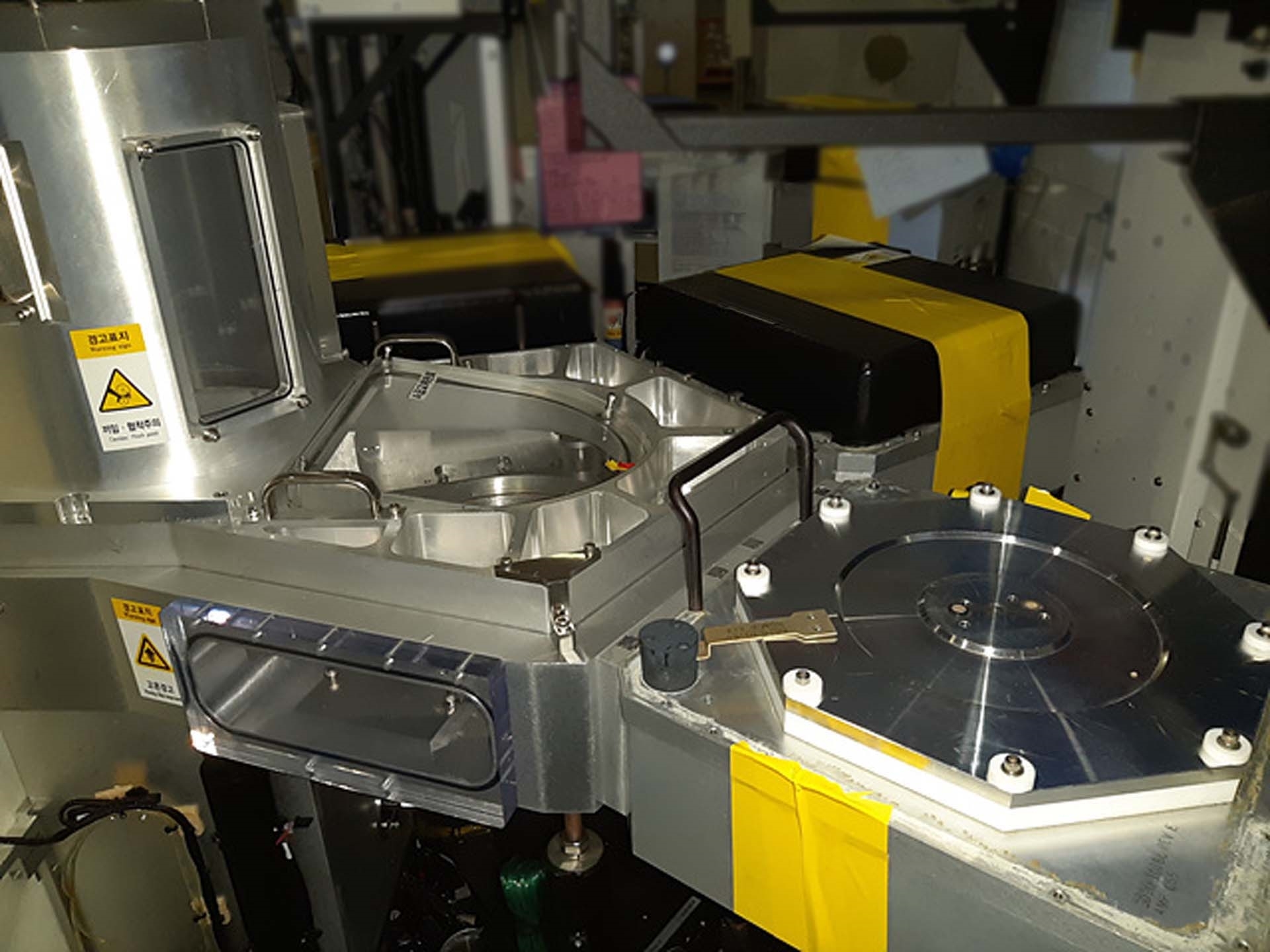

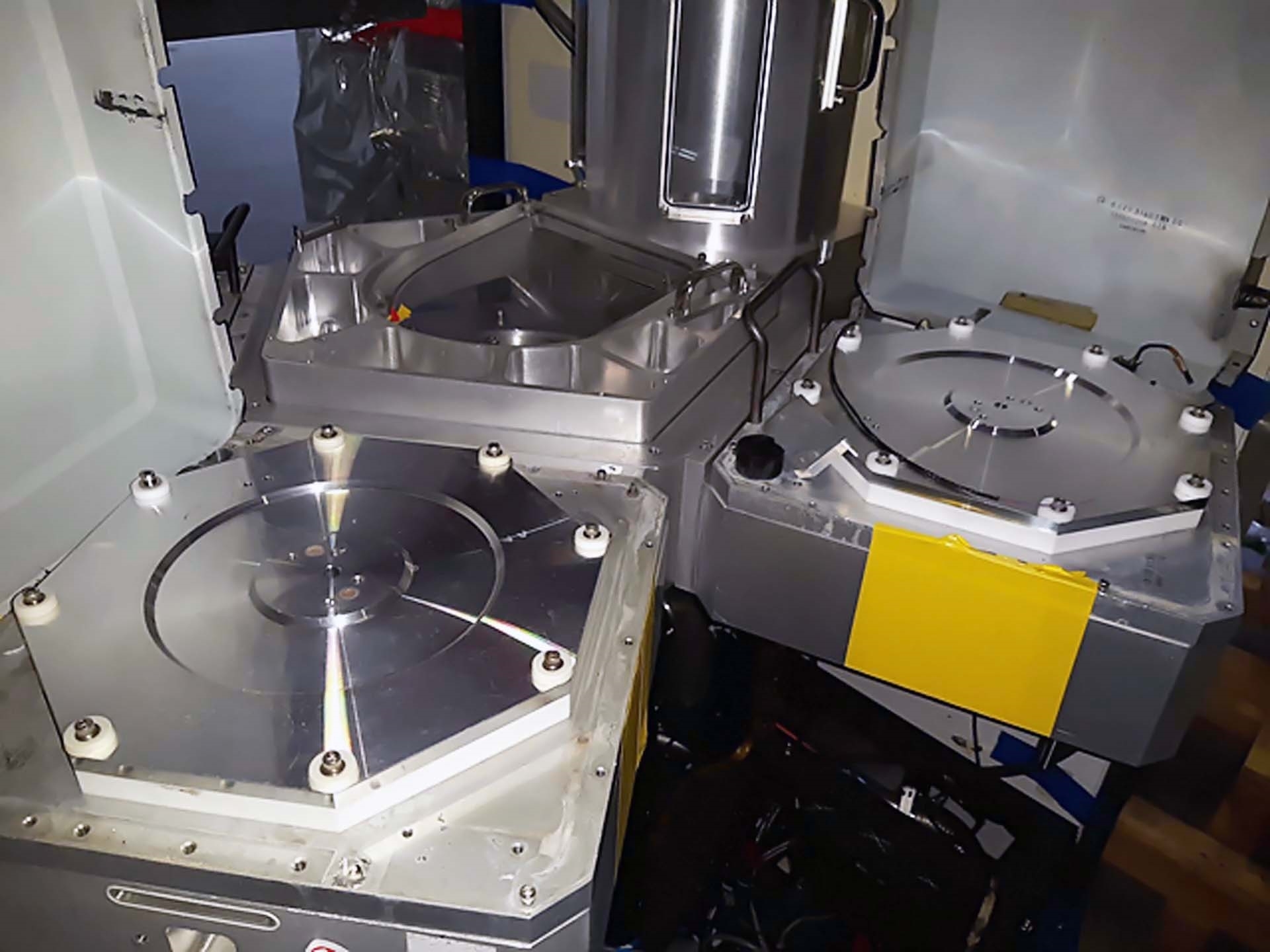

Used AMAT / APPLIED MATERIALS P5000 #9256416 for sale

URL successfully copied!

Tap to zoom

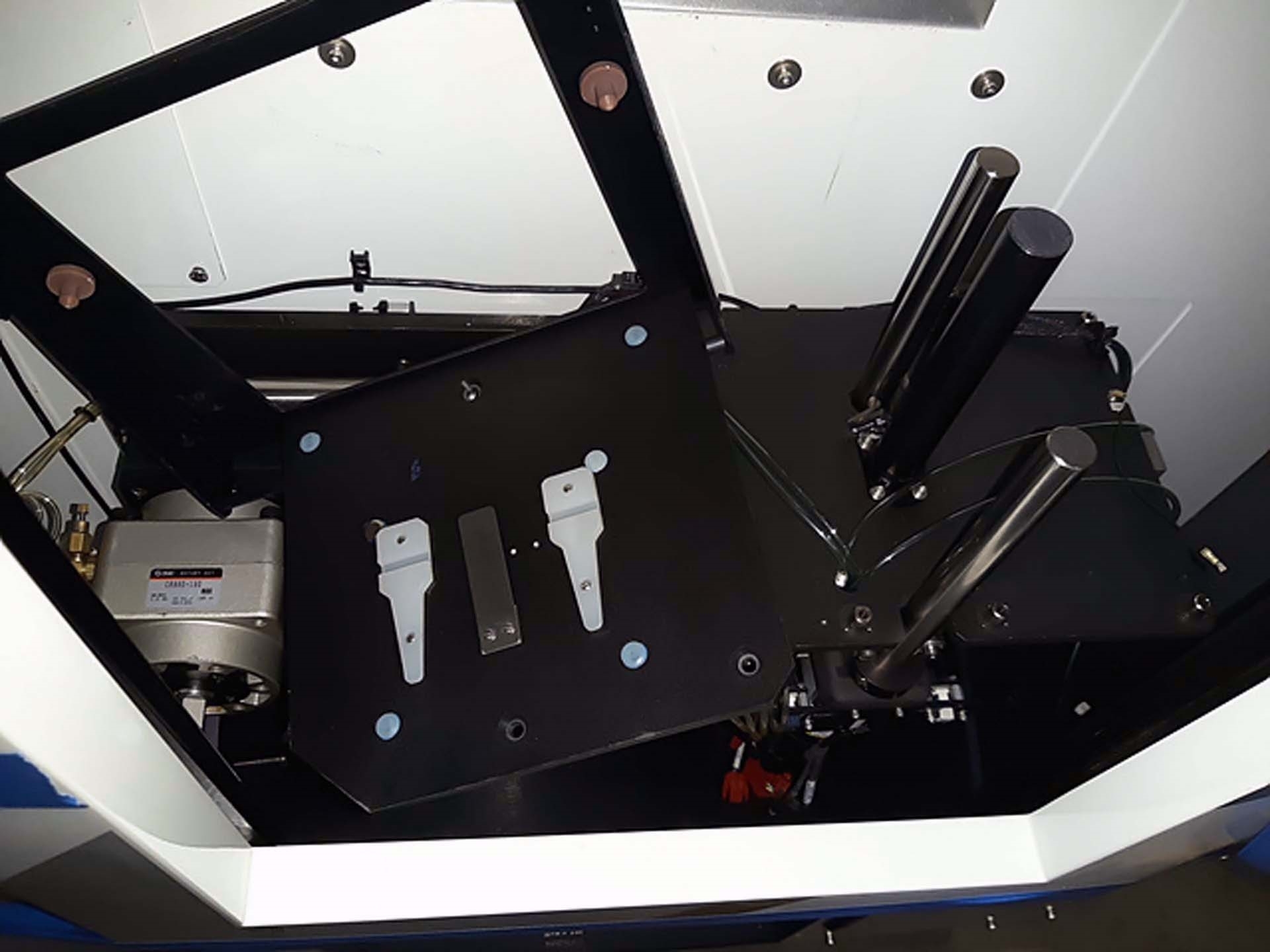

AMAT / APPLIED MATERIALS P5000 Reactor is a state-of-the-art, highly efficient plasma deposition chamber designed to provide critical interface engineering and process capabilities within the industrial production environment. This tool has been developed to offer a wide variety of process opportunities within a robust design that enables quick setup and repeatable high-performance deposition results. AMAT P-5000 reactor features a high temperature (450°C) vacuum chamber with an aluminum alloy chamber liner. Inside, a multi-torch gas injection system is capable of plasma assistedOxide and Nitride film deposition. The design also has excellent energy waveform capabilities, including pulse wave modulation with a high-power magnetron source, enabling precise control of material deposition rates and layers. With its efficient energy-saving design, APPLIED MATERIALS P 5000 reactor is well suited for high-performance deposition processes. In terms of accuracy and precision, the tool enables precise management of ion source, substrate geometry and surface temperature. Its integrated double-chamber architecture means that two separate sets of deposition parameters can be set up to meet challenging requirements. Additionally, film deposition can be adjusted using a powerful, yet flexible, "toggle" switch that enhances film properties during the deposition process. In addition to its robust design, P-5000 reactor is suited for use with a variety of substrates. In particular, it is well suited for silicon wafers, as well as temperature-sensitive substrates such as glass, composites and polyimide. Furthermore, its compatibility with a wide range of materials allows for the complex deposition of multi-layer stacks, usually required in many manufacturing applications. AMAT P 5000 reactor is a powerful deposition tool capable of supporting a range of precise deposition requirements. Its robust design allows for precise and repeatable high-performance deposition results with precise control of process parameters. Its multi-torch gas injection system is capable of precise material deposition rates and layered film deposition. With its efficient energy saving design and wide substrate compatibility, this cutting-edge tool is able to meet the precise requirements of many industrial production applications.

There are no reviews yet