Used AMAT / APPLIED MATERIALS P5000 #9389400 for sale

URL successfully copied!

Tap to zoom

ID: 9389400

Wafer Size: 6"

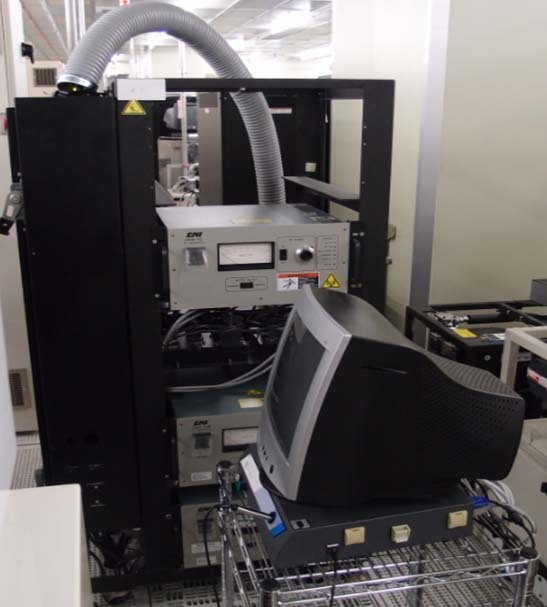

CVD System, 6"

SV21 SBC Board

Main frame type: Mark-II

Cassette indexer, 6" Clamp

8 Slots elevator

(2) CRT Monitor

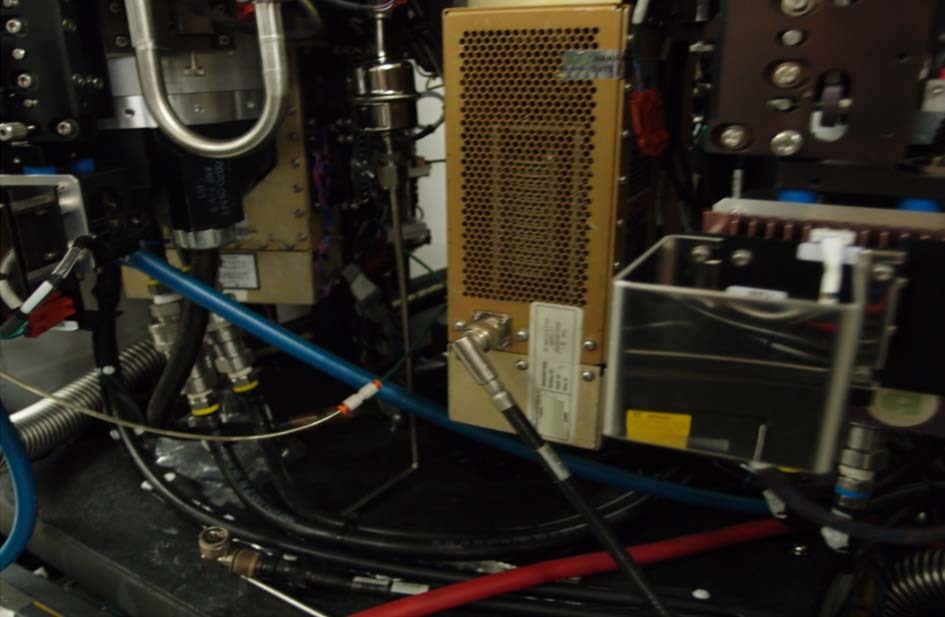

Robots: Phase-III

Robot blade: Standard vacuum

Centerfinder: USE

Cap wafer sensor

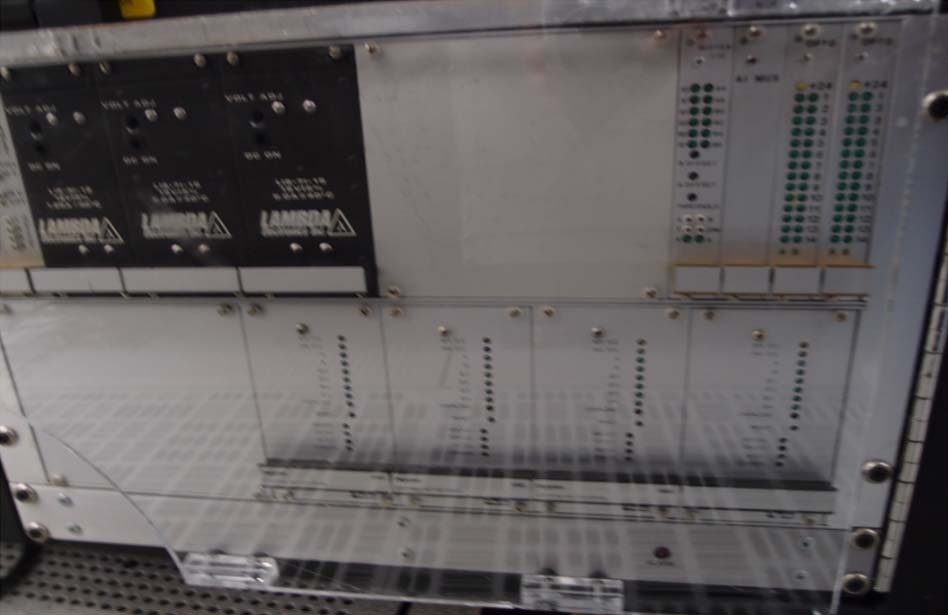

AC Rack: 1 Shrink

Heat exchanger

EMO Option: Turn to release

EMO Button guardrings

Status light tower (Color / Position): Red, Yellow, Green, Blue

Signal cable: 25'

Flash hard disk drive

Floppy: 3.5" SCSI Driver

Gas panel: 12 Channels standard / Minicontroller

RF Generator:

Chamber A: OEM12B-07

Chamber B: OEM12B-02

Chamber C: OEM12B-02

Chamber:

Chamber position: A, B, D

Chamber type: DLH 1-Hole

Process: SiH4 Oxide

Heater type: Lamp

Susceptor type: Al

(3) Matchers

Delta nitride dual spring throttle valve

Gas panel: 20 Standard channels

Gas supply: Top down

MFC: SEC4400MC

Manual valve: NUPRO

Pneumatic 2-Way valve: NUPRO

MKS 122B Baratron gauge, 10 Torr

Gases:

Gas / Range

N2 / 3 SLM

SiH4 / 100 SCCM

CF4 / 2 SLM

N2O / 2 SLM.

AMAT / APPLIED MATERIALS P5000 is a thin film reactor equipment designed for deposition of thin films on substrates, such as glass or silicon wafers. This reaction chamber is designed to provide advanced control over a range of deposition conditions, from ultra-high to ultra-low vacuum levels, over a wide temperature range (-40 to 650°C). It's located inside a clean room equipped with a sophisticated thermal management system for precise thermal control, enabling it to meet the most demanding thin film processing applications. The unit is designed to provide control over several variables related to the growth of thin films. These variables include pressure, temperature, deposition rate, and growth. AMAT P-5000 reactor uses an ultra-high vacuum deposition chamber which is equipped with gas mixing tools, mass flow controllers, capacitance manometers and an FTIR machine. It also contains linear and rotary sources, such as electron beam evaporators and sputter guns. In addition, the chamber has a roughing pump, a turbomolecular pump, and an ion pump, as well as a liquid nitrogen closed-loop chiller, to create an environment in which the thin film can be grown. APPLIED MATERIALS P 5000 reactor is also equipped with an array of process features which make it suitable for a wide range of thin film processing applications. Features of note include automatic film thickness control, temperature mapping, temperature profiling, uniformity control and real-time process monitoring. These features can be configured to ensure the film's uniformity and stress.\ The automation capabilities of AMAT / APPLIED MATERIALS P 5000 make it suitable for a number of applications. In particular, it has been used to deposit oxides, nitrides, and metals, as well as to etch films and perform passivation and ablation of materials. Furthermore, due to its precision pressure control, it is suitable to use for non-evaporation methods of thin film deposition, such as magnetron sputtering and CVD. Finally, APPLIED MATERIALS P5000 is an easy-to-operate tool with advanced safety features. It is equipped with a gas-leak detector, an emergency shut down asset, and strict monitoring of operation parameters to comply with the most stringent safety regulations.

There are no reviews yet