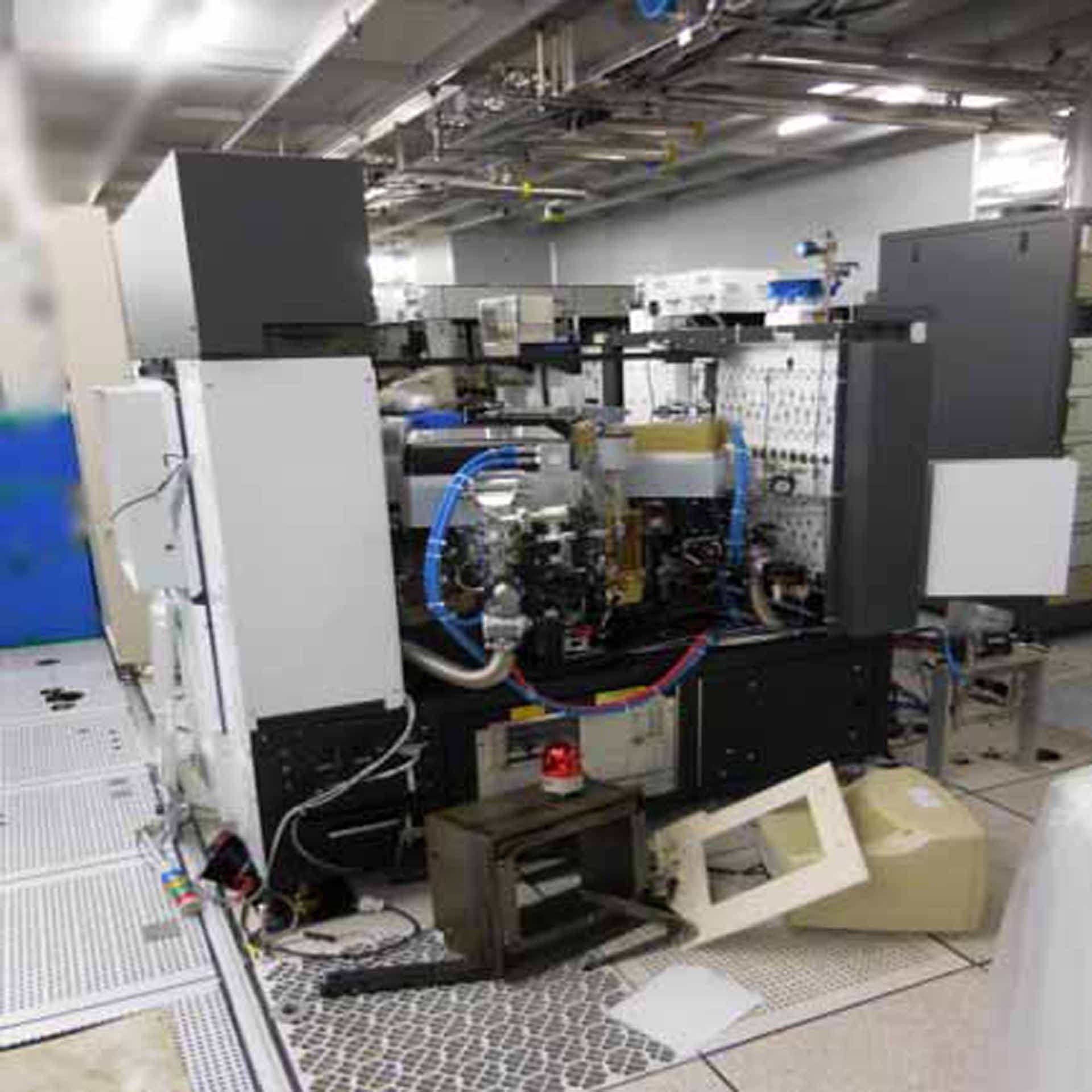

Used AMAT / APPLIED MATERIALS P5000W #9254064 for sale

URL successfully copied!

Tap to zoom

ID: 9254064

Wafer Size: 6"

Vintage: 1996

Systems, 6"

(3) Chambers

Wafer loading type

Processing type: W-Plug

Exhaust:

Main system: NW 50

Gas line:

Unit / Maker / Model

Chamber A:

MFC1 / STEC / SEC-4400

MFC2 / STEC / SEC-4400

MFC3 / UNIT / UFC-8160

MFC4 / UNIT / UFC-1660

MFC5 / STEC / SEC-4400

MFC6 / UNIT / UFC-1661

MFC7 / UNIT / UFC-1660

MFC8 / UNIT / UFC-1660

Chamber B:

MFC1 / STEC / SEC-4400

MFC2 / STEC / SEC-4400

MFC3 / UNIT / UFC-1660

MFC4 / UNIT / UFC-1660

MFC5 / STEC / SEC-4400

MFC6 / UNIT / UFC-1100

MFC7 / UNIT / UFC-1260A

MFC8 / UNIT / UFC-1660

Chamber D:

MFC1 / STEC / SEC-7440

MFC2 / STEC / SEC-4400

MFC3 / UNIT / UFC-1660

MFC4 / STC / UFC-1660

MFC5 / STC / SEC-4400

MFC6 / UNIT / UFC-1660

MFC7 / UNIT / UFC-1660

MFC8 / UNIT / UFC-1660

OEM No marking transfer

Gauge:

Chamber / Maker / Model

Chamber A / MKS / 627A

Chamber B / MKS / 127AA

Chamber D / MKS / 624A

RF Unit:

Chamber / Maker / Model / Unit

Chamber A, B and D / ENI / OEM-12B / Generator

Chamber A / B / D / OEM / 0010-09750R / Matcher

Sub module:

Maker / Model / Unit

(3) EDWARDS / QDP40 / Dry pumps

EBARA / A30W / Dry pump

AMAT / APPLIED MATERIALS / AMAT0 / Heat exchanger

(2) UNISEM / UN2004A-HW / Scrubbers

Power supply: 208 VAC, 3 Phases, 50/60 Hz

1996 vintage.

AMAT / APPLIED MATERIALS P5000W reactor, also known as an airport metalorganic chemical vapor deposition equipment, is a versatile and reliable tool designed for advanced semiconductor processes in a batch or cluster toolset. It is used to deposit ultra-thin layers of material onto silicon wafers in order to fabricate complex structures used in integrated circuit production. AMAT P5000W is a highly efficient piece of equipment that offers superior process repeatability and reliability. APPLIED MATERIALS P5000W has an automated one-step loadlocks which allow the wafers to be placed directly into the reaction chamber. This eliminates the need for wafer transfers and accelerates the process cycle time. The chamber volume is approximately 70 liters and the operating temperature range is between -5˚C and +450˚C. The versatile design allows the system to be used for various processes including single and multi-layer deposition of film structures. P5000W was designed with a PC-base robot and full process control environment. It is equipped with a unique real-time feedback unit that monitors the results of the process. Additionally, AMAT / APPLIED MATERIALS P5000W is optimized for low-temperature operation, making it ideal for complex process recipes. The advanced control machine offers full statistical process control, rapid diagnostics, optimal tuning, and precise research-chemical control capabilities. AMAT P5000W has a Turbo Source technology, which allows for accurate deposition of layers with varying thicknesses. This allows for extremely uniform films to be deposited, resulting in improved cross-sectional uniformity and patterning reproducibility. APPLIED MATERIALS P5000W also features a triple-substrate calibration station, designed to allow for accurate and repeatable substrate thicknesses. P5000W reactor is a powerful and reliable tool designed for advanced semiconductor deposition processes. Its range of features, including automated one-step loadlocks, PC-base robot and process control environment, Turbo Source technology, and triple-substrate calibration station, give it superior process repeatability and reliability for optimal total cost of ownership.

There are no reviews yet