Used AMAT / APPLIED MATERIALS P5000 #9292243 for sale

URL successfully copied!

Tap to zoom

ID: 9292243

Wafer Size: 6"

Vintage: 1995

PECVD SiO2 / SiN /dry etcher, 6"

Mark II frame

Chambers and gas configuration: Dry etch, TEOX, SIN

(3) Chambers for Dry Etch, TEOX, SIN

(1) PTEOS Chamber

(1) Oxide etch Chamber

(1) SiN Chamber

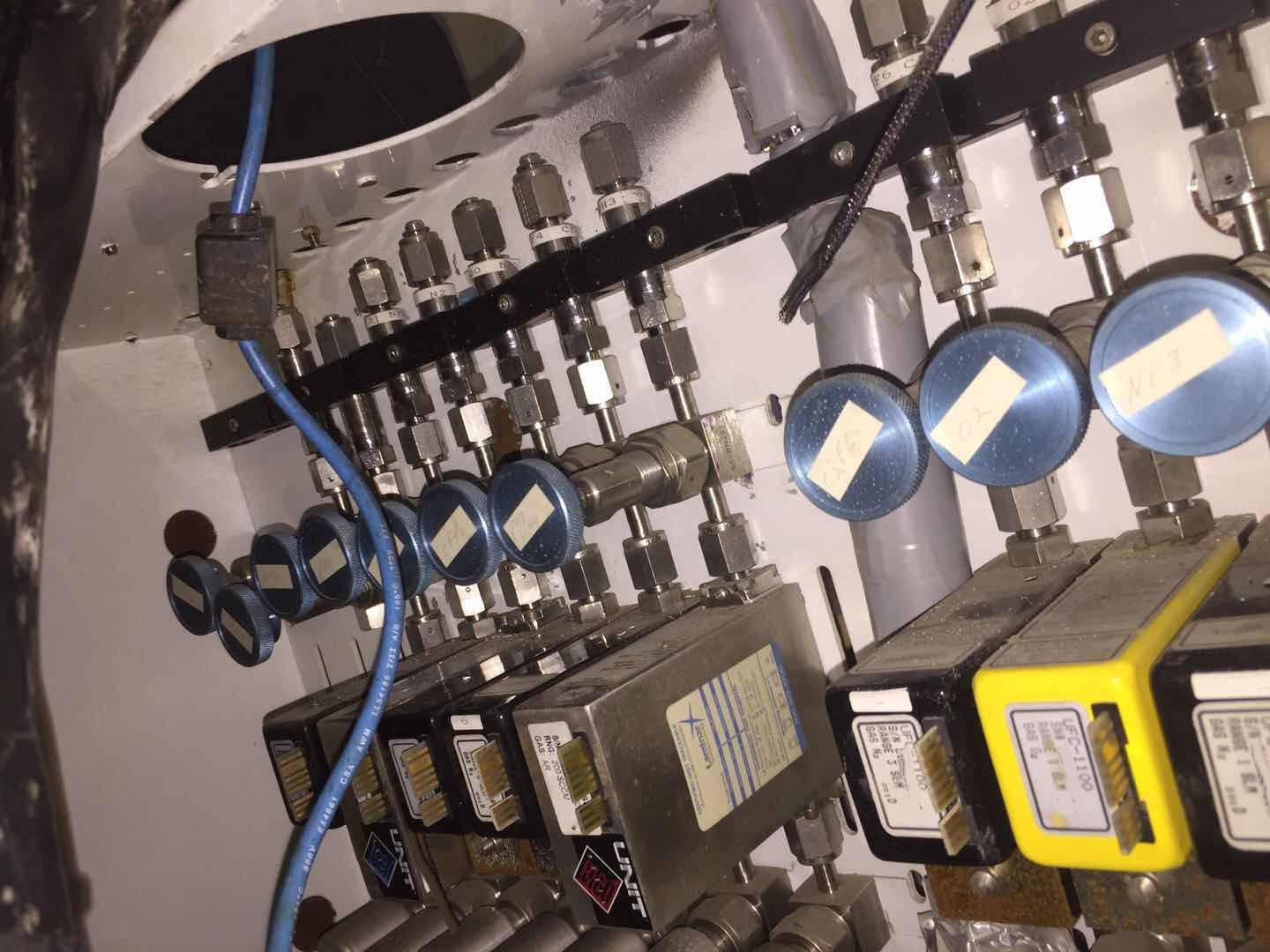

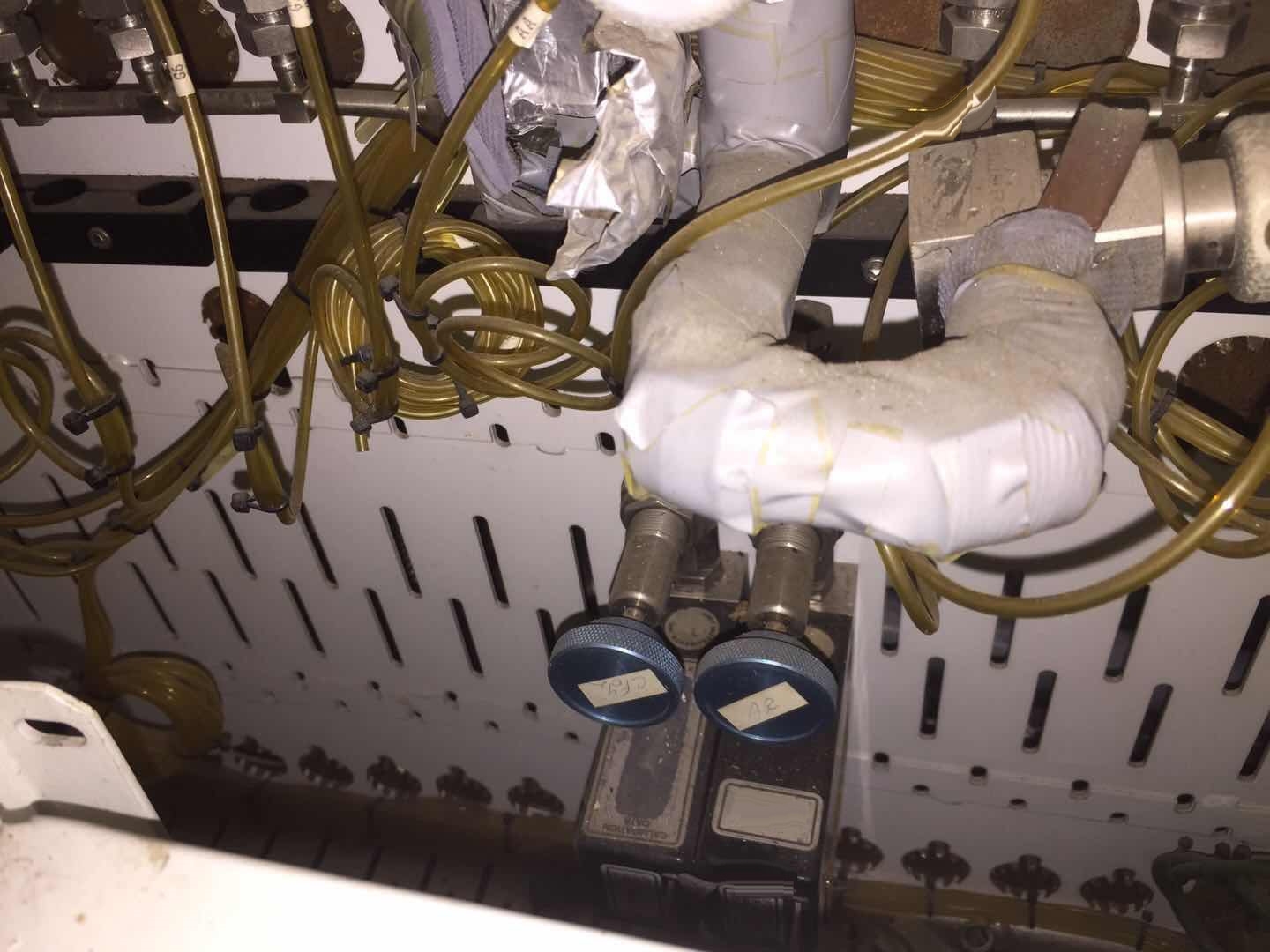

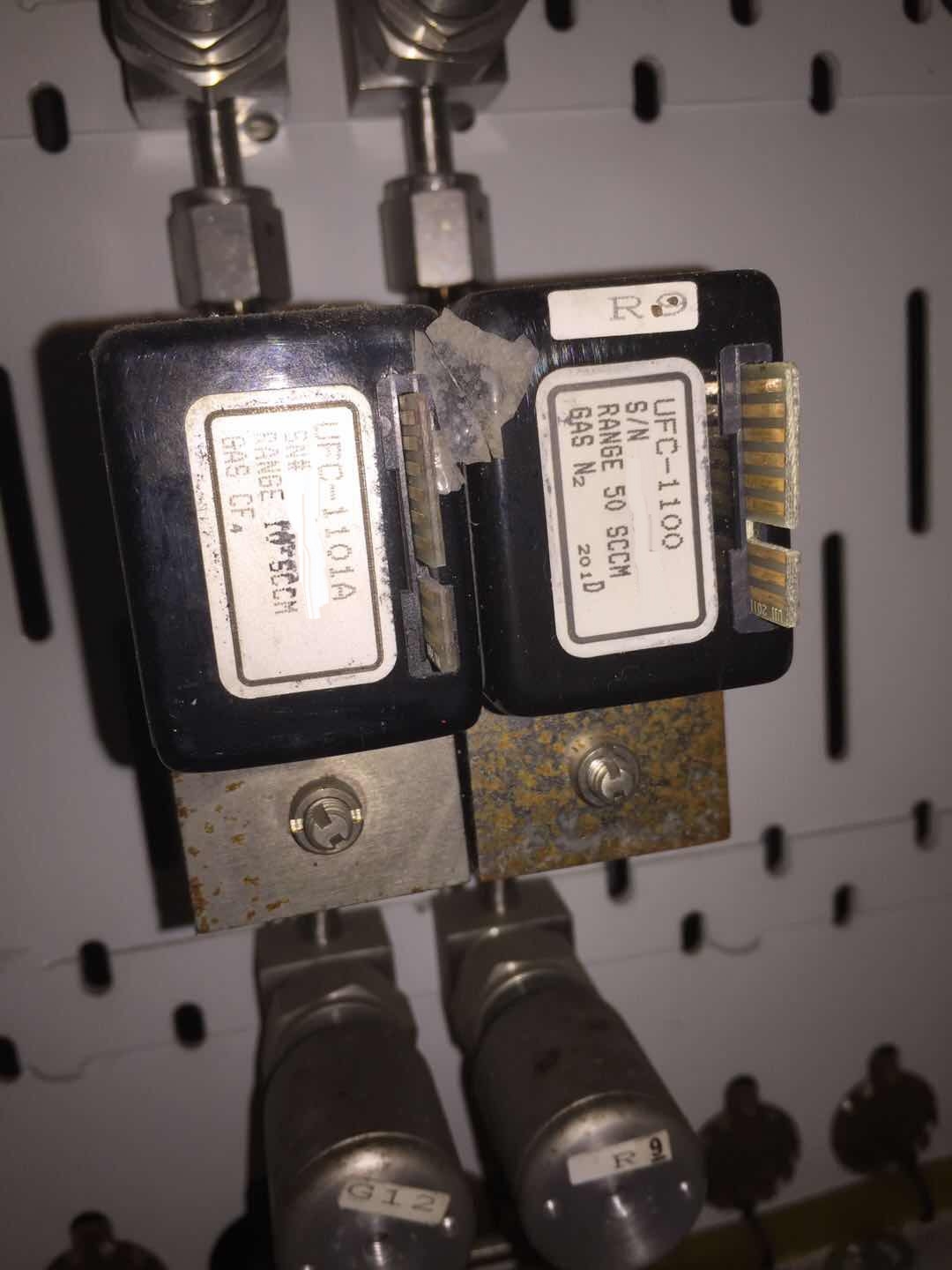

A: 50 sccm N2, 1 slm N2, 1 slm O2, 3 sccm N2, SiH4

B: 200 sccm Ar, 3 slm N2, 3 000sccm N2, 1 slm N2, 100sccm NH3, 500 sccm N2, (SiH4)

C: 1100 sccm N2, 1 sccm N2, 3 slm N2 TEOS Bubbler

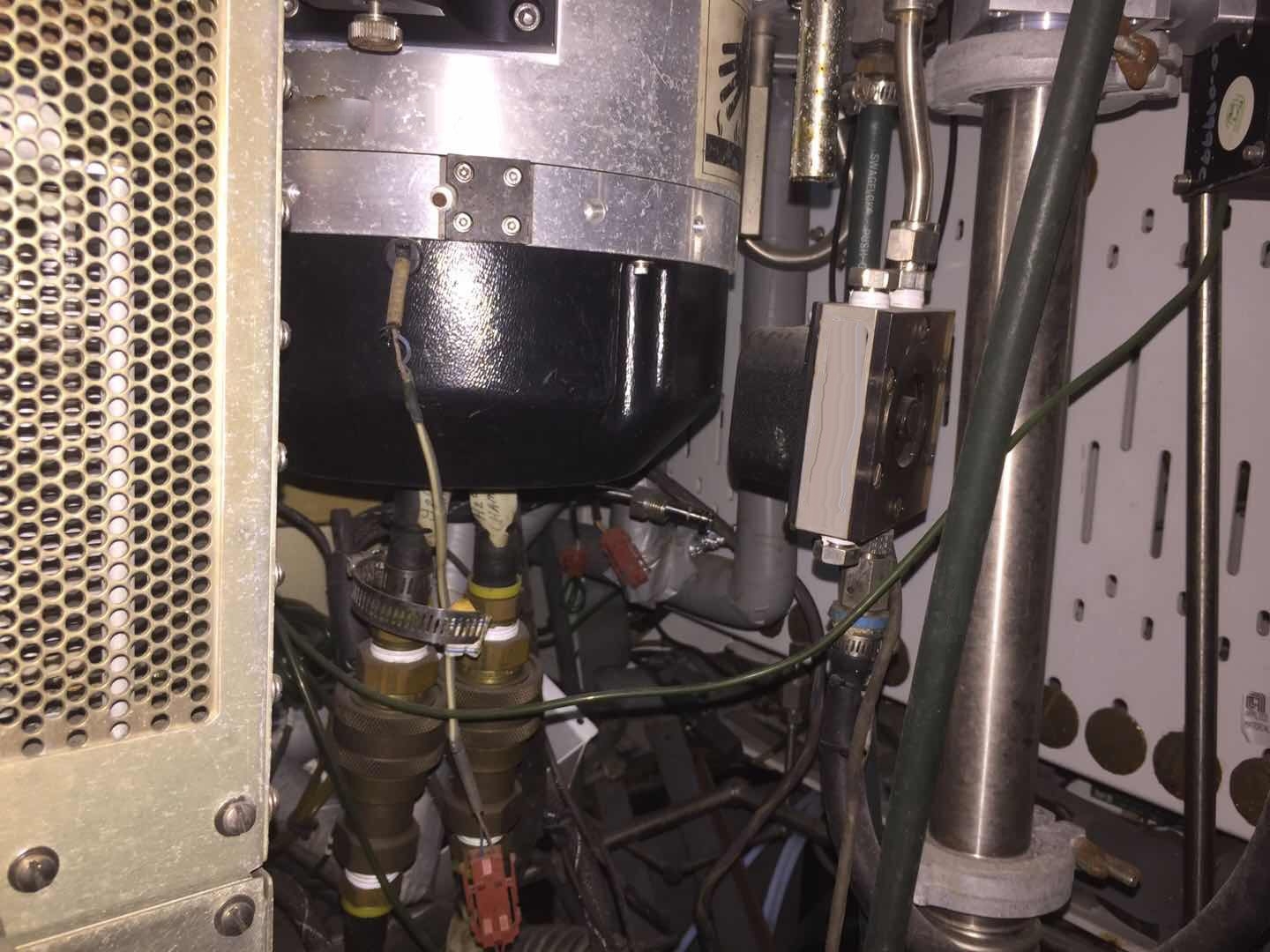

Chuck type: Mechanical clamp

Elevator size: Short

Frame type: Standard

Loader type: Manual

Loadlock

Gas box: Hot

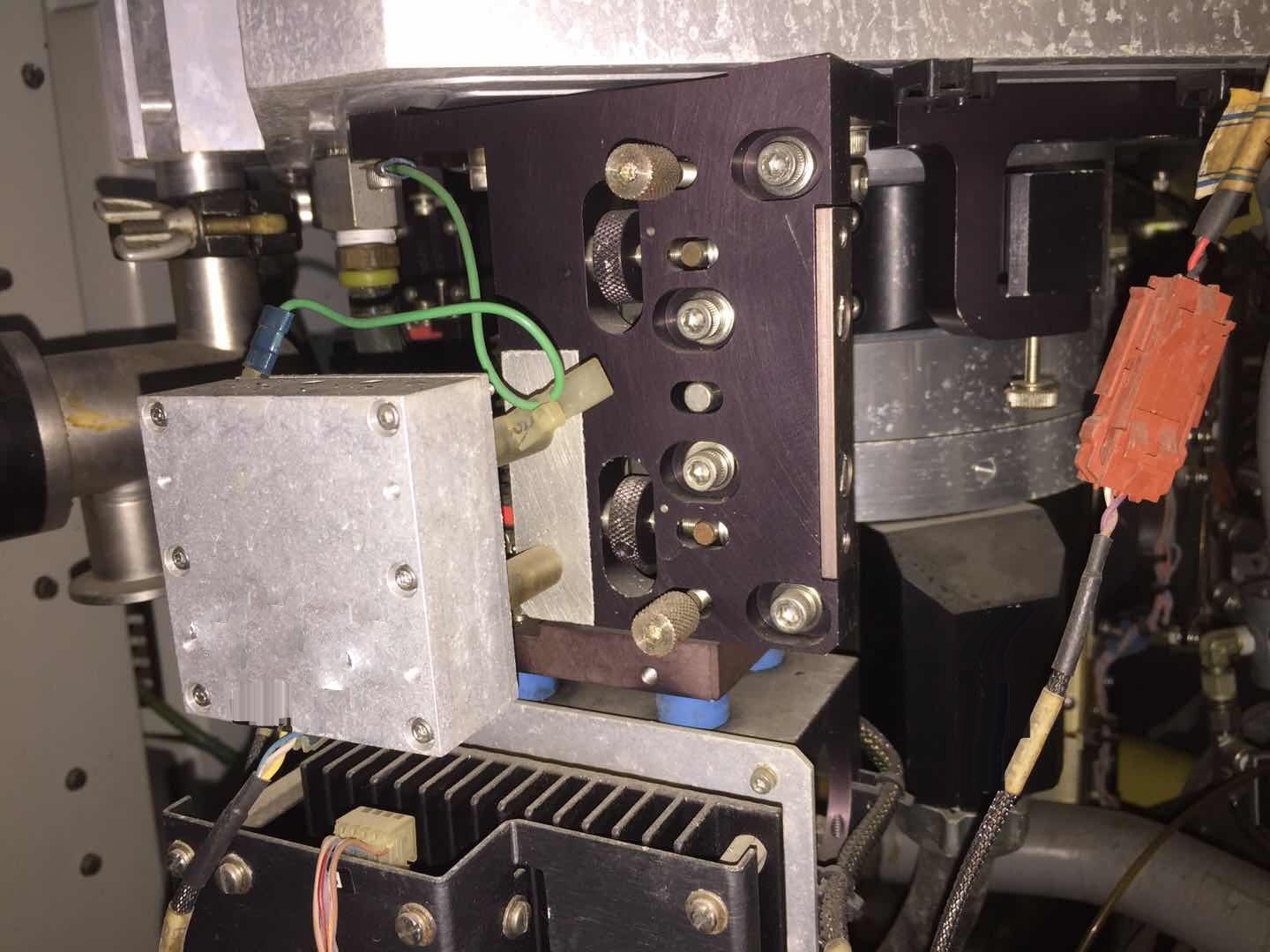

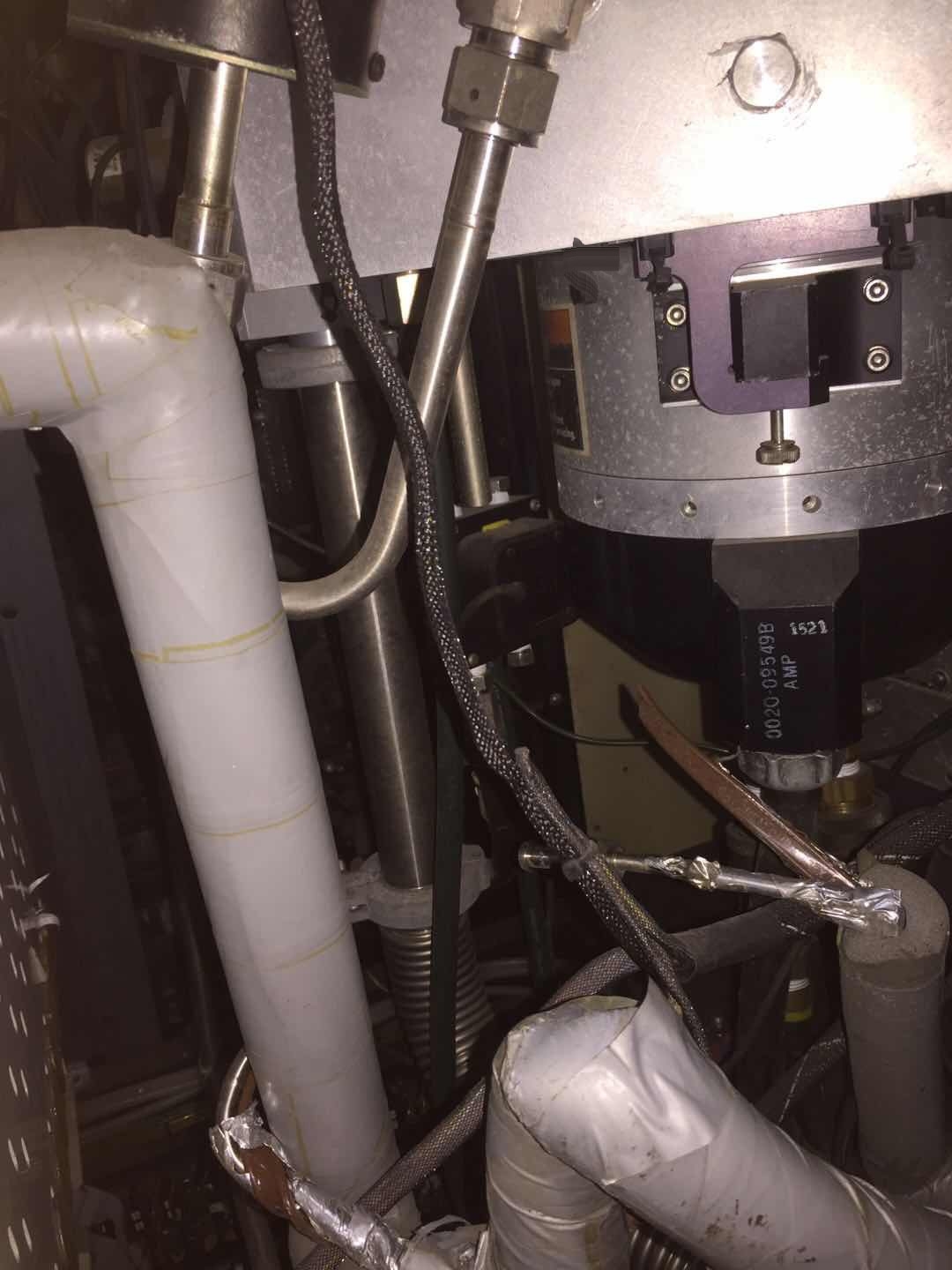

RF Matches

Indexers

Automated cassette-to-cassette handling

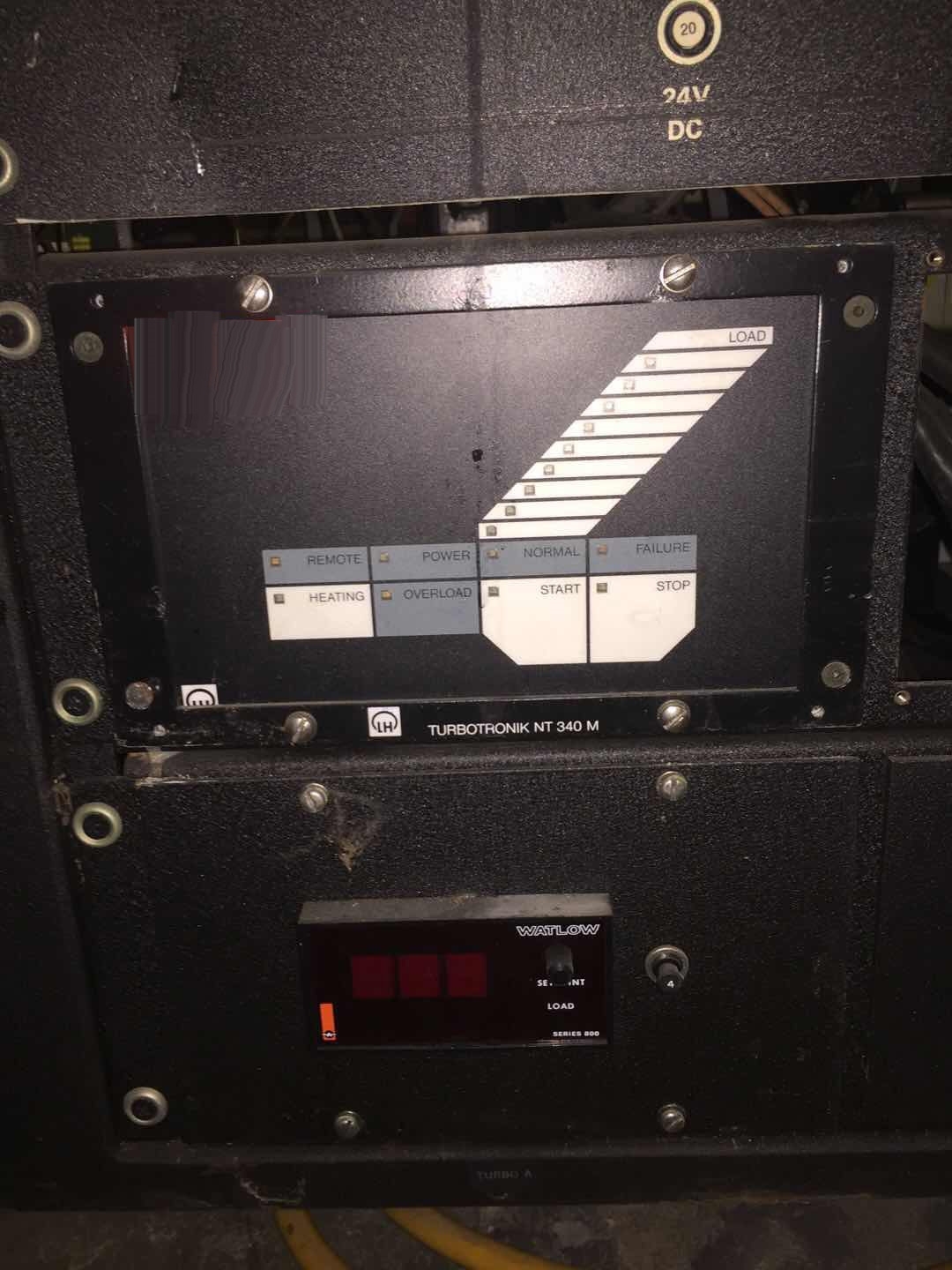

Turbo pumps

Controllers

No Remote AC BOX

No generator rack

1995 vintage.

AMAT / APPLIED MATERIALS P5000 reactor is a high performance re-oxidation tool used in the semiconductor industry. It is specifically designed to improve the design and performance of today's integrated circuits and is used to re-oxidize aluminum films and dielectric films. AMAT P-5000 provides repeatable and reliable oxidation processes which result in reduced cycle time, higher throughput and lower costs. APPLIED MATERIALS P 5000 is the industry's most advanced re-oxidation technology, with a unique and sophisticated architecture that includes powerful hardware, process and software technologies. The hardware of AMAT P5000 reactor includes a high temperature silicon carbide susceptor and furnace, an evaporation source to supply active material, a quartz split tube with guard gas and a process gas delivery system. All these components come together to provide an optimized oxidation process. The process control software of P5000 allows the user to run real-time experiments to optimize their process parameters, control temperature and flow rates, and condition the chemical environment within the chamber. The software includes both kinetic and process control functionality, giving users ultimate control over their oxidation process. APPLIED MATERIALS P5000 utilizes AMAT sophisticated process control technology, which features four different temperature zones for each film delivered to the chamber. This helps ensure a precise, repeatable oxidation process with each and every run. Additionally, the system's 'turbo-mode' allows surges of oxygen power supply during process transients. This helps provide a more uniform oxidation profile across wafers, resulting in improved yield. AMAT / APPLIED MATERIALS P 5000 reactor is an ideal tool for the precise and precise application of electrodes to aluminum films and dielectrics. It is capable of providing precise and repeatable oxidation processes, resulting in reduced cycle time, higher throughput, and lower costs. The system is supported by APPLIED MATERIALS powerful process control software, which gives users ultimate control over their oxidation processes.

There are no reviews yet