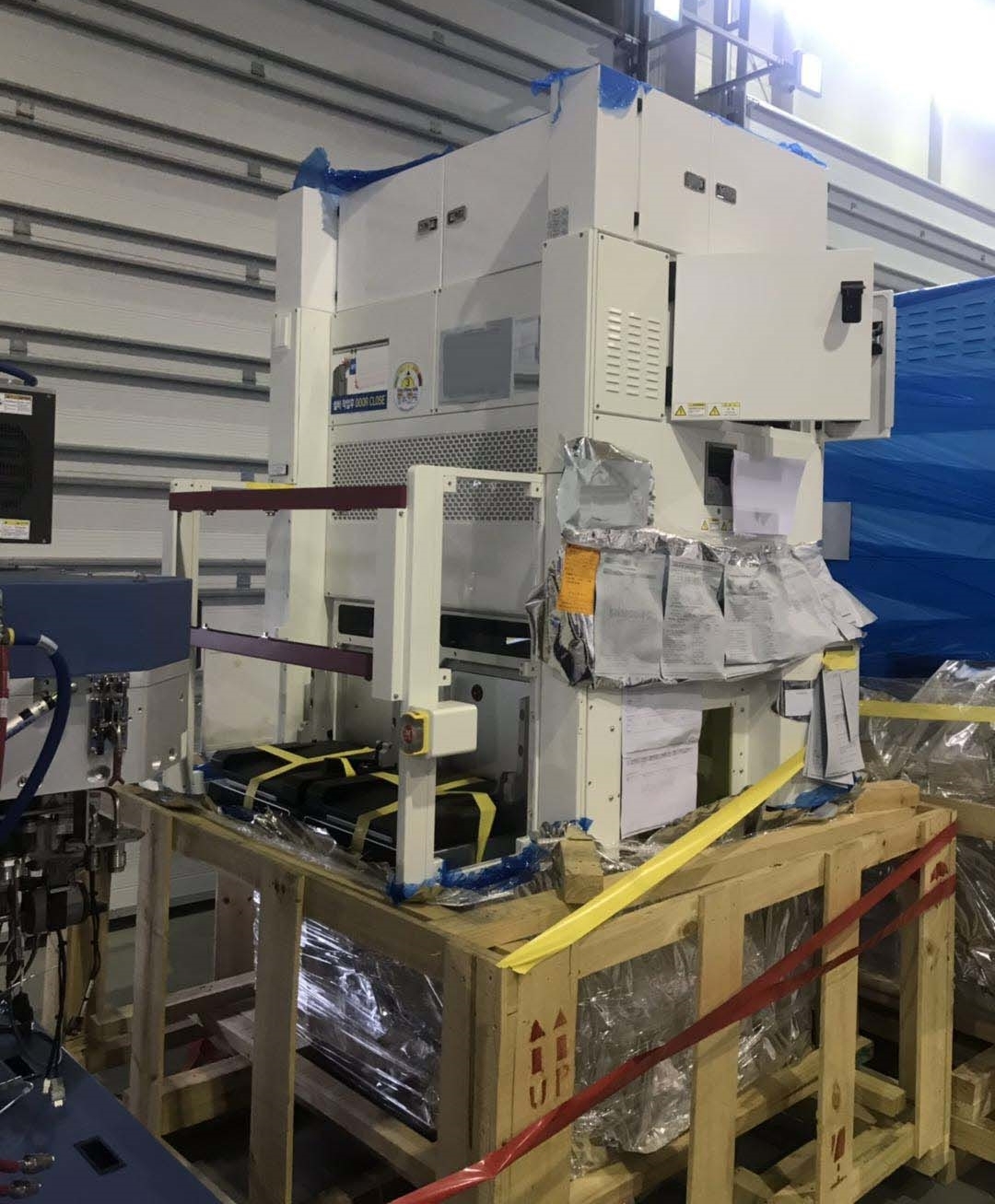

Used AMAT / APPLIED MATERIALS Producer GT #9275950 for sale

URL successfully copied!

Tap to zoom

ID: 9275950

Wafer Size: 12"

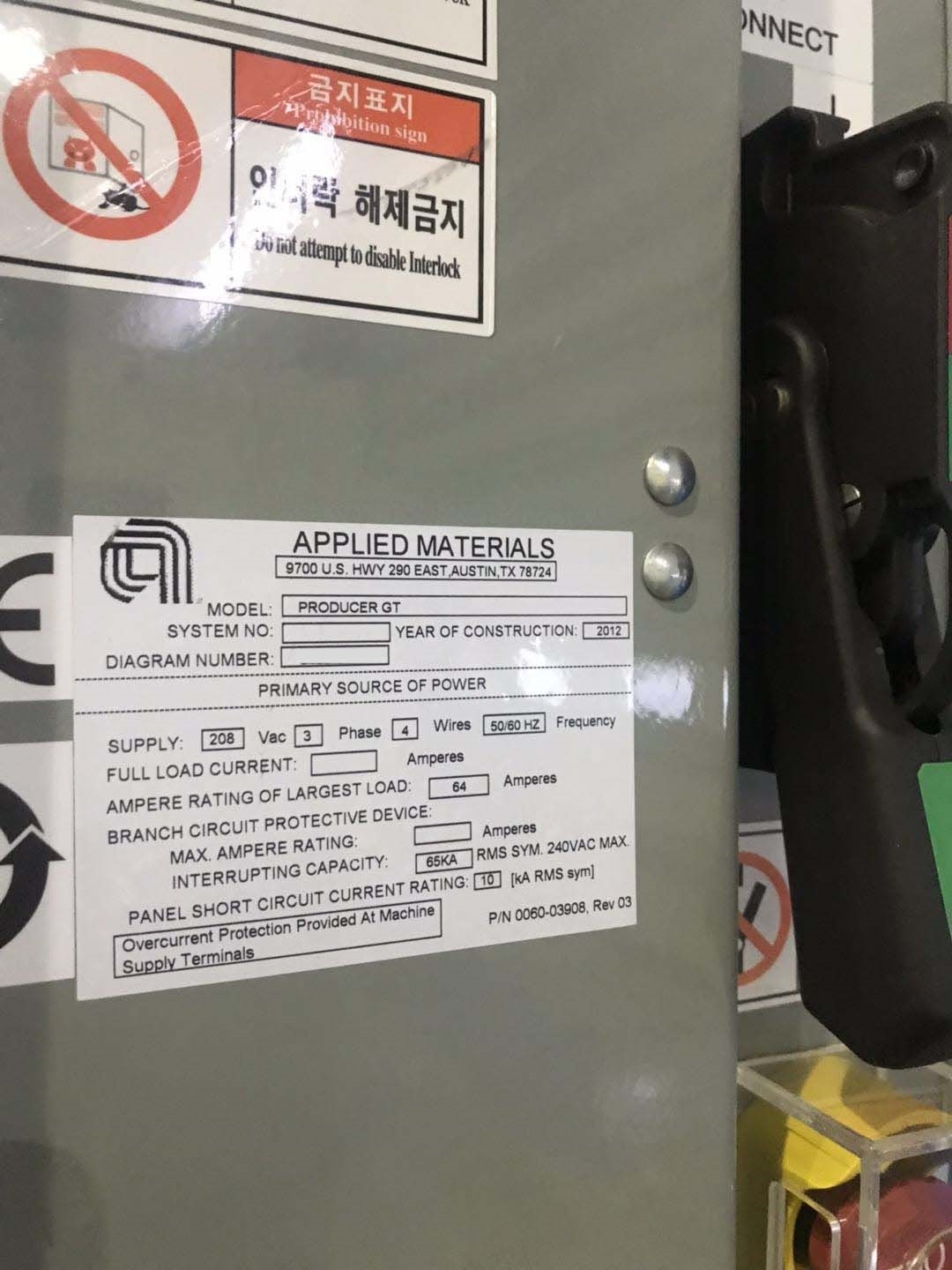

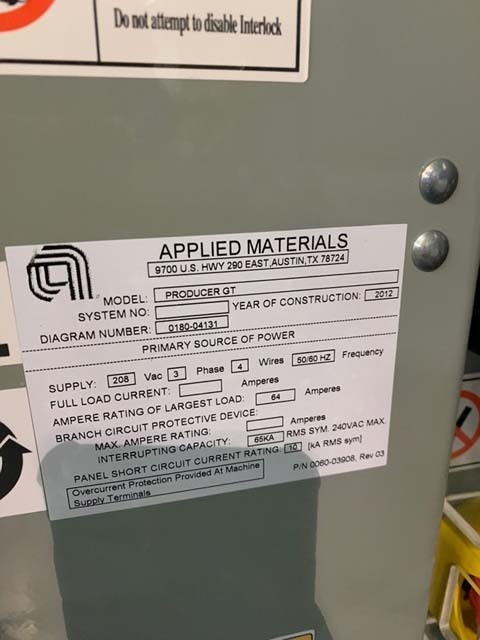

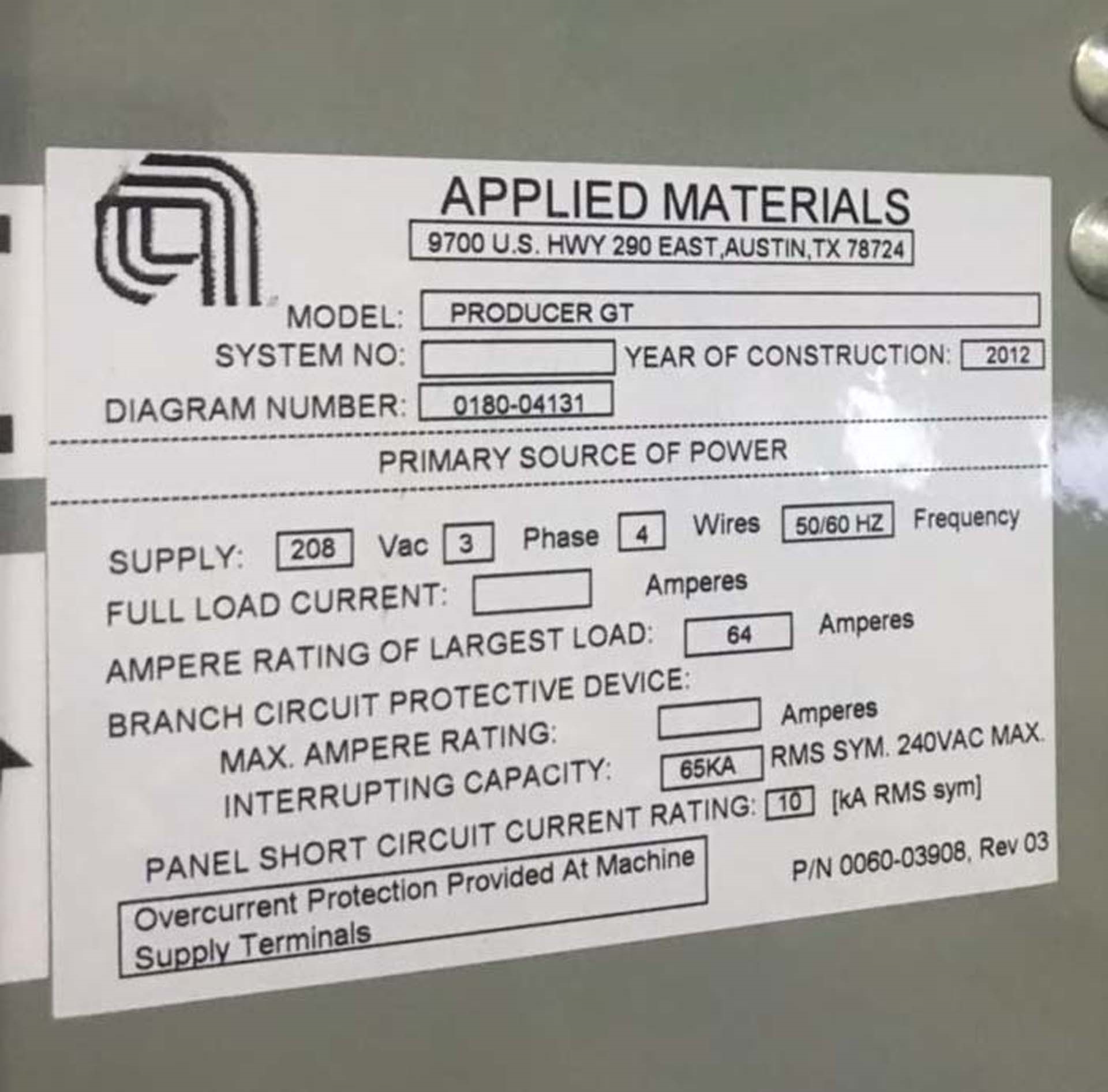

Vintage: 2012

System, 12"

EFEM

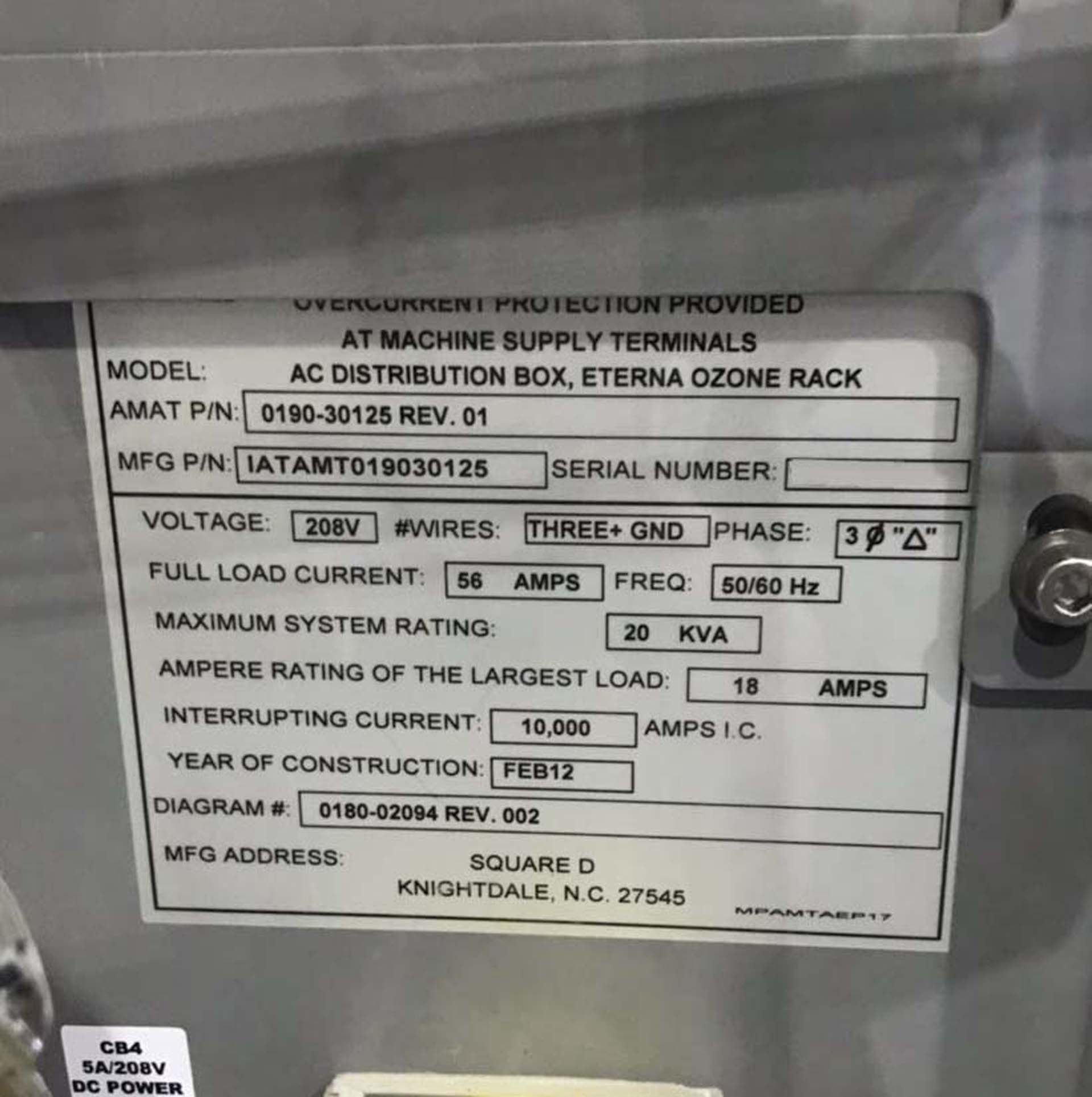

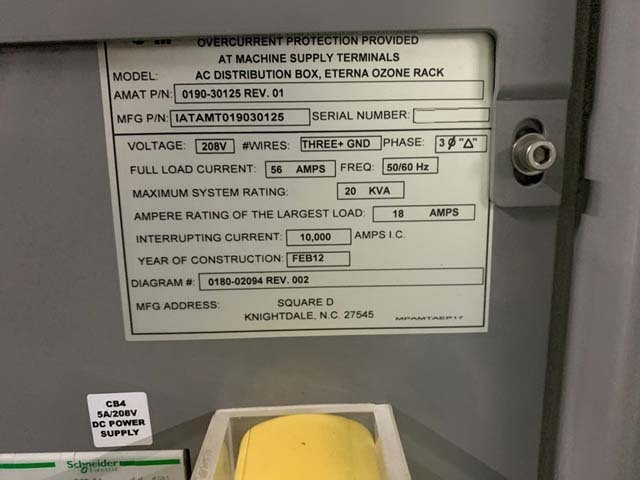

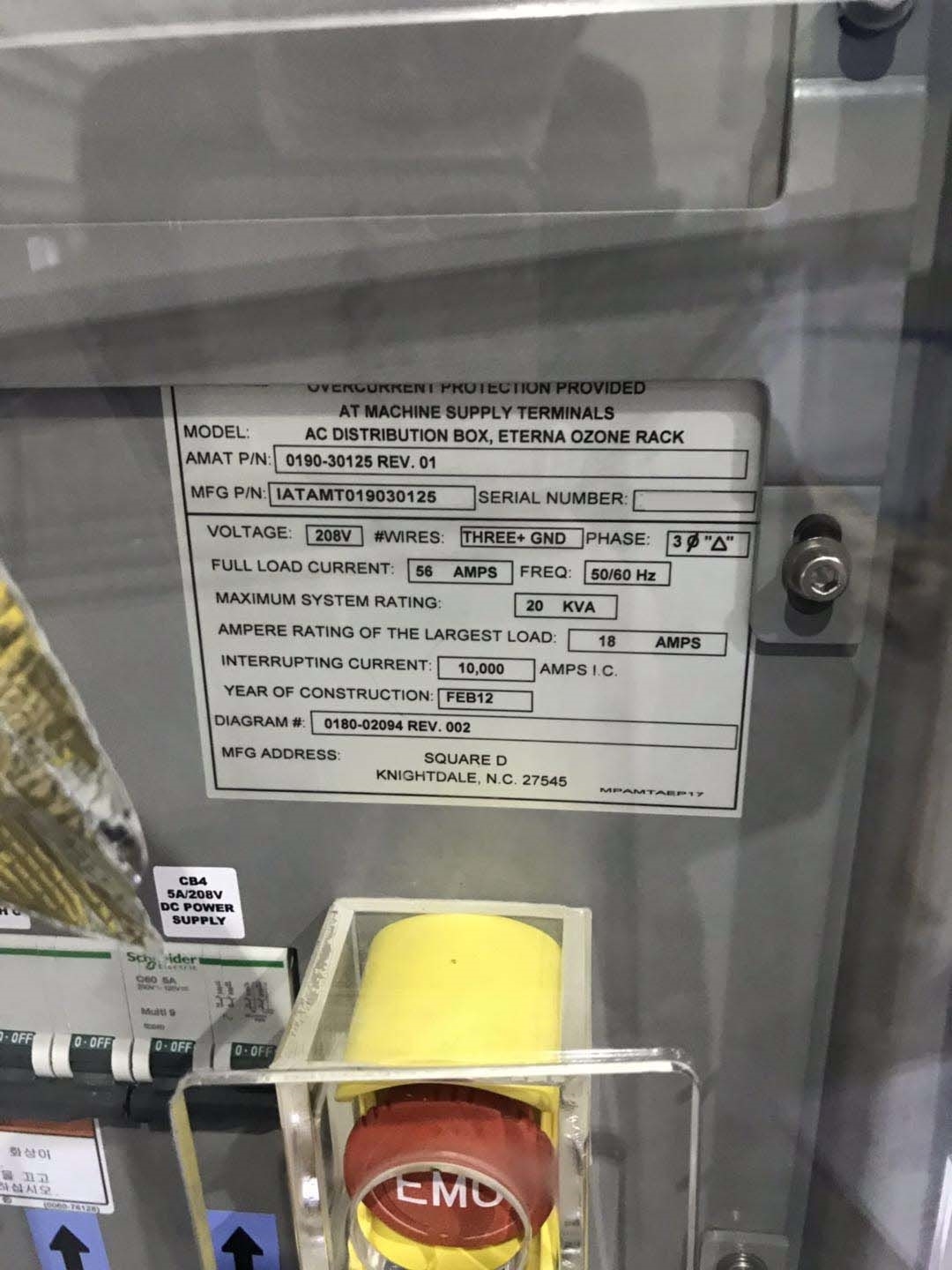

O3 Rack

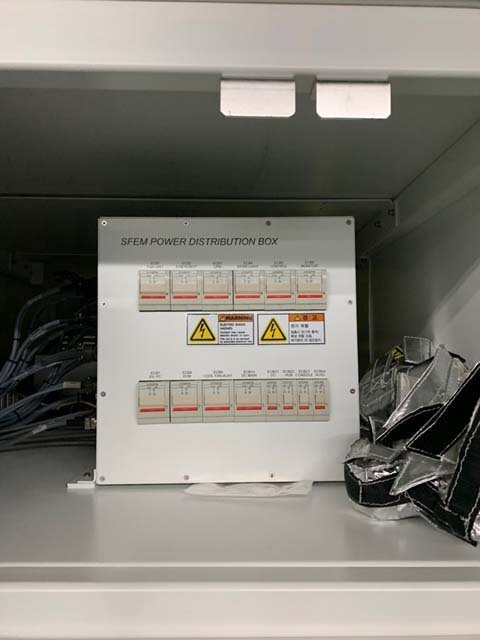

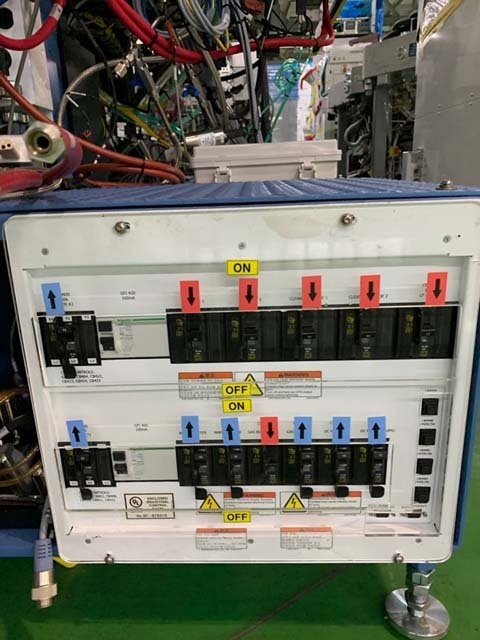

AC Rack

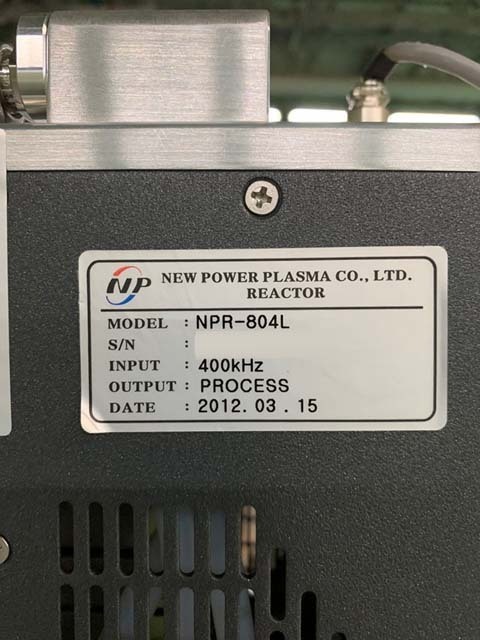

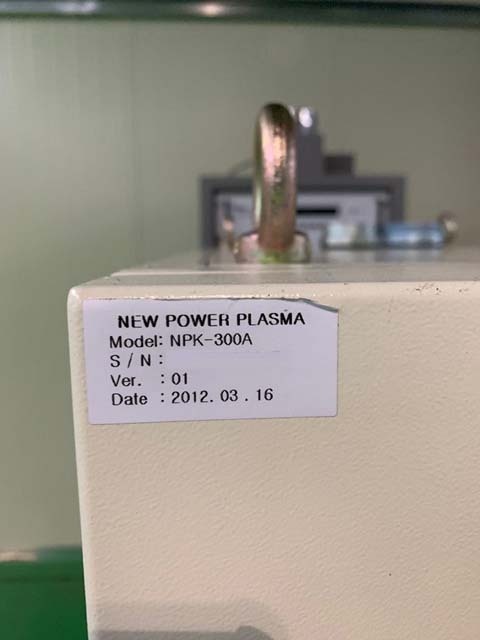

NPP Rack

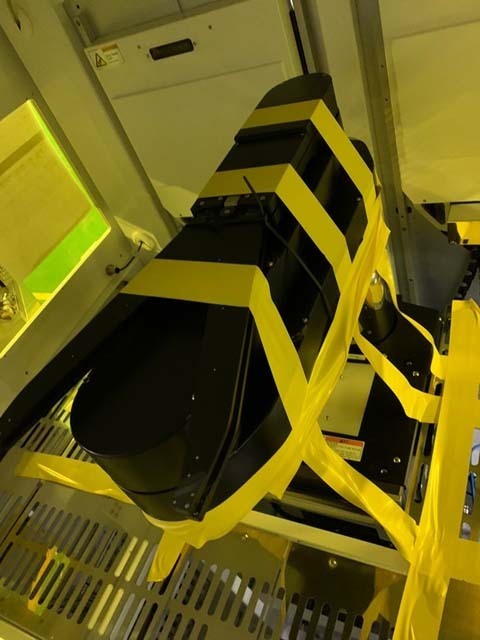

Main TM

HARP USG Chamber

Monitor

(3) Part boxes

(2) KAWASAKI 3NS510B Atmospheric robots

UPS Interface

Front Interface (FI):

(3) Part boxes

WIP Delivery type: OHT

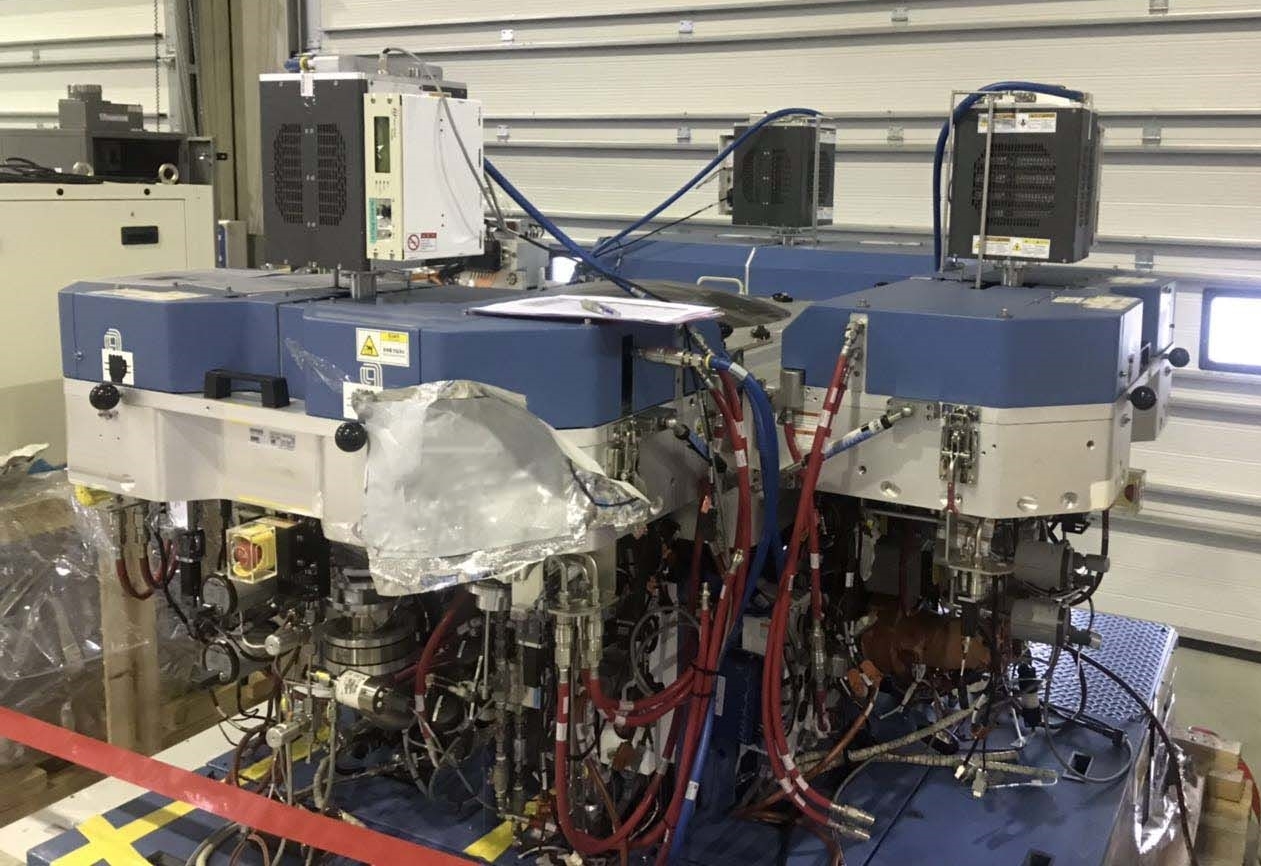

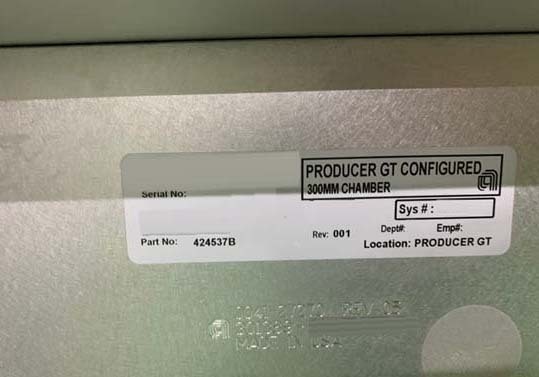

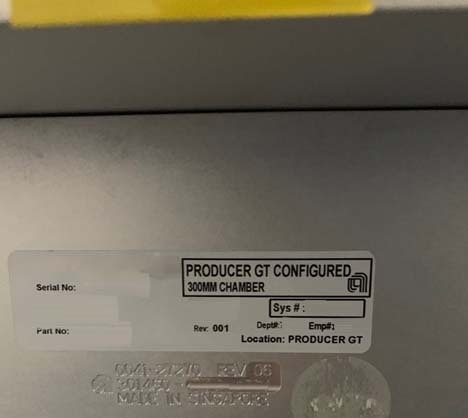

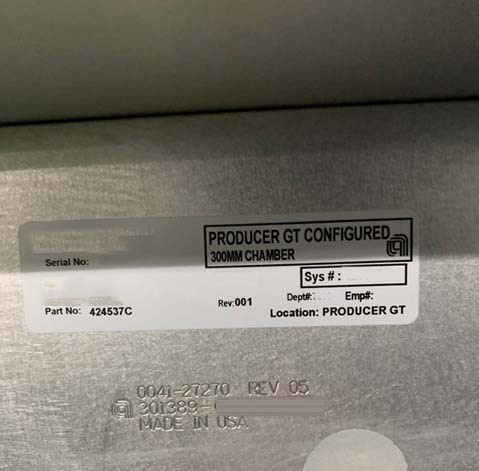

Chamber A, B and C twin: HARP USFG

Local center finder

Robot blade and type: FX Dual deck ceramic

Chamber A, B and C:

HA12 Dual zone heater

Face plate: Water cooled

Manometer: 20/1000 Torr

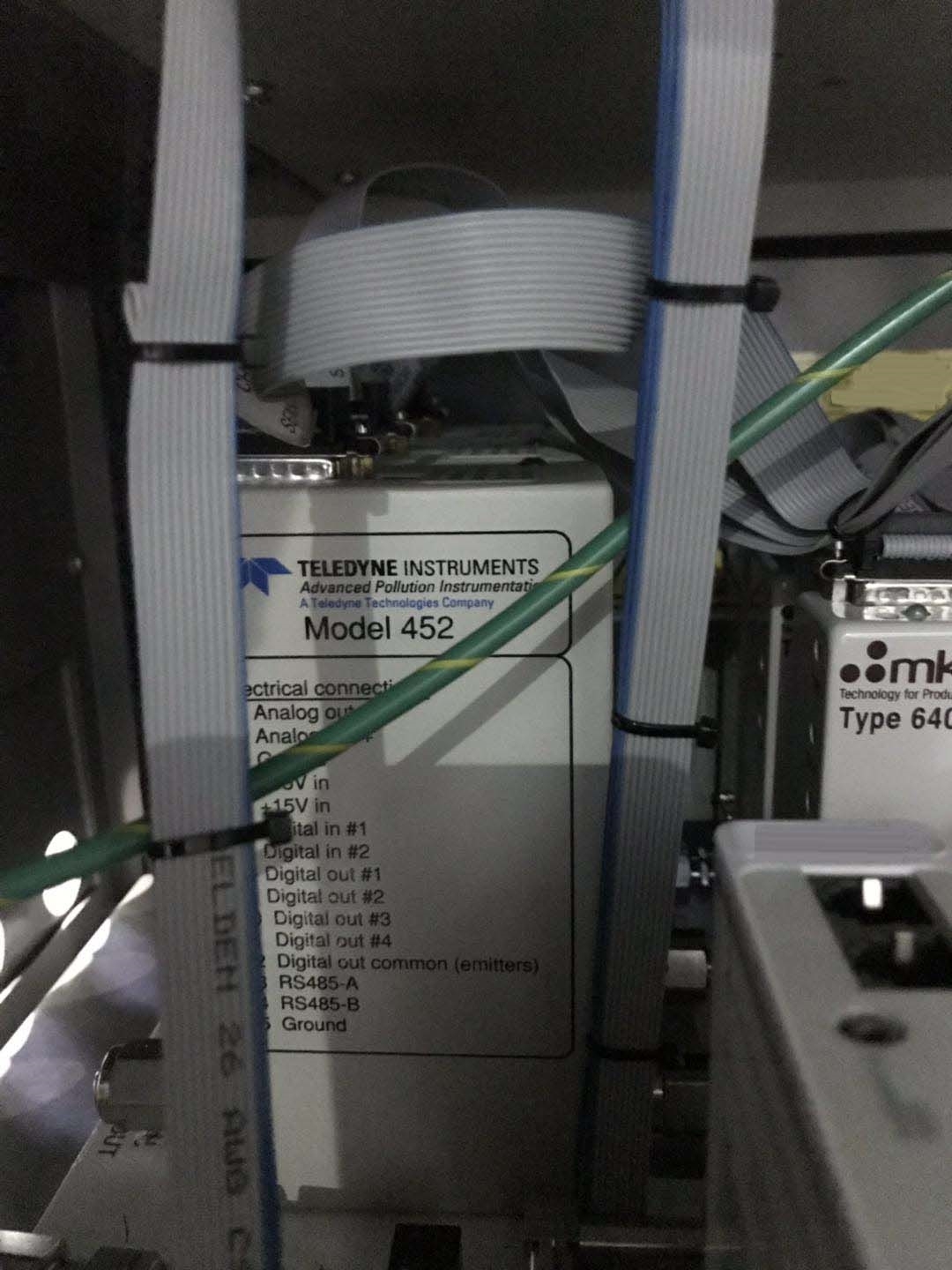

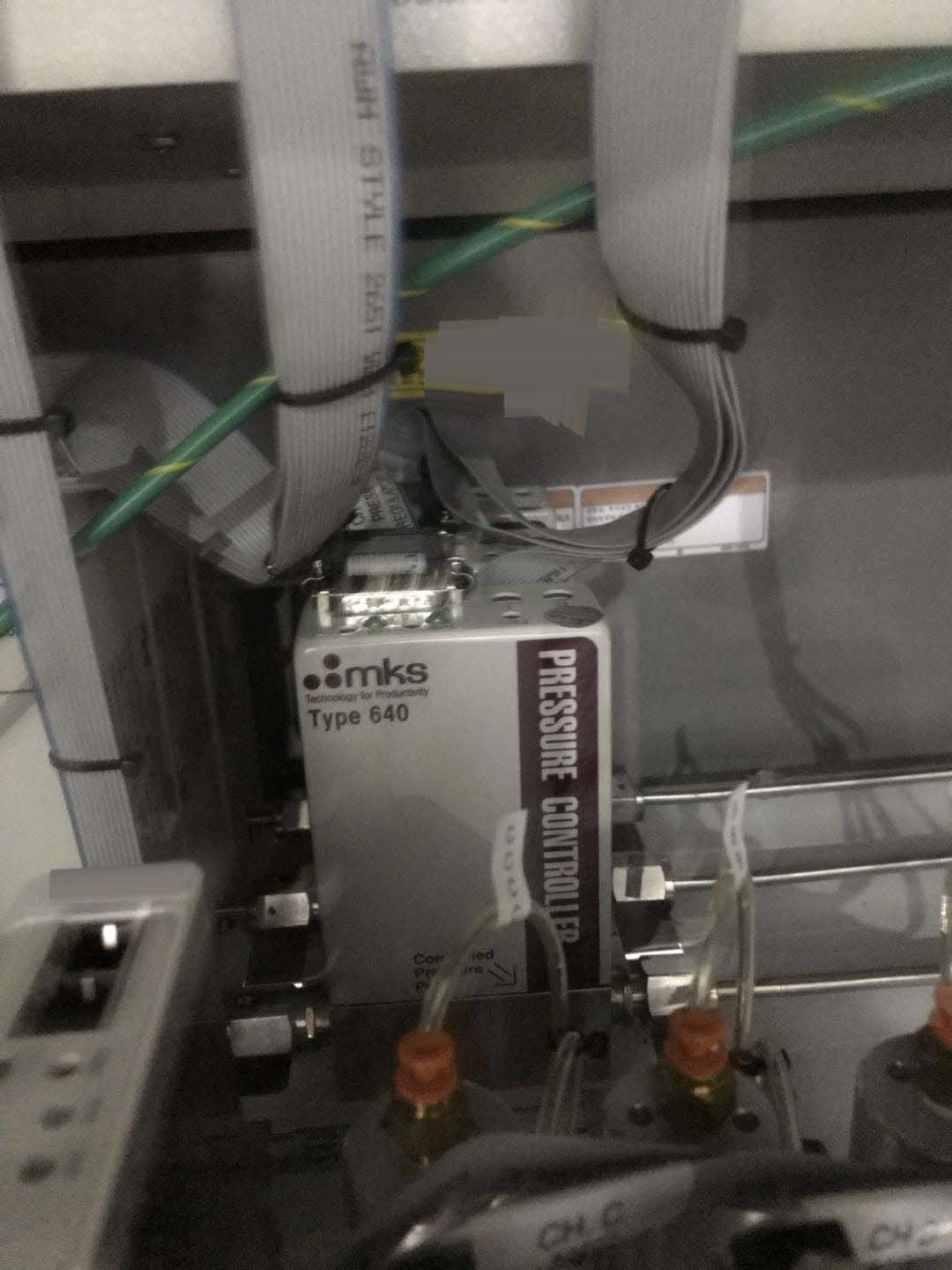

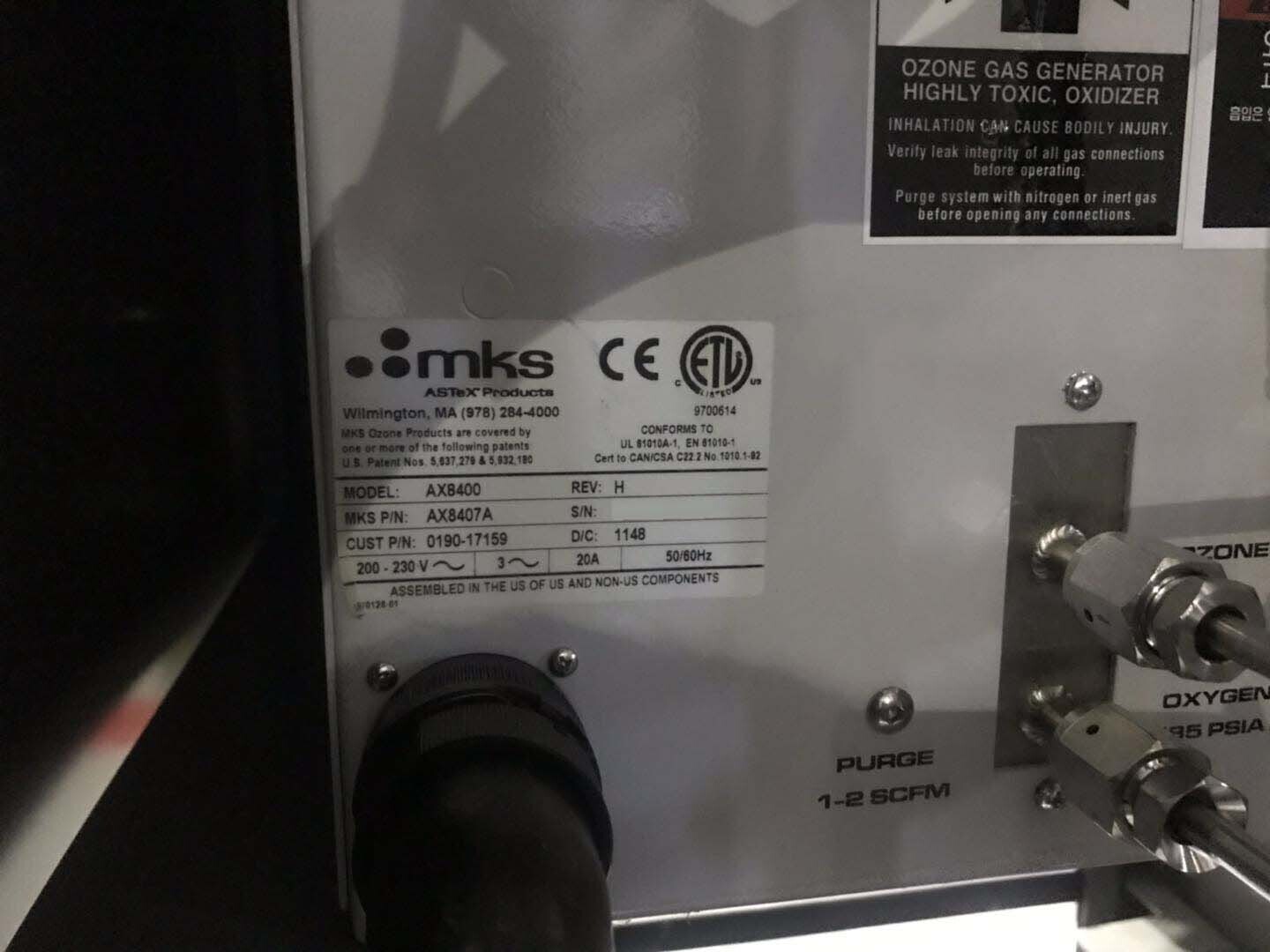

Clean type (RPS): MKS FI80133

No NDTR endpoint

No DPA

Foreline, 2"

ISO: NORCAL 021010-1

TV: MKS 683B-31931

Monitor: Stand alone

Chamber C: AX8407A Ozone generator

Ozone generator rack: Eterna

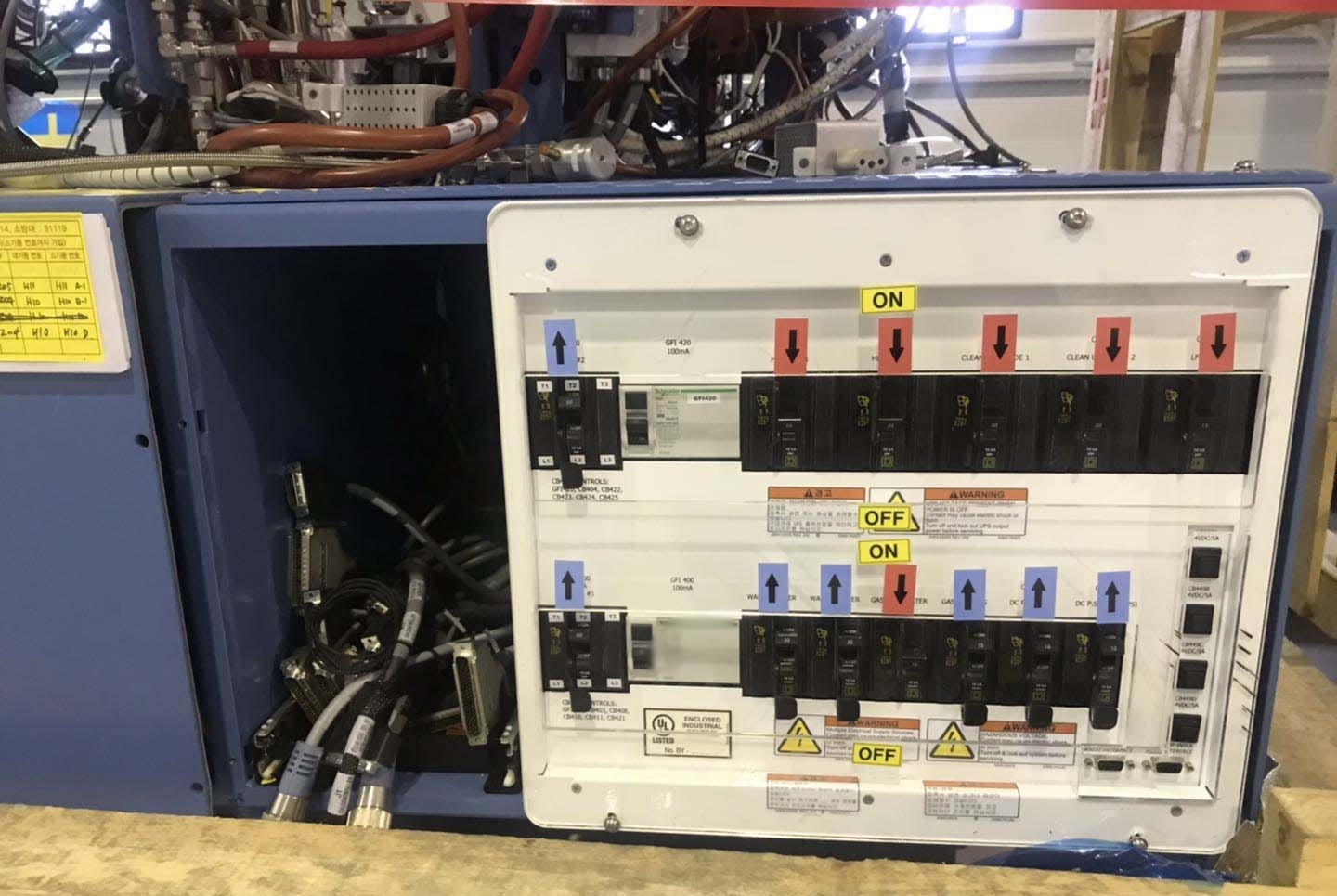

Gas delivery - APF GP:

MFC: GF 125

Gas feed: Bottom

Gas panel cabinet exhaust: Bottom exhaust

NIPPON Filters

Manual valves: FUJIKIN

Pneumatic valves: FUJIKIN

Liquid source

No regulated gas panel

No interlock indicator

No transducers

No display gas pallet

Gas pallet configuration:

Chamber A, B and C:

MFC: N2-Purge

Gas / Size

NF3 / 15000

AR / 15000

N2 / 5000

O2 / 30000

HE / 30000

N2 / 50000

LFM: STEC

TEOS: 7g

Spare parts included

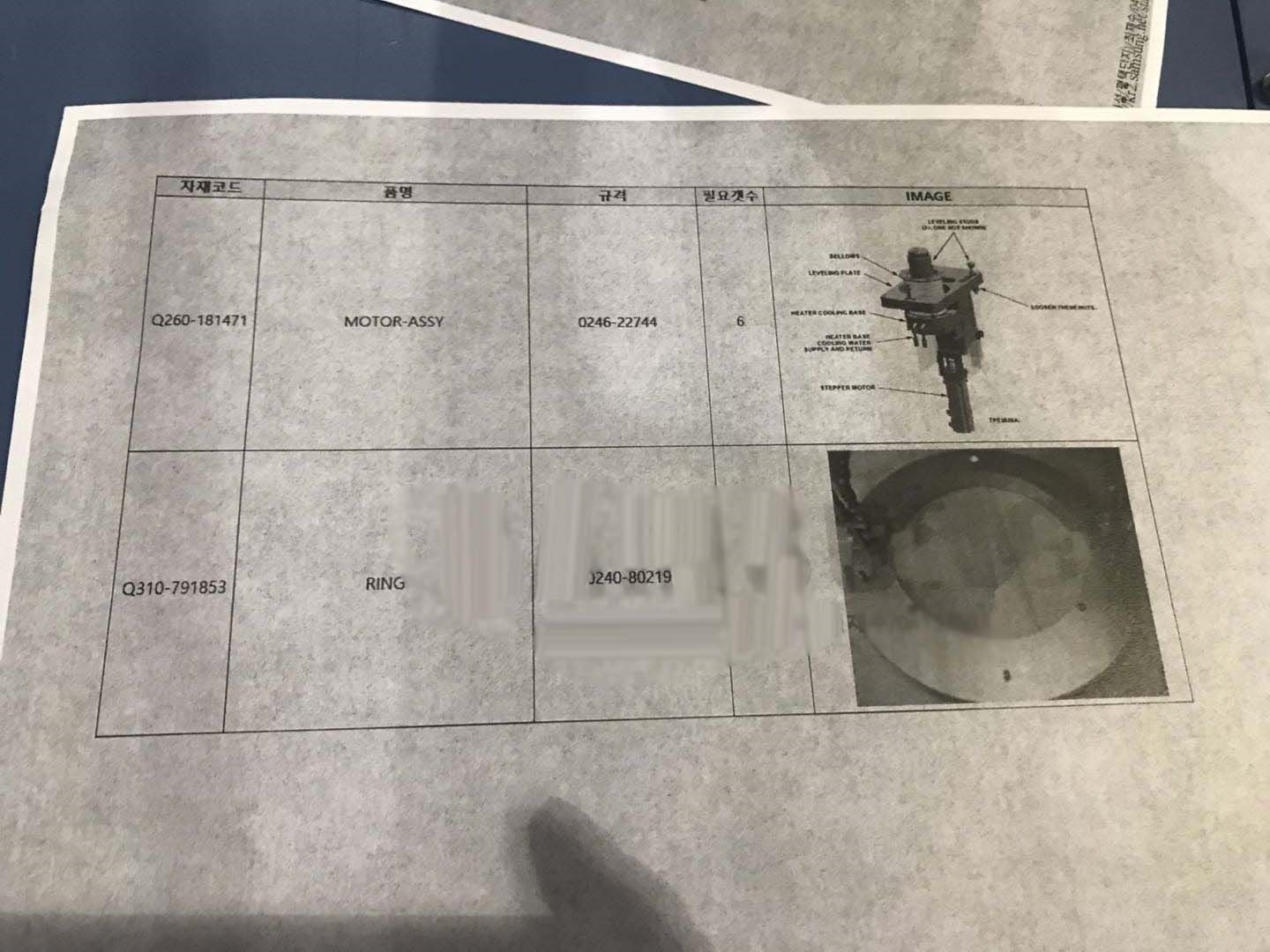

Missing parts:

(2) AX8407A Ozone generators

(6) 0246-22744 Heater lift assemblies

0240-80219 Ring

(2) Ceramic heaters

Chamber B: Lift assembly

Chamber B and C: (2) Controller boxes with board

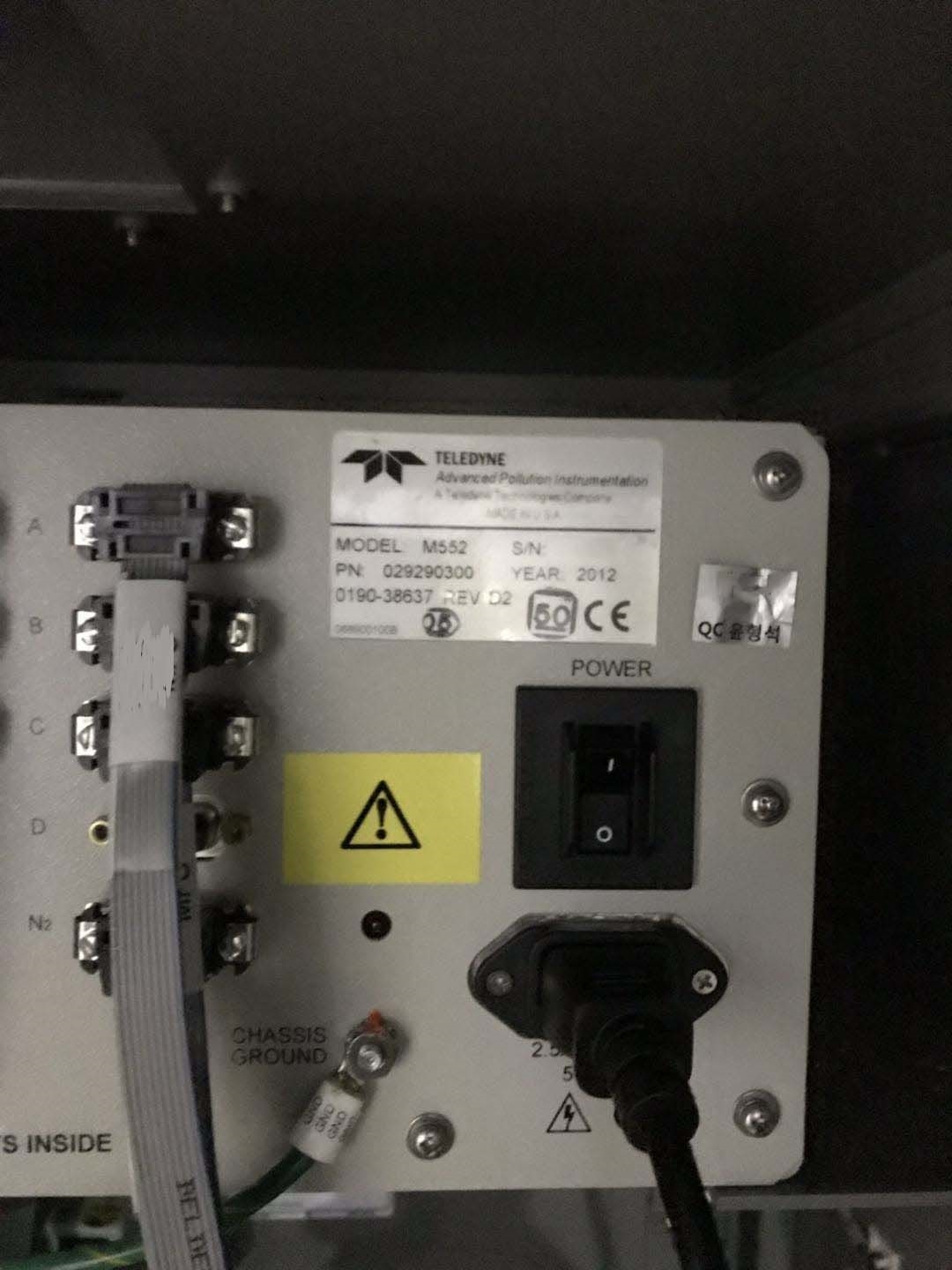

Power supply: 208 V, 50/60 Hz

2012 vintage.

AMAT / APPLIED MATERIALS Producer GT is a highly advanced next-generation reactor for thin-film deposition of photovoltaic materials. It is designed to enable the full automation of photovoltaic (PV) manufacturing processes, from material precursors to high-efficiency PV cells and modules. The combination of automation, flexibility, and high performance makes AMAT Producer GT a revolutionary tool for PV manufacturing. APPLIED MATERIALS Producer GT is based on multiple evolutionary generations of technology and innovation. The advanced 10th-generation platform is composed of a fully automated, dedicated multi-tool reactor with integrated process modules and software control. Features and advancements include substrate-step displacement, substrate size/shape adapter, advanced gas flow control, and low-cost source integration. The integrated process modules included in Producer GT are used to open up new opportunities for PV cell and module generations. These state-of-the-art modules provide the highest levels of performance and flexibility that are necessary for successful production in large capacity and at high throughput. The process modules allow for the deposition of ultra-thin film materials and the precise control of PV material layer thickness and composition. AMAT / APPLIED MATERIALS Producer GT can also enable the production of double and triple junction Thin Film Solar Cells and modules with excellent efficiency. The software control platform also enables advanced operation in combination with the process modules. This includes both manual and automated operation with real-time process monitoring, troubleshooting, and diagnostics. The full automation system enables faster throughput, which can reverse the cost of production, increase yields, and provide tight control over all parameters for maximum output. In synthesis, AMAT Producer GT offers numerous advantages and benefits that enable the efficient production of PV materials. The platform automates the deposition process, reduces error and cost, and drives higher efficiency PV cell and module production. It is the perfect choice for an organization seeking to optimize the production of high-efficiency PV cells and modules.

There are no reviews yet