Used AMAT / APPLIED MATERIALS P5000 #9402081 for sale

URL successfully copied!

Tap to zoom

ID: 9402081

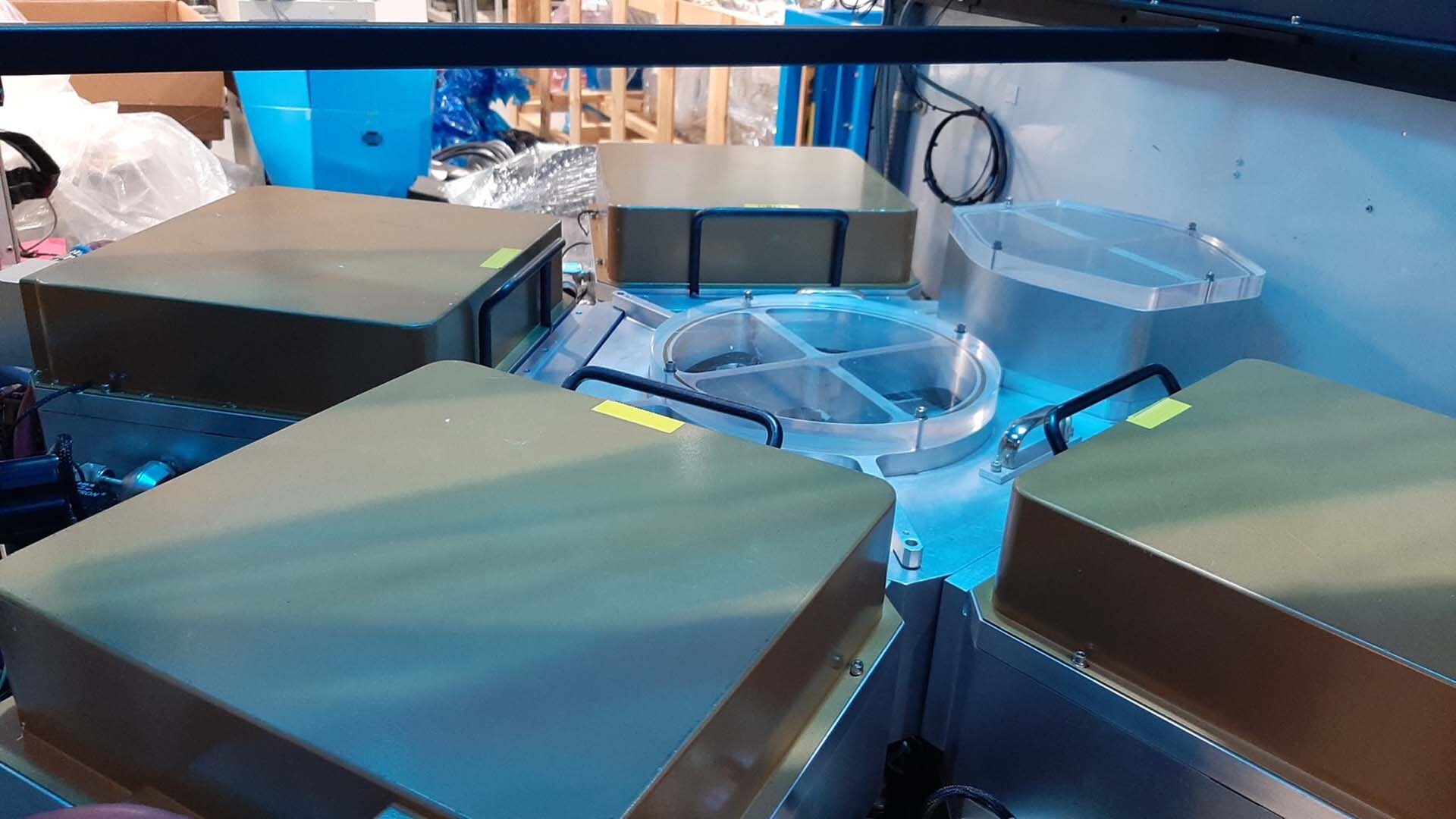

Wafer Size: 6"

CVD System, 6"

Robots: Phase-III

Standard O-Rings

8-Slots elevator

(2) CRT Monitors

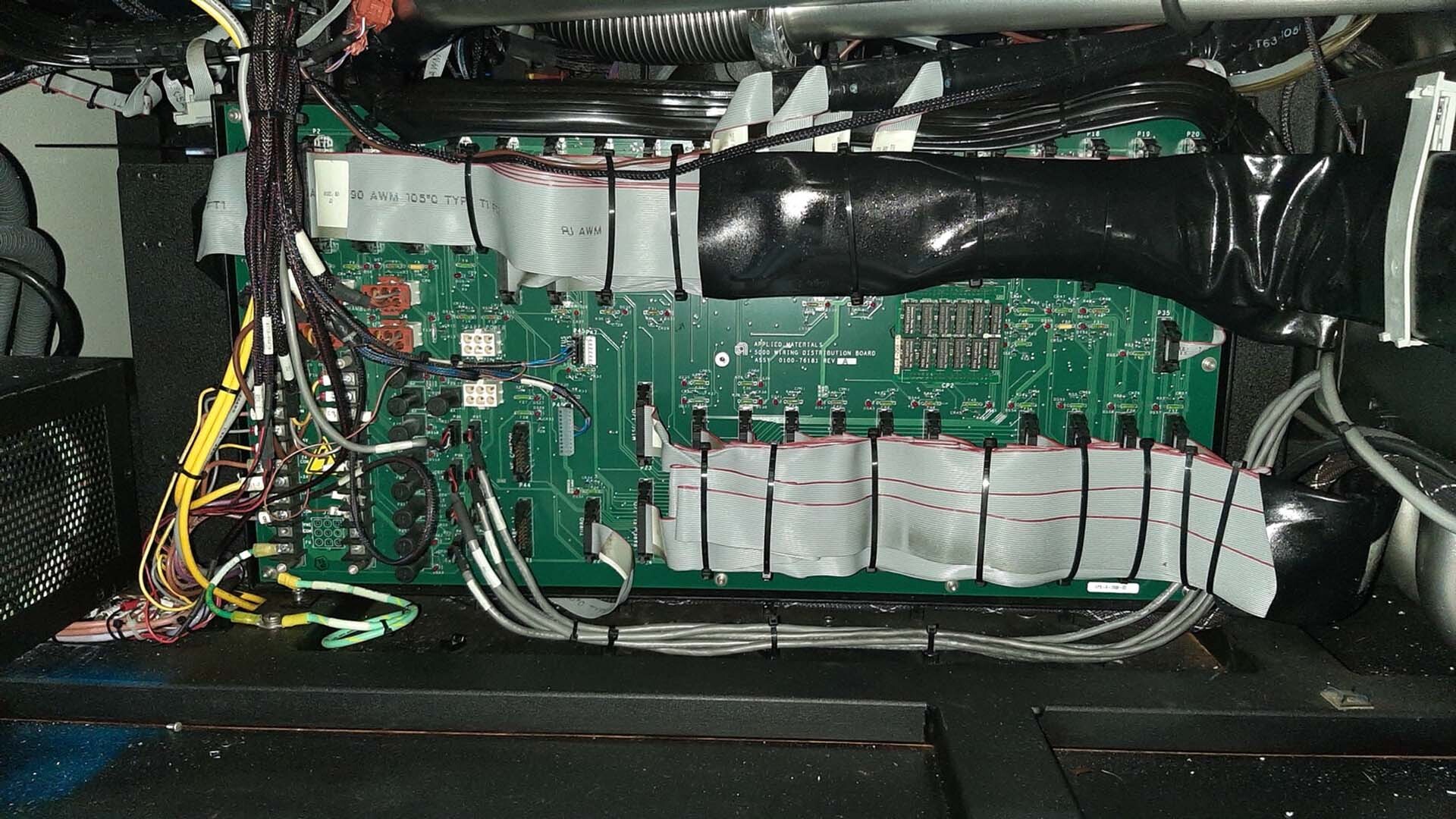

AC Rack: 1 Shrink

Heat exchanger

PROTEUS Water flow sensor

Flexible water hose

Status light tower (Color / Position): Red, yellow, green, blue

Signal cable: 25"

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD), 3.5"

Mini-controller

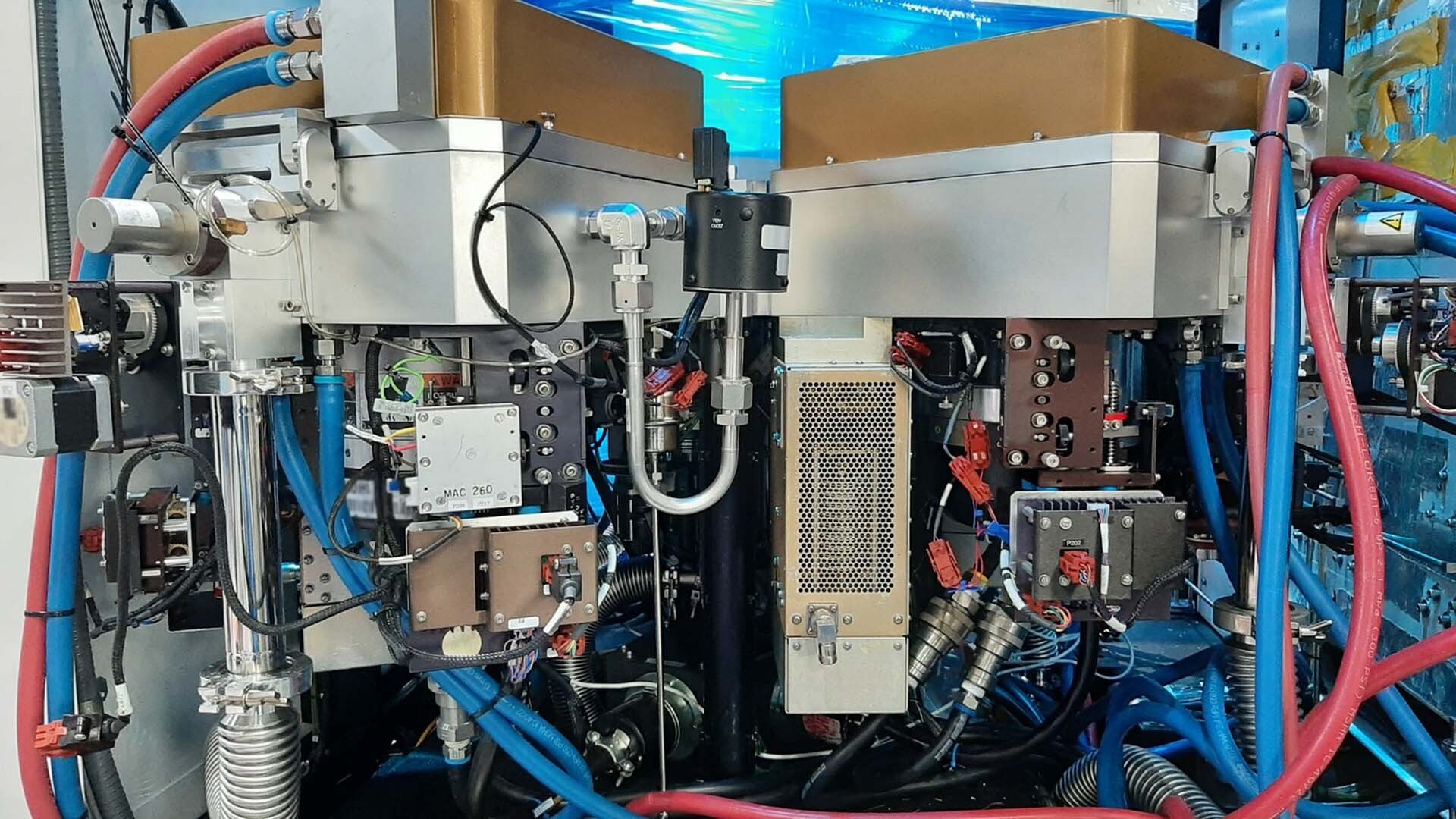

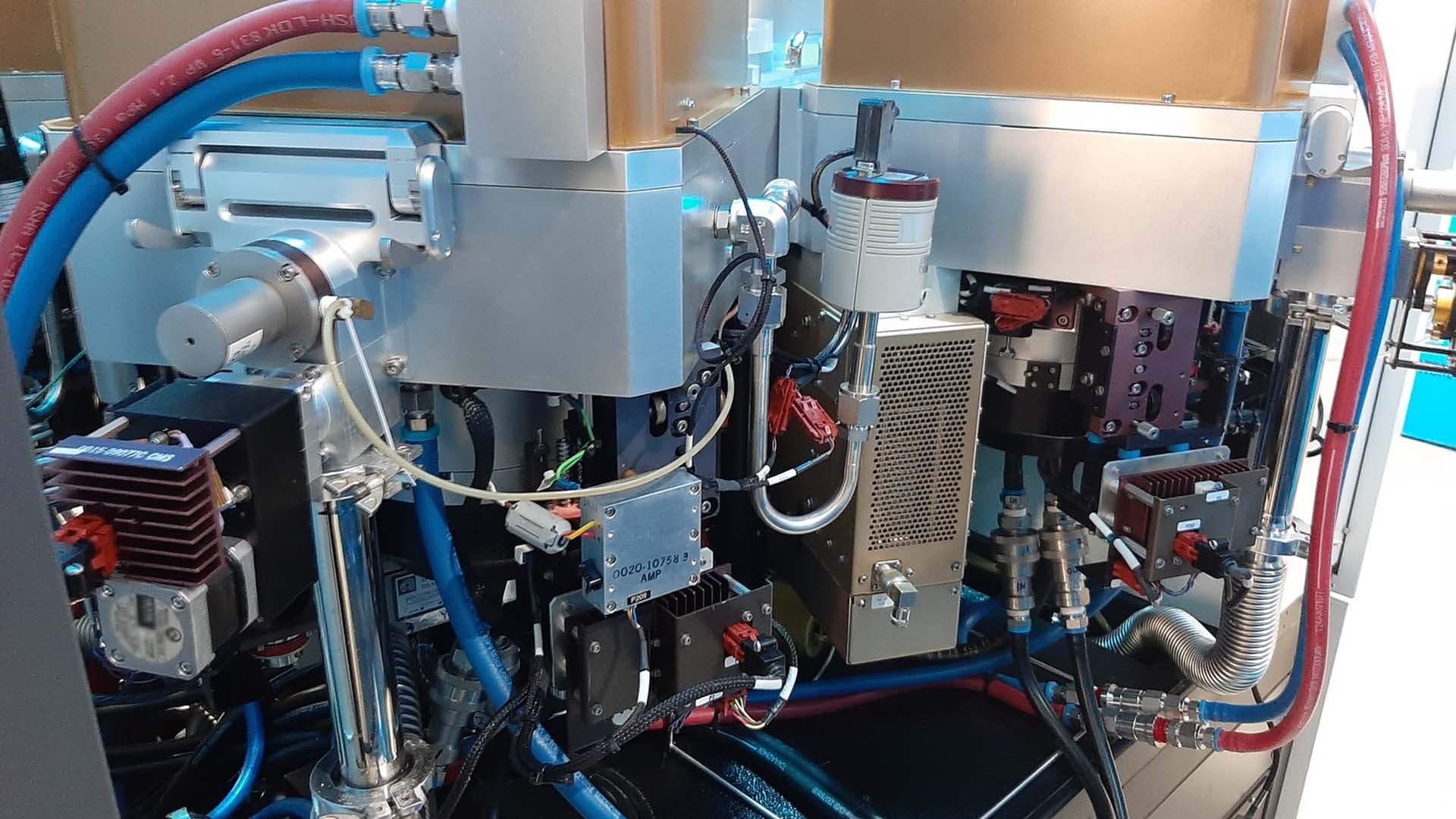

RF Generator:

(2) ENI OEM12B-02

ENI OEM12B-07

Chamber:

Chamber position: A, B, C, D

Chamber type: DLH 1-Hole

Process: SiH4 Oxide

Heater type: Lamp

Susceptor type: AL, 6"

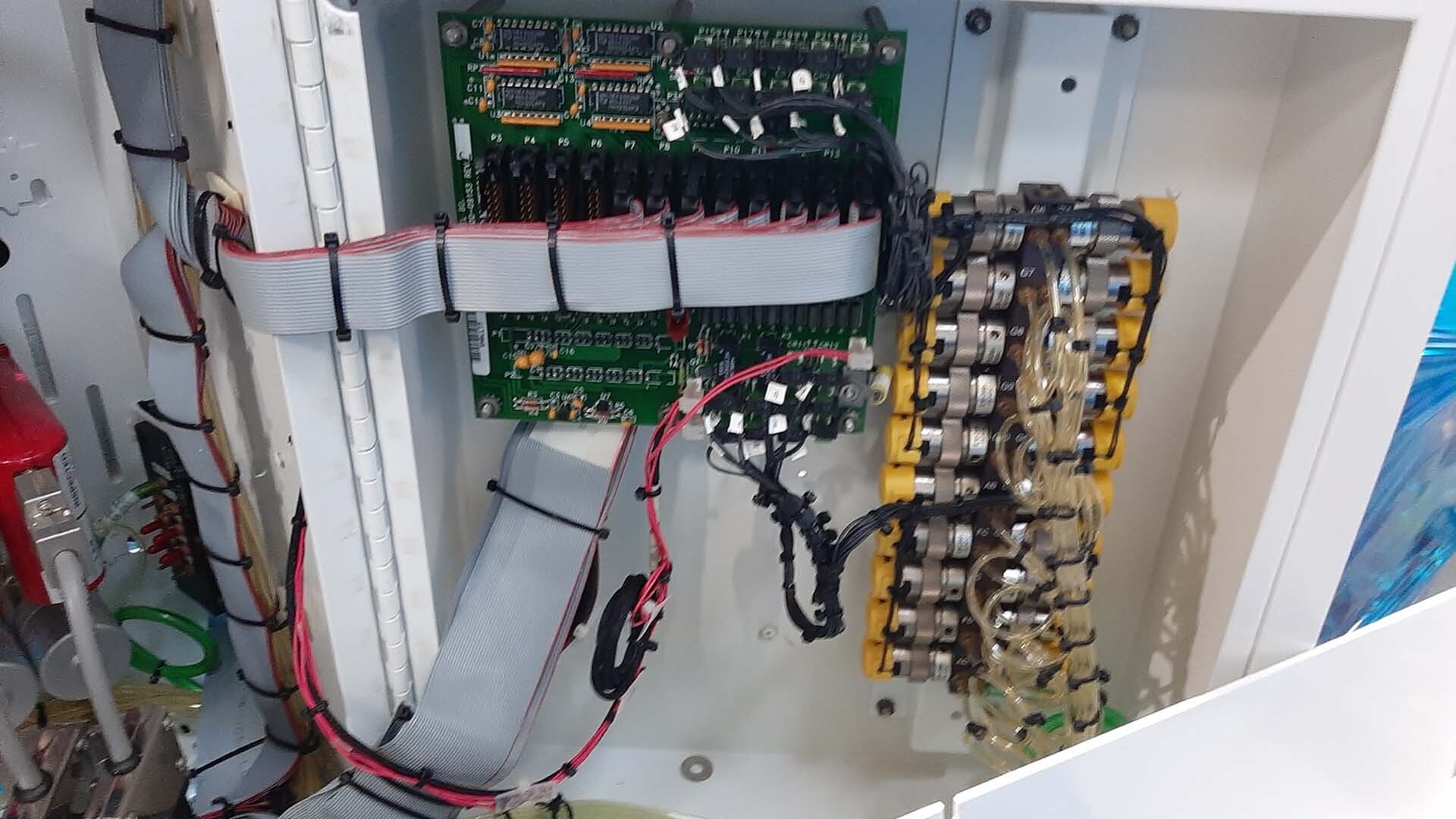

(4) Matchers

Delta nitride dual spring throttle valve

Delta nitride isolation valve

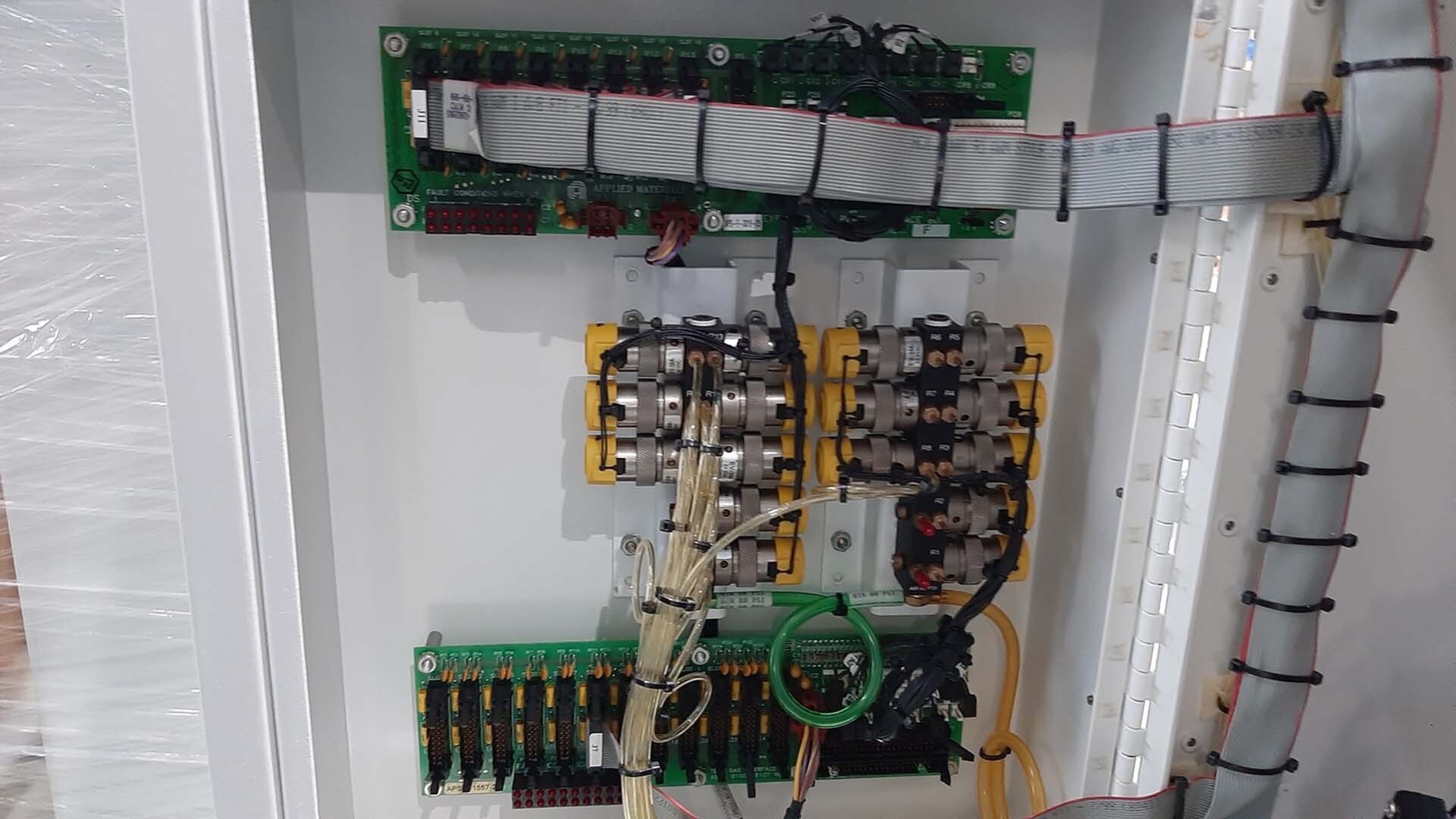

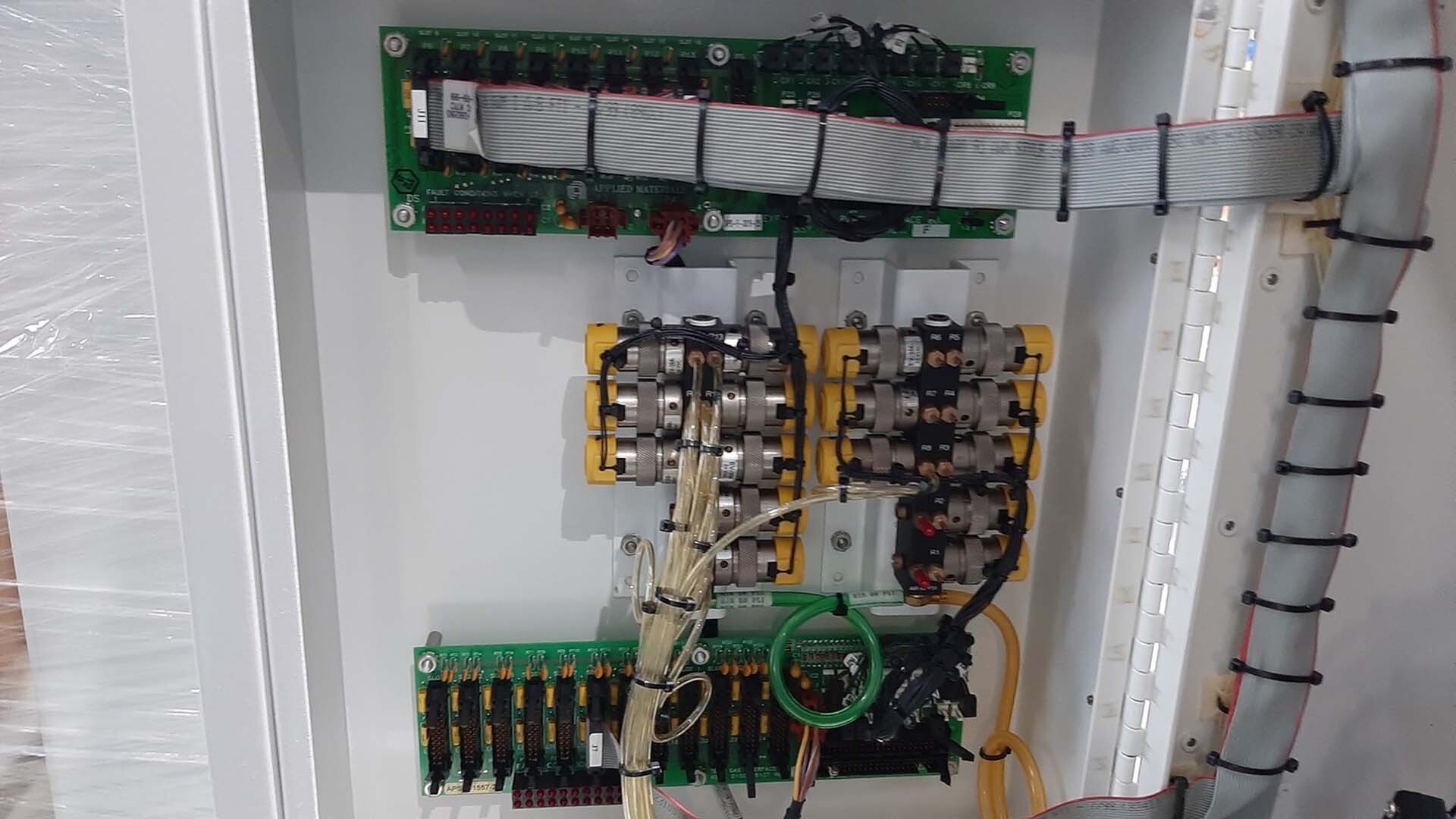

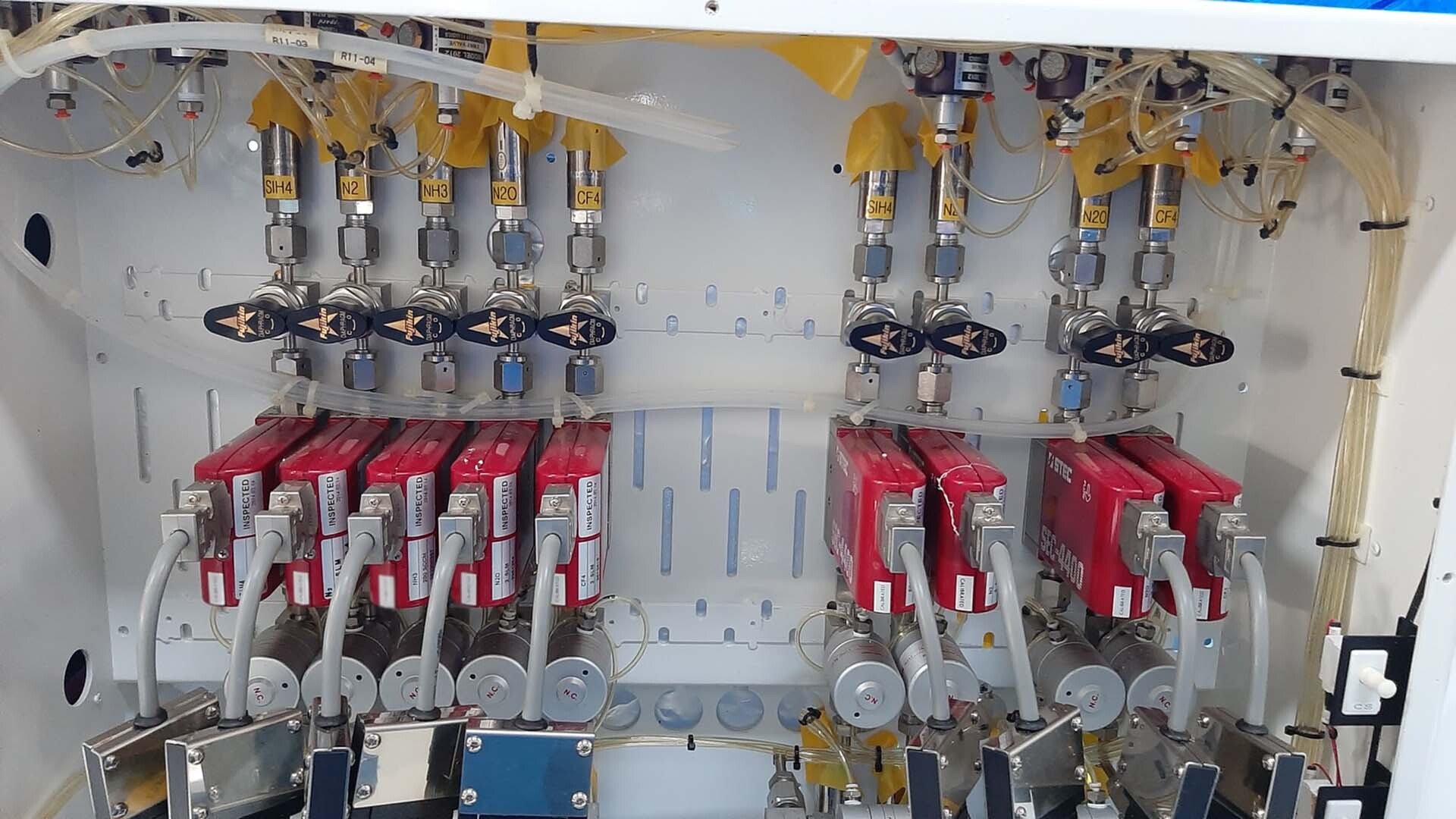

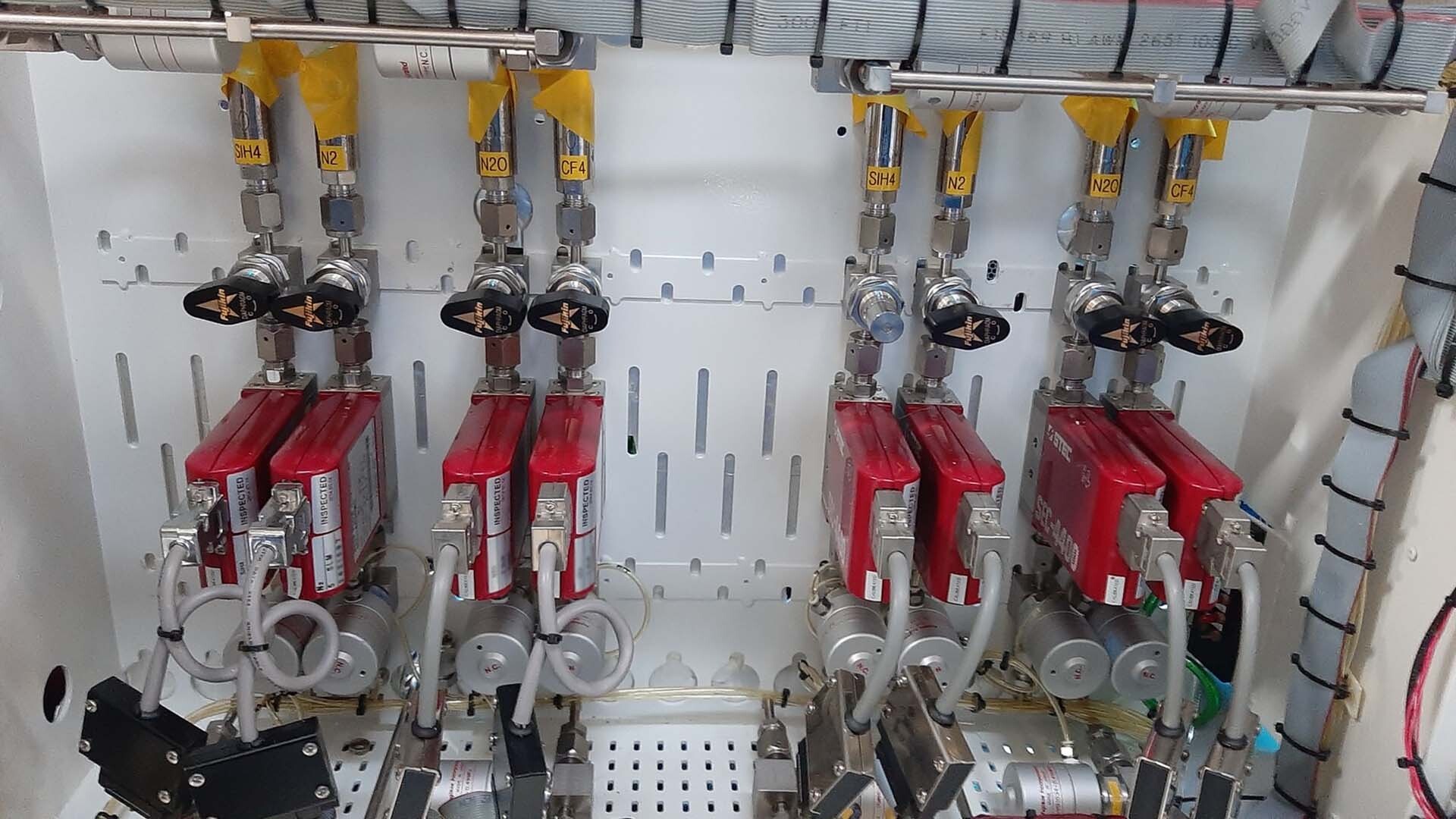

Gas panel: 20 Standard channels

Gas supply: Top down

MFC: SEC 4400MC

Manual valve: FUJIKIN

Pneumatic 2-Way valve: FUJIKIN

MKS 122B Baratron gauge, 10 Torr

Gases:

Gas / Range

N2 / 3 SLM

SiH4 / 100 SCCM

CF4 / 2 SLM

N2O / 2 SLM.

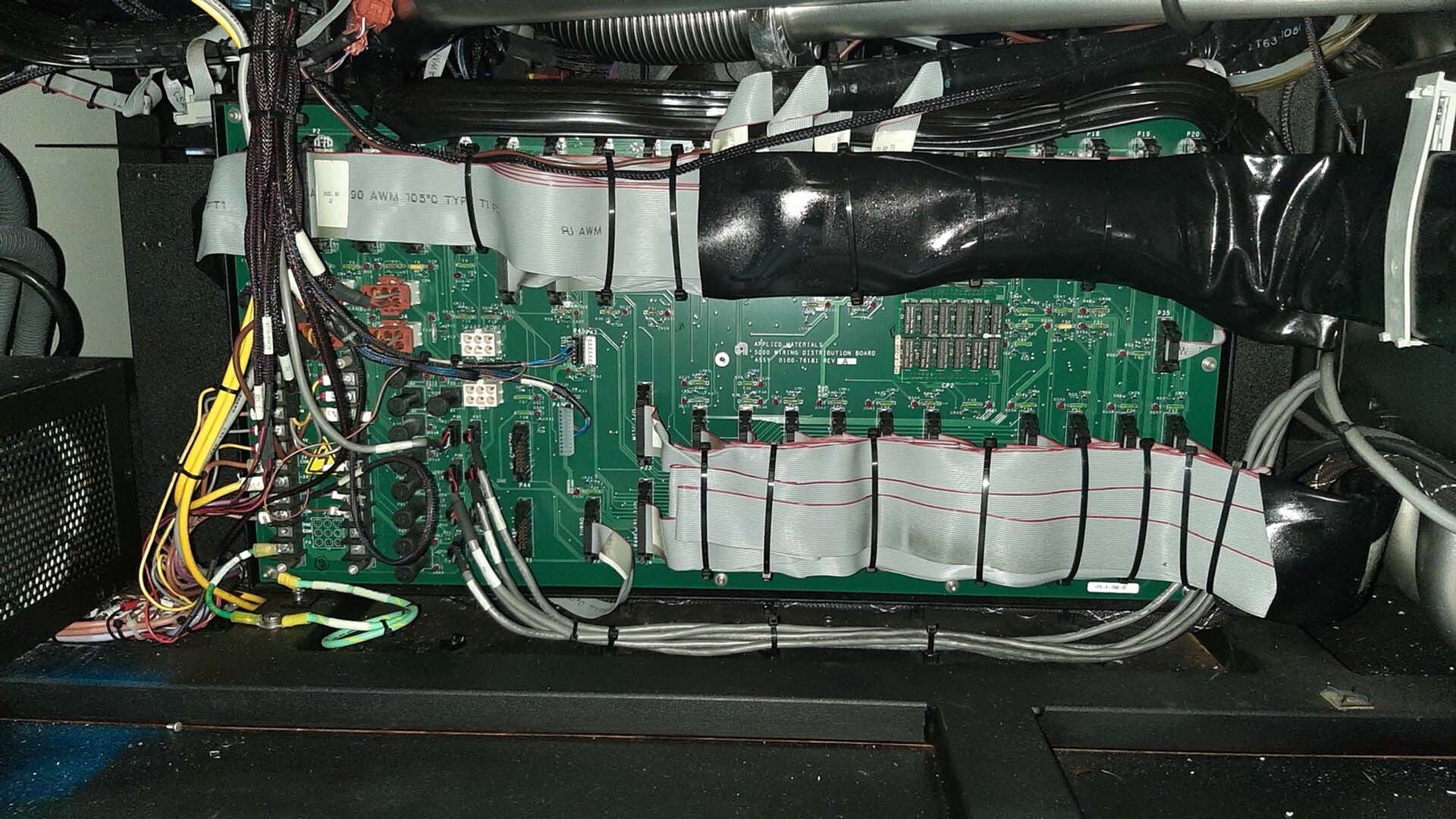

AMAT / APPLIED MATERIALS P5000 reactor is a type of deposition chamber used in the fabrication of microelectronic devices. It is a high-vacuum chamber that is used to deposit thin films of various materials on a substrate. This reactor is capable of depositing both single and multiple layer films with precise control of their physical and chemical properties. The chamber of this reactor is a cylindrical shape with a cone-shaped base. It is made from stainless steel, titanium, and composite materials. The chamber is evacuated using a turbomolecular vacuum pump, providing a low pressure environment suitable for thin film deposition. The chamber contains a lithiated silicon (Si) crucible, which is heated by an electron beam. The electron beam gives precise control over the temperature in the chamber, allowing for precise control of the deposition parameters. This reactor is also equipped with a process mass flow controller that provides precise control of the material flow rates into the chamber. This allows the deposition of different layers with different thicknesses. In addition, the reactor is equipped with an ultra-high purity gas distribution system that is used to provide the appropriate reactive gases for the deposition processes. The reactor is equipped with a loadlock, which is a mechanism that enables samples to be loaded and unloaded as needed. This allows for samples to be mounted and moved in a controlled environment, thus reducing contamination. AMAT P-5000 reactor is highly efficient and provides a high-quality environment for thin film deposition. Its precise control over process parameters and its efficient loading/unloading capabilities make it one of the most popular deposition chambers available. It is suitable for a wide range of applications in microelectronics fabrication, and can easily be integrated into existing production lines.

There are no reviews yet