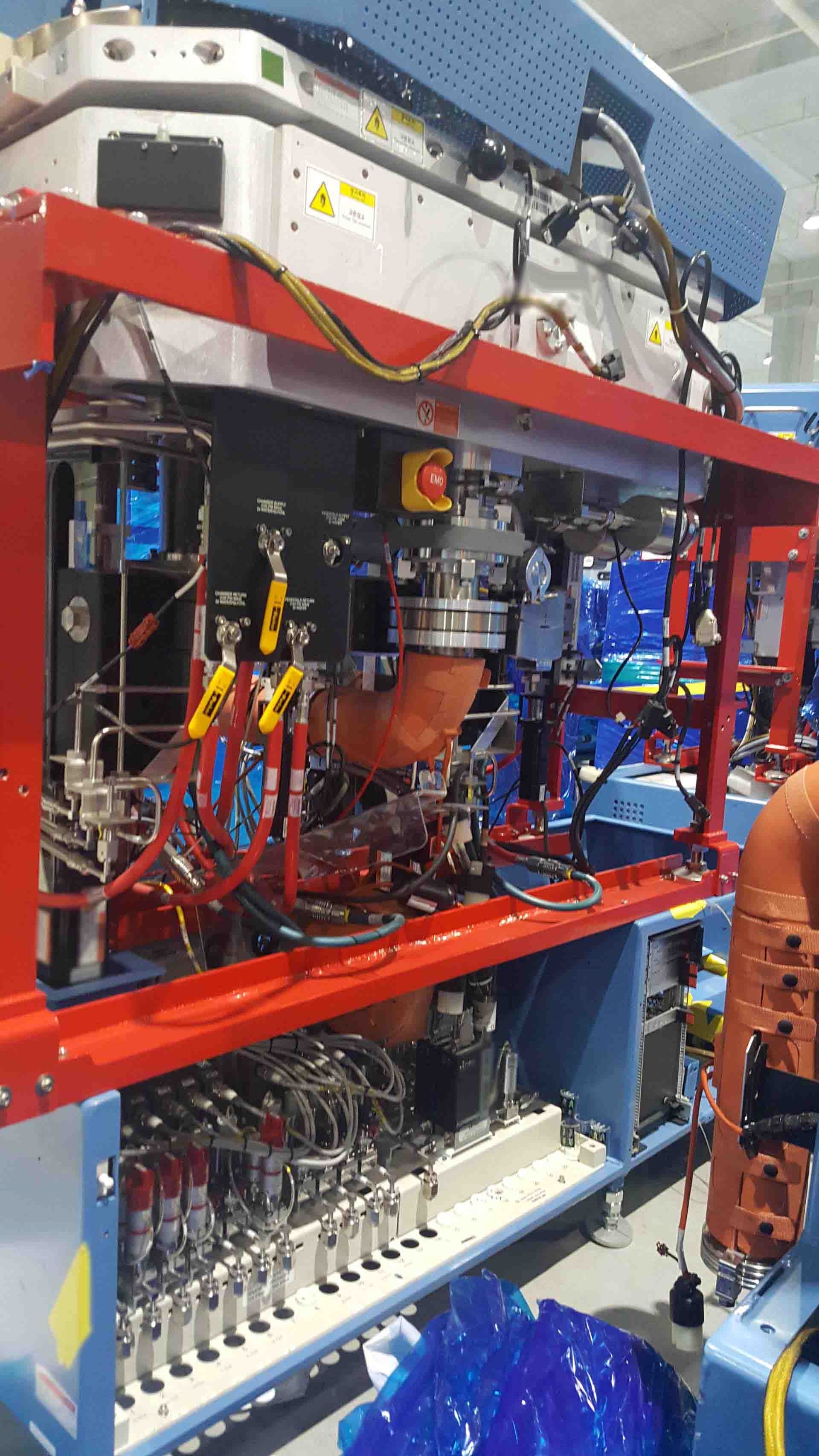

Used AMAT / APPLIED MATERIALS Producer GT #9198380 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9198380

Wafer Size: 12"

Vintage: 2008

CVD System, 12"

Qty / Part number / Description

(1) / 0190- 03068 / PIO Cable board OHT

(1) / 0190- 44306 / Loadlock EUROTHEM

(3) / 0140- 18773 / Pedestal lift motor cable side 1

(3) / 0140- 18772 / Pedastal lift motor cable side 2

(6) / 3700- 01376 / Pedastal O- ring

(1) / 0140- 17152 / Chamber controller signal cable

(2) / 0195- 11067 / Chamber AC box

(3) / 3980- 00027 / RING BOLT, MF80, 5.95OD W /.358

(6) / 0021- 98006 / ENP Cover, crossdrill

(1) / - / LCF Sensor cover

(3) / - / EV3 Manifold

(2) / - / LCF Sensor window

(8) / - / LCF Sensor srew

Currently warehoused

2008 vintage.

AMAT / APPLIED MATERIALS Producer GT is a state of the art Chemical Vapor Deposition (CVD) reactor that is used in semiconductor production. The advanced design of this equipment makes it the ideal tool for producing high-quality, ultra-thin layers of materials on semiconductor substrates. The system utilizes a two chamber design that allows for a flexible process. The main chamber is the reaction chamber and it is equipped with an array of gas inlets which are adjustable for different recipes. This chamber also houses a hot wall susceptor and an electromagnetic plasma source. The susceptor is heated to temperatures of up to 950 °C in order to provide the energy required to begin the chemical reaction process. The plasma source, meanwhile, helps to breakdown gas molecules into their constituent atoms and ensure uniform distribution of these atoms. The unit also comes equipped with a controller and a user interface. The user can enter desired recipes and then the controller will configure the machine accordingly. This ensures that all steps of the CVD process will be accounted for. The user can also adjust various parameters such as temperature, pressure, and flow rate to refine the performance of the tool. Once the process is complete, a cooled exhaust line exits the reaction chamber and directs the used process gases outside the asset. The cooling model also helps to ensure that the temperature and pressure of the chamber is maintained at the optimal levels. In addition to its features, AMAT Producer GT offers a wide range of advanced capabilities, including reactive high aspect ratio CVD, low temperature rapid thermal processing (RTP), ultra-low temperature CVD (LTCVD), and much more. The advanced design of this equipment allows it to accommodate a wide variety of substrates and materials, making it a versatile tool for semiconductor production. In conclusion, APPLIED MATERIALS Producer GT is an advanced CVD reactor that has been designed with the flexibility to accommodate a wide variety of substrates and materials. It offers a wide range of features and capabilities, along with ease of use and a robust controller and user interface. This makes it an ideal tool for producing high-quality layers of materials for semiconductor production.

There are no reviews yet