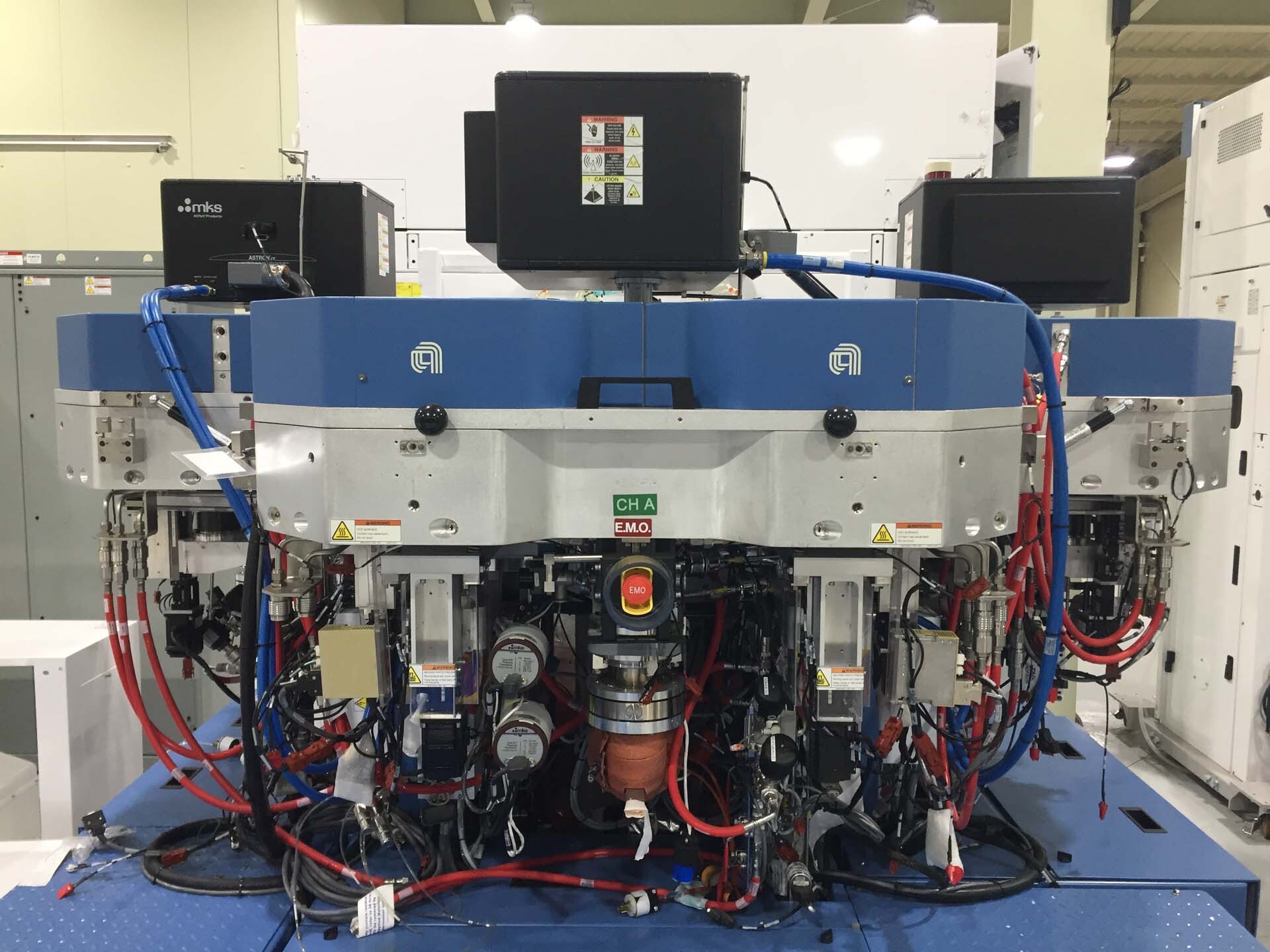

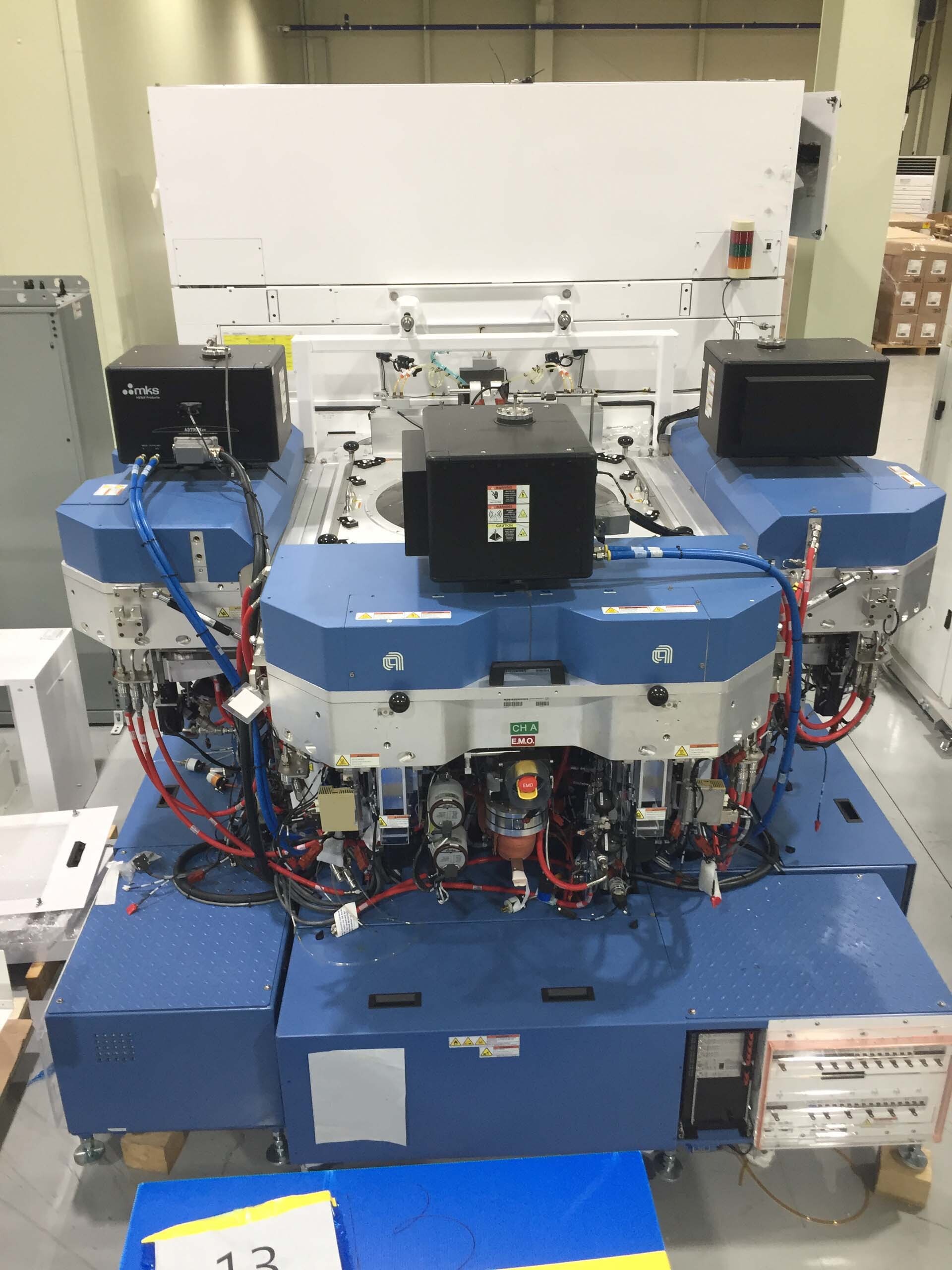

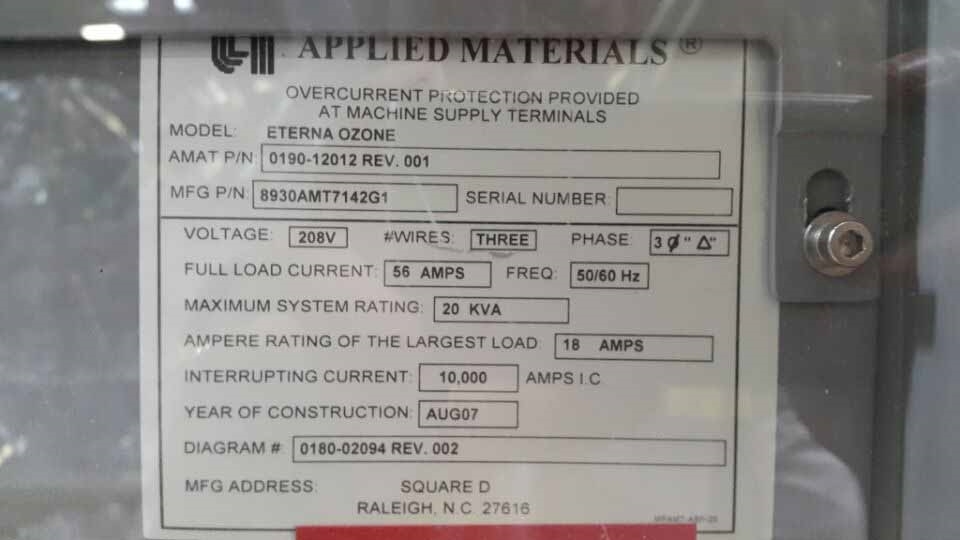

Used AMAT / APPLIED MATERIALS Producer GT #9231995 for sale

URL successfully copied!

Tap to zoom

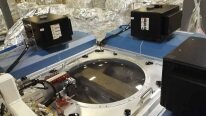

ID: 9231995

Wafer Size: 12"

Vintage: 2008

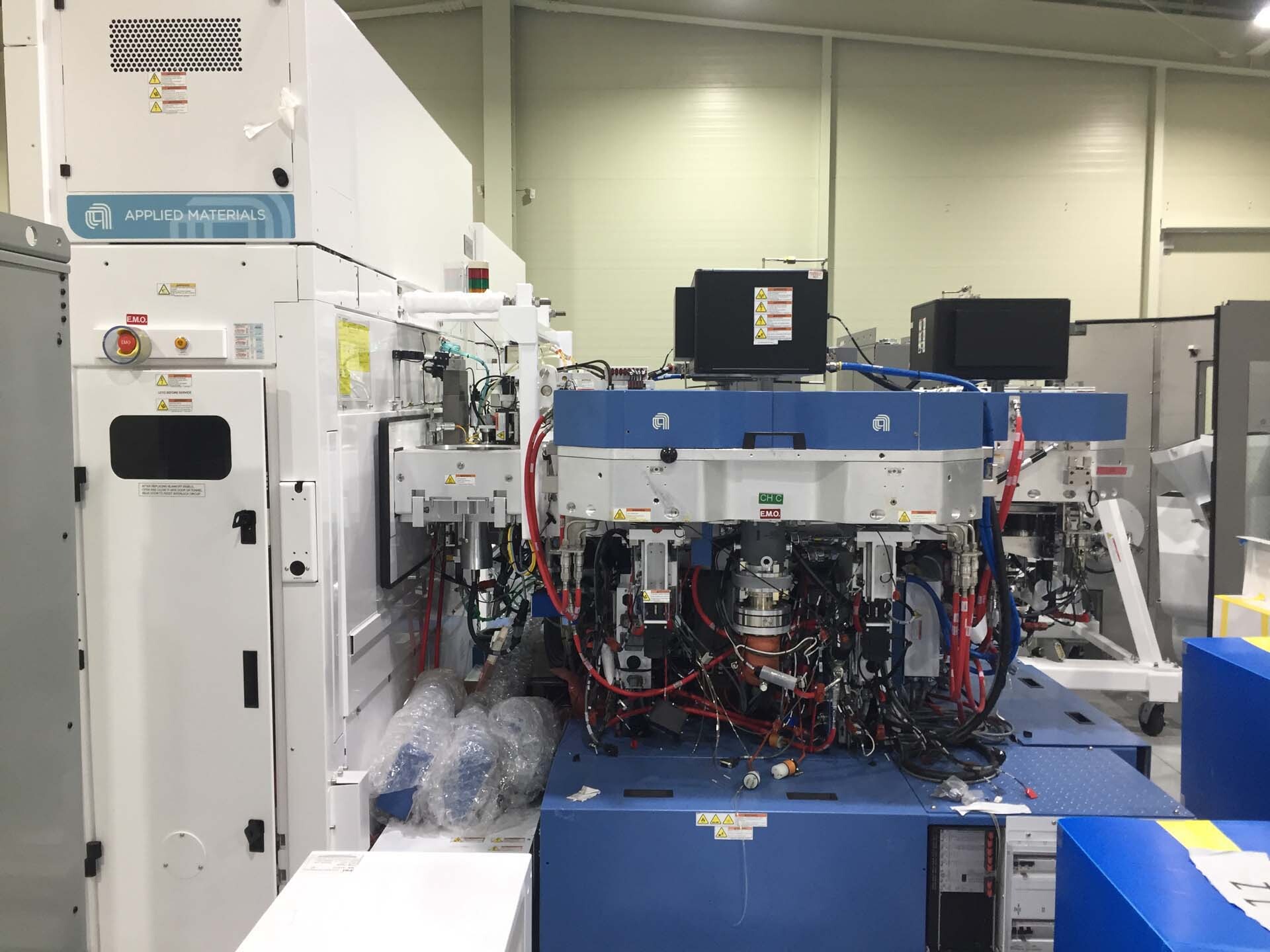

System, 12"

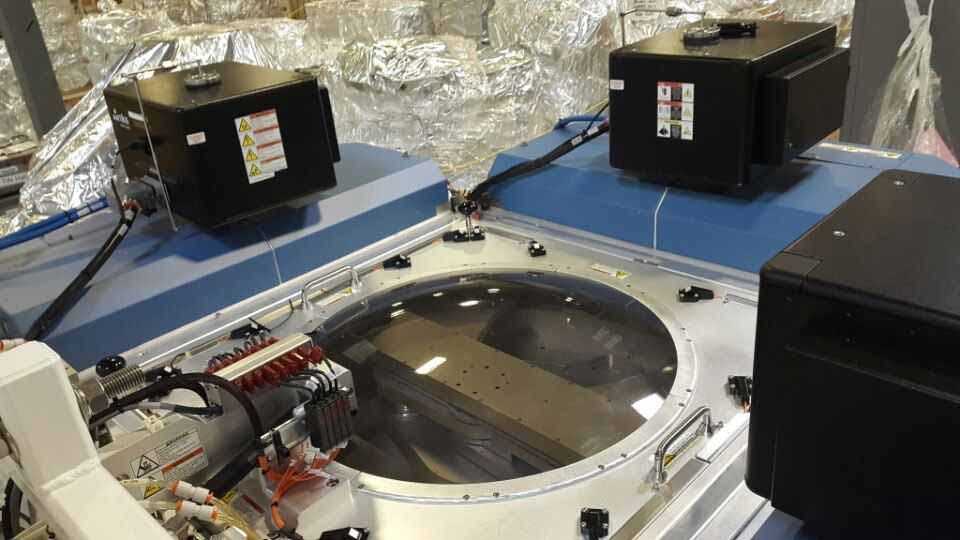

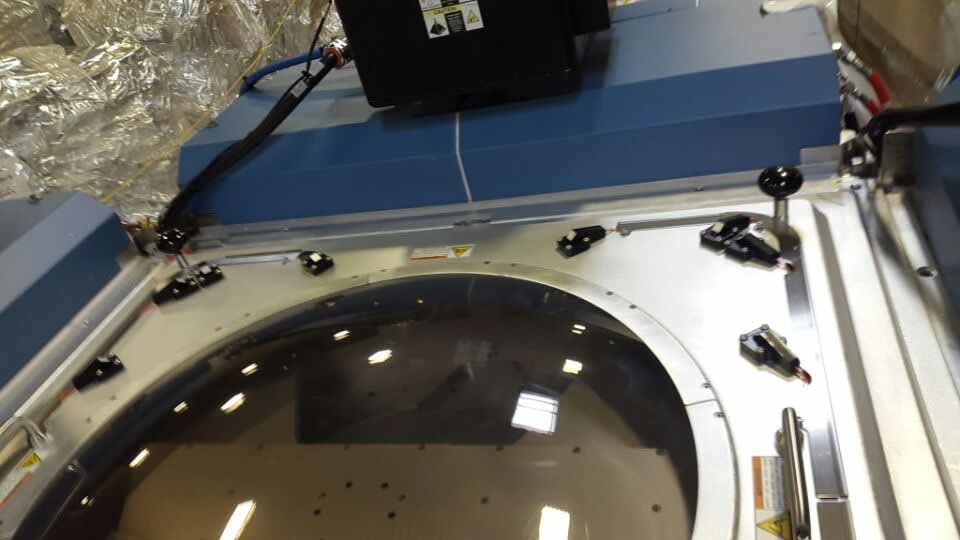

(3) Chambers

(4) Load ports

Factory interface: 5.4

AMHS Configuration: OHT

FE Computer type: FES

FI Computer type: FIS

RT Computer type: CL7

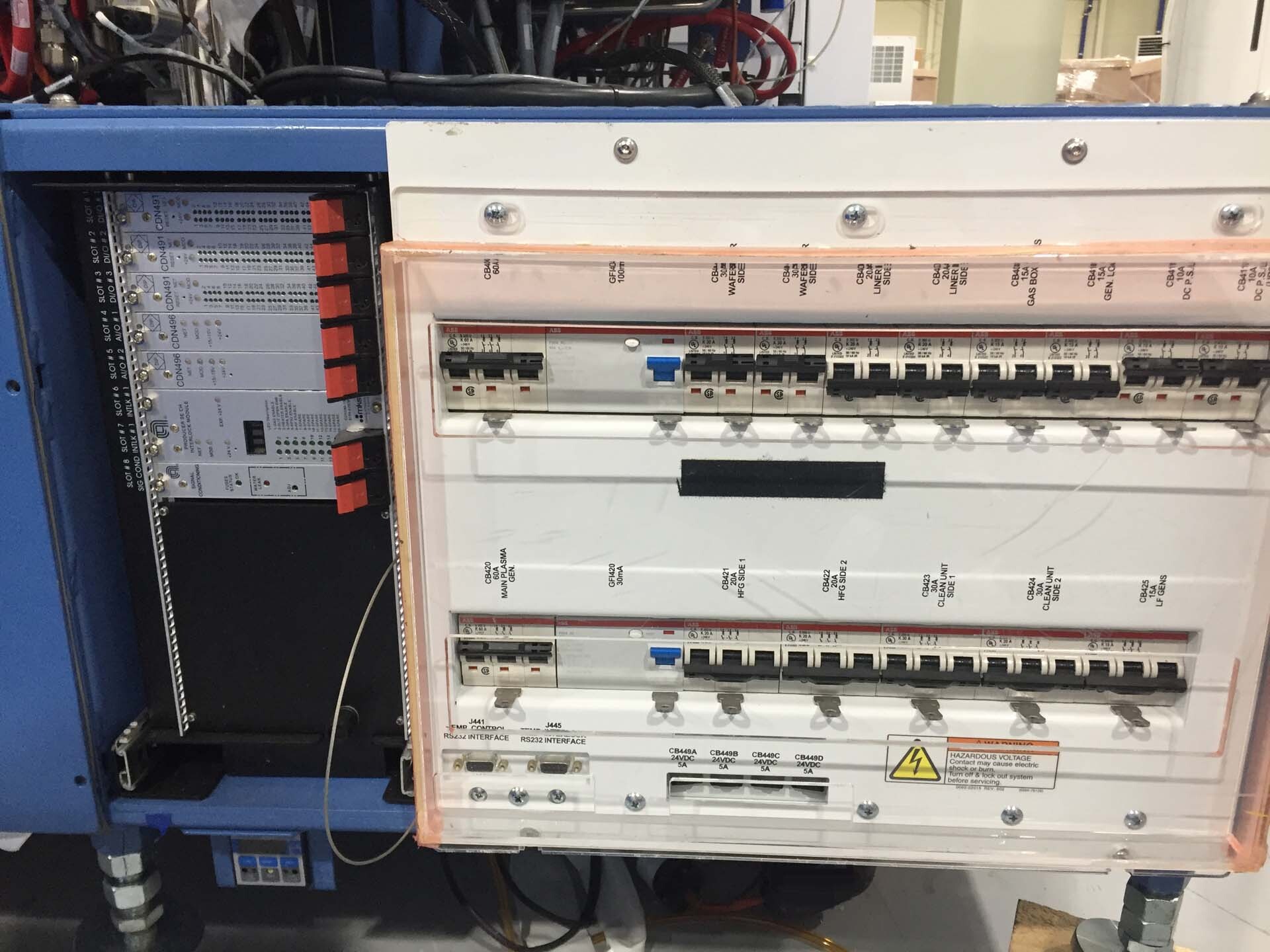

Misc hardware:

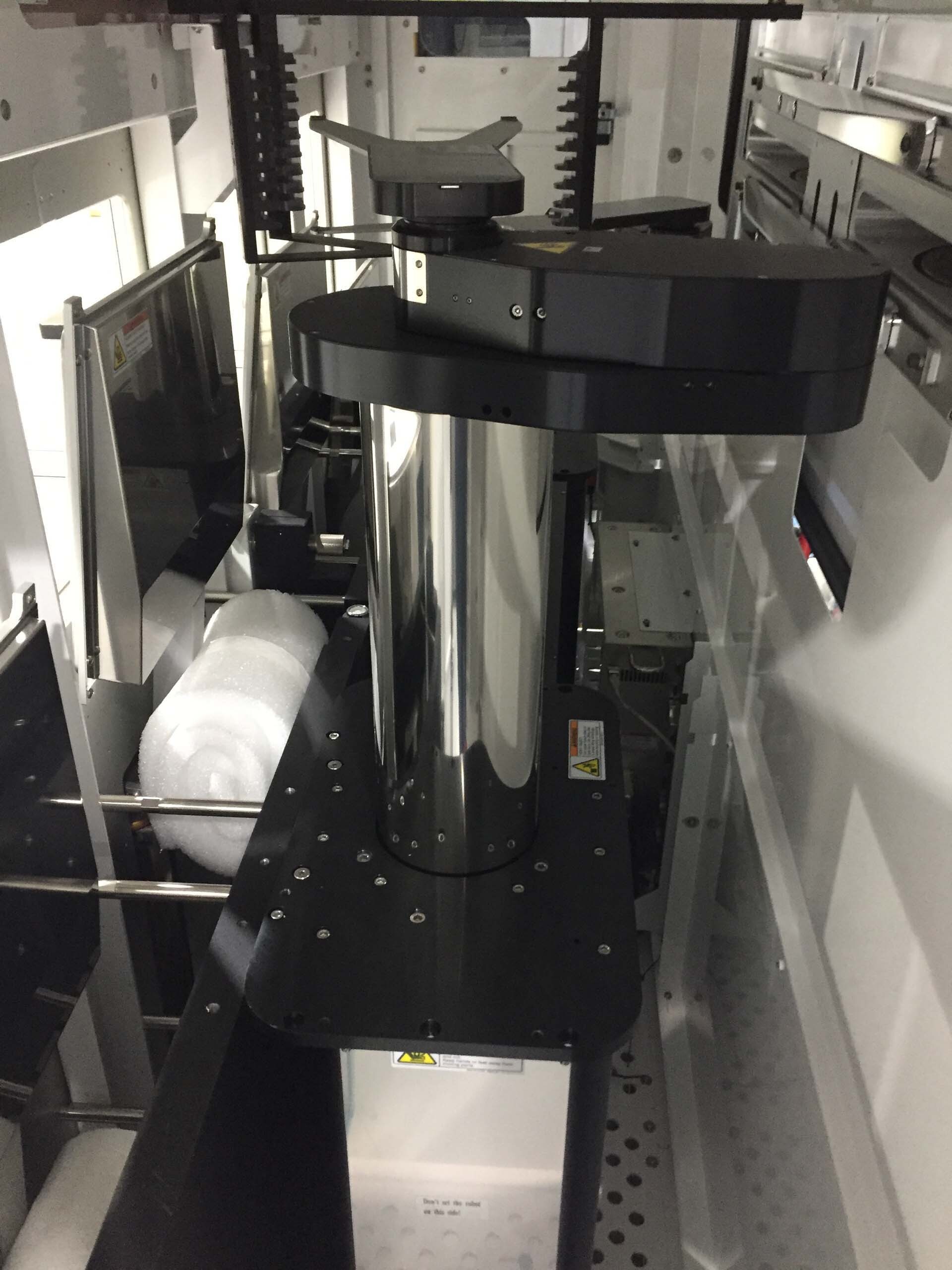

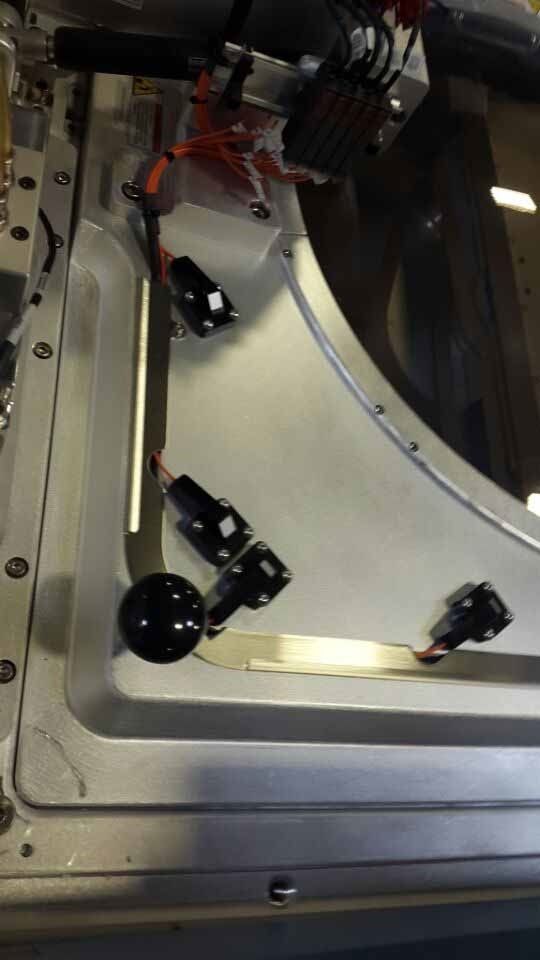

FI Robot type: KAWASAKI Track

FI Robot blade type: Aluminum

LCF

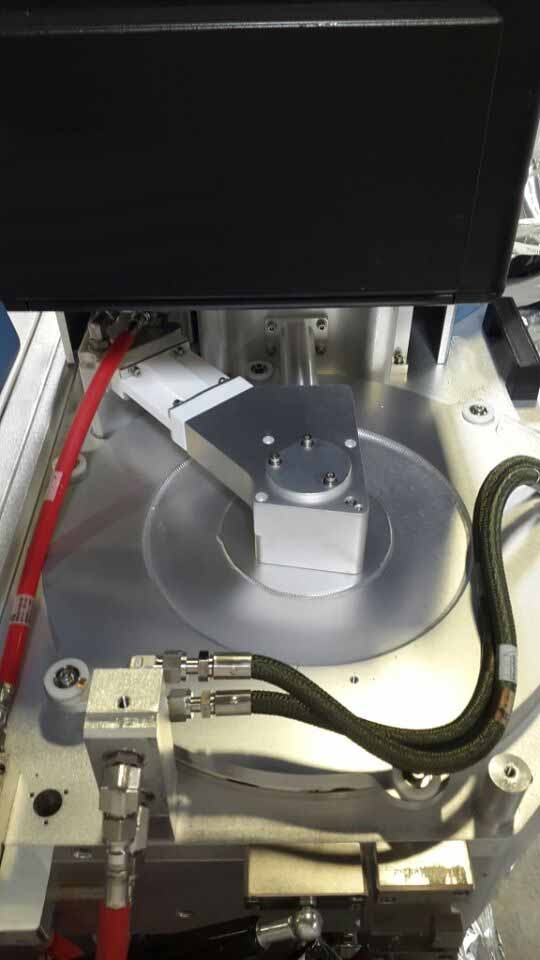

Buffer robot type: GT

Buffer robot blade type: Ceramic

(2) Roll around monitors

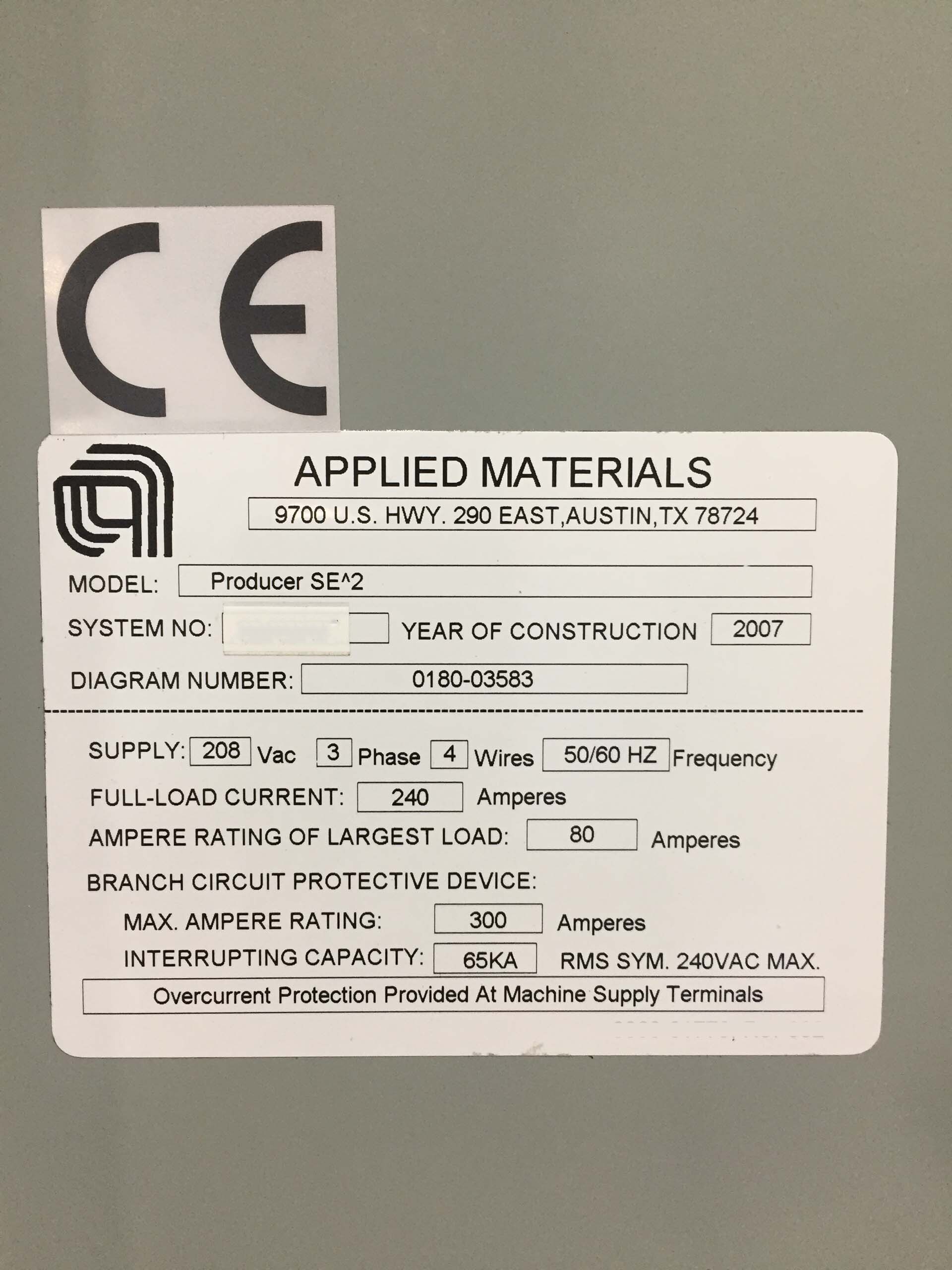

Remote AC: 208 V

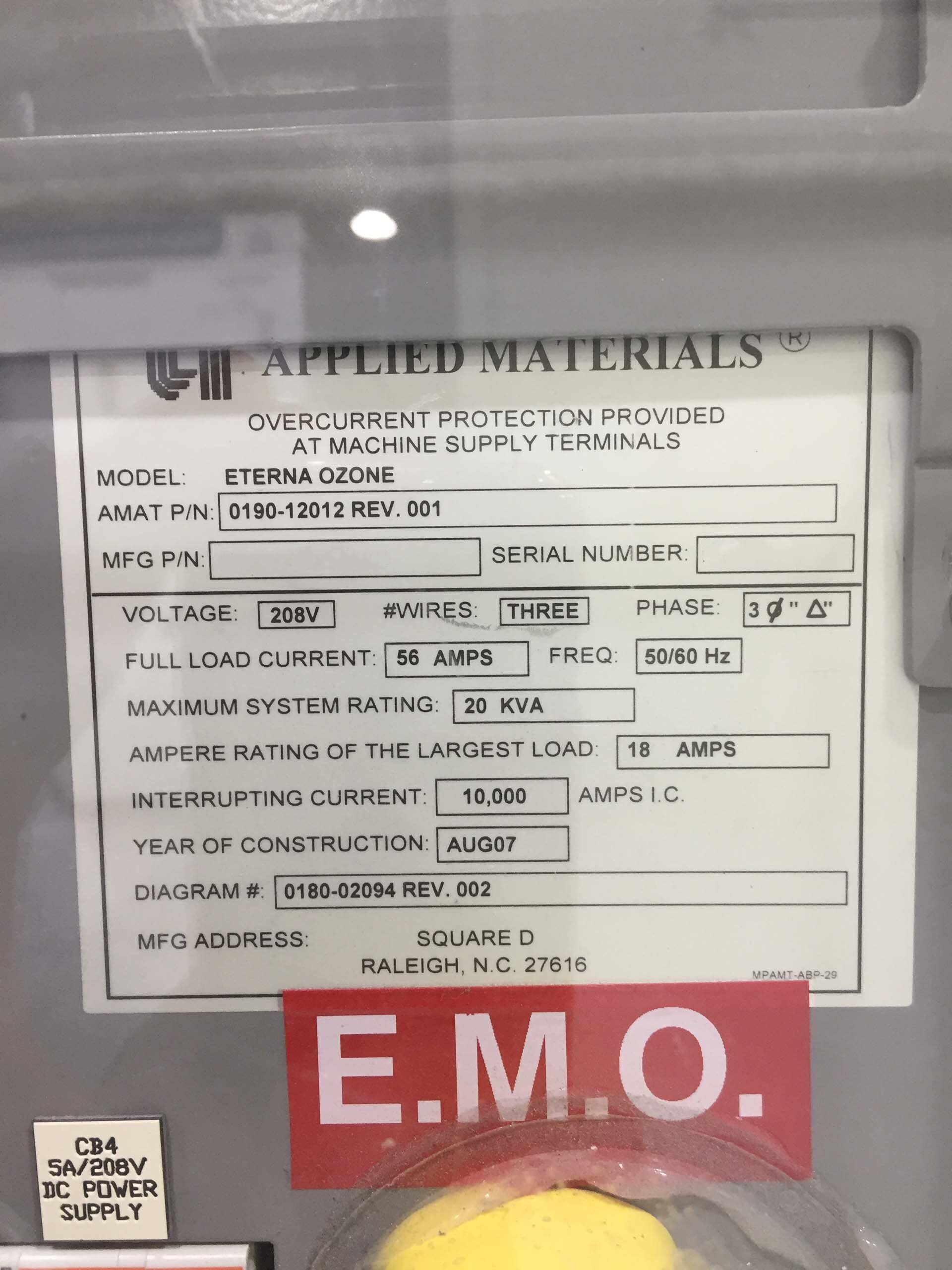

Ozone cabinet: INUSA

Heat exchanger 1: UNISEM

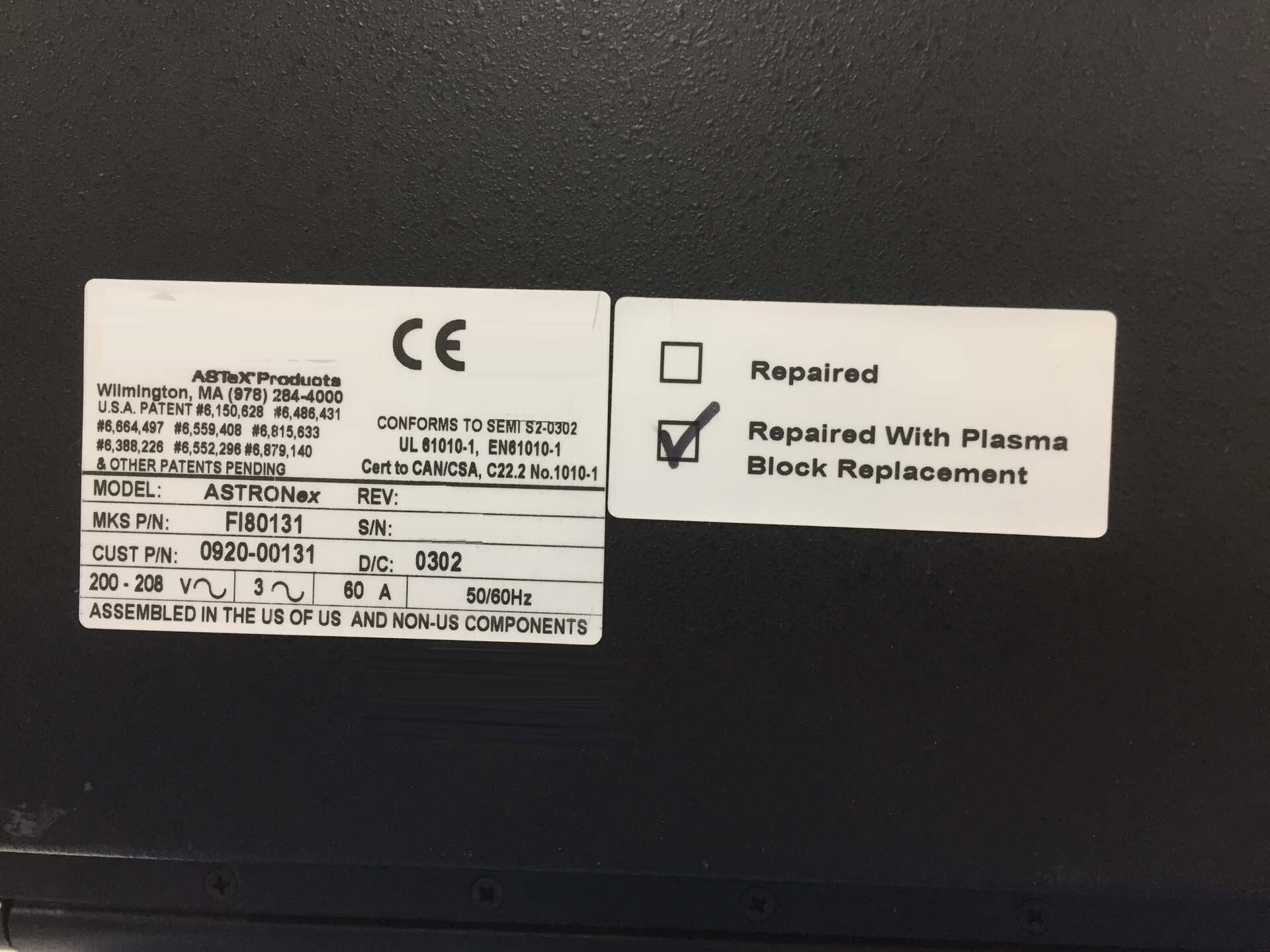

(3) MKS Ozone generators

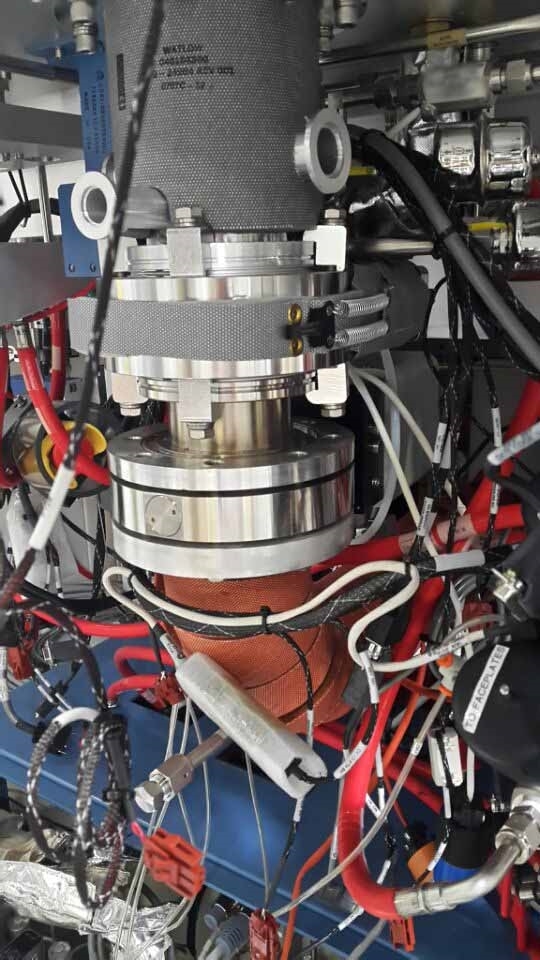

Chamber A, B and C:

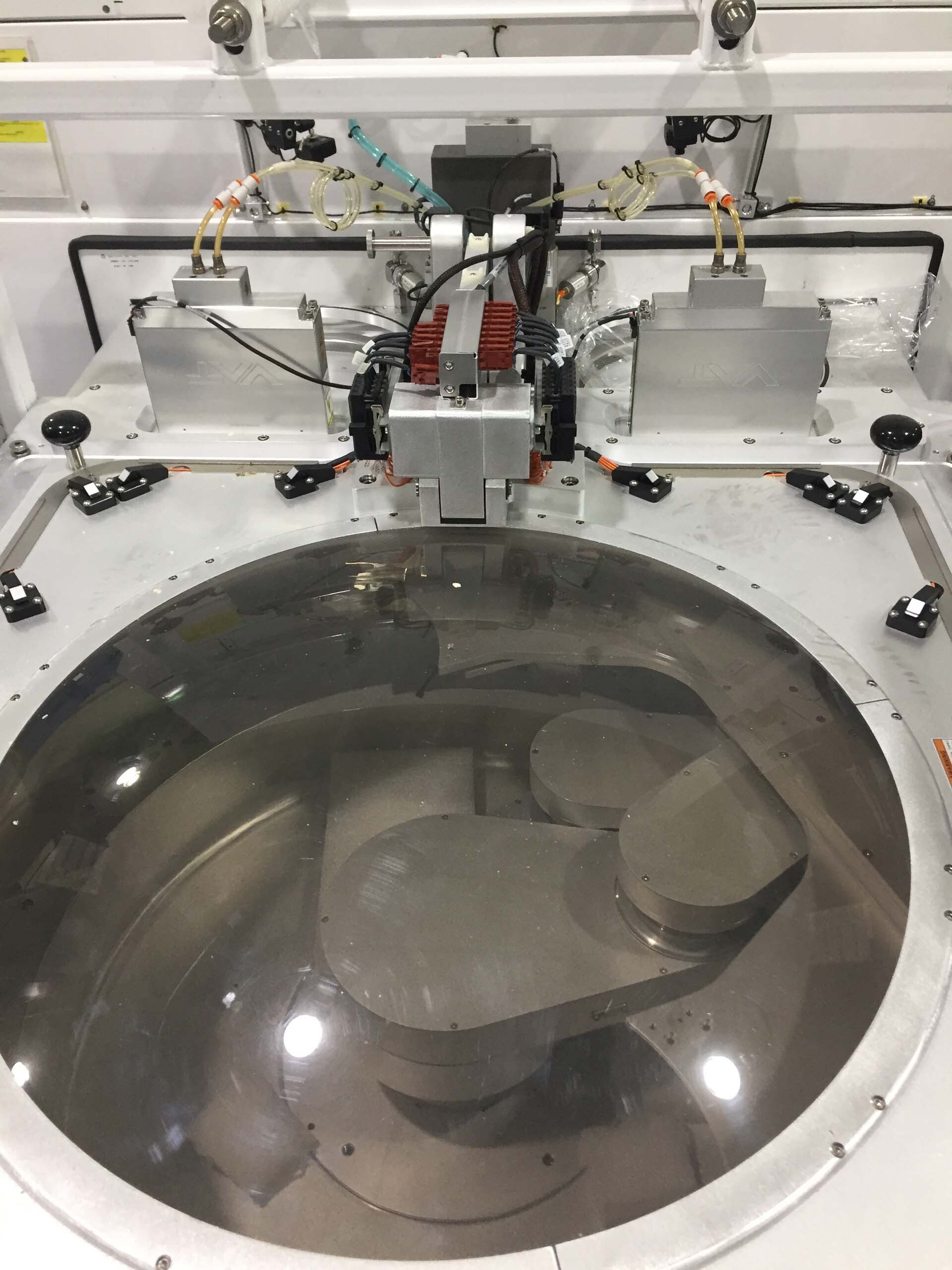

Type: SACVD Twin

Process: HARP USG

RPS Type: 6 Litres

Heater type: Vacuum chuck

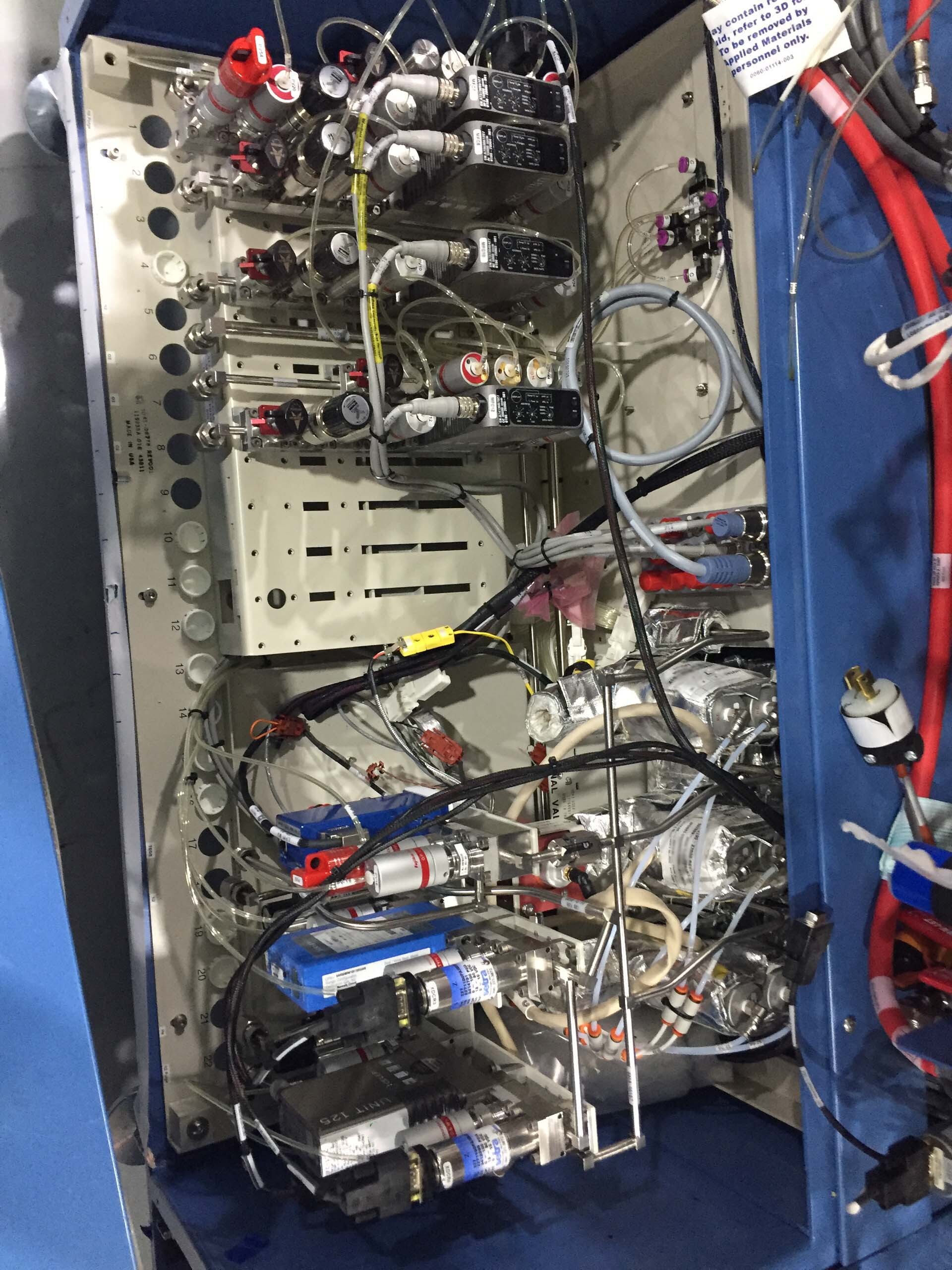

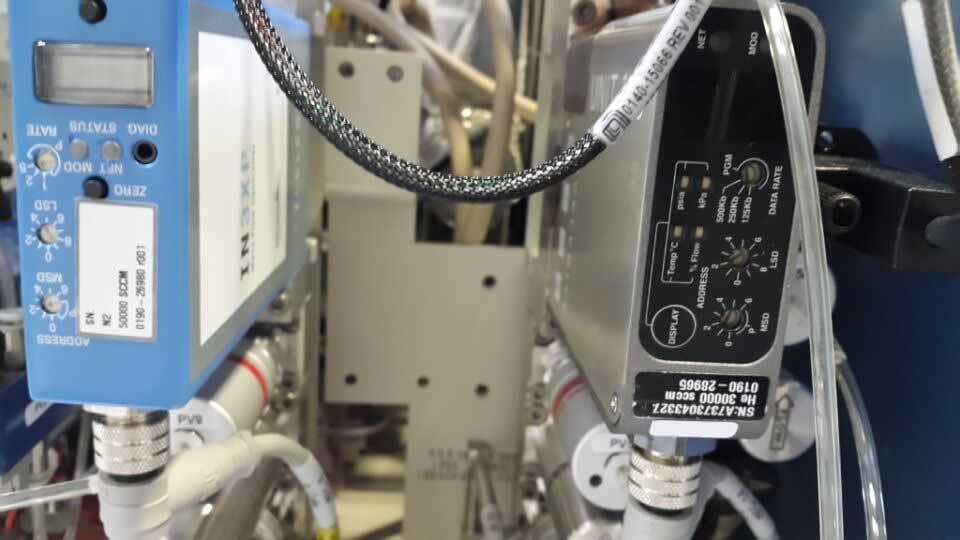

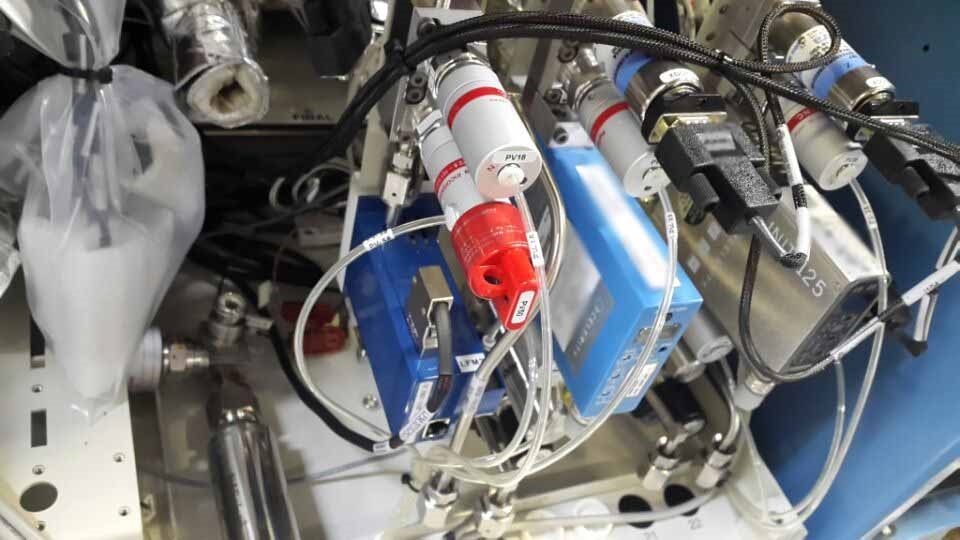

Gas panel configurations:

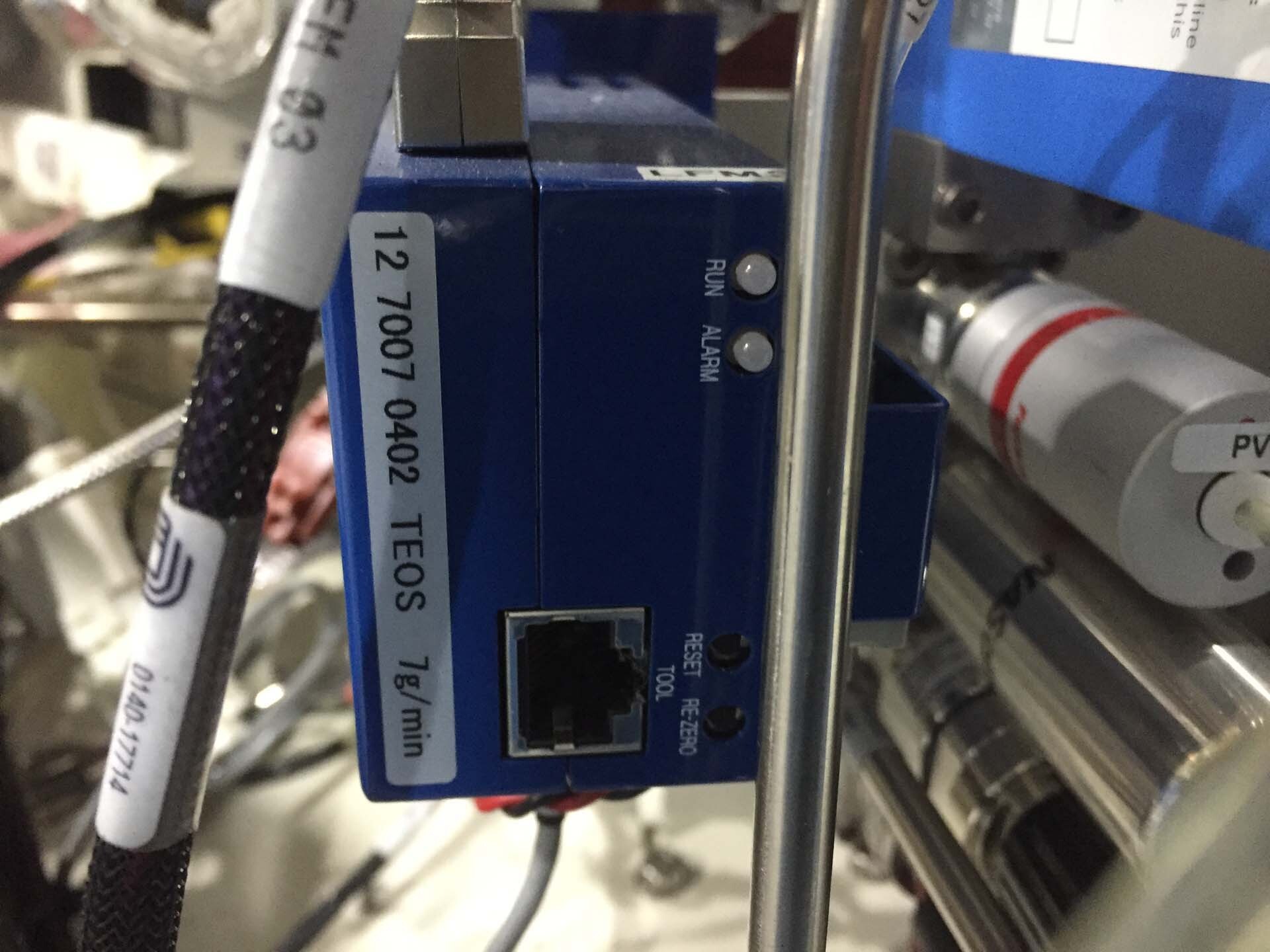

Gas box type / 1-1/8 C-Seal surfacemount

Stick 1 / NF3 - 15000 sccm

Stick 2 / AR - 15000 sccm

Stick 3 / N2 - 5000s ccm

Stick 4 / N2 - 50000 sccm

Stick 5 / He - 30000 sccm

Liquid 1 / TEOS - 7 g/min

2008 vintage.

AMAT / APPLIED MATERIALS Producer GT is a thermal chemical vapor deposition (CVD) thin film deposition reactor, typically used in the semiconductor industry for the deposition of various layers of material onto wafers, such as oxides, polysilicon, and metals. The tool utilizes a cold-wall quartz process chamber to control the temperature of the deposition environment, and a gas inject equipment to disperse the reactant gases into the reaction chamber. The system consists of four main components: the process chamber, the gas inject unit, the wafer transport machine, and the power tool. The process chamber is a large vacuum chamber with a HEPA filtration asset that helps to filter out airborne particles. It also contains a quartz tube, which helps to keep the process temperature regulated. The gas injection model is responsible for providing the precise amount of reactant gases and controlling the rate of introduction into the process chamber. The wafer transport equipment is responsible for loading the wafers into the process chamber, and for moving the wafers within the chamber. The system is designed with a maximum per-wafer throughput of 200 wafers per hour. Finally, a computer-controlled power unit is responsible for controlling the power level to the process chamber. This is important, as different films require different power levels in order to provide the correct deposition. The machine also features an automatic power compensation, which helps maintain a more consistent deposition for different materials. In conclusion, AMAT Producer GT is a complex CVD tool for thin film deposition in the semiconductor industry. It features a number of different components that work together to enable precise deposition of a variety of films onto wafers. The tool is designed to deliver a maximum throughput of 200 wafers per hour, and is capable of automatically compensating for changes in power when different films are being deposited. This helps maintain a consistent and high-quality deposition.

There are no reviews yet