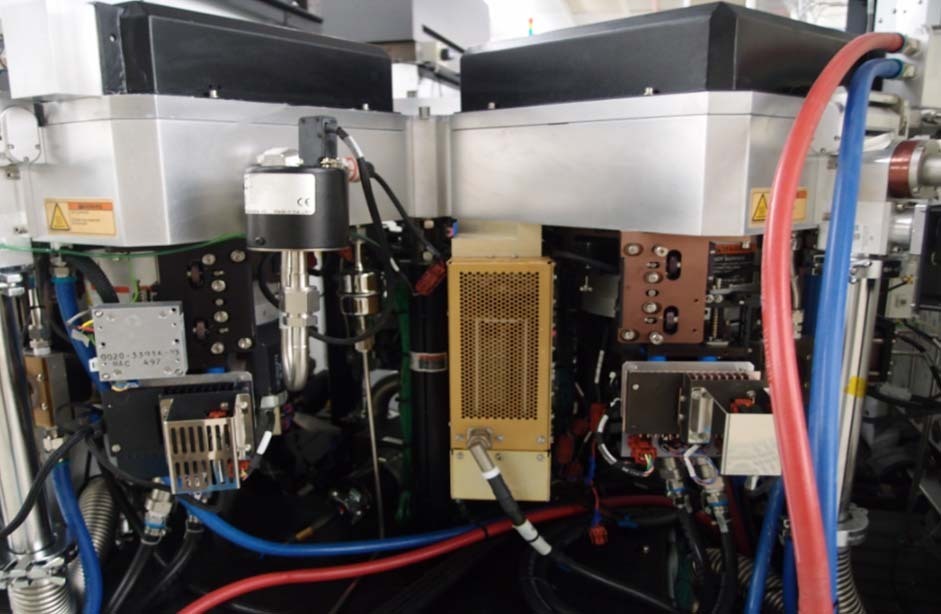

Used AMAT / APPLIED MATERIALS P5000 #9373099 for sale

URL successfully copied!

Tap to zoom

ID: 9373099

CVD system, 6"

SV21 SBC Board

Main frame type: Mark-II

Cassette indexer, 6" clamp

8-Slots elevator

(2) CRT Monitors

Robots: Phase-III

Robot blade: Standard vacuum

Center finder: USE

Cap wafer sensor

AC Rack: 1 Shrink

Heat exchanger

EMO Option: Turn to release

EMO Button guard rings

Status light tower (Color / Position): Red, yellow, green, blue

Signal cable: 25'

Flash Hard Disk Drive (HDD)

Floppy: 3.5" SCSI Driver

Gas panel: 12 Channels standard / Minicontroller

RF Generator:

Chamber A: OEM12B-07

Chamber B: OEM12B-02

Chamber C: OEM12B-02

Chamber:

Chamber position: A, B, D

Chamber type: DLH 1-Hole

Process: SiH4 Oxide

Heater type: Lamp

Susceptor type: Al

(3) Matches

Delta nitride dual spring throttle valve

Gas panel: 20 Standard channels

Gas supply: Top down

MFC: SEC4400MC

Manual valve: NUPRO

Pneumatic 2-Way valve: NUPRO

MKS 122B Baratron gauge, 10 Torr

Gases:

Gas / Range

N2 / 3 SLM

SiH4 / 100 SCCM

CF4 / 2 SLM

N2O / 2 SLM.

AMAT / APPLIED MATERIALS P5000 is a commercially available, high capacity UHV reactor designed for use in a variety of ultra-high temperature processes. The equipment is designed to offer superior cleanliness and temperature uniformity, while also providing high levels of throughput and productivity. It is constructed from stainless steel with a variety of user selected finishes. The system features a high performance water-jet-assisted deposition unit, providing efficient energy input and substrate heating for uniform, repeatable deposition process control. This machine also offers high-speed scanning and full pulsed-plasma excitation capabilities. At the heart of the tool lies an ultra-high vacuum, high performance reactor chamber. This chamber is designed to provide an ultra high vacuum environment with long pumping cycles, enabling a wide variety of ultra high-temperature processes, such as sputtering, high temperature evaporation and several other chemical vapor deposition process. The high temperature, uniformity and modularity of AMAT P-5000 allows for a wide range of process parameters and materials to be tested in one asset. APPLIED MATERIALS P 5000 model is also equipped with advanced materials handling and positioning systems. This includes a wafer positioning equipment and a robotic arm that can be used to manipulate parts, both of which are capable of operating in all three complimentary axes of motion. The system also includes a linear stage for accurate part positioning and point-to-point motion, together with a 3-dimensional encoder for precise part positioning. This unit allows for efficient, repeatable loading and unloading of components into the chamber and enables the user to achieve the desired process results. P5000 machine is designed to support a variety of process recipes, including conformal deposition and etch processing. The stable high-temperature environment and an adjustable gas delivery tool make it suitable for a variety of applications. The asset also incorporates integrated process monitoring tools, such as in-situ monitoring of the process chamber and ejection of the deposited films. The integrated in-process monitoring model provides real time process feedback, allowing users to make timely adjustments to improve production yields and quality. AMAT P 5000 Reactor is an ideal choice for users looking for an optimized and highly productive process platform for a range of deposition and etching processes. With its combination of efficient energy input, high temperature uniformity and integrated process control capabilities make it the perfect choice for efficient and repeatable production runs. Its user-friendly design means that even inexperienced users can quickly set up and run the equipment to achieve maximum process yields.

There are no reviews yet