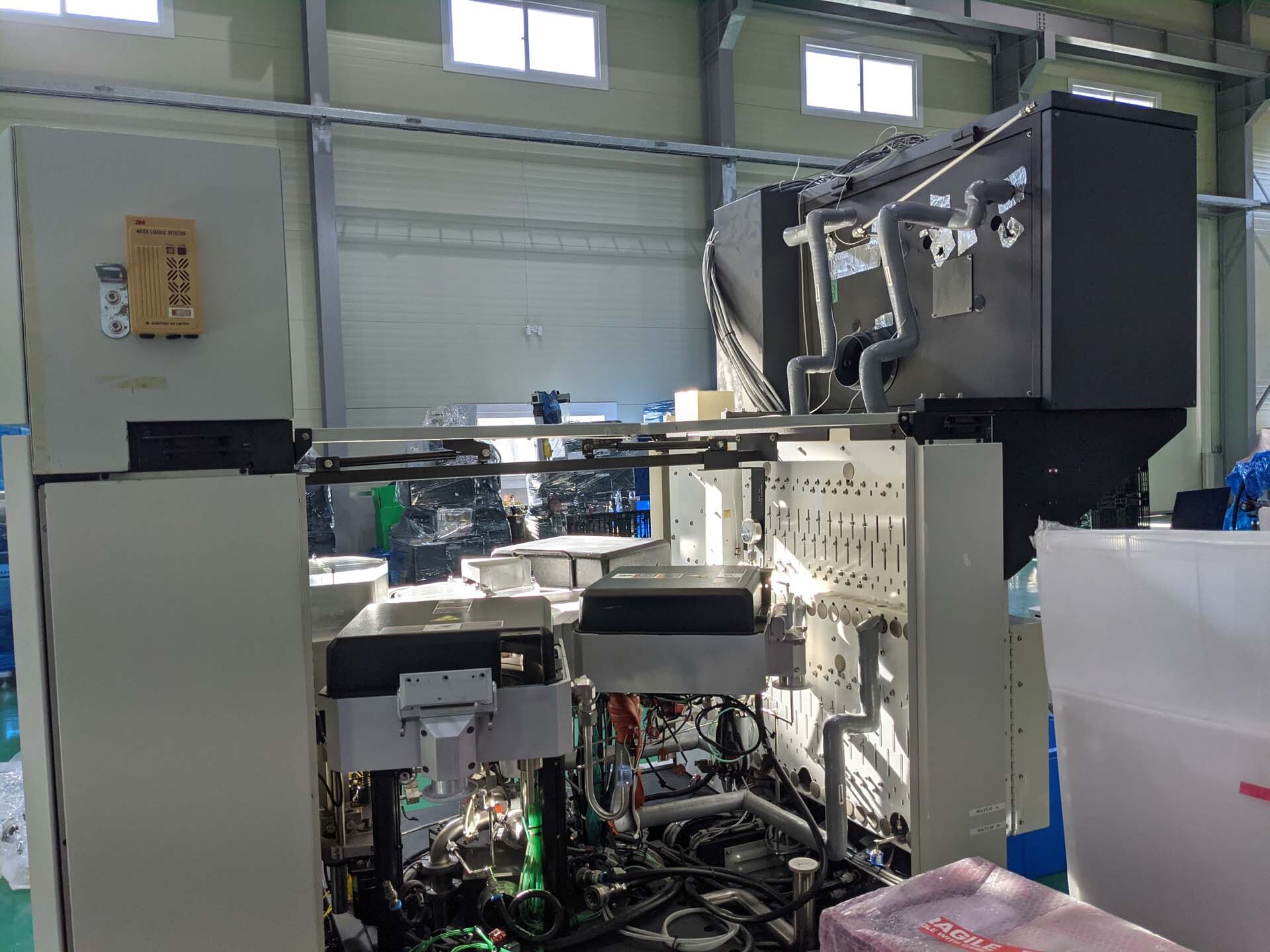

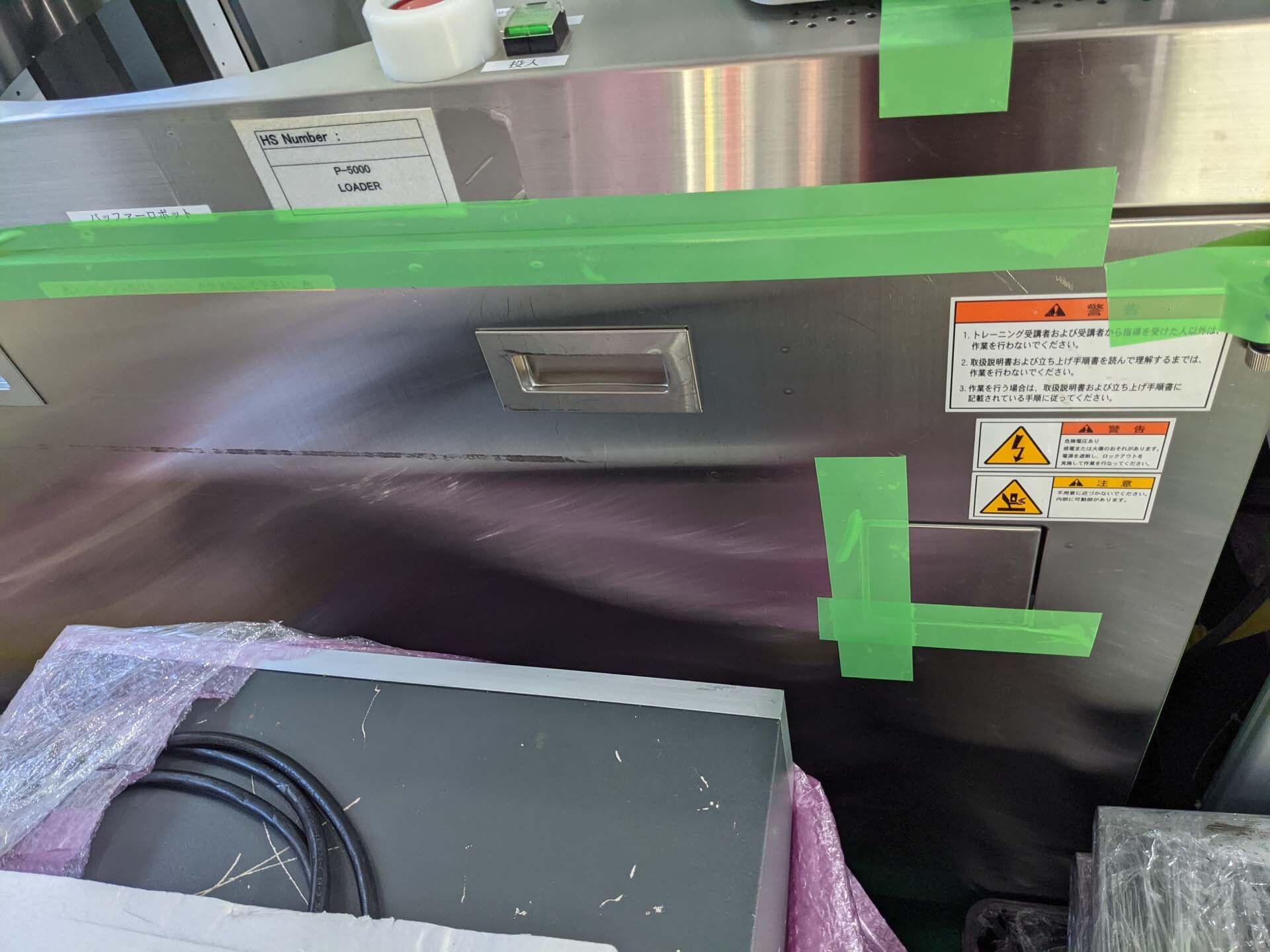

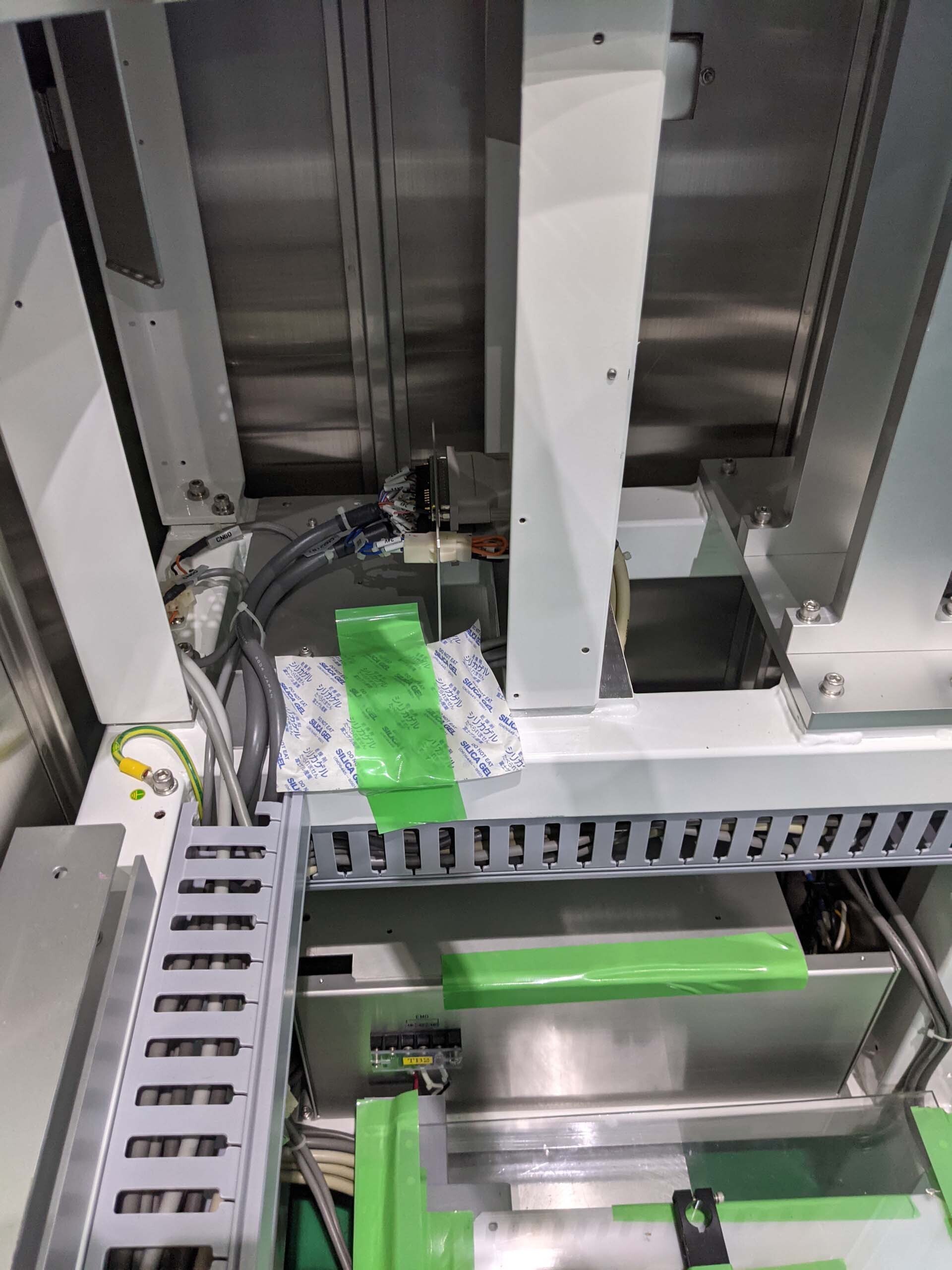

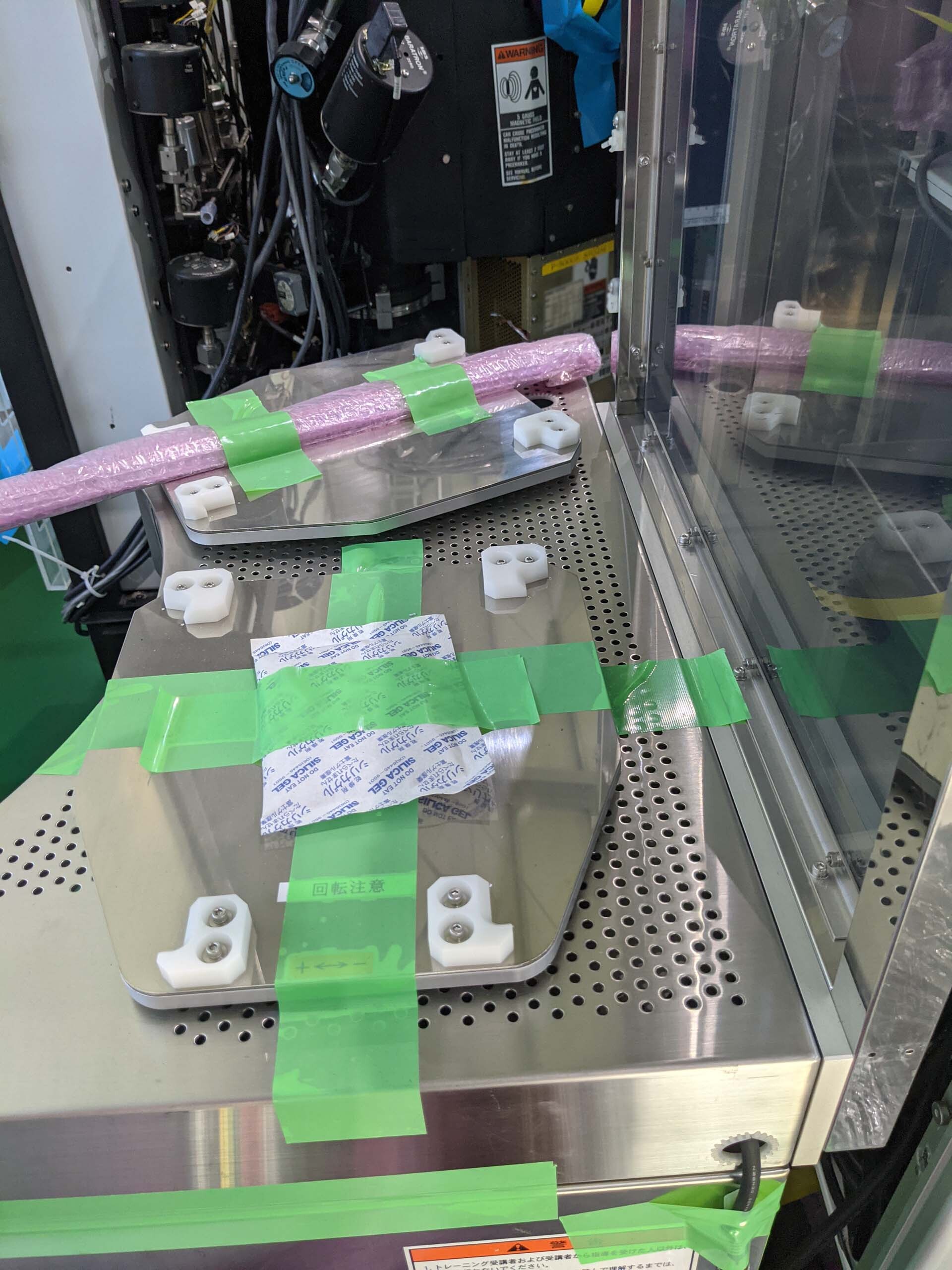

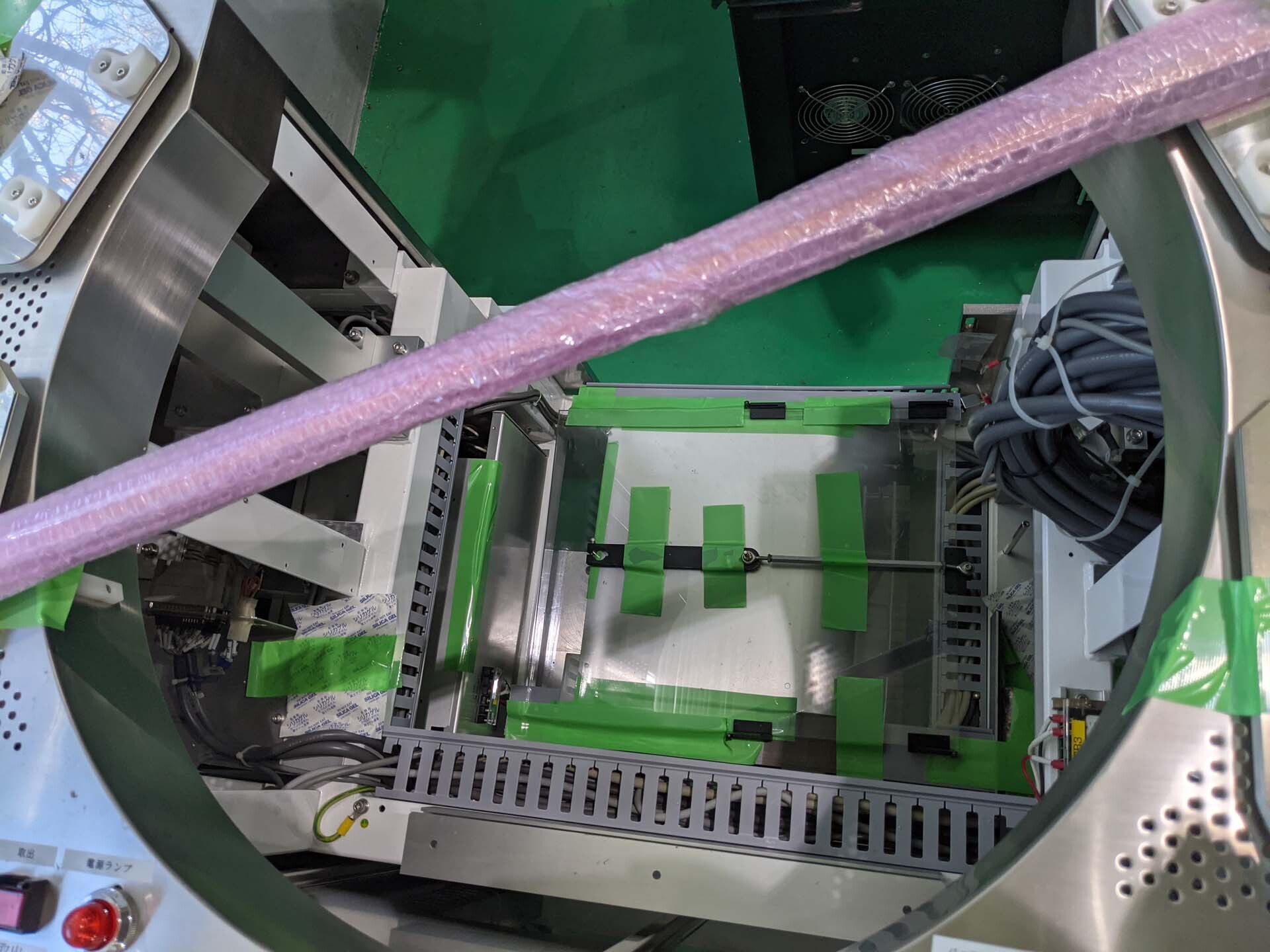

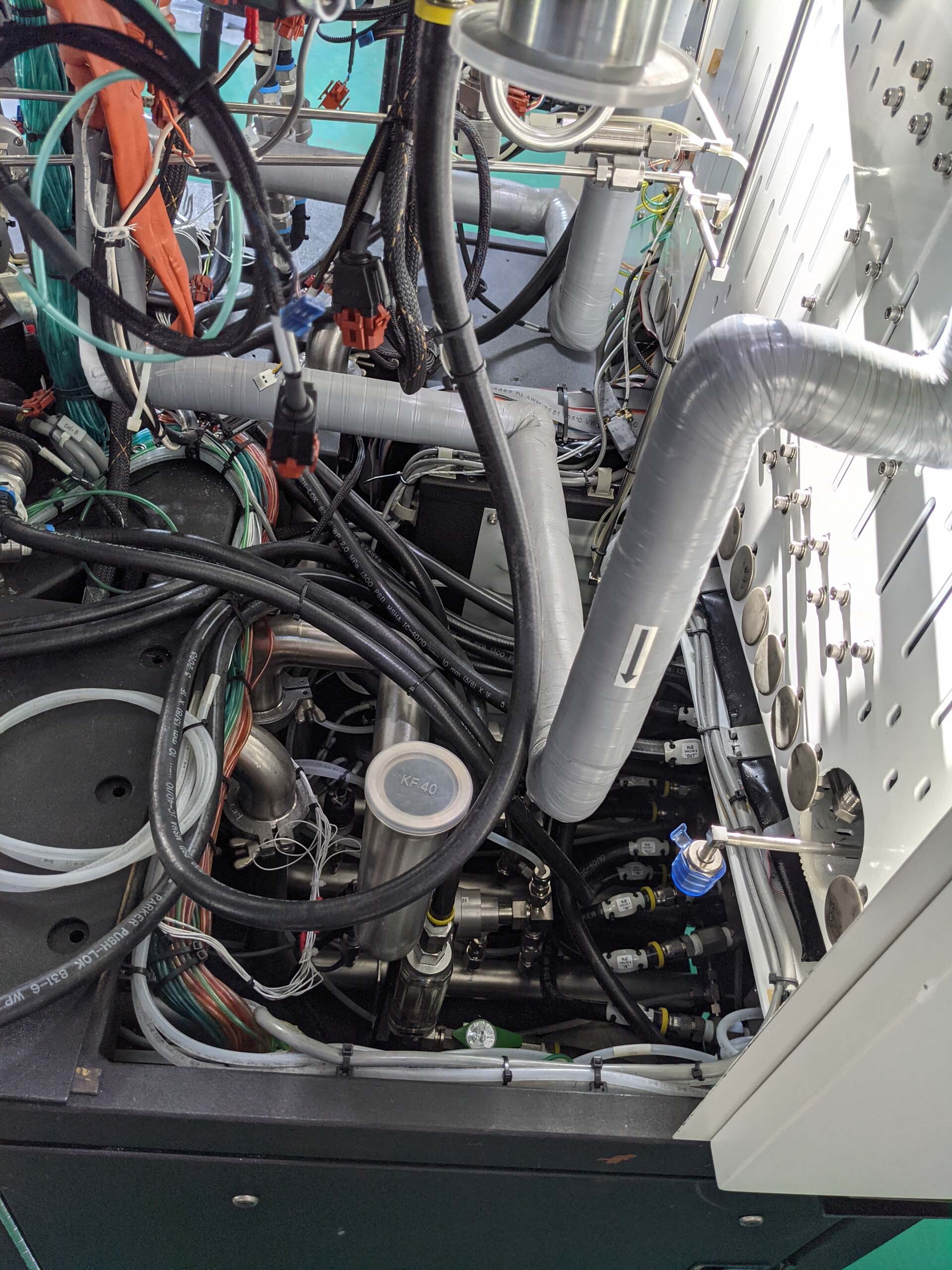

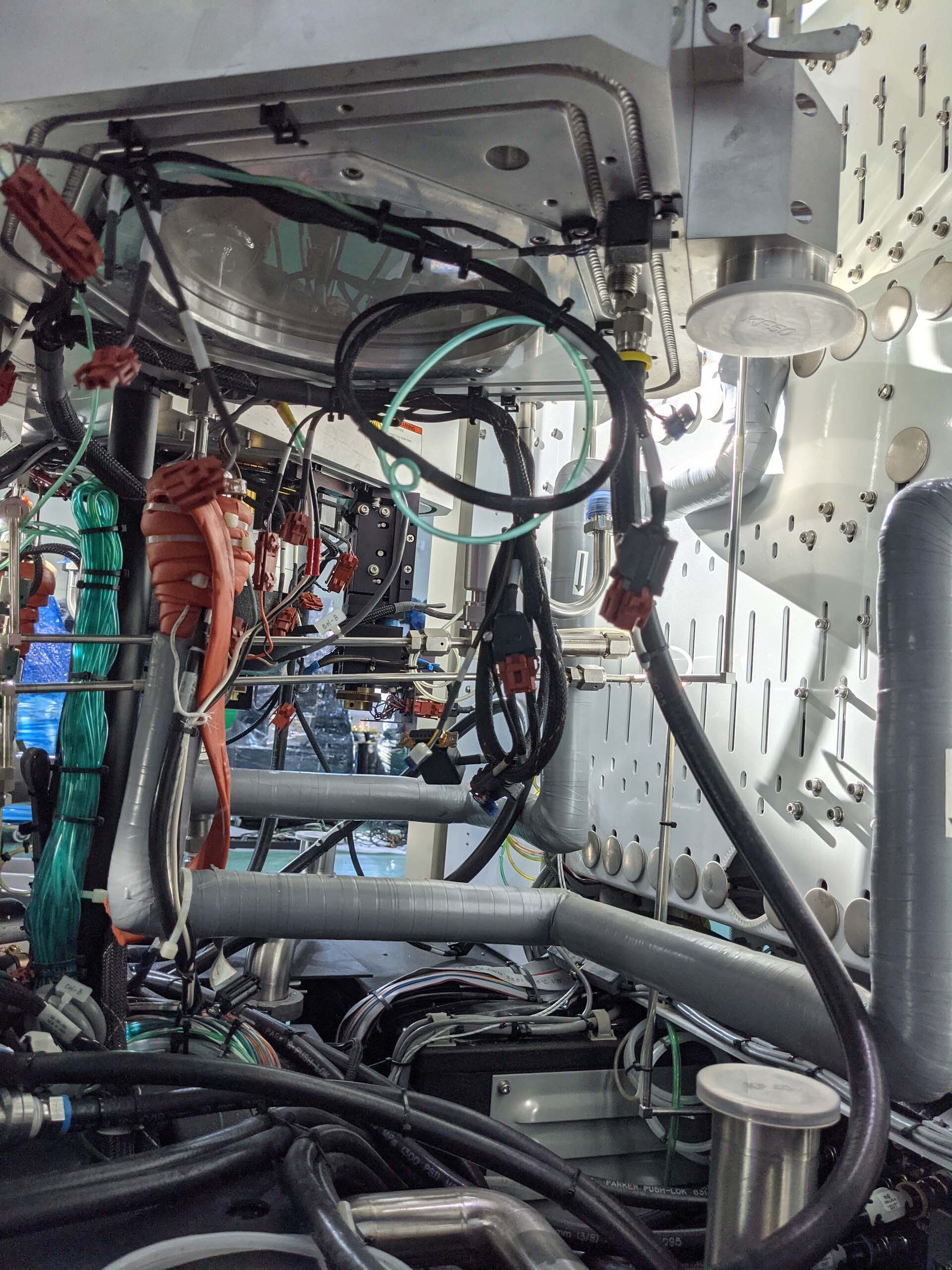

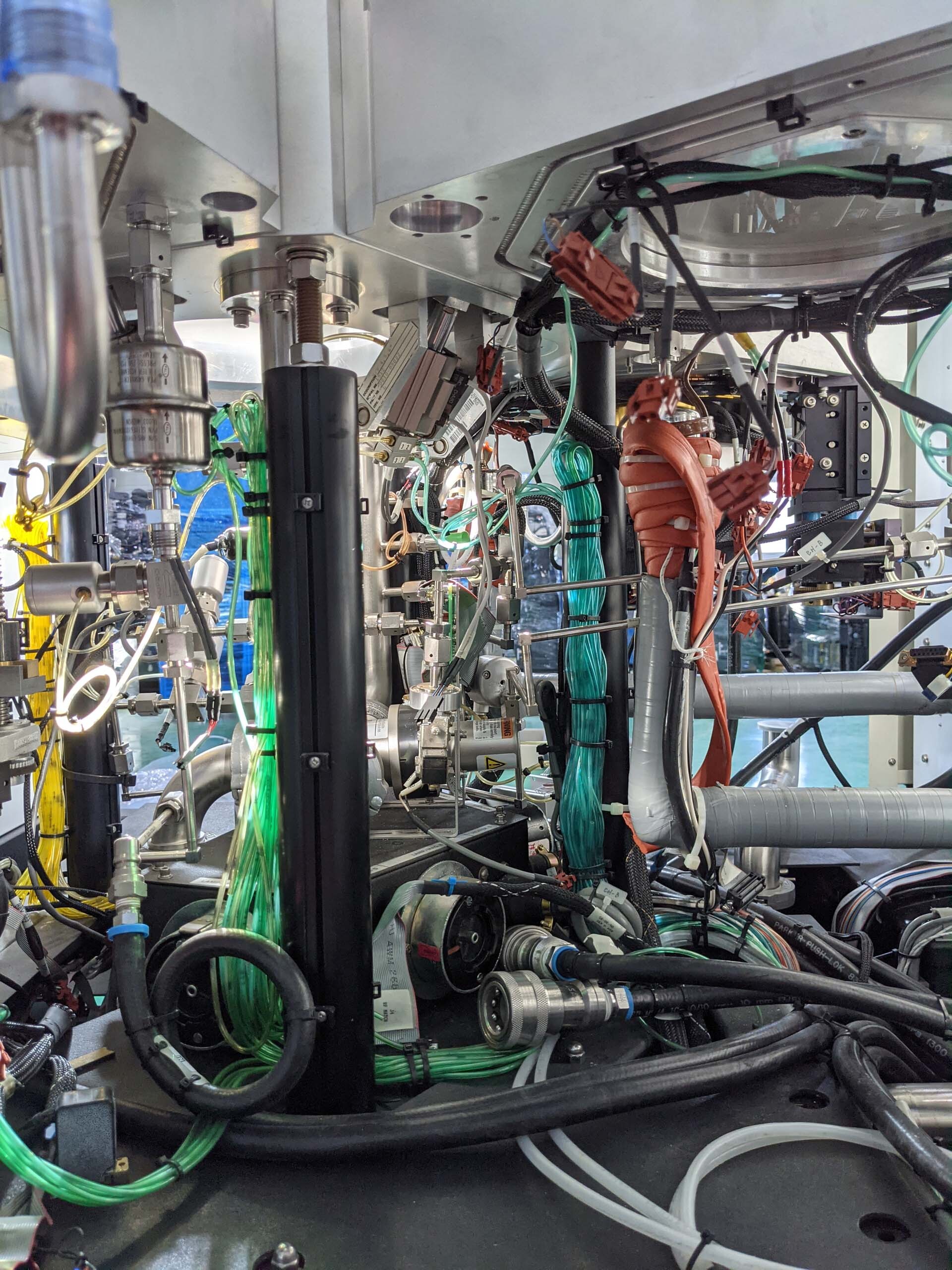

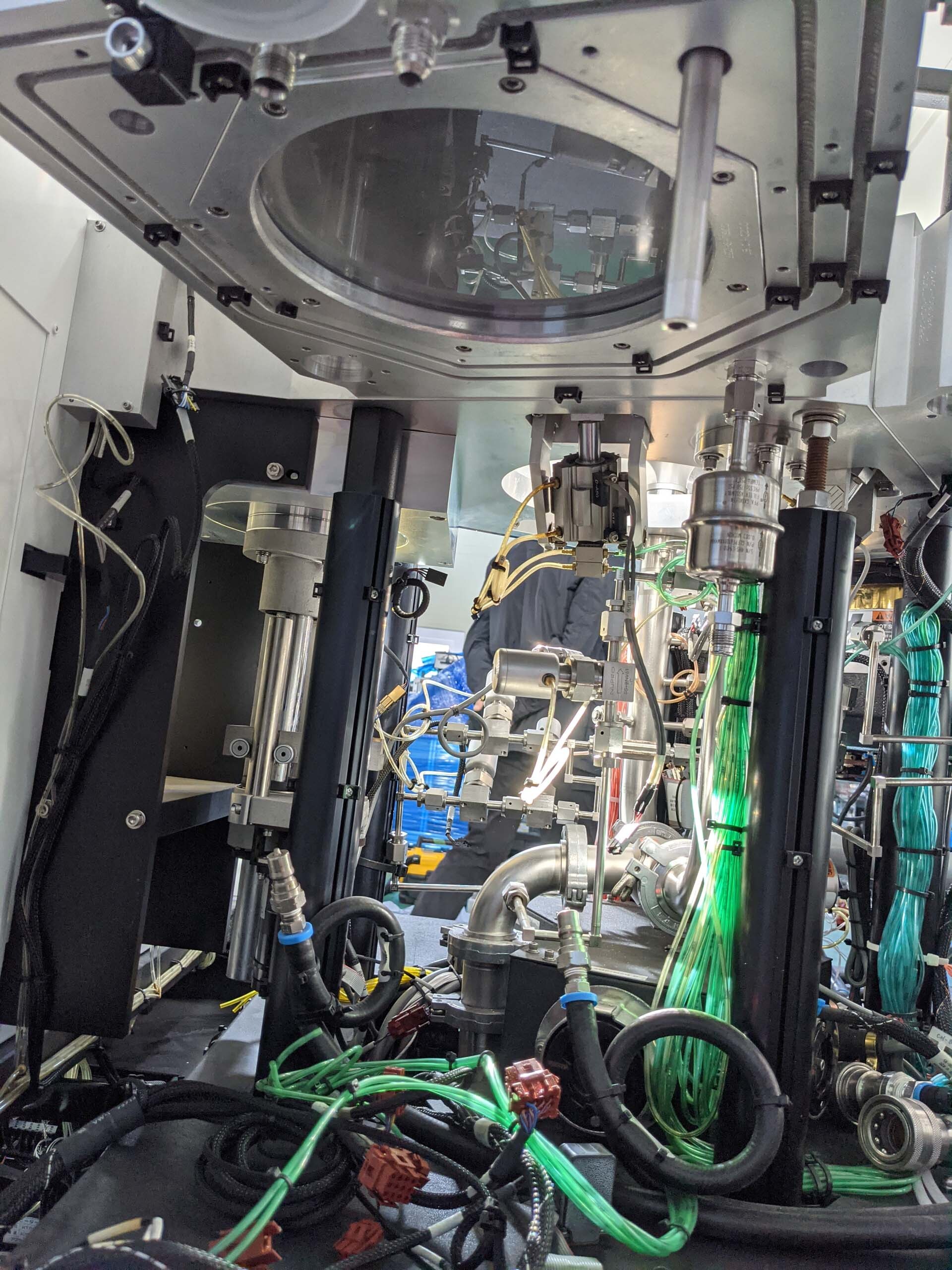

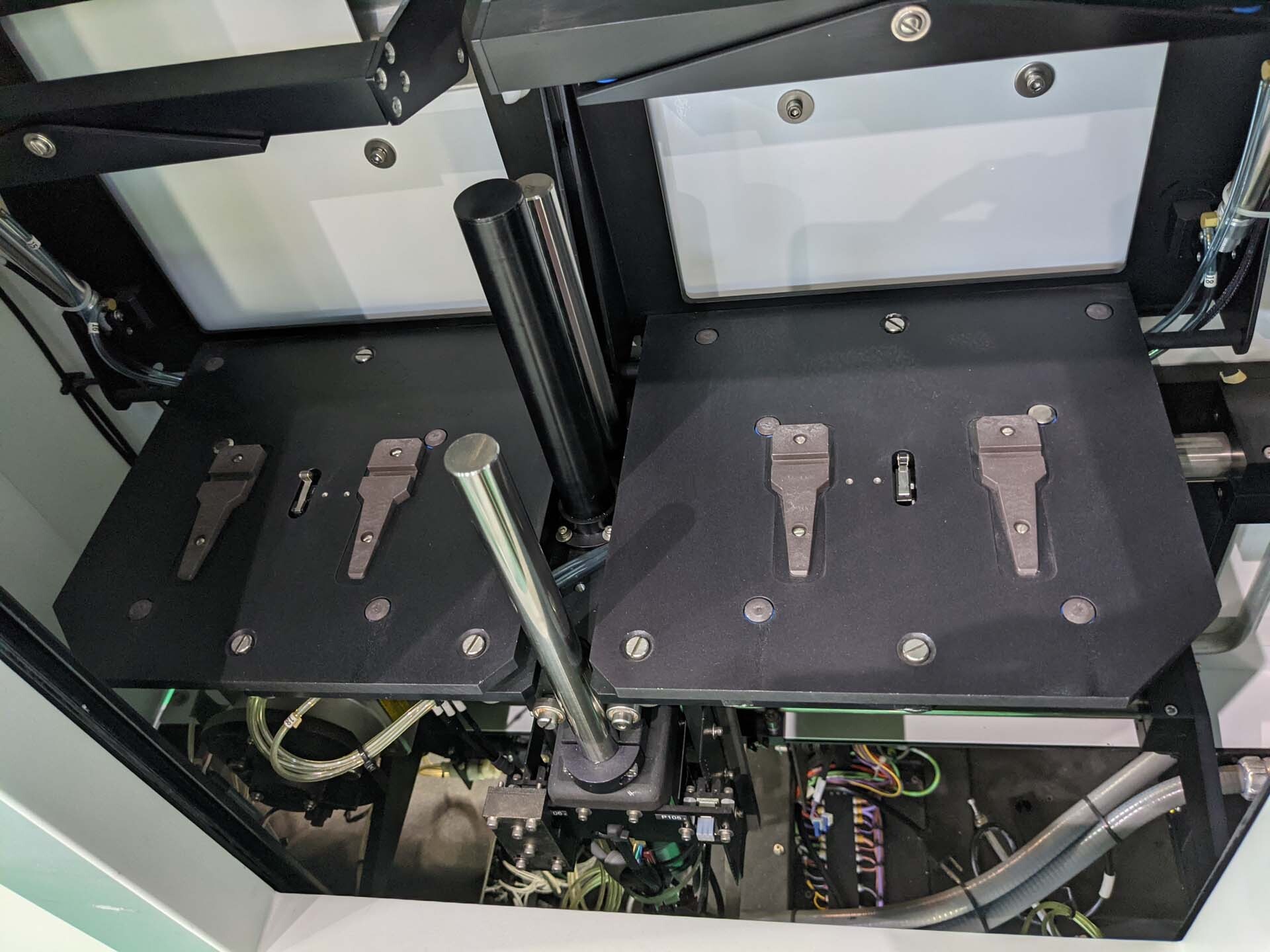

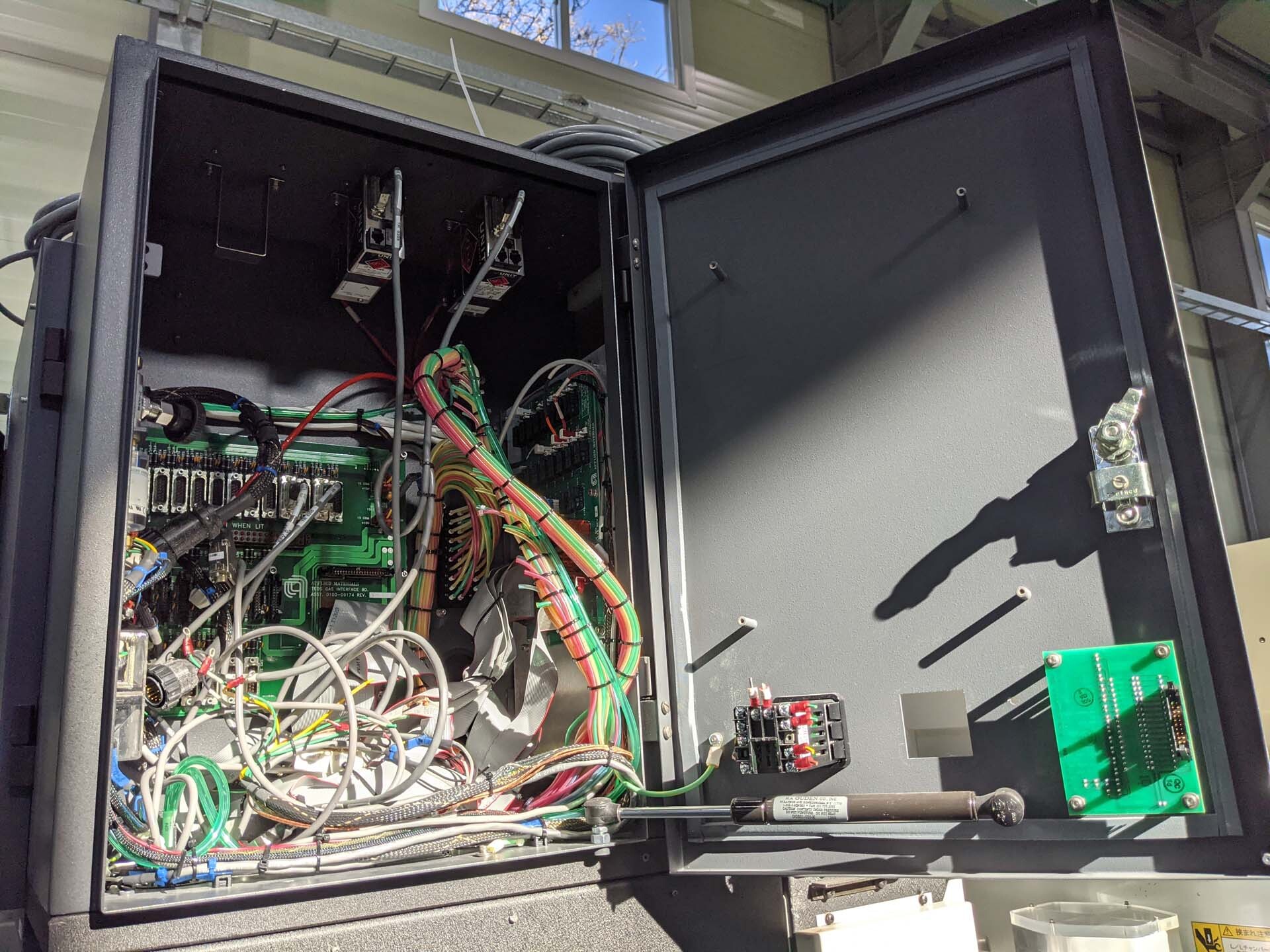

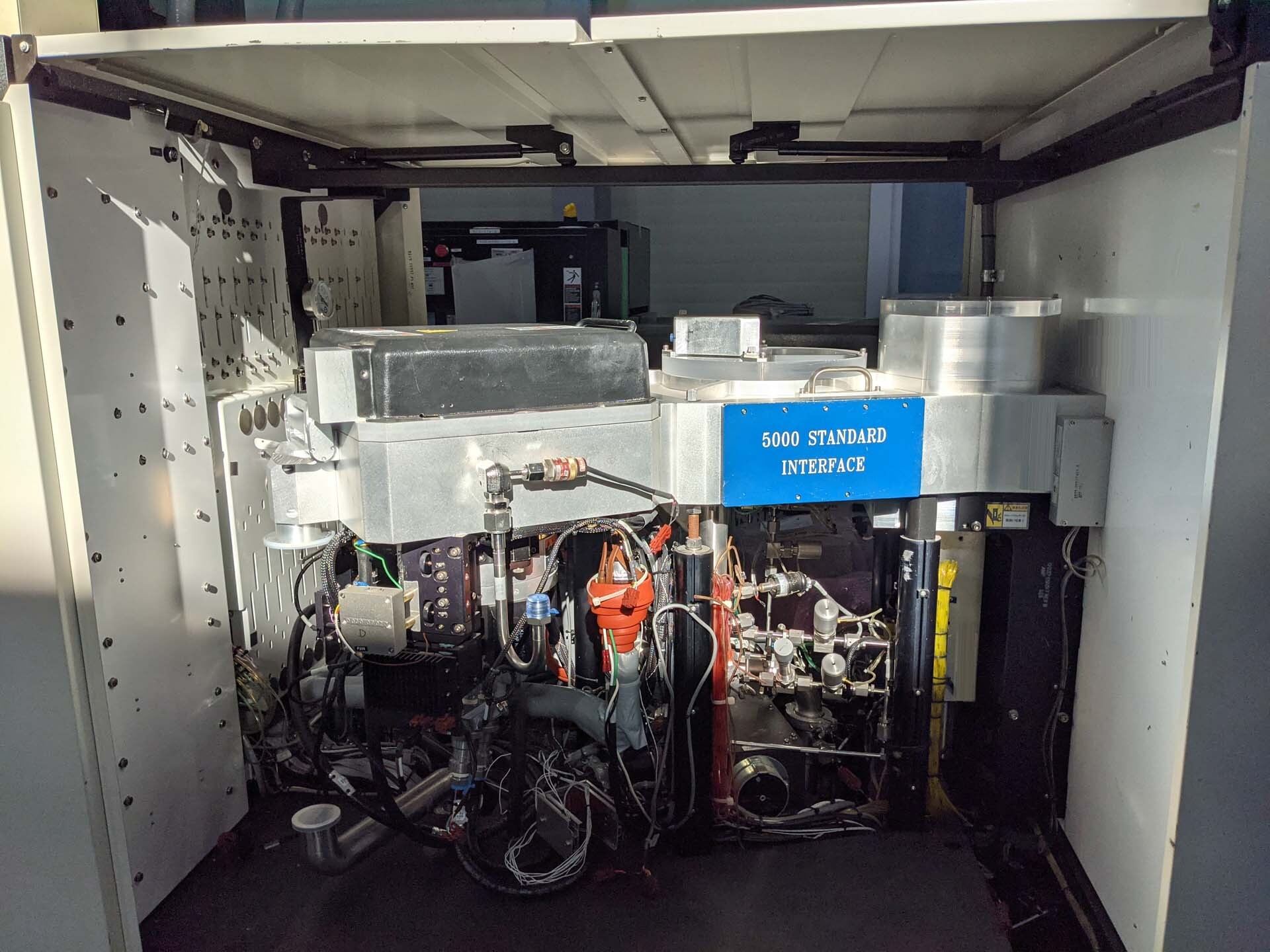

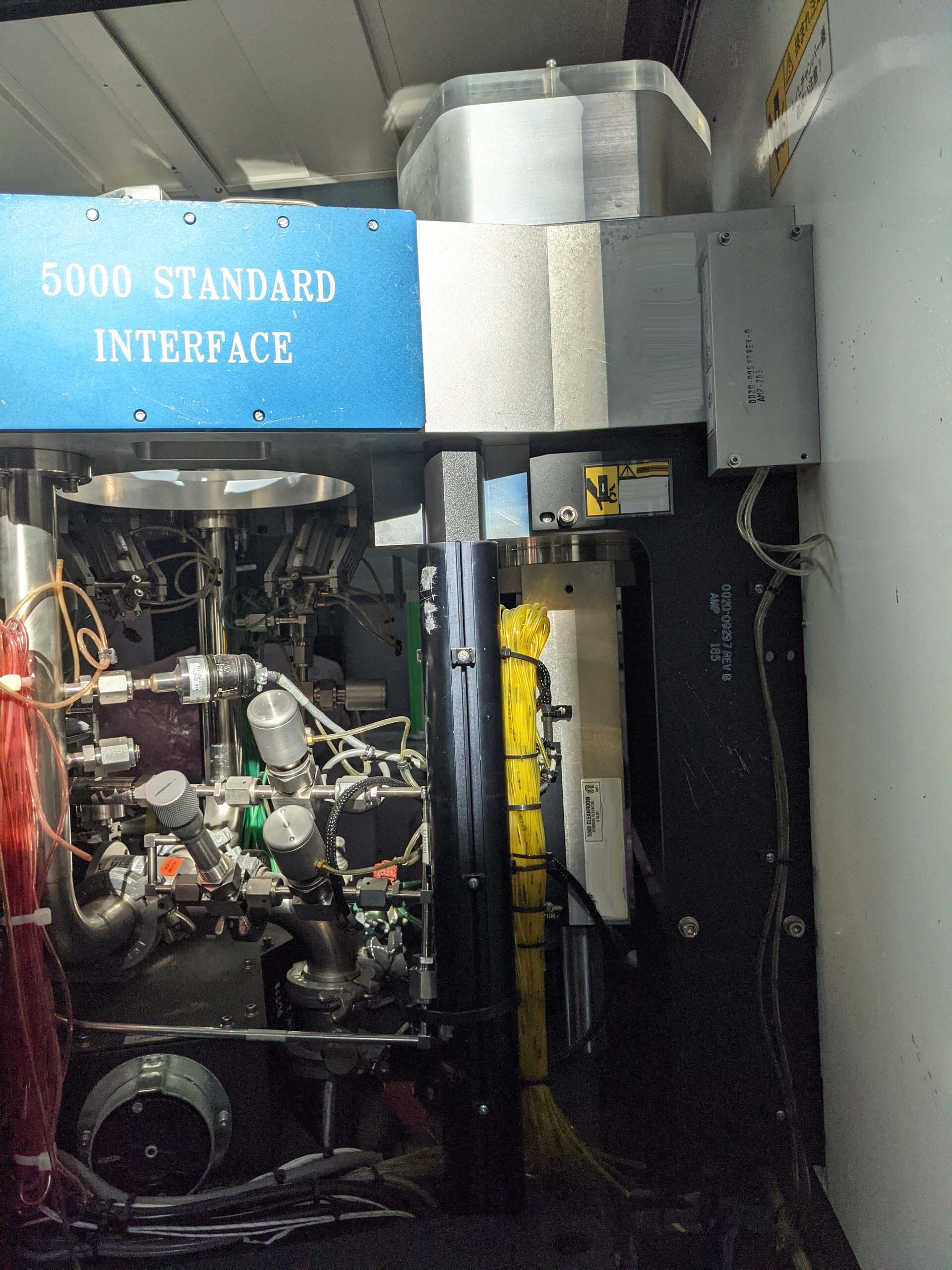

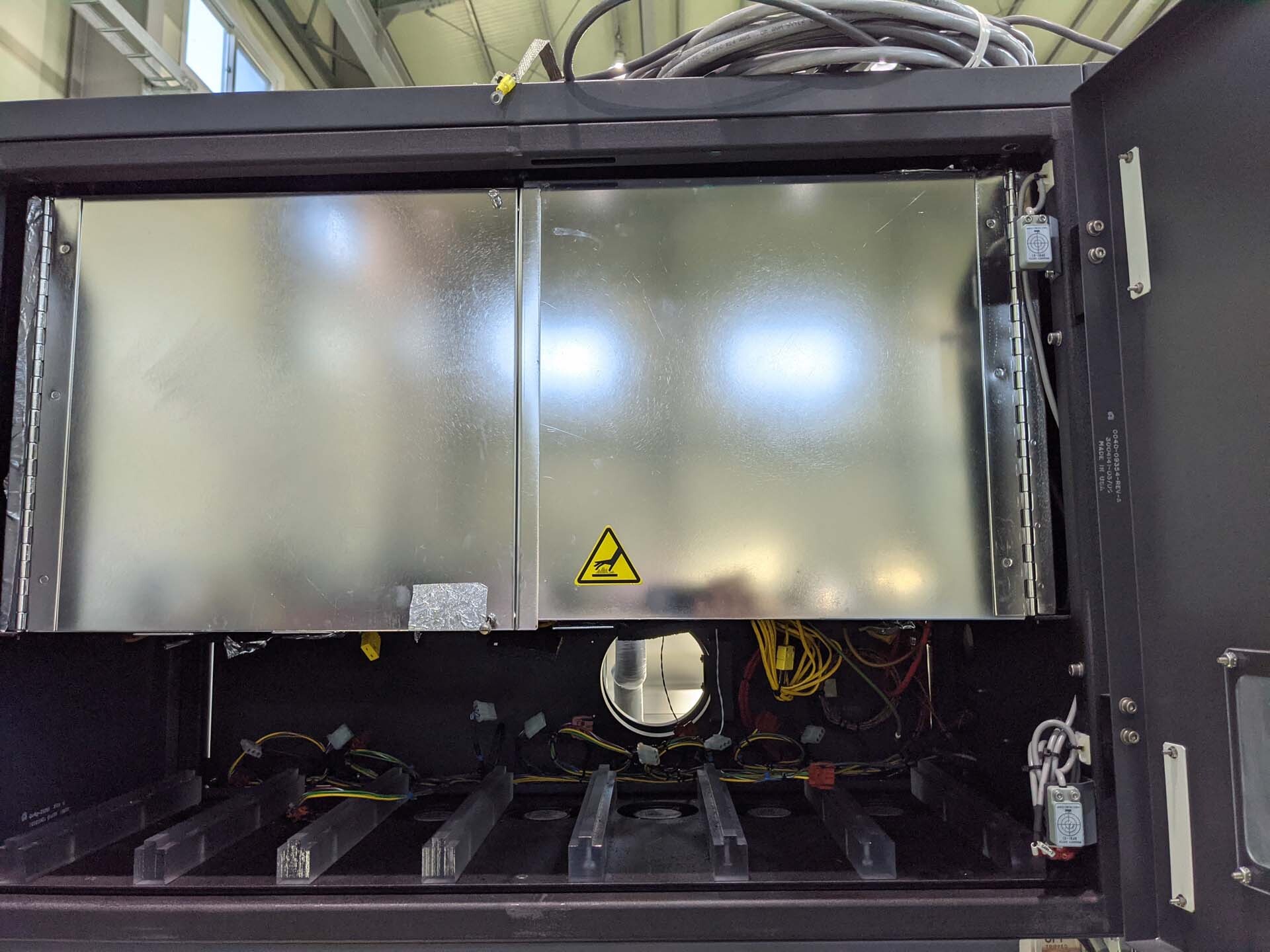

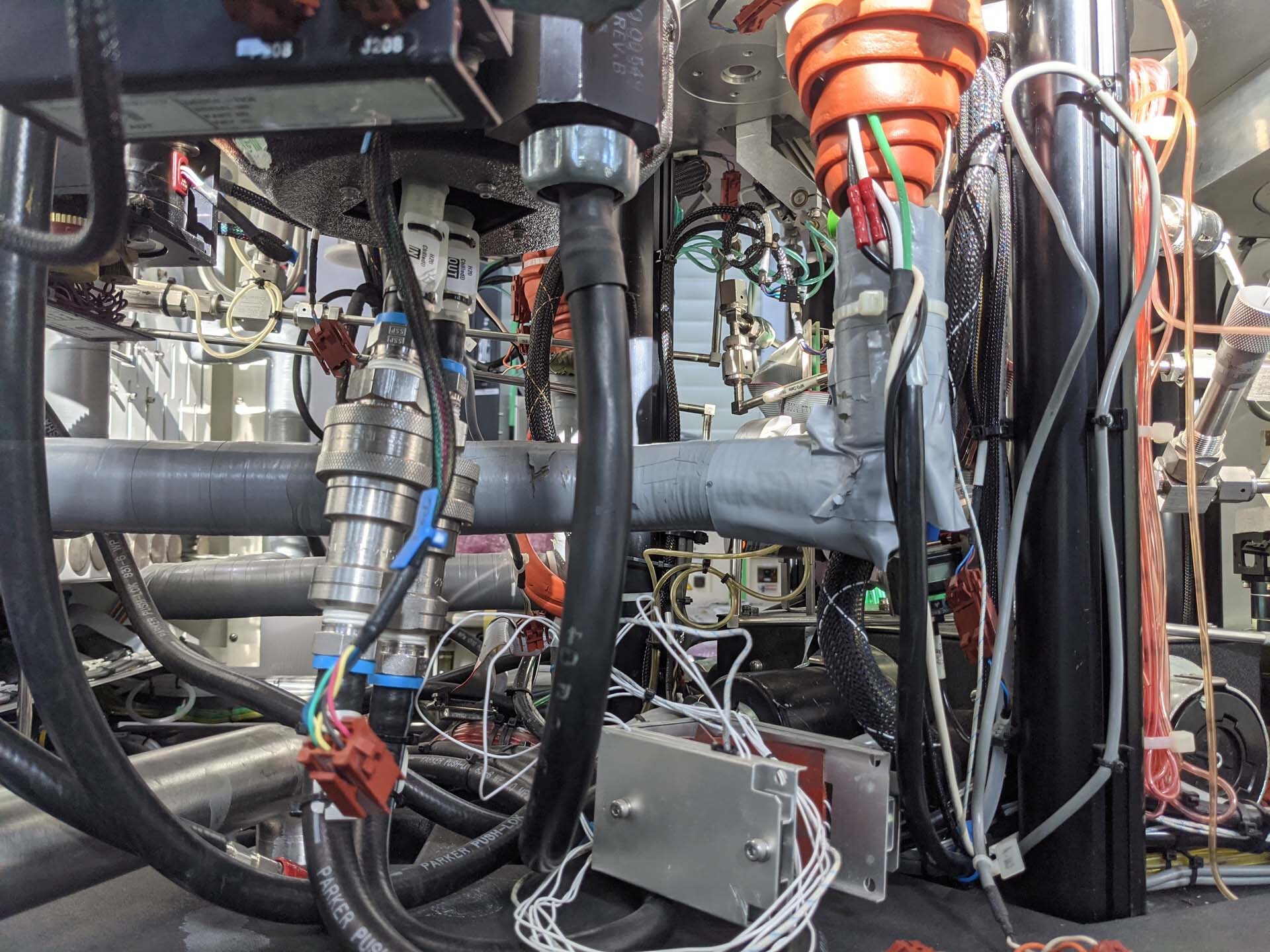

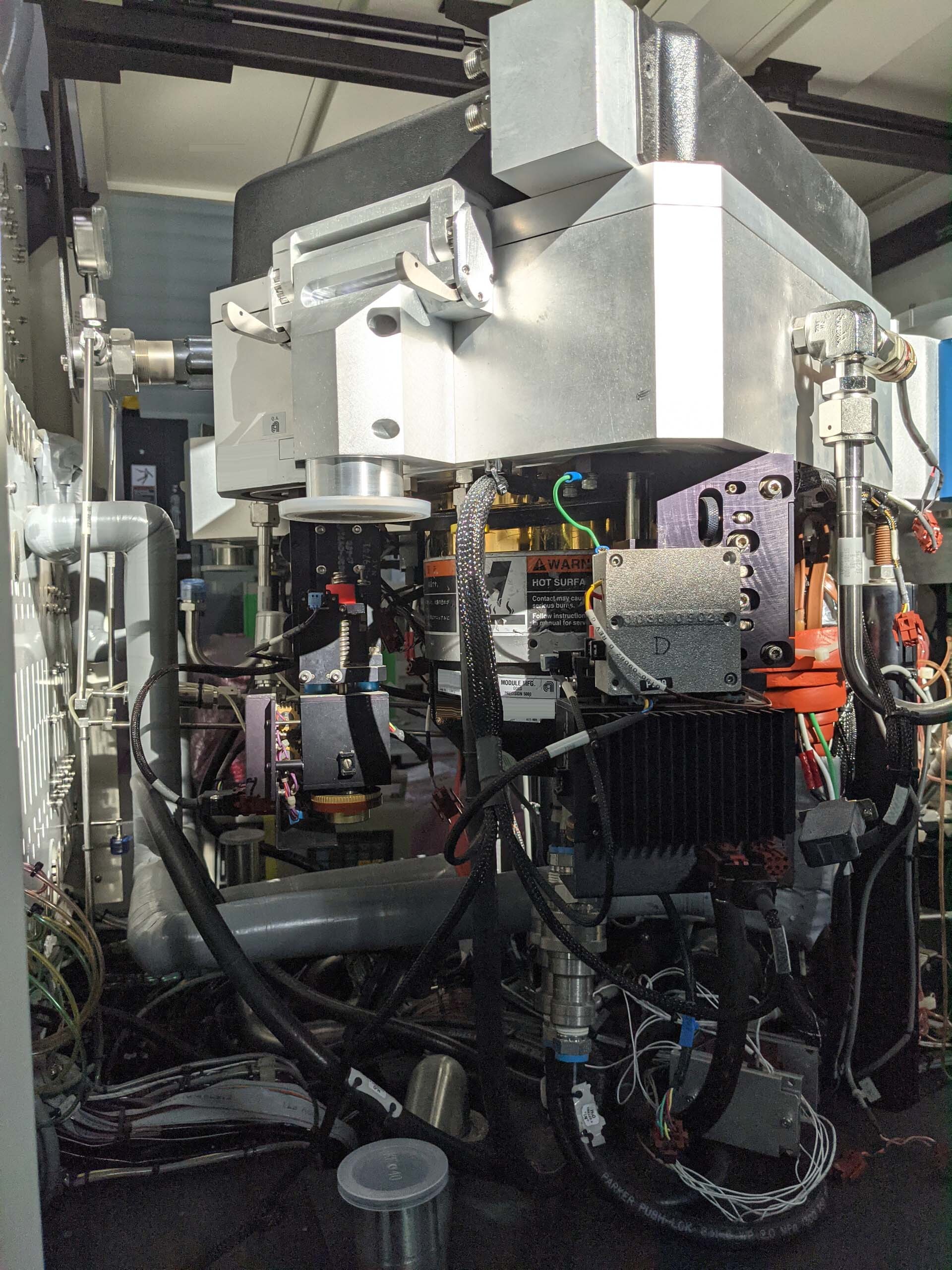

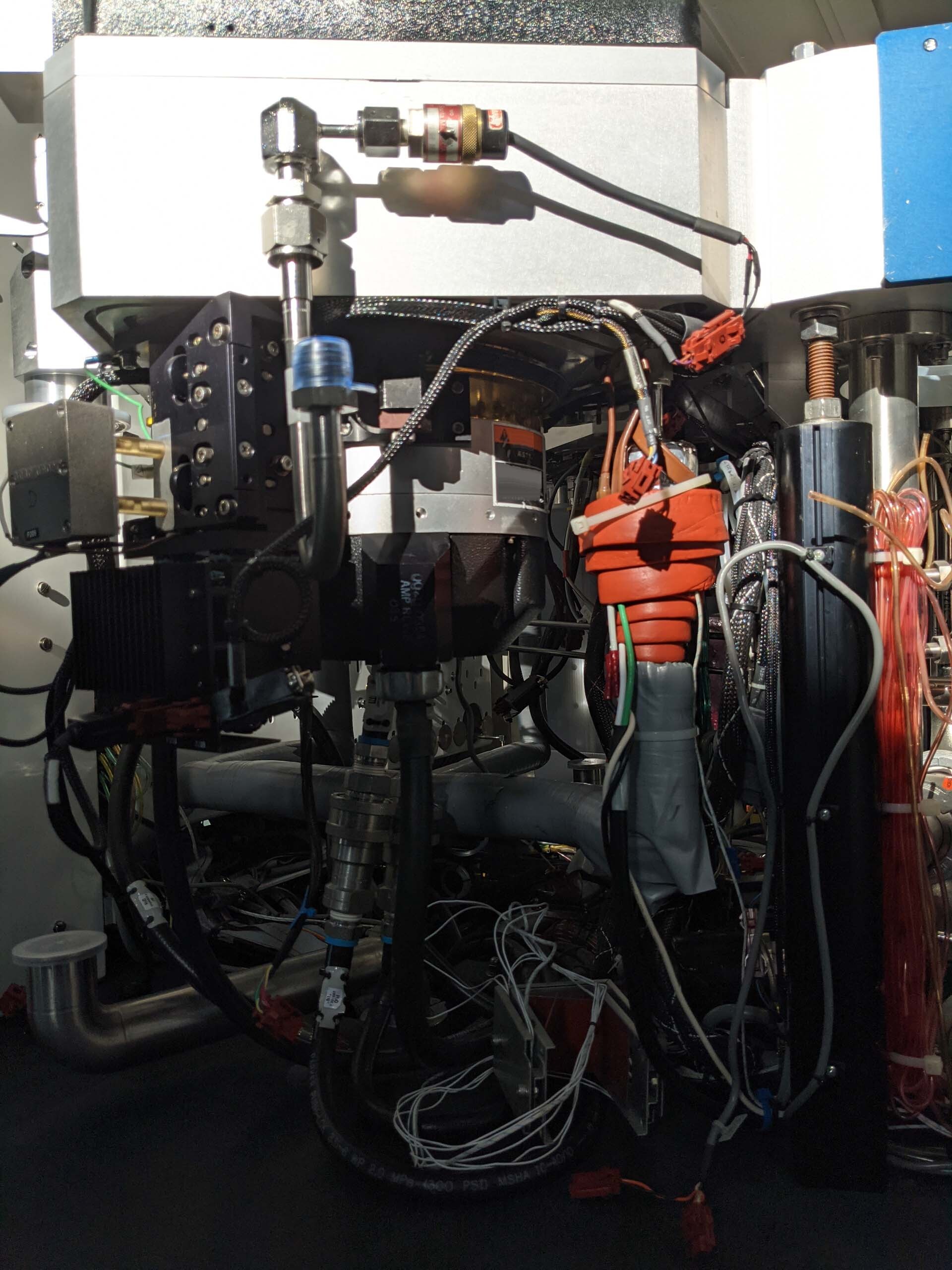

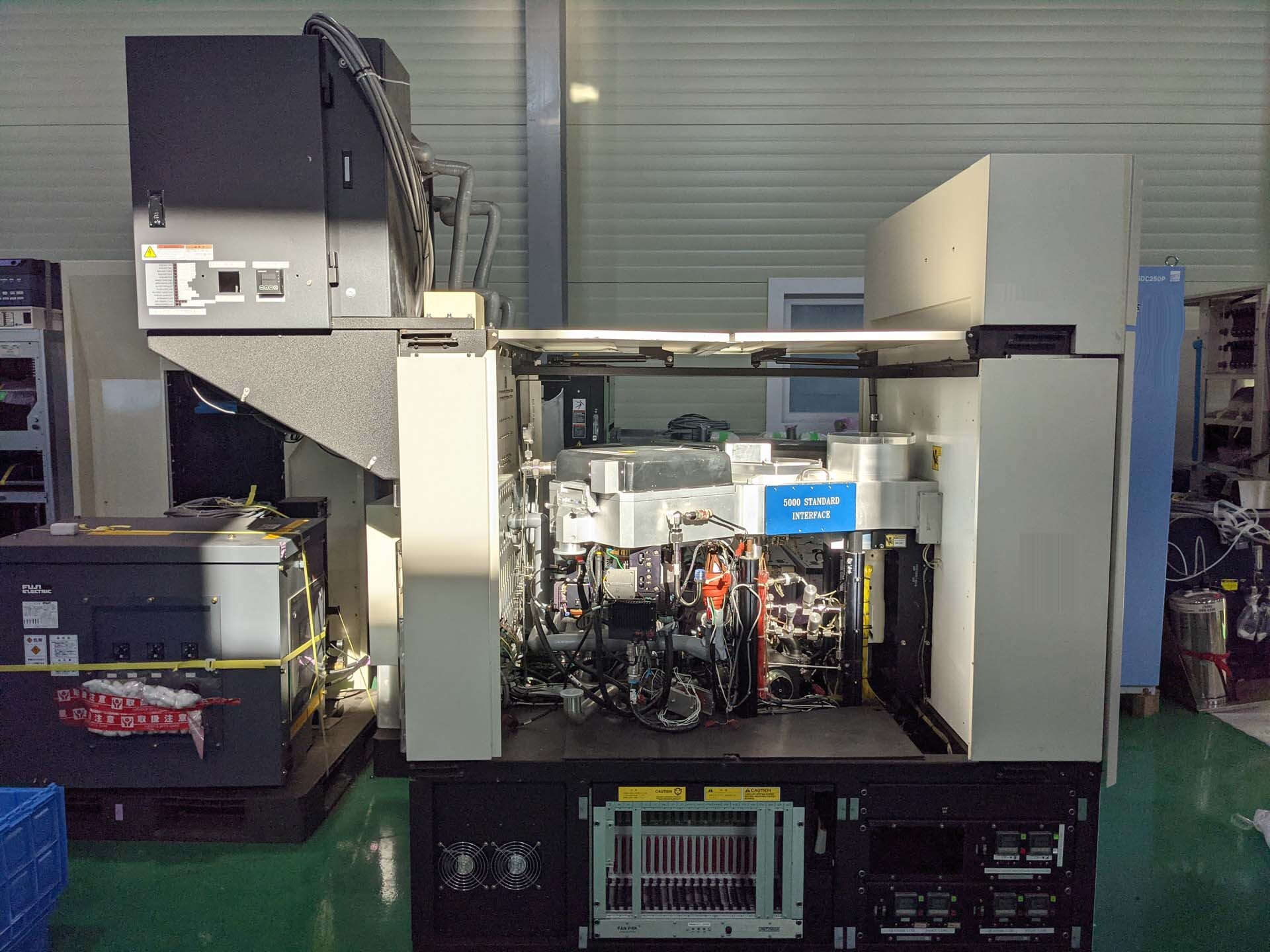

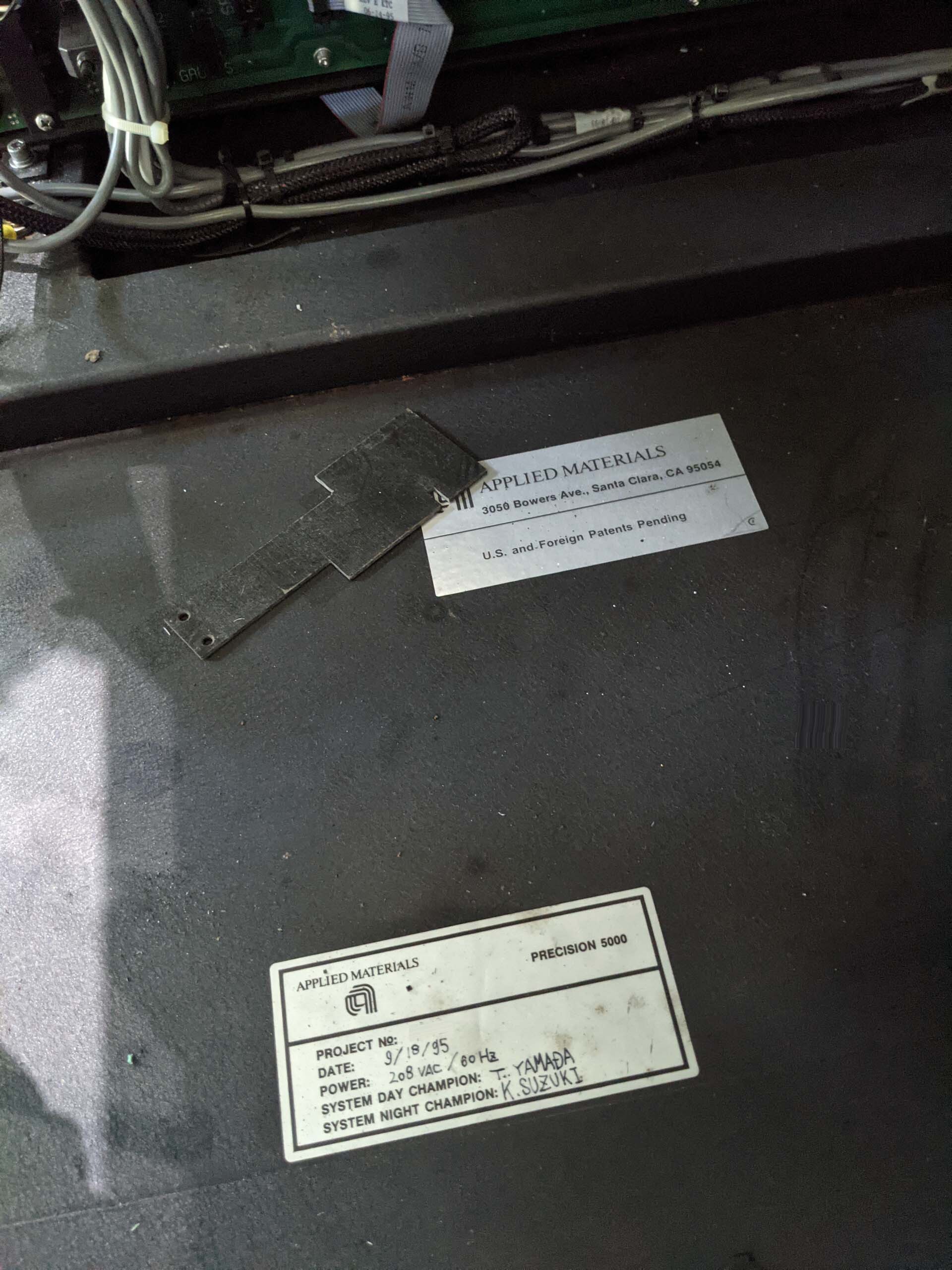

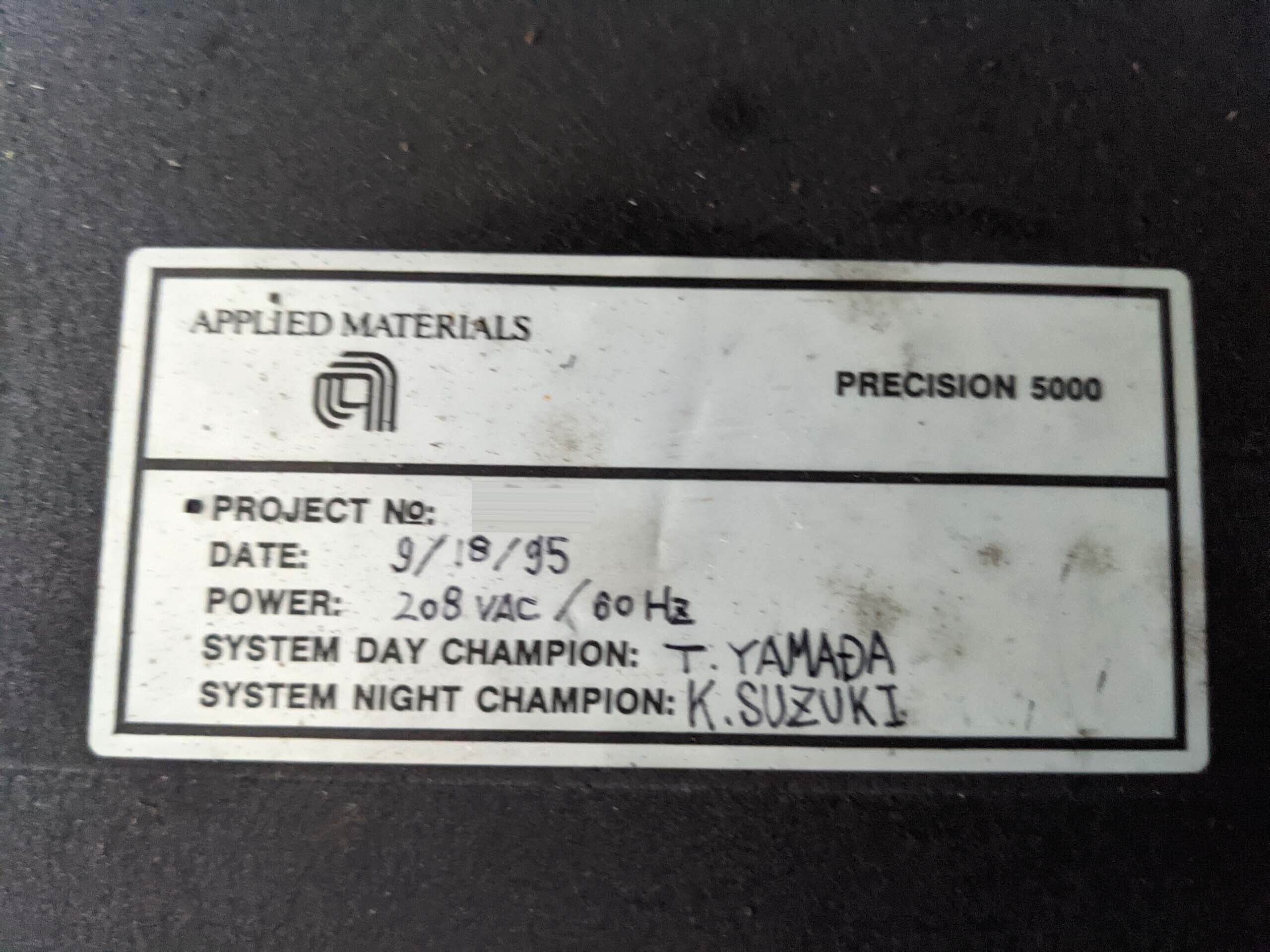

Used AMAT / APPLIED MATERIALS P5000 #9400971 for sale

URL successfully copied!

Tap to zoom

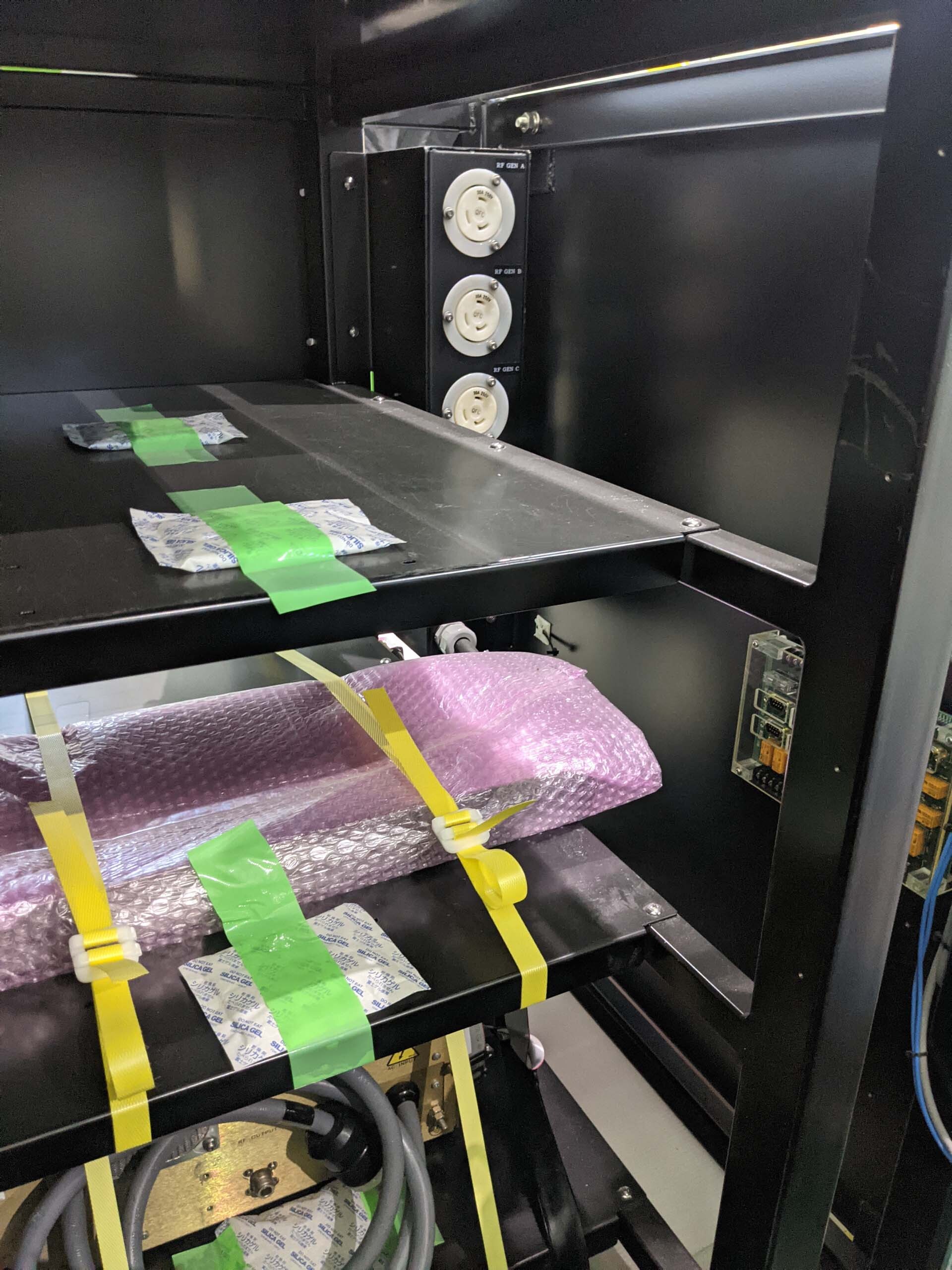

ID: 9400971

Vintage: 1995

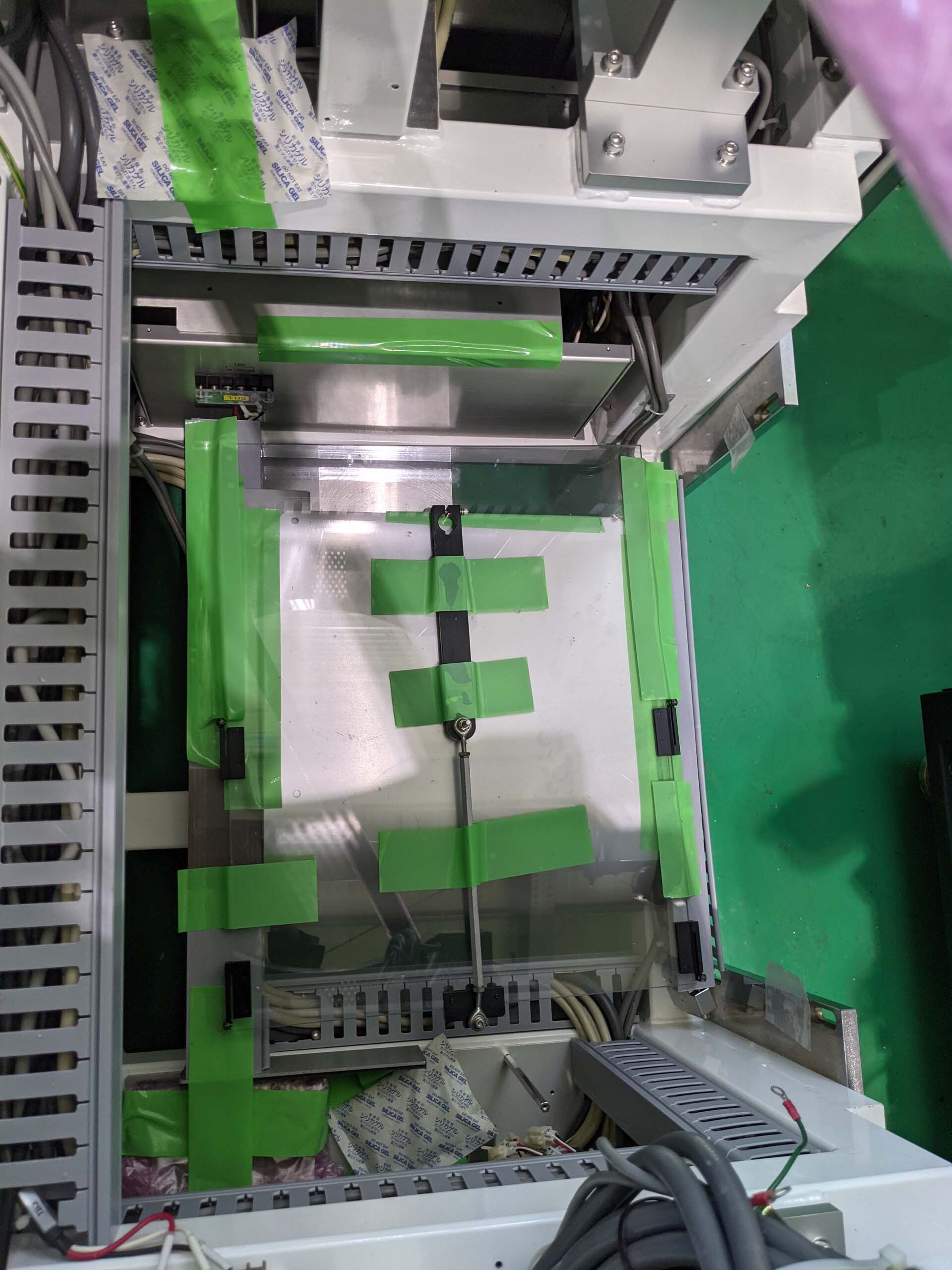

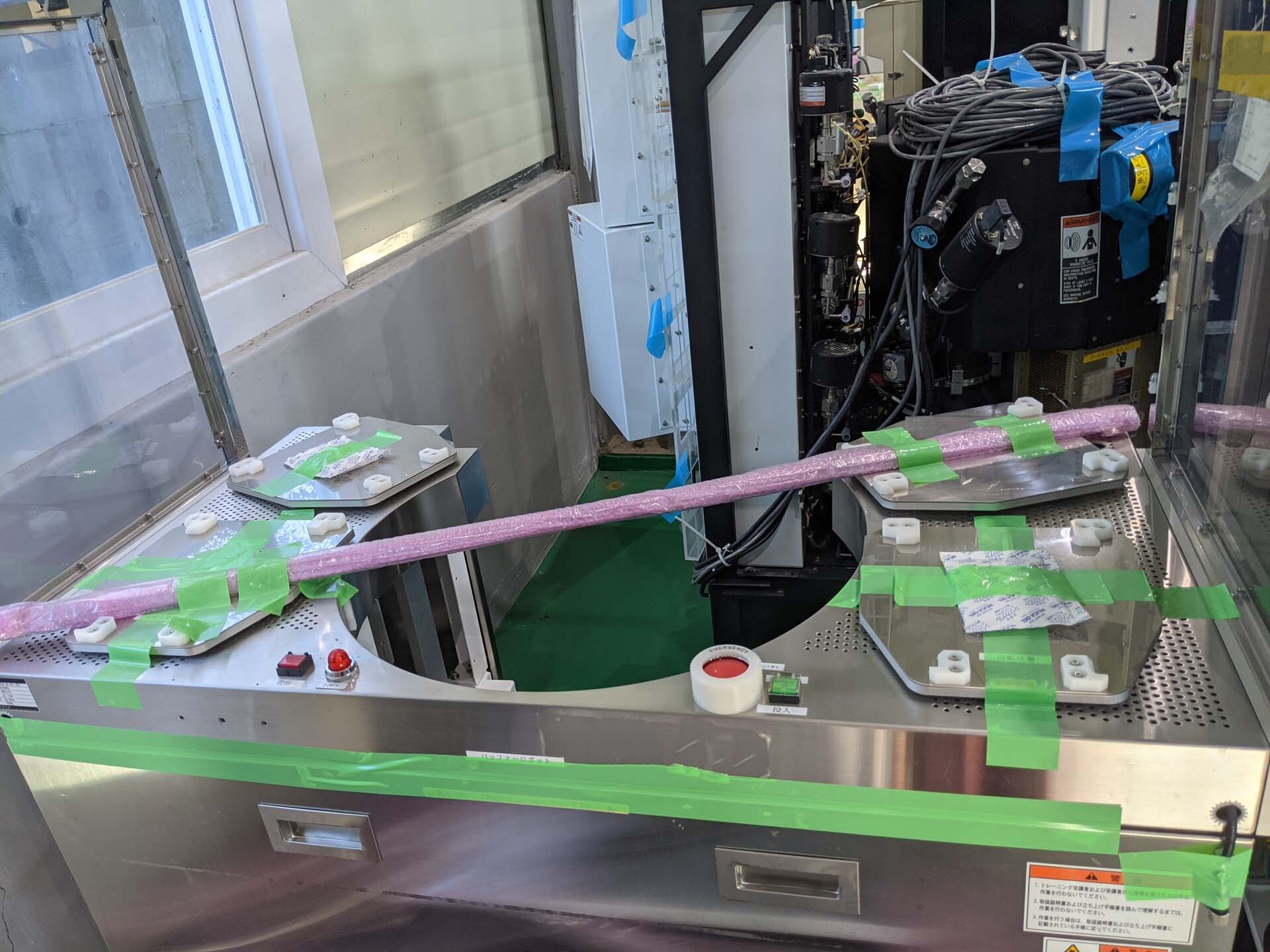

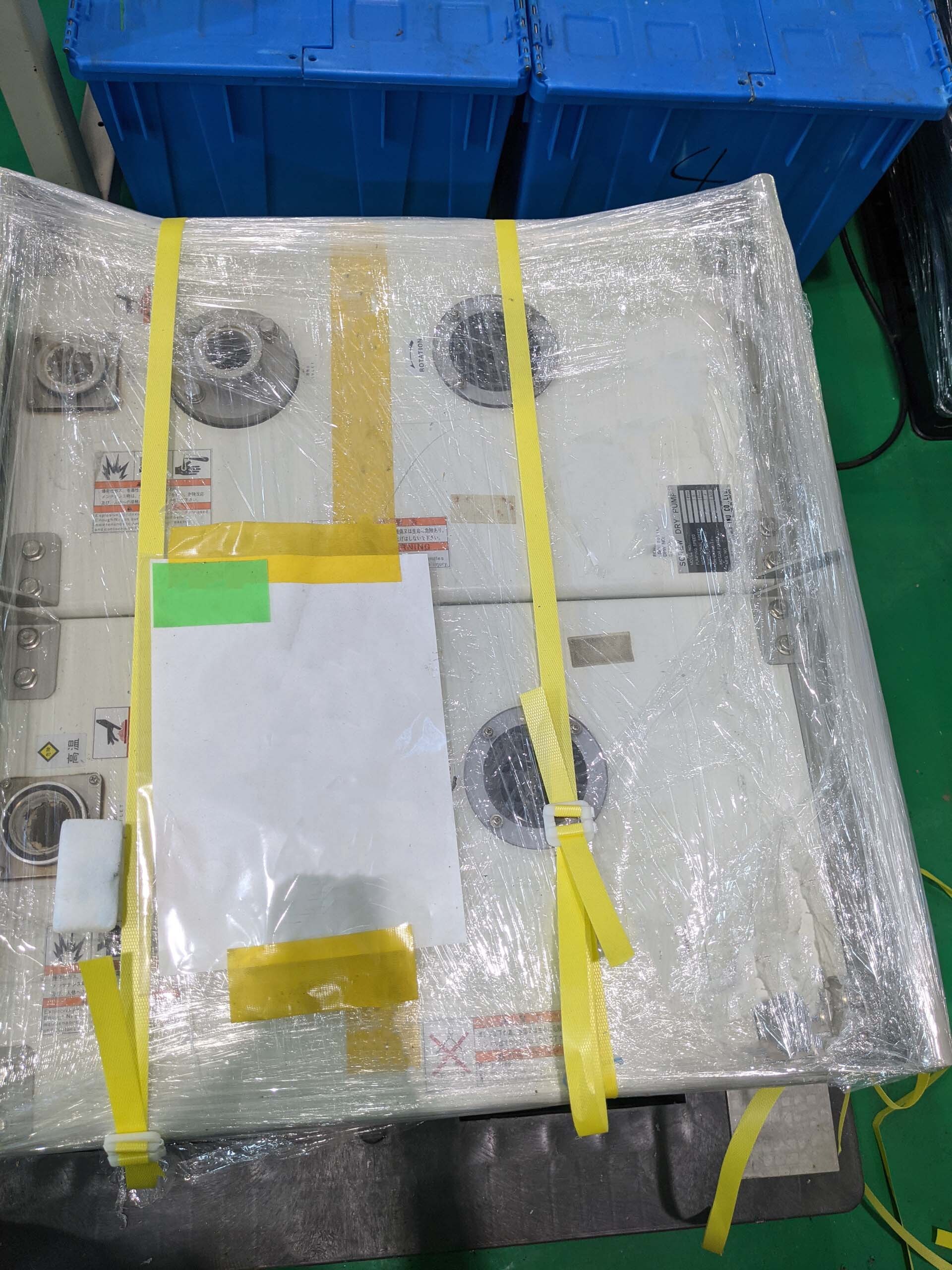

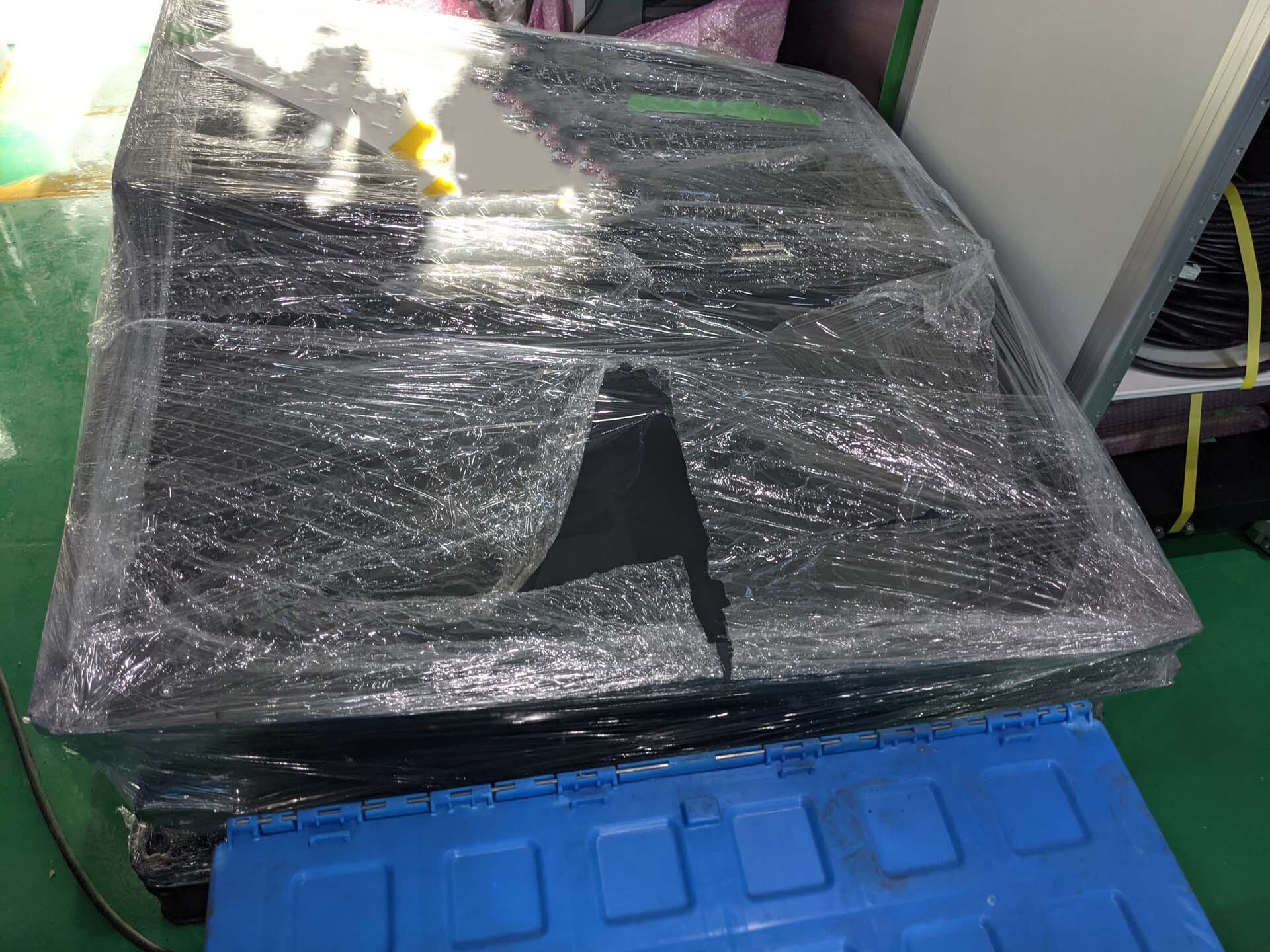

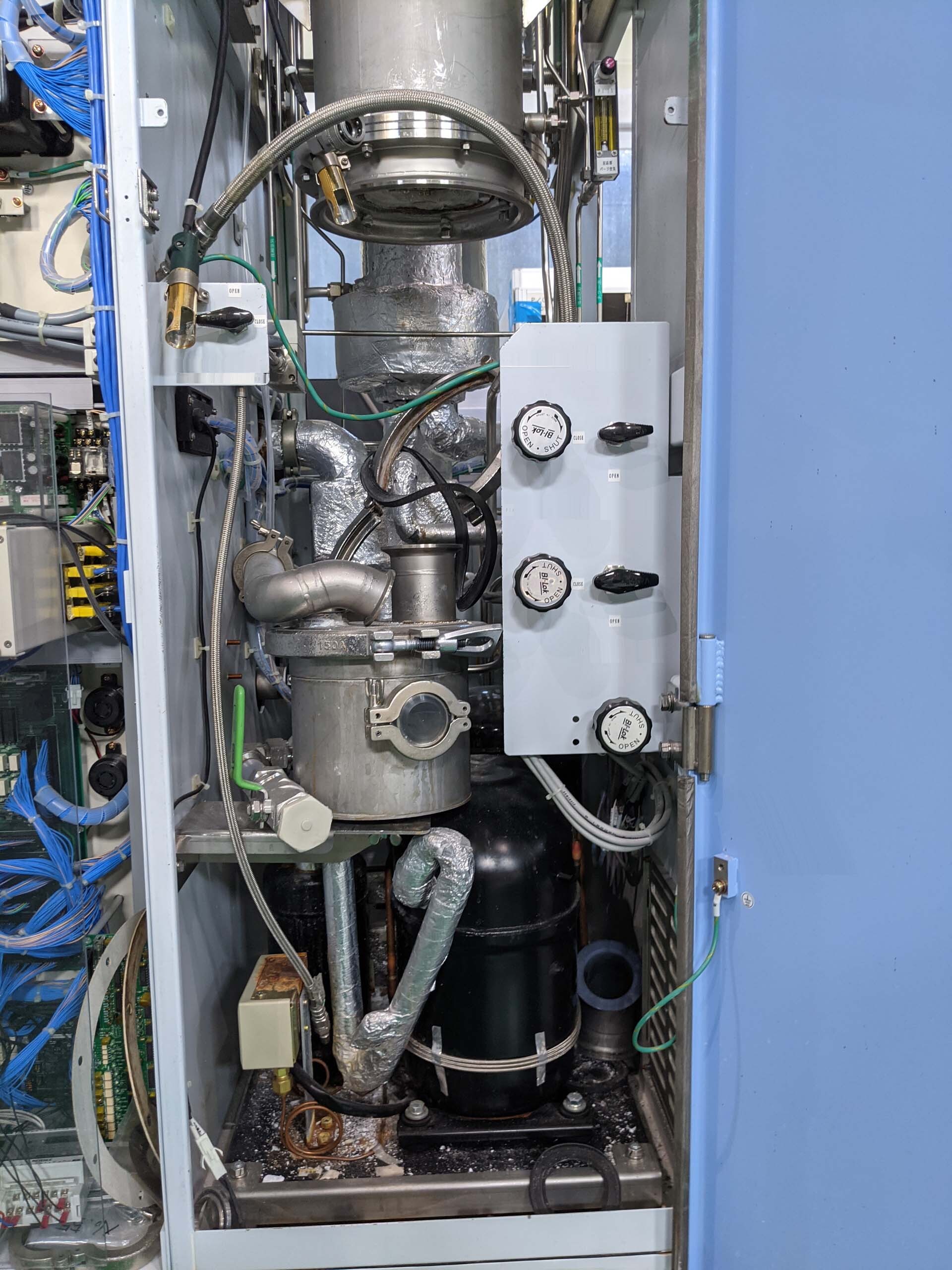

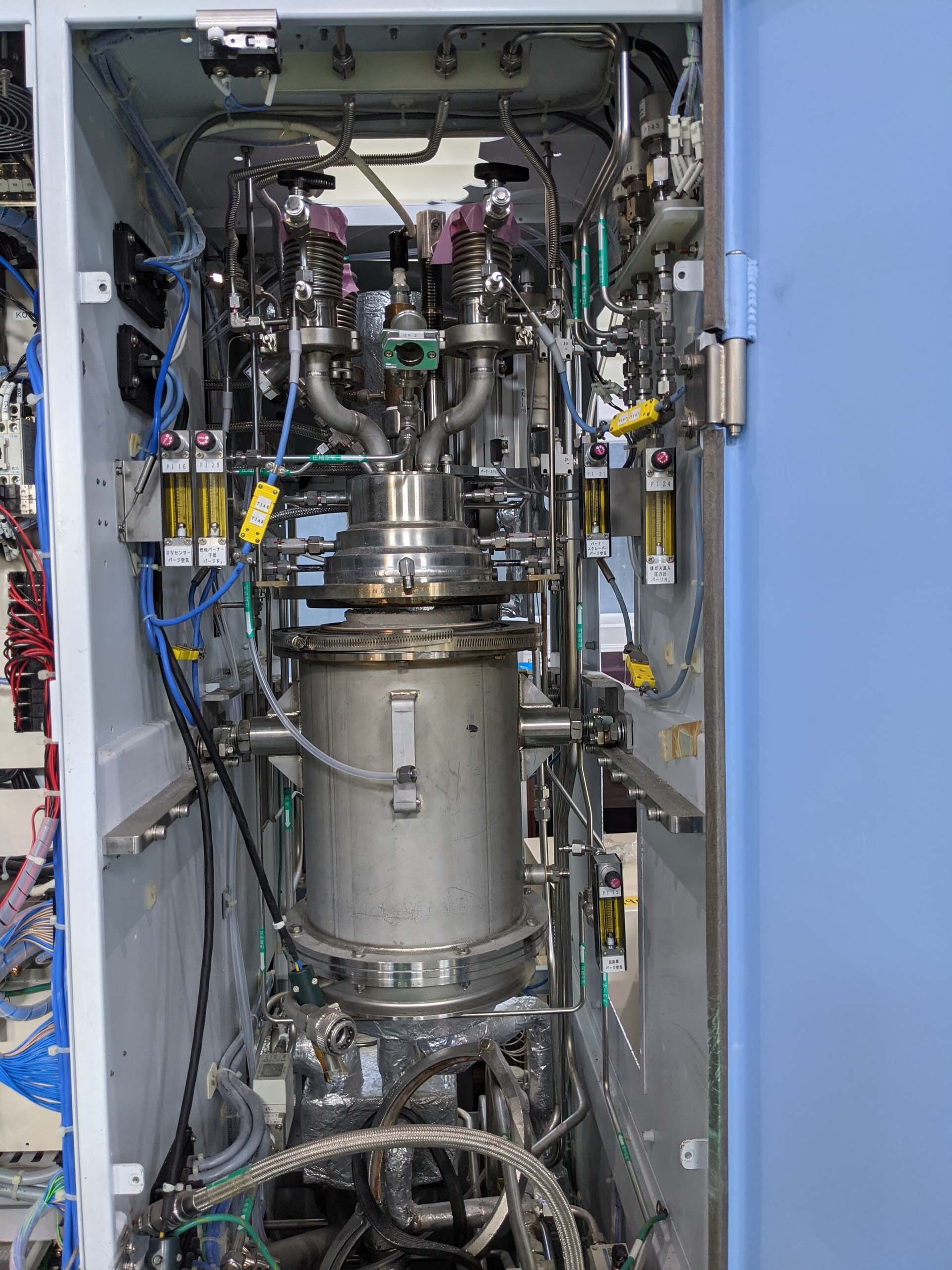

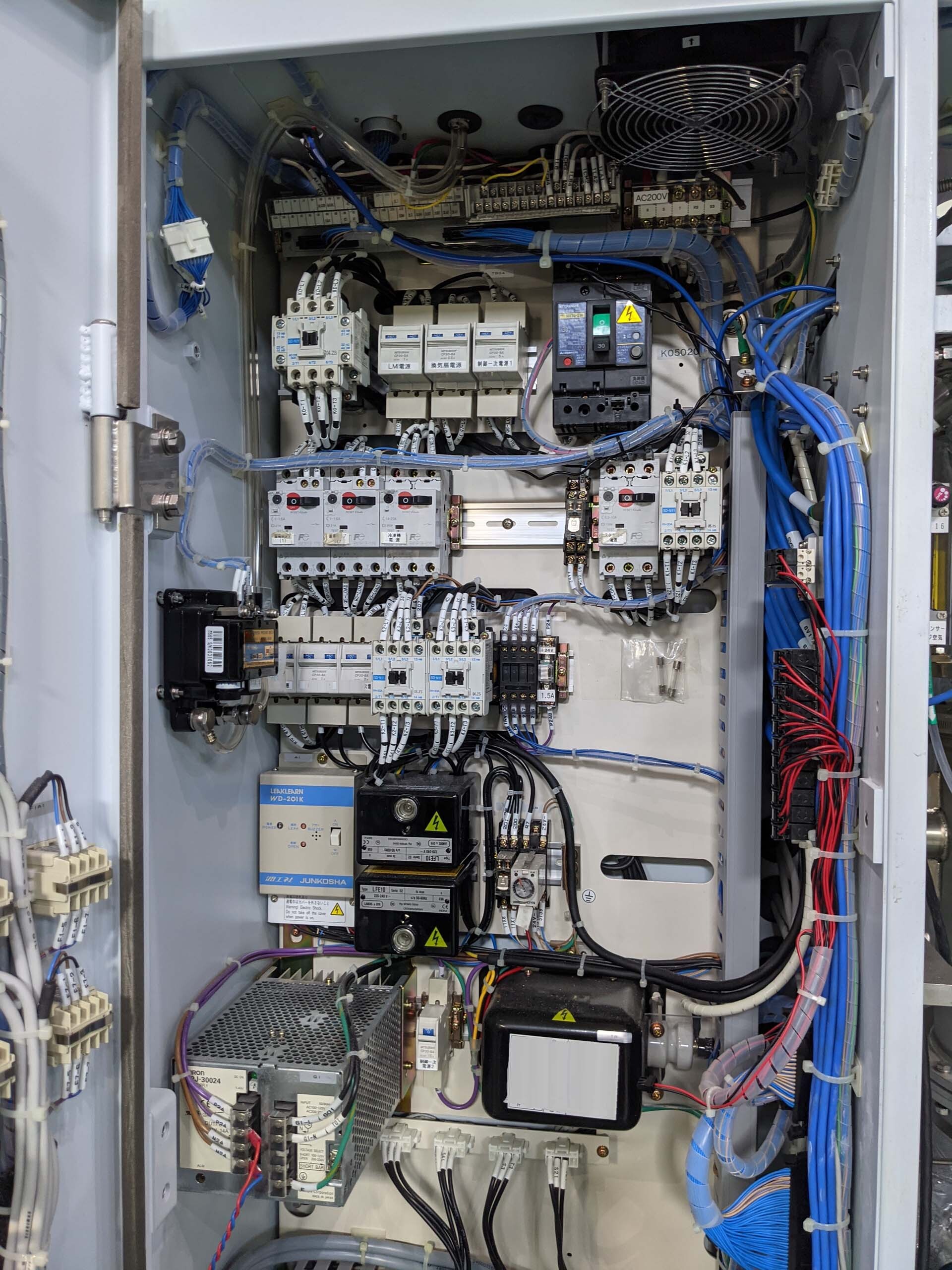

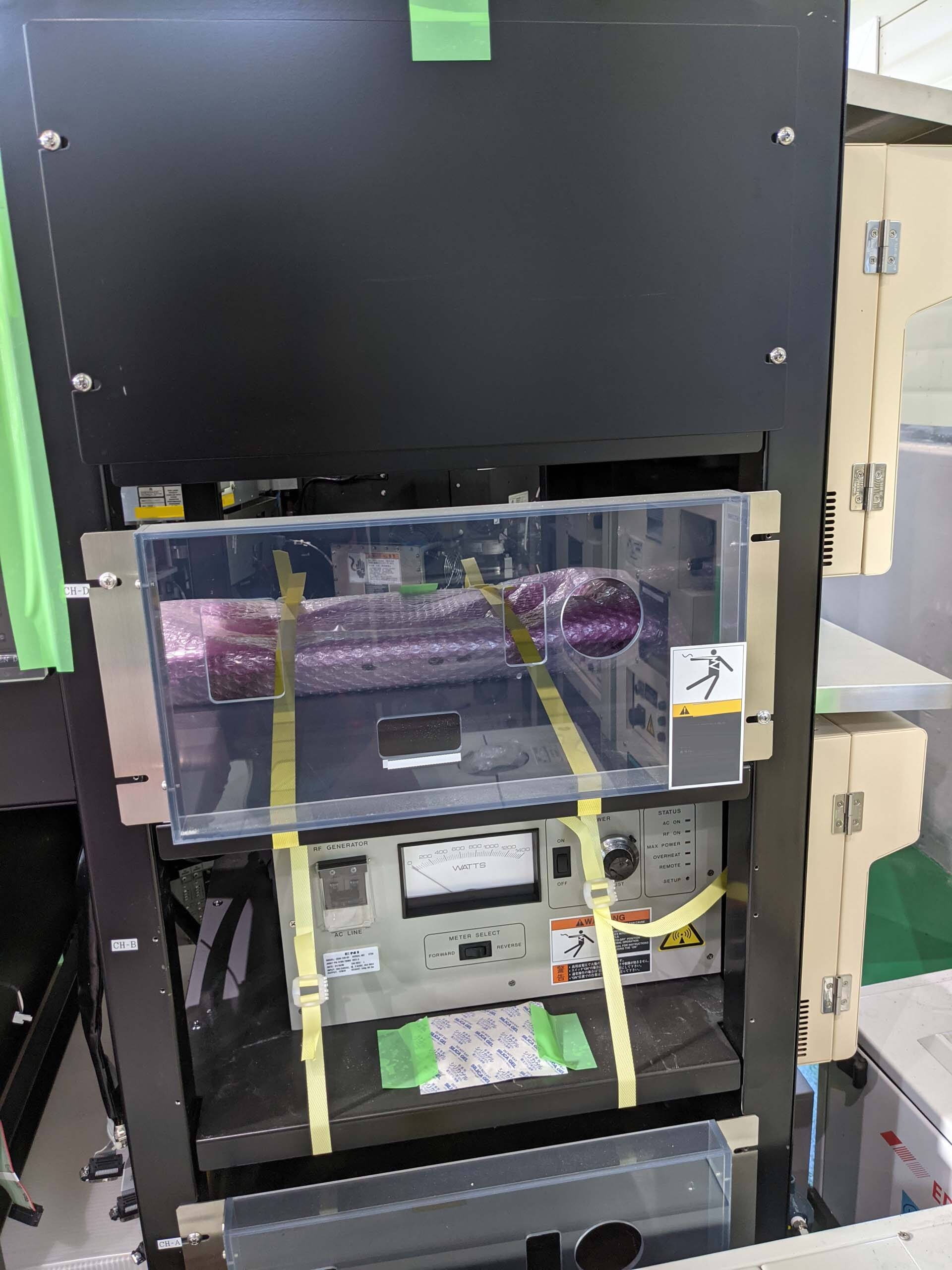

CVD System

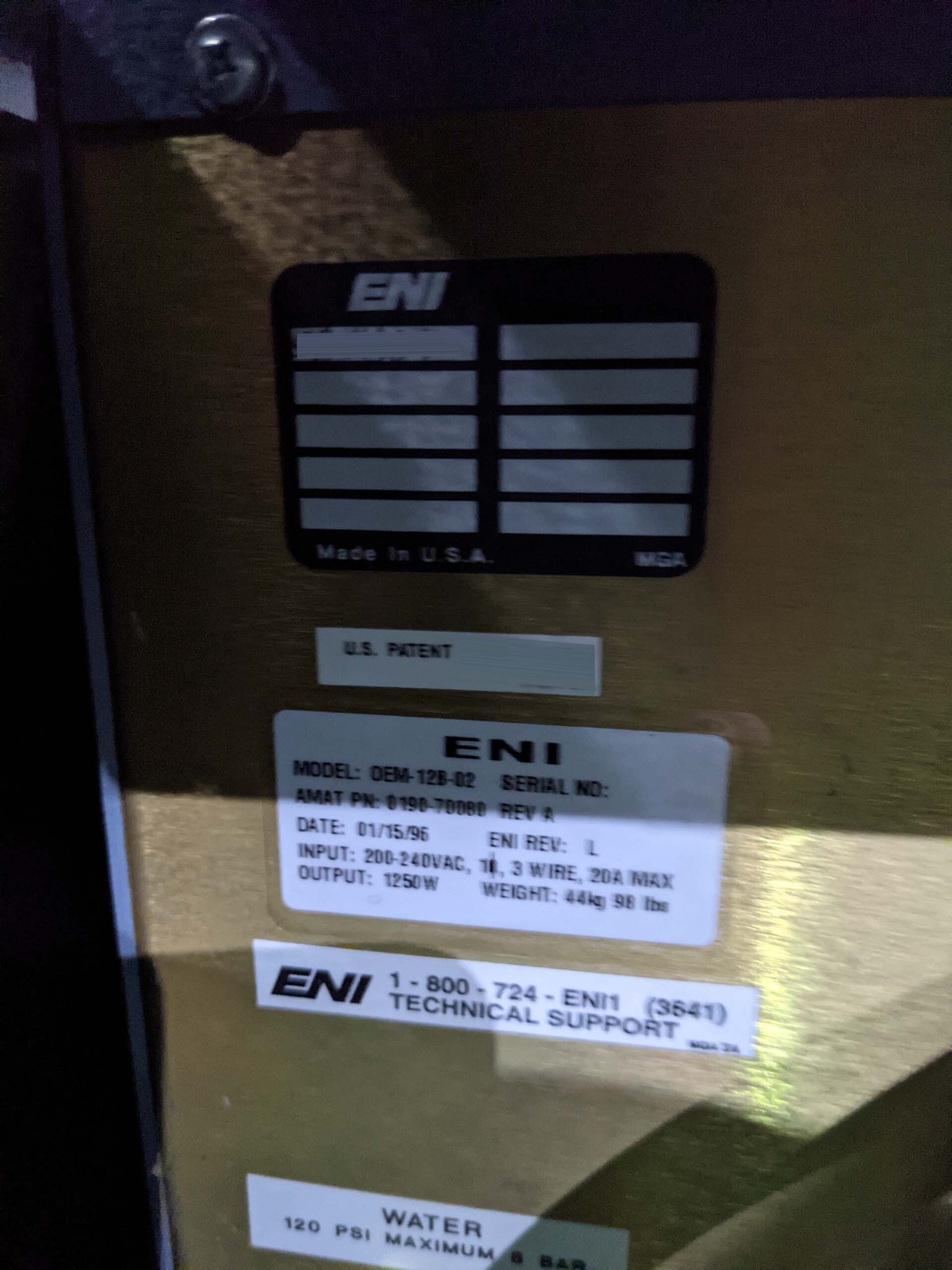

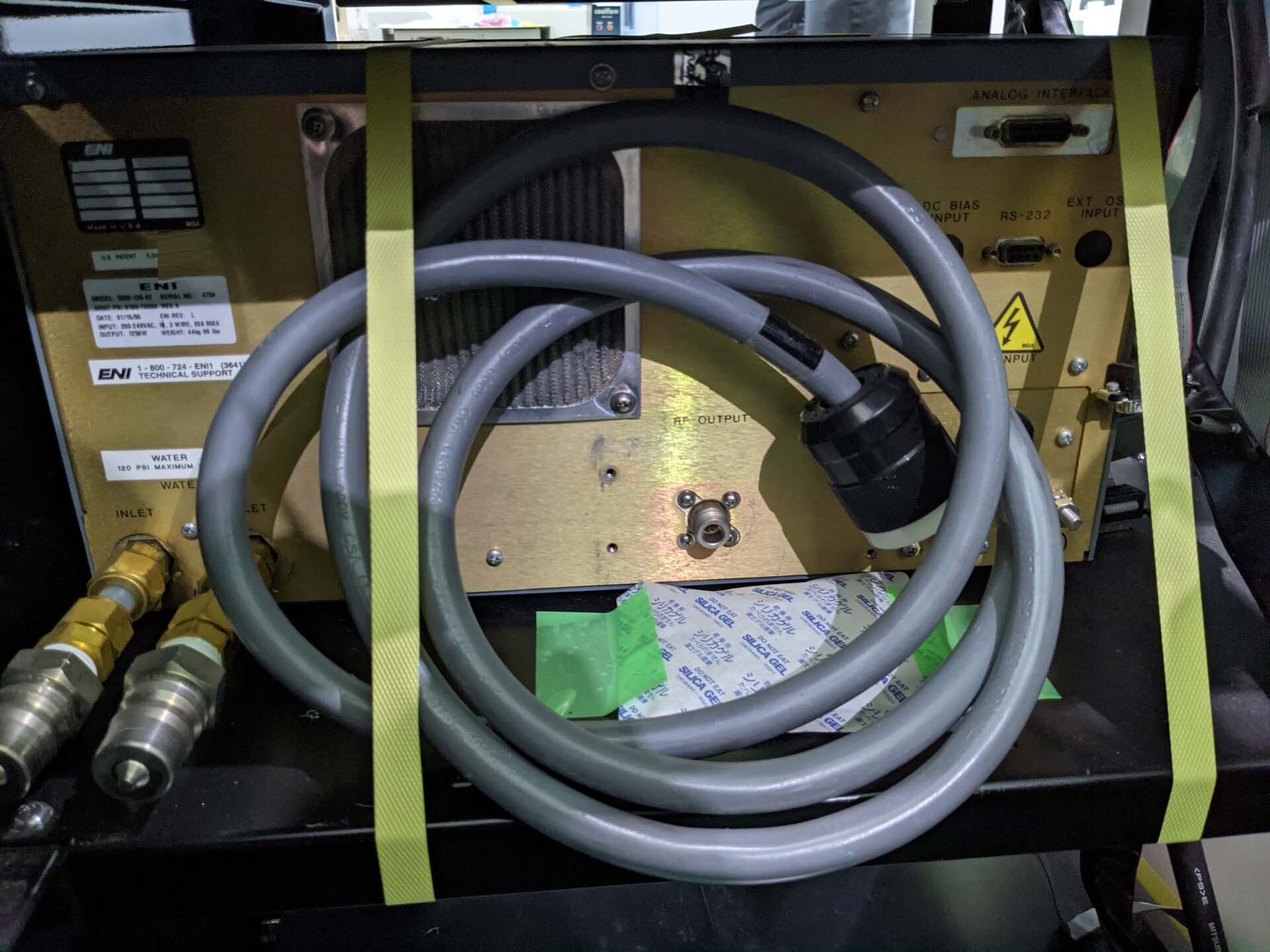

Generator 5000

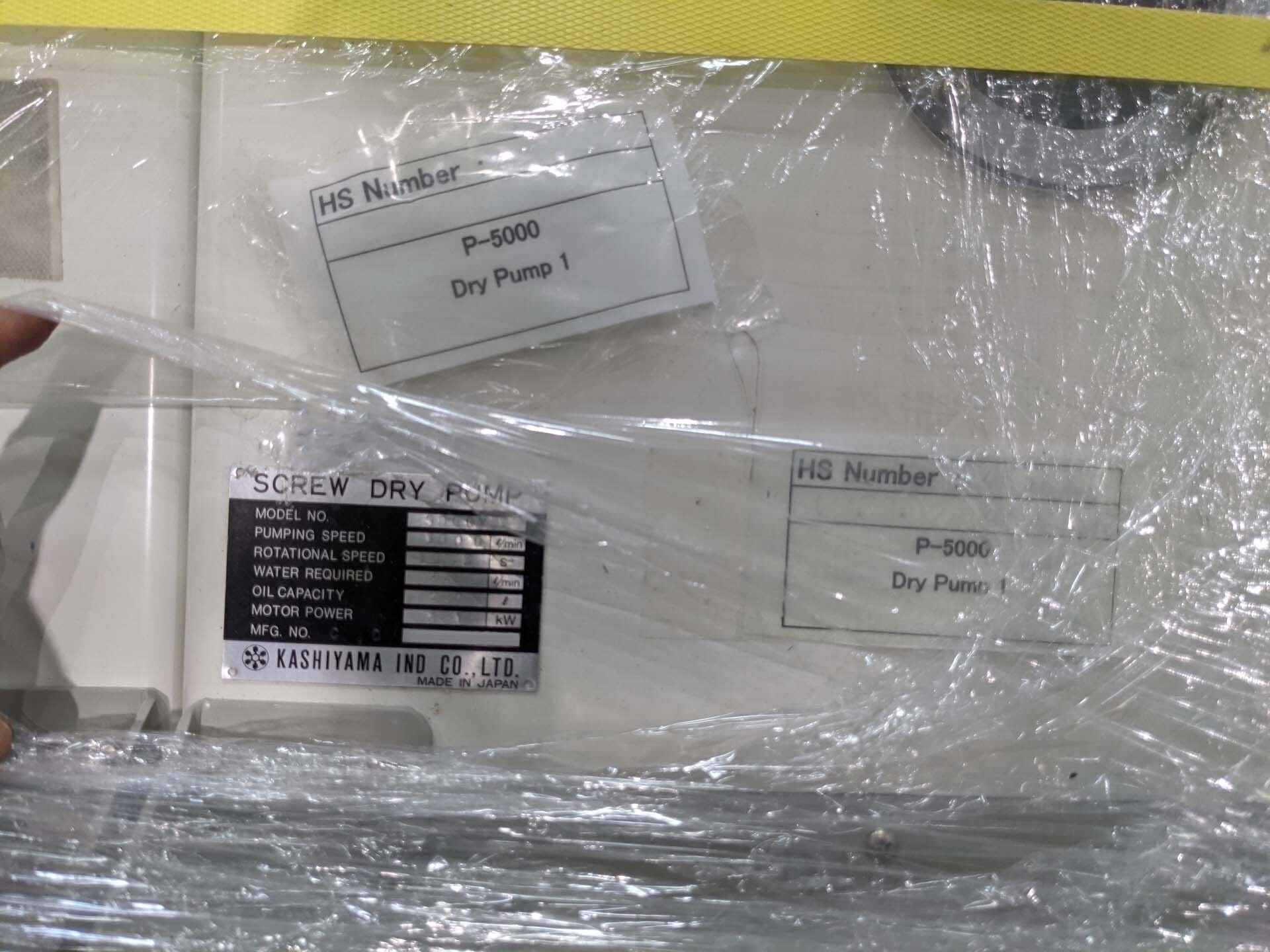

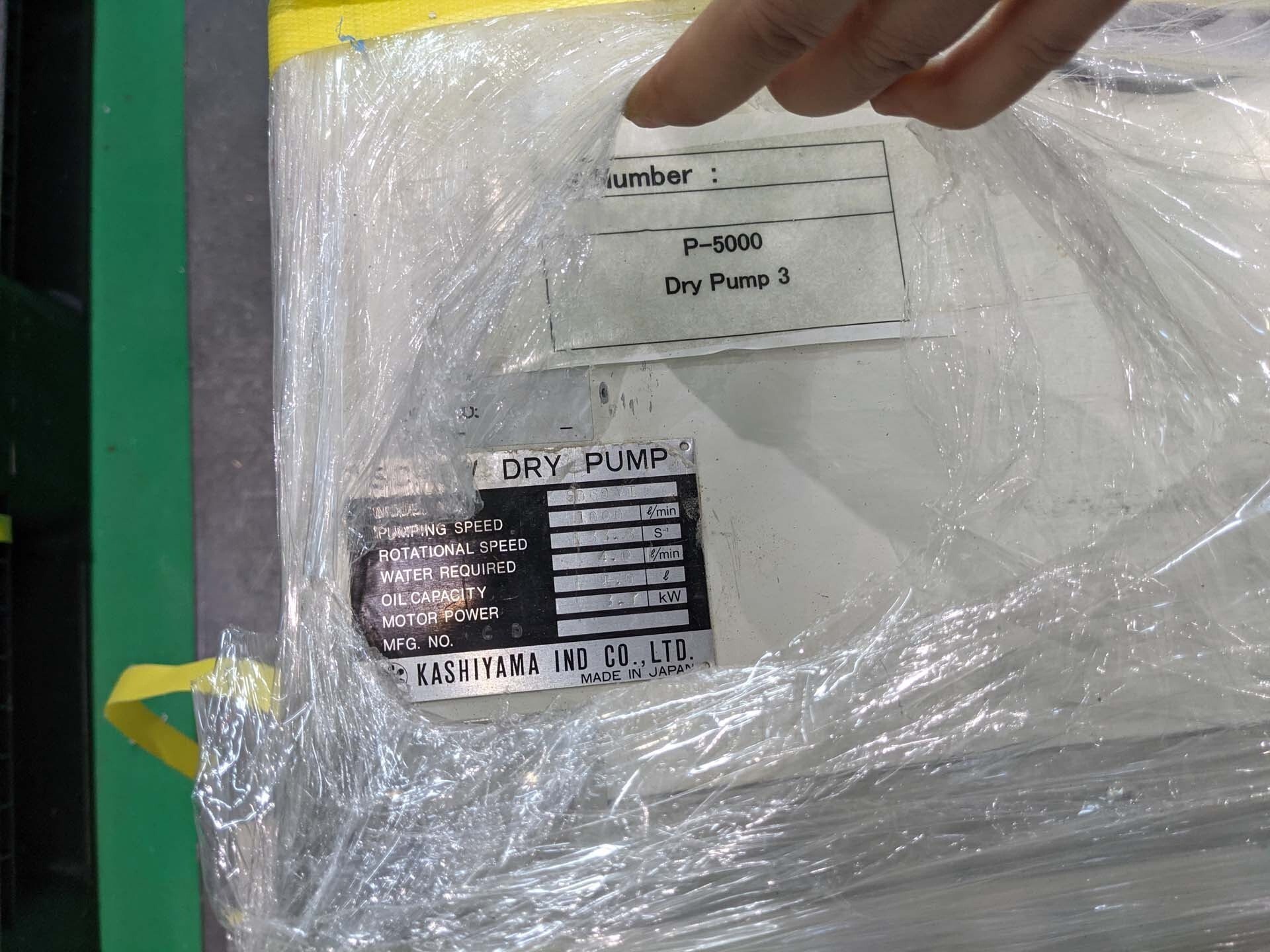

KASHIYAMA SD60VT Dry pump

With fire extinguisher

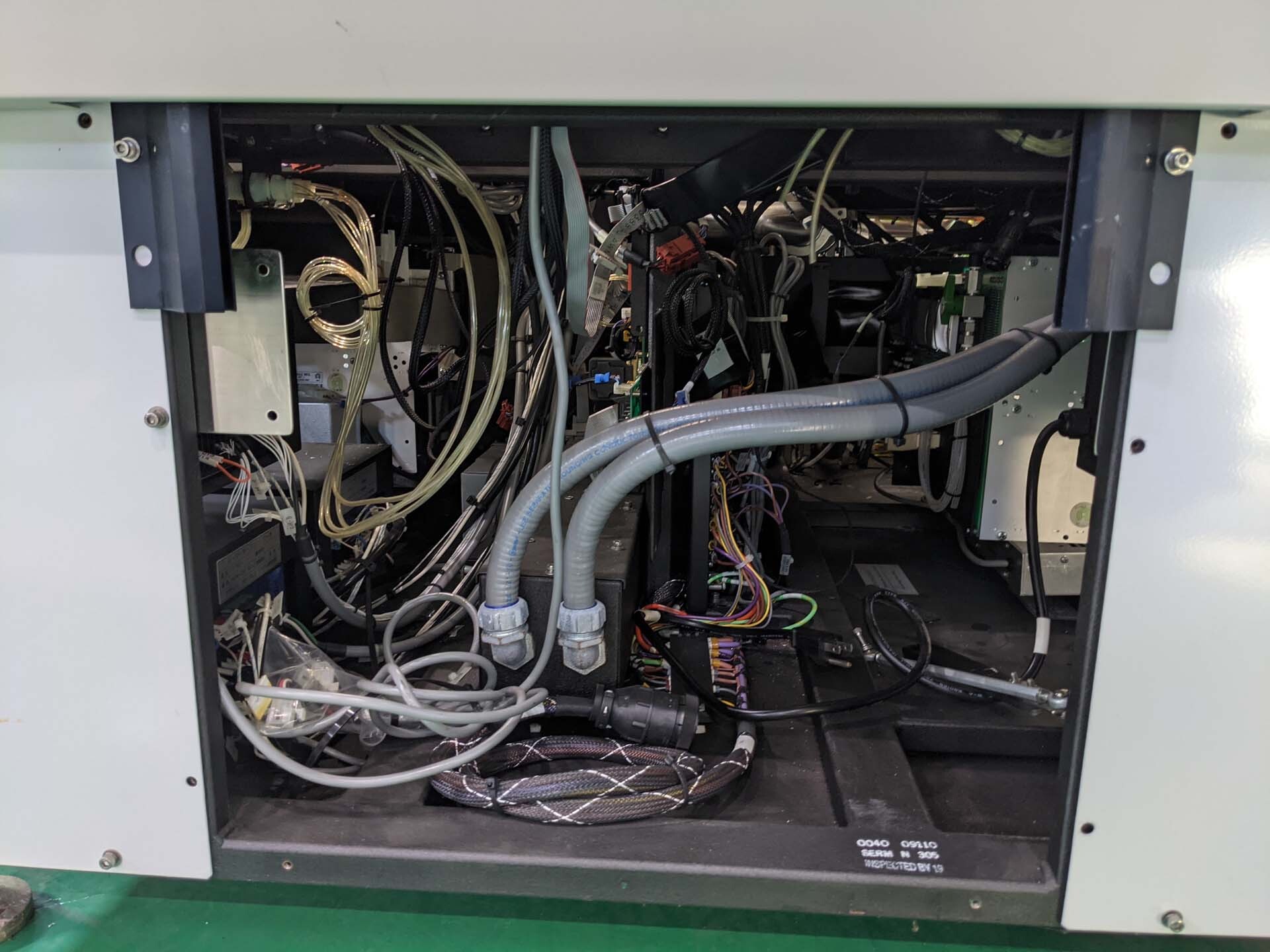

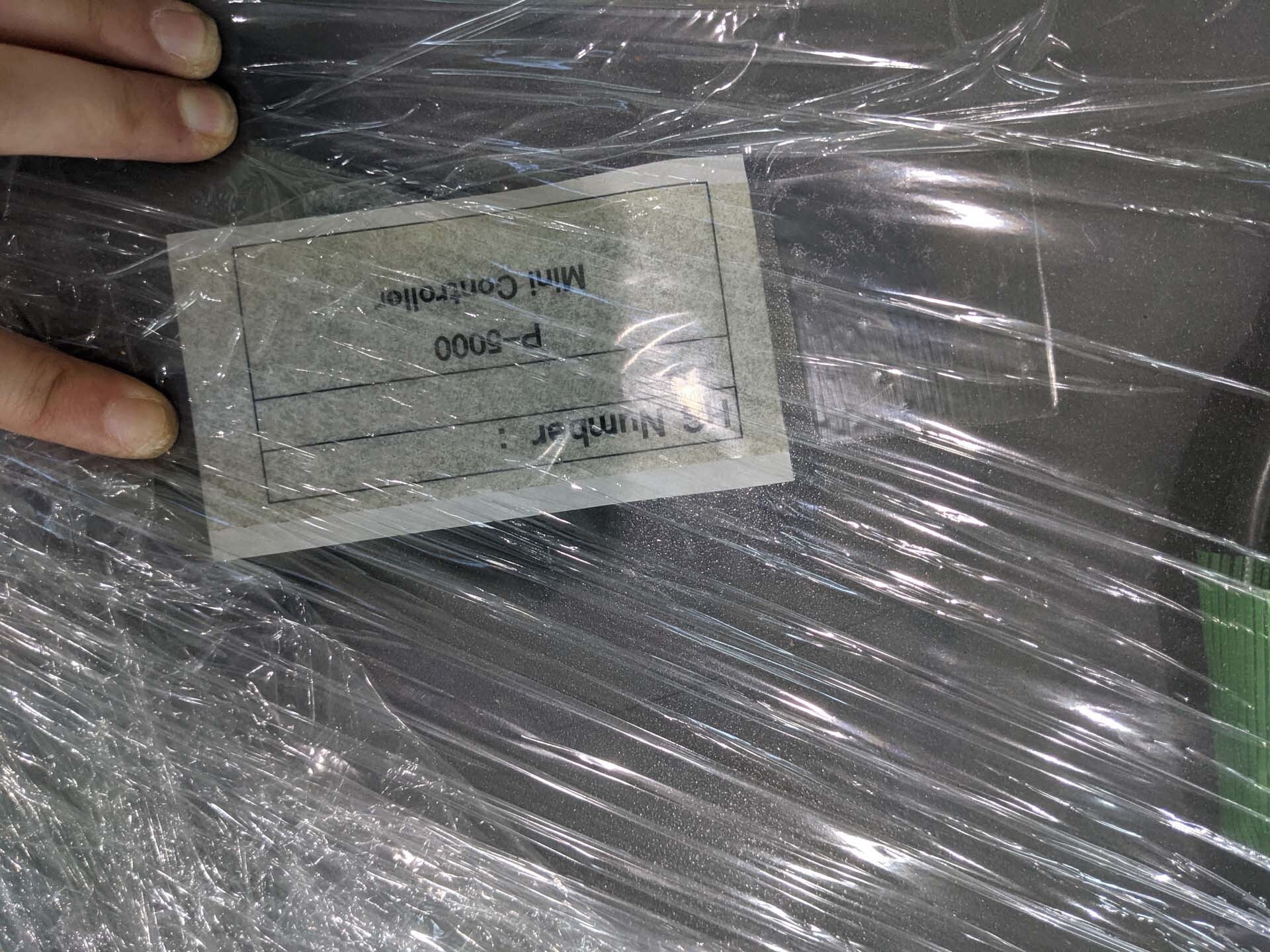

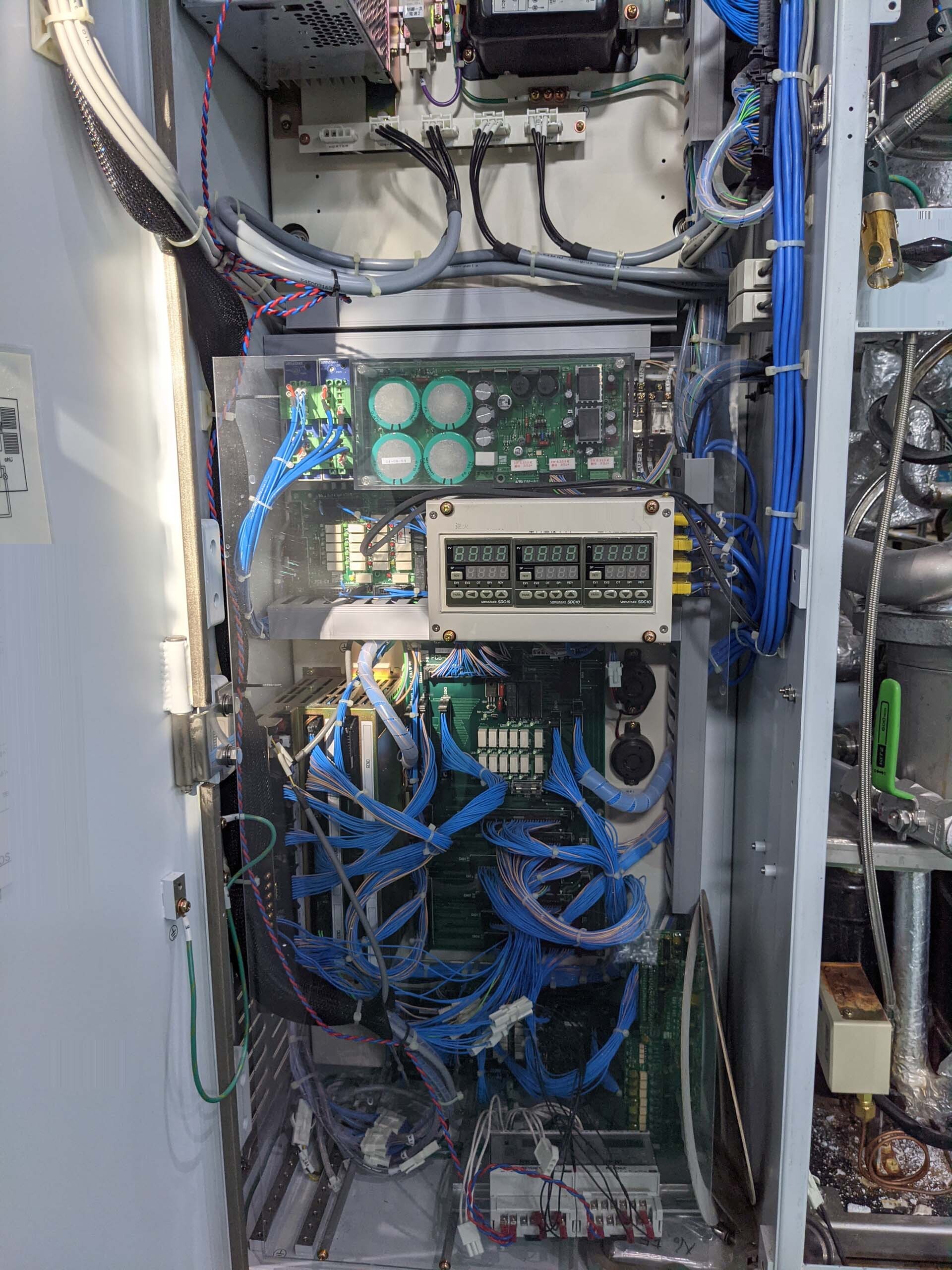

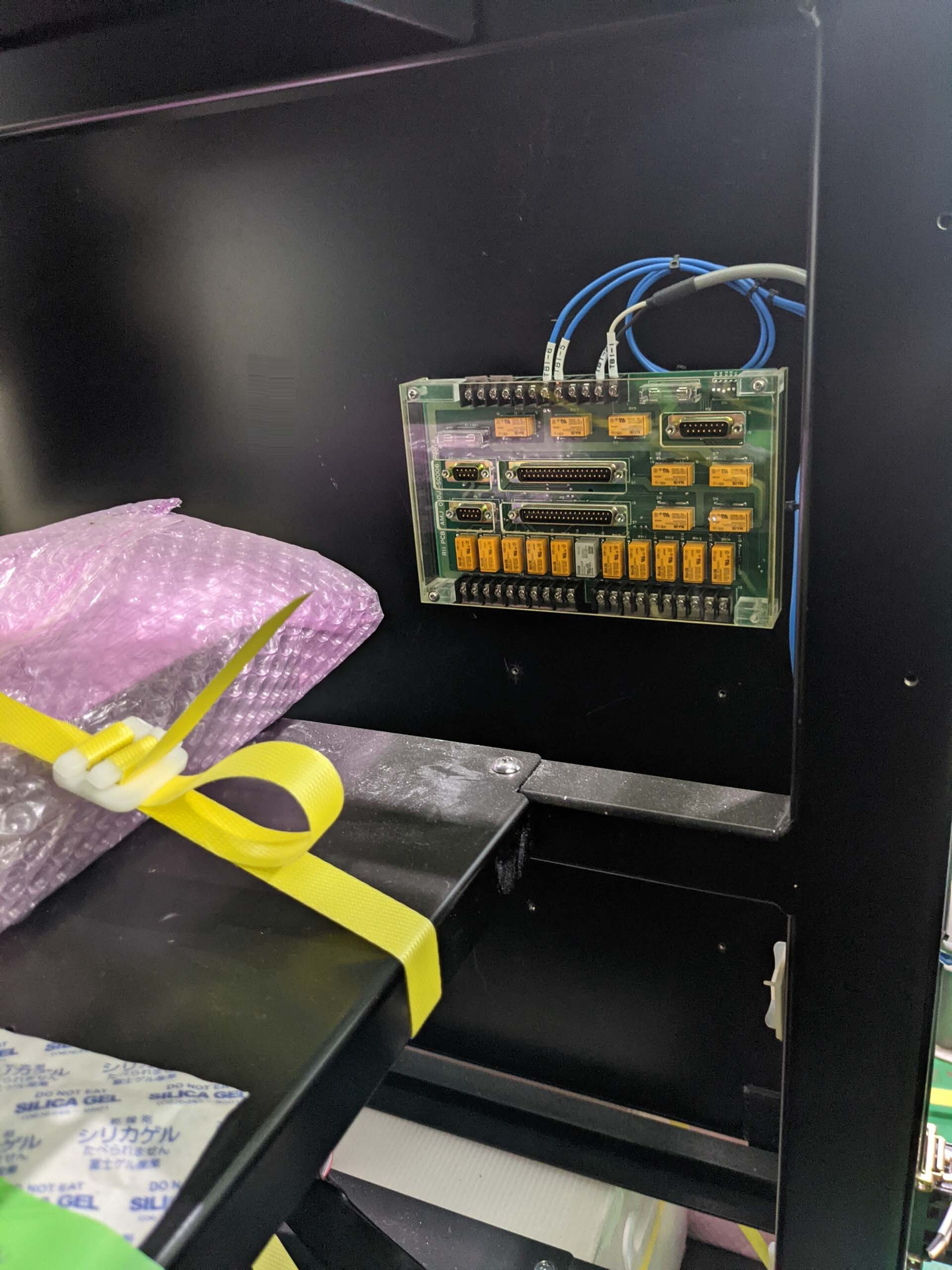

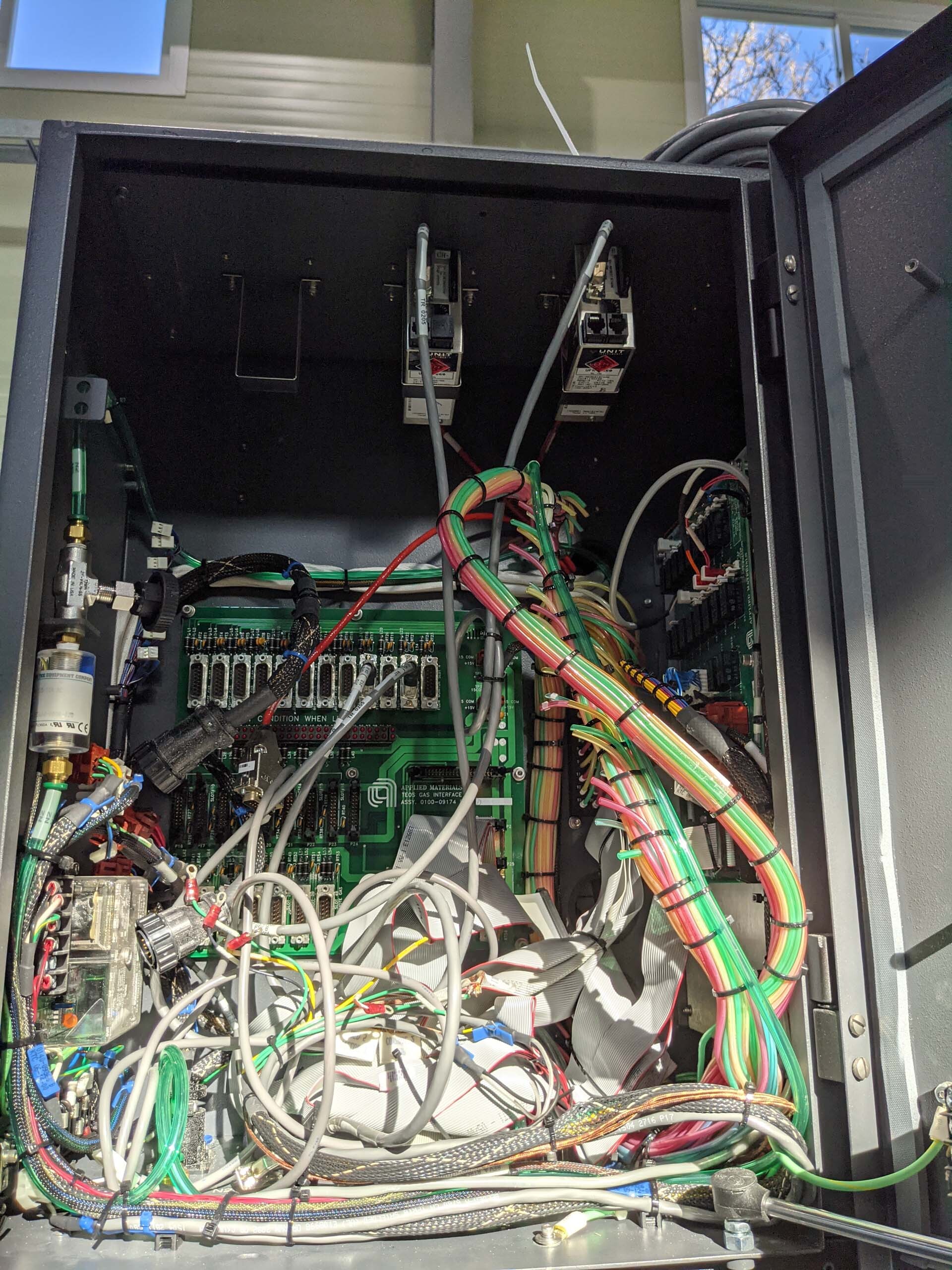

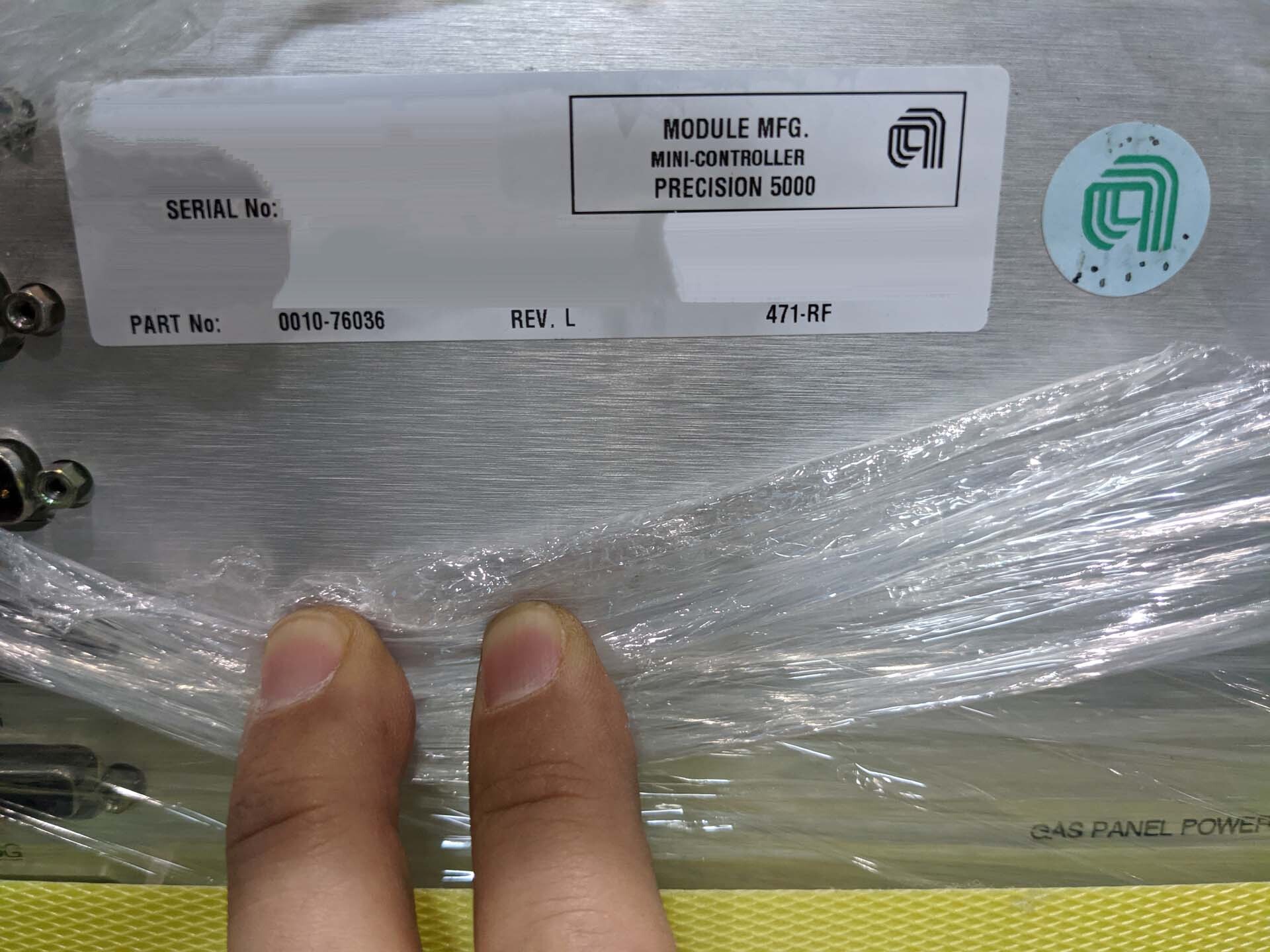

0010-76036 Mini controller

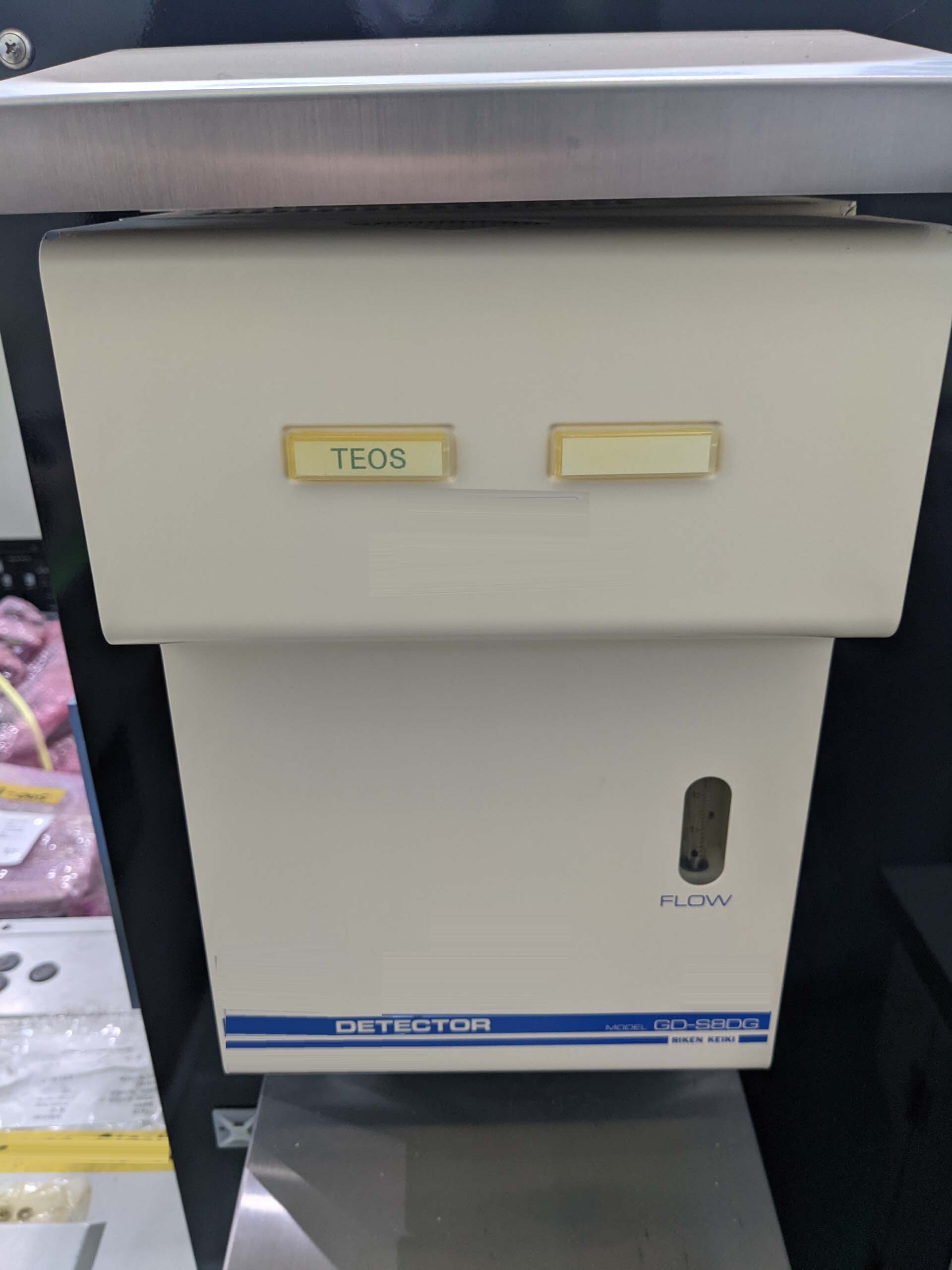

Gas scrubber

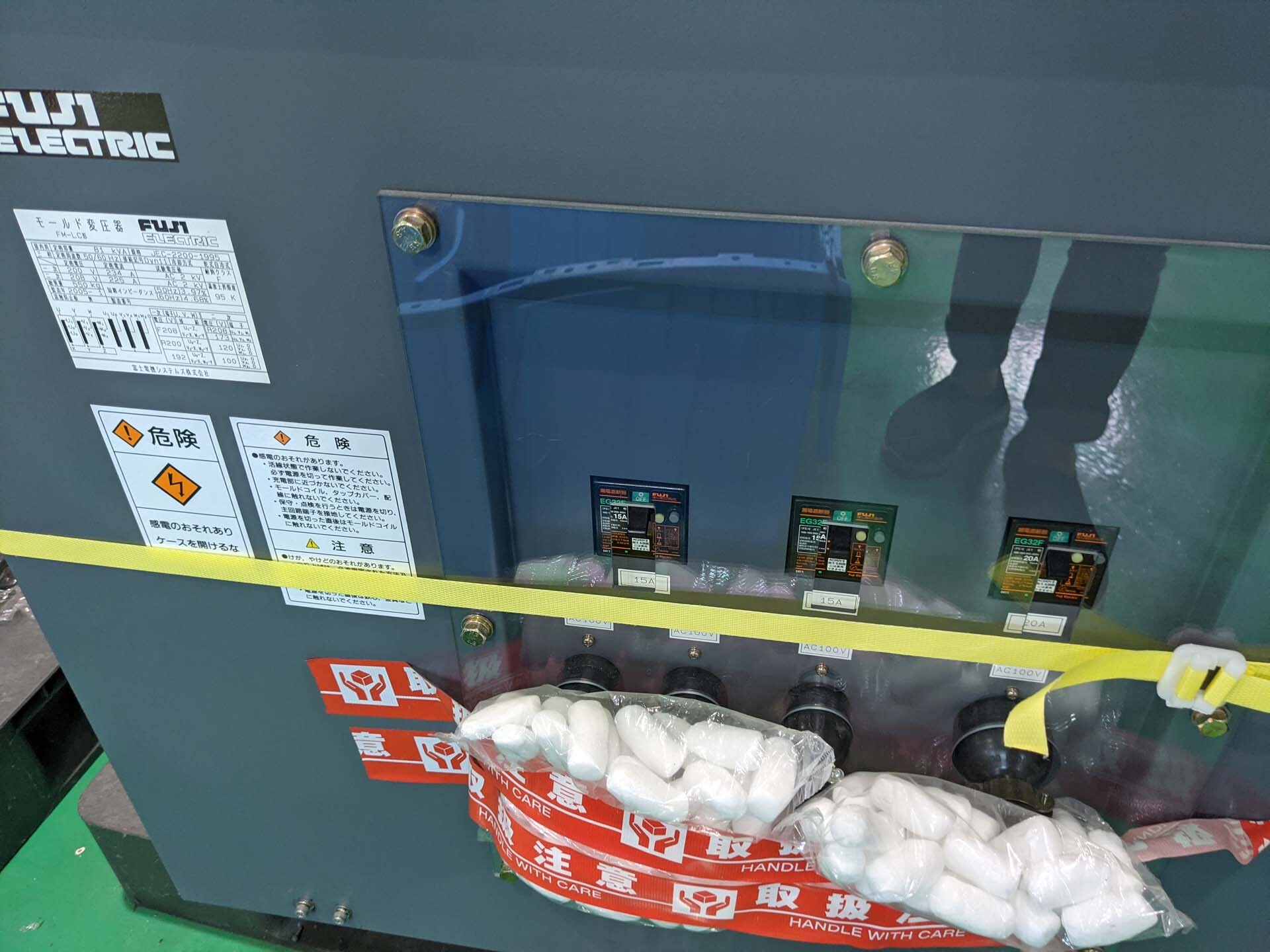

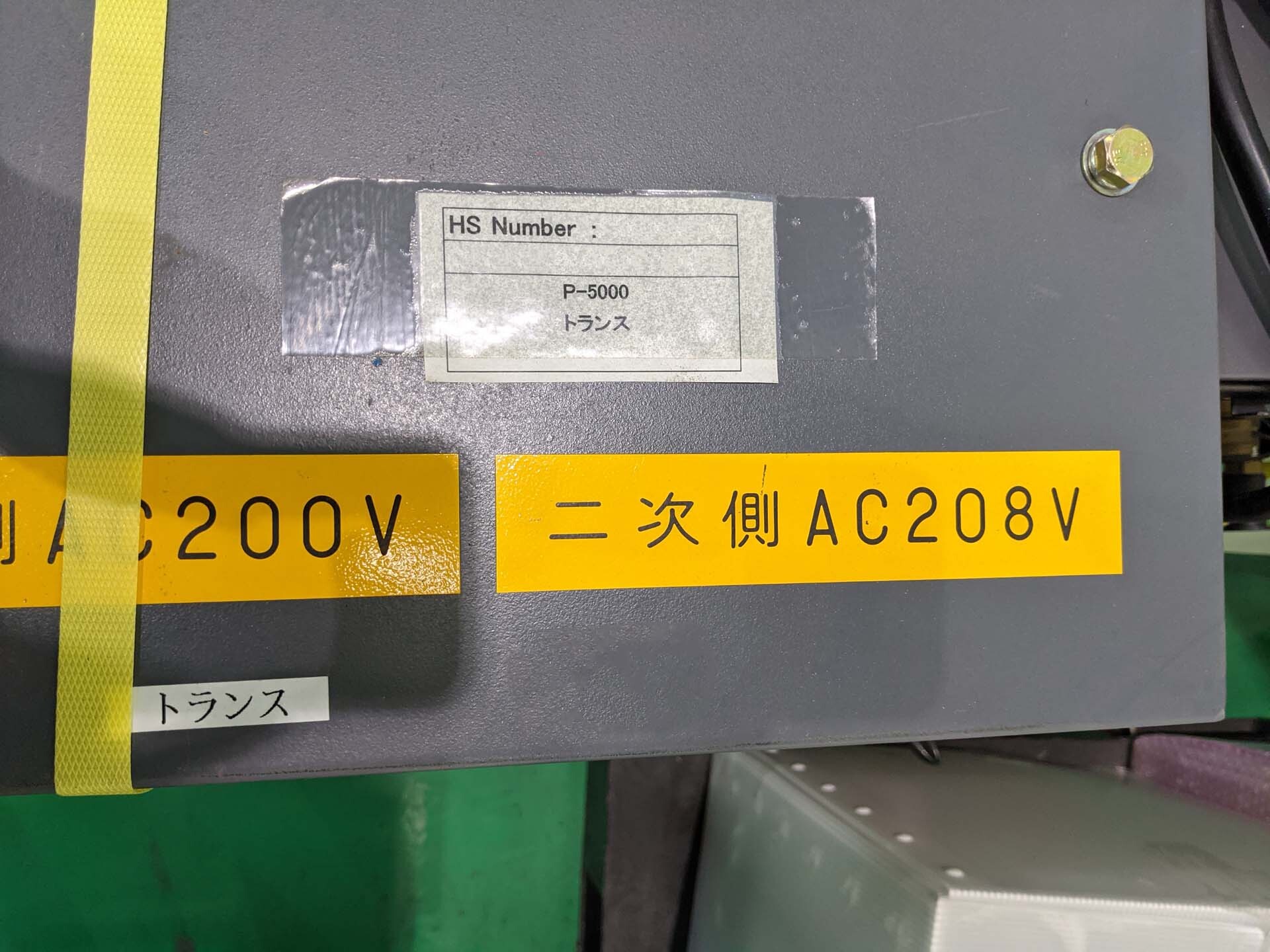

Transformer

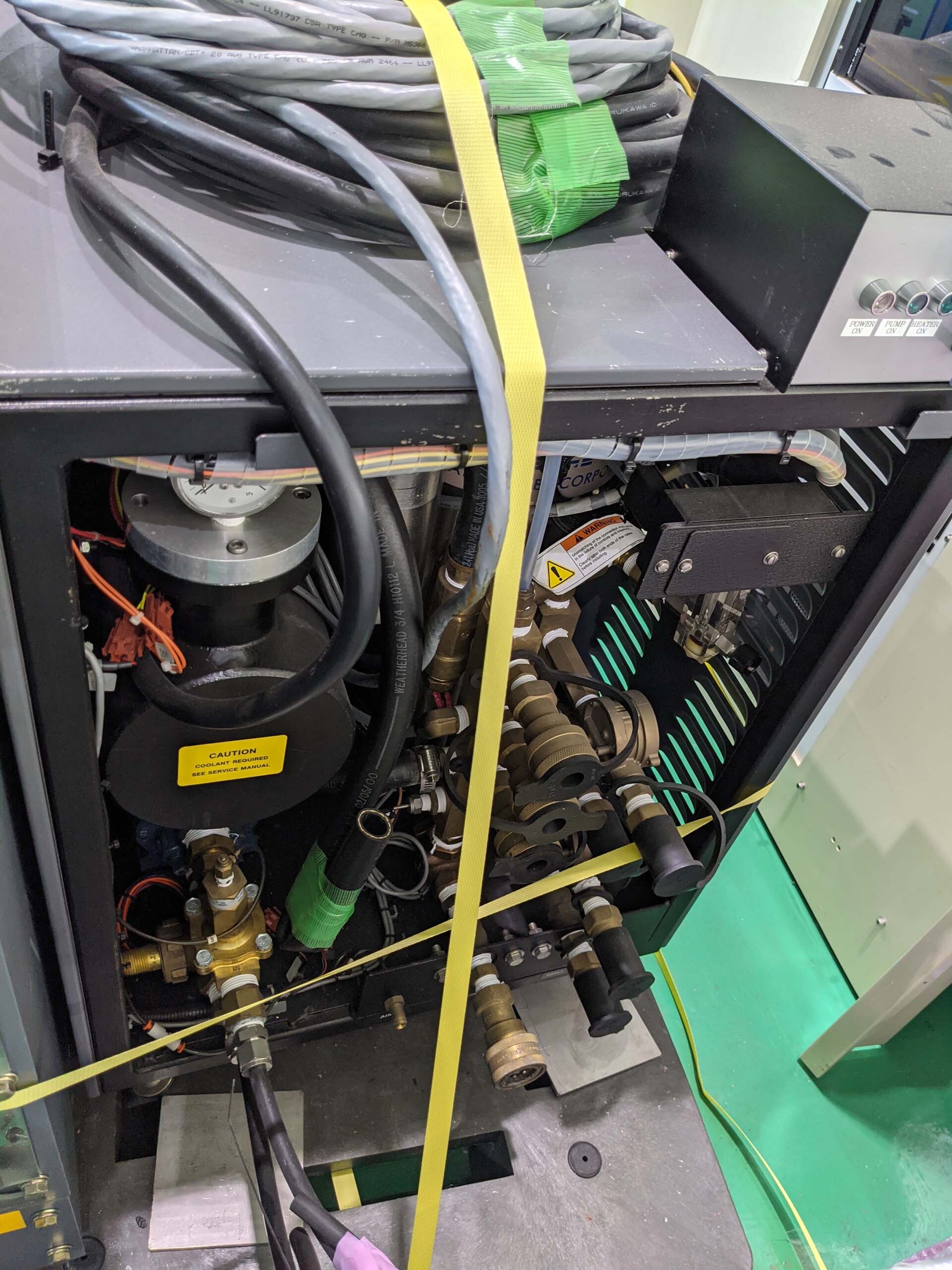

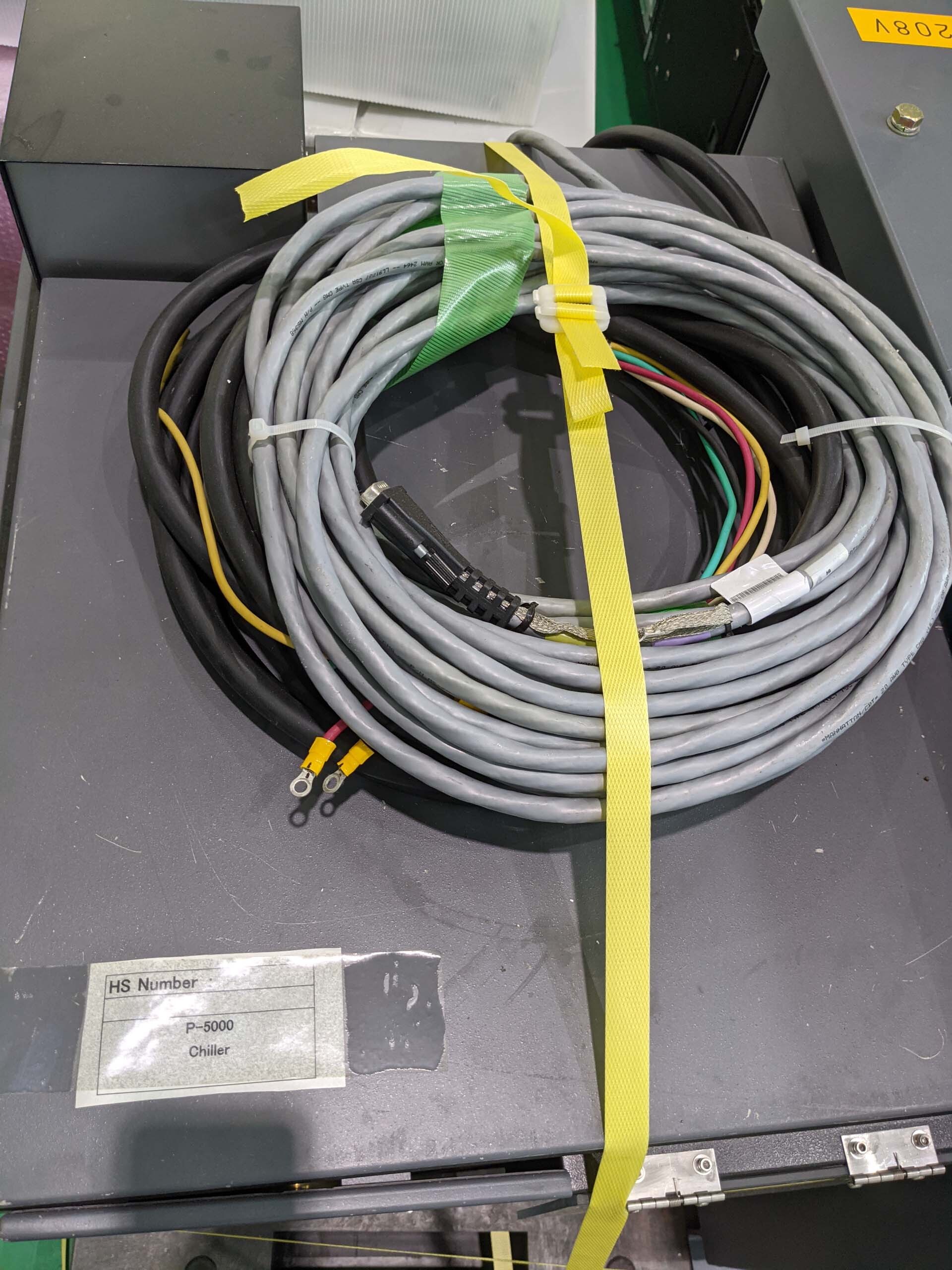

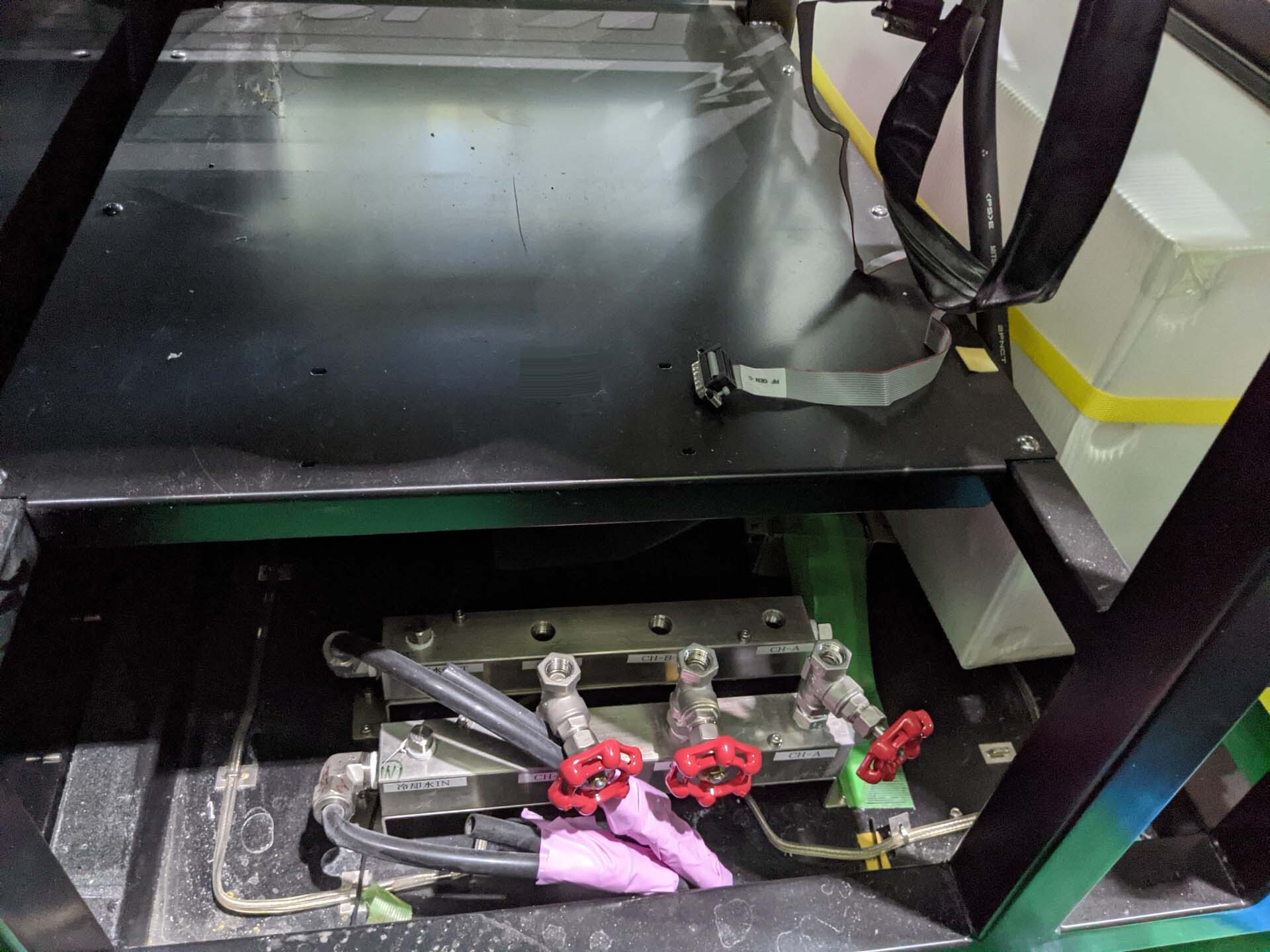

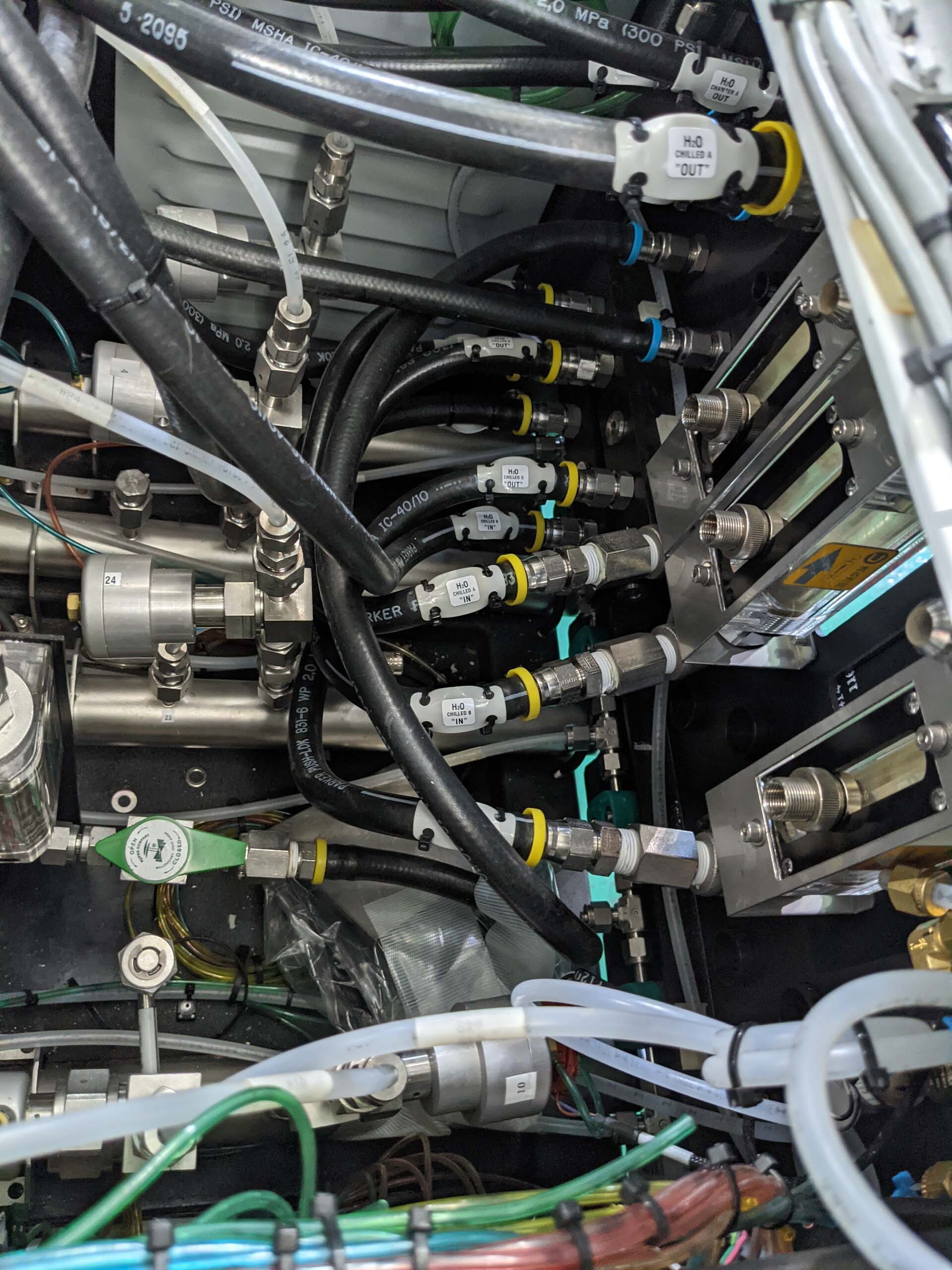

Chiller

(2) Dry pumps

(3) Boxes

1995 vintage.

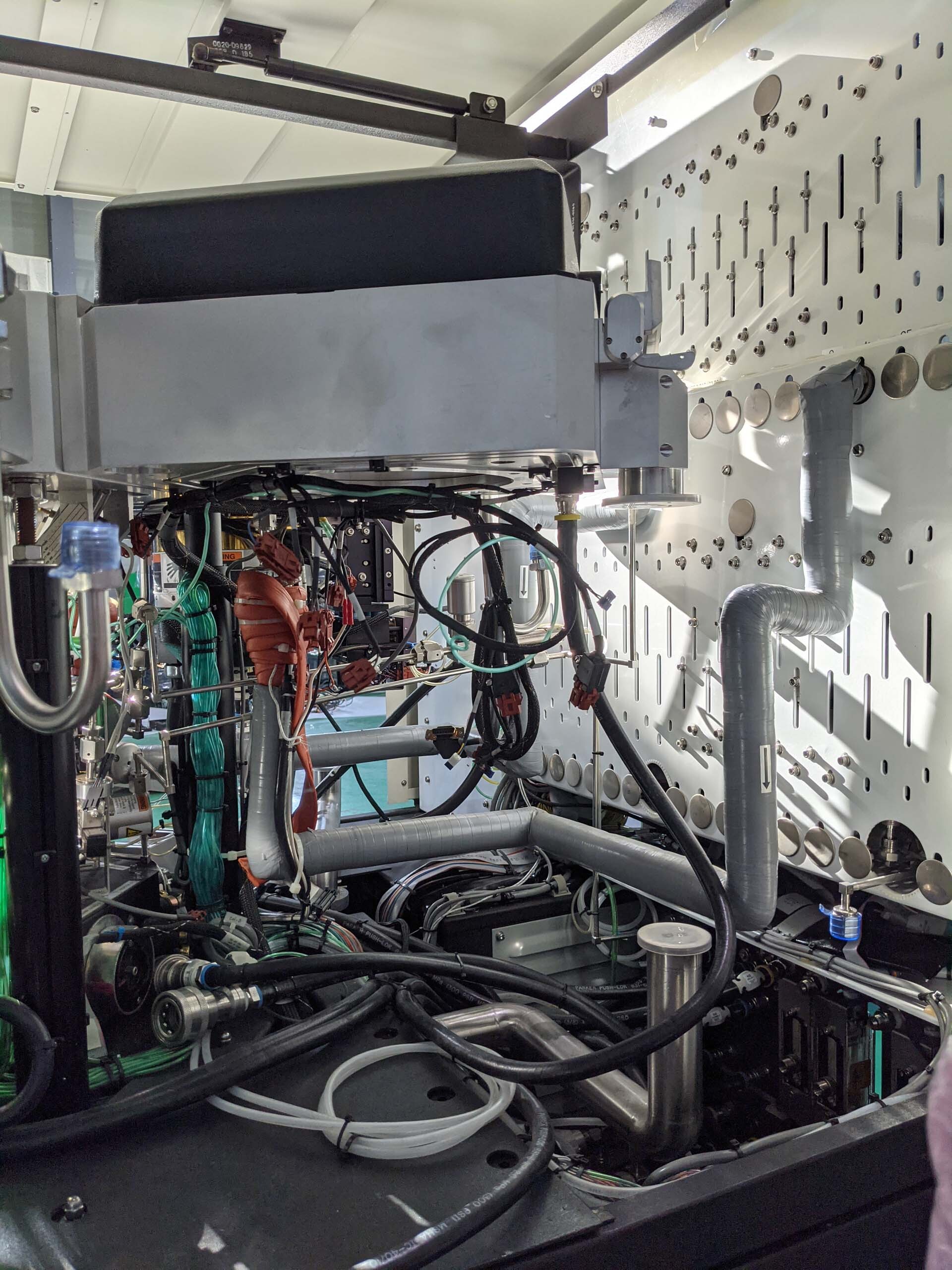

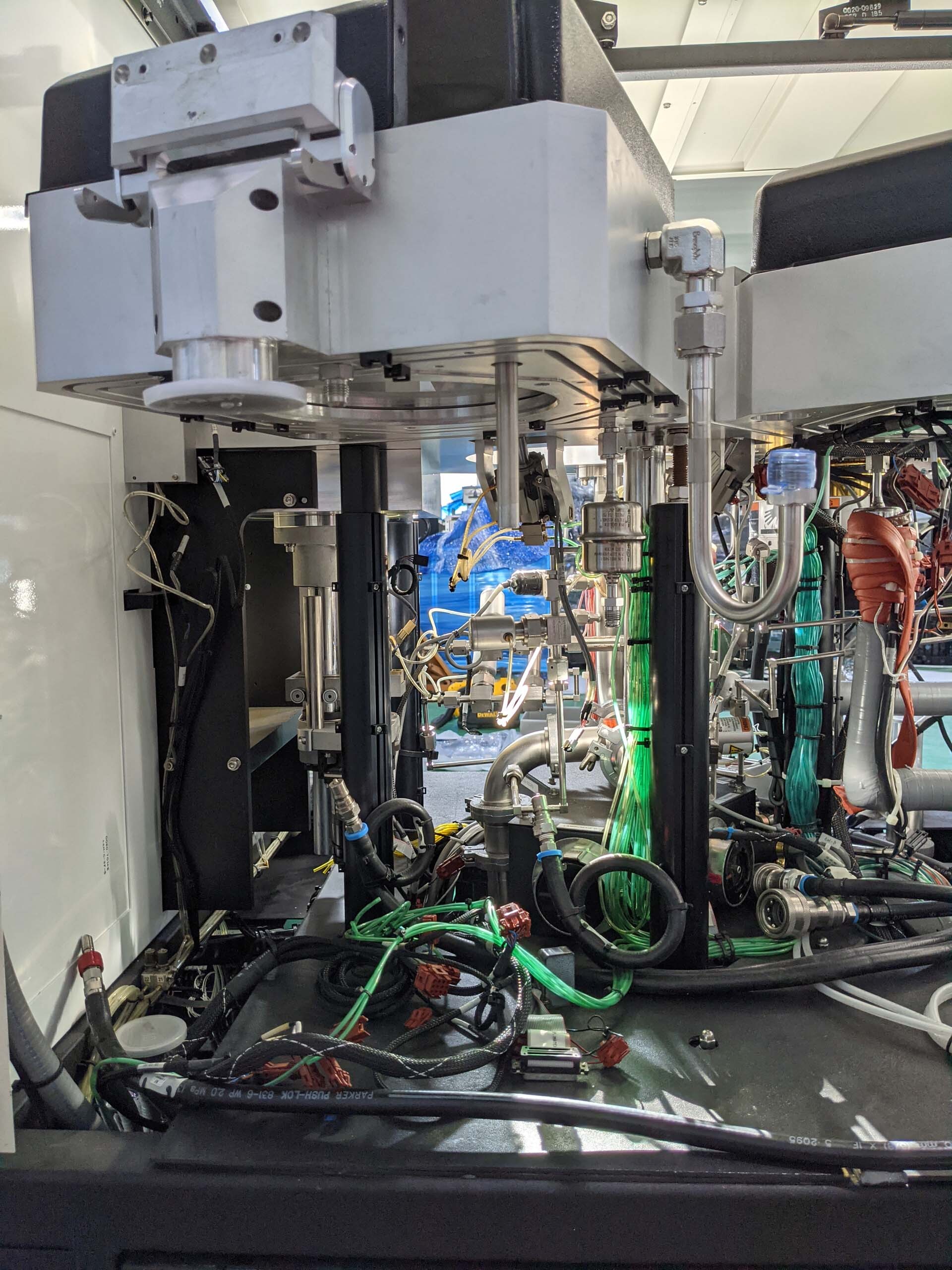

AMAT / APPLIED MATERIALS P5000 is a fully-integrated cluster tool for complex Process/Chemical Vapor Deposition (P/CVD) applications. It is designed for use in scientific research, semiconductor and electronics operations, solar panel fabrication and various industrial settings. This reactor has a unique low-temperature process to achieve ideal material quality for a range of materials. Built with the latest thermal processing technology, AMAT P-5000 cluster tool uses a vacuum technology known as the inductively-coupled plasma source. This provides an intense source of electromagnetic radiation, which is combined with a gas that brings the electrons and ions to a plasma state and creates highly energized particles in the form of a propellant. This intensifies the reaction and makes it easier to create highly complex structures in different materials. APPLIED MATERIALS P 5000 can handle a variety of process parameters, making it suitable for most research applications and industrial processes. The reactor is highly sensitive and able to accurately measure and monitor temperatures, pressure, and other process variables. As a result, it offers a wide range of control parameters that can be fine-tuned according to the needs of each application. This is especially useful for substrate growth and surface modification. AMAT / APPLIED MATERIALS P 5000 is able to achieve perfect uniformity in a wide variety of application areas. Its unique high-temperature and low-pressure process also ensures a safe working environment with minimal risk of damaging material or harming personnel. This allows for samples to be prepared quickly and with high precision. AMAT / APPLIED MATERIALS P-5000 is highly automated and offers the possibility of customization. Many aspects of the CVD process are preconfigured to minimize the time, complexity and cost of the system. This all makes it easy to understand how the process works and how it should be operated. In summary, AMAT P 5000 is an advanced CVD process/chemical reactor designed to provide precise, repeatable, and reliable material quality and uniform deposition. It has a wide range of control parameters that can be customized to the application and offers an integrated solution for fast processing. The combination of low-temperature, high-pressure and low-pressure processing and the wide range of control parameters makes it suitable for a variety of industrial and scientific processes.

There are no reviews yet