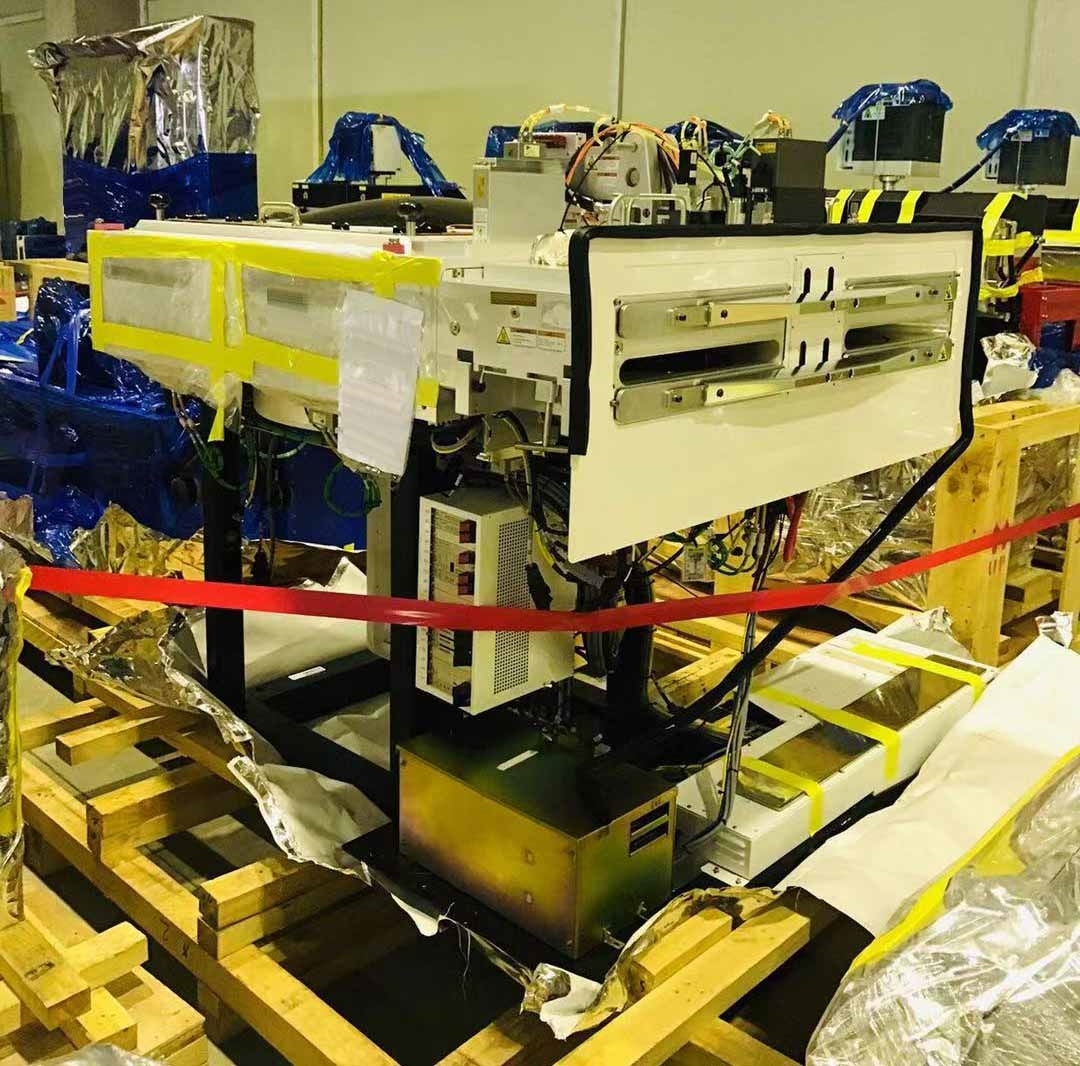

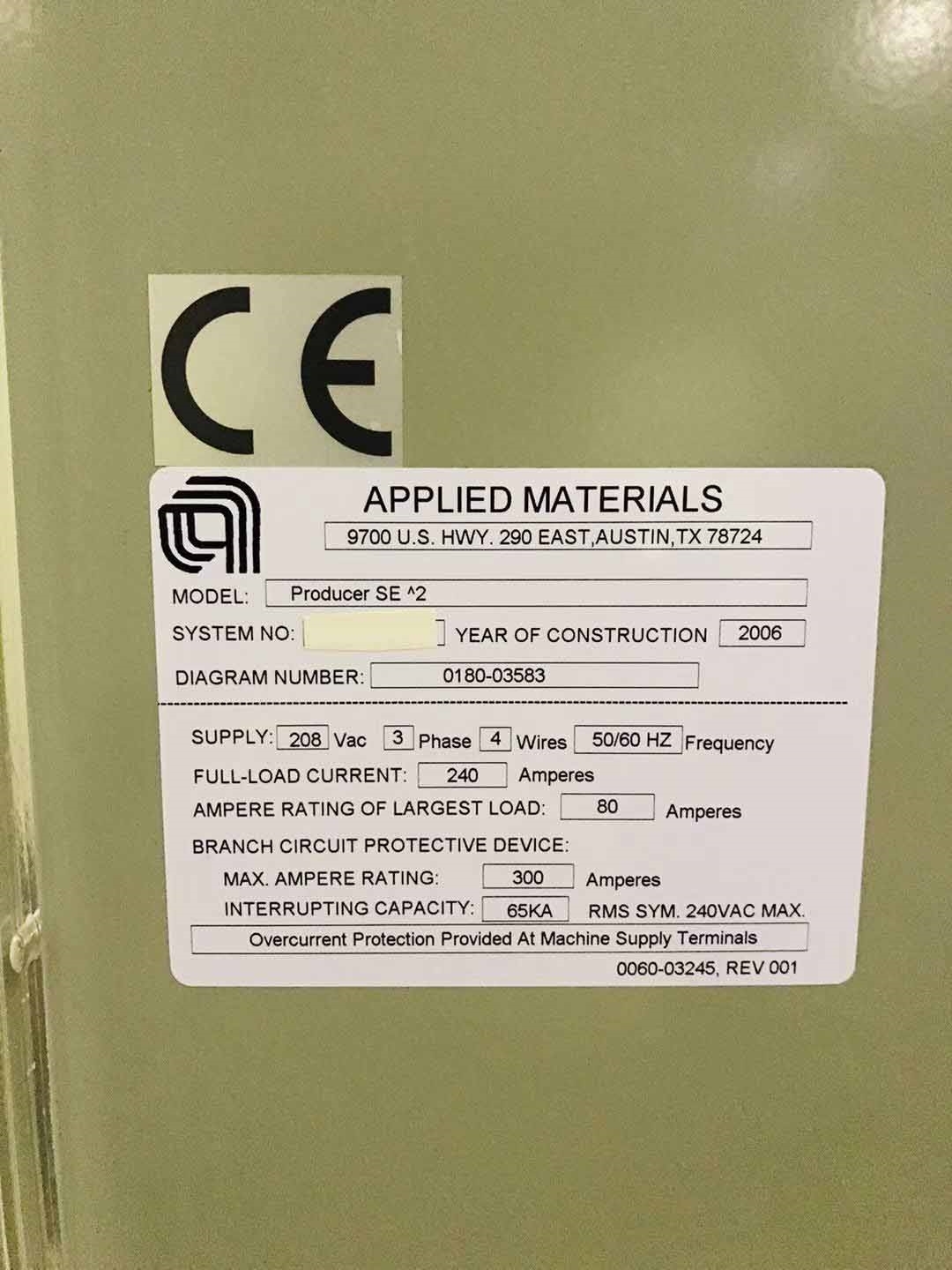

Used AMAT / APPLIED MATERIALS Producer GT #9265758 for sale

URL successfully copied!

Tap to zoom

ID: 9265758

Wafer Size: 12"

Vintage: 2006

CVD System, 12"

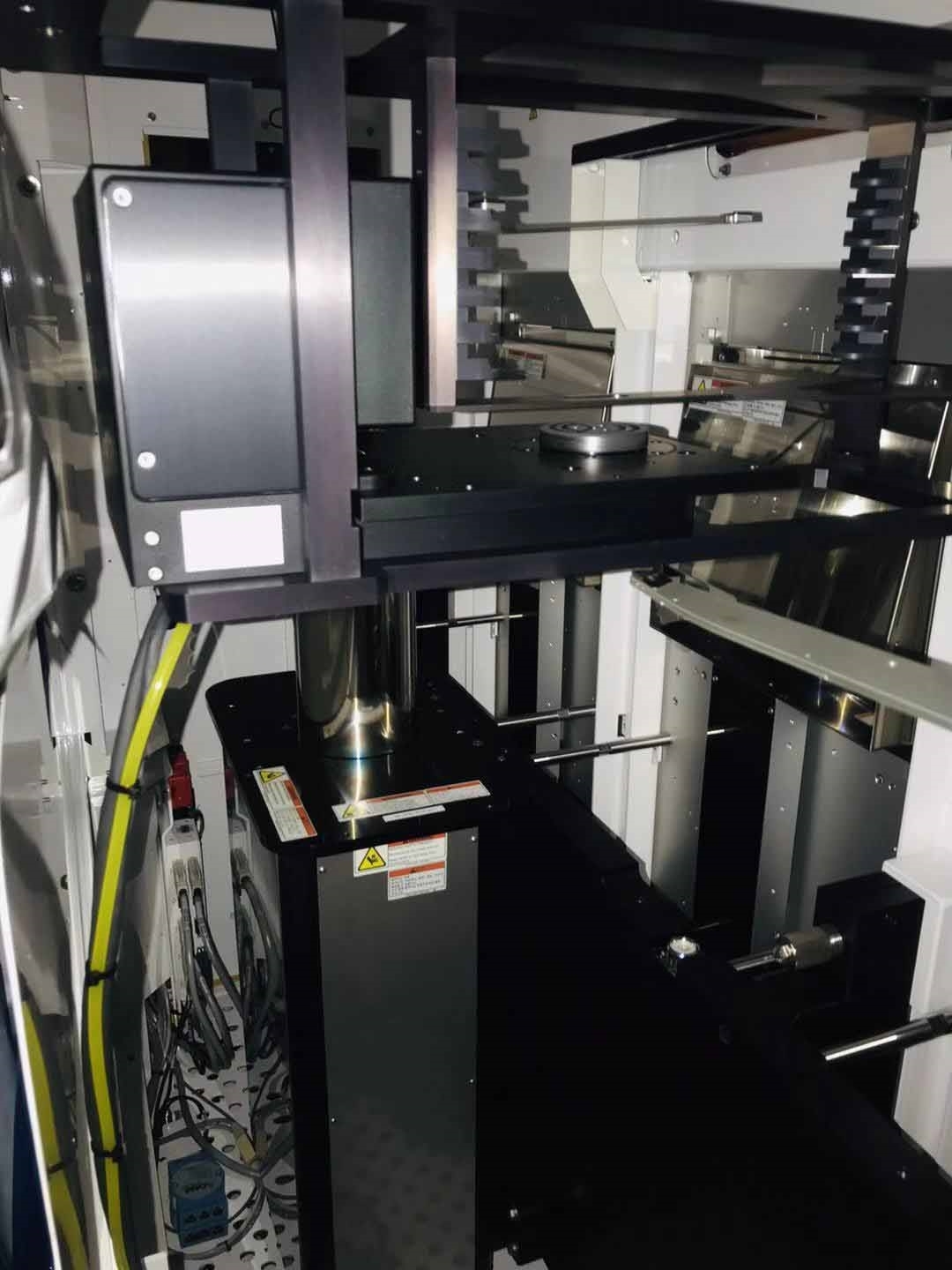

EFEM

Transfer module

AC Rack

NPP Rack

WIP Delivery type: OHT

Pre-alignment and centering: Single axis aligner

Wafer pass thru and storage: 7 Slots wafer pass thru

KAWASAKI 3NS510B Atmospheric robots

(4) Load ports

E84 Sensors and cables

OMRON With RF

Light curtain

Carrier ID host interface

Light towers

UPS Interface

Chamber process: HARP USG

Process chamber type:

Chamber A, B and C Twin: HT-ACL

Local center finder

Robot blade and type: FX Dual deck ceramic

Chamber A, B and C:

Frequency: Single

APEX 3000 RF Generator

Heater: HA12 Dual zone heater

Single source with RF cap

Manometer: 10 / 100 Torr / 70 Trip

Clean type (RPS): Single (NPR804L)

No NDTR endpoint

No DPA

Foreline, 2"

ISO: MKS 99D0654

TV: MKS 683B-26033

Monitors:

Stand alone

TTW With keyboard

Gas delivery - APF GP:

MFC:

UNIT 125

GF 125

No regulated gas panel

Gas feed: Bottom

Gas panel cabinet exhaust: Bottom exhaust

No interlock indicator

No transducers

No display gas pallet

No liquid source

Gas pallet configuration:

Chamber A:

Gas / Size / Model

AR / 4000 / Unit 125

O2 / 15000 / Unit 125

C3H6 / 3000 / GF 125

HE / 5000 / Unit 125

N2 / 10000 / Unit 125

C3H6 / 3000 / Unit 125

O2 / 10000 / Unit 125

AR / 10000 / Unit 125

NF3 / 5000 / Unit 125

Chamber B and C:

Gas / Size / Model

AR / 4000 / Unit 125

O2 / 15000 / Unit 125

C3H6 / 3000 / Unit 125

HE / 5000 / Unit 125

N2 / 10000 / Unit 125

C3H6 / 3000 / Unit 125

O2 / 10000 / Unit 125

AR / 10000 / Unit 125

NF3 / 5000 / Unit 125

Missing parts:

A1 RF Signal cable

L/L EUROTHERM controller

(2) PIRANI Gauges

Chamber C: (2) Heaters

(2) L/L Lift LM guides

Upper L/L foreline

(3) Chamber AC box kits

Mainframe box

Driver box kit

Power supply: 208 V, 50/60 Hz

2006 vintage.

AMAT (APPLIED MATERIALS) AMAT / APPLIED MATERIALS Producer GT is a high-temperature chemical vapor deposition (CVD) reactor designed to meet the needs of the semiconductor industry. The reactor enables a number of processes such as oxidation, nitridation, and carbidization. AMAT Producer GT is available in either a single wafer configuration or a batch configuration and is designed for long-term stability and reliability. The reactor utilizes an proven, forced-flow gas delivery equipment, which is capable of producing uniform temperature and concentration profiles inside the reactor chamber. This ensures consistent film quality and a very uniform doping profile. The reactor is equipped with robust air-cooled heaters and a state-of-the-art temperature control system for improved process uniformity. The heating elements in the reactor use an active water jacket to ensure temperature uniformity at the wafer surface. This prevents overheating of the wafer and ensures a more uniform deposition. The reactor is constructed of stainless steel and features a vacuum chamber, a batch plate, a gas delivery unit, and an induction generator. The reactor utilizes a high capacity scroll pump for high vacuum and rapid control and cycling of the pressure levels. The chamber is insulated with quartz or graphite to reduce heat load losses. APPLIED MATERIALS Producer GT utilizes a high capacity, low power RF generator and RF power delivery machine for robust and reliable plasma generation. The temperature control tool is highly accurate and precise, enabling high quality, uniform deposition rates over a large range of flow rates, temperatures, and pressures. The reactor includes a wide range of process recipes for various materials and applications, as well as customization of the flow routes and valve selections. It is also available with an optional recipe library and computer control package for operating multiple reactors in suite. In summary, Producer GT is a highly reliable and efficient CVD reactor designed to deliver consistent film quality and uniform doping profile. Its robust air-cooled heaters and superior temperature control asset ensure uniform film properties and performance, while its wide range of process recipes enable it to be used for versatile applications.

There are no reviews yet