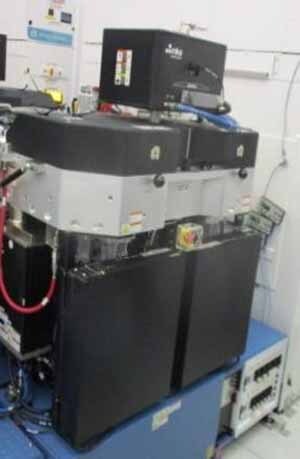

Used AMAT / APPLIED MATERIALS Producer GT3 #293610775 for sale

URL successfully copied!

Tap to zoom

ID: 293610775

Wafer Size: 12"

Vintage: 2015

PECVD System, 12"

Process: TEOS

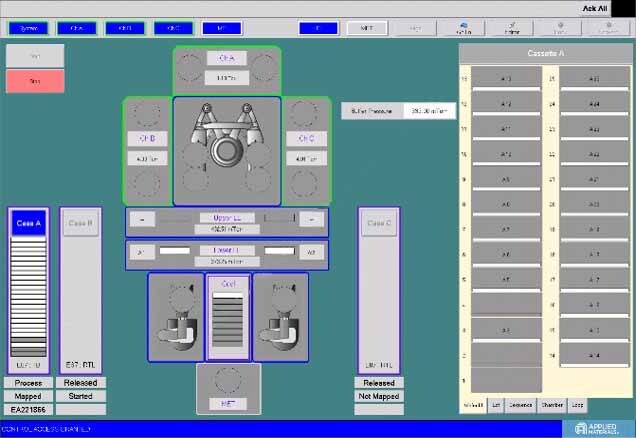

(4) SELOP Load ports

FOUP: (25) Wafers

FX Robot

0200-08346 Robot blades

0090-04659 Load lock preheater

9992-00594 Slit valve door

EBARA ESR 80WN MF Pump

Laod lock pump: EPX 180 Twin dry vacuum pump (P/N: 3620-00517)

0190-37371 Diffuser

KASHIYAMA SDE1203B Process pump

Chamber:

Type: PE Silane

0920-00139 RF Generator

0190-08677 RF Generator

0010-36734 Heater

9992-00594 Slit valve

0010-42371 RF Filter

0190-32100 Foreline TV

3870-06775 Foreline ISO

0040-53688 Gas box

0040-95475 Faceplate

0021-26544 Blocker

(2) Pumping liner sides (P/N: 0200-02407; 0200-02408)

0200-06758 Liner ceramic top

0200-02973 Liner ceramic middle

0200-02974 Liner ceramic bottom

0021-27290 Ceramic isolator

0200-03314 Lift pins

0200-03312 Lift hoop

(2) Sapcer sides (P/N: 0021-24181; 0021-24182)

0190-40602 RPS

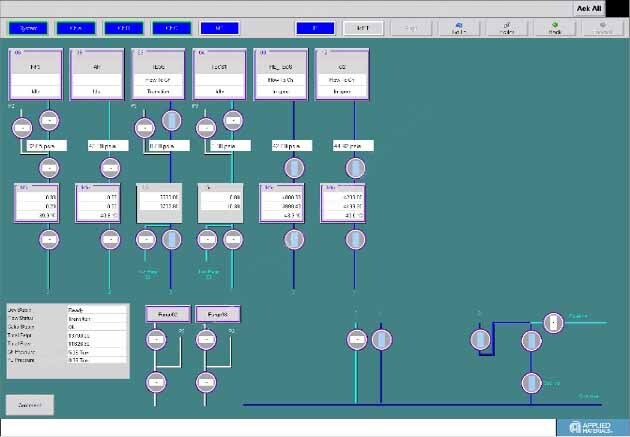

Gas box:

Line / Gas / Size

3 / TEOS-1 / 7000

4 / TEOS-2 / 7000

6 / NF3 / 5000

8 / Ar / 10000

9 / He-TEOS / 15000

12 / O2 / 15000

18 / Purge02 / -

19 / Purge03 / -

Liquid line temperature:

TEOS-1, 2 Injection: 150°

Heated line-2, 3, 4, 5, 6, 7: 120°

Does not include Hard Disk Drive (HDD)

Power supply: 208 VAC, 3-Phase

2015 vintage.

AMAT / APPLIED MATERIALS Producer GT3 is an advanced thermal chemical vapor deposition reactor that is well-equipped to help users meet their substrata deposition needs. This state-of-the-art deposition equipment is capable of producing high quality films of many materials, including single-crystal silicon, germanium, carbon, and diamond. It features precise process control, a wide variety of thermal processes, and tight uniformity control capabilities. AMAT Producer GT3 is designed with a process chamber that is 10-cm in diameter and 20-cm in height, making it highly customizable and perfect for a wide range of applications. An efficient thermal transfer equipment helps maintain a consistent substrate temperature, which is critical in achieving quality film deposition. This reactor also offers a range of pre-programmable processes, allowing users to refine their film deposition for ultimate control. To ensure reliable and repeatable results, the GT3 incorporates a Rapid Thermal Anneal system within the substrate plane to minimize unwanted stress between material layers. This reactor unit is also equipped with AMAT patented Arc Control Technology, designed to achieve superior deposits at even lower temperatures than typical CVD processes. Apart from being used for advanced substrata deposition, APPLIED MATERIALS Producer GT3 is designed to accommodate a broad range of materials, including III-V materials for power semiconductor device development. The machine also features state-of-the-art controls for electrode biasing, which is critical for developing high-performance materials. The Broad Ion Source present in the GT3 allows for simultaneous deposition of two different materials. This is especially useful in the production of electrical devices, in which the combination of two materials can lead to superior results. In addition, the reactor is equipped with a Heating Conductor Angle Rectification Gear, allowing users to precisely manipulate the heating impedance of the substrate. Producer GT3 is an advanced chemical vapor deposition reactor that offers reliable performance and numerous customizable capabilities. With its broad range of thermal processes, advanced electrodes, and tight uniformity control, the GT3 is an ideal choice for those seeking quality film deposition.

There are no reviews yet