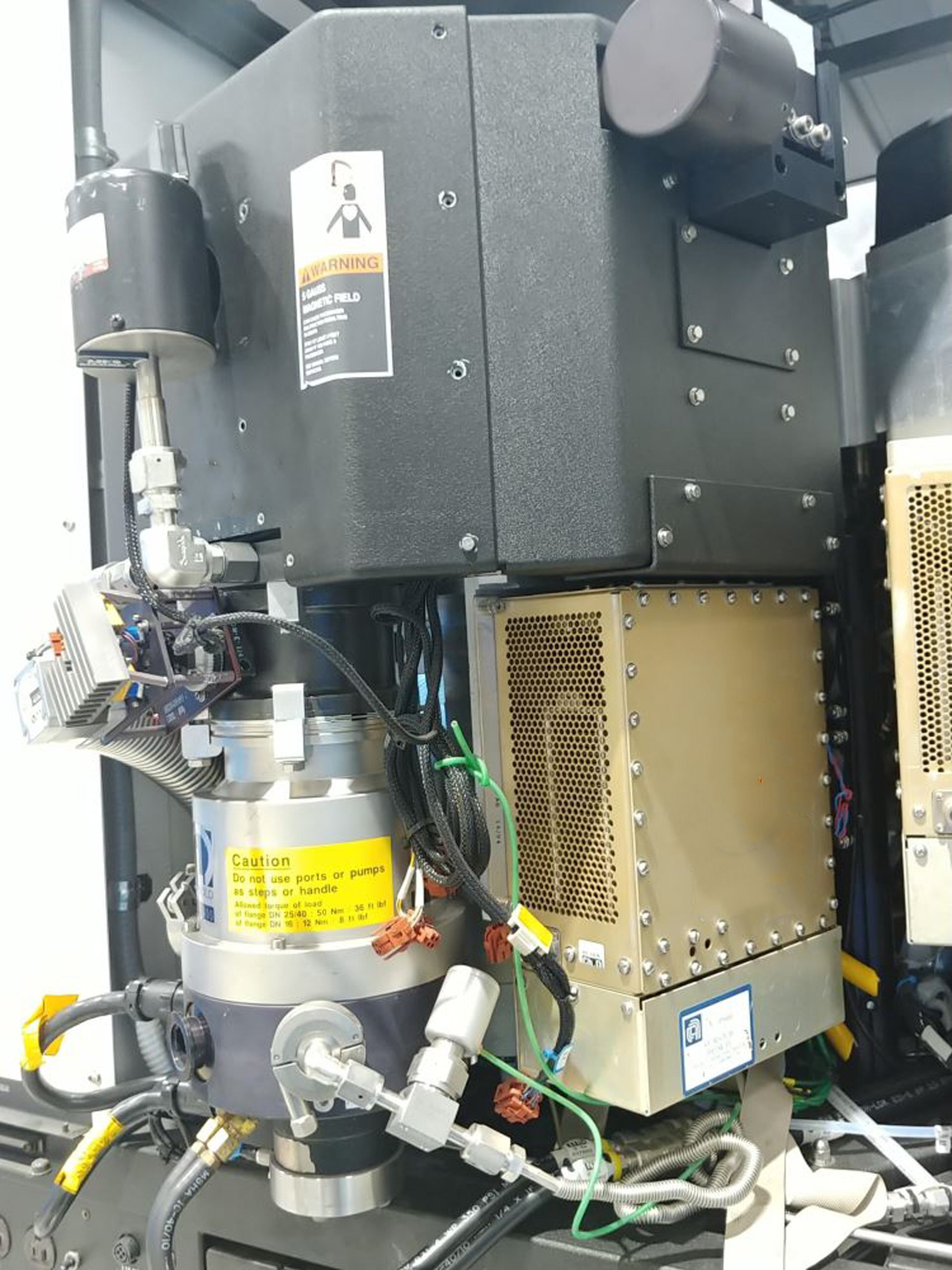

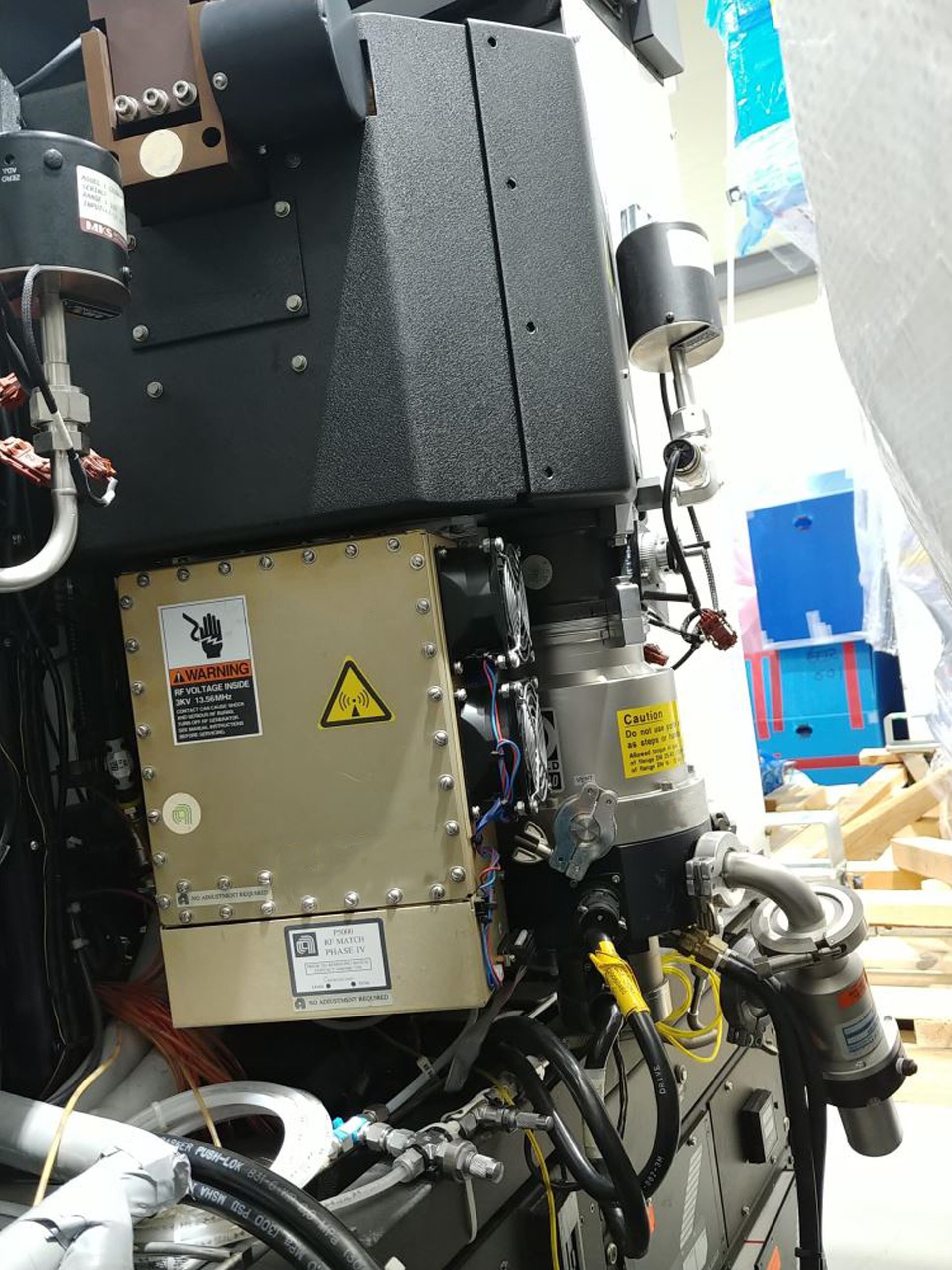

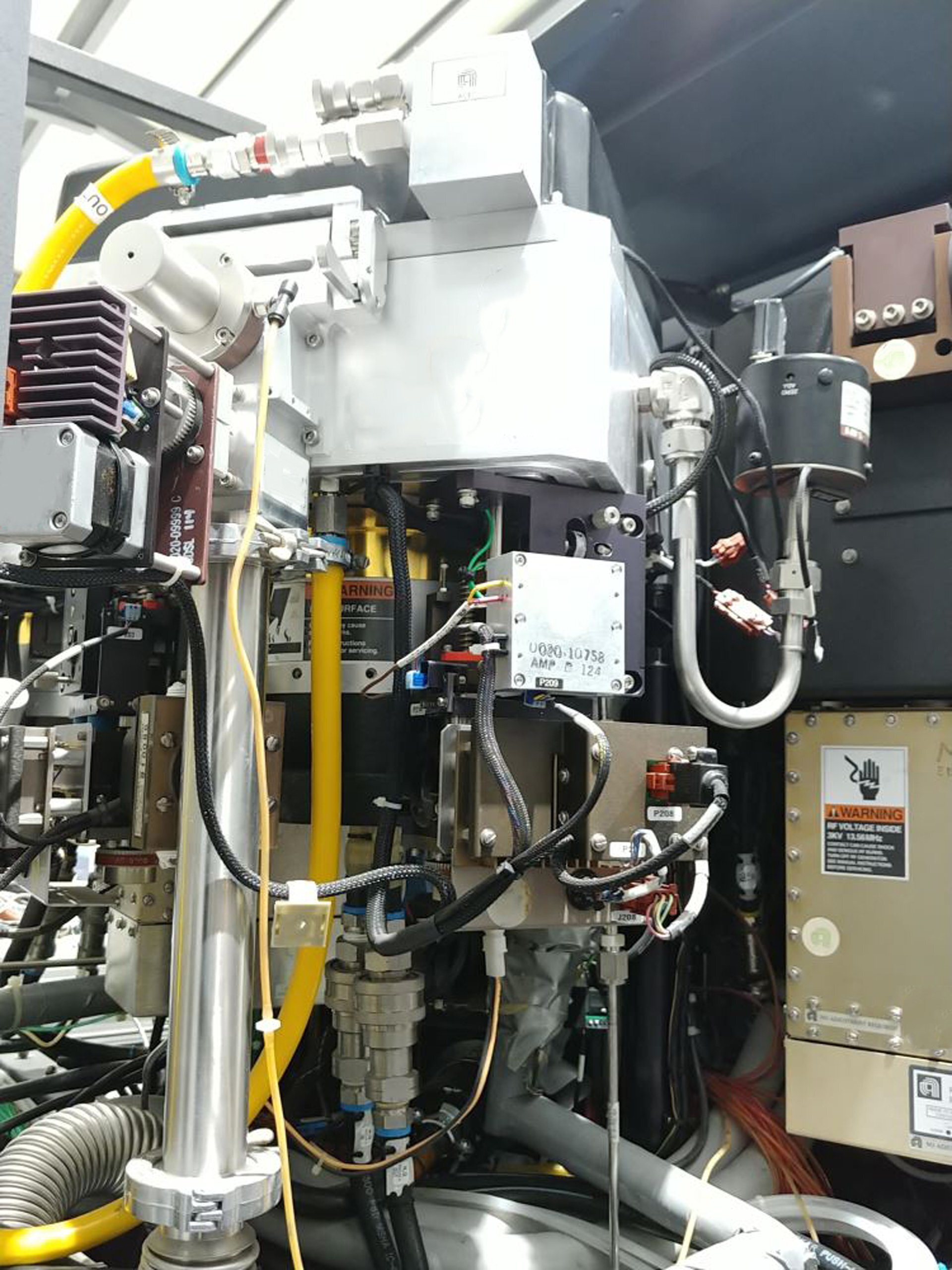

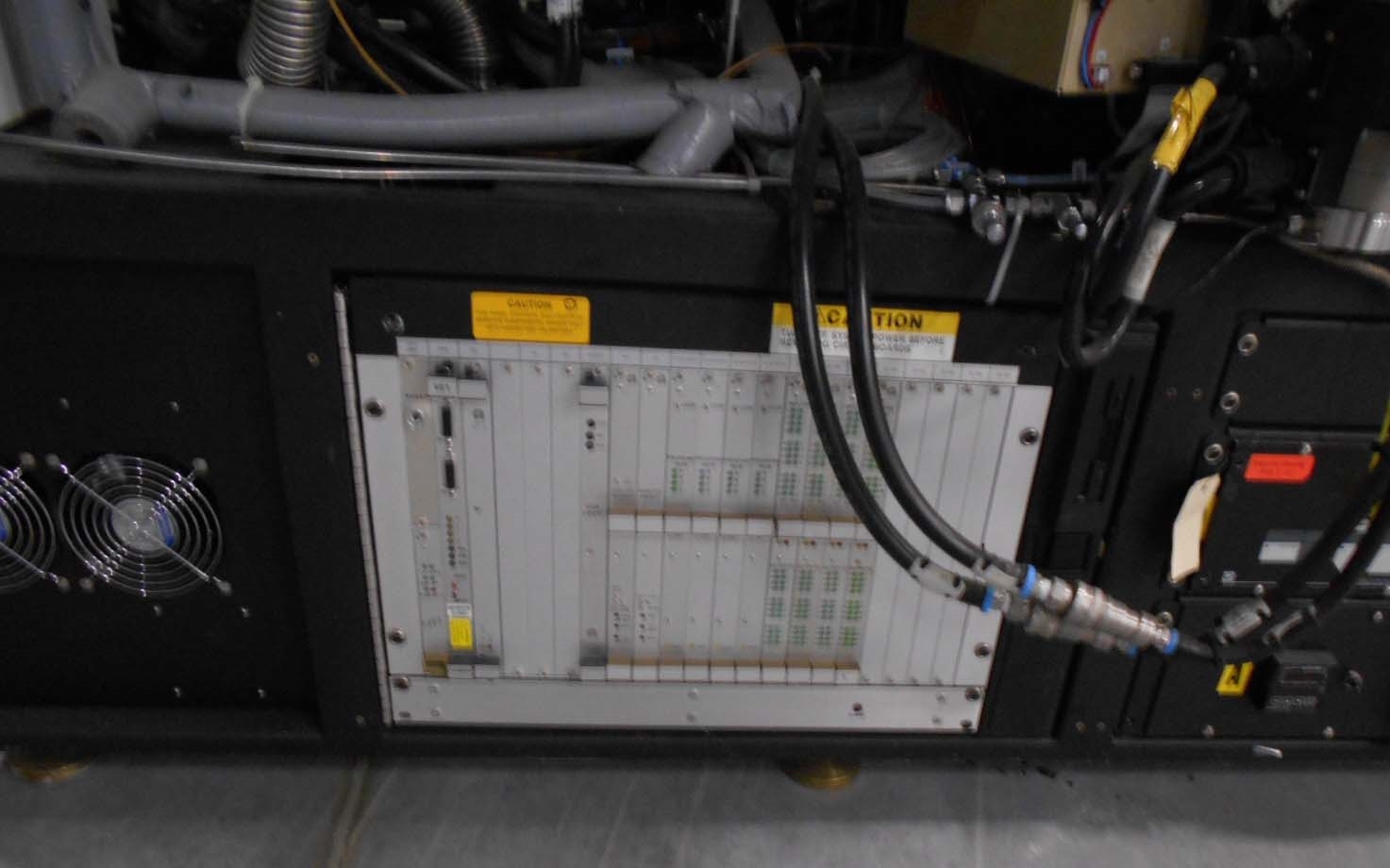

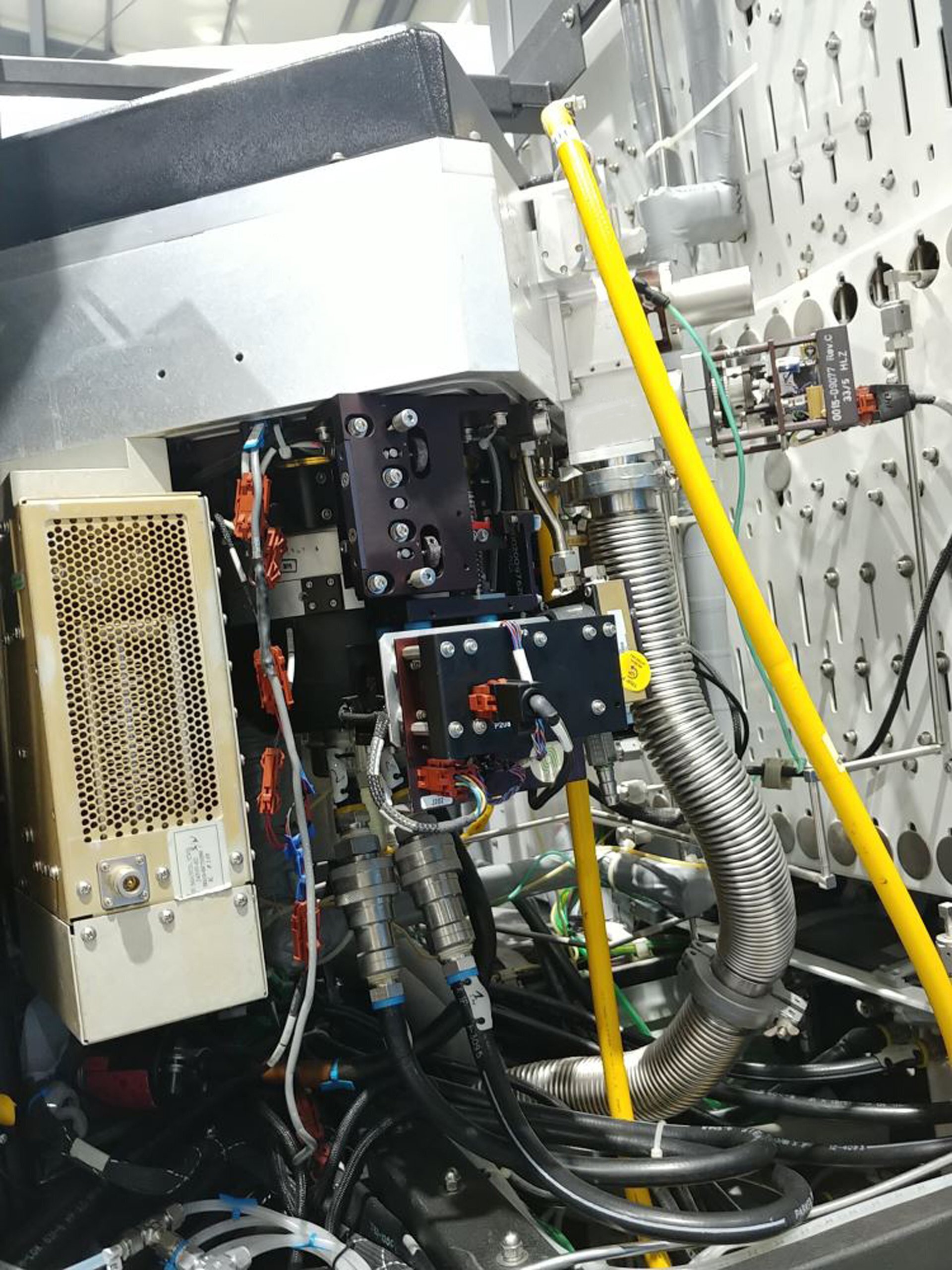

Used AMAT / APPLIED MATERIALS P5000 #9252545 for sale

URL successfully copied!

Tap to zoom

ID: 9252545

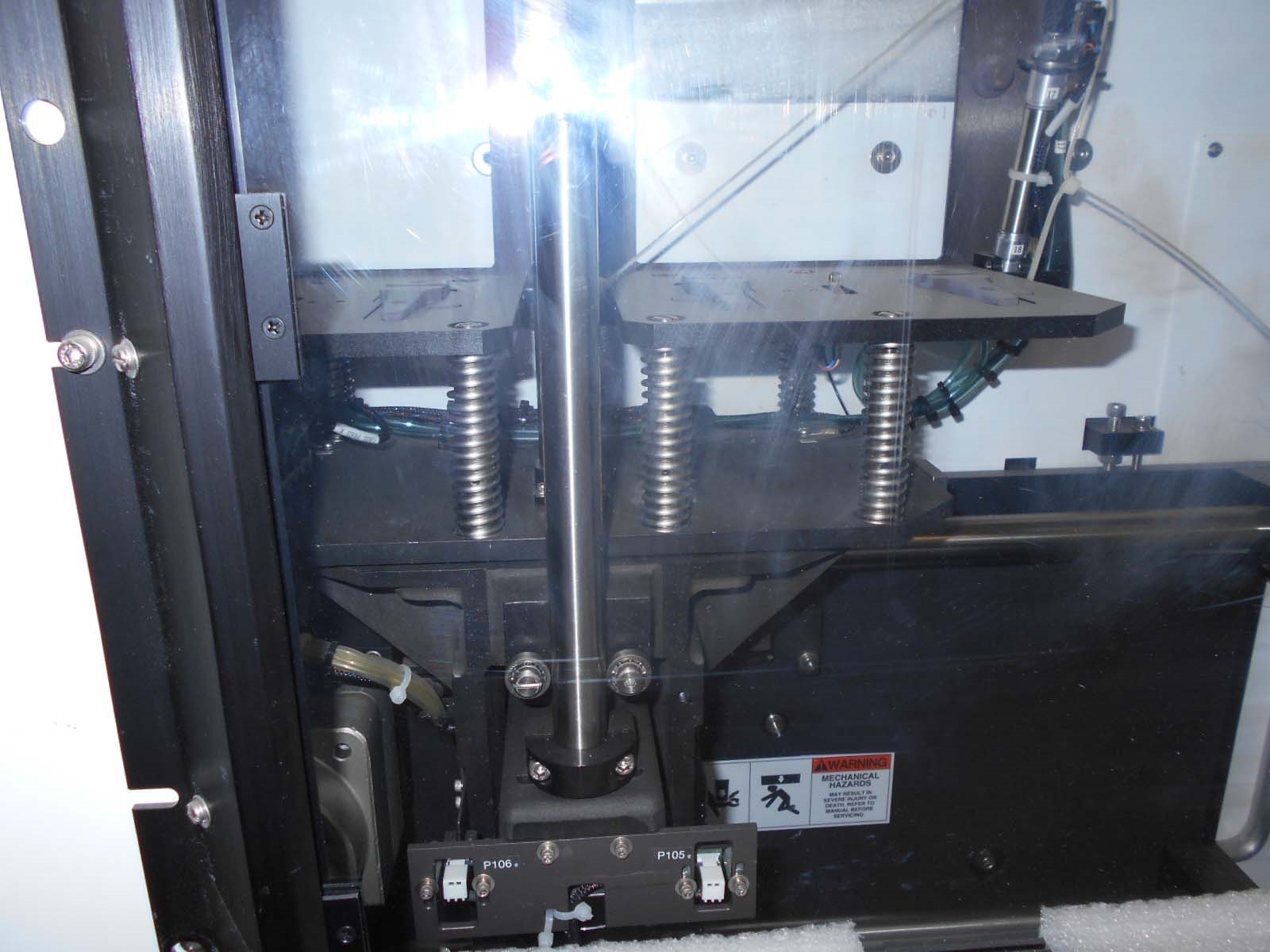

Wafer Size: 6"

Vintage: 1994

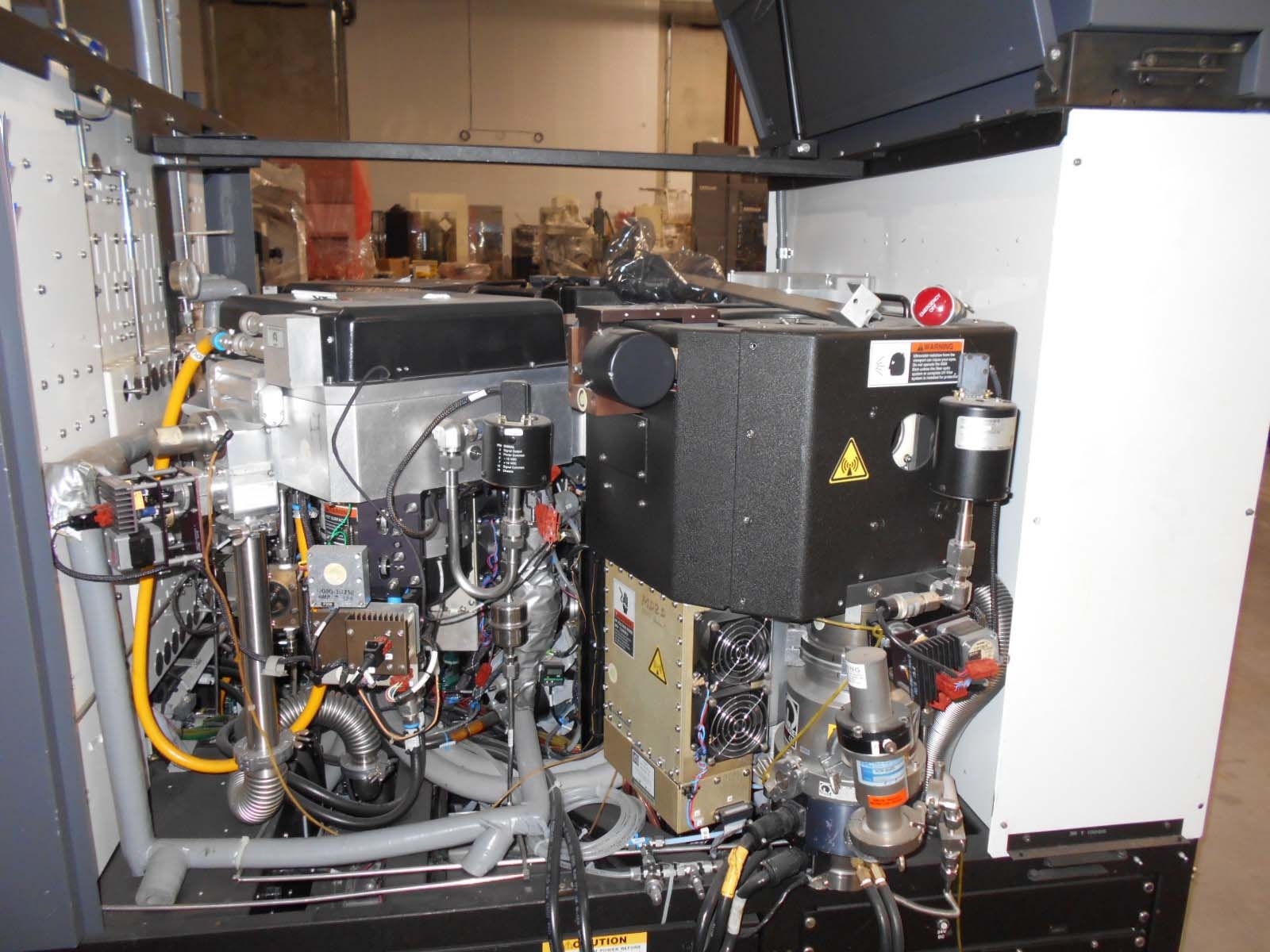

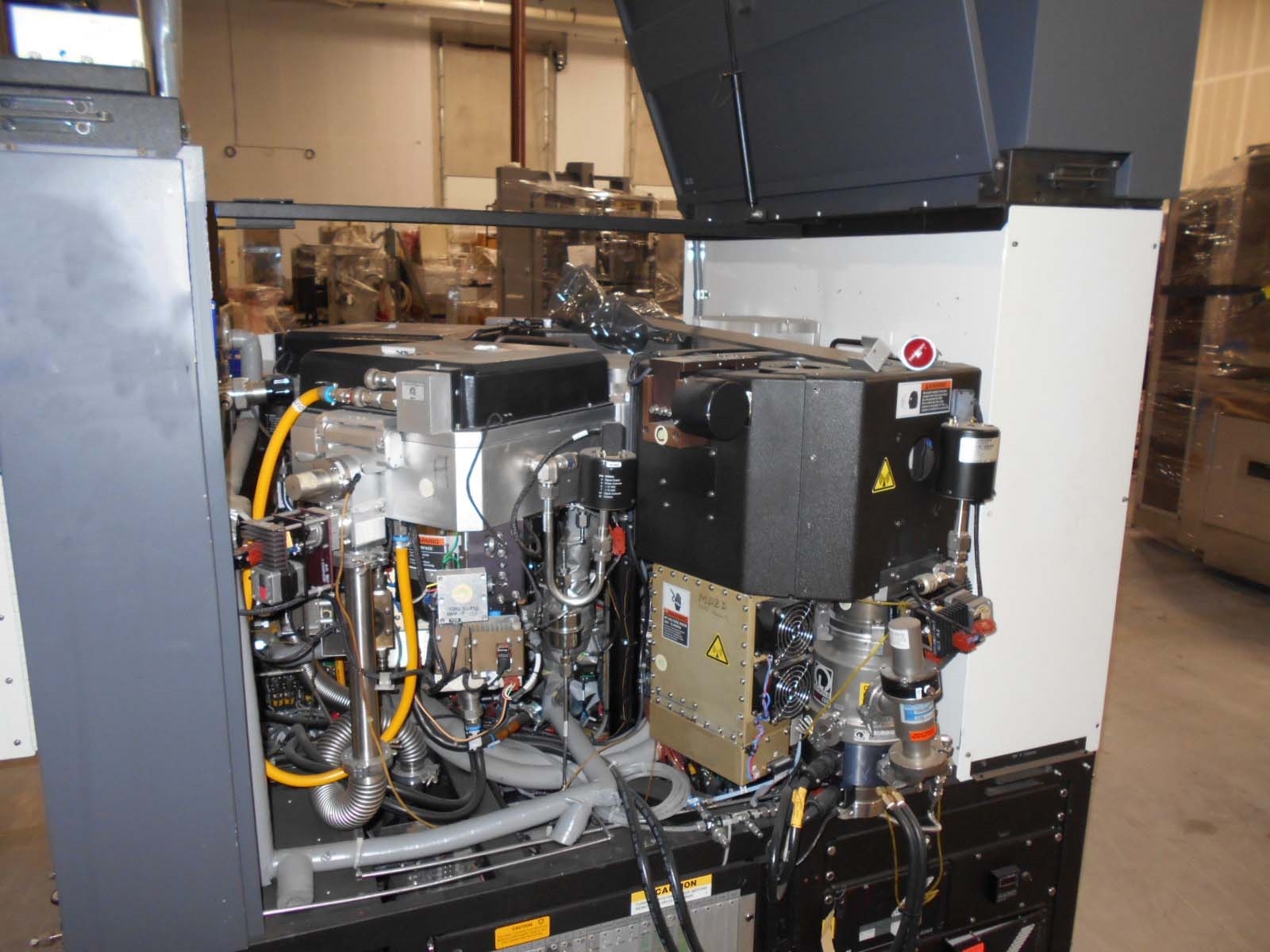

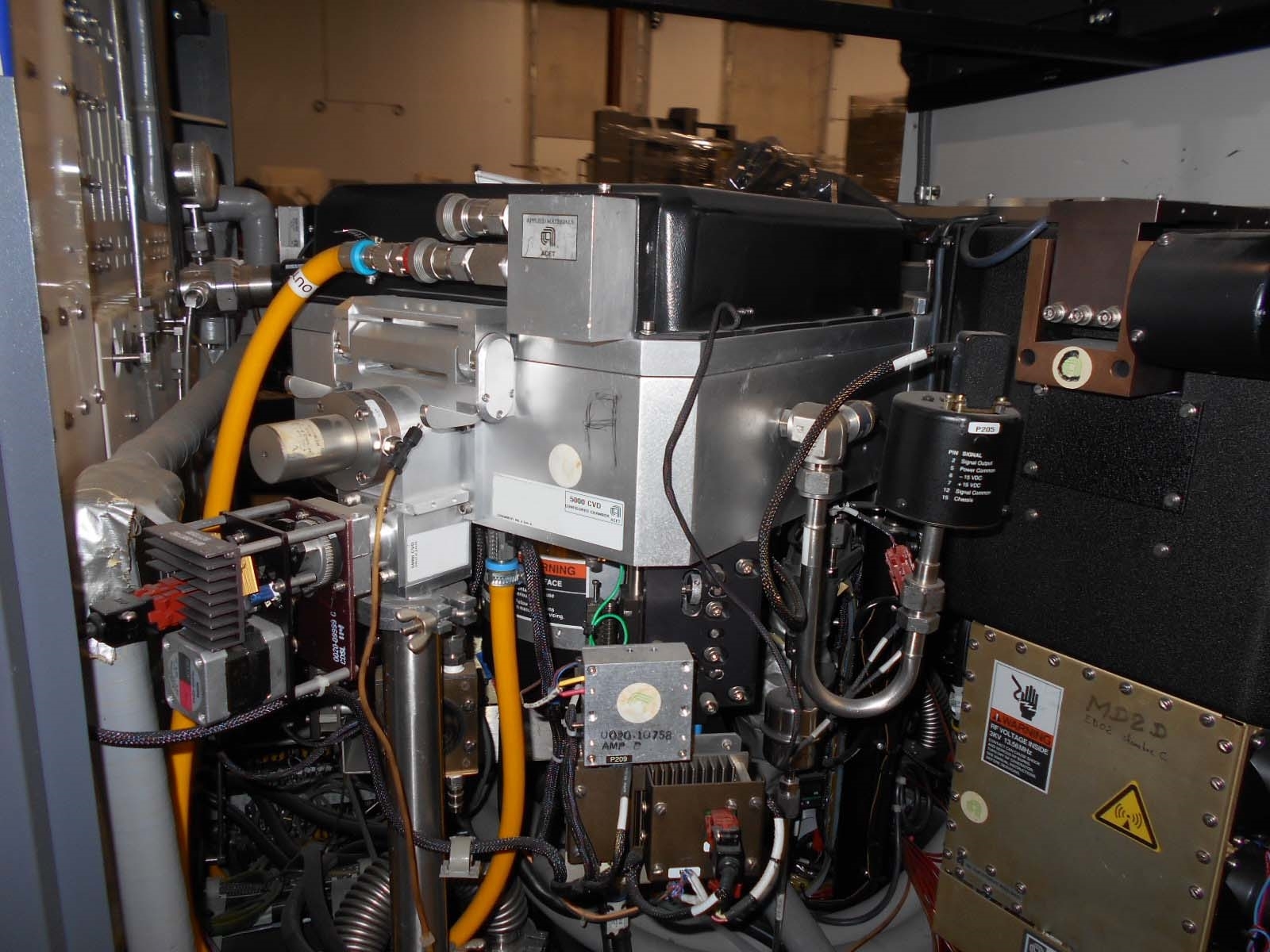

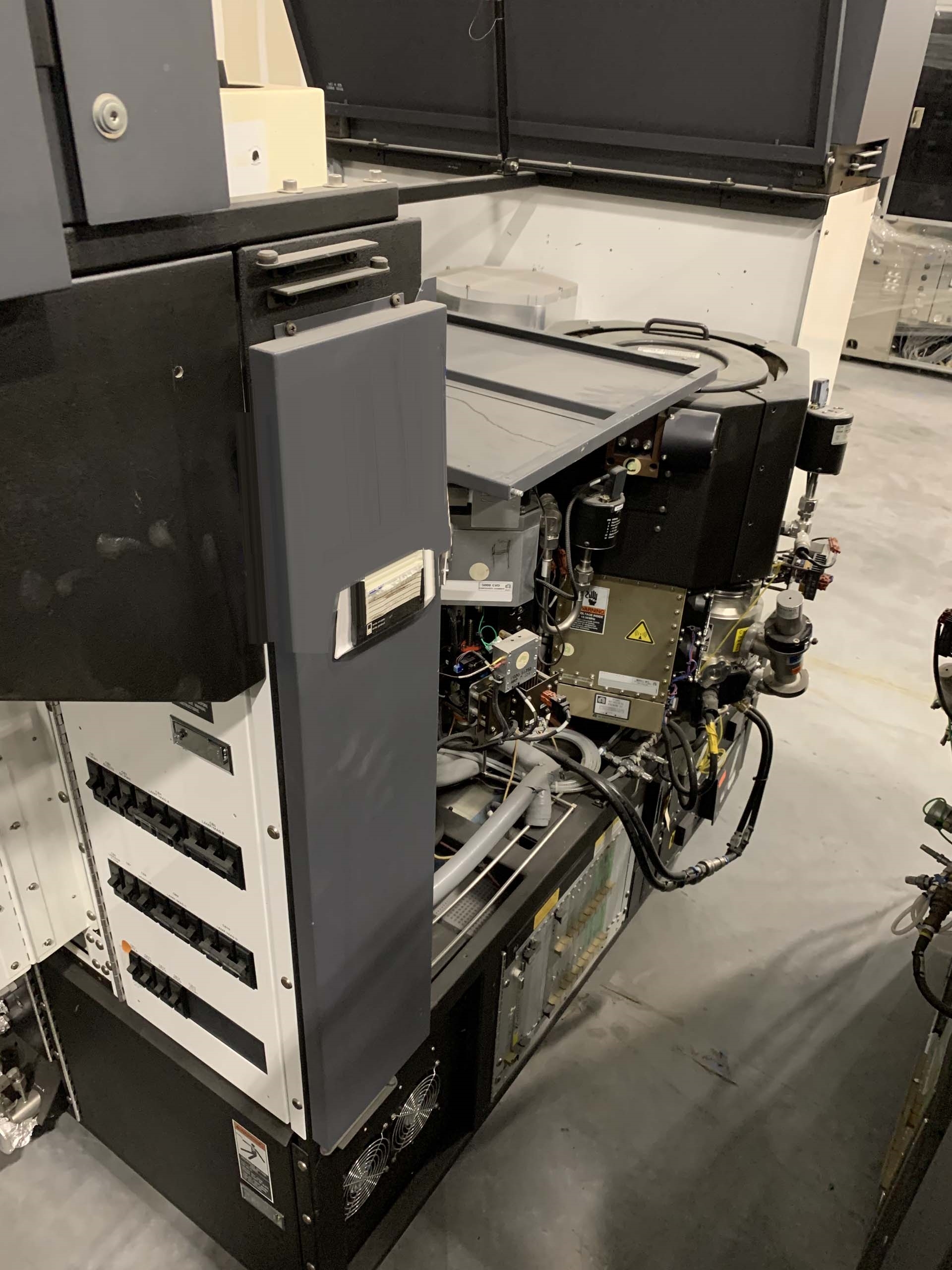

TEOS System, 6"

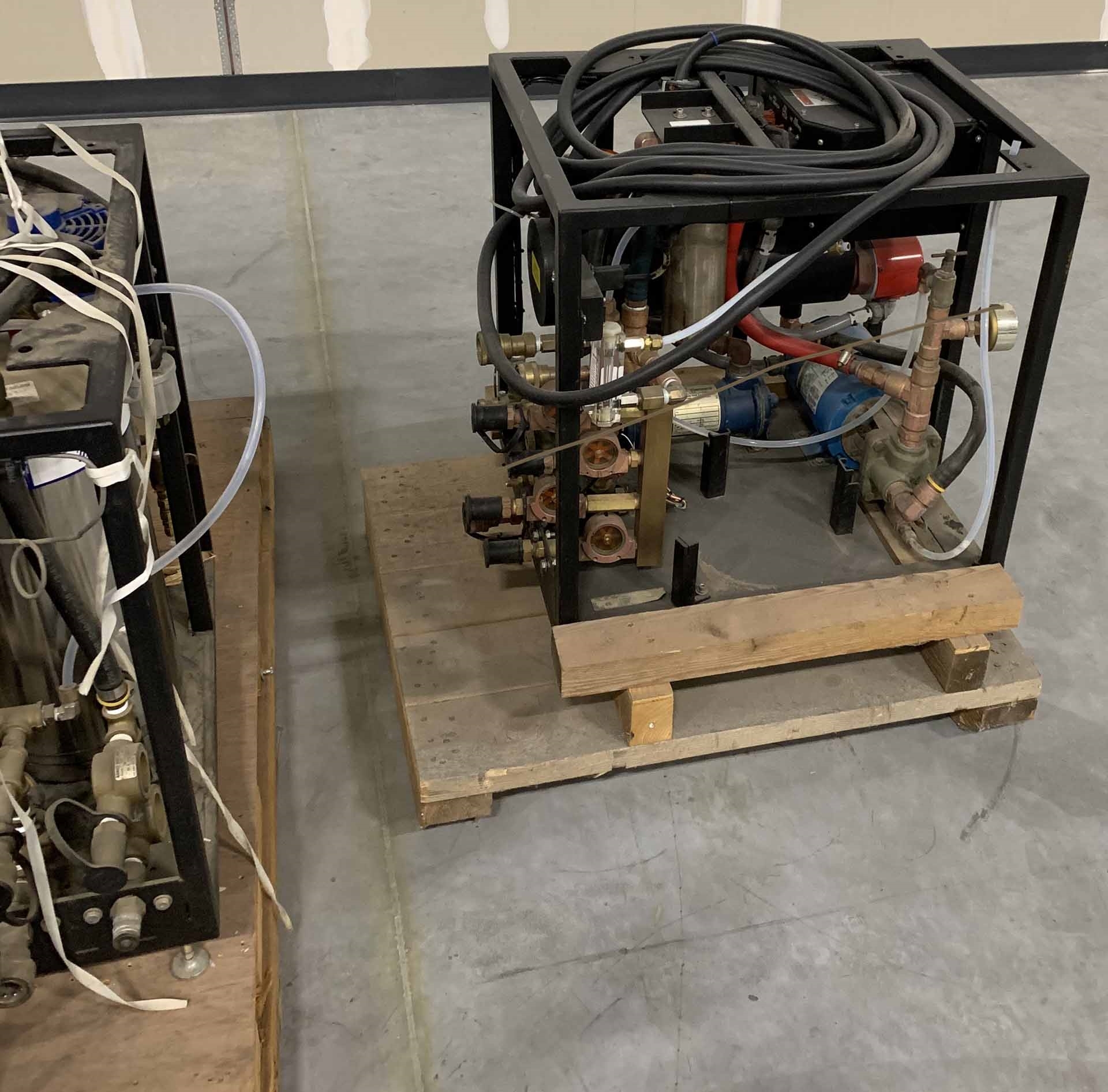

With heat exchanger

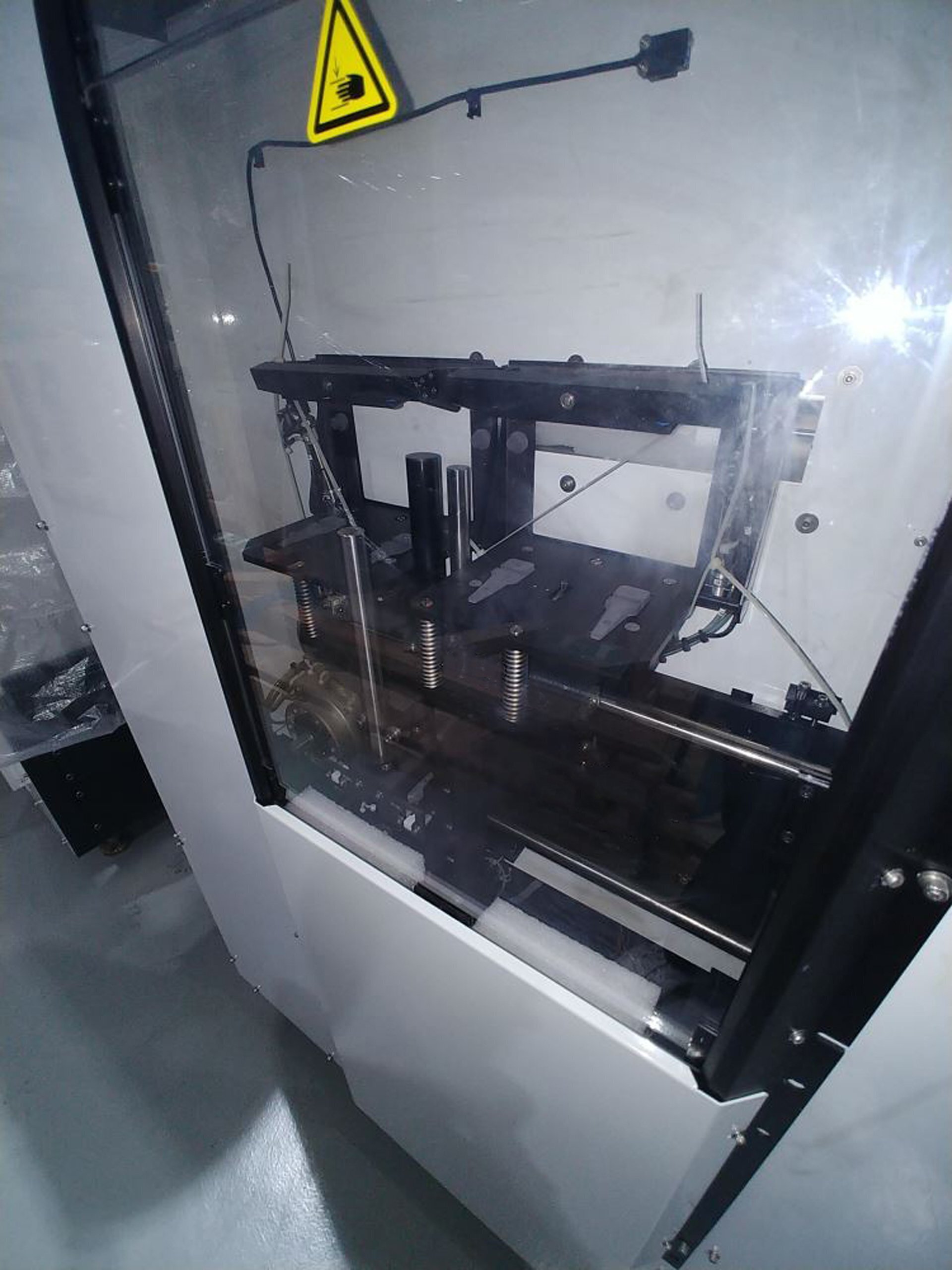

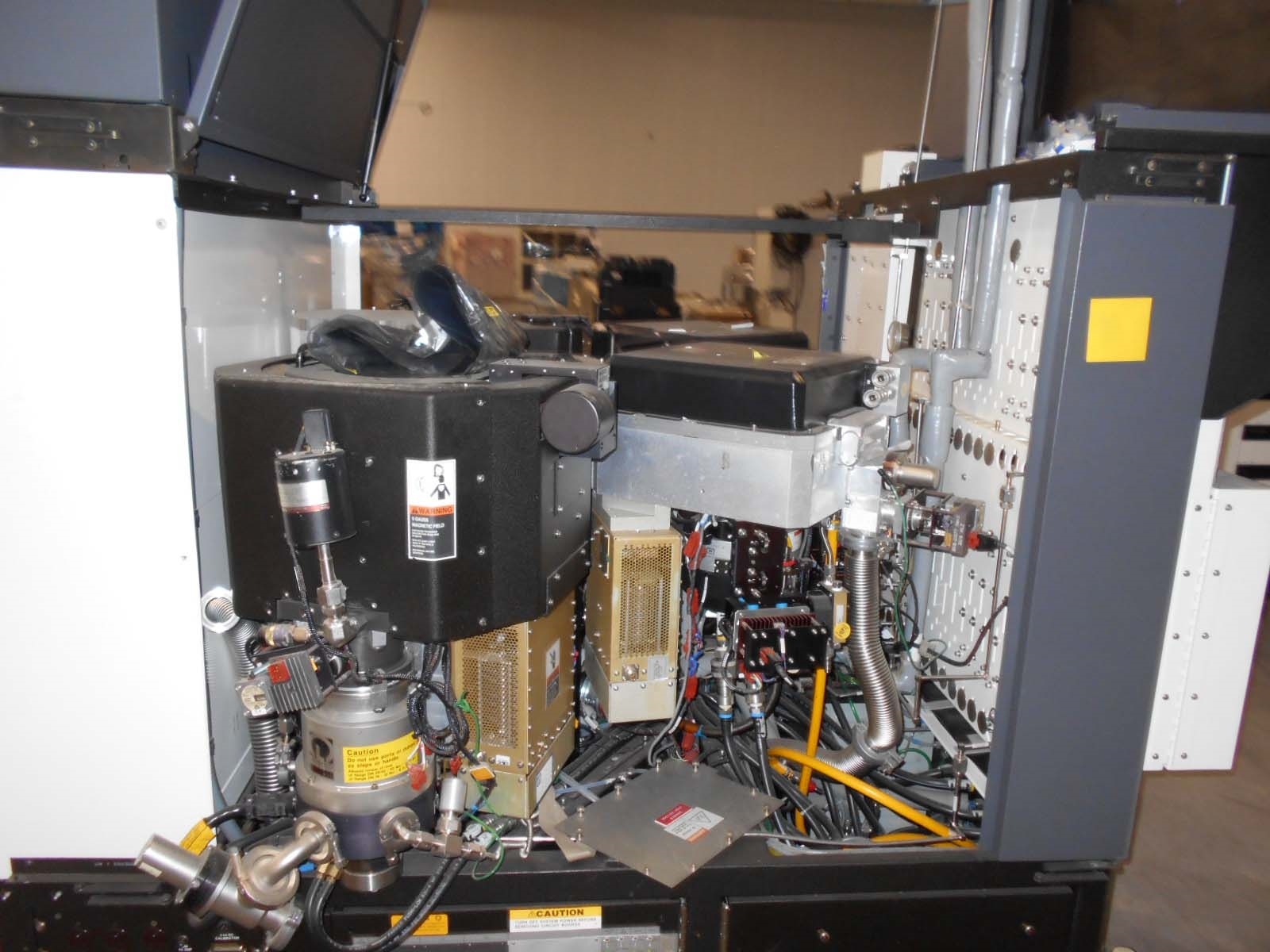

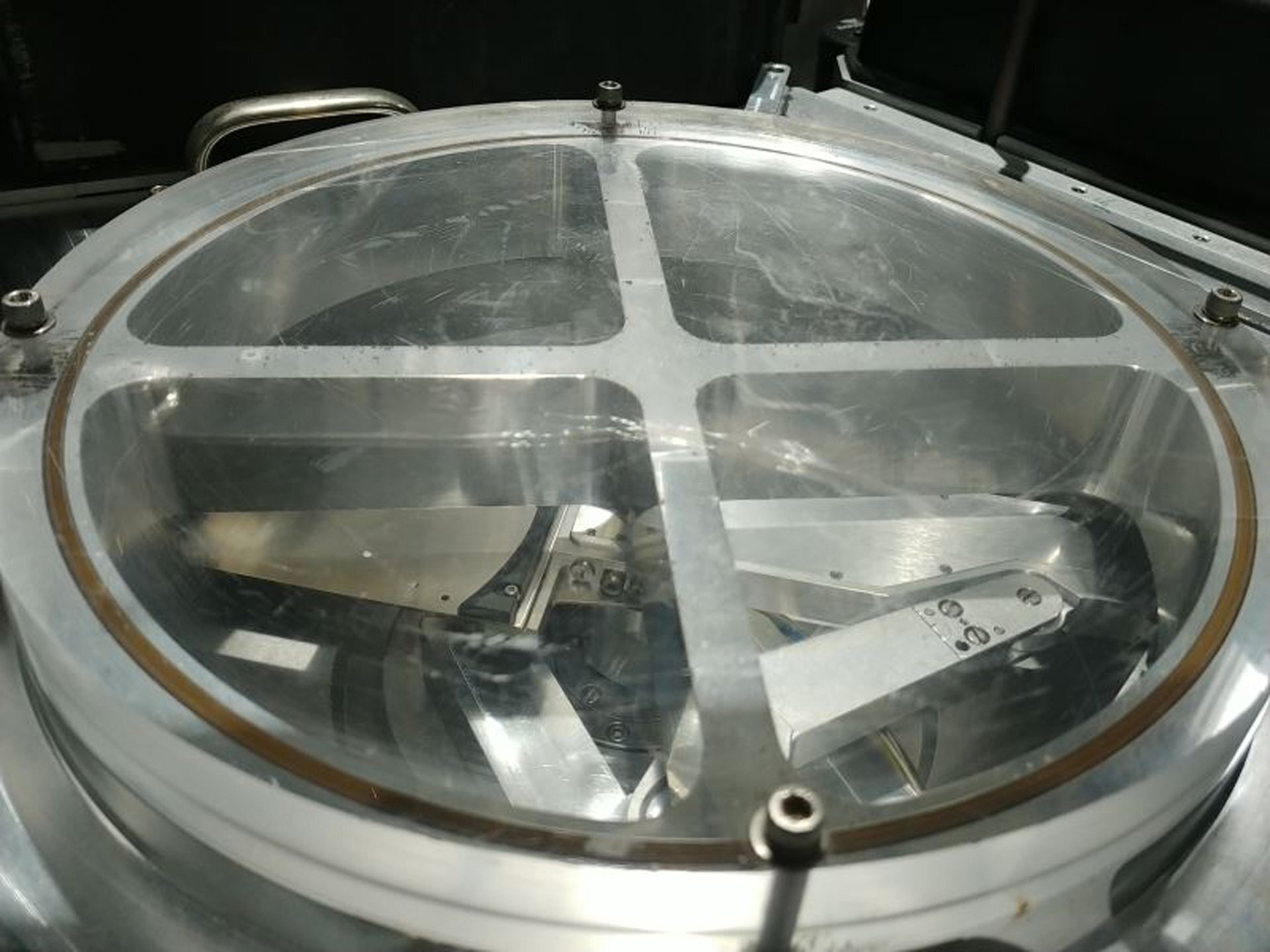

(3) CVD Chambers

Etch back chamber

(2) DxL Chambers

(2) Etch Chambers

8-Slot storage

Hot box

1994 vintage.

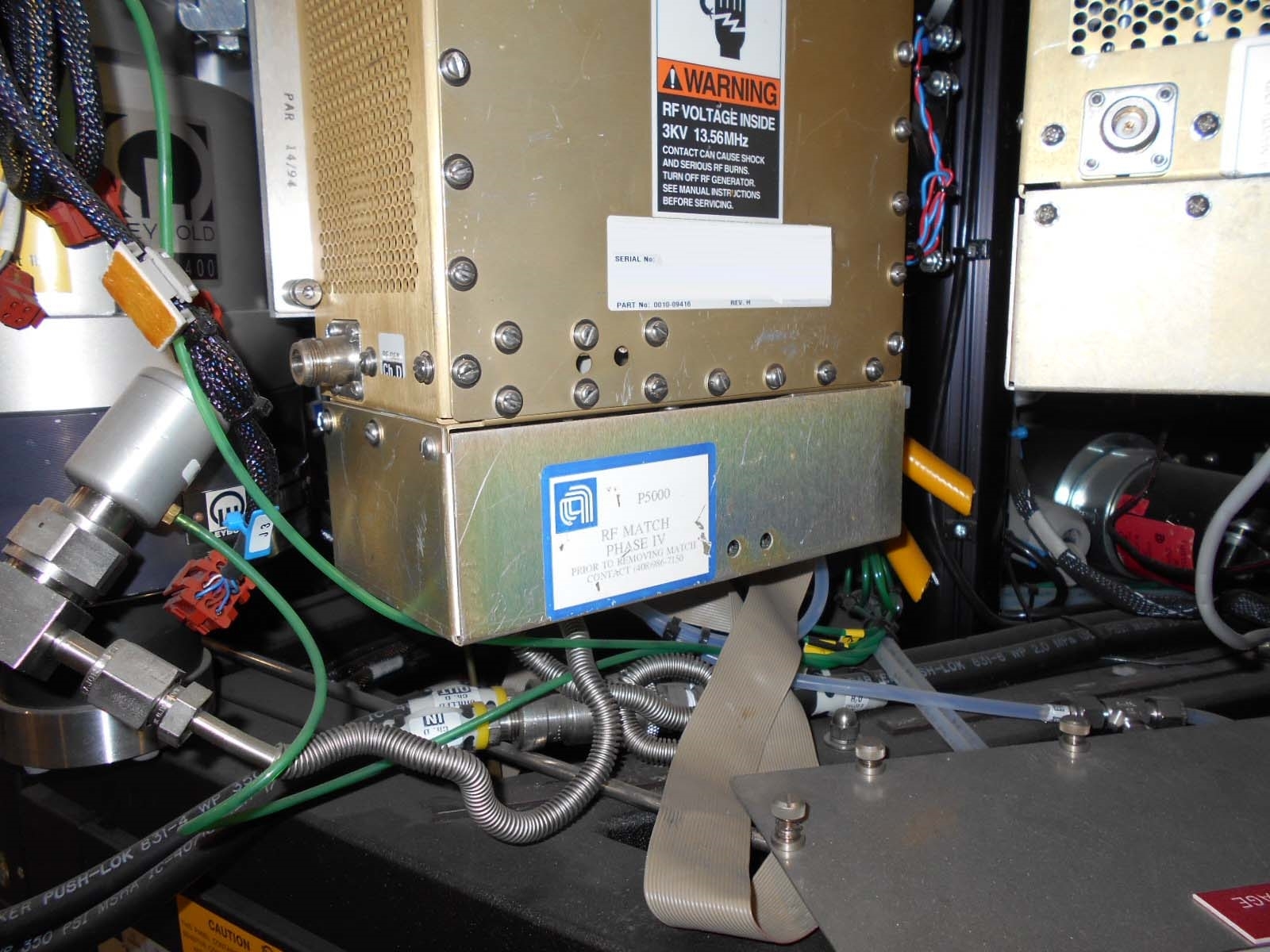

AMAT Inc. AMAT / APPLIED MATERIALS P5000 reactor is a chemical vapor deposition (CVD) tool used to deposit thin films from various volatile precursors in the semiconductor industry. The design is based on a horizontally configured, single-wafer based processing chamber, which provides sufficient ambient temperature and pressure to maintain a uniform film thickness while maintaining total process control and flexibility. The equipment utilizes a hot-wall directed flow chamber which is heated in a range of 150 - 600°C. The internal pressure is kept low, which allows for efficient thermal control of the process. This reduced pressure also helps to minimize contamination in a controlled deposition environment. The chamber is filled with a carrier gas of argon or nitrogen, which is used to transport the volatile precursors, such as silanes and nitrides, to the substrate surface. To ensure uniform film growth on the wafer surface, the chamber is equipped with an automated distribution and mixing system, which controls the distribution of reactants and the overall flow rate. AMAT P-5000 unit includes a variety of process monitoring tools and diagnostics. A multi-channel machine is available, allowing for in-situ reading of multiple parameters, such as deposition rate and film thickness. An integrated optical emission spectroscopy (OES) tool can detect off-site contamination, permitting fast reaction and optimization of the deposition process. Additionally, the reactor can be combined with a post-CVD etch asset to permit etching of complex structures such as those used in advanced CMOS and MEMS applications, while keeping the overall process in the safe and compatibility of the hot-wall chamber. In summary, APPLIED MATERIALS P 5000 embodiment represents one of the most complete and advanced CVD systems enabling superior control of deposition parameters, process monitoring and diagnostics. The model offers superior film uniformity, quality, and compatibility with sophisticated deposition processes such as metal organic chemical vapor deposition (MOCVD) and low-pressure chemical vapor deposition (LPCVD).

There are no reviews yet