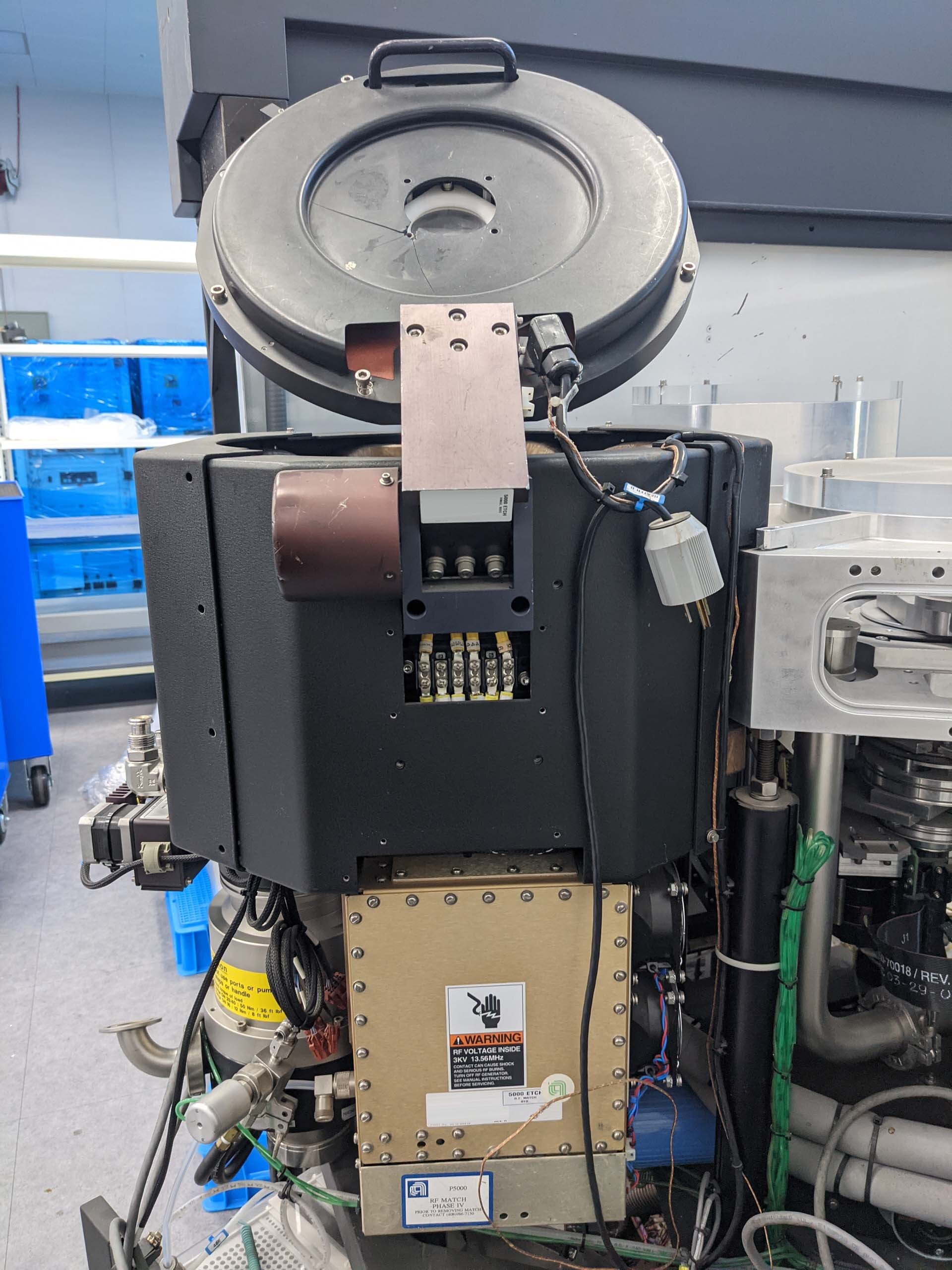

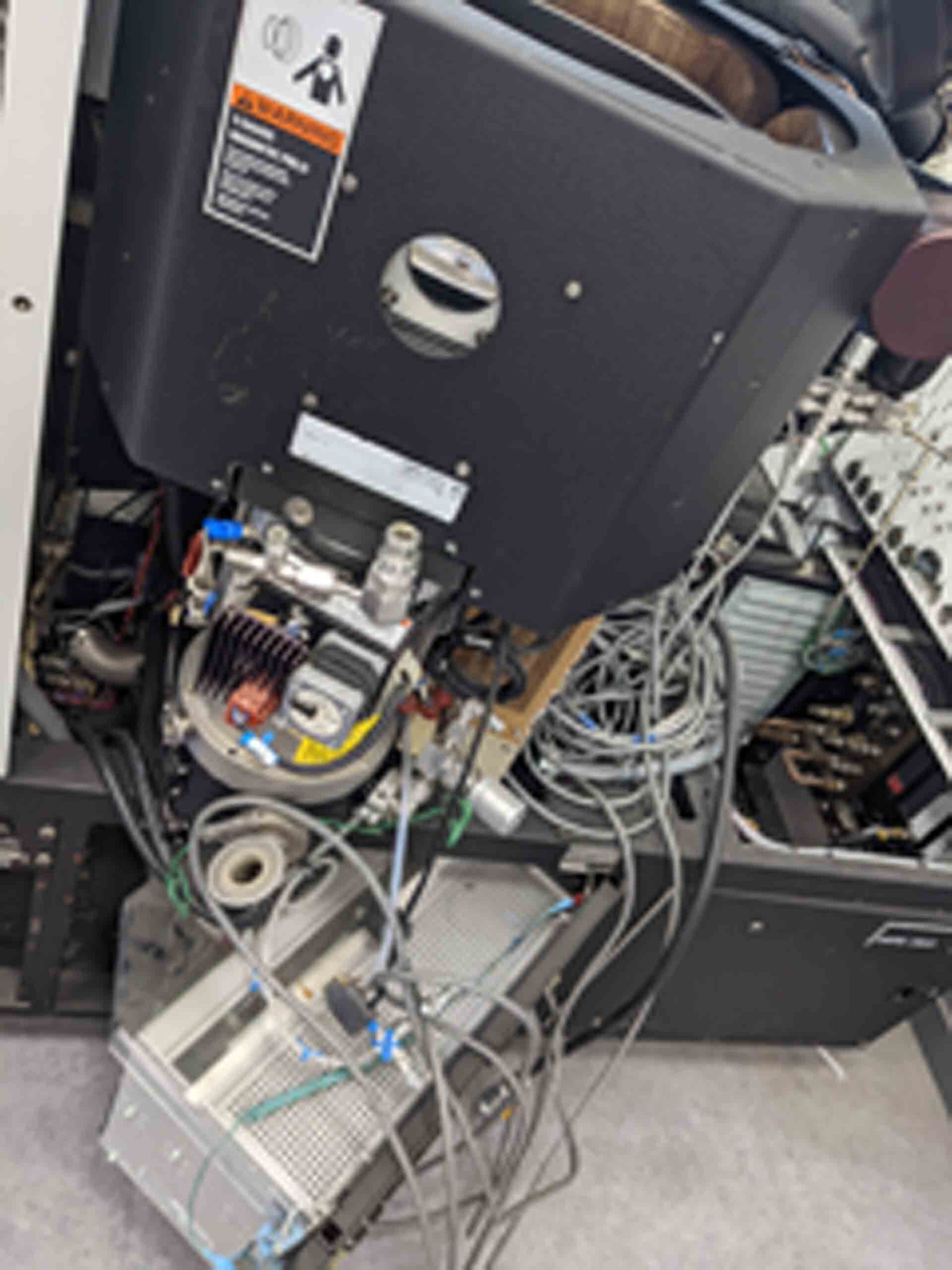

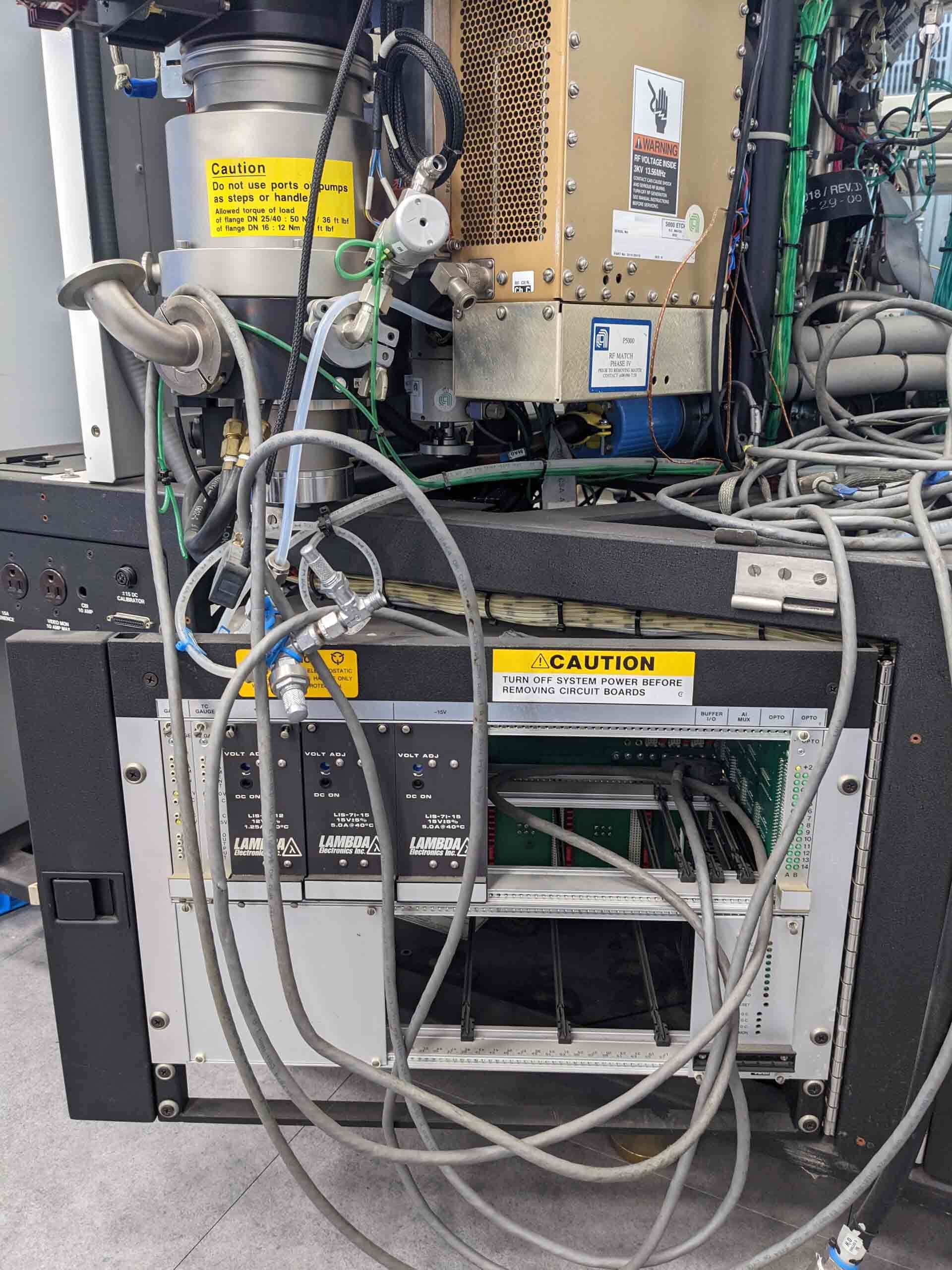

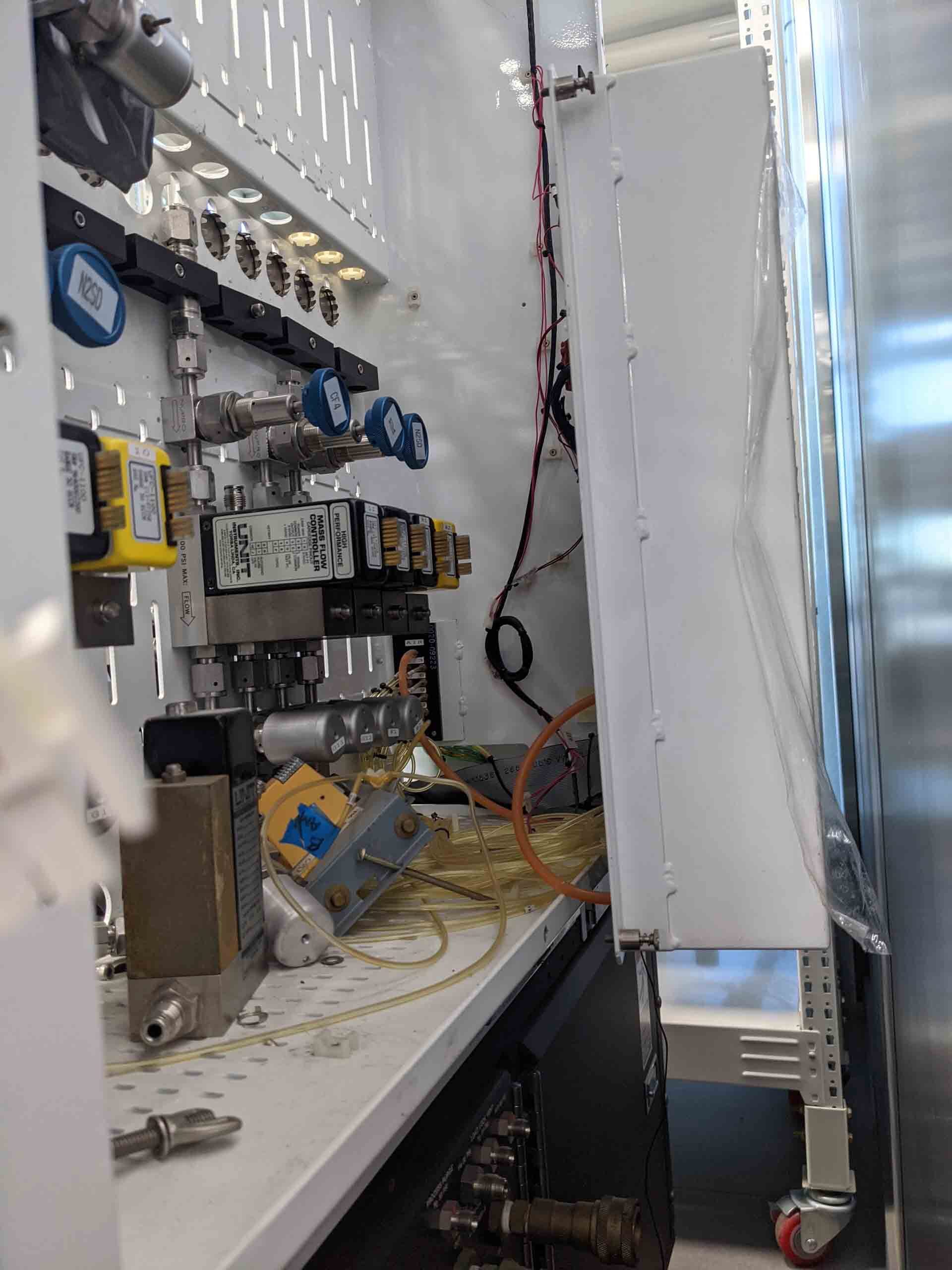

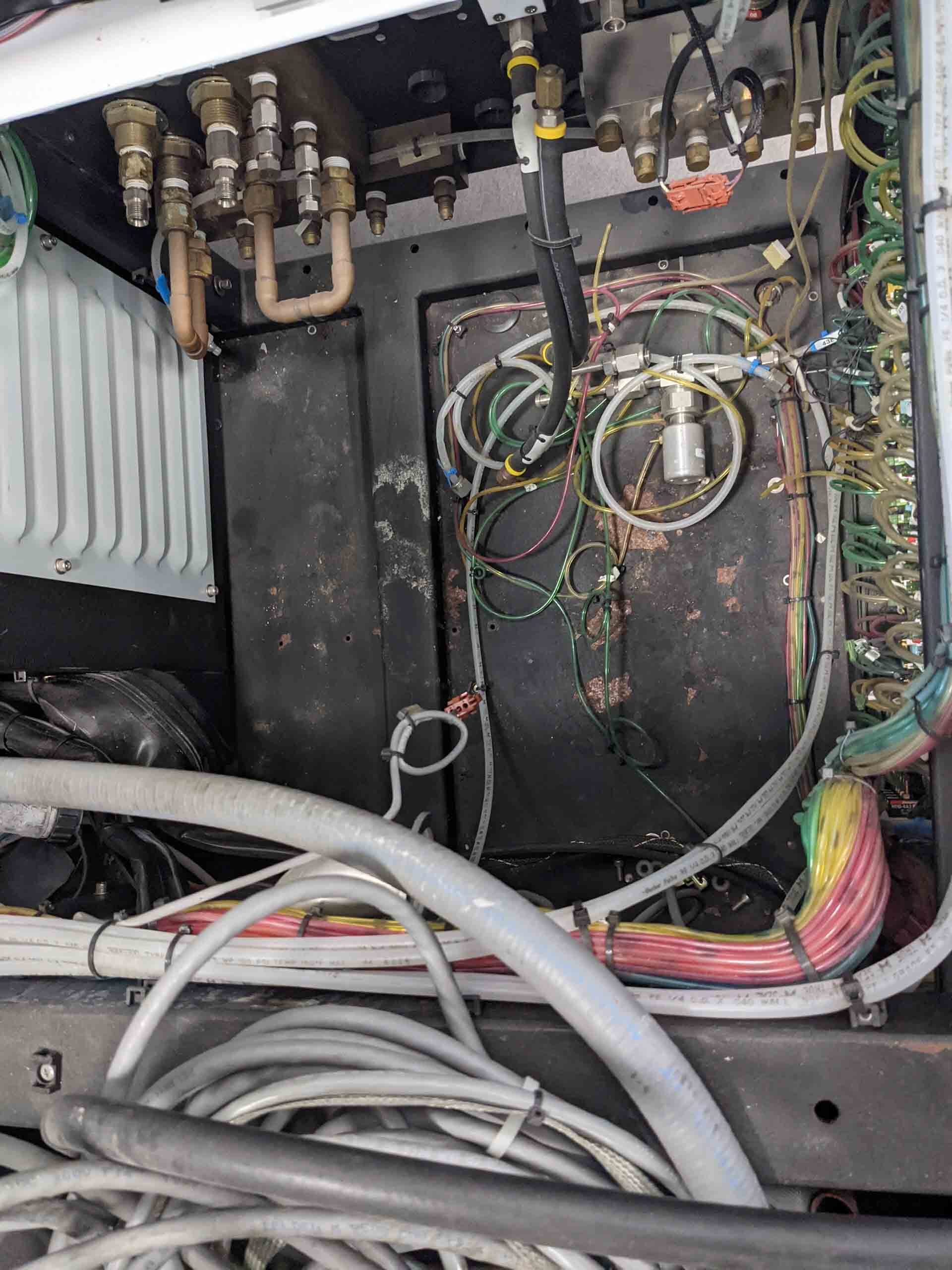

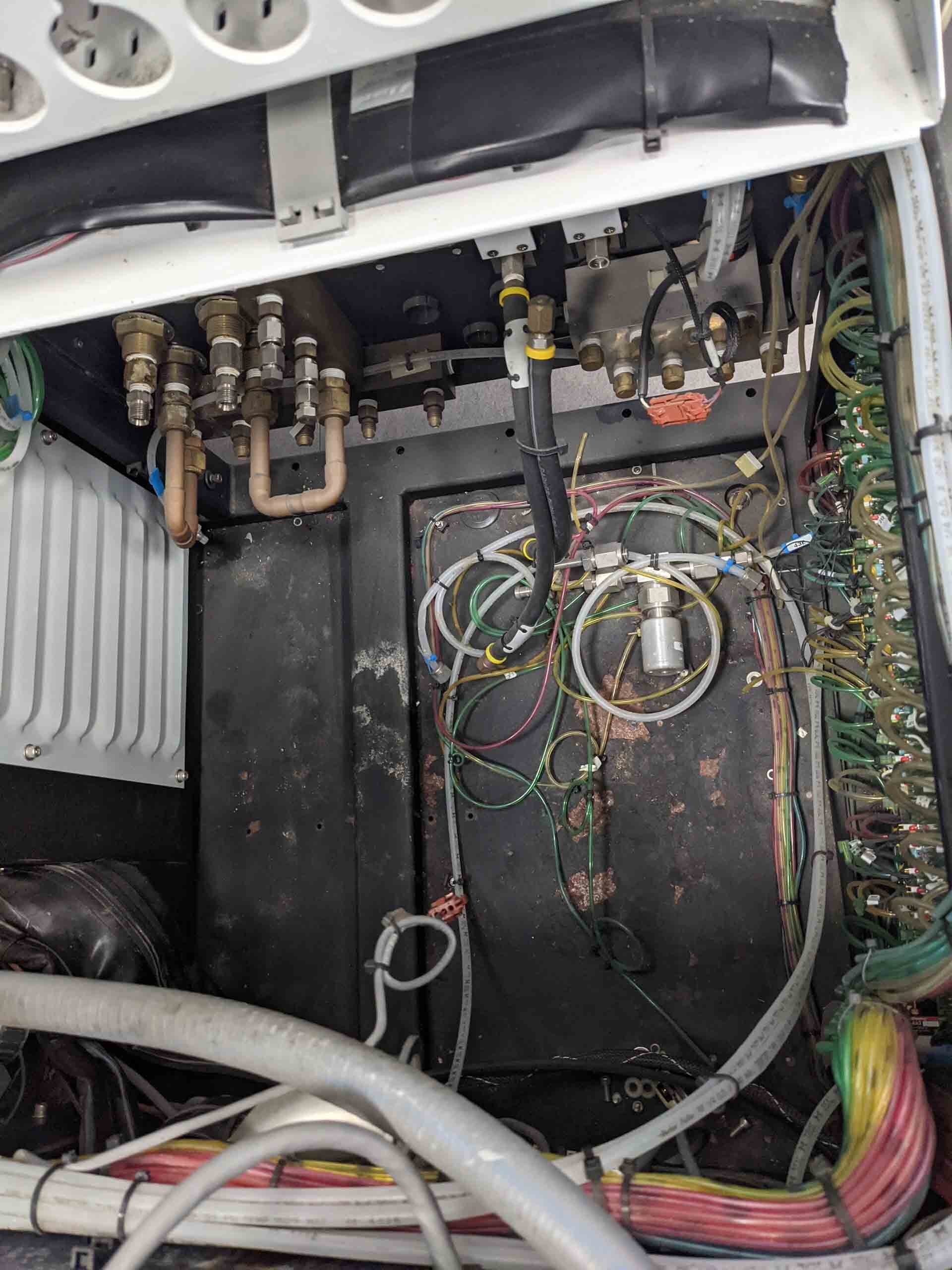

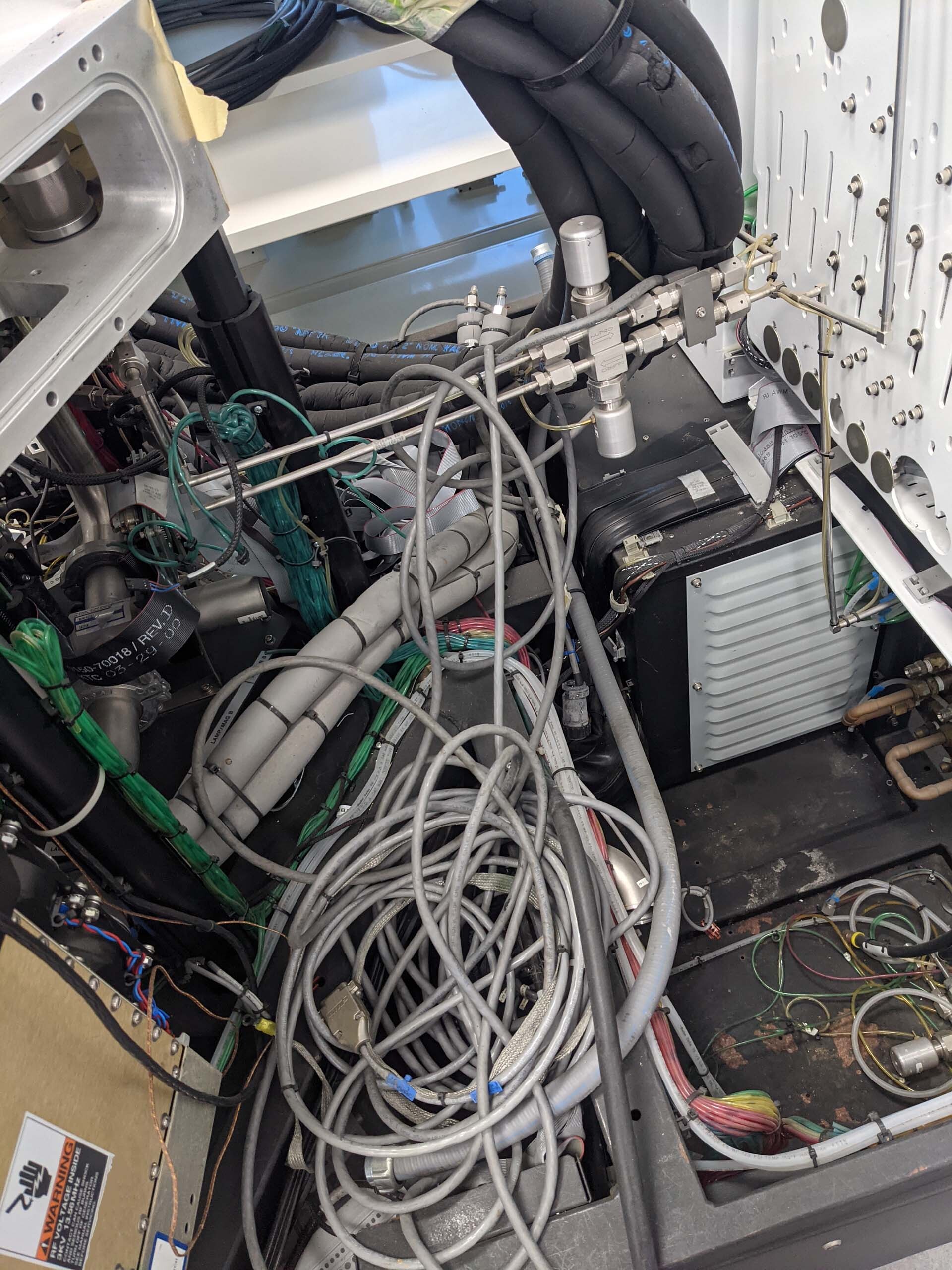

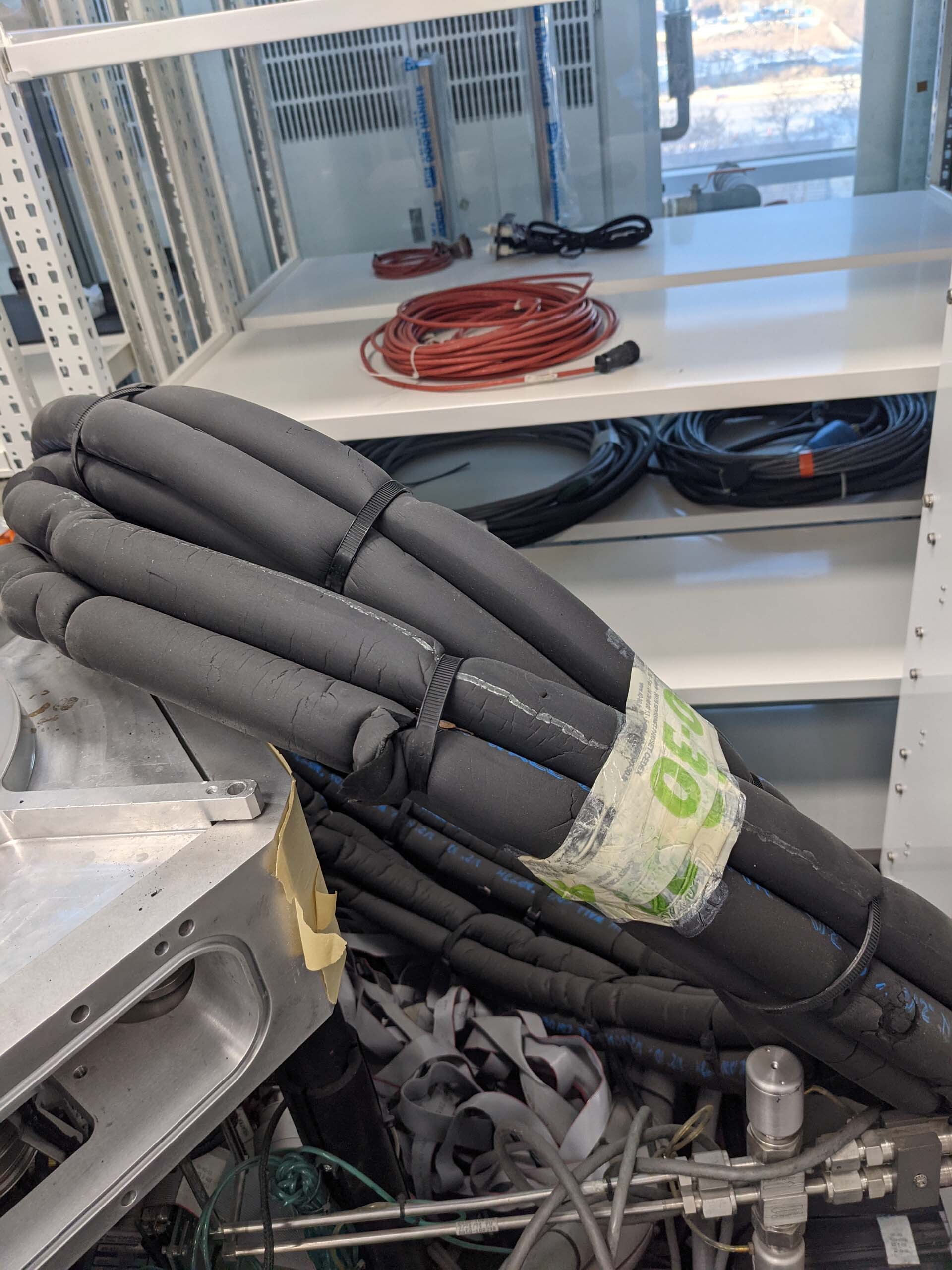

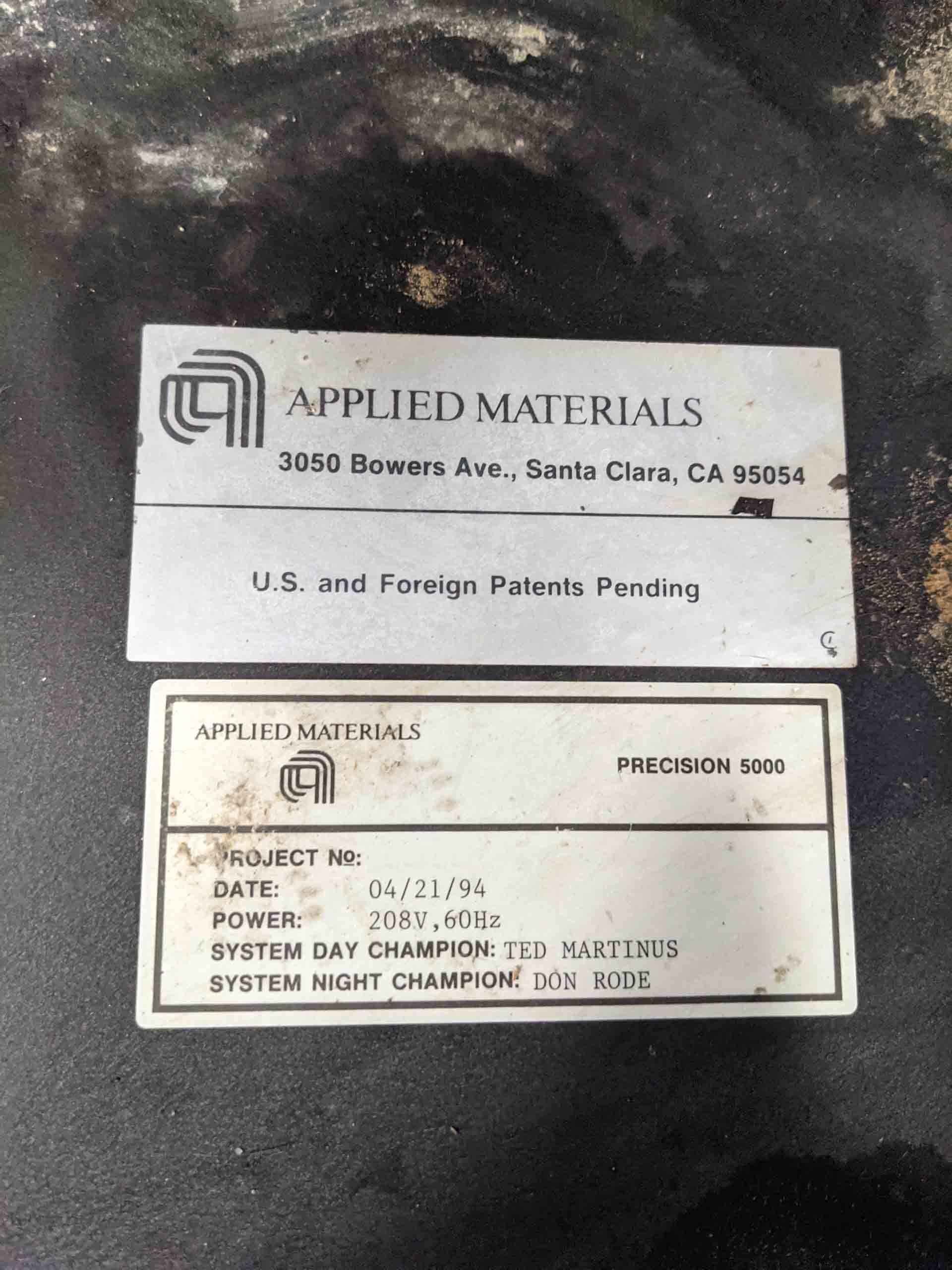

Used AMAT / APPLIED MATERIALS P5000 #9400991 for sale

URL successfully copied!

Tap to zoom

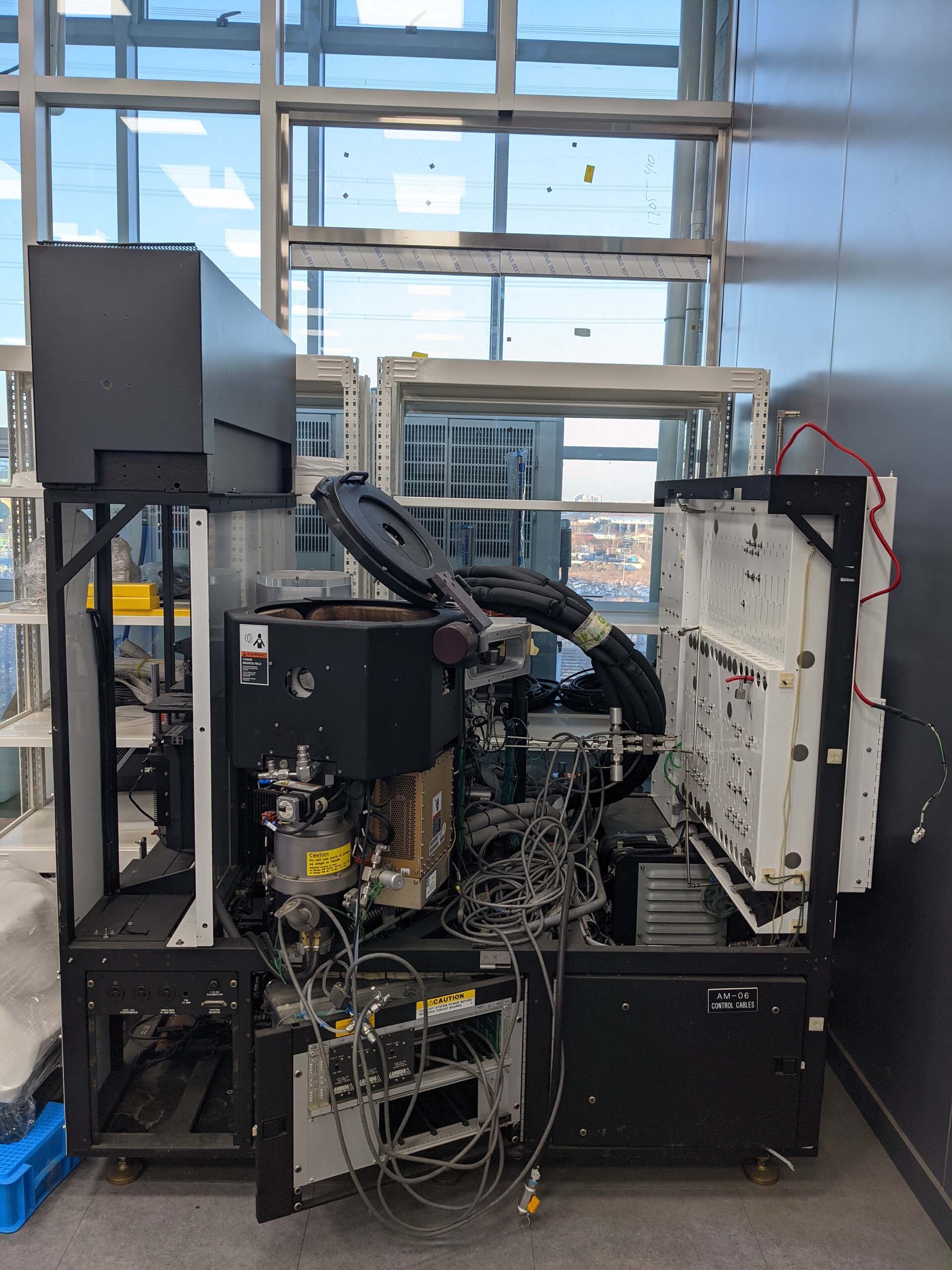

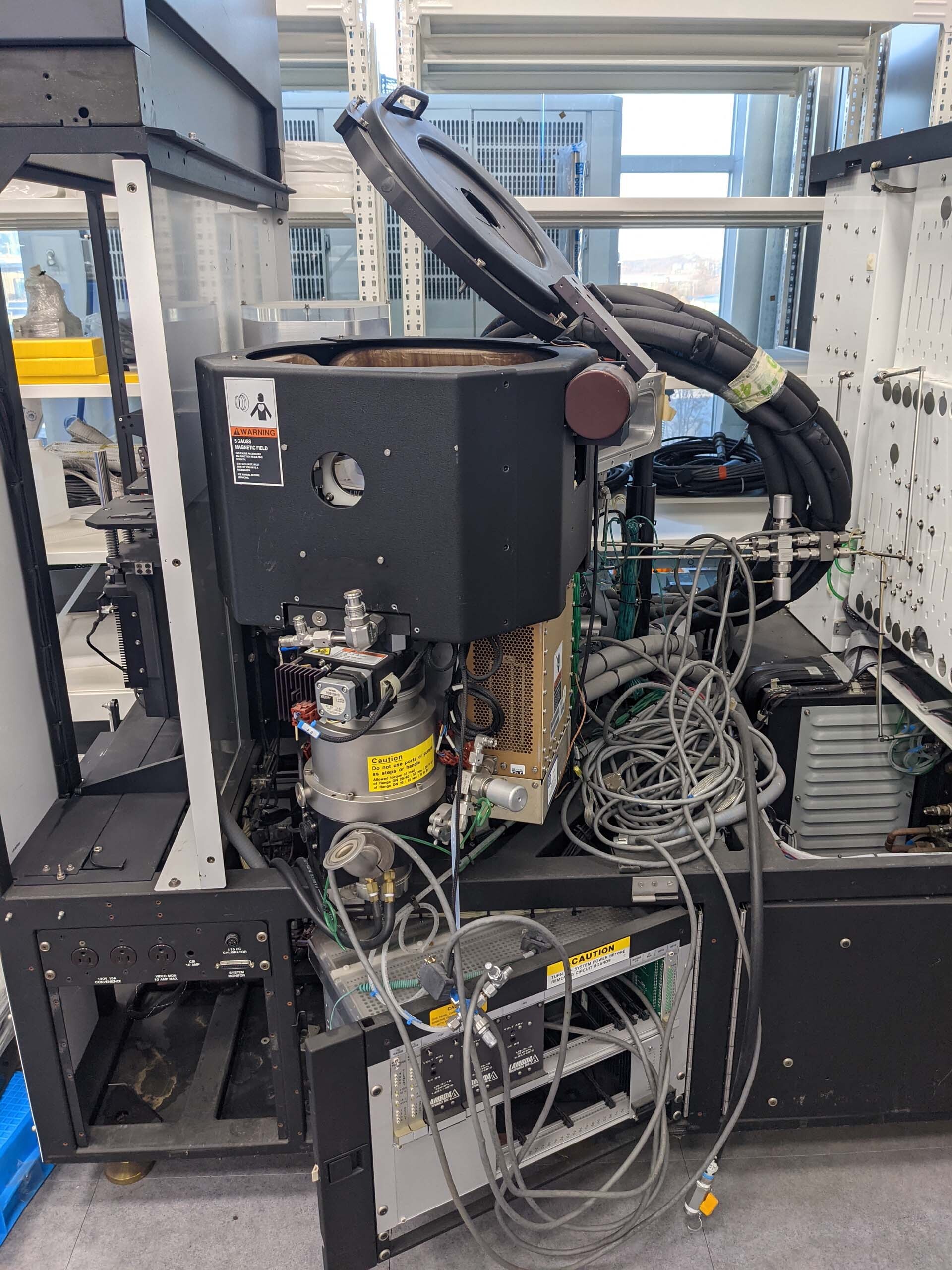

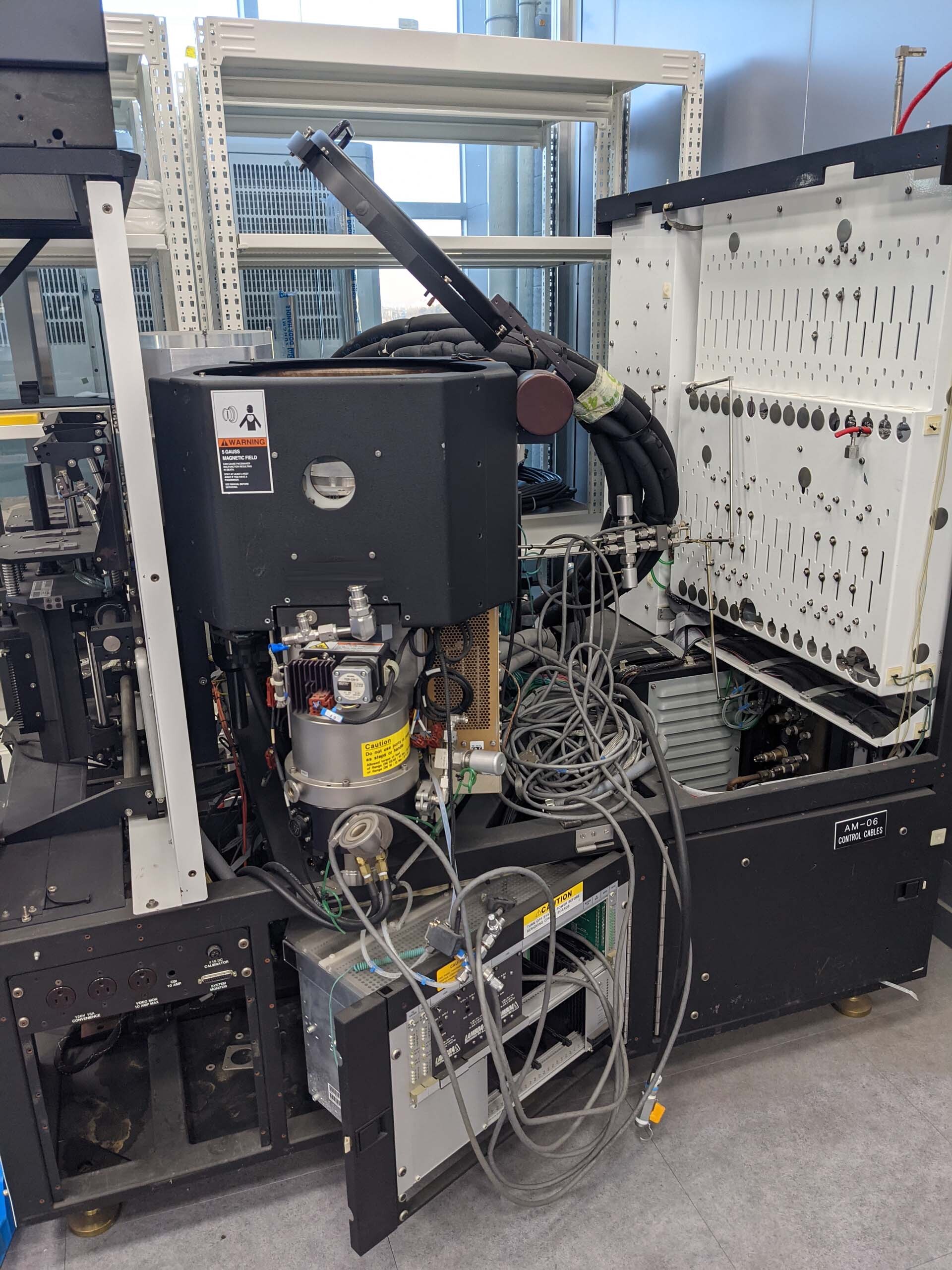

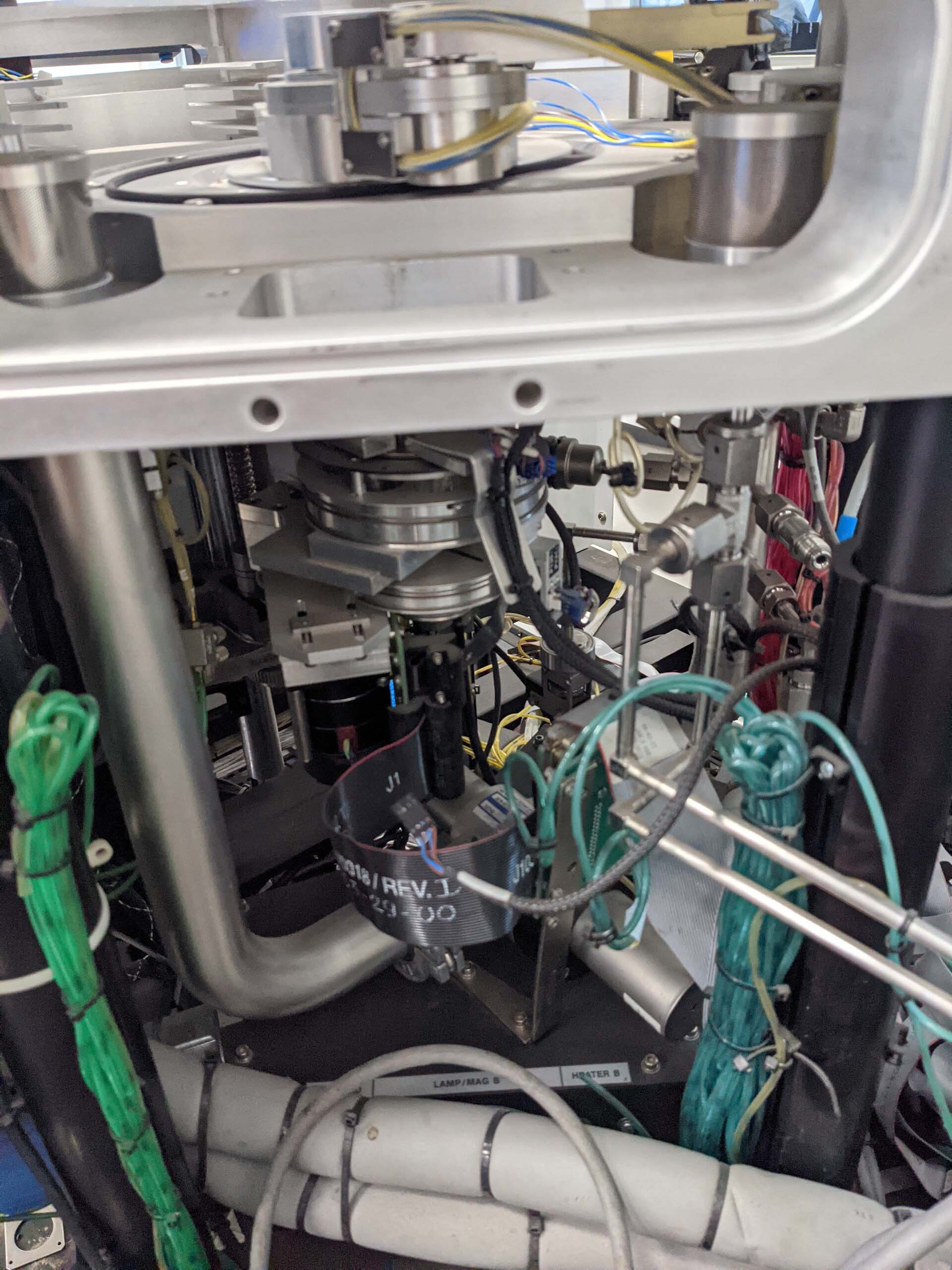

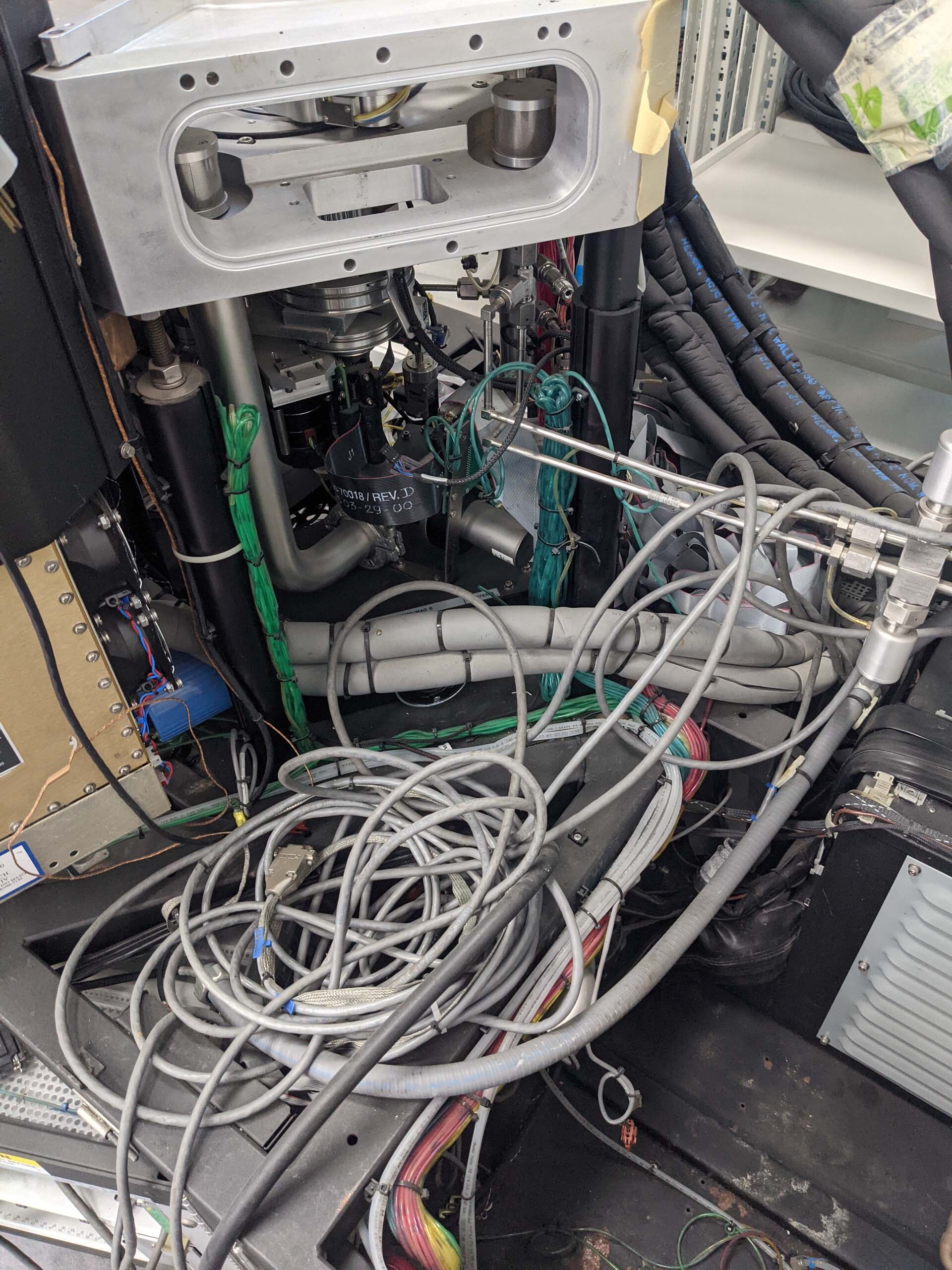

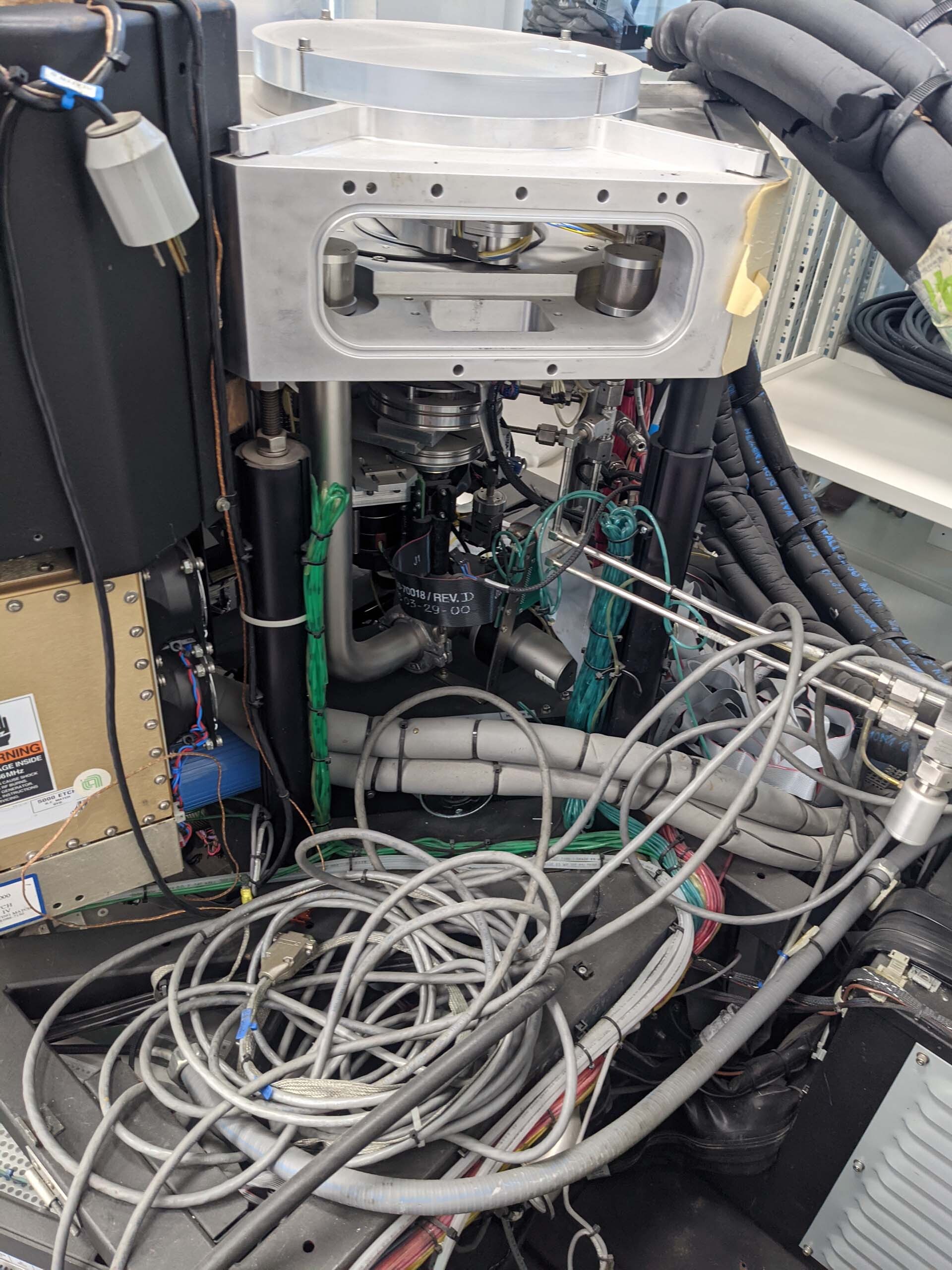

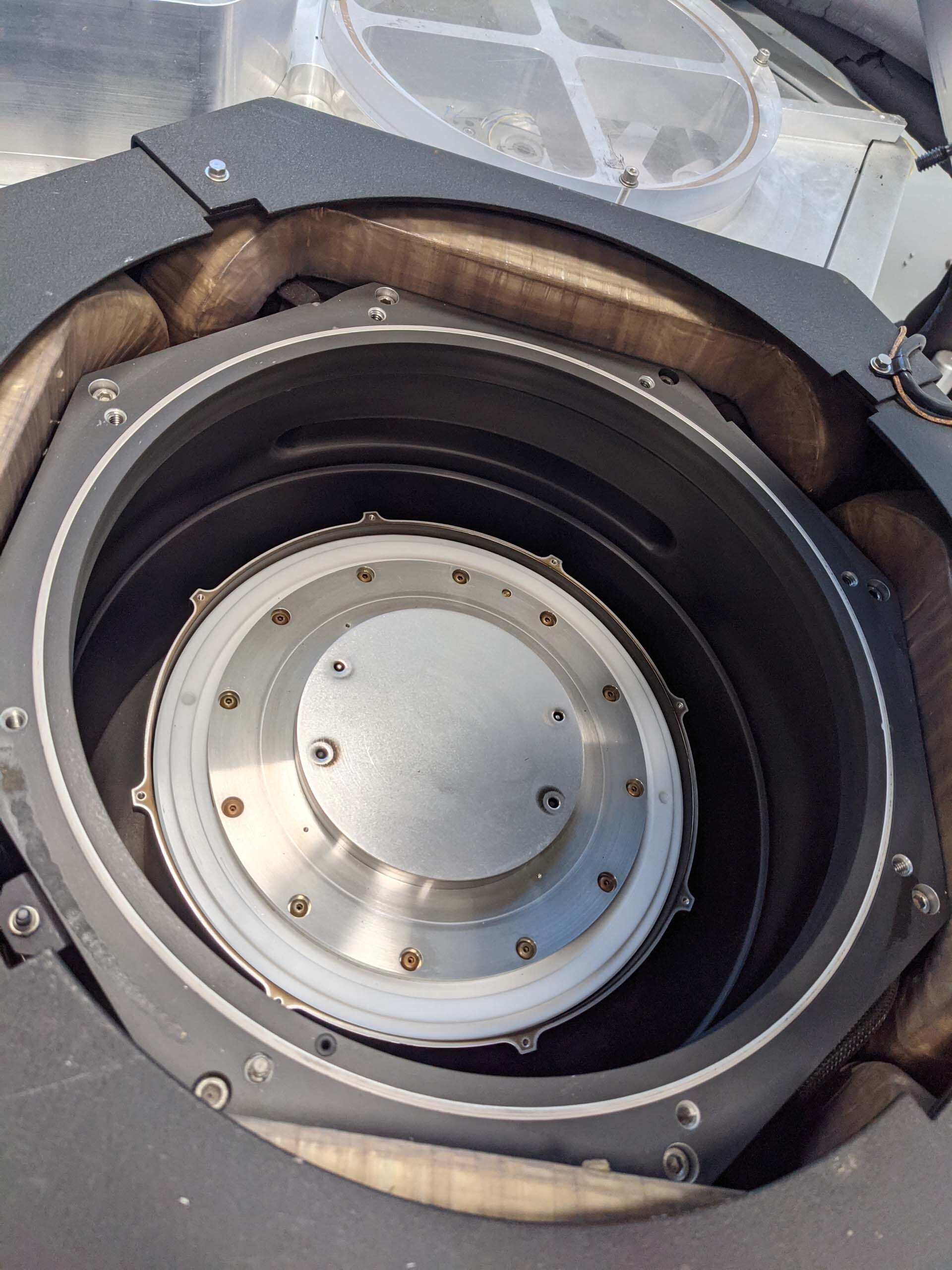

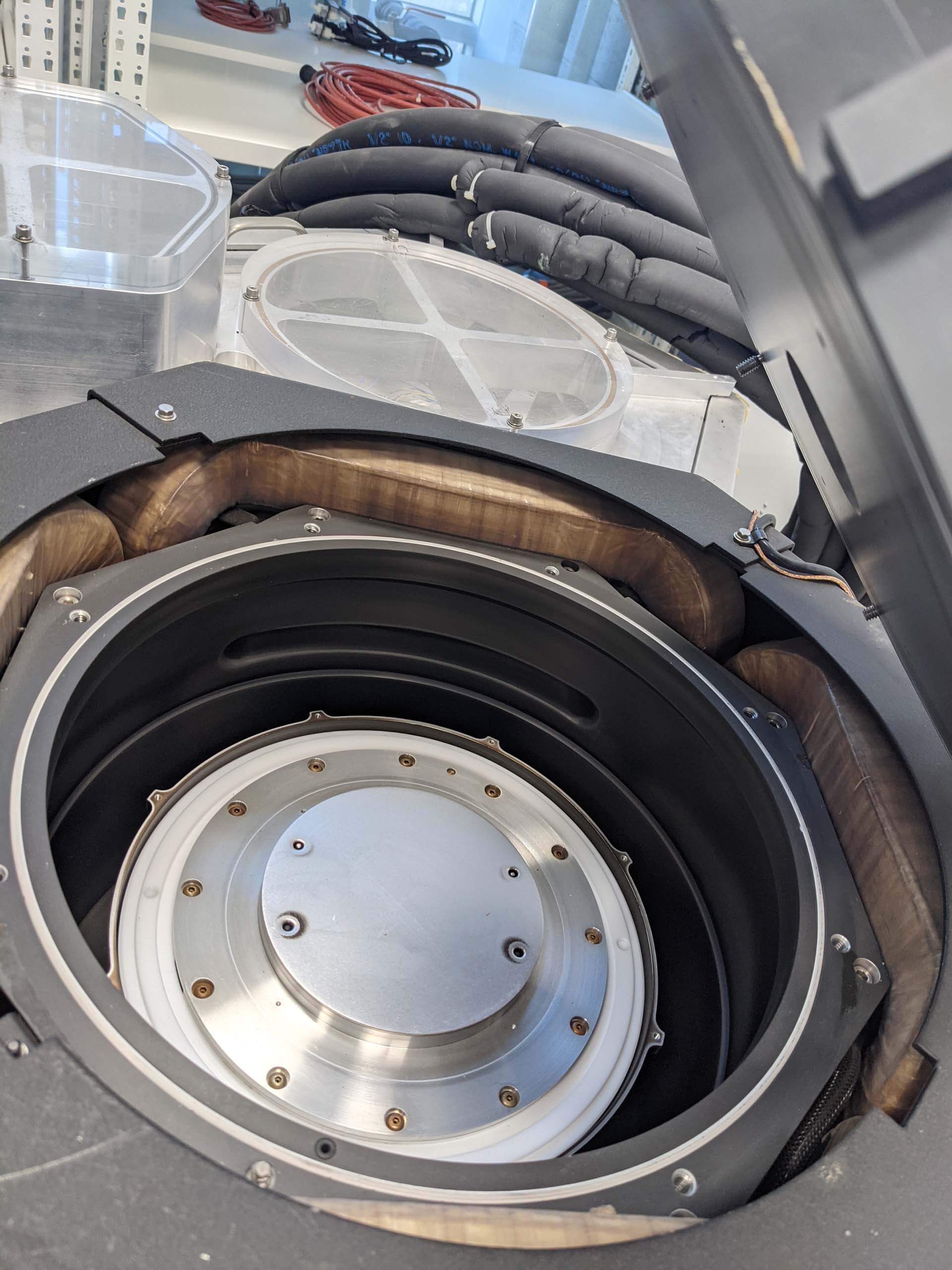

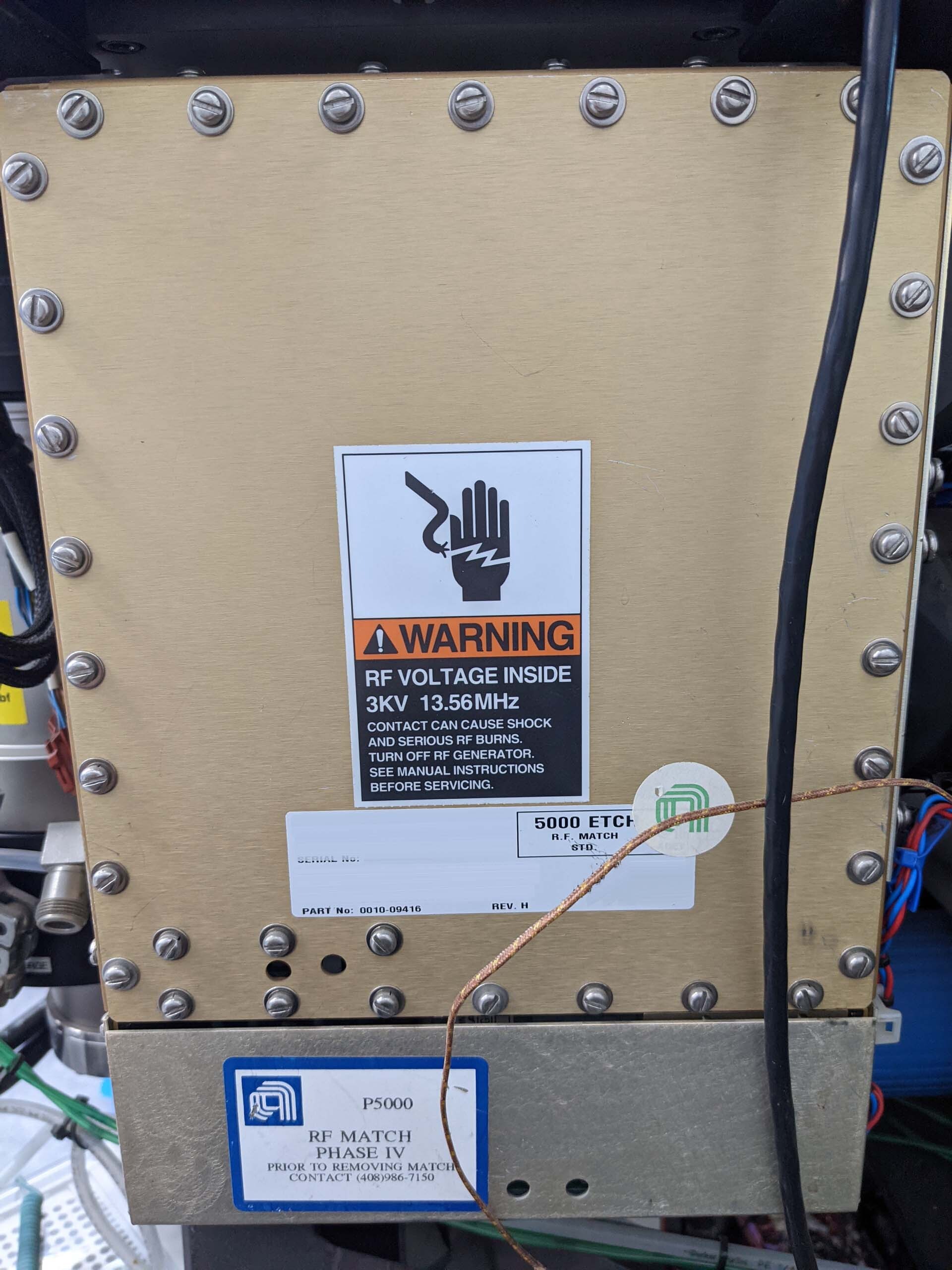

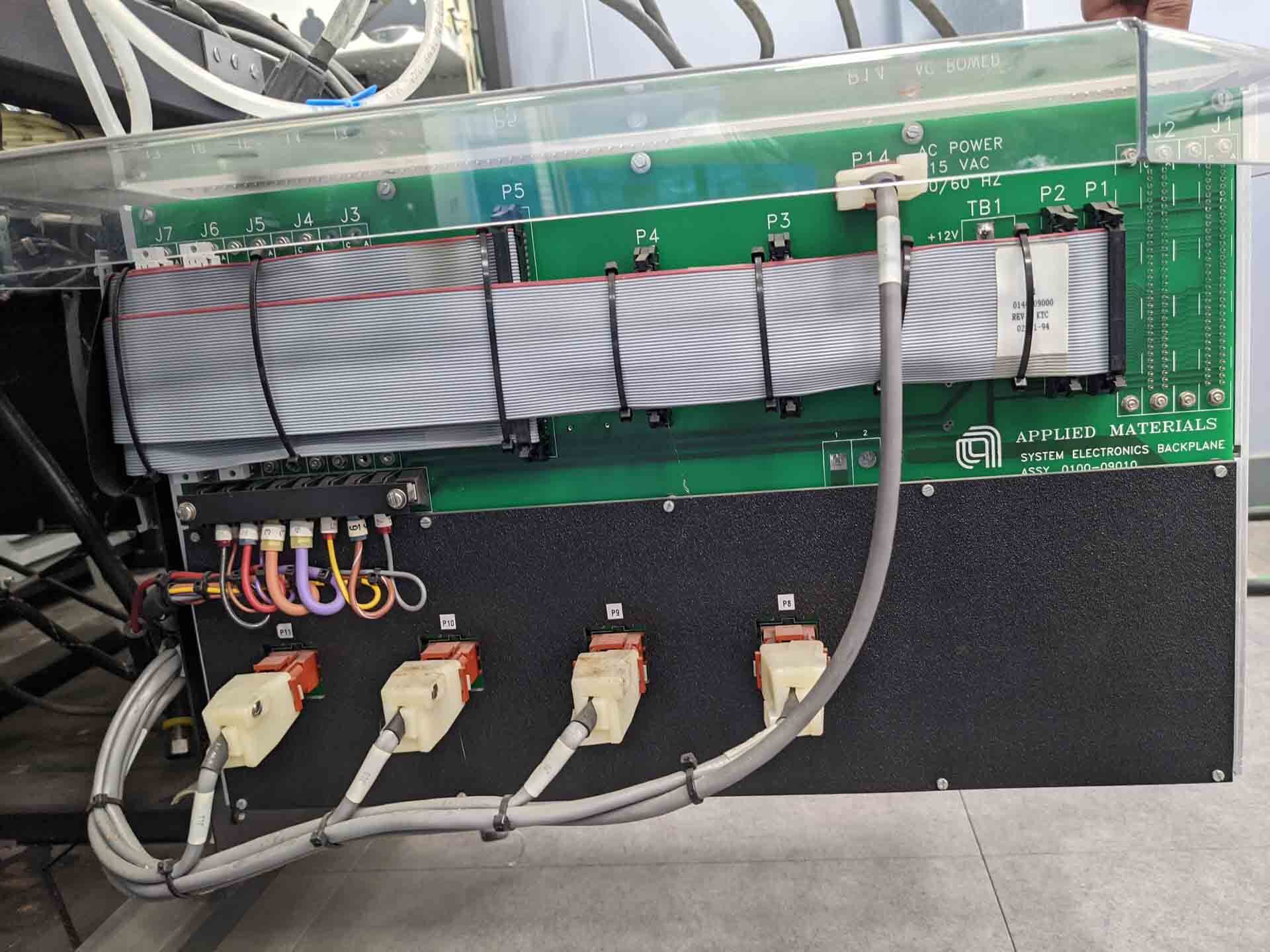

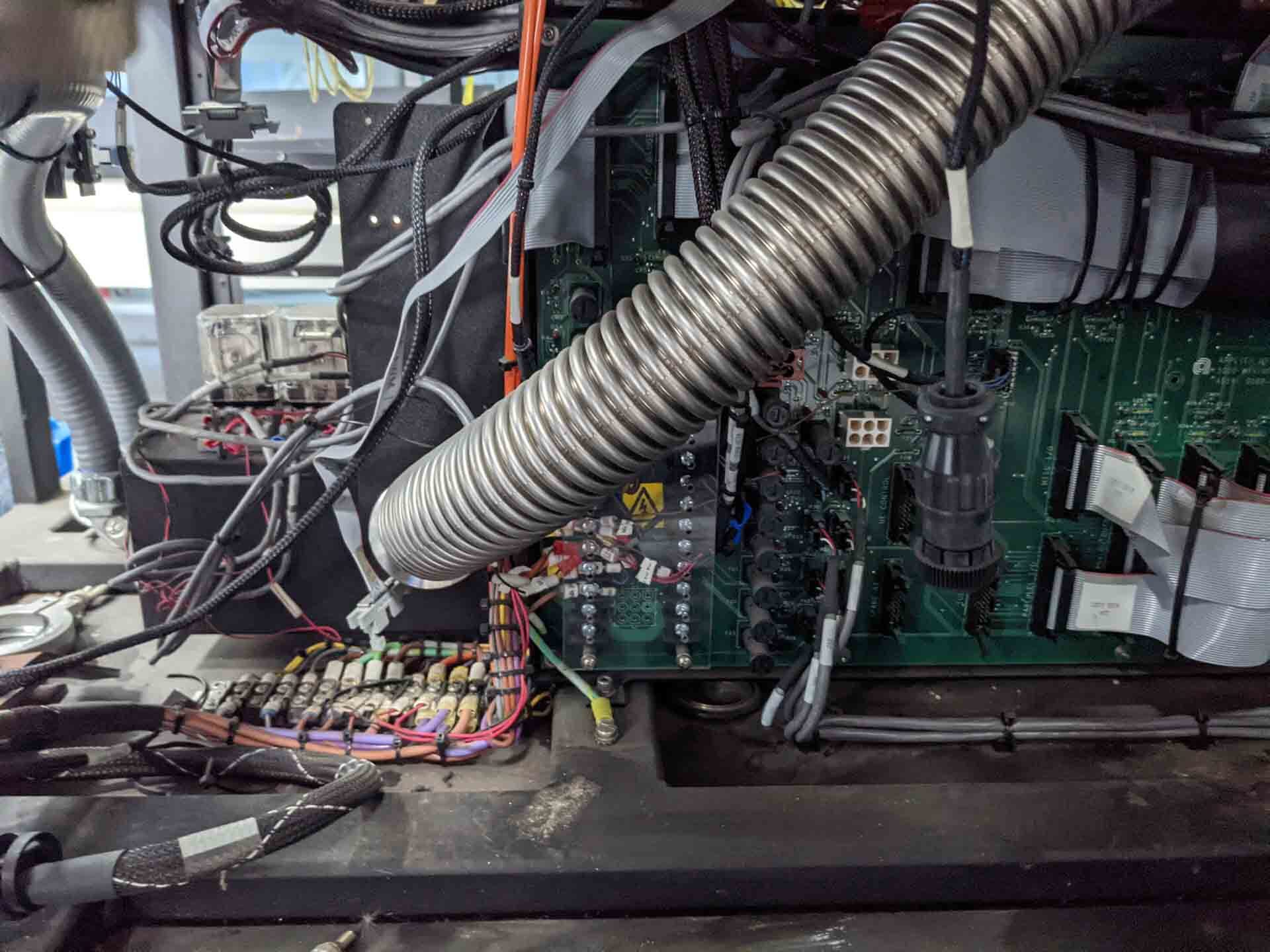

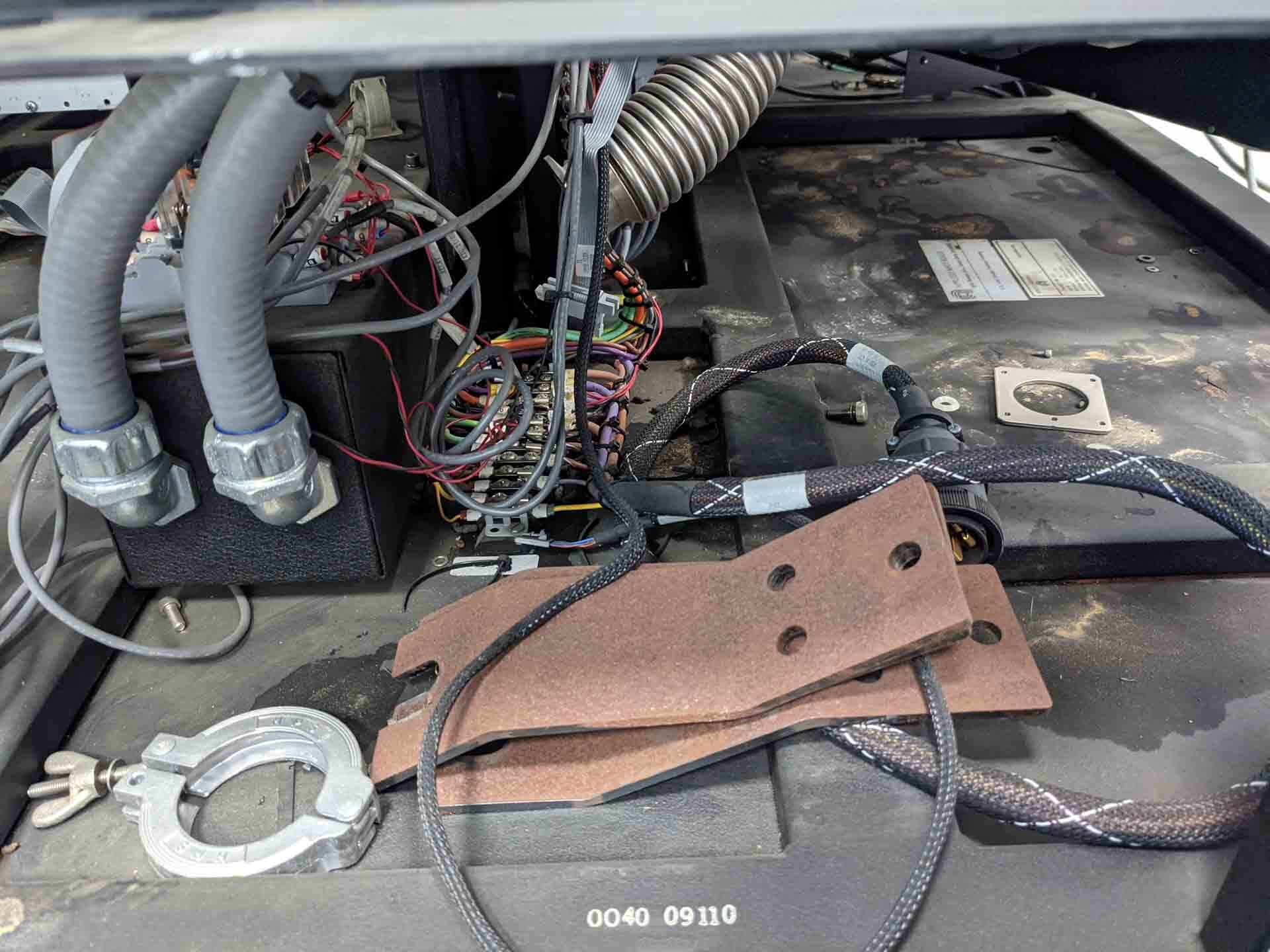

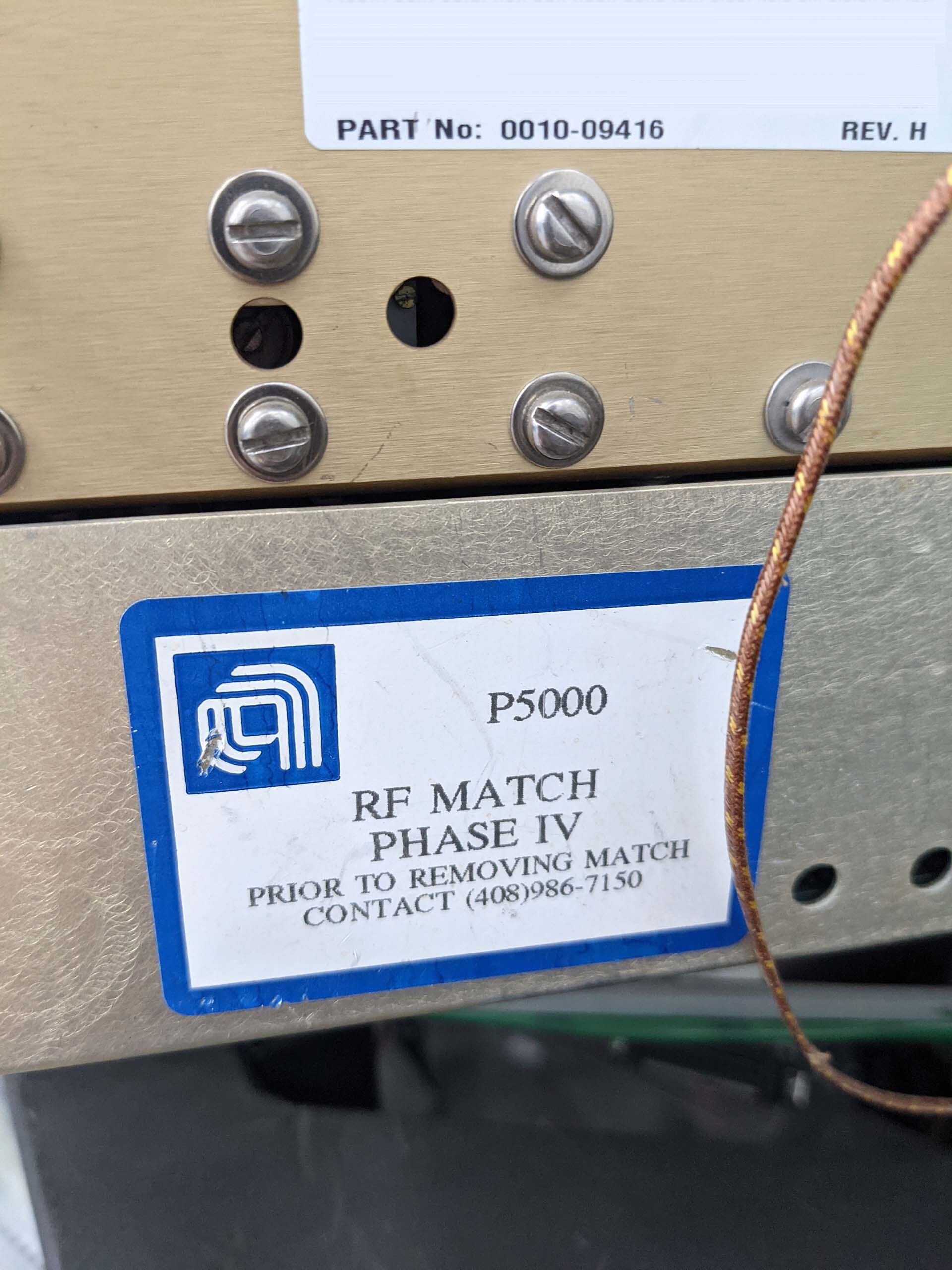

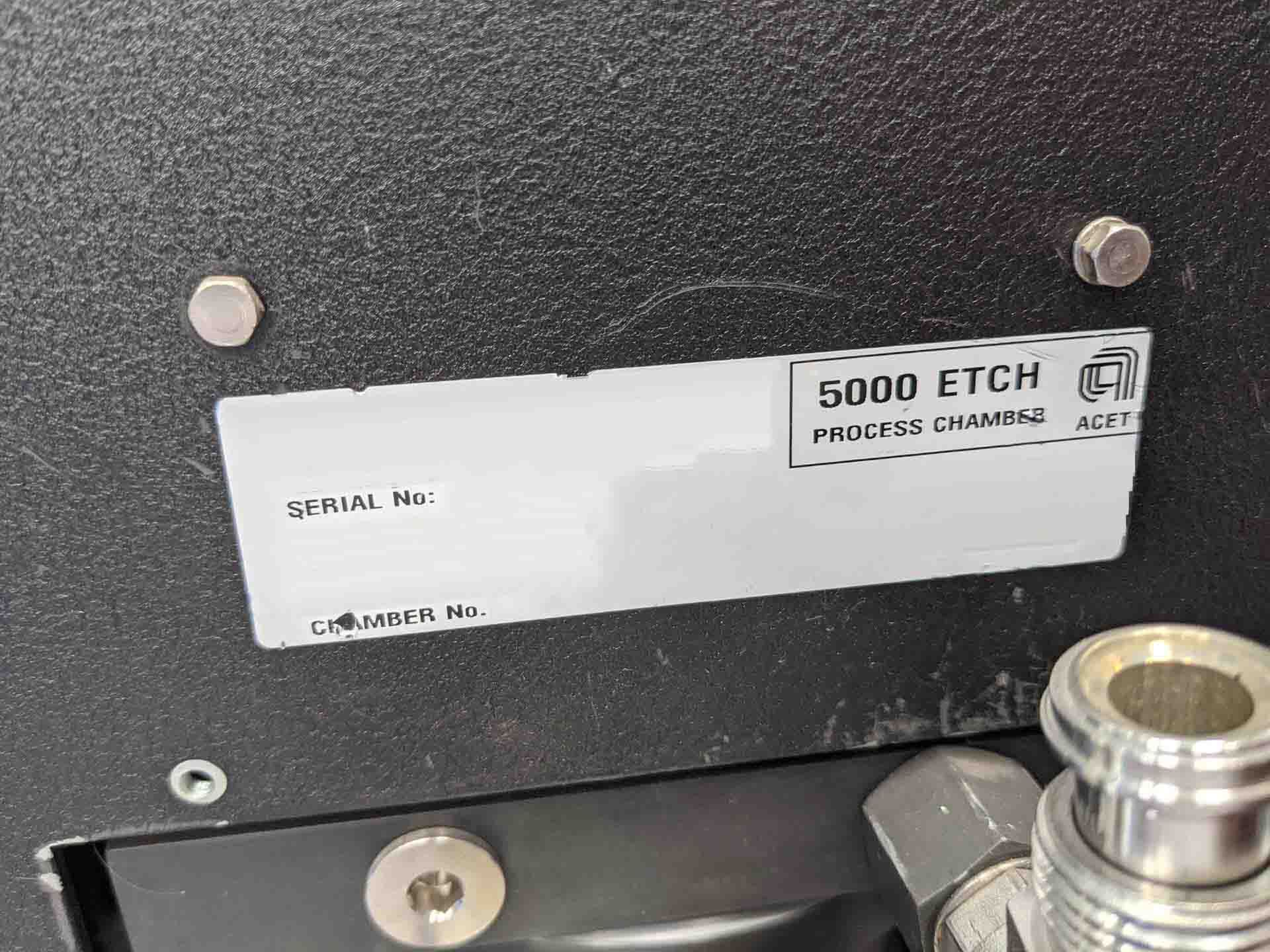

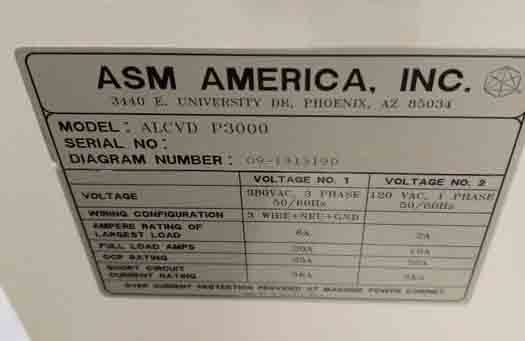

AMAT / APPLIED MATERIALS P5000 is a discontinuously operated batch reactor specifically designed for use in the semiconductor industry. It features a titanium-clad chamber that allows for extreme temperatures, vacuum and pressures for ultra-low defect applications such as vacuum deposition, etching, and chemical vapor deposition (CVD). AMAT P-5000 has a working volume of up to 500 liters with a minimum chamber temperature of -100° C, a maximum chamber temperature of 6100° C, and a maximum working pressure of 7.5 atmospheres. It also has a gas tight lid with a manual closure mechanism and an O-ring seal for maximum control of the environment inside the chamber. In addition to its reaction chamber, APPLIED MATERIALS P 5000 also features a plasma generator and numerous inlet and exhaust ports for controlling the pressure, temperature, and flow rate of the gases pumped into the chamber. The plasma generator ranges in power from 100 to 1000 Watts and can work at frequencies up to 60MHz, allowing for great accuracy and precision when manipulating the materials within. The system is made to operate ergonomically and efficiently. Integrated safety features have been implemented into the reactor's hardware to allow for fast start up and protected shutdowns. An interactive touchscreen user interface offers a comprehensive set of data acquisition, analysis and reporting tools that can be used for quality control. Overall, AMAT P 5000 is a reliable and advanced reactor system that offers superb process control through precise temperature, pressure and plasma modulation. It's right out of the box and can immediately meet high-end requirements. With its easy functionality and robust build, AMAT P5000 is a great choice for advanced applications in the semiconductor industry.

There are no reviews yet