Used AMAT / APPLIED MATERIALS P5000 #9351563 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9351563

Wafer Size: 8"

Vintage: 2000

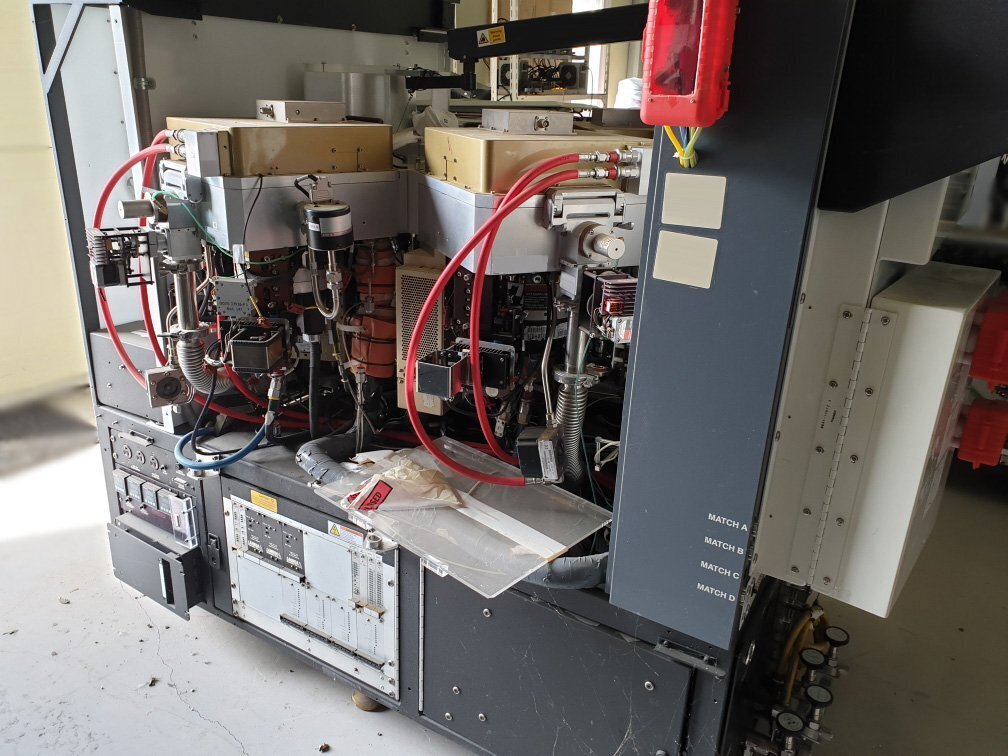

CVD System, 8"

Chamber A / B / D:

Type: DCVD Universal

Process: Delta / TEOS

Process kit: Plasma C-Chuck

Manometer: Dual 20-1000 Torr / MKS

Clean method: RF Clean

Throttle valve: Direct drive dual spring W/C plug

Gas box MFC: UNIT MFC

Lamp driver

RF Match: Phase IV

Chamber C:

Process: Sputter etcher

Standard process kit

Manometer: Single Torr / MKS

Clean method: RF Clean

Standard throttle valve

Gas box MFC: UNIT MFC

21-Controller slots

Floppy Disk Drive (FDD), 3.5"

Robot type: Phase III

Auto-load / Unload cassette handler

Silicon-Tin-Oxide (STO) elevator type: 15-Slots

WPS Sensor

I/O Wafer sensor

Loadlock purge

Loadlock slow vent

Slit valve type: ZA Slit valve

Hot box version: Version IV

Top / Standard exhaust line

(28) Gas line panels

Mini controller

Missing parts:

Turbo pump (Chamber C)

RF Match (Chamber C)

SBC Board

Video board

Ampule

RF Generator OEM 12B I, II

2000 vintage.

AMAT / APPLIED MATERIALS P5000 reactor is a robust, high performance production tool designed to enable the deposition of materials ranging from alloys to oxides to dielectrics with complete surface coverage and optimized microstructures. The reactor is powered by a highly efficient source with a pulsed electron beam and a high-efficiency ionizer, capable of producing high deposition rates with a high degree of coverage and homogeneity. AMAT P-5000 reactor has an integrated, high power pulsed electron beam (PEB) that uniformly decelerates ions, allowing for uniform coverage in a broad range of etch processes, offering complete coverage to deep structures. The PEB also allows for high-temperature annealing of the materials during deposition, allowing for improved metal bonding and better material properties. An adjustable dual-direction end-effusion ionizer allows for fine tuning of ion populations, which enables efficient ion bombardment and uniform coverage of the substrate. APPLIED MATERIALS P 5000 is a high throughput, cost-effective reactor system with a wide range of applications. It is suitable for a range of processes in the field of microelectronics, including deposition of dielectrics, metal evaporation, and plating of metals. The reactor is also well-suited for deposition of organic, inorganic and hybrid films such as insulators, conductors, and other types of substrates. Moreover, the reactor is suitable for both hard and soft annealing processes to modify the properties and microstructure of the substrate. P-5000 reactor features a multi-stage design that enables high-speed washing of wafers prior to deposition, and drying of wafers after etching is complete, for improved processing quality. The system also includes a dedicated plasma monitor to ensure efficient and accurate control of chamber parameters. Moreover, APPLIED MATERIALS P-5000 utilizes a gas panel, enabling users to employ a wide variety of gases for calibration or chamber cleaning. The highly efficient P5000 reactor is ideally suited for production level operations in a wide range of applications, and is backed by AMAT extensive technical support, training, and services. P 5000 is an ideal solution for semiconductor manufacturing processes requiring high quality, reliable, and repeatable results.

There are no reviews yet