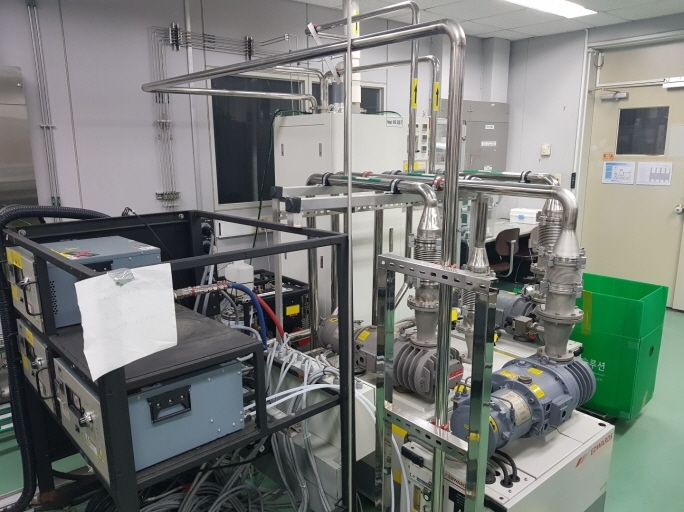

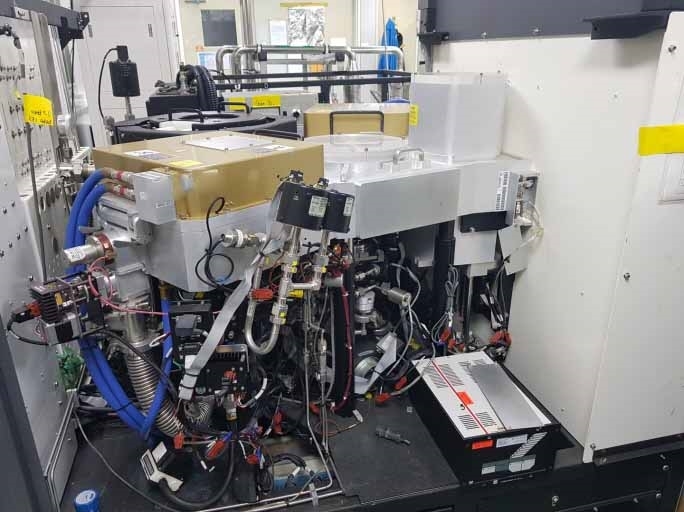

Used AMAT / APPLIED MATERIALS P5000 #9291585 for sale

URL successfully copied!

Tap to zoom

ID: 9291585

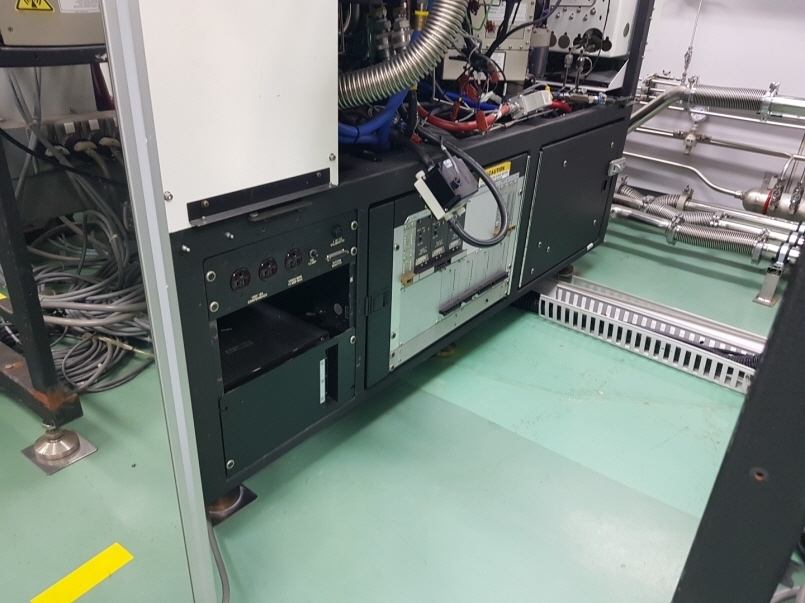

System

Chamber position: A, B, D

Downstream Plasma Apparatus (DPA)

Slit valve type: S Slit

Slit valve o-ring: Kalrez

Lamp module: Standard

Heater window: Quartz

Throttle valve: Cluster

No lamp module water flow switch

No Endpoint detector

No RGA port

Manometer:

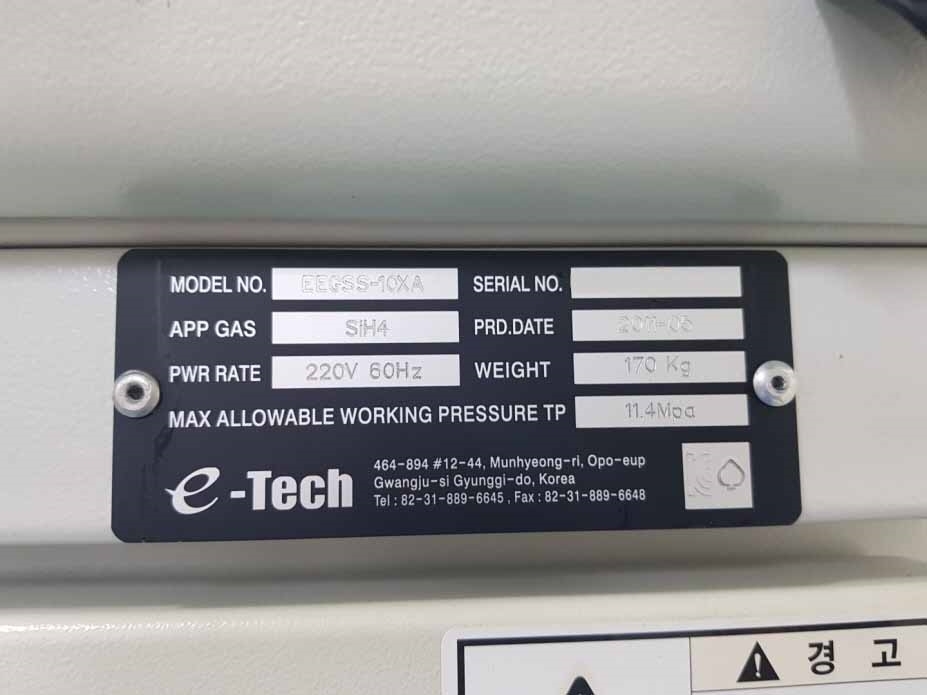

VCR: 10T (Silane)

VCO

Process kit:

Wafer lift: Metal (Standard)

Pumping plate: 0020-30059

GDP / Blocker: 0020-30286 / 0020-34775

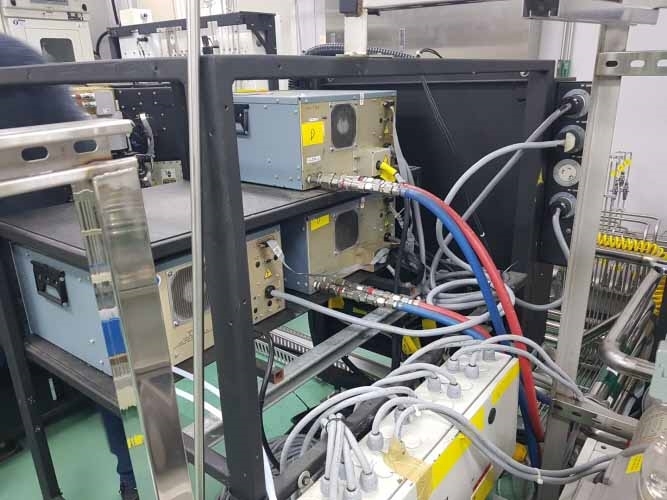

Gas delivery options:

Silane chamber, 8"

Pallet / Process / Flow / Cal / MFC

Position / Gas / Size / Gas / Type

1 / SiH4 / 500 cc / SiH4 / Unit 1660

2 / NH3 / 300 cc / NH3 / Unit 1660

3 / N2O / 3 slm / N2O / Unit 1660

4 / NF3 / 5 slm / CF4 / Unit 1660

5 / N2 / 10 slm / N2 / Unit 1660

RF frequency: Single.

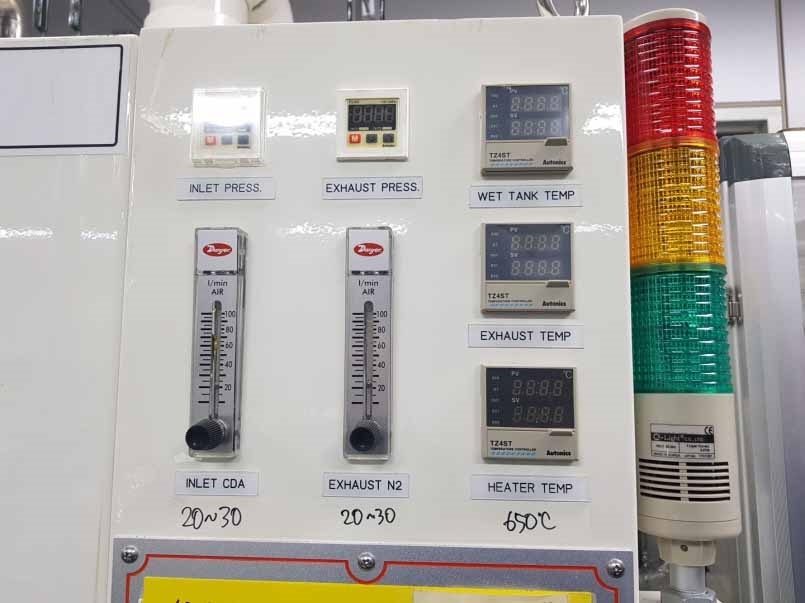

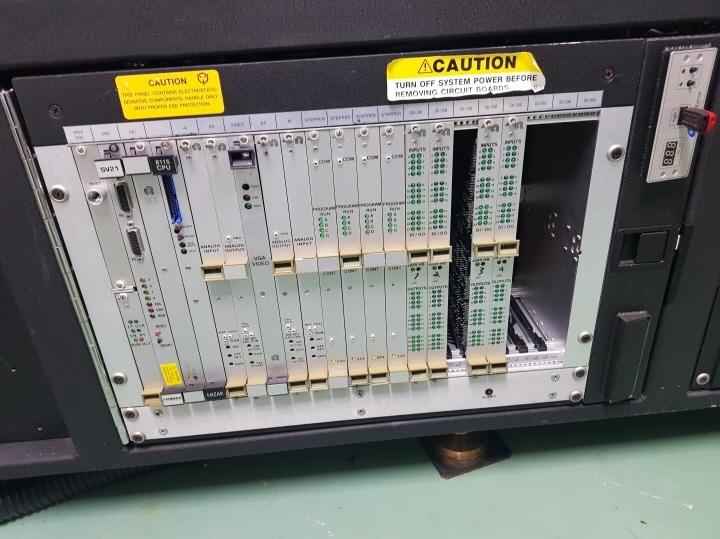

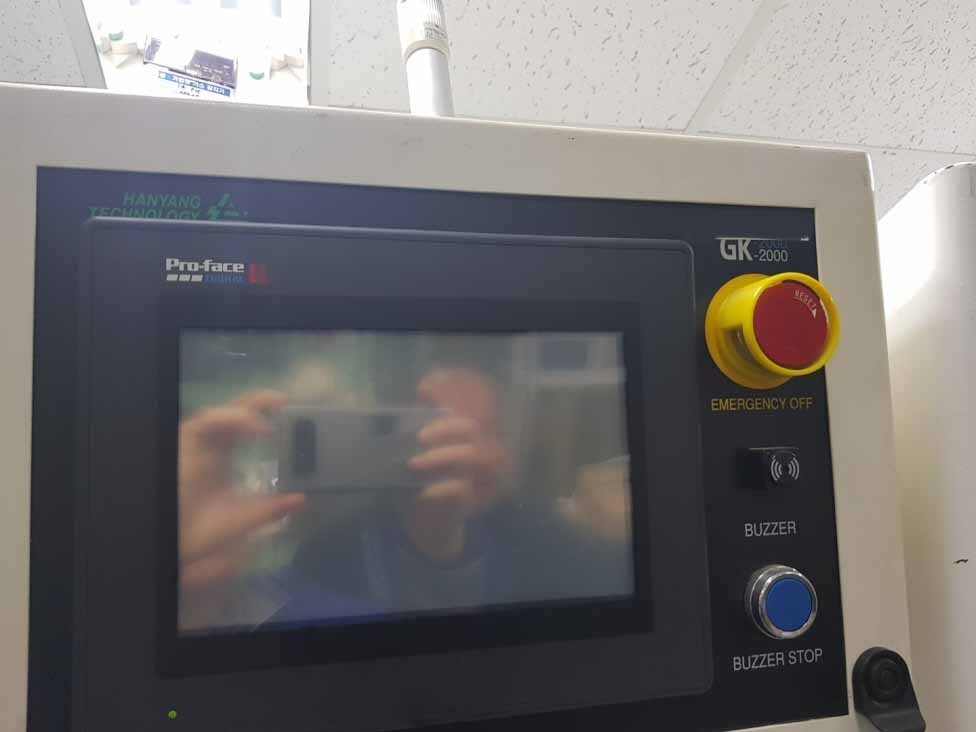

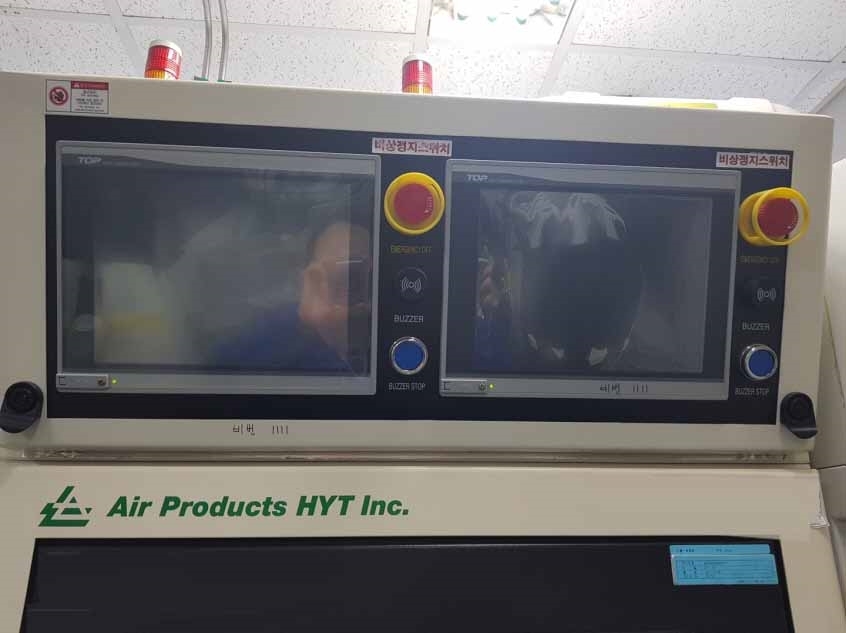

AMAT / APPLIED MATERIALS P5000 Reactor is a state-of-the-art manufacturing equipment designed specifically for semiconductor production. It is a powerful, versatile tool that can be used to produce many different types of semiconductor devices such as logic, memory, and mixed-signal integrated circuits (ICs). AMAT P-5000 consists of several modules, including a reactor chamber, gas distribution system, and a computerized controller. The primary component of APPLIED MATERIALS P 5000 is the reactor chamber, a stainless steel unit that houses the reaction process. This chamber can be configured to a wide variety of temperatures, pressures, and gas flows, allowing a variety of processes to be performed. The chamber is also fitted with a quartz window that allows for real-time monitoring and performance analysis of the process. APPLIED MATERIALS P5000 also includes a gas distribution unit and computerized controller. This machine ensures that the correct gas mixture is delivered to the chamber, regardless of the processing conditions. The tool also allows for fine-tuning of parameters such as pressure, temperature, and reaction chamber dimensions. This ensures that the desired end result is obtained. Finally, AMAT / APPLIED MATERIALS P-5000 also includes several safety features, including an alarms asset for both low and high temperatures, a pressure-monitoring model, and over-pressure protection valves. The reactor is also equipped with sensors to monitor the chemical composition of the gases, helping to ensure that the process is safe and efficient. In conclusion, P5000 Reactor is a powerful and versatile tool for the manufacture of semiconductor devices. Its extensive range of features can be configured to meet the exact requirements of a variety of processes, ensuring that the desired end result is obtained. Its numerous safety features also ensure that any process is safe and efficient.

There are no reviews yet