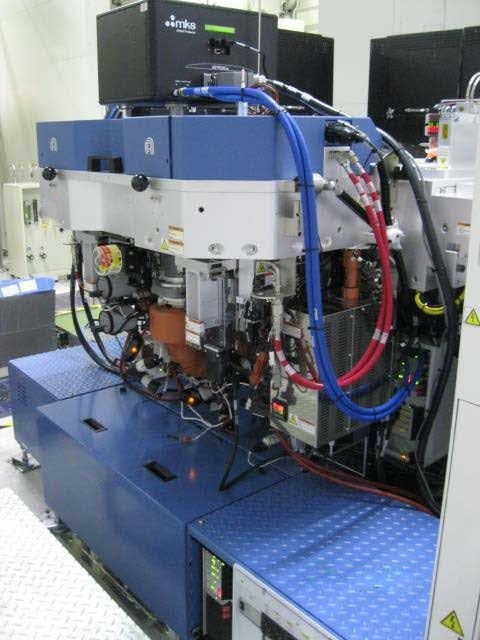

Used AMAT / APPLIED MATERIALS Producer GT #9208937 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9208937

Wafer Size: 12"

Vintage: 2011

CVD System, 12"

Items: FI

FI Robot

FI Robot controller

Aligner

Cool station

FES

FIS

TCS/RT

FFU

Items: LL

LL Upper lifts

LL Upper lift drivers

LL Lower lifts

LL Lower lift drivers

LL Pump

LL Foreline

Items: BUFFER FX

Robot

FX Robot linkage (batwing/bridge)

Robot blades

Robot controller

LCF

Buffer pump

Buffer foreline

MF Controller

Chamber A- ETERNA FCVD

RPS

Upper lid stack (gas box, face plate, isolator)

Ceramic process kit

Heaters: Pedestal

Pin lifts

Pin lift driver

Heater lifts

Heater lift drivers

Ch FL, TV, Iso valve

Gas panel (MFC, LFM intact)

Chamber controller

Chamber B- SACVD

RPS

Upper lid stack (gas box, face plate, isolator)

Ceramic process kit

Heaters

RF Filters

Pin lifts

Pin lift driver

Heater lifts

Heater lift drivers

Ch FL, TV, Iso valve

Gas panel (MFC, LFM intact)

Chamber controller

Chamber C- ETERNA FCVD

RPS

Upper lid stack (gas box, face plate, Isolator)

Ceramic process kit

Heaters: Pedestal

RF filters: N/A Pin lifts

Pin lift driver

Heater lifts

Heater lift drivers

Ch FL, TV, Iso valve

Gas panel (MFC, LFM intact)

Chamber controller

2011 vintage.

AMAT / APPLIED MATERIALS Producer GT is a high-throughput, single-chamber, horizontal, closed-frame reactor used for the production of monocrystalline and polycrystalline semiconductor materials. This equipment offers high throughput capabilities, resulting in reduced cycle times, as well as improved material yields. The system includes an advanced graphical user interface, allowing for fast and easy parameter control. It also consists of a turbo-pumped, horizontally-supported chamber for optimal thermal performance and uniformity. AMAT Producer GT includes an integrated source crucible with an advanced temperature control unit for perfect crystal growth. An automatic substrate holder allows for precise substrate positioning and controlled movement of the substrate. It also has an advanced pyrometer for more accurate temperature readings, as well as a low-pressure in-situ gas injection machine for optimal growth conditions. APPLIED MATERIALS Producer GT is conveniently sized for easy installation and operation in a standard semiconductor fabrication lab. It utilizes high-performance magnets that provide optimal and uniform field intensity for uniform crystal growth. It is also equipped with a dynamic cooling tool to reduce thermal cycling of the chamber and reduce contaminant deposition. Additionally, the asset includes advanced substrate edge profiling capabilities to ensure uniform crystal growth, as well as an integrated wafer cooling model to reduce thermal stress. Overall, Producer GT is an advanced, ultra-fast semiconductor materials production reactor that provides unparalleled performance, reliability, and efficiency. With its advanced user interface, robust temperature control equipment, integrated source crucible, dynamic cooling system, and advanced wafer cooling unit, this high-performance reactor is the ideal choice for state-of-the-art semiconductor production.

There are no reviews yet