Used AMAT / APPLIED MATERIALS P5000 #9389401 for sale

URL successfully copied!

Tap to zoom

ID: 9389401

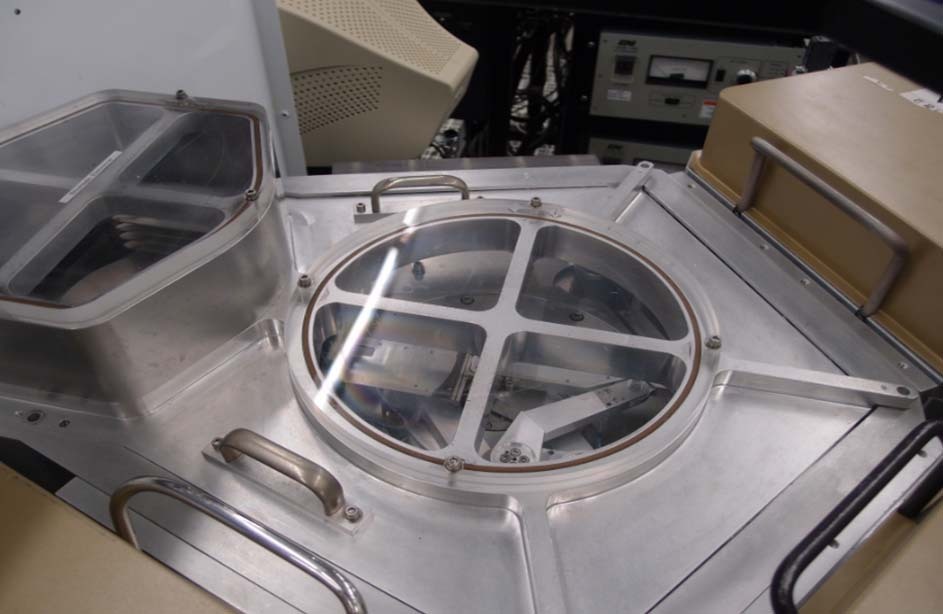

Wafer Size: 6"

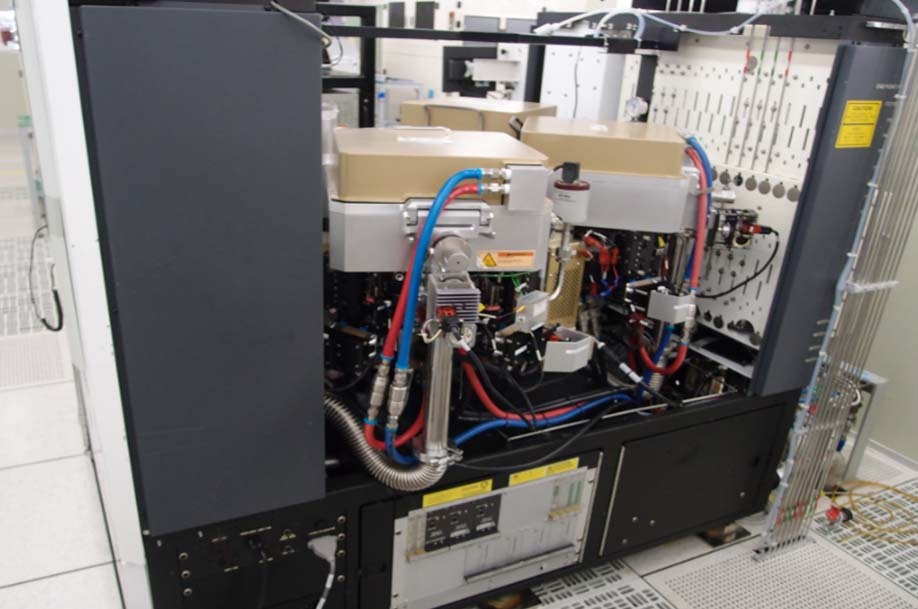

CVD System, 6"

SV21 SBC Board

Main frame type: Mark-II

Cassette indexer, 6" Clamp

8 Slots elevator

(2) CRT Monitor

Robots: Phase-III

Robot blade: Standard vacuum

Centerfinder: USE

Cap wafer sensor

AC Rack: 1 Shrink

Heat exchanger

EMO Option: Turn to rekease

EMO Button guardrings

Status light tower (Color / Position): Red, Yelow, Green, Blue

Signal cable: 25'

Flash hard disk drive

Floppy: 3.5" SCSI Driver

Gas panel: 12 Channels standard / Minicontroller

RF Generator:

Chamber A: OEM12B-02

Chamber B: OEM12B-02

Chamber C: OEM12B-07

Chamber:

Chamber position: A, B, D

Chamber type: DLH 1-Hole

Process: SiH4 Oxide

Heater type: Lamp

Susceptor type: Al

(3) Matchers

Delta nitride dual spring throttle valve

Gas panel: 20 Standard channels

Gas supply: Top down

MFC: UFC-1660

Manual valve: NUPRO

Pneumatic 2-Way valve: NUPRO

MKS 122B Baratron gauge, 10 Torr

Gases:

Gas / Range

N2 / 3 SLM

SiH4 / 100 SCCM

CF4 / 2 SLM

N2O / 2 SLM.

AMAT / APPLIED MATERIALS P5000 reactor is a high quality and reliable tool used in the semiconductor industry to improve process performance and monitor device reliability. This type of reactor typically consists of an ion source, process chamber, and an electron gun. The ion source is used to generate a controlled plasma that is used to deposit materials on the surface of the workpiece. The process chamber acts as a reaction chamber where the plasma is modified to the desired process conditions. This is accomplished by controlling the gas flow, pressure, power, and other parameters. The electron gun is a powerful beam of electrons that is used to physically modify the surface of the material being treated. The main features of AMAT P-5000 reactor are its ability to deliver precise and repeatable processing results, as well as its ability to perform sensitive process monitoring. This type of reactor relies on a multi-channel feedback system and advanced automation software to ensure consistent, repeatable results. This type of reactor also has an advanced diagnostics system that monitors the condition of components, allowing for more efficient use of resources. APPLIED MATERIALS P 5000 reactor is relatively compact and robust, making it ideal for use in harsh environments. It also has an integrated diagnostics system that monitors and records data throughout the entire process, allowing for efficient operations, troubleshooting and maintenance. Additionally, the unit provides a safe working environment, with safety functions that prevent and monitor accidental overheating or power shutdowns. P5000 reactor is well-suited for a variety of applications in the semiconductor industry and is often used in deposition and etching processes. It is capable of processing substrates with high electrical, thermal, and optical properties, making it suitable for a range of materials including polymers, ceramics, metals, and compound semiconductors. Furthermore, the reactor can be used for a wide range of processes, such as ion implantation, PECVD, sputtering, and a variety of chemical etching applications. In conclusion, APPLIED MATERIALS P5000 reactor is an advanced, reliable, and precise tool used in the semiconductor industry to improve process performance and enable more precise monitoring. It has a range of features that make it ideal for a variety of applications, offering precise and repeatable results, precise monitoring, and robust operation in a safe work environment. It is the perfect choice for precision processing in the semiconductor industry.

There are no reviews yet