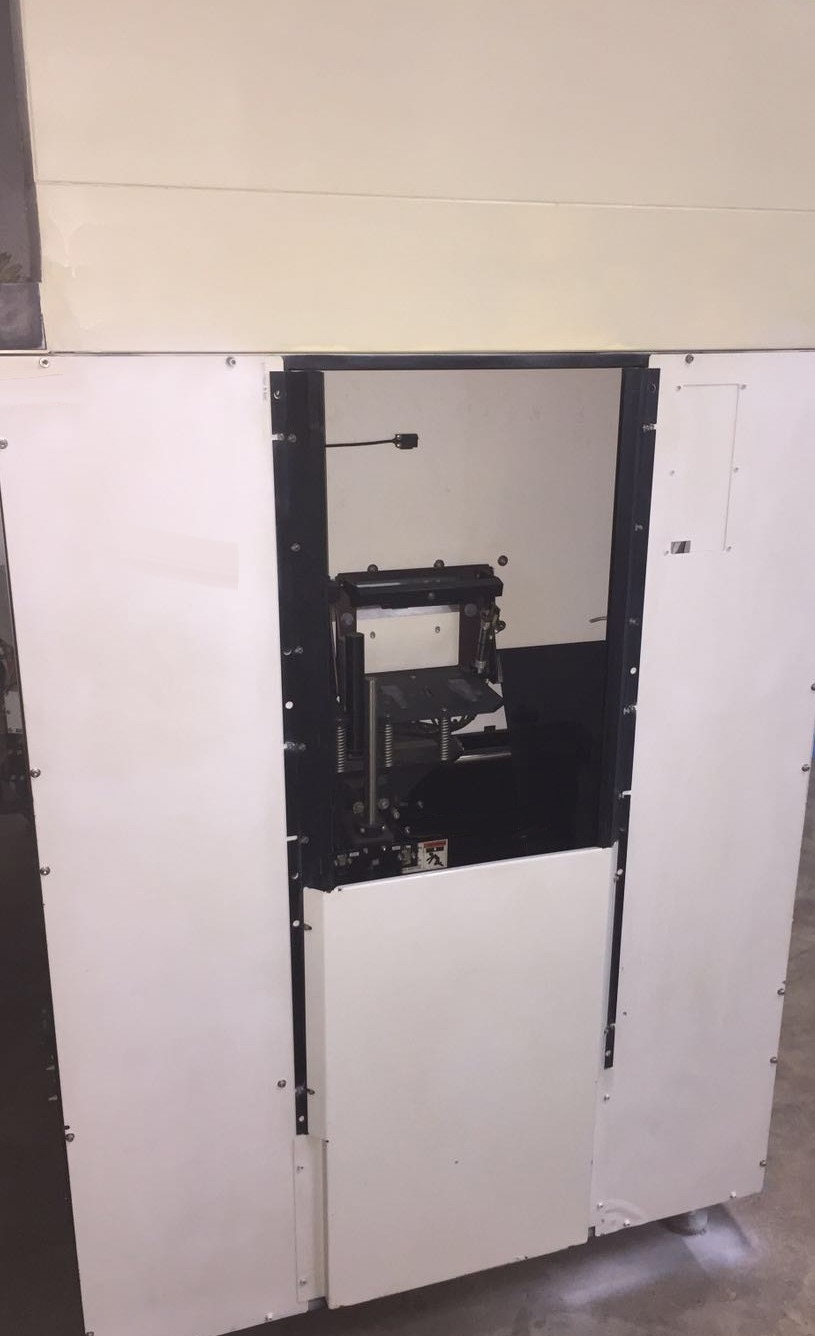

Used AMAT / APPLIED MATERIALS P5000 #9292241 for sale

URL successfully copied!

Tap to zoom

ID: 9292241

Wafer Size: 6"

Vintage: 1995

PECVD System, 6"

Mark II frame

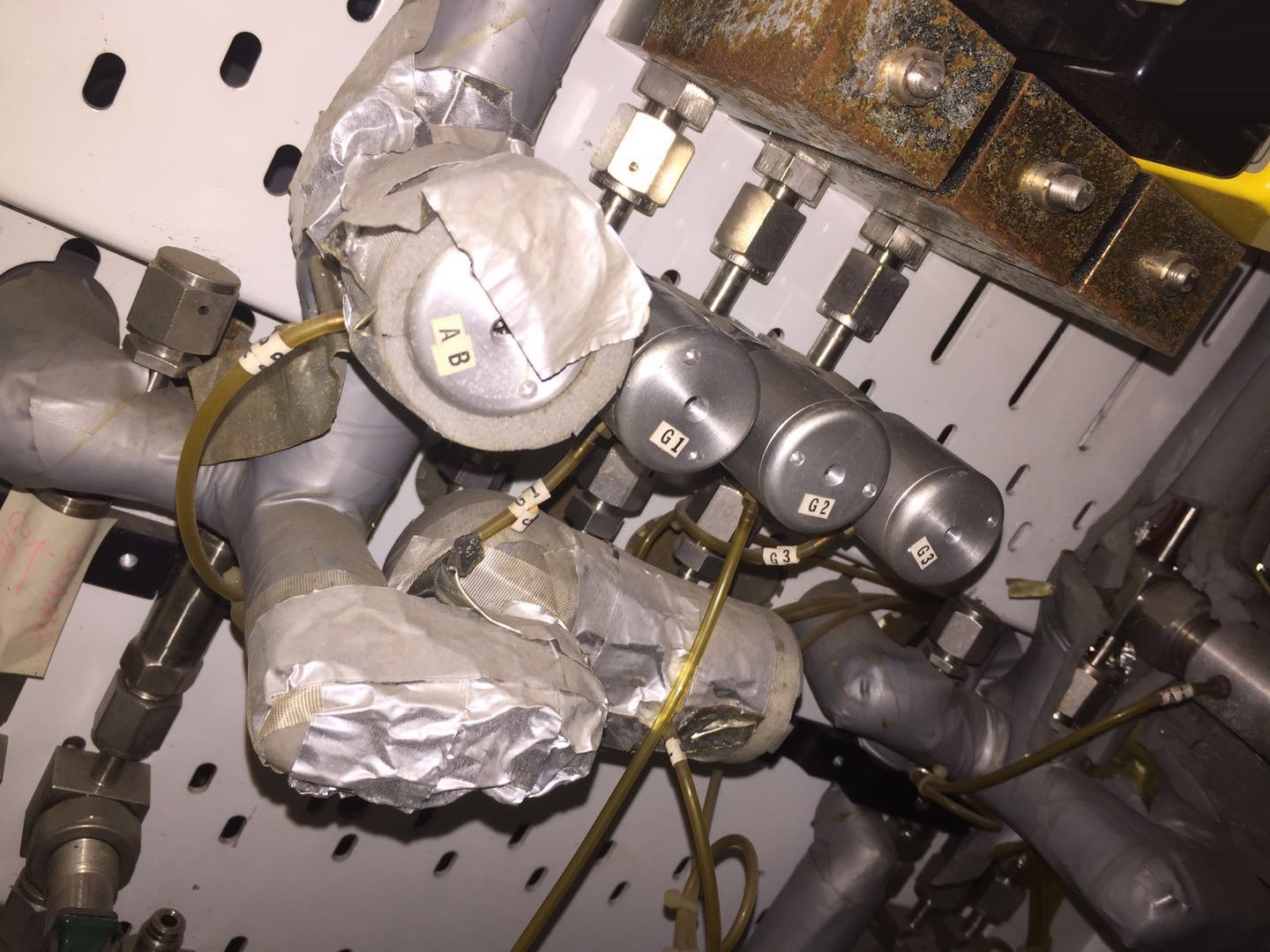

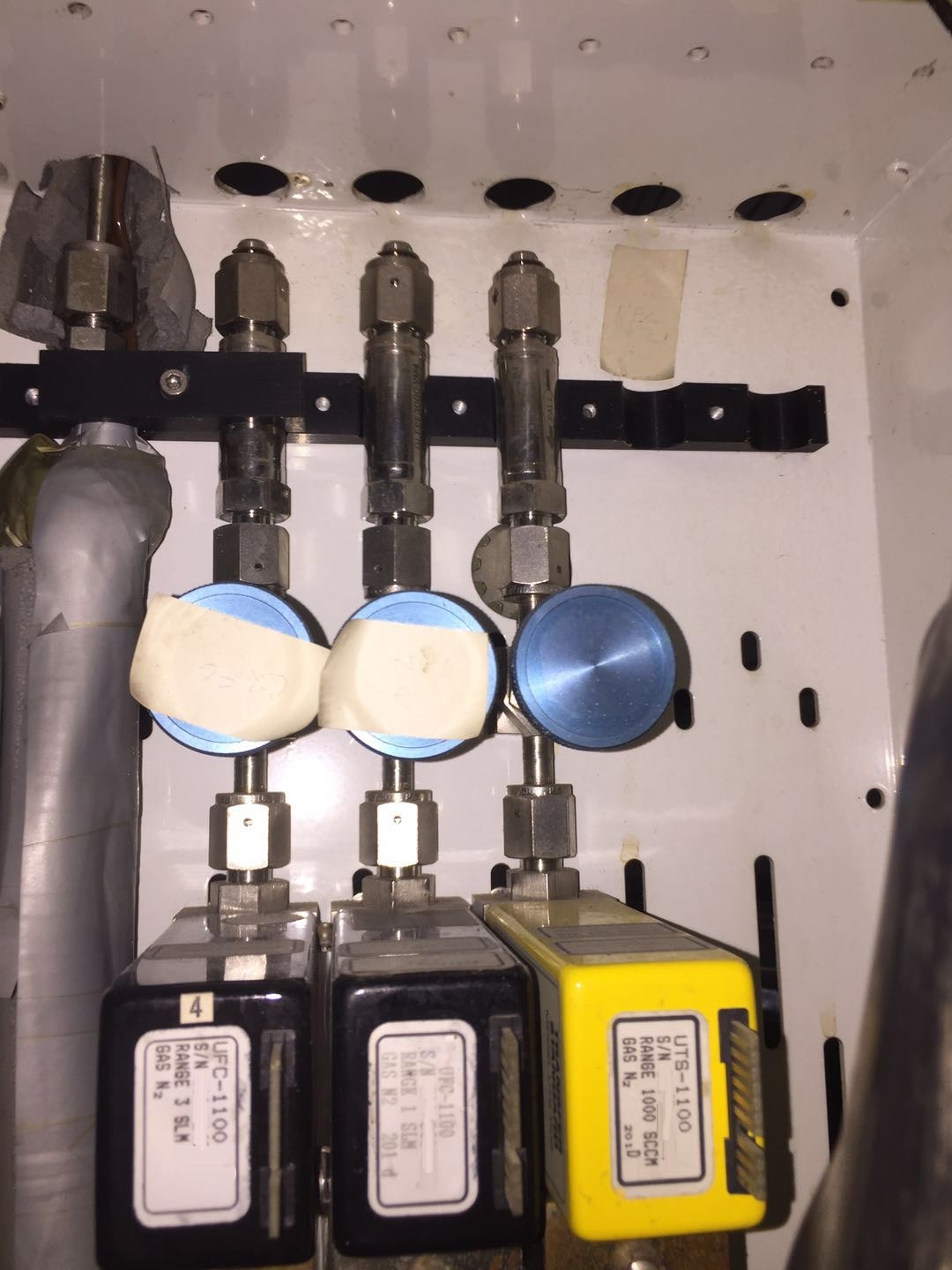

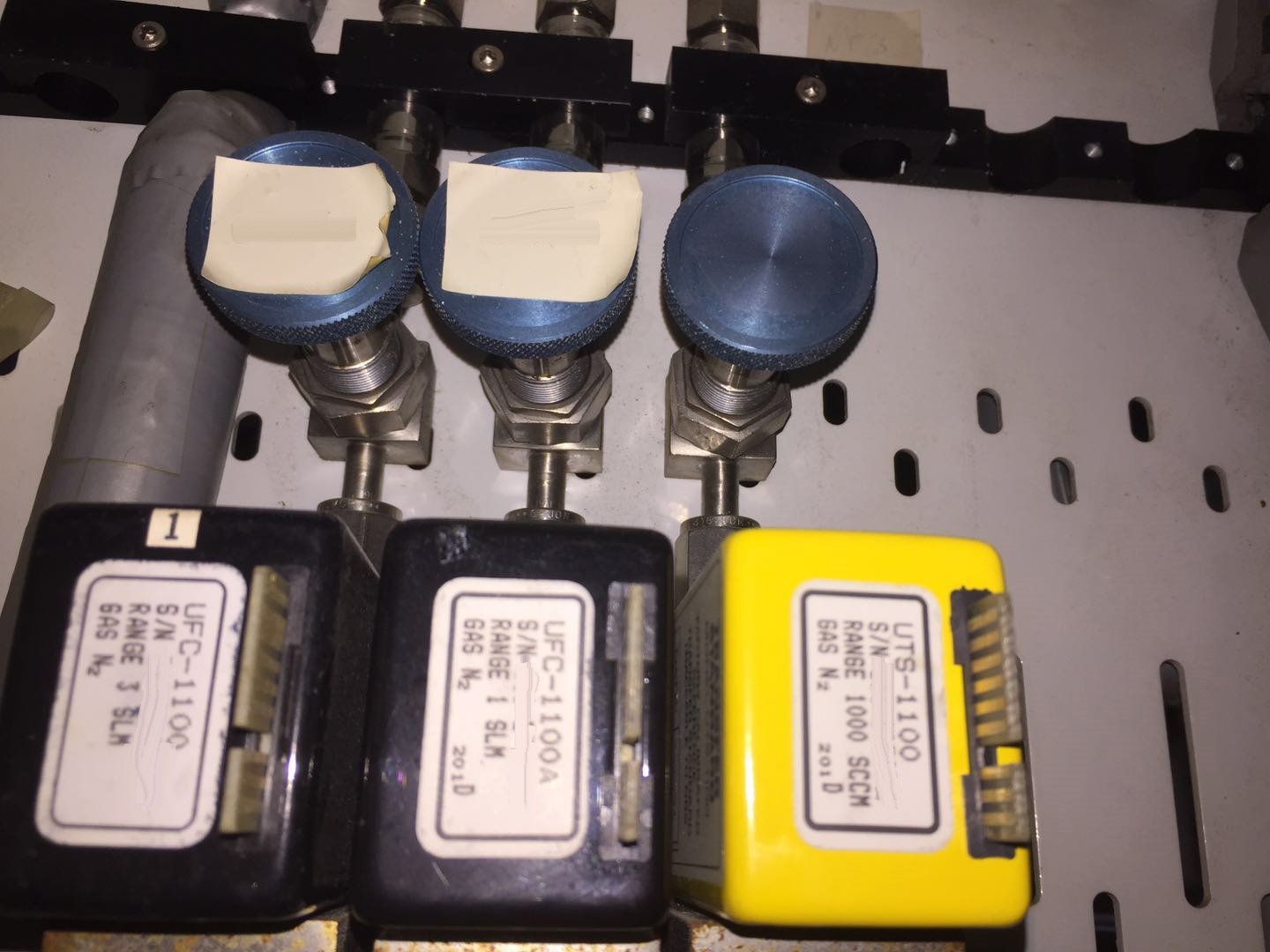

Chamber and gas configuration:

(3) PETEOS Etch

(4) TEOS chamber and etch back

A: 1100 sccm N2, 1 sccm N2, 3 slm N2 TEOS Bubbler

B: 1100 sccm N2, 1 sccm N2, 3 slm N2 TEOS Bubbler

C: 1100 sccm N2, 1 sccm N2, 3 slm N2 TEOS Bubbler

D: 5sccm CF4, 100CC AR

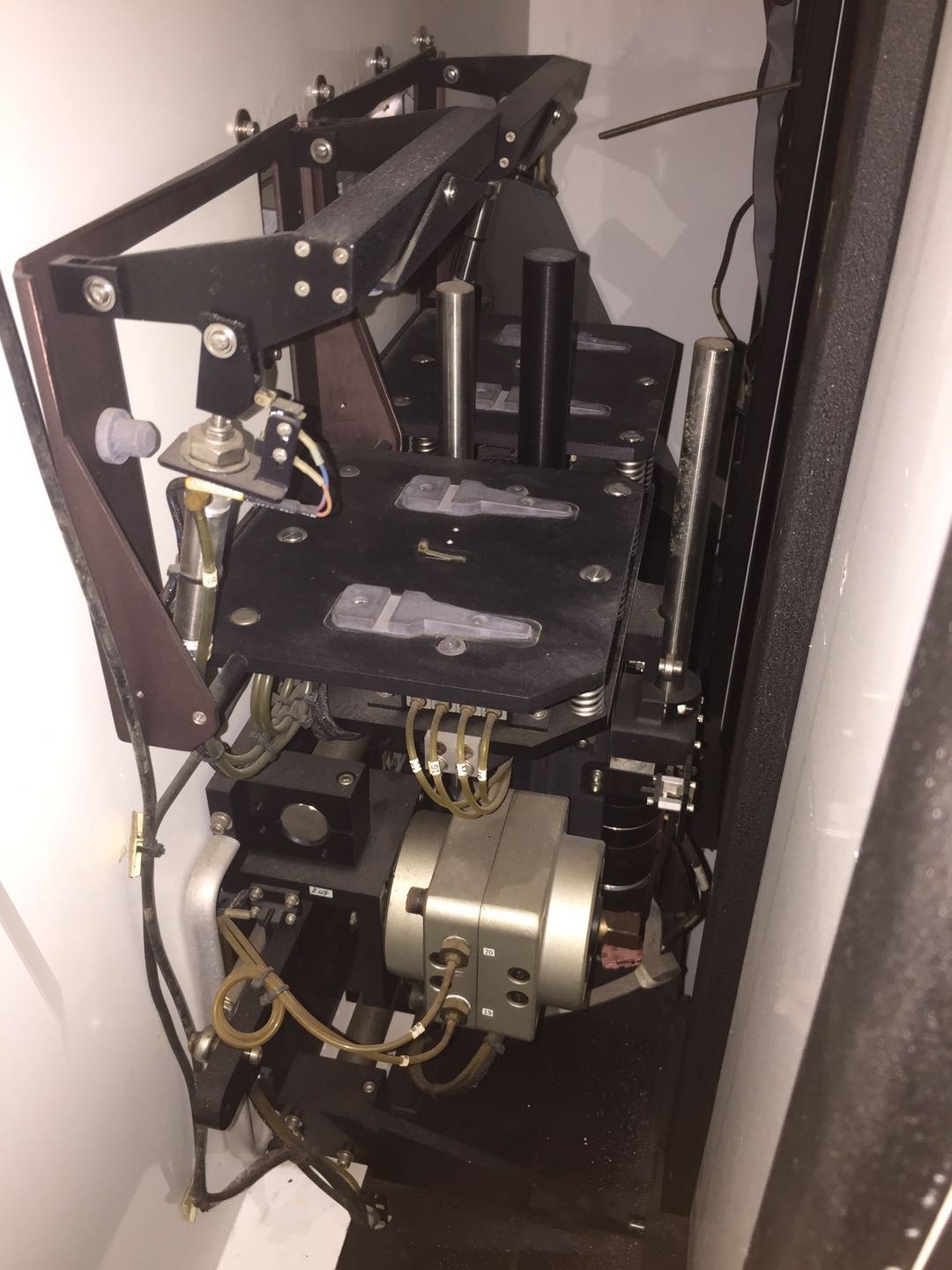

Chuck type: Mechanical clamp

Elevator size: Short

Frame type: Standard

Loader type: Manual

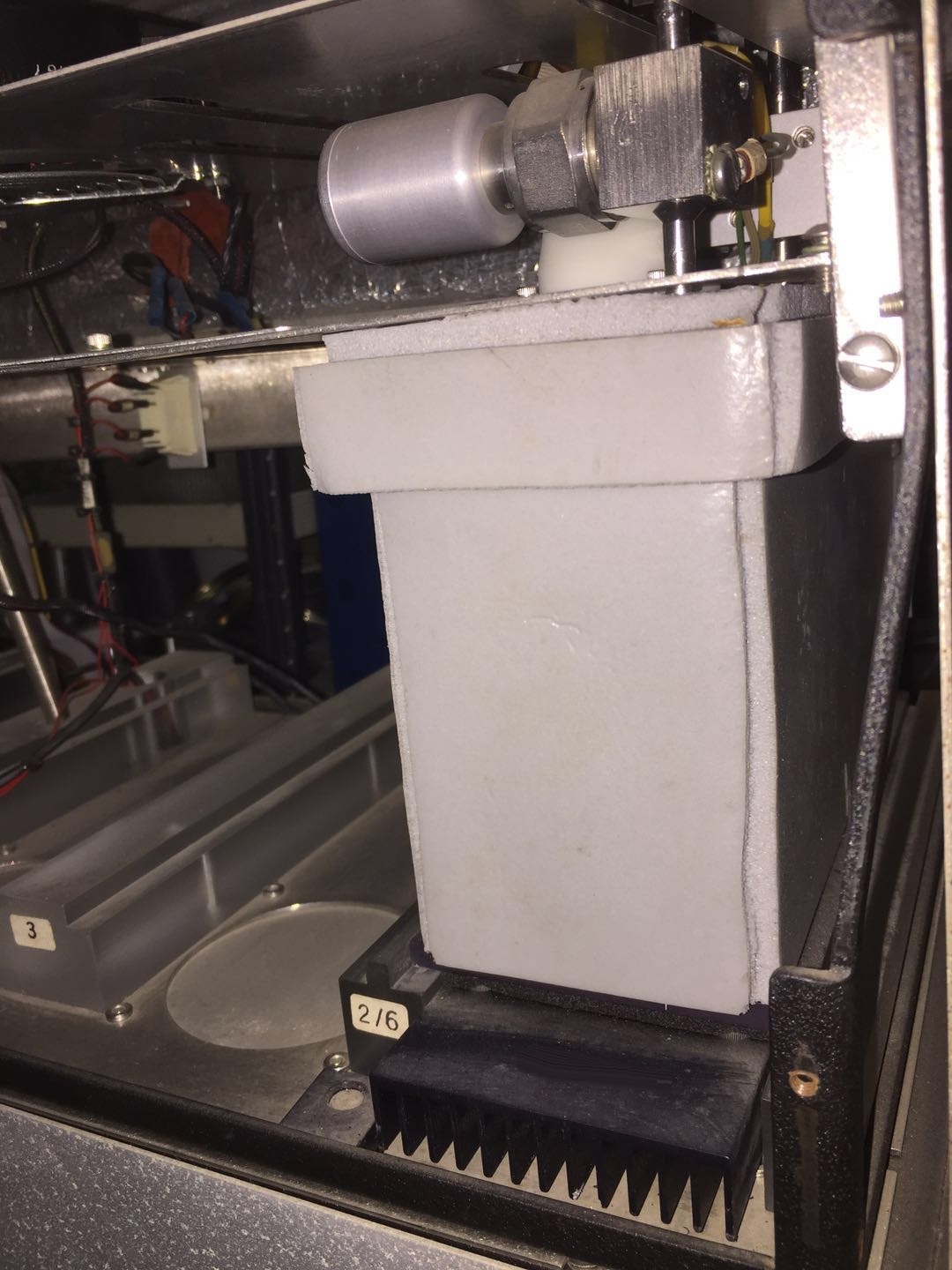

Loadlock

Gas box: Hot

RF Matches

Indexers

Automated cassette-to-cassette handling

Include:

Chiller

Turbo pumps

Controllers

No Remote AC BOX

No generator rack

1995 vintage.

AMAT / APPLIED MATERIALS P5000 is a multi-chamber, high throughput surface-processing chamber with state-of-the-art features designed to provide high-performance precision processing for a wide range of sub-10nm integrated circuit applications. The chamber offers a range of feature sizes down to 0.3nm and offers robust performance even at extremely low doses up to single digit nanoamperes. It offers superior parallelism for accurate profile control, high hydrogen sensitivity and nanoscale precision control to meet the requirements for IC production. AMAT P-5000 is an advanced Plasma Enhanced Chemical Vapor Deposition (PECVD) source. It uses a powerful source chamber, a hyper-fast pump speed, and advanced variable-temperature process control to reduce the time required for processing almost any substrate. This capability allows the customer to place their process into production in a fraction of the time. The reactor is unique in that it offers unprecedented precision of process reference by providing variable temperature control as standard on the system. APPLIED MATERIALS P 5000 uses the four-quadrant temperature control to ensure the temperature of the gas in the reactor zone can precisely match the customer's temperature profile. P-5000 also offers a unique "plasma-in-place" feature, which can ensure minimal thermal damages due to rapid cooling and re-heating of the substrate. This plasma-in-place capability also helps prevent deposition anomalies on the substrate by maintaining uniform substrate temperature during the thermal-accelerated cycle of deposition cycles. AMAT / APPLIED MATERIALS P-5000 is designed to offer superior performance and enable customers to achieve their desired process results without the need for a high level of expertise. P 5000 offers a user friendly control interface, which allows the customer to monitor process parameters, make adjustments on the fly and incorporate process feedback for improved process control. APPLIED MATERIALS P5000 also features a Fully Leveraged PECVD feature that allows customers to leverage the benefits of PECVD in a single, cost efficient system. AMAT P 5000 supports multiple different process recipes, including substrate-level patching, lithography, anneal and oxidation processes. The integrated hardware, software and pre-configured recipe databases simplify the setup process and minimize the time required to develop and tune dielectric stacks and other applications. In conclusion, P5000 is a robust, feature-rich and advanced surface-processing chamber for sub-10nm IC applications. The reactor offers superior precision and performance, along with the user interface and support for multiple recipes for a simplified, cost-effective and efficient process.

There are no reviews yet