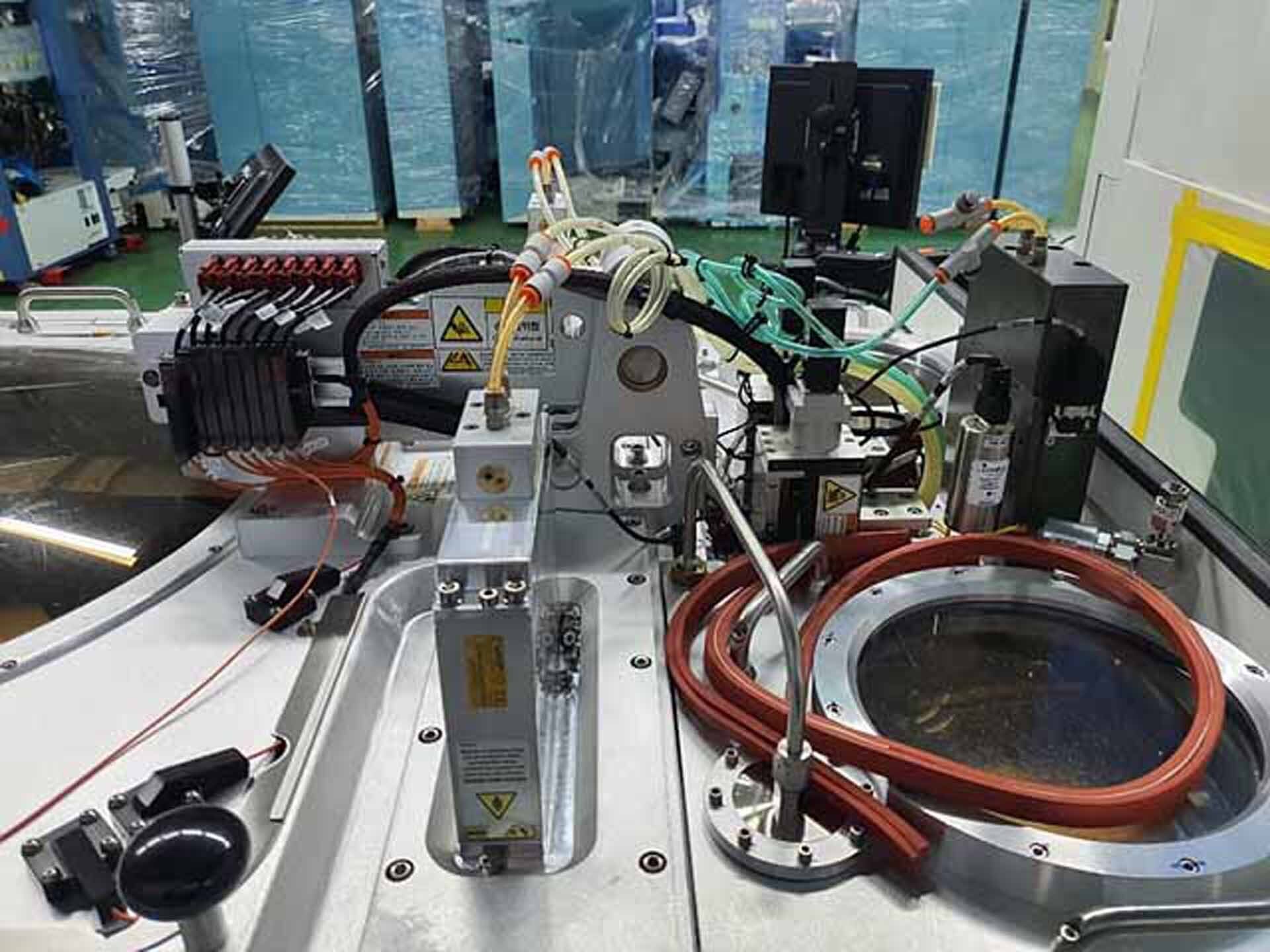

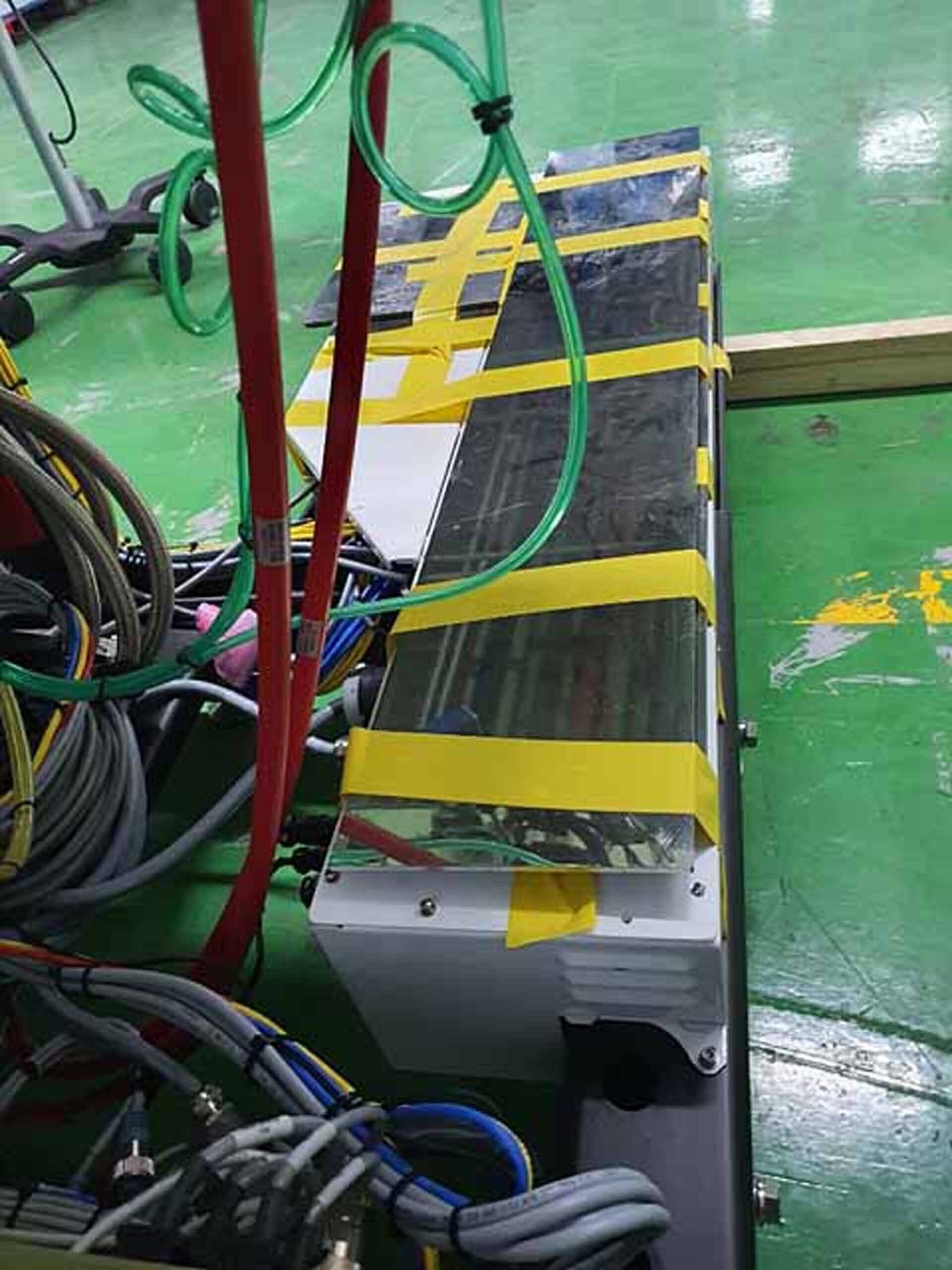

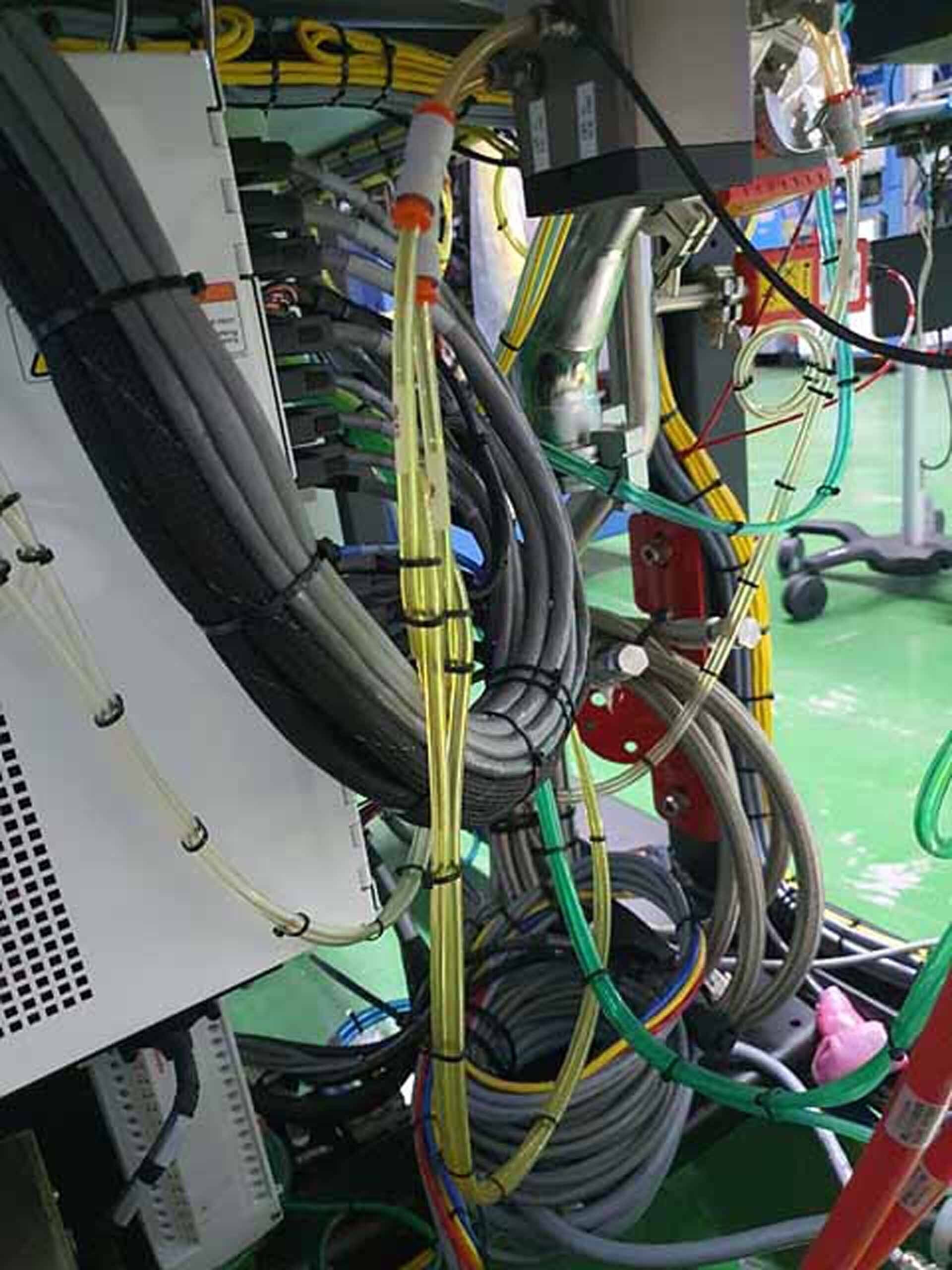

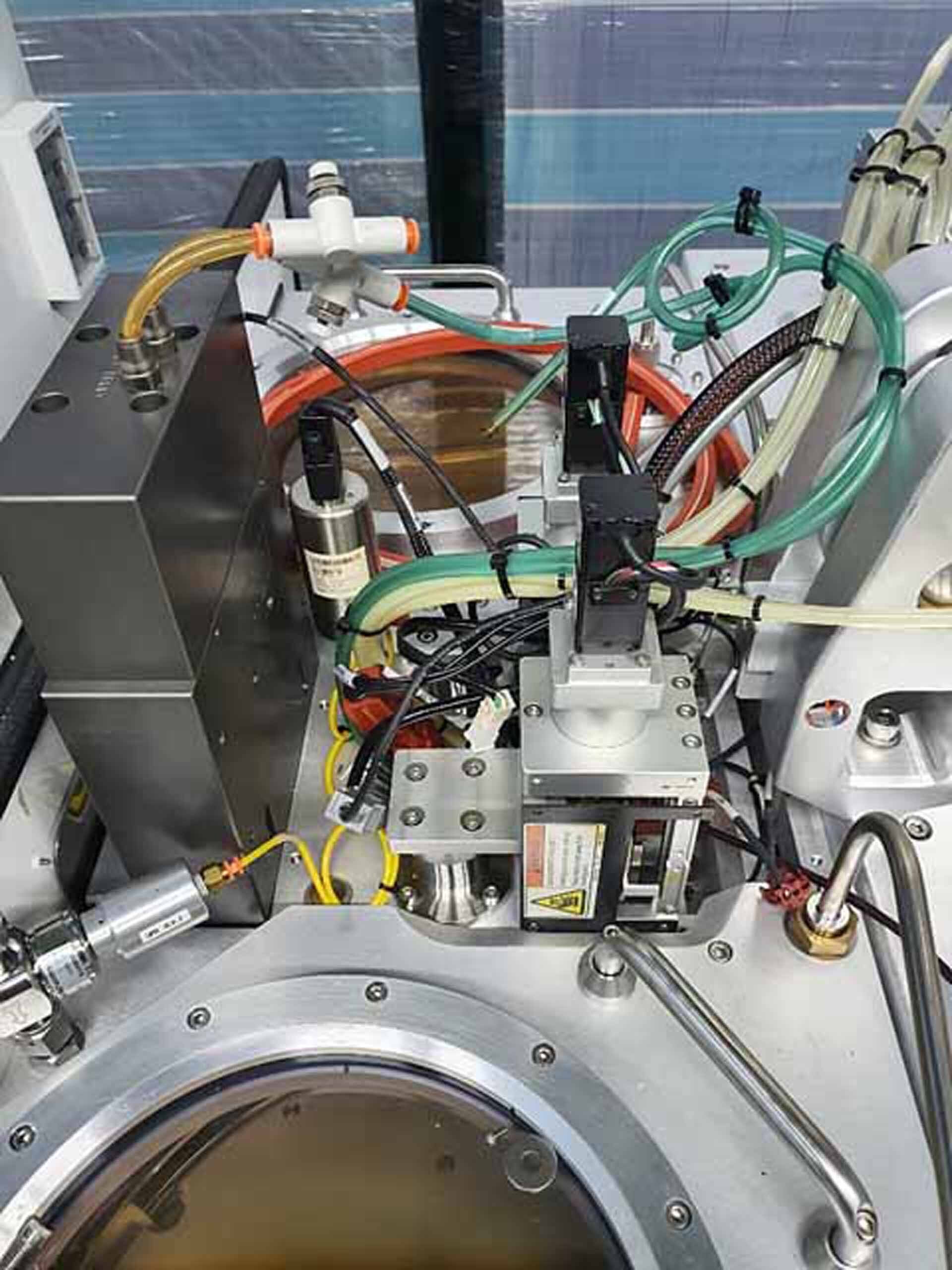

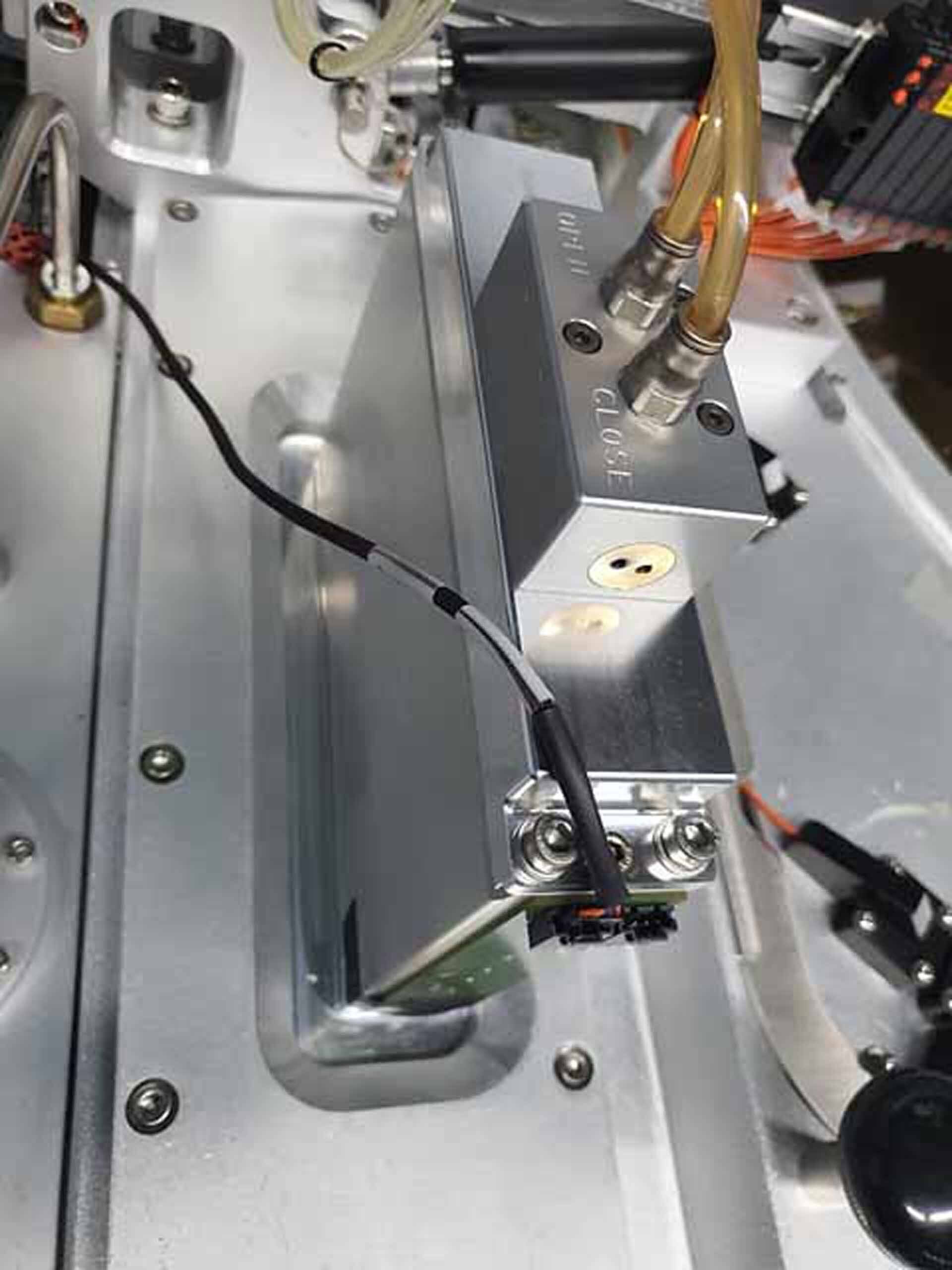

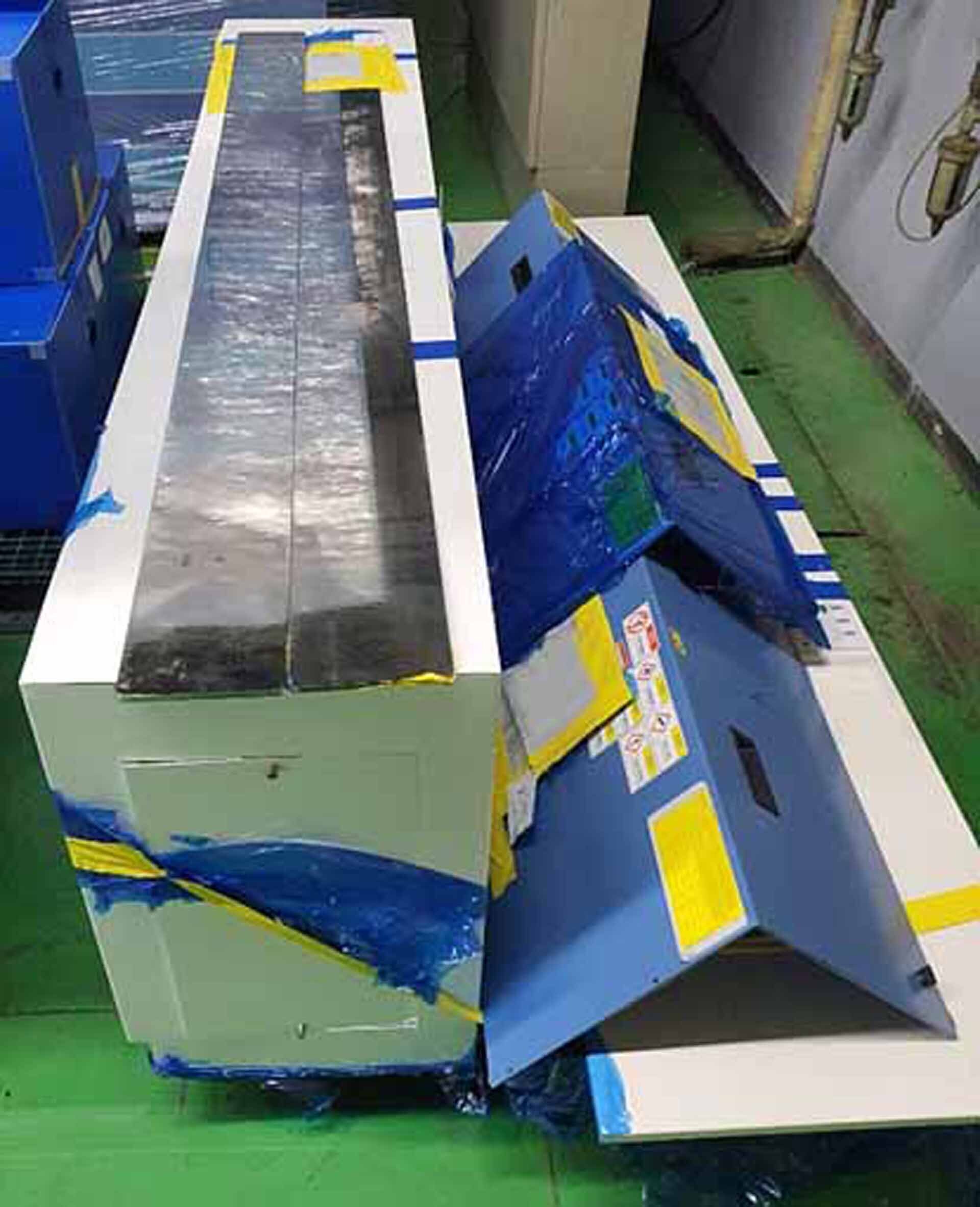

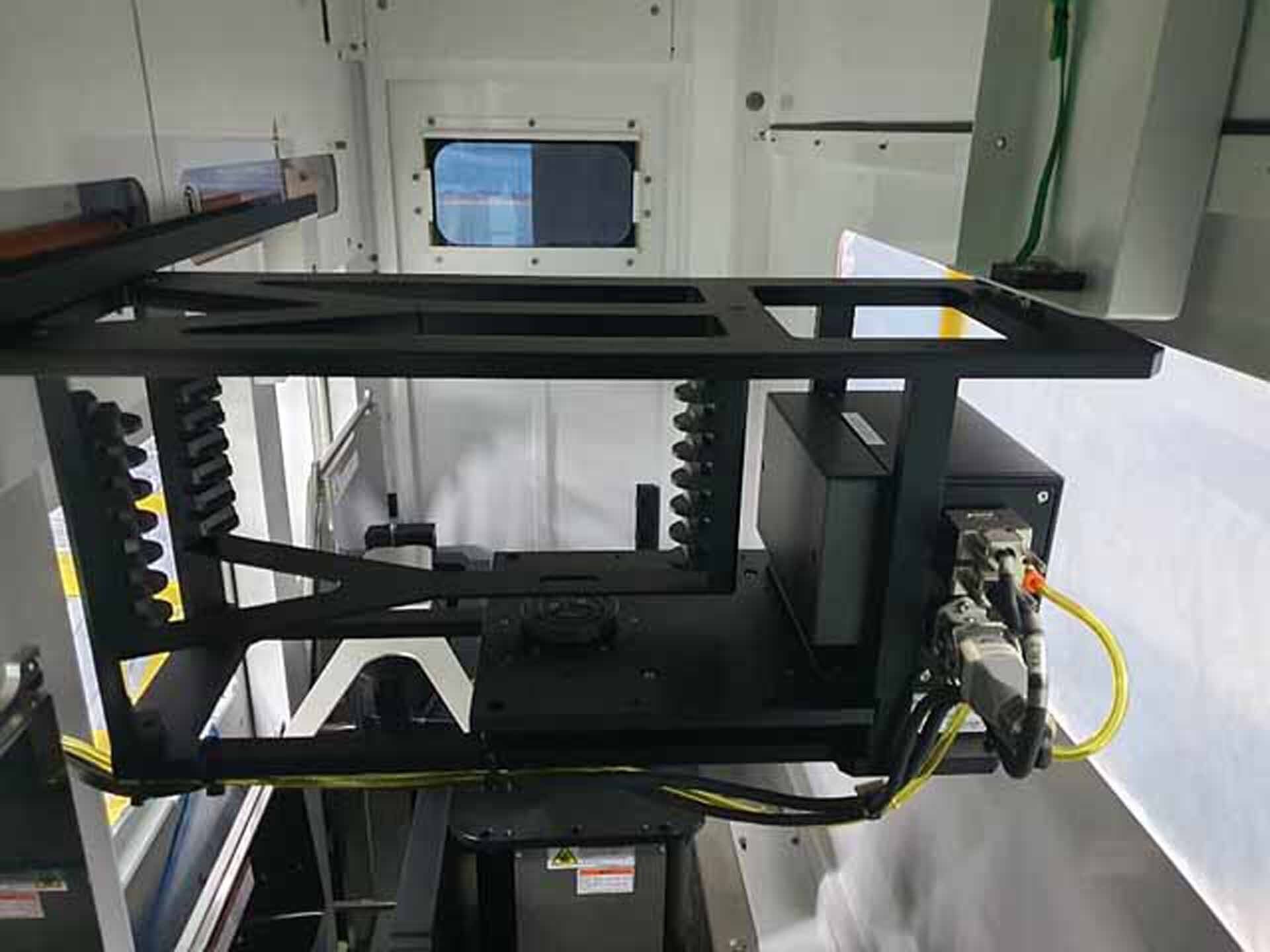

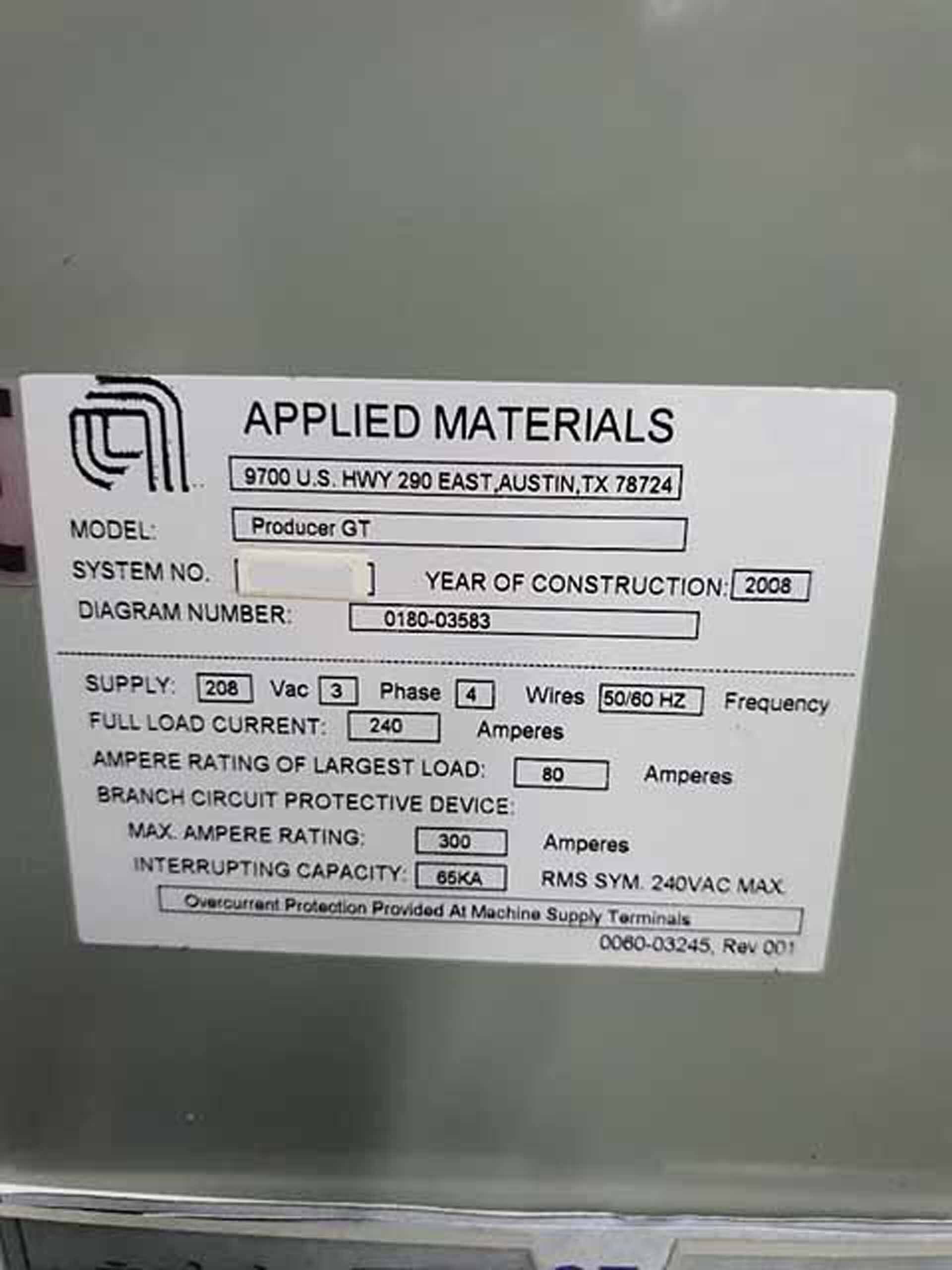

Used AMAT / APPLIED MATERIALS Producer GT #9281276 for sale

URL successfully copied!

Tap to zoom

ID: 9281276

Wafer Size: 12"

Vintage: 2008

System, 12"

(3) Ht ALC Chambers

2008 vintage.

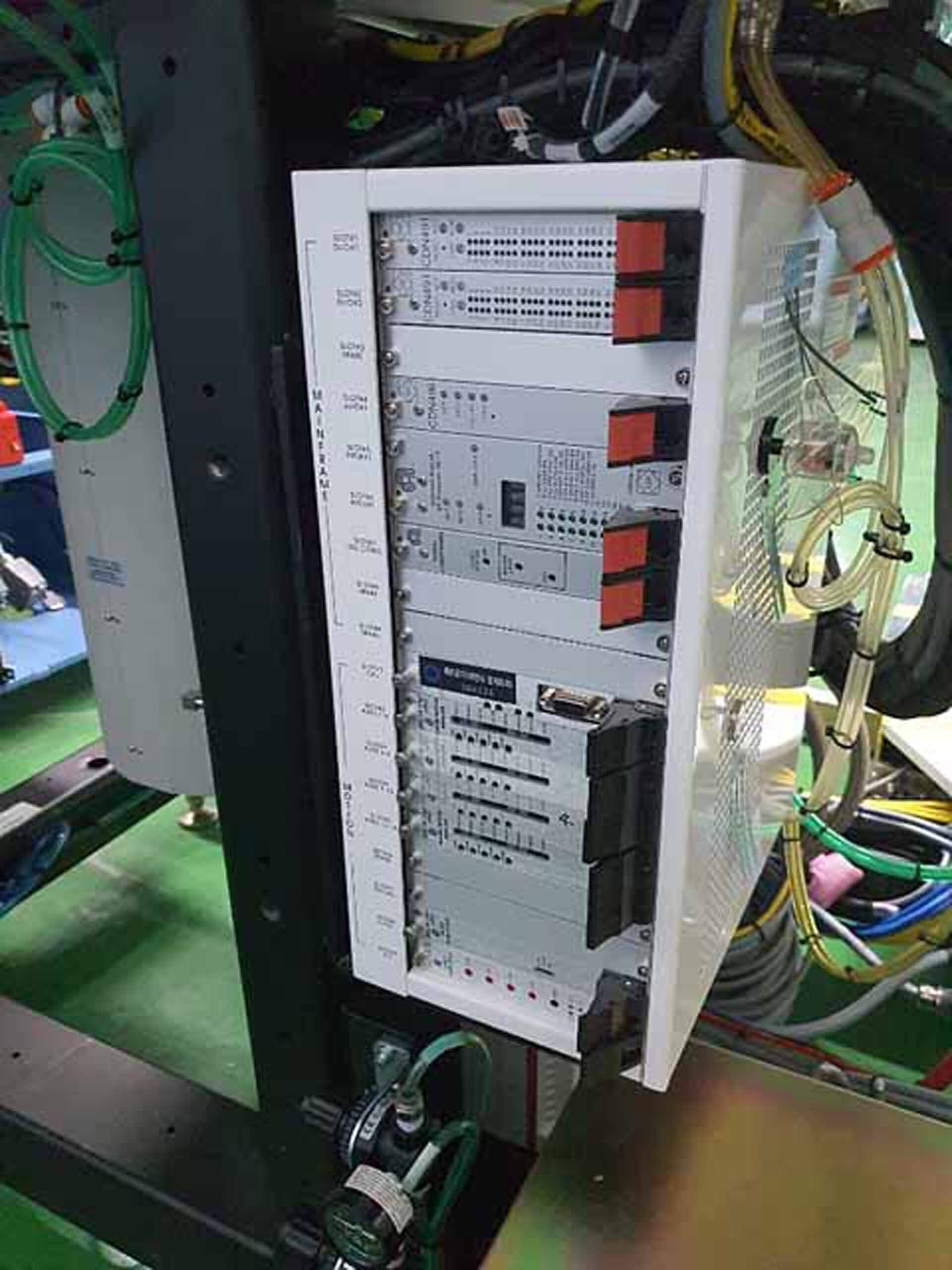

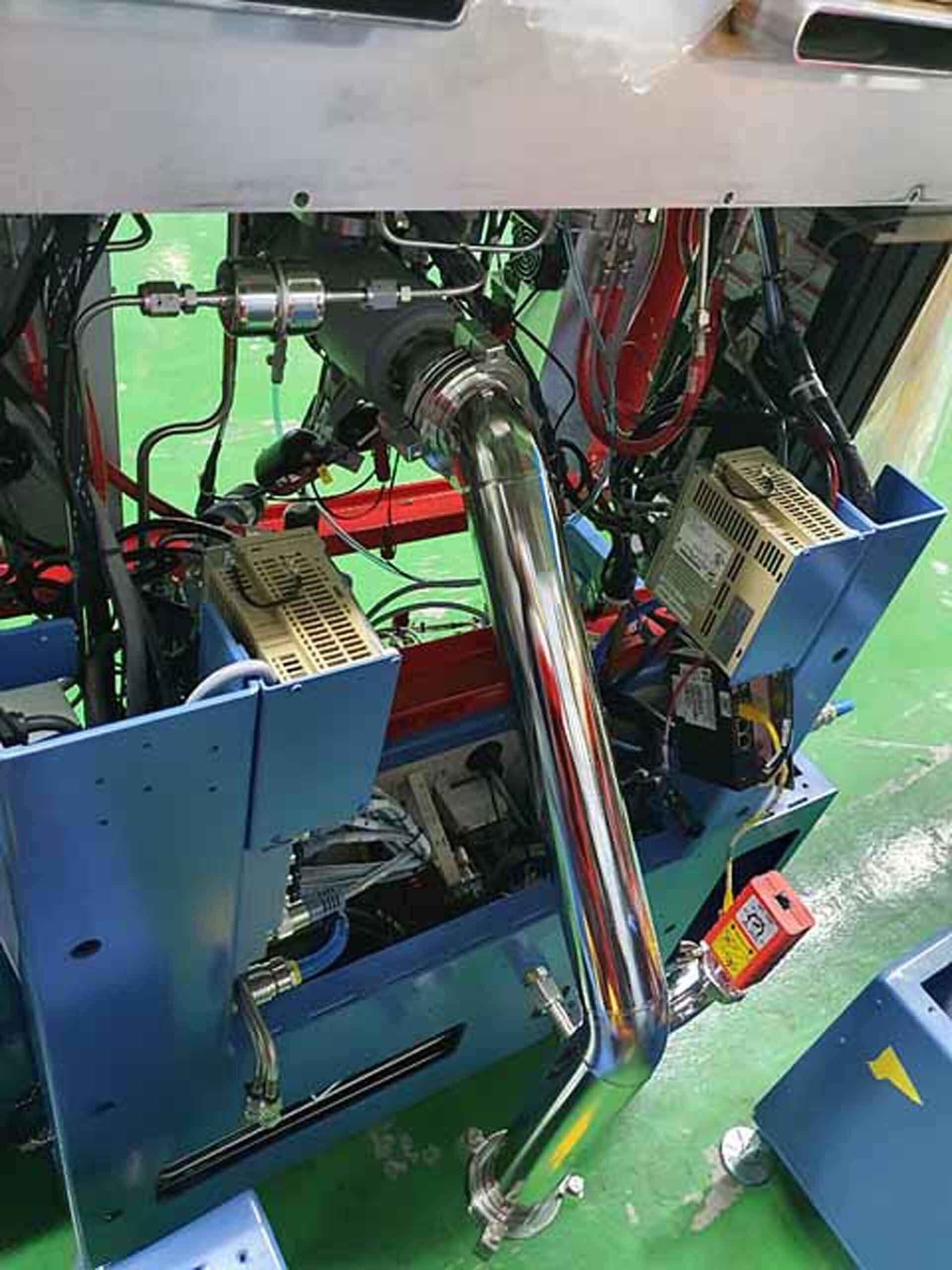

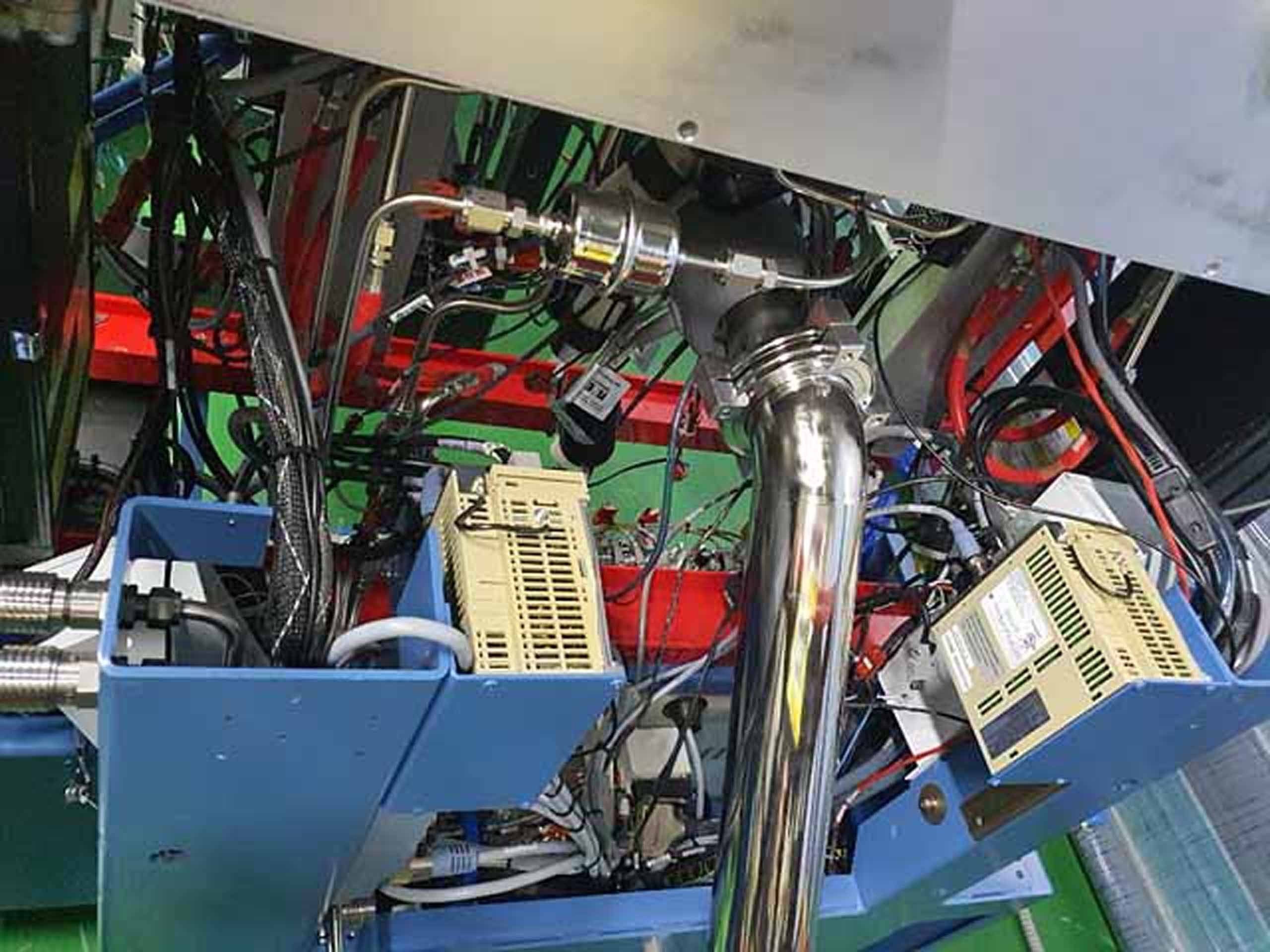

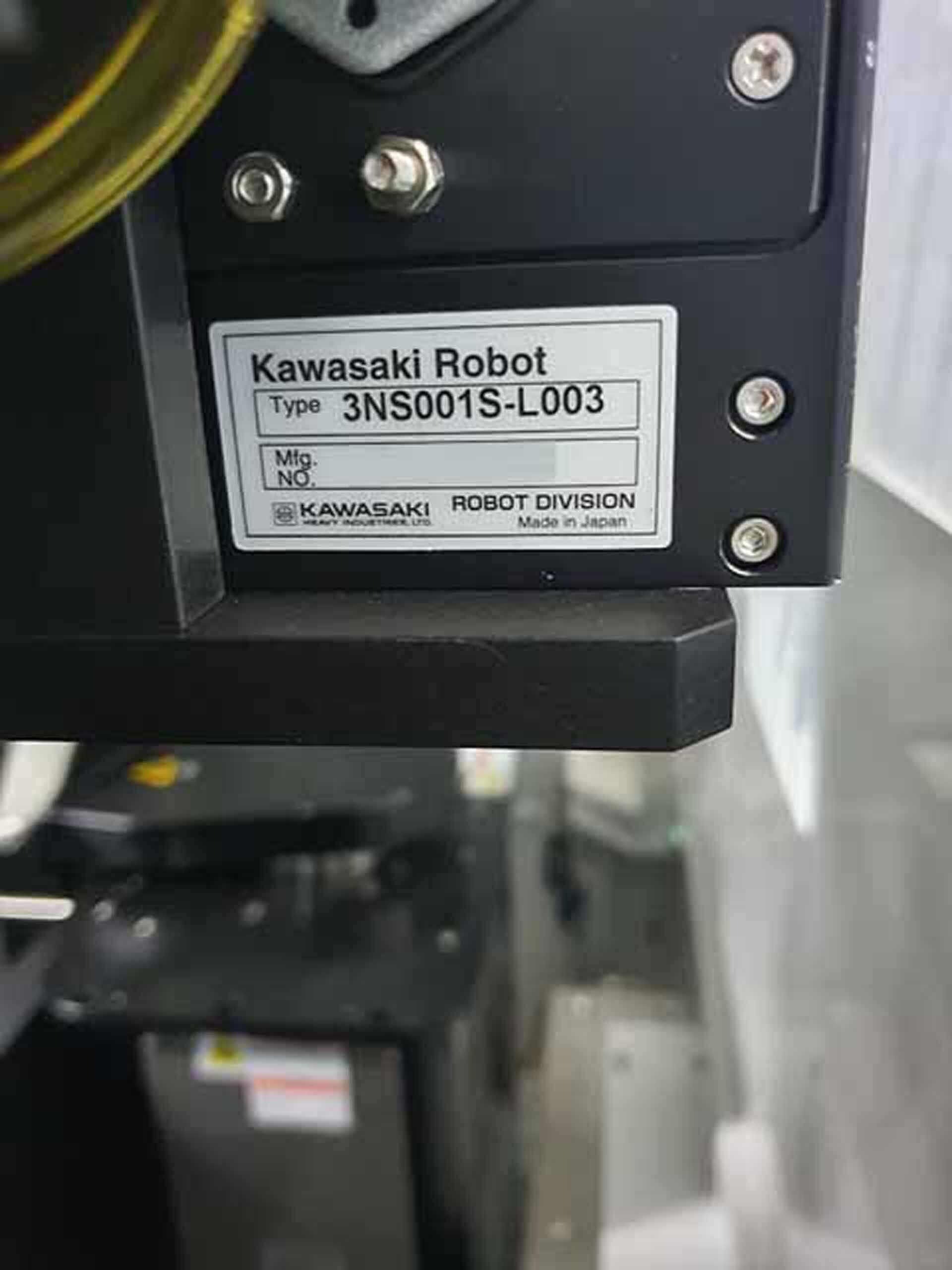

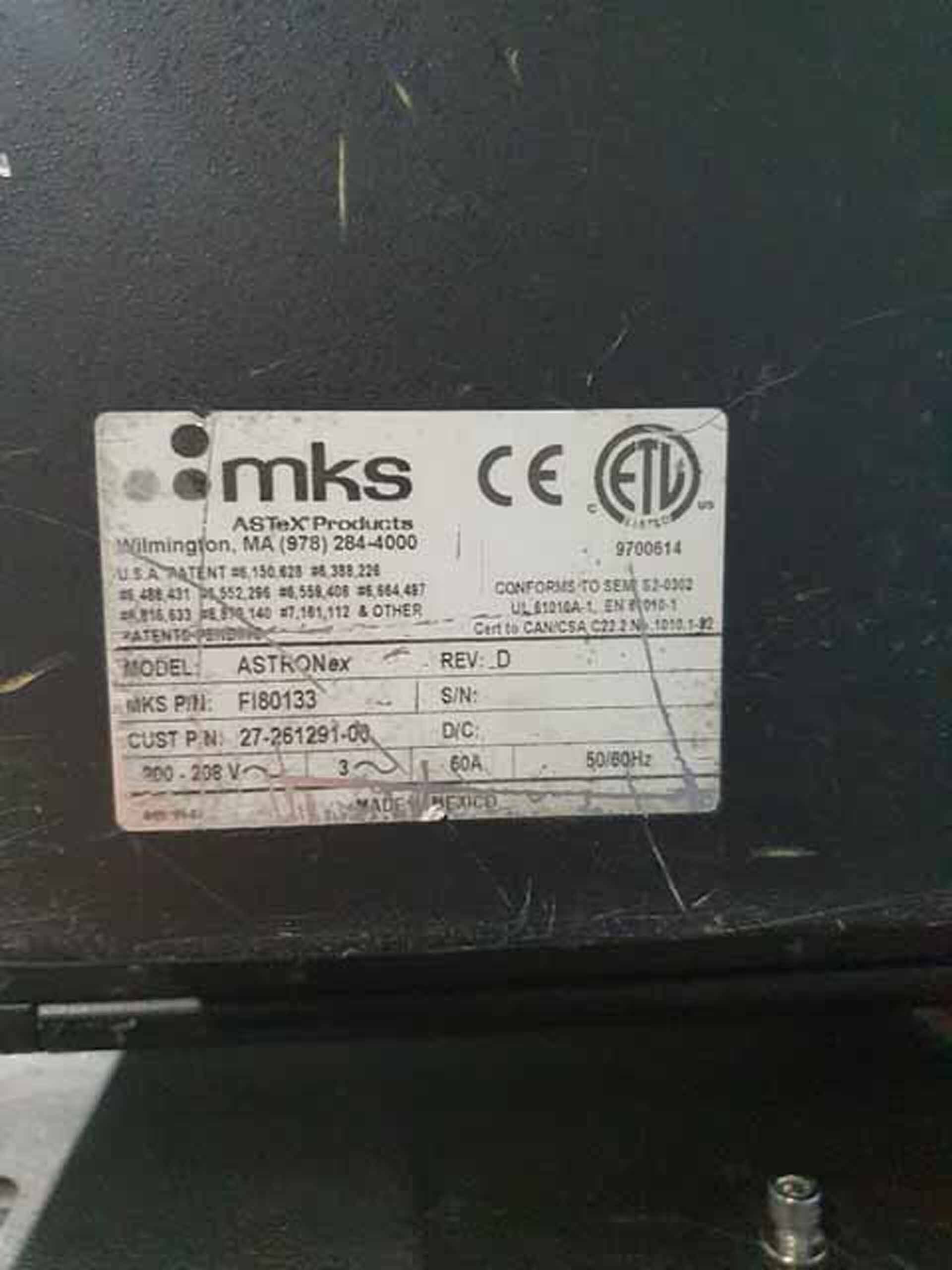

AMAT / APPLIED MATERIALS Producer GT Reactor is a tool used in semiconductor fabrication to engineer surfaces with modifications such as thin film growth, etching, and deposition. This equipment enables precise manipulation of surfaces in order to create desired material properties. The system is based on the platform of an "Inductively Coupled Plasma" (ICP) source, providing an uniform plasma over the entire sample. The GT Reactor also features an ICP source, which is powered by RF energy transmitted to the source by an inductive coil. The ICP source enables higher current densities than traditional plasma sources, allowing for greater flexibility in process parameters. AMAT Producer GT Reactor provides precise placement of multiple sources of energy at the same time so that desired modifications can be achieved efficiently while minimizing "cocktailing" or intermixing of materials. The precise placement of sources also allows control over the process, allowing for tailor-made solutions to individual device architecture. Furthermore, the GT Reactor features a low-pressure/high-conductance configuration to limit gas-phase reactions, and an oxidizing gas capability to ensure oxides are properly grown with low contamination rates. The GT Reactor has a gas-flow controlling unit which allows the operator to regulate the process temperature as well as gas flow dynamics, resulting in reliable operation and producing products with desired geometries and properties. The gas-flow machine also allows the operator to vary gas pressures, oxidation and other conditions to engineer thin films layers. This facilitates a high degree of process control characteristic of Process Chamber tools. APPLIED MATERIALS Producer GT Reactor also uses the ICP source to generate a high-density plasma for etching processes. This helps reduce thermal budgets by allowing high etch rates while keeping the etch byproduct formation on the surface to a minimum. Additionally, the GT Reactor has a "Front End Load Lock" tool, allowing easy tooling wafer exchanges to be made without breaking the vacuum. Wafers can quickly and easily be moved in and out of the tool without sacrificing integrity, allowing for process versatility and seamless adjustment to changing production needs. Producer GT Reactor is a state-of-the-art tool used in semiconductor fabrication to precisely engineer surfaces with desired material properties. It is based on an ICP source, allowing higher current densities and precise placement of multiple sources of energy suitable for modifications from thin film growth to etching. The GT Reactor includes a gas-flow controlling asset, front end load locks, and a low-pressure/high-conductance configuration to ensure reliable operation and minimize contamination. Utilizing the ICP source, it is capable of providing high etch rates, ideal for advanced device fabrication requirements.

There are no reviews yet