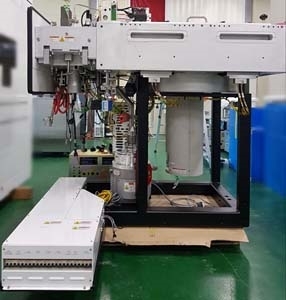

Used AMAT / APPLIED MATERIALS Producer GT #9228298 for sale

URL successfully copied!

Tap to zoom

ID: 9228298

Wafer Size: 12"

Vintage: 2009

CVD System, 12"

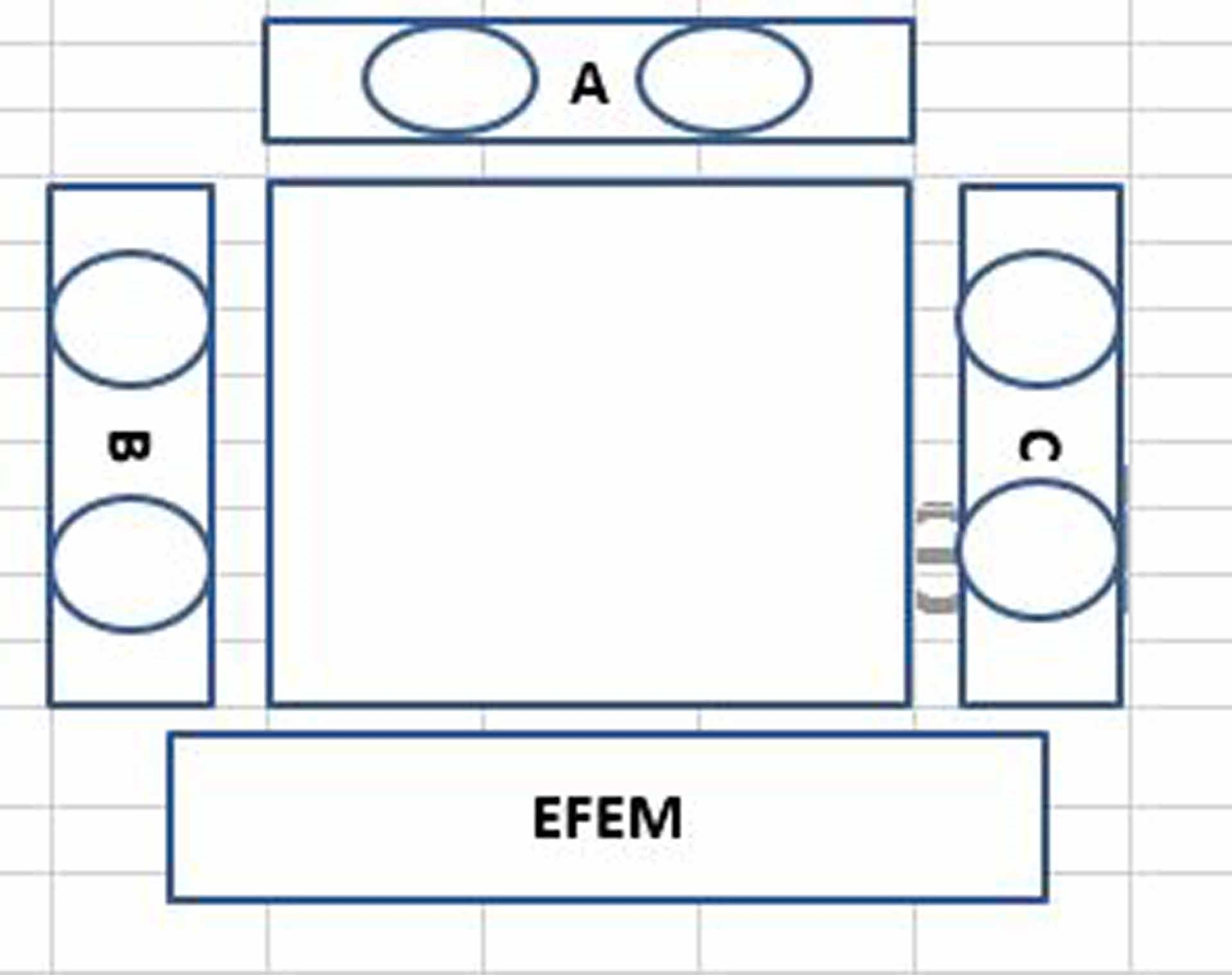

(3) Chambers

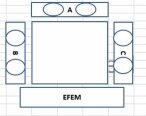

EFEM:

(4) Load ports

Load port type: TDK / TAS300 / G1

(2) EFEM Robots

ATM 0090-25011 Robot

KAWASAKI 3NX510B-D001 ATM Robot

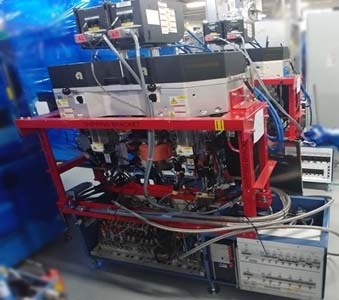

TM and chamber robot

BROOKS 0190-25011 Vacuum robot

Chambers:

623B-24562 Throttle valve

APEX 3013 RF Generator

MKS ASTRON 2L Remote plasma system

Chamber A / B / C:

Gas line position / Process gas / MFC Size / Maker

1 / N2 Purge

2 / NF3 / 15000 sccm / Unit

3 / AR / 10000 sccm / Unit

4 / SIH4 / 1000 sccm / Unit

5 / N2 PURGE / - / -

6 / NH3 / 700 sccm / Unit

7 / N2 PURGE / 25000 sccm / Unit

8 / AR / 10000 sccm / Unit

10 / O2 / 10000 sccm / Unit

11 / N2O / 1000 sccm / Unit

12 / N2O / 15000 sccm / Unit

20 / TEOS / 7 g/min / HORIBA STEC

21 / AR / - / -

22 / N2 PURGE / 15000 sccm / Unit

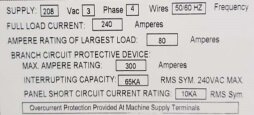

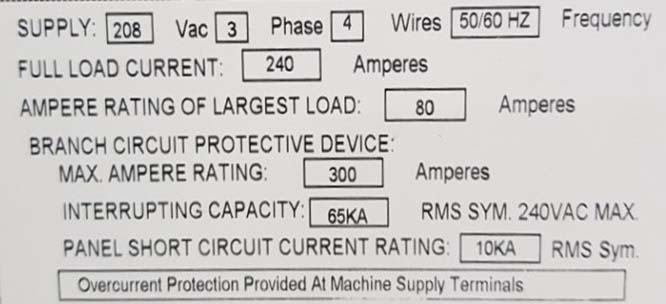

Electrical requirements:

Power supply: 208 VAC, 50/60 Hz, 3-Phase, 4-Wires

Full load current: 240 Amp

2009 vintage.

AMAT / APPLIED MATERIALS Producer GT is a next-generation semiconductor reactor that is used in semiconductor manufacturing. This reactor is tailored for high-end lithography equipment and offers the latest in distributed heat and particle control. The reactor is designed to optimize processes that require low defectivity and critical feature precision. AMAT Producer GT consists of two main components, the process chamber and the sub-components. The process chamber contains the wafer cassettes as well as the process modules with overhead optics, microwaves, magnetic resonance, laser, and ion implant systems. The sub-components include the plasma source, the pump, the chillers, the gas delivery system, the power supplies, and the automation. The plasma source is designed to generate high ion density plasma ion source with low particle entrainment. It is enclosed in an RF-shielded enclosure to prevent EMI disturbances. The gas delivery system is used to ensure precise control of gas flows, pressure, and temperature. The gas is engineered to be isolated and leak-free. The power supplies are specially designed for low power consumption and evenly distribute power to all process modules. They are capable of accommodating system voltage fluctuations, reducing the risk of process disruption. The vacuum pump is a turbomolecular design that allows for precise control and reliable operation, even with large variations of pressure needs. The chillers provide a consistent cooling that is required for reliable substrates processing. The reactors are engineered using a 3D scan imaging technology to create the optimized process parameter requirements for lithography. This combination of components ensures highly uniform processing of features down to 22nm and low defectivity. The automation capabilities of APPLIED MATERIALS Producer GT make it an ideal solution for high-mix and low-volume semiconductor production. It is designed to handle multi-chamber processing needs with programmable wafer scheduling and tight control of process parameters and process recipe management. The automation also provides self-monitoring and self-adjustment capabilities that reduce time to start-up and increase platform up-time. AMAT has designed Producer GT to maximize productivity and yield while minimizing cost of ownership. This reactor is the ideal solution for manufacturers looking to optimize their semiconductor process control capabilities.

There are no reviews yet