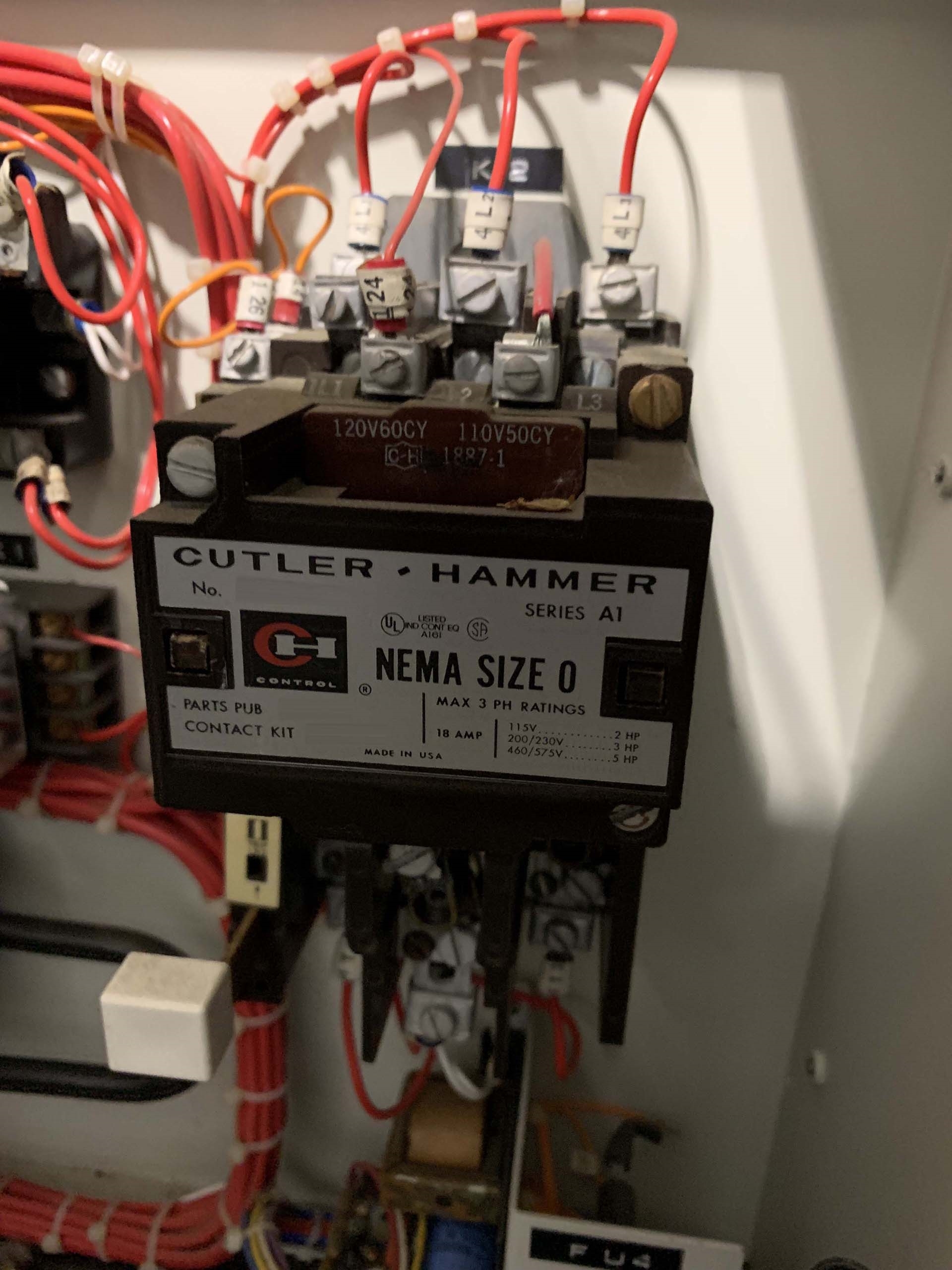

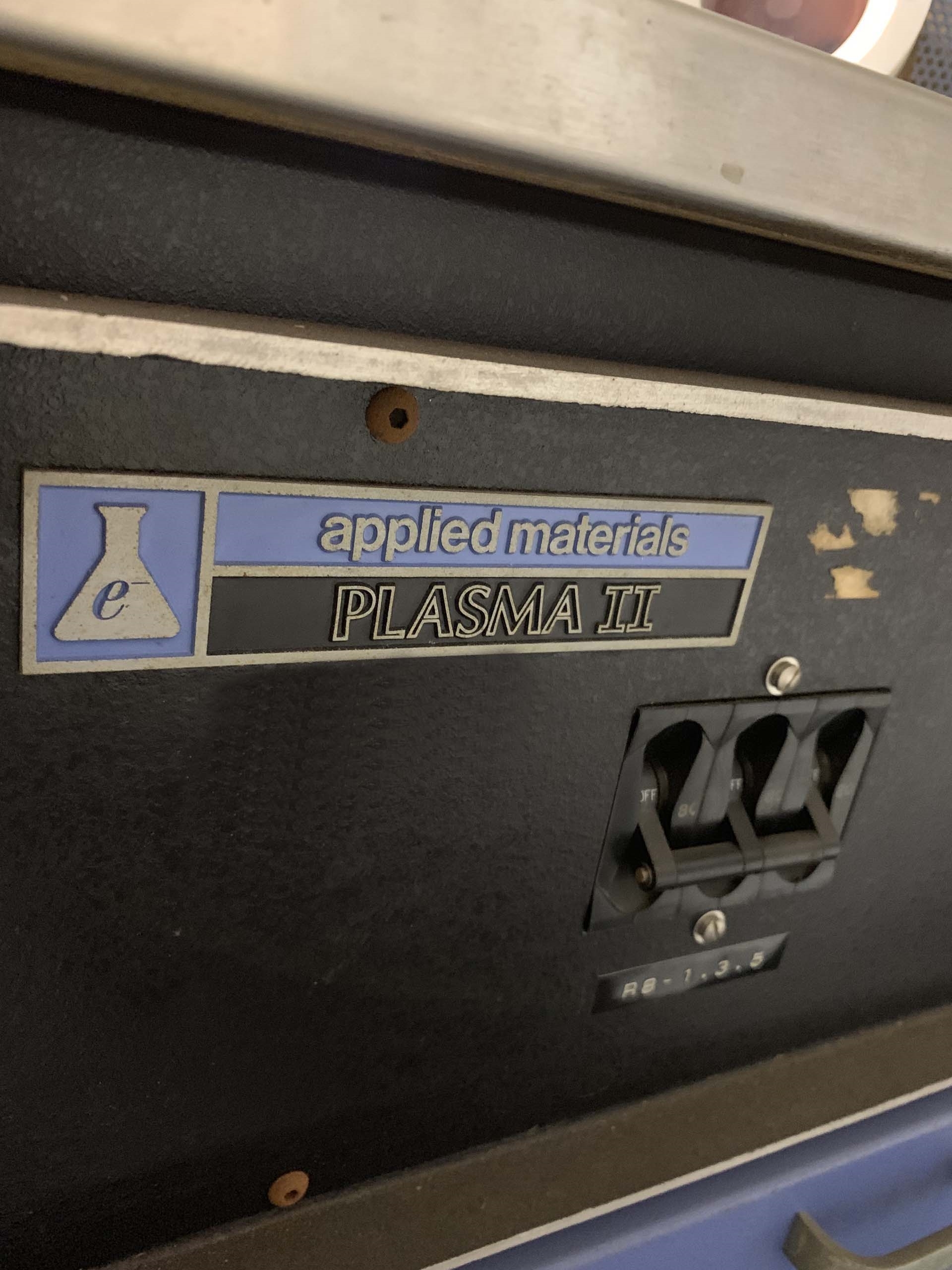

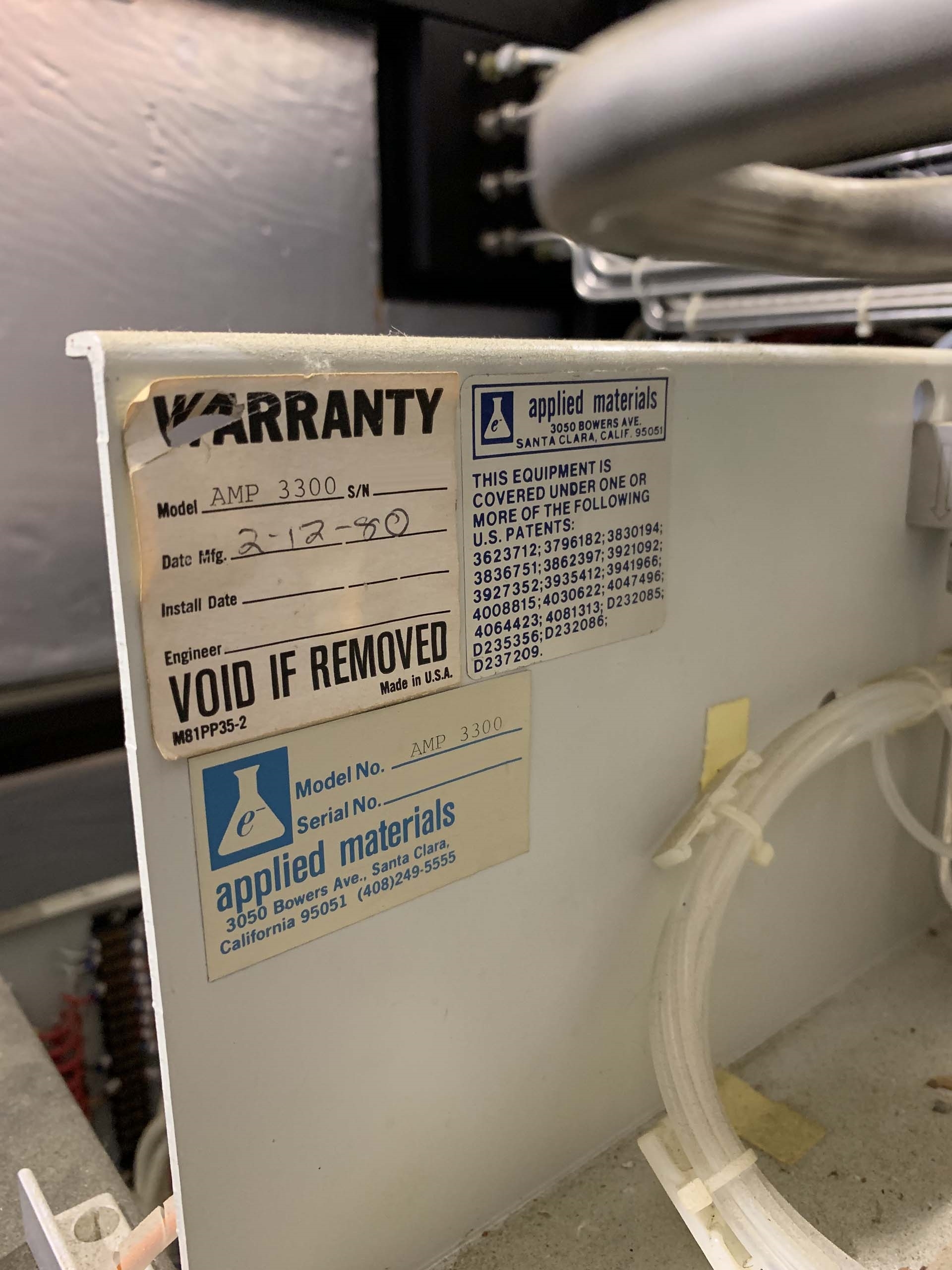

Used AMAT / APPLIED MATERIALS Plasma II #9239745 for sale

URL successfully copied!

Tap to zoom

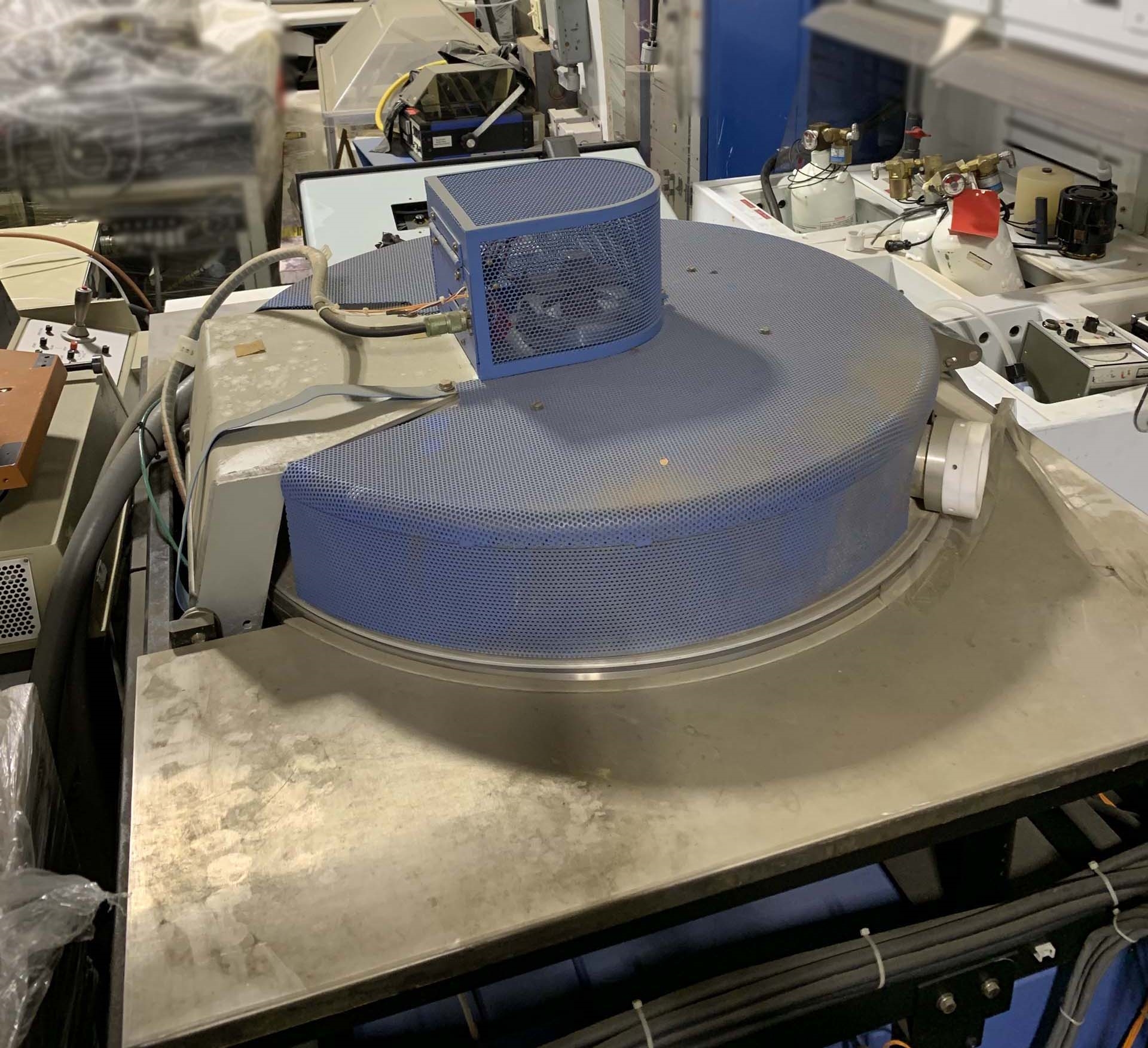

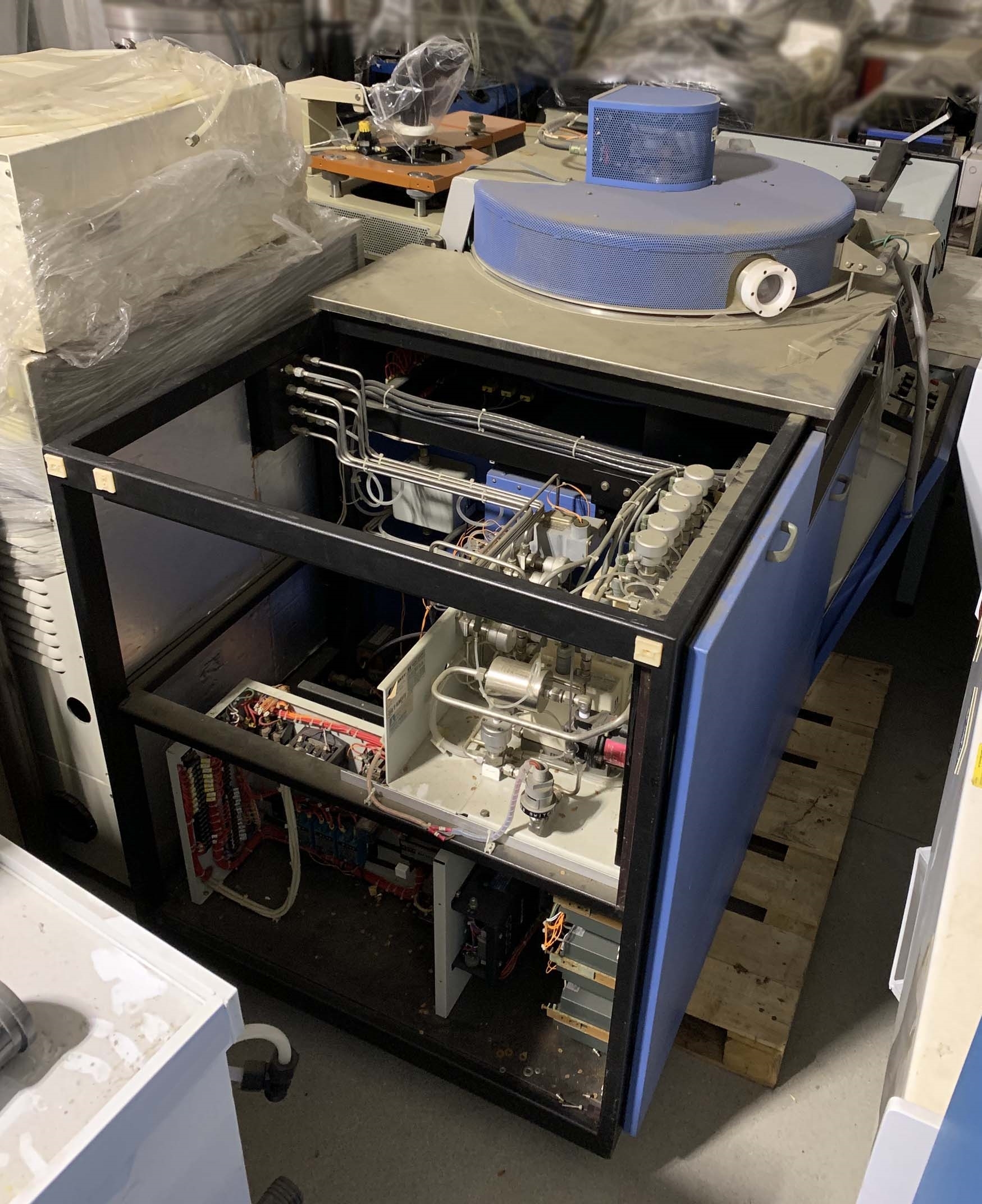

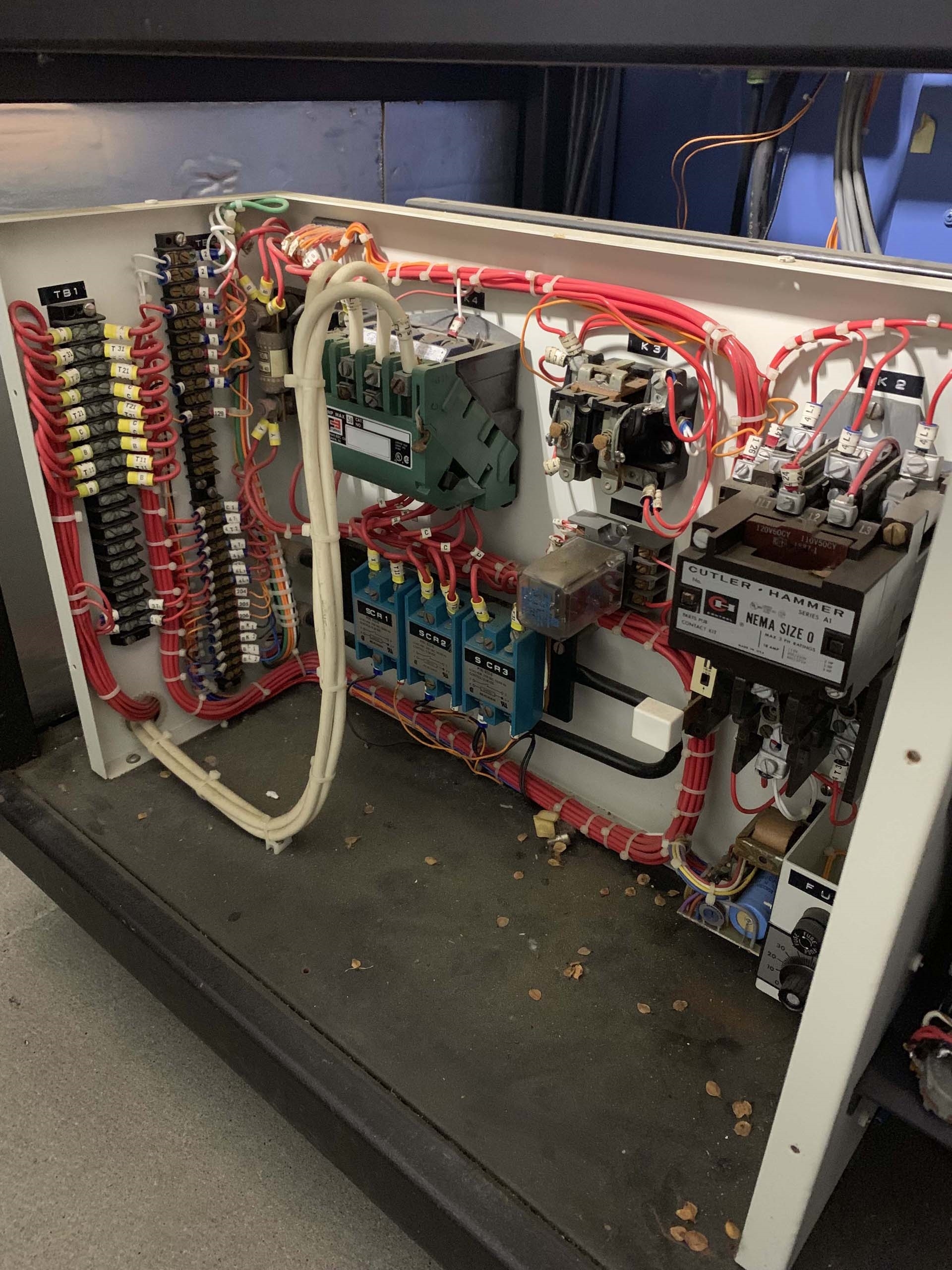

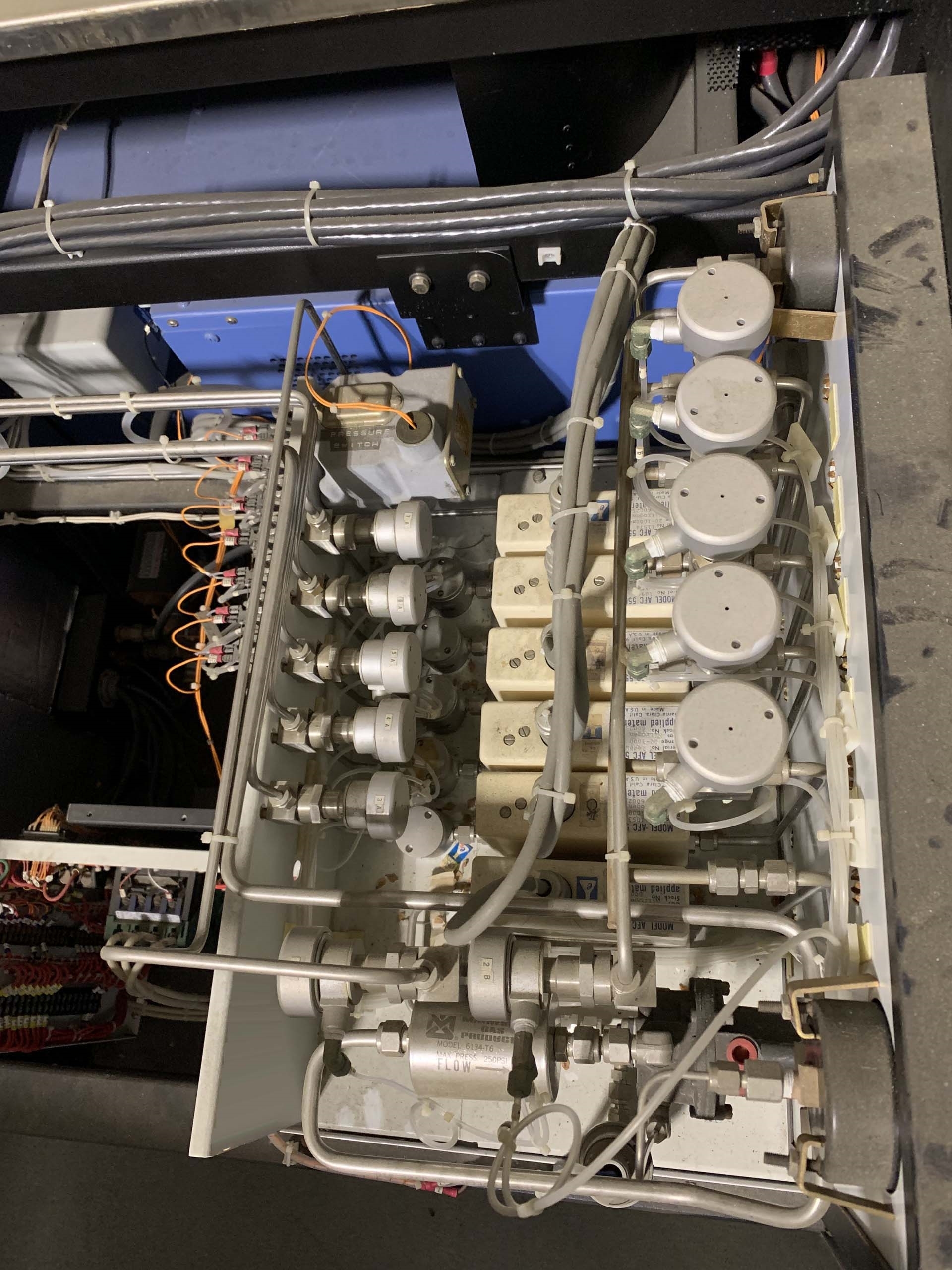

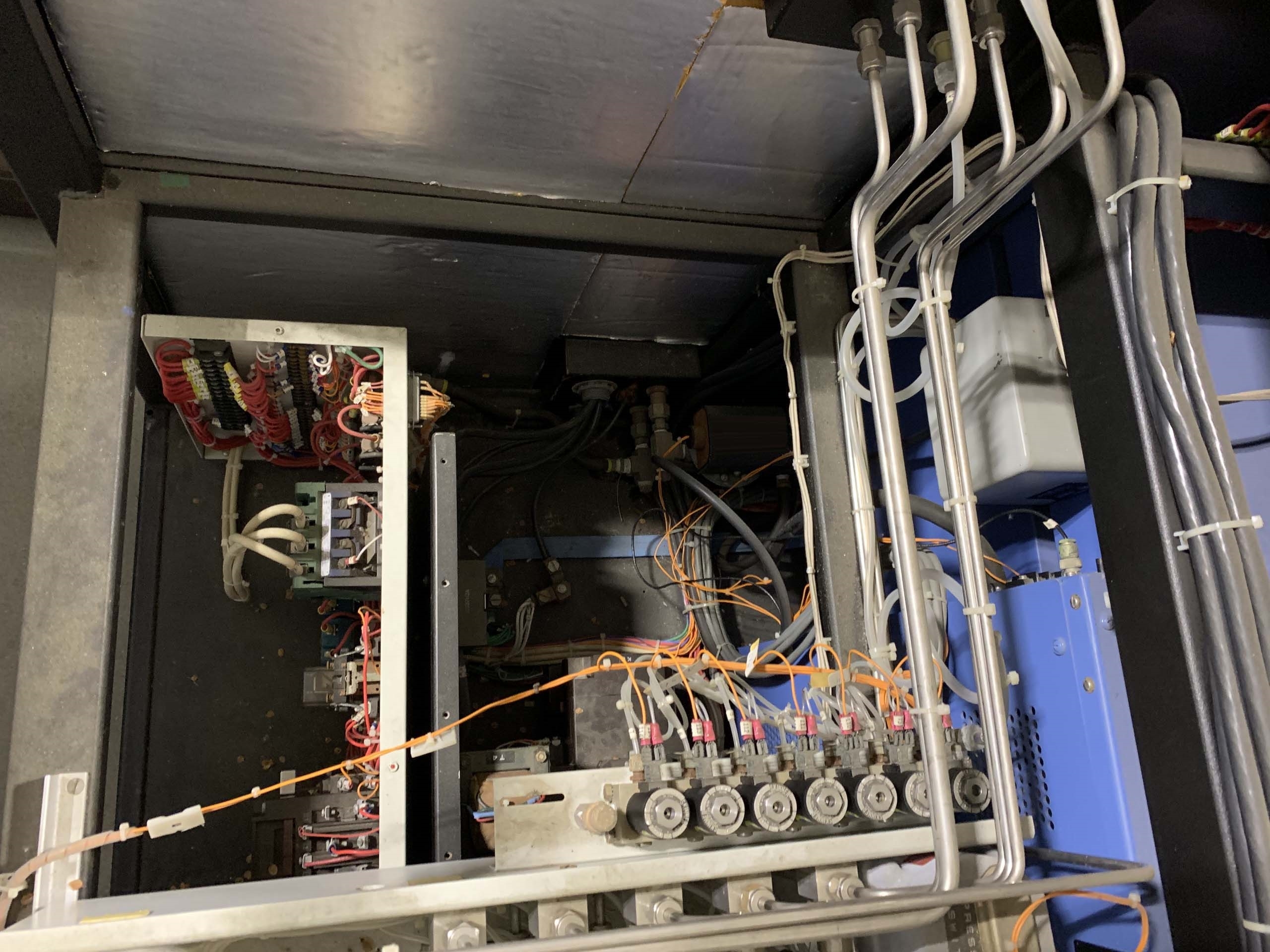

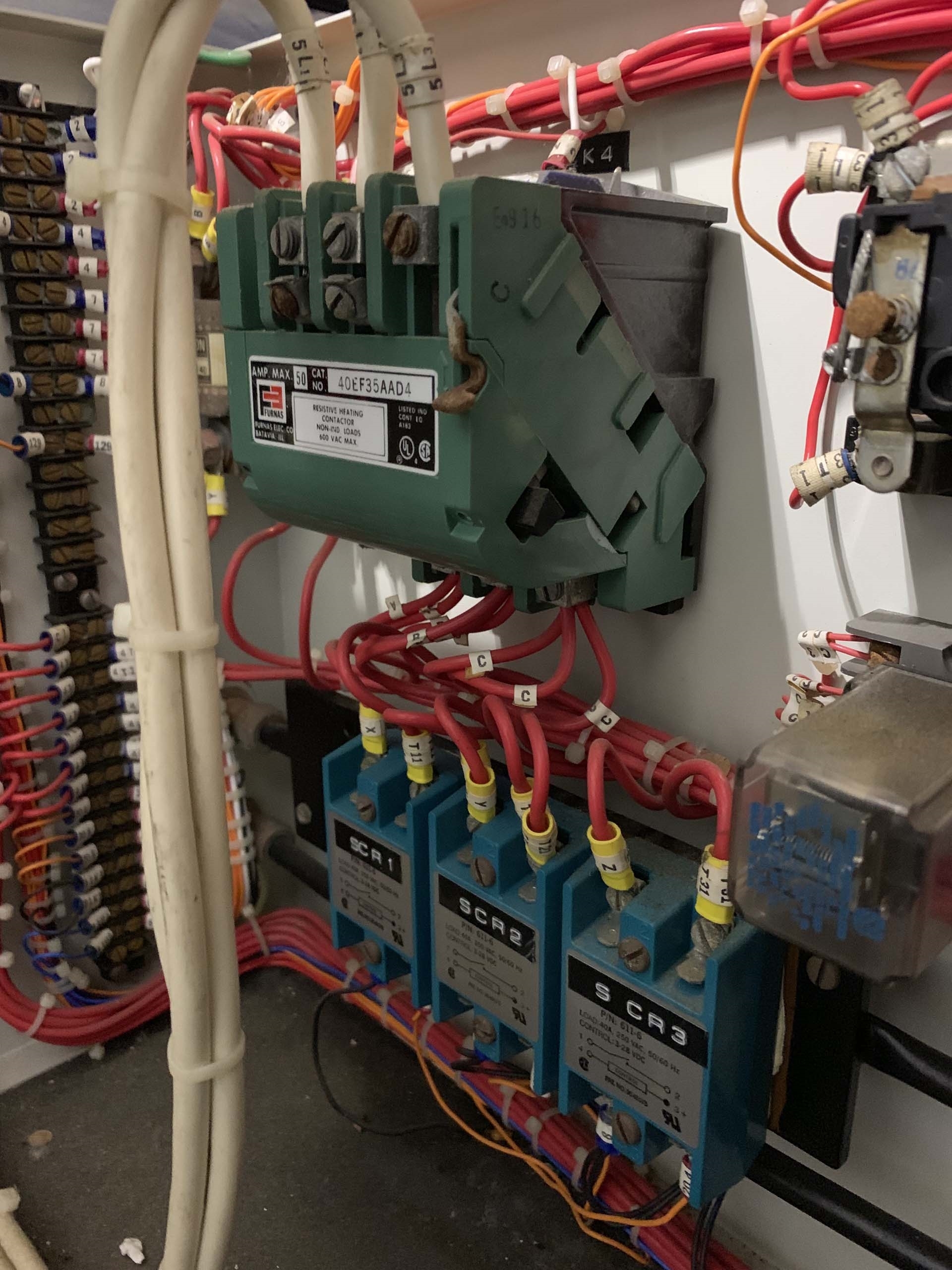

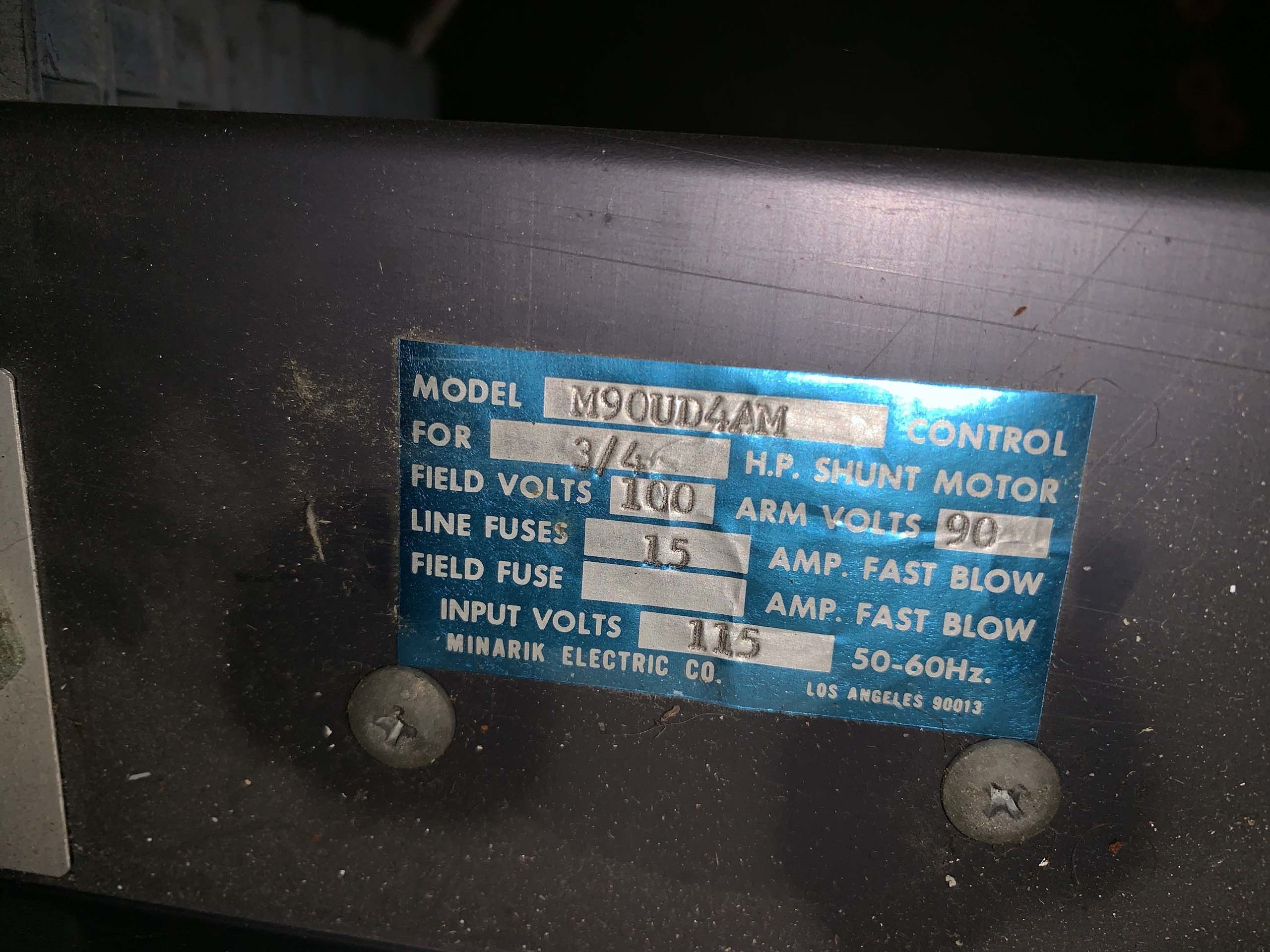

AMAT / APPLIED MATERIALS Plasma II is a thin-film deposition reactor used for a variety of thin-film applications. AMAT Plasma II uses a plasma-enhanced chemical vapor deposition (PECVD) process and can provide high-grade silicon nitride, silicon dioxide, and other thin films. The chamber is designed with an internal shutter allowing the user to control the pressure of the atmosphere. The closed atmosphere provides excellent surface uniformity and control. APPLIED MATERIALS Plasma II has an optimized heating equipment, utilizing dual zone resistive heating technology to provide precise temperature control. The operator can control the temperature separately for the top and bottom portions of the chamber. This allows for precise control of volatile (VOC) gases during the plasma formation process and helps ensure material deposition uniformity. The precise temperature control also enables the precise control of reaction processes during the deposition process. Plasma II uses a plasma source to enhance the reaction rate in the reaction chamber. The plasma is generated from a radio-frequency (RF) energy source that passes into the reaction chamber and is converted into a plasma by a set of magnetically coupled electrodes, creating secure plasma formation. This plasma helps transform the precursor molecules of the thin-film material into the desired film. AMAT / APPLIED MATERIALS Plasma II is designed with a two-compartment rotation system and is capable of rotating up to 1200 rpm. The rotation unit helps maintain uniform temperatures across the sample surface as well as increase mass transport, allowing films to be produced quickly and efficiently. This uniform temperature also helps reduce the occurrence of thermal stresses on the sample surface, resulting in higher-quality films. AMAT Plasma II is also designed with a base pressure controller, allowing the operator to control the pressure of the reaction chamber during the deposition process. It also has a gas-flow machine, allowing for precise control of the gas flow rate within the chamber to ensure the desired deposition rate and composition. APPLIED MATERIALS Plasma II utilizes its advanced technology and features to provide precise control over thin-film materials deposition processes, resulting in films that are of high quality and uniformity. The advanced temperature control and rotation tool also allows for rapid growth and deposition of thin films.

There are no reviews yet